Femtosecond Laser-Induced Periodic Surface Structures on Different Tilted Metal Surfaces

Abstract

1. Introduction

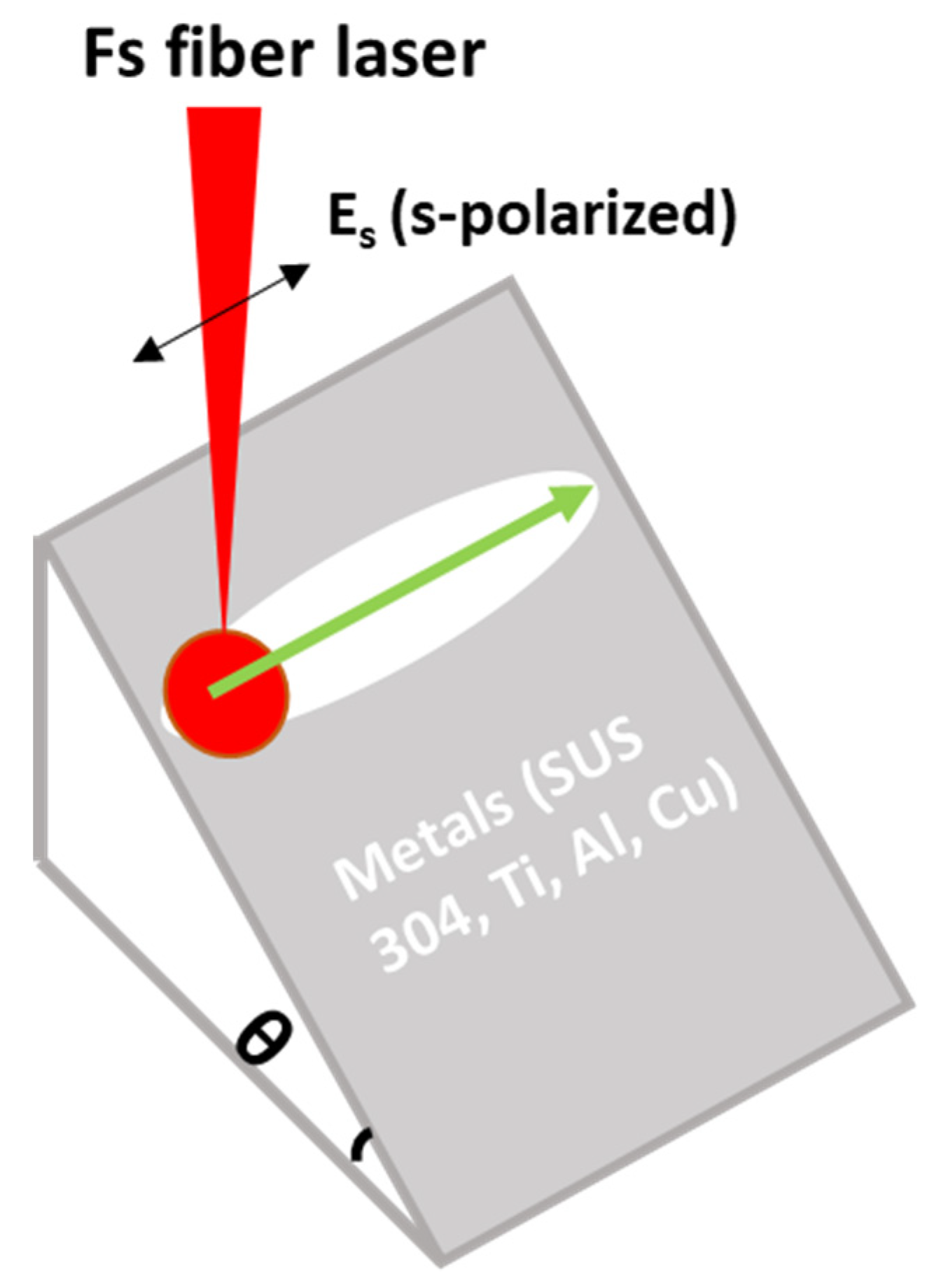

2. Materials and Methods

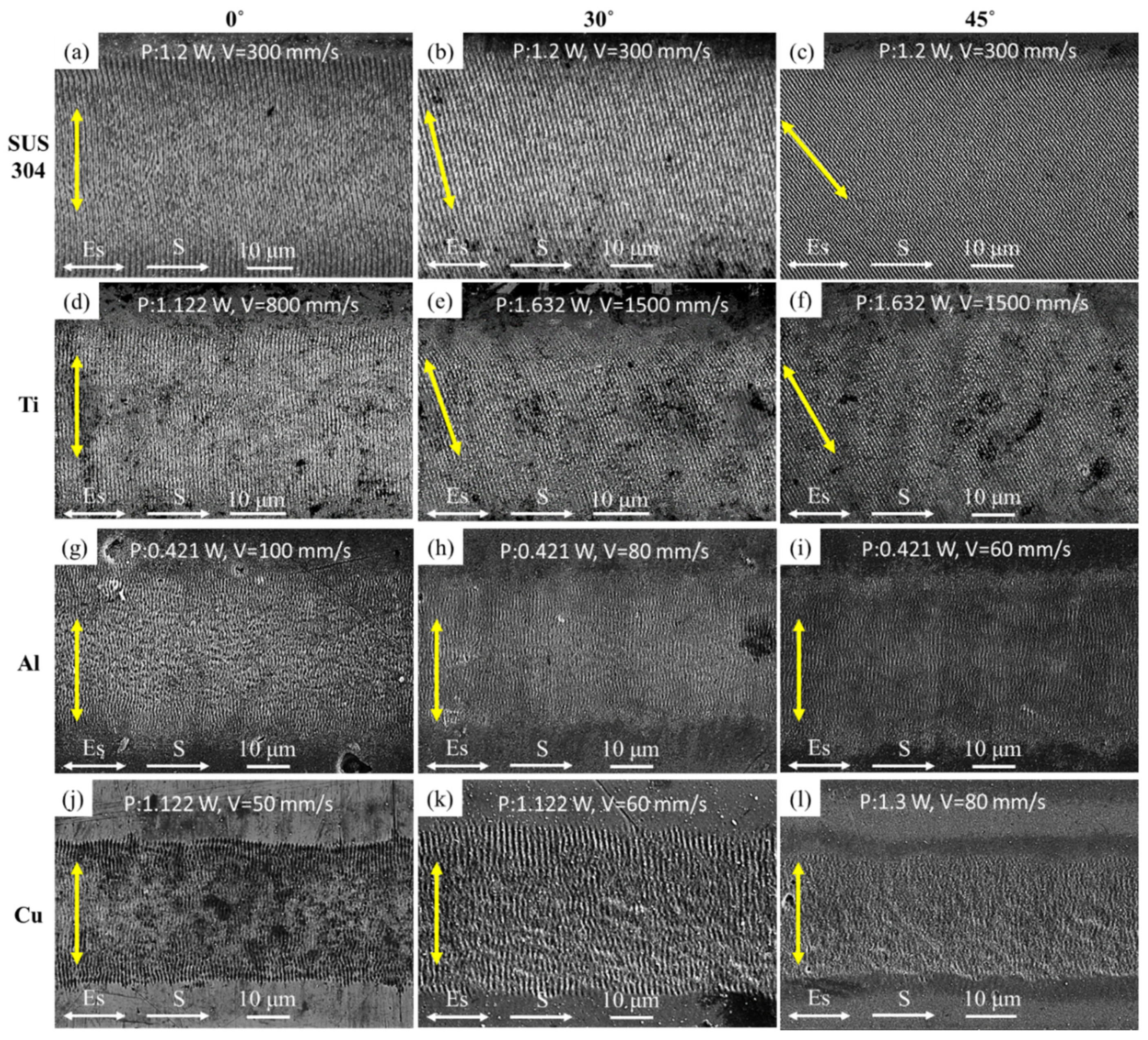

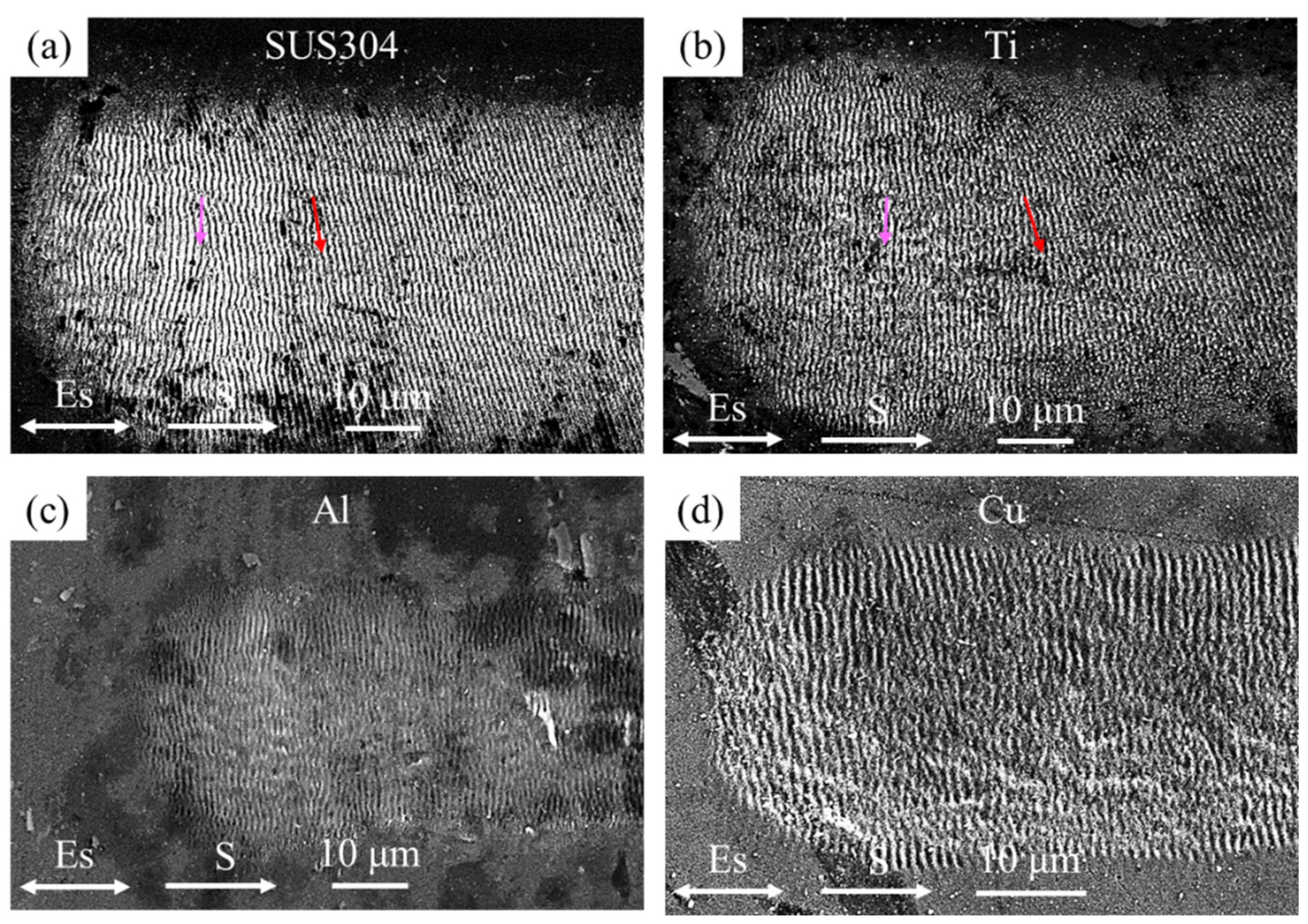

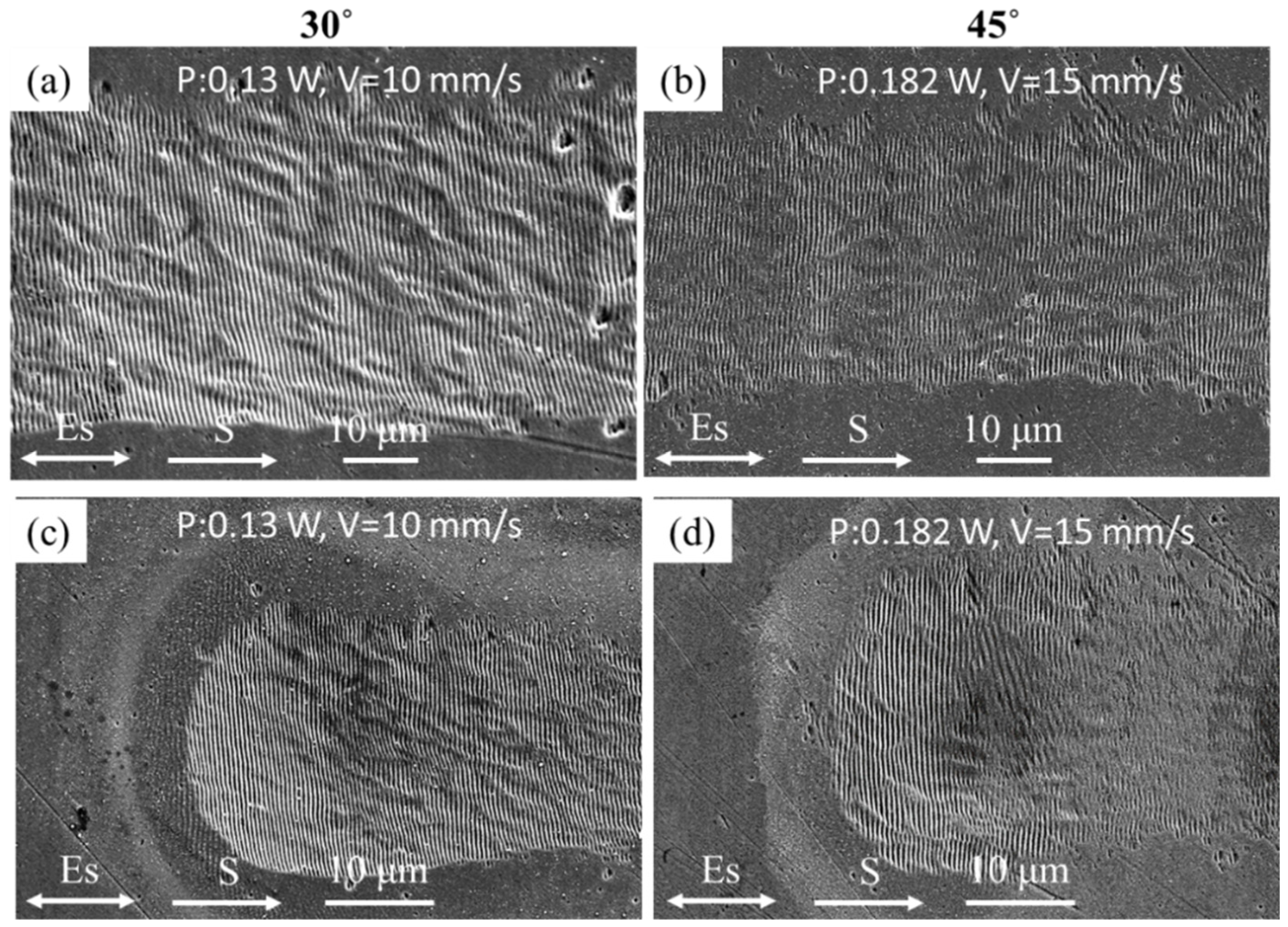

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Birnbaum, M. Semiconductor Surface Damage Produced by Ruby Lasers. J. Appl. Phys. 1965, 36, 3688–3689. [Google Scholar] [CrossRef]

- Bonse, J. Quo Vadis LIPSS?—Recent and Future Trends on Laser-Induced Periodic Surface Structures. Nanomaterials 2020, 10, 1950. [Google Scholar] [CrossRef] [PubMed]

- Bonse, J.; Gräf, S. Maxwell meets Marangoni—A review of theories on laser-induced periodic surface structures. Laser Photonics Rev. 2020, 14, 2000215. [Google Scholar] [CrossRef]

- Florian, C.; Kirner, S.V.; Krüger, J.; Bonse, J. Surface functionalization by laser-induced periodic surface structures. J. Laser Appl. 2020, 32, 022063. [Google Scholar] [CrossRef]

- Buividas, R.; Mikutis, M.; Juodkazis, S. Surface and bulk structuring of materials by ripples with long and short laser pulses: Recent advances. Prog. Quantum Electron. 2014, 38, 119–156. [Google Scholar] [CrossRef]

- Gečys, P. Ripple Formation by Femtosecond Laser Pulses for Enhanced Absorptance of Stainless Steel. J. Laser Micro/Nanoeng. 2015, 10, 129–133. [Google Scholar] [CrossRef]

- Lazzini, G.; Romoli, L.; Tantussi, F.; Fuso, F. Nanostructure patterns on stainless-steel upon ultrafast laser ablation with circular polarization. Opt. Laser Technol. 2018, 107, 435–442. [Google Scholar] [CrossRef]

- Razi, S.; Varlamova, O.; Reif, J.; Bestehorn, M.; Varlamov, S.; Mollabashi, M.; Madanipour, K.; Ratzke, M. Birth of periodic Micro/Nano structures on 316L stainless steel surface following femtosecond laser irradiation; single and multi scanning study. Opt. Laser Technol. 2018, 104, 8–16. [Google Scholar] [CrossRef]

- Ding, K.; Li, M.; Wang, C.; Lin, N.; Wang, H.; Luo, Z.; Duan, J. Sequential Evolution of Colored Copper Surface Irradiated by Defocused Femtosecond Laser. Adv. Eng. Mater. 2020, 22, 1901310. [Google Scholar] [CrossRef]

- Pham, K.X.; Tanabe, R.; Ito, Y. Laser-induced periodic surface structures formed on the sidewalls of microholes trepanned by a femtosecond laser. Appl. Phys. A 2012, 112, 485–493. [Google Scholar] [CrossRef]

- Austin, D.R.; Kafka, K.R.P.; Trendafilov, S.; Shvets, G.; Li, H.; Yi, A.Y.; Szafruga, U.B.; Wang, Z.; Lai, Y.H.; Blaga, C.I.; et al. Laser induced periodic surface structure formation in germanium by strong field mid IR laser solid interaction at oblique incidence. Opt. Express 2015, 23, 19522–19534. [Google Scholar] [CrossRef]

- Garcell, E.M.; Lam, B.; Guo, C. Femtosecond laser-induced herringbone patterns. Appl. Phys. A 2008, 124, 405. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Cong, C.; Lei, Y.; Yang, J.; Guo, C. Formation of Slantwise Surface Ripples by Femtosecond Laser Irradiation. Nanomaterials 2018, 8, 458. [Google Scholar] [CrossRef]

- Schwarz, S.; Rung, S.; Hellmann, R. One-dimensional low spatial frequency LIPSS with rotating orientation on fused silica. Appl. Surf. Sci. 2017, 411, 113–116. [Google Scholar] [CrossRef]

- Liu, Y.H.; Tseng, Y.K.; Cheng, C.W. Direct fabrication of rotational femtosecond laser-induced periodic surface structure on a tilted stainless steel surface. Opt. Laser Technol. 2021, 134, 106648. [Google Scholar] [CrossRef]

- R. Info. Available online: https://refractiveindex.info/?shelf=main&book=Cu&page=Johnson (accessed on 14 August 2020).

- Lin, Z.; Zhigilei, L.V.; Celli, V. Electron-phonon coupling and electron heat capacity of metals under conditions of strong electron-phonon nonequilibrium. Phys. Rev. B 2008, 77, 075133. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, F.; Cheng, Y.; Xu, N.; Xu, Z. Origin of Laser-Induced Near-Subwavelength Ripples: Interference between Surface Plasmons and Incident Laser. ACS Nano 2009, 3, 4062–4070. [Google Scholar] [CrossRef] [PubMed]

- Terekhin, P.; Benhayoun, O.; Weber, S.; Ivanov, D.; Garcia, M.; Rethfeld, B. Influence of surface plasmon polaritons on laser energy absorption and structuring of surfaces. Appl. Surf. Sci. 2020, 512, 144420. [Google Scholar] [CrossRef]

- Gnilitskyi, I.; Derrien, T.J.-Y.; Levy, Y.; Bulgakova, N.M.; Mocek, T.; Orazi, L. High-speed manufacturing of highly regular femtosecond laser-induced periodic surface structures: Physical origin of regularity. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef]

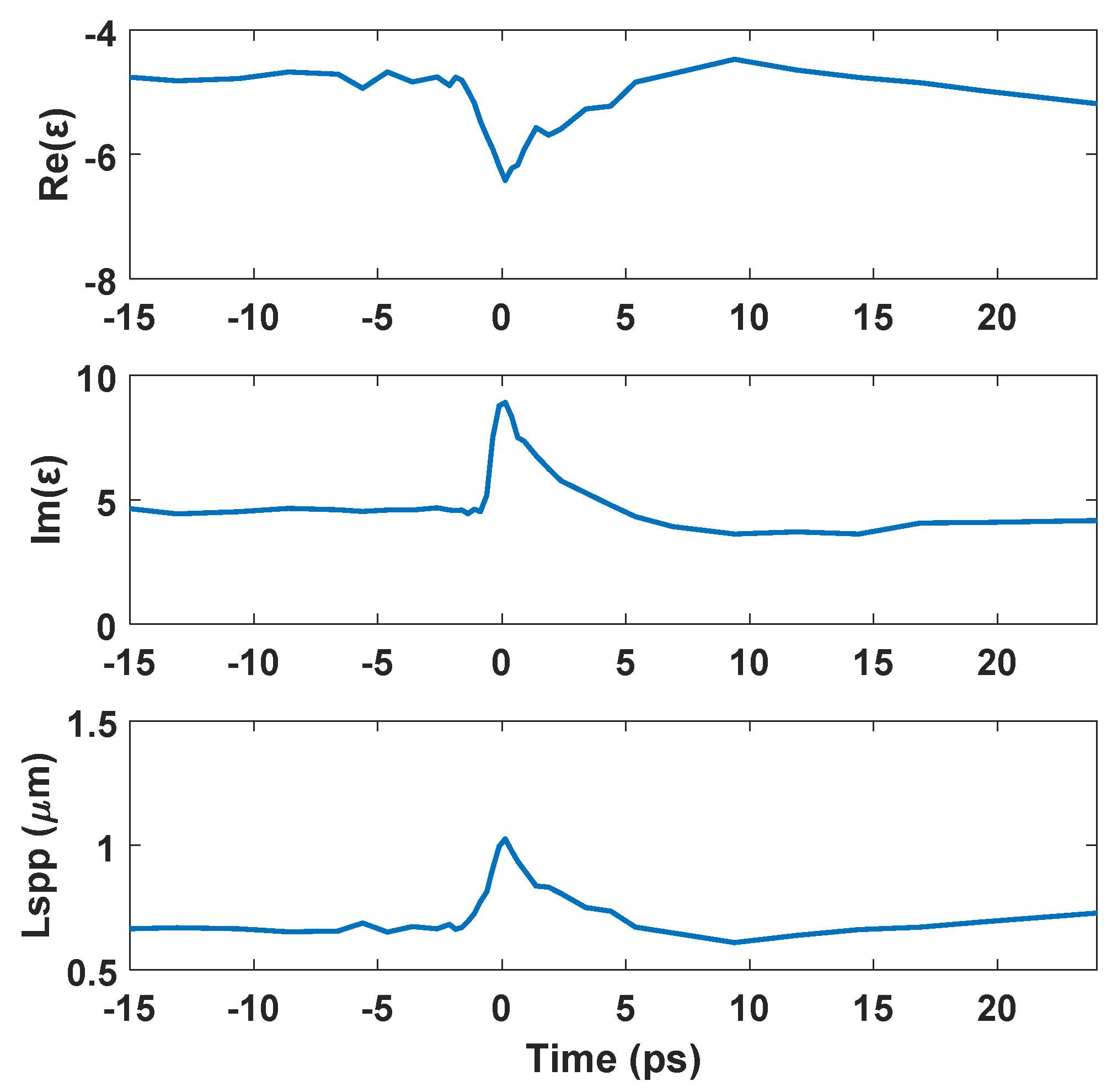

- Winter, J.; Rapp, S.; Schmidt, M.; Huber, H.P. Ultrafast laser energy deposition in copper revealed by simulation and experimental determination of optical properties with pump-probe ellipsometry. In Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XXII; International Society for Optics and Photonics: San Francisco, CA, USA, 2017; Volume 10091, p. 100910. [Google Scholar]

- Gurevich, E.L.; Levy, Y.; Bulgakova, N.M. Three-Step Description of Single-Pulse Formation of Laser-Induced Periodic Surface Structures on Metals. Nanomaterials 2020, 10, 1836. [Google Scholar] [CrossRef]

- Wang, J.; Guo, C. Numerical study of ultrafast dynamics of femtosecond laser-induced periodic surface structure formation on noble metals. J. Appl. Phys. 2007, 102, 53522. [Google Scholar] [CrossRef]

- Hwang, T.Y.; Vorobyev, A.Y.; Guo, C. Ultrafast dynamics of femtosecond laser-induced nanostructure formation on metals. Appl. Phys. Lett. 2009, 95, 123111. [Google Scholar] [CrossRef]

| Material | SUS 304 | Ti | Al | Cu | Cu |

|---|---|---|---|---|---|

| Wavelength λ (nm) | 1030 | 1030 | 1030 | 1030 | 515 |

| LSFL period (nm) at θ = 0° | 959 | 976 | 907 | 919 | 420 |

| LSFL period (nm) at θ = 30° | 893 | 917 | 906 | 932 | 438 |

| LSFL period (nm) at θ = 45° | 788 | 864 | 814 | 1019 | 496 |

| Optical parameters | |||||

| Re (ϵ) at 300 K [16] | −6.6275 | −4.2656 | −95.117 | −45.761 | −5.3328 |

| Im (ϵ) at 300 K [16] | 23.004 | 27.277 | 27.653 | 4.5744 | 6.1794 |

| SPP propagation length Lspp (μm) | 4.02 | 4.52 | 57.32 | 73.35 | 0.78 |

| Thermal parameters | |||||

| Electron-phonon coupling factor G at = 10,000 K (Wm−3K−1 × 1017) [17] | 30.04 | 36.74 | 3.62 | 5.29 | 5.29 |

| Thermal conductivity at 300 K (W/m-K) | 16.2 | 22 | 235 | 385 | 385 |

| Melting Temperature (K) | 1723 | 1930 | 933 | 1356 | 1356 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.-H.; Kuo, K.-K.; Cheng, C.-W. Femtosecond Laser-Induced Periodic Surface Structures on Different Tilted Metal Surfaces. Nanomaterials 2020, 10, 2540. https://doi.org/10.3390/nano10122540

Liu Y-H, Kuo K-K, Cheng C-W. Femtosecond Laser-Induced Periodic Surface Structures on Different Tilted Metal Surfaces. Nanomaterials. 2020; 10(12):2540. https://doi.org/10.3390/nano10122540

Chicago/Turabian StyleLiu, Yi-Hsien, Kong-Kai Kuo, and Chung-Wei Cheng. 2020. "Femtosecond Laser-Induced Periodic Surface Structures on Different Tilted Metal Surfaces" Nanomaterials 10, no. 12: 2540. https://doi.org/10.3390/nano10122540

APA StyleLiu, Y.-H., Kuo, K.-K., & Cheng, C.-W. (2020). Femtosecond Laser-Induced Periodic Surface Structures on Different Tilted Metal Surfaces. Nanomaterials, 10(12), 2540. https://doi.org/10.3390/nano10122540