Highly Conductive PDMS Composite Mechanically Enhanced with 3D-Graphene Network for High-Performance EMI Shielding Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

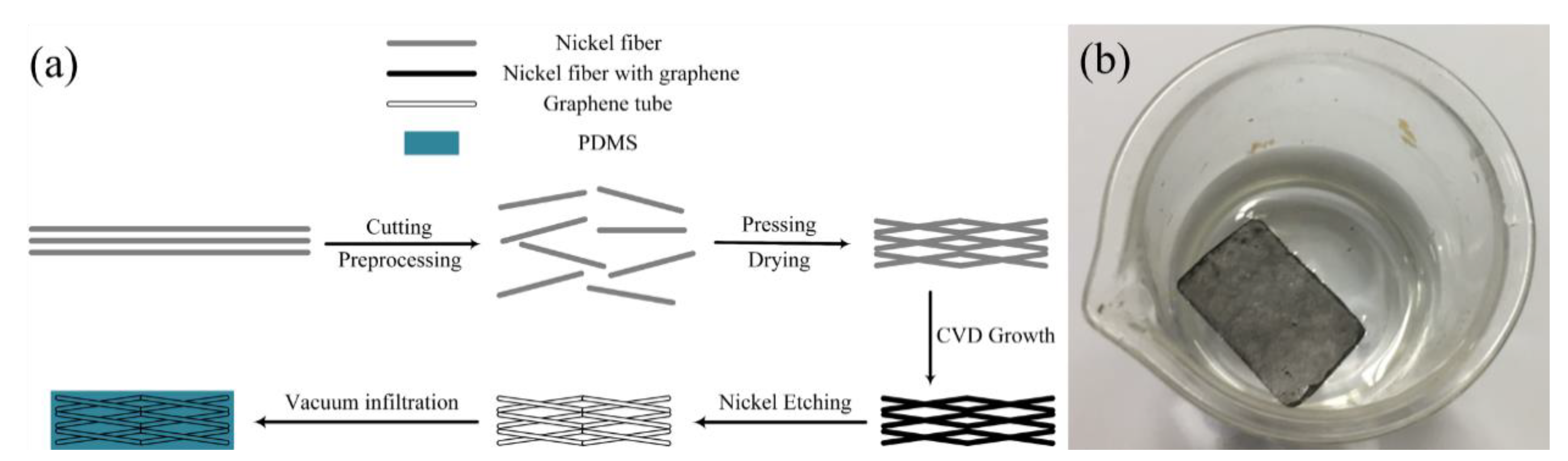

2.2. Preparation of Polydimethylsiloxane/Graphene Network (PDMS/GN) Composite

2.3. Characterization Methods

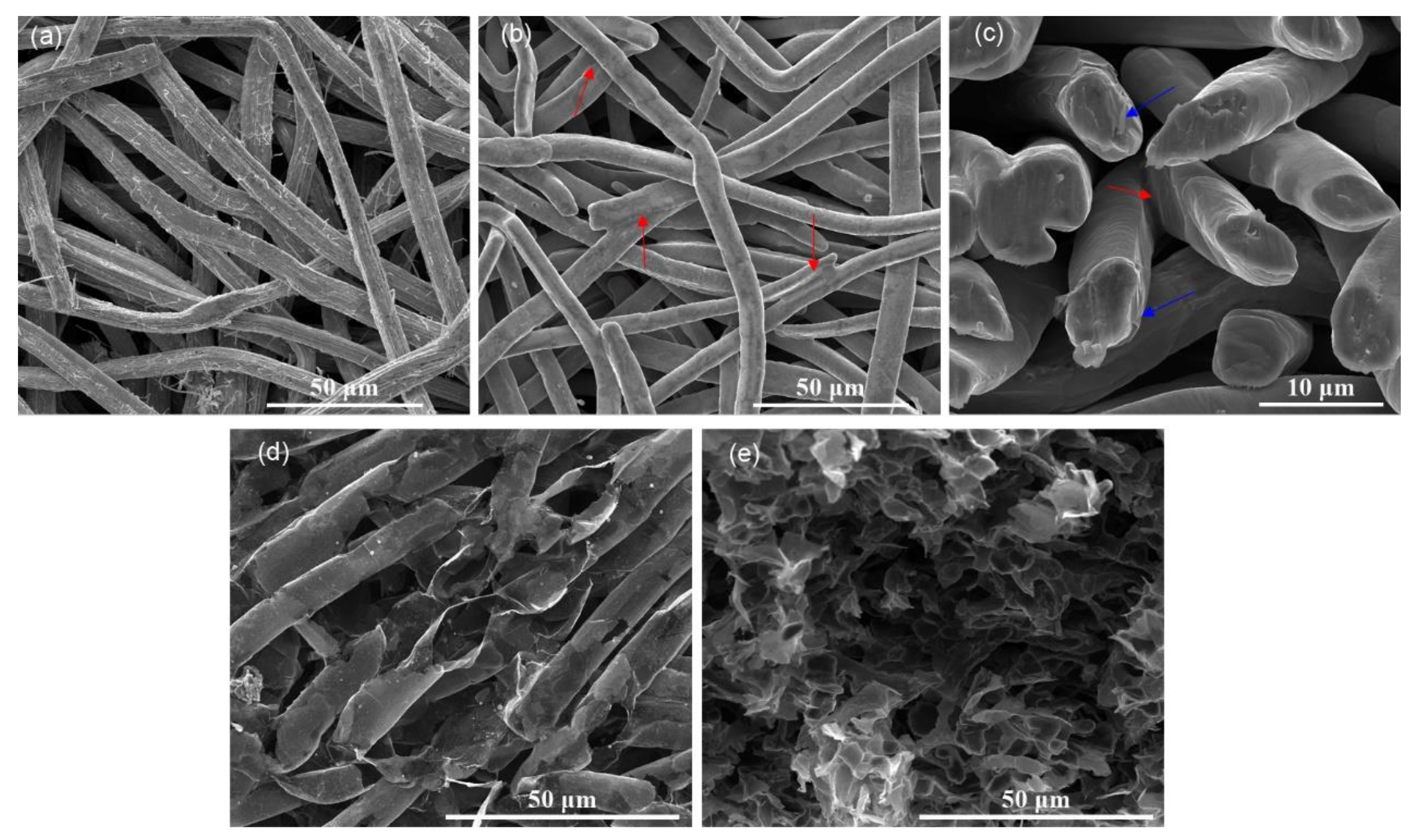

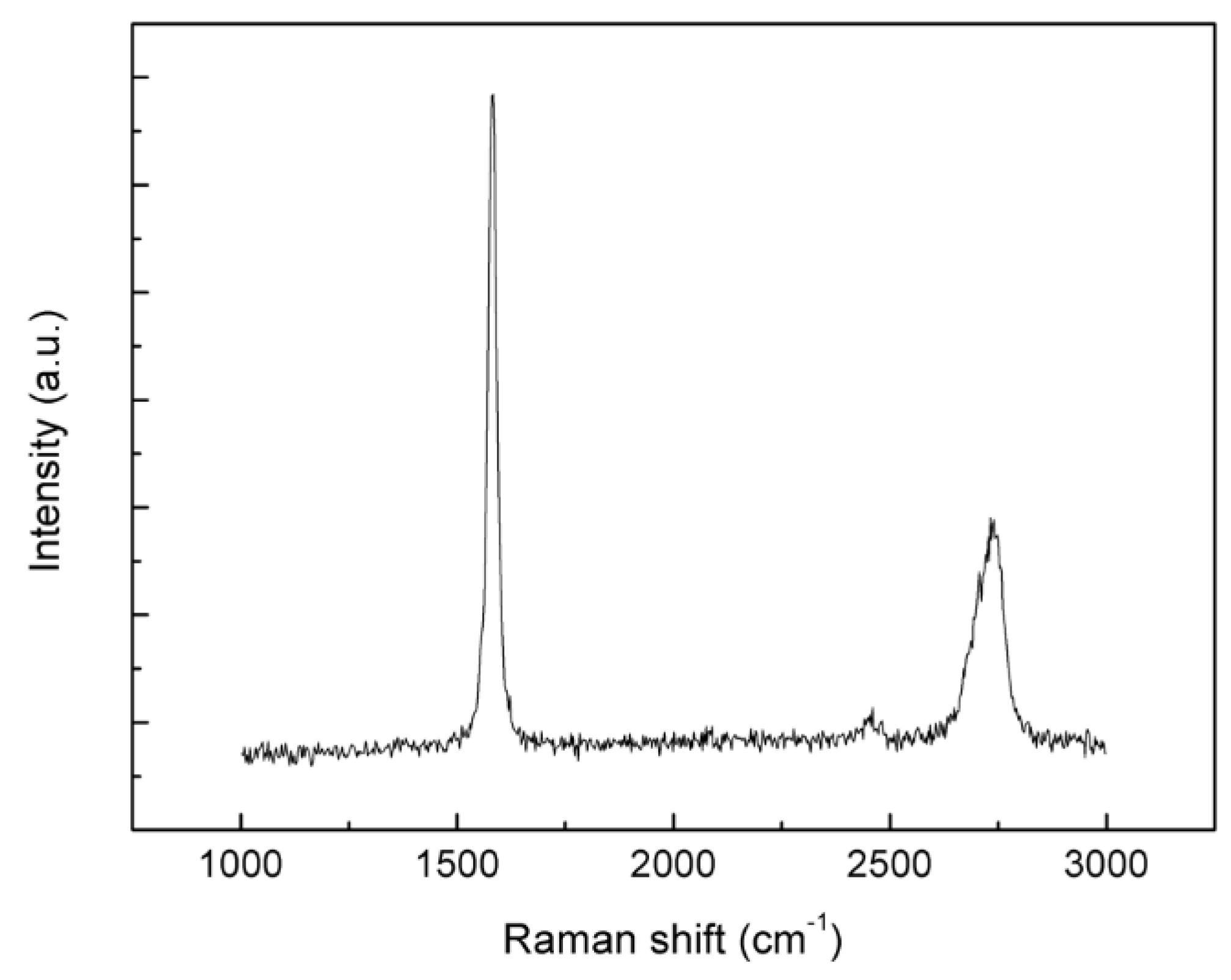

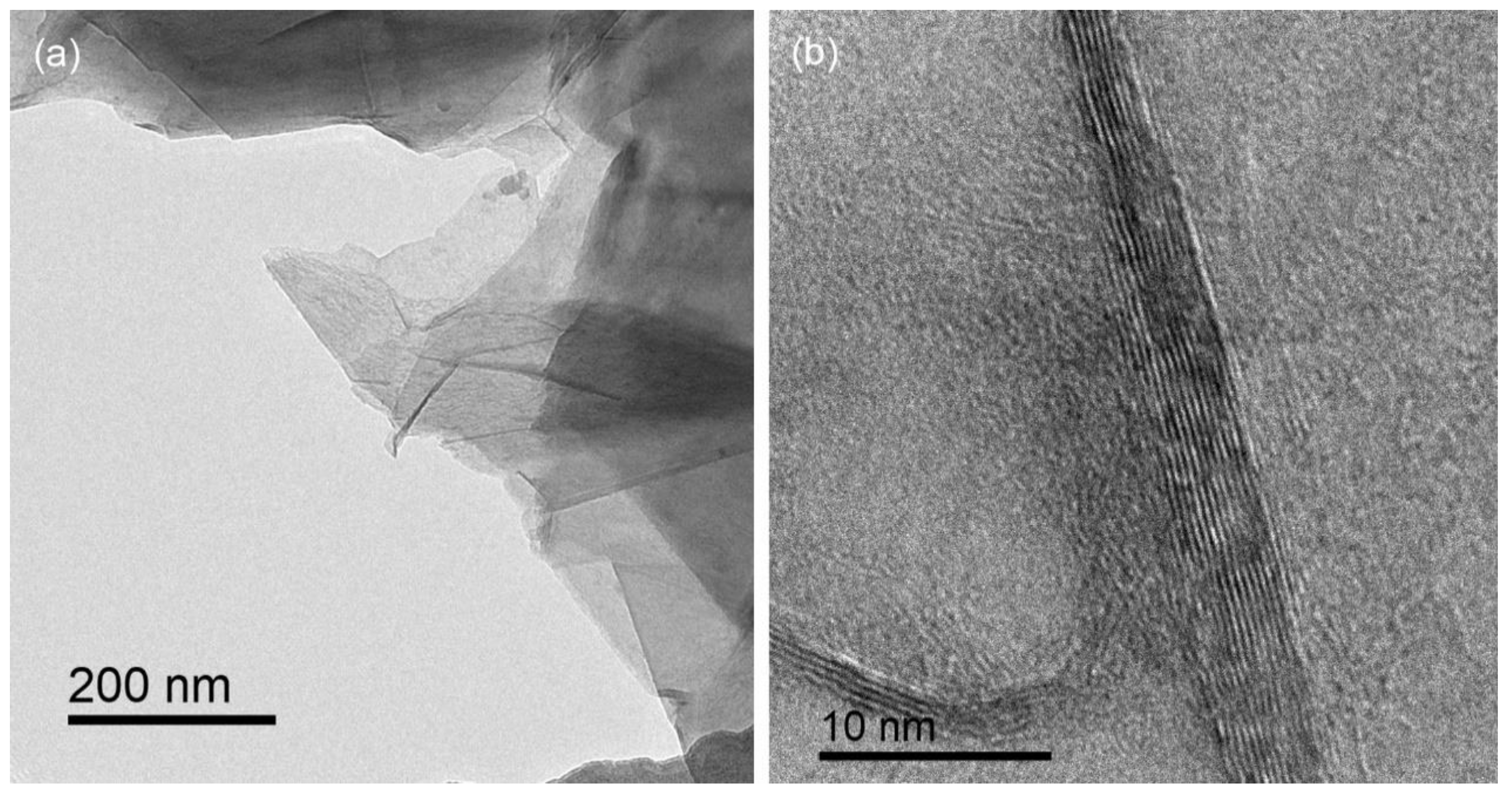

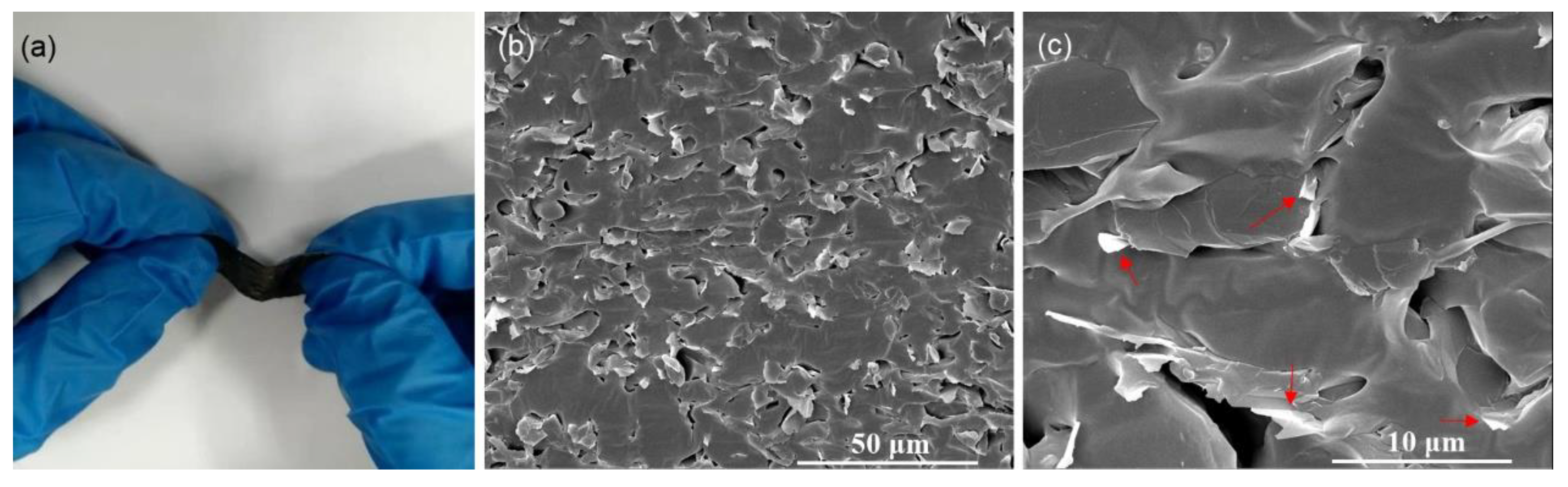

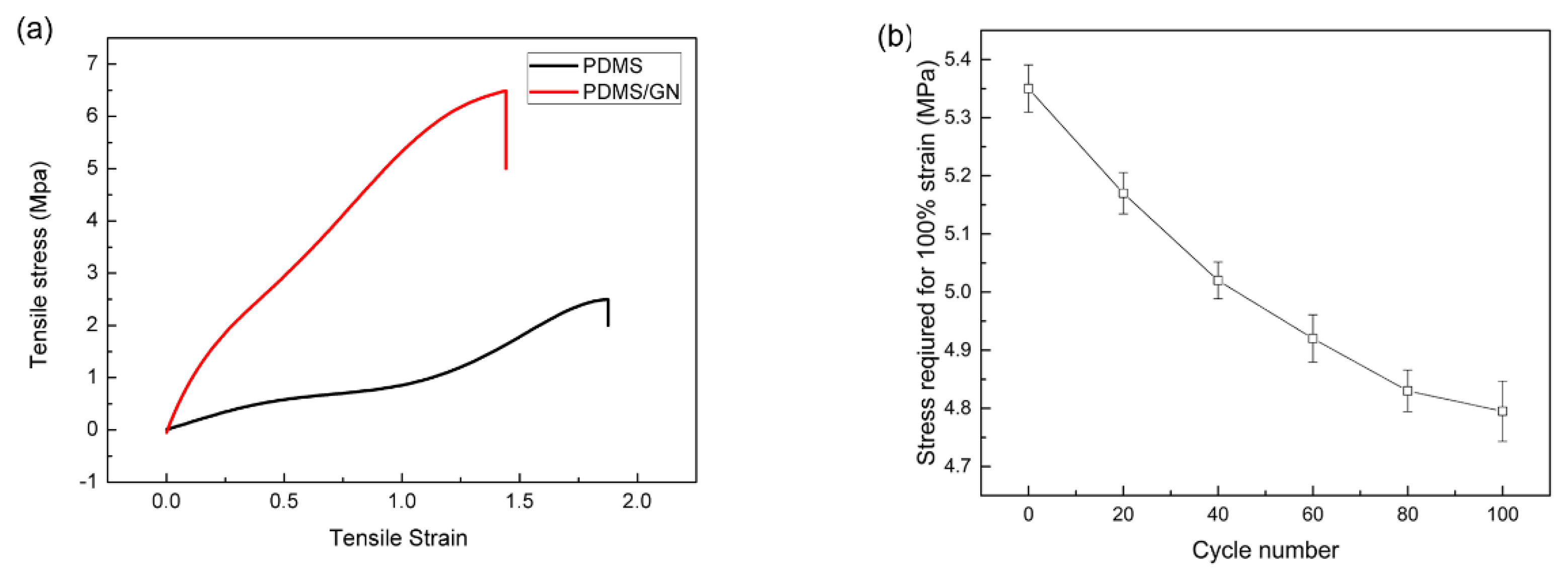

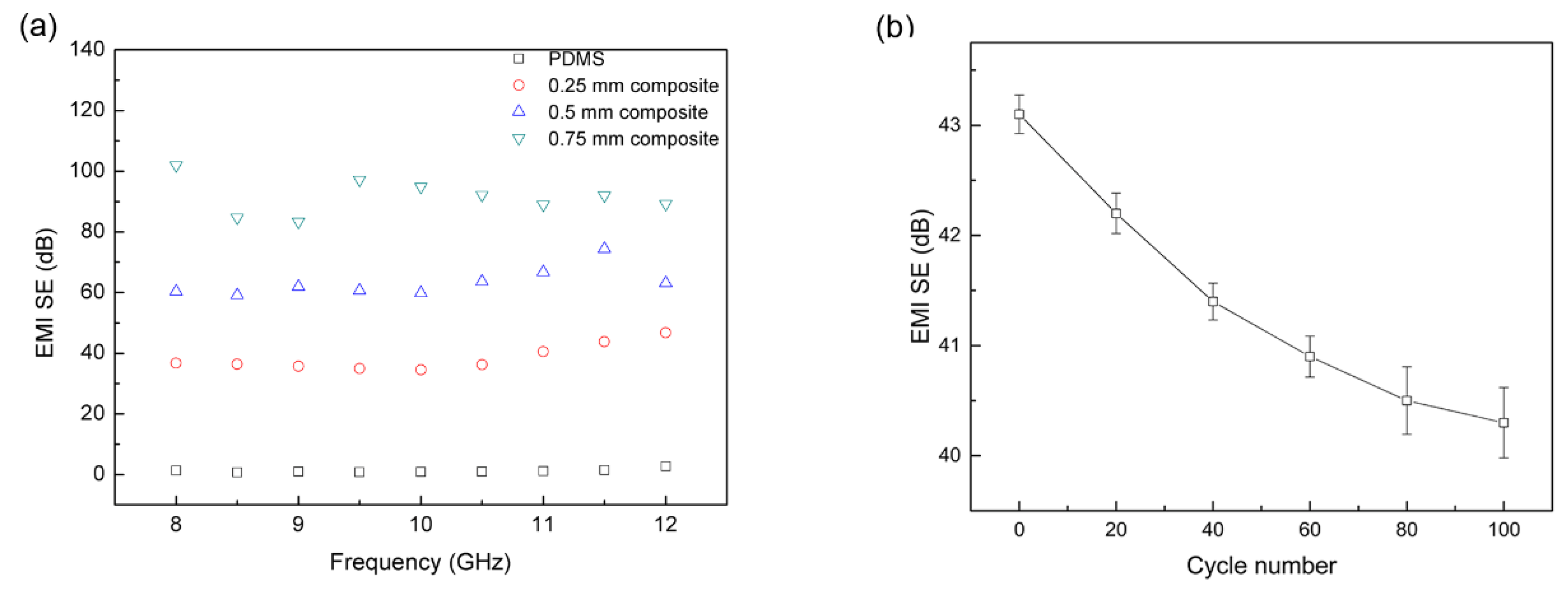

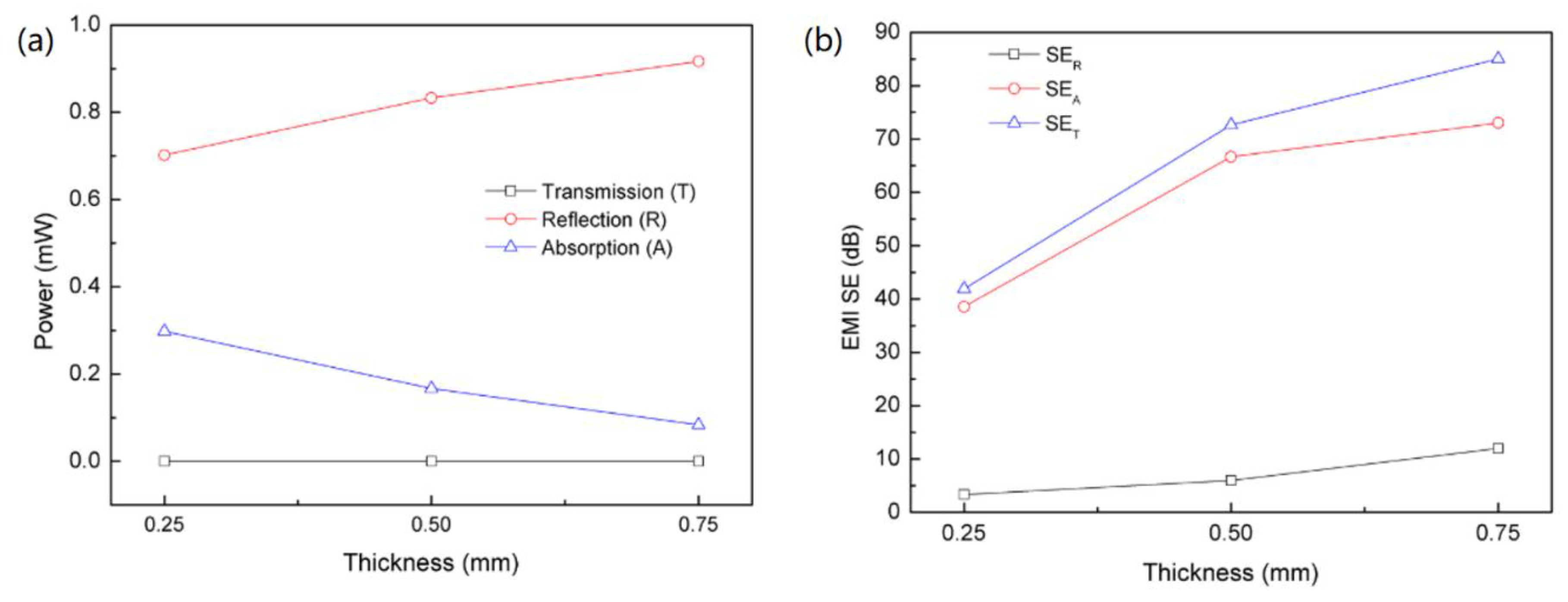

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kasar, V.; Pawar, A. A Novel Approach to Electromagnetic Interference Shielding for Cell Phones. Int. J. Sci. Res. 2014, 3, 1869–1872. [Google Scholar]

- Li, J.; Liu, H.; Guo, J.; Hu, Z.; Wang, Z.J.; Wang, B.; Liu, L.; Huang, Y.D.; Guo, Z.H. Flexible, conductive, porous, fibrillar polymer–gold nanocomposites with enhanced electromagnetic interference shielding and mechanical properties. J. Mater. Chem. C 2017, 5, 1095–1105. [Google Scholar] [CrossRef]

- Miranda-Rius, J.; Lahor-Soler, E.; Brunet-Llobet, L.; de la Cruz, X.S. Risk of electromagnetic interference induced by dental equipment on cardiac implantable electrical devices. Eur. J. Oral Sci. 2016, 124, 559–565. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Shishkin, A.; Koppel, T.; Gupta, N. A review of porous lightweight composite materials for electromagnetic interference shielding. Compos. Part B Eng. 2018, 149, 188–197. [Google Scholar] [CrossRef]

- Han, S.B.; Zhu, Y.M.; Cai, C.; Zhu, J.K.; Han, W.B.; Chen, L.; Zu, X.T.; Yang, H.; Gu, M. Failure mechanism of Au@Co9S8 yolk-shell anode in Li-ion batteries unveiled by in-situ transmission electron microscopy. Appl. Phys. Lett. 2019, 114, 113901. [Google Scholar] [CrossRef]

- Han, Y.; Liu, Y.X.; Han, L.; Lin, J.; Jin, P. High-performance hierarchical graphene/metal-mesh film for optically transparent electromagnetic interference shielding. Carbon 2017, 15, 34–42. [Google Scholar] [CrossRef]

- Wang, Y.P.; Jiang, F.C.; Chen, J.F.; Sun, X.F.; Xian, T.; Yang, H. In situ construction of CNT/CuS hybrids and their application in photodegradation for removing organic dyes. Nanomaterials 2020, 10, 178. [Google Scholar] [CrossRef]

- Vishwanath, S.K.; Kim, D.G.; Kim, J. Electromagnetic interference shielding effectiveness of invisible metal-mesh prepared by electrohydrodynamic jet printing. Jpn. J. Appl. Phys. 2014, 53, 5. [Google Scholar] [CrossRef]

- Zheng, C.X.; Yang, H.; Cui, Z.M.; Zhang, H.M.; Wang, X.X. A novel Bi4Ti3O12/Ag3PO4 heterojunction photocatalyst with enhanced photocatalytic performance. Nanoscale Res. Lett. 2017, 12, 608. [Google Scholar] [CrossRef]

- Yan, Y.X.; Yang, H.; Yi, Z.; Li, R.S.; Xian, T. Design of ternary CaTiO3/g-C3N4/AgBr Z-scheme heterostructured photocatalysts and their application for dye photodegradation. Solid State Sci. 2020, 100, 106102. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Z.Y.; Liu, X.; Shen, X.; Zheng, Q.B.; Xue, Q.; Kim, J.K. Ultralight graphene foam/conductive polymer composites for exceptional electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2017, 9, 9059–9069. [Google Scholar] [CrossRef]

- Pu, J.; Li, G.P.; Jiang, Q.Q.; Zu, X.T. Deformed dispersion relation constraint with hydrogen atom 1S-2S transition. Chin. Phys. C 2020, 44, 014001. [Google Scholar] [CrossRef]

- Yan, Y.X.; Yang, H.; Yi, Z.; Xian, T.; Li, R.S.; Wang, X.X. Constructuion of Ag2S@CaTiO3 heterojunction photocatalysts for enhanced photocatalytic degradation of dyes. Desalin. Water Treat. 2019, 170, 349–360. [Google Scholar] [CrossRef]

- Qin, F.; Chen, Z.Q.; Chen, X.F.; Yi, Z.; Yao, W.T.; Duan, T.; Wu, P.H.; Yang, H.; Li, G.F.; Yi, Y.G. A Tunable Triple-Band Near-Infrared Metamaterial Absorber Based on Au Nano-Cuboids Array. Nanomaterials 2020, 10, 207. [Google Scholar] [CrossRef]

- Yu, W.C.; Zhang, G.Q.; Liu, Y.H.; Xu, L.; Yan, D.X.; Huang, H.D.; Tang, J.H.; Xu, J.Z.; Li, Z.M. Selective electromagnetic interference shielding performance and superior mechanical strength of conductive polymer composites with oriented segregated conductive networks. Chem. Eng. J. 2019, 373, 556–564. [Google Scholar] [CrossRef]

- Li, J.K.; Chen, Z.Q.; Yang, H.; Yi, Z.; Chen, X.F.; Yao, W.T.; Duan, T.; Wu, P.H.; Li, G.F.; Yi, Y.G. Tunable Broadband Solar Energy Absorber Based on Monolayer Transition Metal Dichalcogenides Materials Using Au Nanocubes. Nanomaterials 2020, 10, 257. [Google Scholar] [CrossRef]

- Cai, C.; Mi, Y.; Han, S.B.; Wang, Q.; Liu, W.; Wu, X.Q.; Zheng, Z.; Xia, X.; Qiao, L.; Zhou, W.L.; et al. Engineering ordered dendrite-like nickel selenide as electrocatalyst. Electrochim. Acta 2019, 295, 92–98. [Google Scholar] [CrossRef]

- Yan, Y.X.; Yang, H.; Yi, Z.; Wang, X.X.; Li, R.S.; Xian, T. Evolution of Bi nanowires from BiOBr nanoplates through a NaBH4 reduction method with enhanced photodegradation performance. Environ. Eng. Sci. 2020, 37, 64–77. [Google Scholar] [CrossRef]

- Zeng, Z.H.; Jin, H.; Chen, M.J.; Li, W.W.; Zhou, L.C.; Xue, X.; Zhang, Z. Microstructure design of lightweight, flexible, and high electromagnetic shielding porous multiwalled carbon nanotube/polymer composites. Small 2017, 13, 1701388. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S.; Ghosh, S.; Ganguly, S.; Das, P.; Ravindren, R.; Sit, S.; Chakraborty, G.; Das, N.C. Highly conductive and flexible nano-structured carbon-based polymer nanocomposites with improved electromagnetic-interference-shielding performance. Mater. Res. Express 2017, 4, 105039. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, K.; Zhang, X.; Ding, X.; Zhang, Z.X.; Bao, C.; Guo, L.; Chen, L.; Tian, X.Y. 3D network porous polymeric composites with outstanding electromagnetic interference shielding. Compos. Sci. Technol. 2016, 125, 22–29. [Google Scholar] [CrossRef]

- Zeng, Z.H.; Jin, H.; Chen, M.J.; Li, W.W.; Zhou, L.C.; Zhang, Z. Lightweight and anisotropic porous MWCNT/WPU composites for ultrahigh performance electromagnetic interference shielding. Adv. Funct. Mater. 2016, 26, 303–310. [Google Scholar] [CrossRef]

- Theravalappil, R.; Svoboda, P.; Vilcakova, J.; Poongavalappil, S.; Slobodian, P.; Svobodova, D. A comparative study on the electrical, thermal and mechanical properties of ethylene–octene copolymer based composites with carbon fillers. Mater. Design 2014, 60, 458–467. [Google Scholar] [CrossRef]

- Mahapatra, S.S.; Yadav, S.K.; Lee, B.H.; Cho, J.W. Nanodiamond-grafted hyperbranched polymers anchored with carbon nanotubes: Mechanical, thermal, and photothermal shape-recovery properties. Polymer 2019, 160, 204–209. [Google Scholar] [CrossRef]

- Tang, Y.L.; Li, D.J.; Ao, D.Y.; Li, S.; Zu, X.T. Ultralight, highly flexible and conductive carbon foams for high performance electromagnetic shielding application. J. Mater. Sci. Mater. Electron. 2018, 29, 13643–13652. [Google Scholar] [CrossRef]

- Yan, D.X.; Ren, P.G.; Peng, H.; Fu, Q.; Yang, M.B.; Li, Z.M. Efficient electromagnetic interference shielding of lightweight graphene/polystyrene composite. J. Mater. Chem. 2012, 22, 18772–18774. [Google Scholar] [CrossRef]

- Yun, J.J.; Khan, F.A.; Baik, S. Janus graphene oxide sponges for high-purity fast separation of both water-in-oil and oil-in-water emulsions. ACS Appl. Mater. Interfaces 2017, 9, 16694–16703. [Google Scholar] [CrossRef]

- Chen, P.H.; Sie, M.C.; Jeng, P.D.; Wu, R.C.; Wang, C.N. Graphene sponge as an efficient and recyclable oil sorbent. In Proceedings of the 4th International Conference on the Advancement of Materials and Nanotechnology, Universiti Teknologi MARA, Malaysia, AIP Conference Proceedings, Langkawi, Malaysia, 9–11 November 2016; Volume 1877, p. 030005. [Google Scholar]

- Ye, S.B.; Feng, J.C.; Wu, P.Y. Deposition of three-dimensional graphene aerogel on nickel foam as a binder-free supercapacitor electrode. ACS Appl. Mater. Interfaces 2013, 5, 7122–7129. [Google Scholar] [CrossRef]

- Bello, A.; Makgopa, K.; Fabiane, M.; Dodoo-Ahrin, D.; Ozoemena, K.I.; Manyala, N. Chemical adsorption of NiO nanostructures on nickel foam-graphene for supercapacitor applications. J. Mater. Sci. 2013, 48, 6707–6712. [Google Scholar] [CrossRef]

- Tang, Y.L.; Peng, P.; Wang, S.Y.; Liu, Z.H.; Zu, X.T.; Yu, Q.K. Continuous production of graphite nanosheets by bubbling chemical vapor deposition using molten copper. Chem. Mater. 2017, 29, 8404–8411. [Google Scholar] [CrossRef]

- Jiang, W.; Xin, H.; Li, W. Microcellular 3D graphene foam via chemical vapor deposition of electroless plated nickel foam templates. Mater. Lett. 2016, 162, 105–109. [Google Scholar] [CrossRef]

- Chen, Z.P.; Xu, C.; Ma, C.Q.; Ren, W.C.; Cheng, H.M. Lightweight and flexible graphene foam composites for high-performance electromagnetic interference shielding. Adv. Mater. 2013, 25, 1296–1300. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [PubMed]

- Kolanowska, A.; Janas, D.; Herman, A.P.; Jedrysiak, R.; Gizewski, T.; Boncel, S. From blackness to invisibility—Carbon nanotubes role in the attenuation of and shielding from radio waves for stealth technology. Carbon 2018, 126, 31–52. [Google Scholar] [CrossRef]

- Hu, X.D.; Qian, W.; Li, X.C.; Fei, G.X.; Luo, G.X.; Wang, Z.H.; Xia, H.S. A novel method to prepare homogeneous biocompatible graphene-based PDMS composites with enhanced mechanical, thermal and antibacterial properties. Polym. Compos. 2019, 40, E1397–E1406. [Google Scholar] [CrossRef]

- Fang, H.M.; Zhao, Y.H.; Zhang, Y.F.; Ren, Y.J.; Bai, S.L. Three-dimensional graphene foam-filled elastomer composites with high thermal and mechanical properties. ACS Appl. Mater. Interfaces 2017, 9, 26447–26459. [Google Scholar] [CrossRef]

- Liang, J.J.; Wang, Y.; Huang, Y.; Ma, Y.F.; Liu, Z.F.; Cai, J.M.; Zhang, C.D.; Gao, H.J.; Chen, Y.S. Electromagnetic interference shielding of graphene/epoxy composites. Carbon 2009, 47, 922–925. [Google Scholar] [CrossRef]

- Huang, Y.; Li, N.; Ma, Y.F.; Du, F.; Li, F.F.; He, X.B.; Lin, X.; Gao, H.J.; Chen, Y.S. The influence of single-walled carbon nanotube structure on the electromagnetic interference shielding efficiency of its epoxy composites. Carbon 2007, 45, 1614–1621. [Google Scholar] [CrossRef]

- Al-Saleh, M.H. Influence of conductive network structure on the EMI shielding and electrical percolation of carbon nanotube/polymer nanocomposites. Synth. Met. 2015, 205, 78–84. [Google Scholar] [CrossRef]

- Yan, D.X.; Pang, H.; Li, B.; Vajtai, R.; Xu, L.; Ren, P.G.; Wang, J.H.; Li, Z.M. Structured Reduced Graphene Oxide/Polymer Composites for Ultra-Efficient Electromagnetic Interference Shielding. Adv. Funct. Mater. 2015, 25, 559–566. [Google Scholar] [CrossRef]

- Shahzad, F.; Yu, S.; Kumar, P.; Lee, J.W.; Kim, Y.H.; Hong, S.M.; Koo, C.M. Sulfur doped graphene/polystyrene nanocomposites for electromagnetic interference shielding. Compos. Struct. 2015, 133, 1267–1275. [Google Scholar] [CrossRef]

- Arjmand, M.; Apperley, T.; Okoniewski, M.; Sundararaj, U. Comparative study of electromagnetic interference shielding properties of injection molded versus compression molded multi-walled carbon nanotube/polystyrene composites. Carbon 2012, 50, 5126–5134. [Google Scholar] [CrossRef]

- Liu, Z.F.; Bai, G.; Huang, Y.; Ma, Y.F.; Du, F.; Li, F.F.; Guo, T.Y.; Chen, Y.S. Reflection and absorption contributions to the electromagnetic interference shielding of single-walled carbon nanotube/polyurethane composites. Carbon 2007, 45, 821–827. [Google Scholar] [CrossRef]

- Hsiao, S.T.; Ma, C.C.M.; Tien, H.W.; Liao, W.H.; Wang, Y.S.; Li, S.M.; Huang, Y.C. Using a non-covalent modification to prepare a high electromagnetic interference shielding performance graphene nanosheet/water-borne polyurethane composite. Carbon 2013, 60, 57–66. [Google Scholar] [CrossRef]

- Theilmann, P.; Yun, S.J.; Asbeck, P.; Park, S.H. Superior electromagnetic interference shielding and dielectric properties of carbon nanotube composites through the use of high aspect ratio CNTs and three-roll milling. Org. Electron. 2013, 14, 1531–1537. [Google Scholar] [CrossRef]

- Hsiao, S.T.; Ma, C.C.M.; Tien, H.W.; Liao, W.H.; Wang, Y.S.; Li, S.M.; Yang, C.Y.; Lin, S.C.; Yang, R.B. Effect of covalent modification of graphene nanosheets on the electrical property and electromagnetic interference shielding performance of a water-borne polyurethane composite. ACS Appl. Mater. Interfaces 2015, 7, 2817–2826. [Google Scholar] [CrossRef]

- Eswaraiah, V.; Sankaranarayanan, V.; Ramaprabhu, S. Functionalized graphene–PVDF foam composites for EMI shielding. Macromol. Mater. Eng. 2011, 296, 894–898. [Google Scholar] [CrossRef]

- Moglie, F.; Micheli, D.; Laurenzi, S.; Marchetti, M.; Primiani, V.M. Electromagnetic shielding performance of carbon foams. Carbon 2012, 50, 1972–1980. [Google Scholar] [CrossRef]

| Polymer Matrix | Filler | Filler Loading (%) | Conductivity (S/m) | Thickness (mm) | Frequency | EMI SE (dB) | Ref. |

|---|---|---|---|---|---|---|---|

| Epoxy | r-GO | 15 wt | ~4 | 2 | X-band | 21 | [38] |

| Epoxy | SWCNT | 15 wt | 0.2 | 2 | X-band | 25 | [39] |

| PE | MWCNT | 10 wt | - | 1 | X-band | 50 | [40] |

| PS | r-GO | 7.0 wt | 43.5 | 2.5 | X-band | 45.1 | [41] |

| PS | S doped r-GO | 7.5 vol | 33 | 2 | 12–18 GHz | 24.5 | [42] |

| PS | MWCNT | 20 wt | 0.0072 | 2 | X-band | 63.3 | [43] |

| PU | SWCNT | 20 wt | 0.00022 | 1 | X-band | 17 | [44] |

| WPU | r-GO | 7.7 wt | 5.1 | 2 | X-band | 32 | [45] |

| PU | Gr | 20 wt | 2500 | 1 | X-band | 80 | [31] |

| PDMS | GN | 0.8 wt | 200 | 1 | X-band | 19.98 | [33] |

| PDMS | MWCNT | 5.7 vol | 301 | 2 | X-band | 80 | [46] |

| PDMS | GN | 1.2 wt | 6100 | 0.75 | X band | 90 | Present work |

| silicone | Ag + Al | / | 12,500 | / | 10 GHz | 85 | Commercial products (Holland Shielding Systems B.V.) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ao, D.; Tang, Y.; Xu, X.; Xiang, X.; Yu, J.; Li, S.; Zu, X. Highly Conductive PDMS Composite Mechanically Enhanced with 3D-Graphene Network for High-Performance EMI Shielding Application. Nanomaterials 2020, 10, 768. https://doi.org/10.3390/nano10040768

Ao D, Tang Y, Xu X, Xiang X, Yu J, Li S, Zu X. Highly Conductive PDMS Composite Mechanically Enhanced with 3D-Graphene Network for High-Performance EMI Shielding Application. Nanomaterials. 2020; 10(4):768. https://doi.org/10.3390/nano10040768

Chicago/Turabian StyleAo, Dongyi, Yongliang Tang, Xiaofeng Xu, Xia Xiang, Jingxia Yu, Sean Li, and Xiaotao Zu. 2020. "Highly Conductive PDMS Composite Mechanically Enhanced with 3D-Graphene Network for High-Performance EMI Shielding Application" Nanomaterials 10, no. 4: 768. https://doi.org/10.3390/nano10040768

APA StyleAo, D., Tang, Y., Xu, X., Xiang, X., Yu, J., Li, S., & Zu, X. (2020). Highly Conductive PDMS Composite Mechanically Enhanced with 3D-Graphene Network for High-Performance EMI Shielding Application. Nanomaterials, 10(4), 768. https://doi.org/10.3390/nano10040768