Mode II Interfacial Fracture Toughness of Multi-Walled Carbon Nanotubes Reinforced Nanocomposite Film on Aluminum Substrate

Abstract

1. Introduction

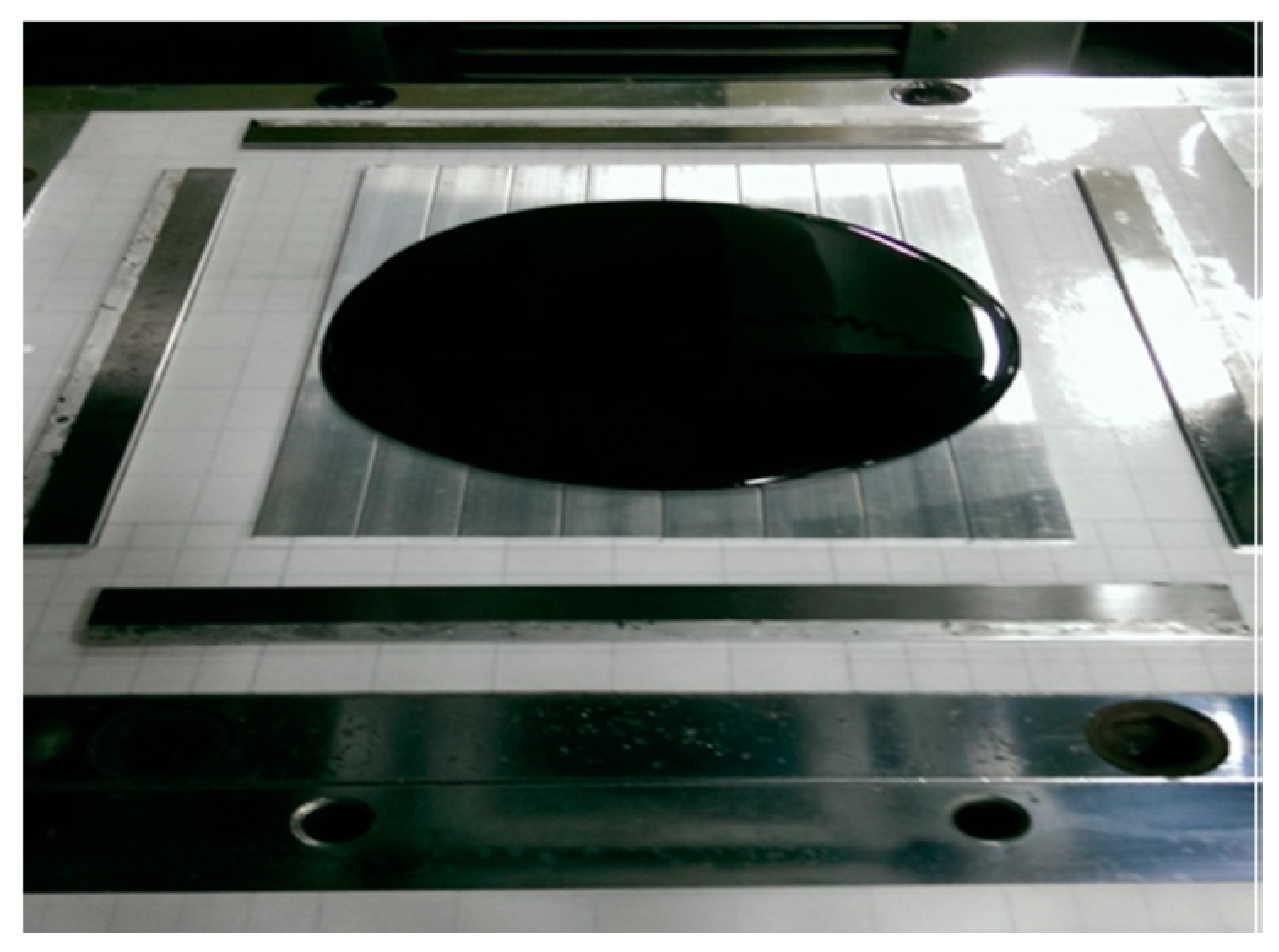

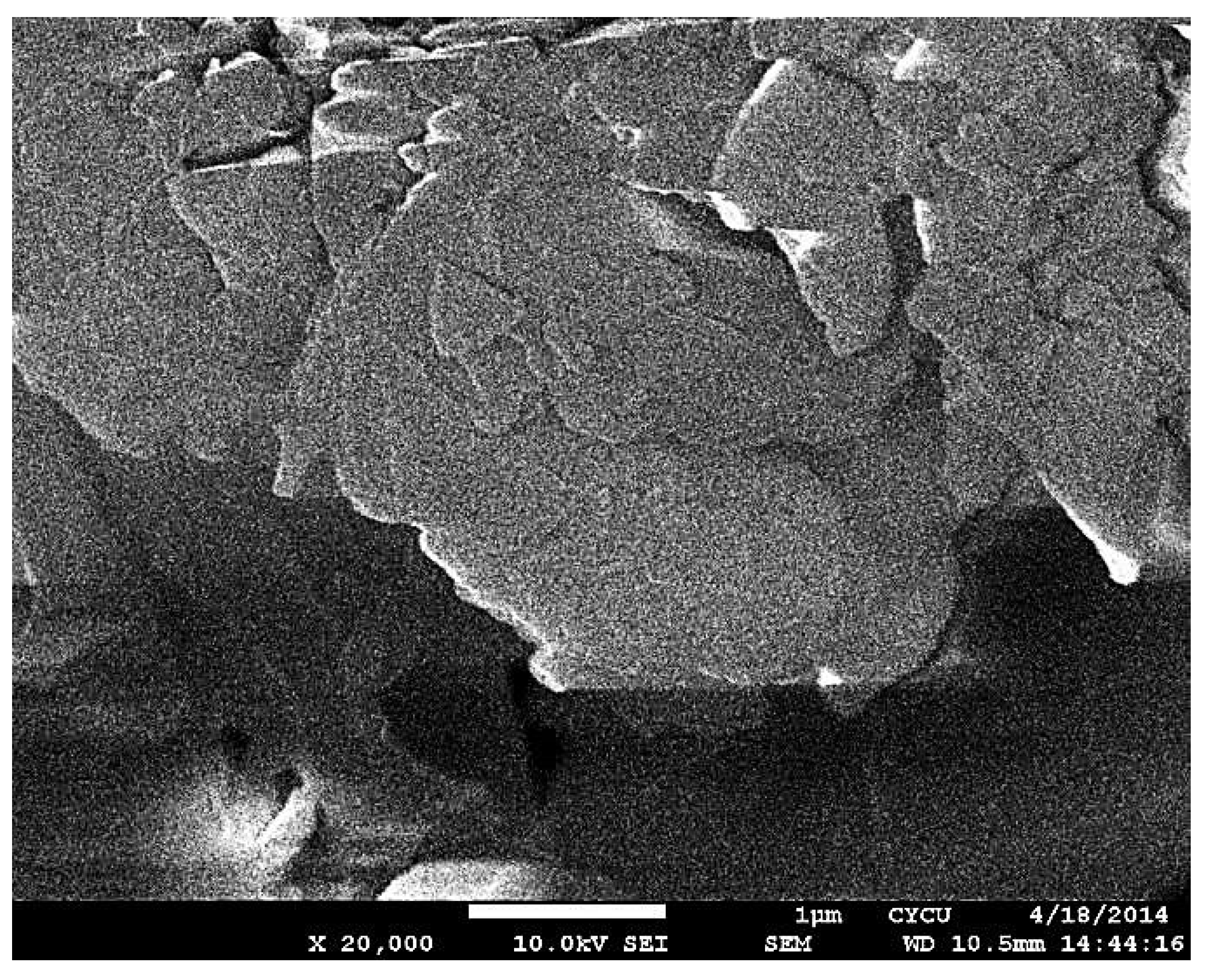

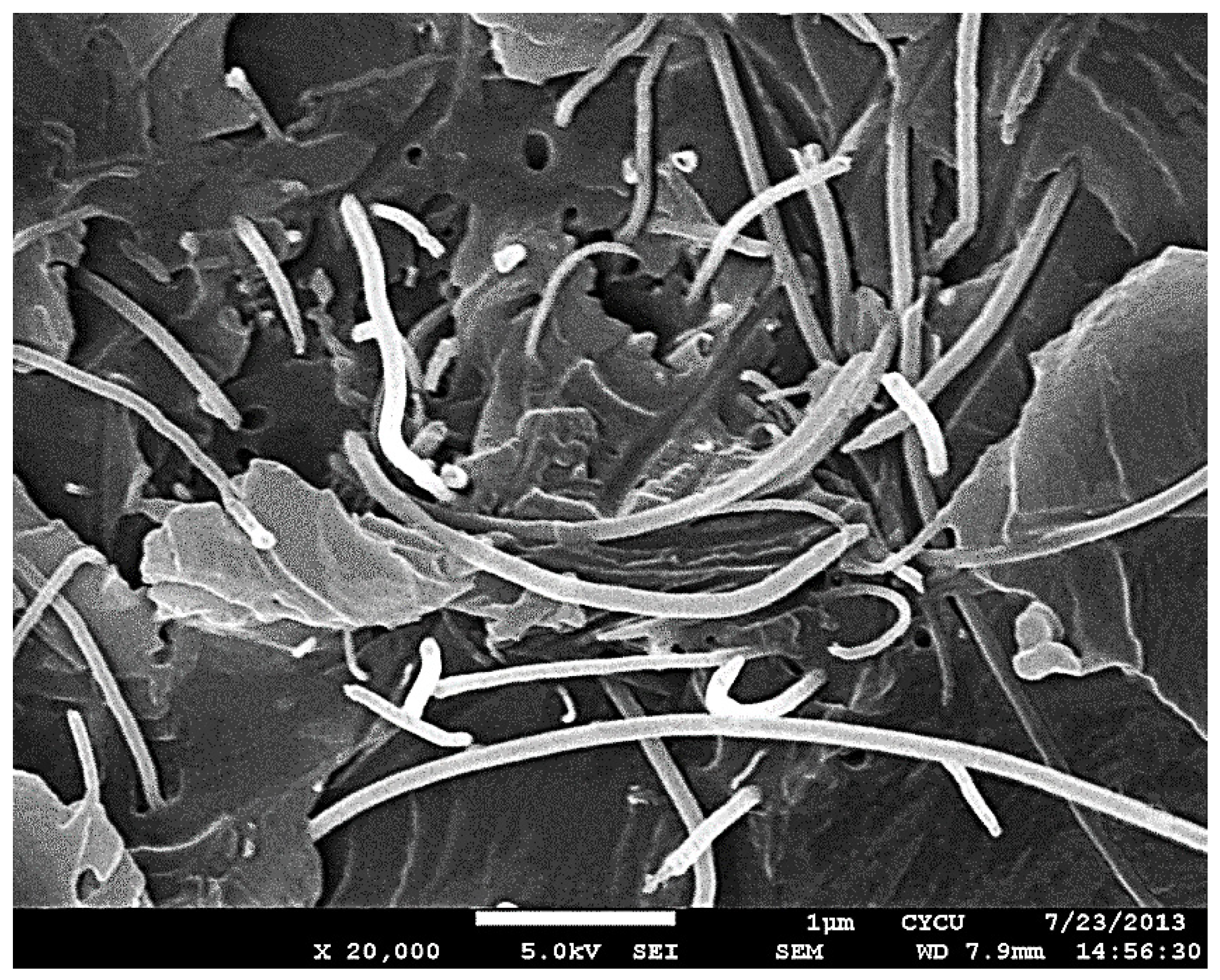

2. Preparation of MWCNT/Epoxy Nanocomposite

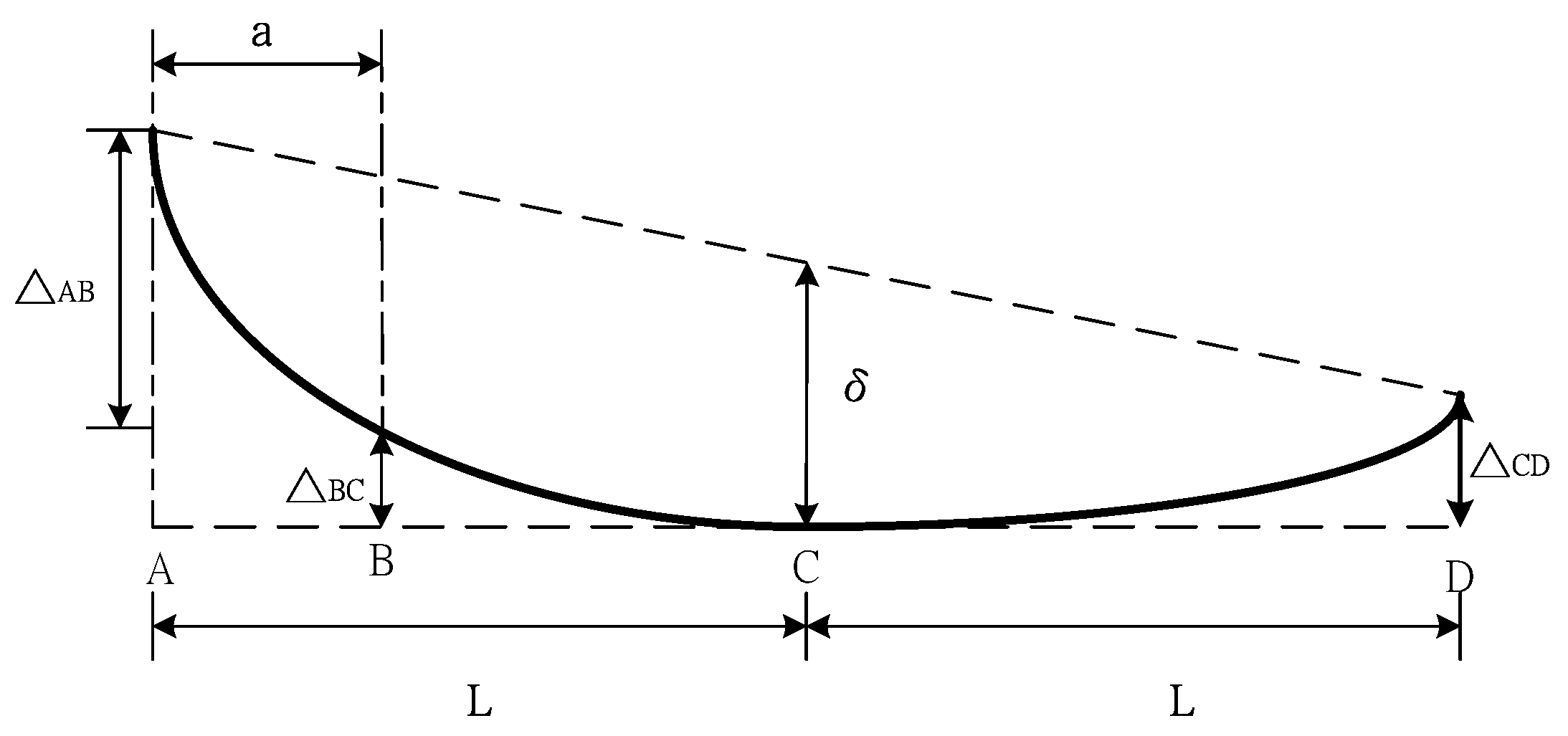

3. Derivation of Mode II Strain Energy Release Rate

4. Experimental Results

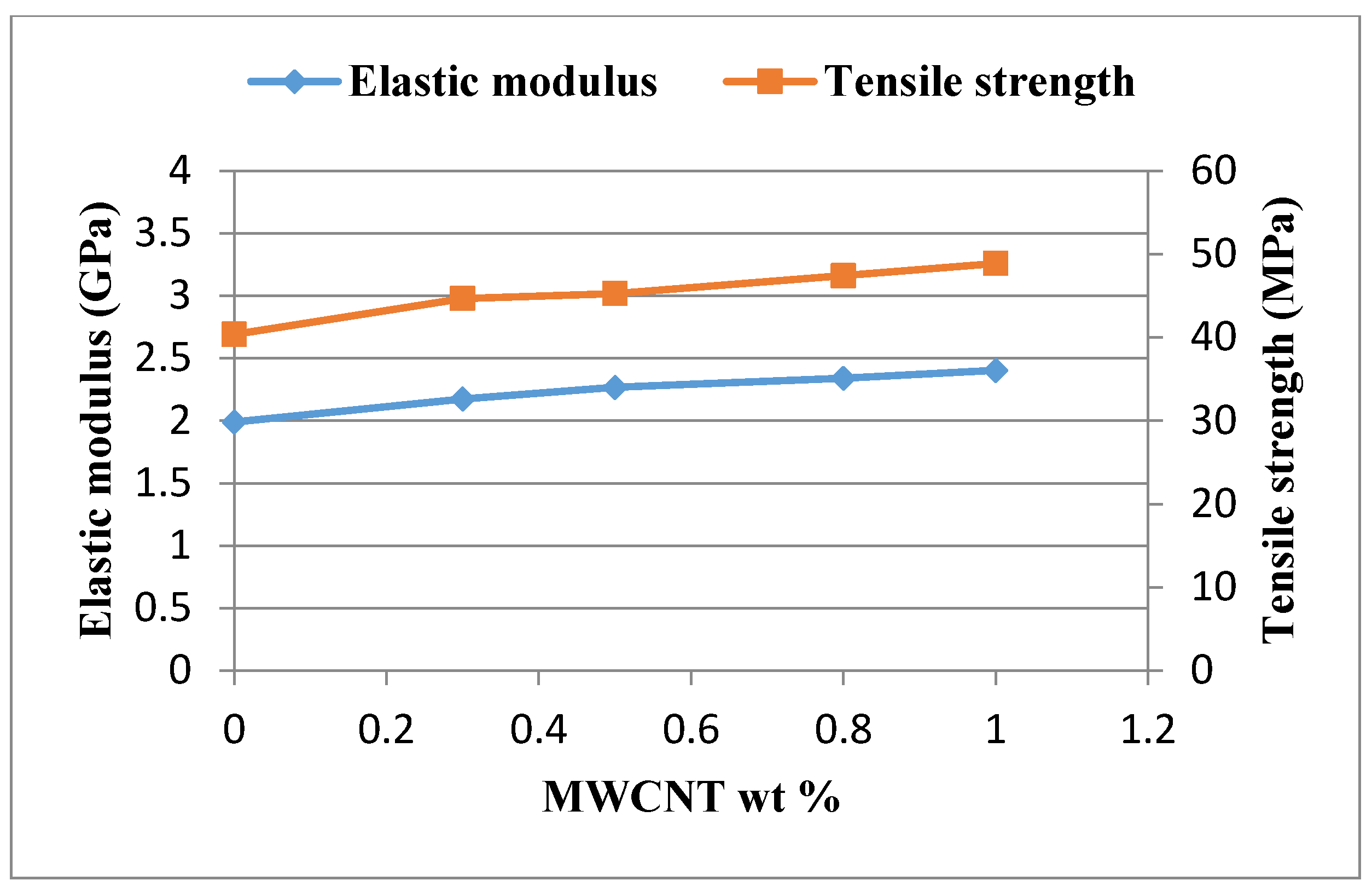

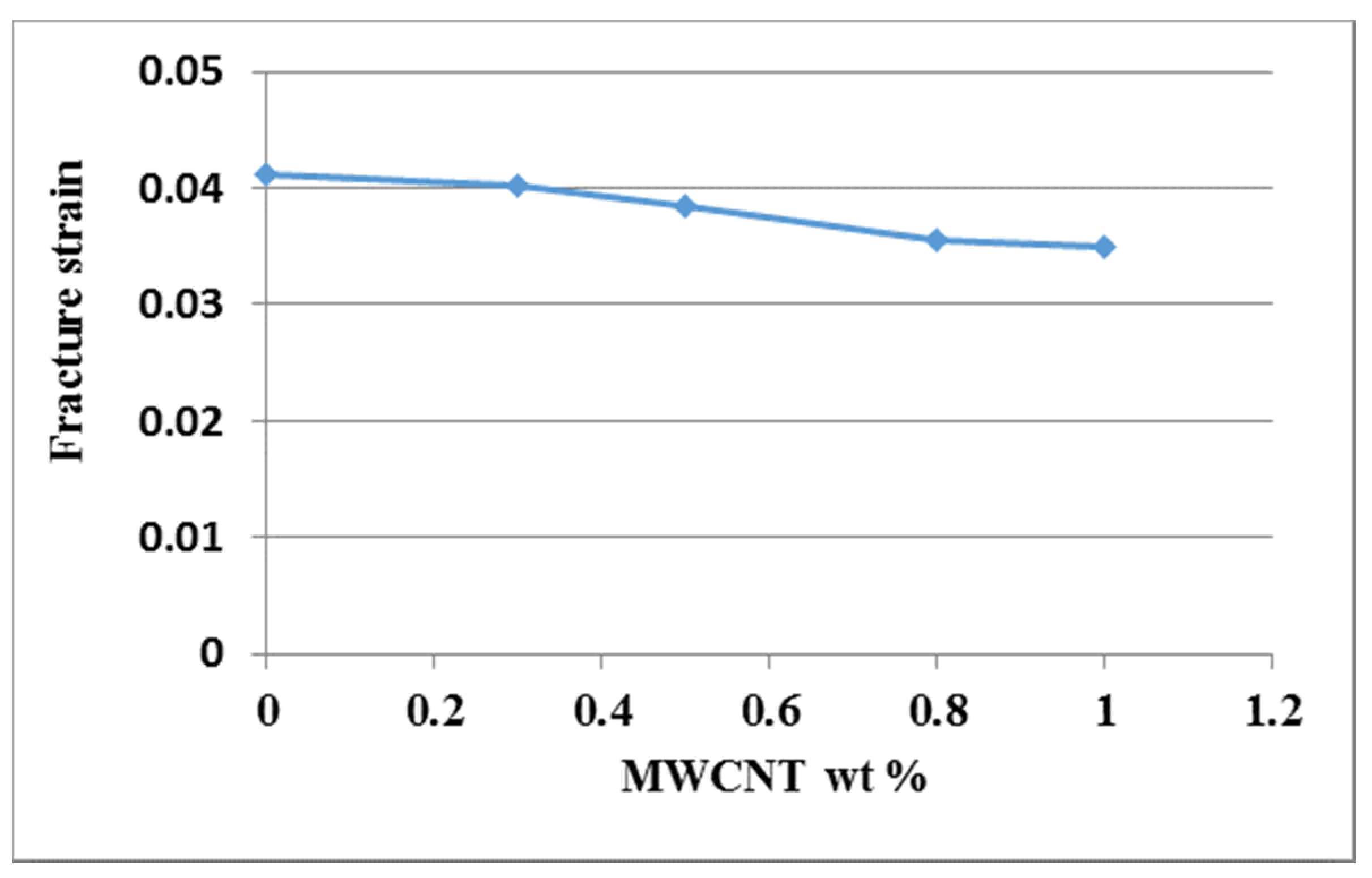

4.1. Tensile Properties

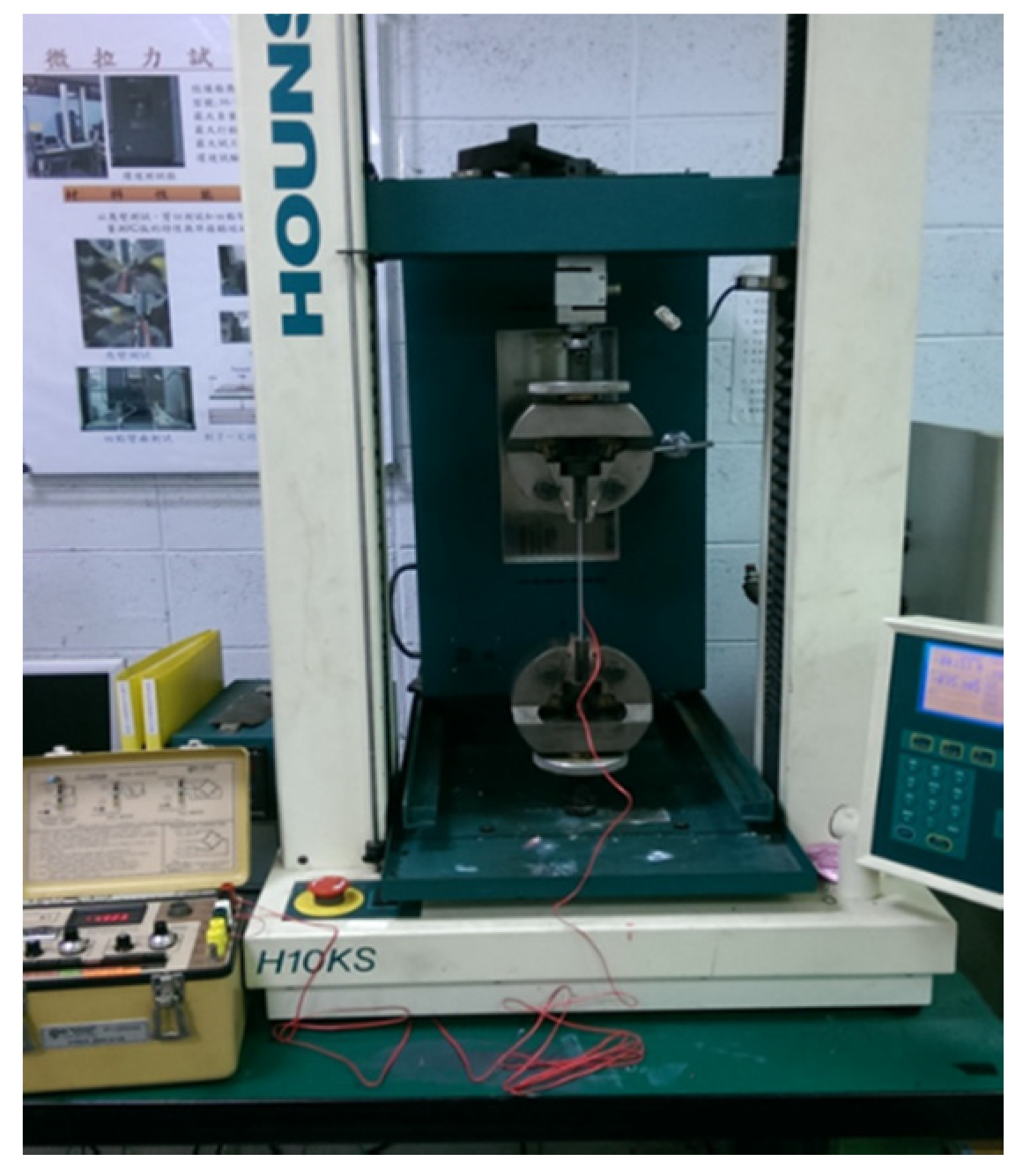

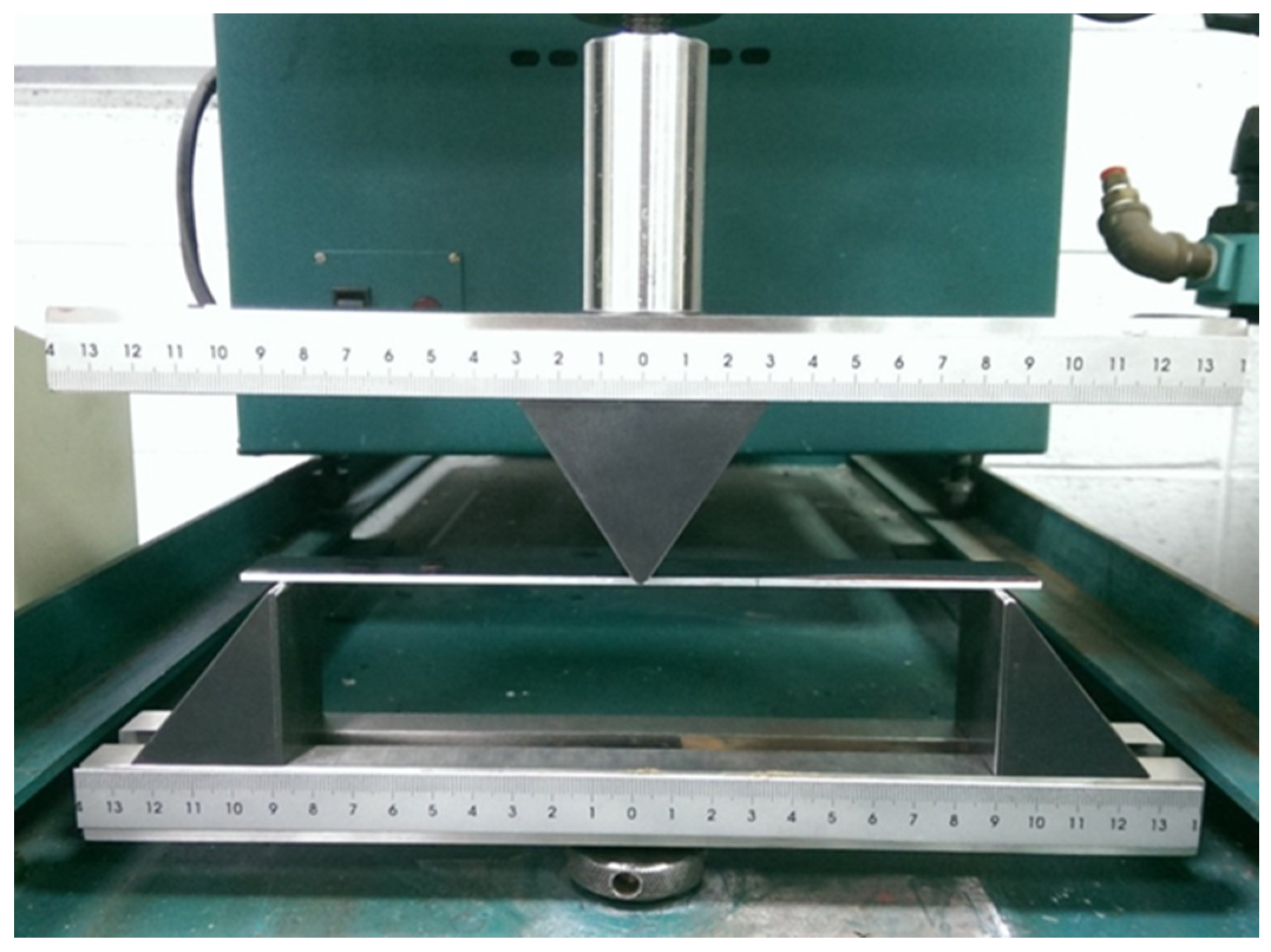

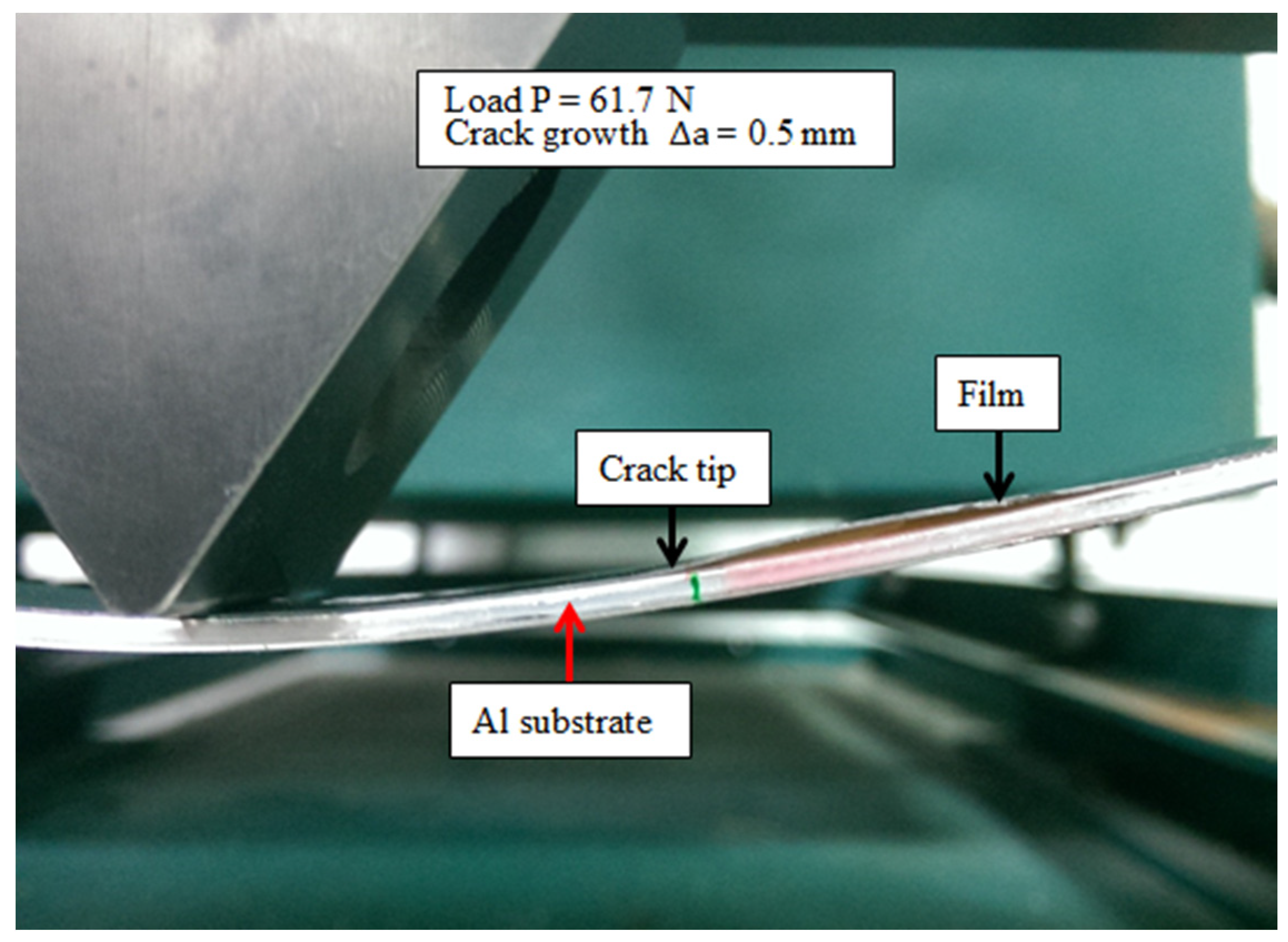

4.2. Mode II Fracture Toughness

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liao, Y.H.; Marietta-Tondin, O.; Liang, Z.; Zhang, C.; Wang, B. Investigation of the dispersion process of SWNTs/SC-15 epoxy resin nanocomposites. Mater. Sci. Eng. A 2004, 385, 175–181. [Google Scholar] [CrossRef]

- Chen, H.; Jacobs, O.; Wu, W.; Rudiger, G.; Schadel, B. Effect of dispersion method on tribological properties of carbon nanotube reinforced epoxy resin composites. Polym. Test. 2007, 26, 351–360. [Google Scholar] [CrossRef]

- Bagchi, A.; Nomura, S. On the effective thermal conductivity of carbon nanotube reinforced polymer composites. Compos. Sci. Technol. 2006, 66, 1703–1712. [Google Scholar] [CrossRef]

- Wei, B.Q.; Vajtai, R.; Ajayan, P.M. Reliability and current carrying capacity of carbon nanotubes. Appl. Phys. Lett. 2001, 79, 1172–1174. [Google Scholar] [CrossRef]

- Zare, Y. New models for yield strength of polymer/clay nanocomposites. Compos. Part B 2015, 73, 111–117. [Google Scholar] [CrossRef]

- Rafique, I.; Kausar, A.; Muhammad, B. Epoxy resin composite reinforced with carbon fiber and inorganic filler: Overview on preparation and properties. Polym. Plast. Technol. Eng. 2016, 55. [Google Scholar] [CrossRef]

- Cha, J.; Jun, G.H.; Park, J.K.; Kim, J.C.; Ryu, H.J.; Hong, S.H. Improvement of modulus, strength and fracture toughness of CNT/Epoxy nanocomposites through the functionalization of carbon nanotubes. Compos. Part B 2017, 129, 169–179. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, X.; Zhu, Y.; Hui, D.; Qiu, Y. Mechanical, electrical and thermal properties of aligned carbon nanotube/polyimide composites. Compos. Part B 2014, 56, 408–412. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Y.; Prada-Silvy, R.; Tan, Y.; Azad, S.; Krause, B.; Pötschke, P.; Grady, B.P. Aspect ratio effects of multi-walled carbon nanotubes on electrical, mechanical, and thermal properties of polycarbonate/MWCNT composites. J. Polym. Sci. Part B 2014, 52, 73–83. [Google Scholar] [CrossRef]

- Allen, R.J.; Ghita, O.; Farmer, B.; Beard, M.; Evans, K.E. Mechanical testing and modelling of a vertically aligned carbon nanotube composite structure. Compos. Sci. Technol. 2013, 77, 1–7. [Google Scholar] [CrossRef]

- Gantayat, S.; Rout, D.; Swain, S.K. Mechanical properties of functionalized multiwalled carbon nanotube/epoxy nanocomposites. Mater. Today 2017, 4, 4061–4064. [Google Scholar] [CrossRef]

- Rafiee, M.; Nitzsche, F.; Labrosse, M.R. Effect of functionalization of carbon nanotubes on vibration and damping characteristics of epoxy nanocomposites. Polym. Test. 2018, 69, 385–395. [Google Scholar] [CrossRef]

- Schulz, S.C.; Faiella, G.; Buschhorn, S.T.; Prado, L.A.S.A.; Giordano, M.; Schulte, K.; Bauhofer, W. Combined electrical and rheological properties of shear induced multiwall carbon nanotube agglomerates in epoxy suspensions. Eur. Polym. J. 2011, 47, 2069–2077. [Google Scholar] [CrossRef]

- Michelis, P.; Vlachopoulos, J. Complete CNT disentanglement–dispersion–functionalisation in a pulsating micro-structured reactor. Chem. Eng. Sci. 2013, 90, 10–16. [Google Scholar] [CrossRef]

- Li, W.; Dichiara, A.; Zha, J.; Su, Z.; Bai, J. On improvement of mechanical and thermomechanical properties of glass fabric/epoxy composites by incorporating CNT–Al2O3 hybrids. Compos. Sci. Technol. 2014, 103, 36–43. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Akil, H.M.; Kudus, M.H.A.; Kadarman, A.H. Improving flexural and dielectric properties of MWCNT/epoxy nanocomposites by introducing advanced hybrid filler system. Compos. Struct. 2015, 132, 50–64. [Google Scholar] [CrossRef]

- Esbat, A.H.; Irani, S. Effect of functionalized process and CNTs aggregation on fracture mechanism and mechanical properties of polymer nanocomposite. Mech. Mater. 2018, 118, 106–119. [Google Scholar] [CrossRef]

- Zhu, L.; Moon, K.S.; Bertram, B.; Hess, D.W.; Wong, C.P. Assembling carbon nanotube bundles using transfer process for fine-pitch electrical interconnect applications. In Proceedings of the Electronic Components and Technology Conference, Reno, NV, USA, 29 May–1 June 2007; pp. 1981–1985. [Google Scholar]

- Chai, Y.; Gong, J.; Zhang, K.; Chan, P.C.H.; Yuen, M.M.F. Low temperature transfer of aligned carbon nanotube films using liftoff technique. In Proceedings of the Electronic Components and Technology Conference, Reno, NV, USA, 29 May–1 June 2007; pp. 429–434. [Google Scholar]

- Tummala, R.R.; Raj, P.M.; Aggarwal, A.; Mehrotra, G.; Koh, S.W.; Bansal, S. Copper interconnections for high performance and fine pitch flipchip digital applications and ultra-miniaturized RF module applications. In Proceedings of the Electronic Components and Technology Conference, San Diego, CA, USA, 30 May–2 June 2006; pp. 102–111. [Google Scholar]

- Faraji, M.; Aydisheh, H.M. Facile and scalable preparation of highly porous polyvinyl chloride-multi walled carbon nanotubes-polyaniline composite film for solid-state flexible supercapacitor. Compos. Part B 2019, 168, 432–441. [Google Scholar] [CrossRef]

- Arai, S.; Suwa, Y.; Endo, M. Cu/Multiwalled carbon nanotube composite film fabricated by pulse-reverse electrodeposition. J. Electrochem. Soc. 2011, 158, D49–D53. [Google Scholar] [CrossRef]

- Kwon, O.H.; Kim, J.; Koh, W.G.; Kang, Y.H.; Jang, K.S.; Cho, S.Y.; Yoo, Y. Flexible and free-standing thermoelectric devices prepared from poly (vinylidene fluoride-co-hexafluoropropylene)/graphite nanoplatelet/single-walled carbon nanotube composite films. Mater. Sci. Eng. B 2019, 243, 199–205. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Cheng, X.; Hei, Y.; Xing, L.; Li, Z. Lightning strike damage on the composite laminates with carbon nanotube films: Protection effect and damage mechanism. Compos. Part B 2019, 168, 342–352. [Google Scholar] [CrossRef]

- Guillén-Hernández, T.; Reinosob, J.; Paggi, M. Fracture analysis of thin films on compliant substrates: Anumerical study using the phase field approach of fracture. Int. J. Press. Vessel. Pip. 2019, 175, 103913. [Google Scholar] [CrossRef]

- Mei, H.; Landis, C.M.; Huang, R. Concomitant wrinkling and buckle-delamination of elastic thin films on compliant substrates. Mech. Mater. 2011, 43, 627–642. [Google Scholar] [CrossRef]

- Reinoso, J.; Paggi, M.; Rolfes, R. A computational framework for the interplay between delamination and wrinkling in functionally graded thermal barrier coatings. Comput. Mater. Sci. 2016, 116, 82–95. [Google Scholar] [CrossRef]

- Goyal, S.; Srinivasan, K.; Subbarayan, G.; Siegmund, T. On instability-induced debond initiation in thin film systems. Eng. Fract. Mech. 2010, 77, 1298–1313. [Google Scholar] [CrossRef]

- De Moura, M.F.S.F.; Dourado, N. Mode I fracture characterization of wood using the TDCB test. Appl. Fract. Mech. 2018, 94, 40–45. [Google Scholar] [CrossRef]

- Zabala, H.; Aretxabaleta, L.; Castillo, G.; Aurrekoetxea, J. Loading rate dependency on mode I interlaminar fracture toughness of unidirectional and woven carbon fibre epoxy composites. Compos. Struct. 2015, 121, 75–82. [Google Scholar] [CrossRef]

- Her, S.C.; Chien, P.C. Fracture analysis of MWCNT/Epoxy nanocomposite film deposited on aluminum substrate. Materials 2017, 10, 408. [Google Scholar] [CrossRef]

- Jagannathan, N.; Anil Chandra, A.R.; Manjunatha, C.M. Onset-of-growth behavior of mode II delamination in a carbon fiber composite under spectrum fatigue loads. Compos. Struct. 2015, 132, 477–483. [Google Scholar] [CrossRef]

- Quan, D.; Urdániz, J.L.; Ivankovi, A. Enhancing mode-I and mode-II fracture toughness of epoxy and carbon fibre reinforced epoxy composites using multi-walled carbon nanotubes. Mater. Des. 2018, 143, 81–92. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Shadlou, S.; Shokrieh, M.M. Fracture toughness of epoxy/multi-walled carbon nanotube nano-composites under bending and shear loading conditions. Mater. Des. 2011, 32, 2115–2124. [Google Scholar] [CrossRef]

- De Moura, M.F.S.F.; Silva, M.A.L.; Morais, J.J.L.; Dourado, N. Mode II fracture characterization of wood using the Four-Point End-Notched Flexure (4ENF) test. Theor. Appl. Fract. Mech. 2018, 98, 23–29. [Google Scholar] [CrossRef]

- Ast, J.; Ghidelli, M.; Durst, K.; Göken, M.; Sebastiani, M.; Korsunsky, A.M. A review of experimental approaches to fracture toughness evaluation at the micro-scale. Mater. Des. 2019, 173, 107762. [Google Scholar] [CrossRef]

- Sebastiani, M.; Johanns, K.E.; Herbert, E.G.; Pharr, G.M. Measurement of fracture toughness by nanoindentation methods: Recent advances and future challenges. Curr. Opin. Solid State Mater. Sci. 2015, 19, 324–333. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Johanns, K.E.; Pharr, G.M. Effects of indenter angle on micro-scale fracture toughness measurement by pillar splitting. J. Am. Ceram. Soc. 2017, 100, 5731–5738. [Google Scholar] [CrossRef]

- Liu, H.T.; Yang, L.W.; Han, S.; Cheng, H.F.; Mao, W.G.; Molina-Aldareguía, J.M. Interface controlled micro- and macro- mechanical properties of aluminosilicate fiber reinforced SiC matrix composites. J. Eur. Ceram. Soc. 2017, 37, 883–890. [Google Scholar] [CrossRef]

- Wicks, S.S.; de Villoria, R.G.; Wardle, B.L. Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes. Compos. Sci. Technol. 2010, 70, 20–28. [Google Scholar] [CrossRef]

- Saha, R.; Nix, W.D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 2002, 50, 23–38. [Google Scholar] [CrossRef]

| MWCNT wt % | Specimen 1 | Specimen 2 | Specimen 3 | Average Strain Energy Release Rate (J/m2) | |||

|---|---|---|---|---|---|---|---|

| Critical Load (N) | Strain Energy Release Rate (J/m2) | Critical Load (N) | Strain Energy Release Rate (J/m2) | Critical Load (N) | Strain Energy Release Rate (J/m2) | ||

| 0% | 61.7 | 102.54 | 62.0 | 103.54 | 61.7 | 102.54 | 102.87 0.67 |

| 0.3% | 67.3 | 121.99 | 67.3 | 121.99 | 67.0 | 120.91 | 121.63 0.72 |

| 0.5% | 70.3 | 133.11 | 70.0 | 131.98 | 70.3 | 133.11 | 132.73 0.75 |

| 0.8% | 73.7 | 146.30 | 73.3 | 144.71 | 73.3 | 144.71 | 145.24 1.06 |

| 1% | 77.0 | 159.69 | 76.7 | 158.45 | 76.7 | 158.45 | 158.87 0.82 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Her, S.-C.; Chien, P.-C. Mode II Interfacial Fracture Toughness of Multi-Walled Carbon Nanotubes Reinforced Nanocomposite Film on Aluminum Substrate. Nanomaterials 2020, 10, 904. https://doi.org/10.3390/nano10050904

Her S-C, Chien P-C. Mode II Interfacial Fracture Toughness of Multi-Walled Carbon Nanotubes Reinforced Nanocomposite Film on Aluminum Substrate. Nanomaterials. 2020; 10(5):904. https://doi.org/10.3390/nano10050904

Chicago/Turabian StyleHer, Shiuh-Chuan, and Pao-Chu Chien. 2020. "Mode II Interfacial Fracture Toughness of Multi-Walled Carbon Nanotubes Reinforced Nanocomposite Film on Aluminum Substrate" Nanomaterials 10, no. 5: 904. https://doi.org/10.3390/nano10050904

APA StyleHer, S.-C., & Chien, P.-C. (2020). Mode II Interfacial Fracture Toughness of Multi-Walled Carbon Nanotubes Reinforced Nanocomposite Film on Aluminum Substrate. Nanomaterials, 10(5), 904. https://doi.org/10.3390/nano10050904