Review of Domain Wall Dynamics Engineering in Magnetic Microwires

Abstract

1. Introduction

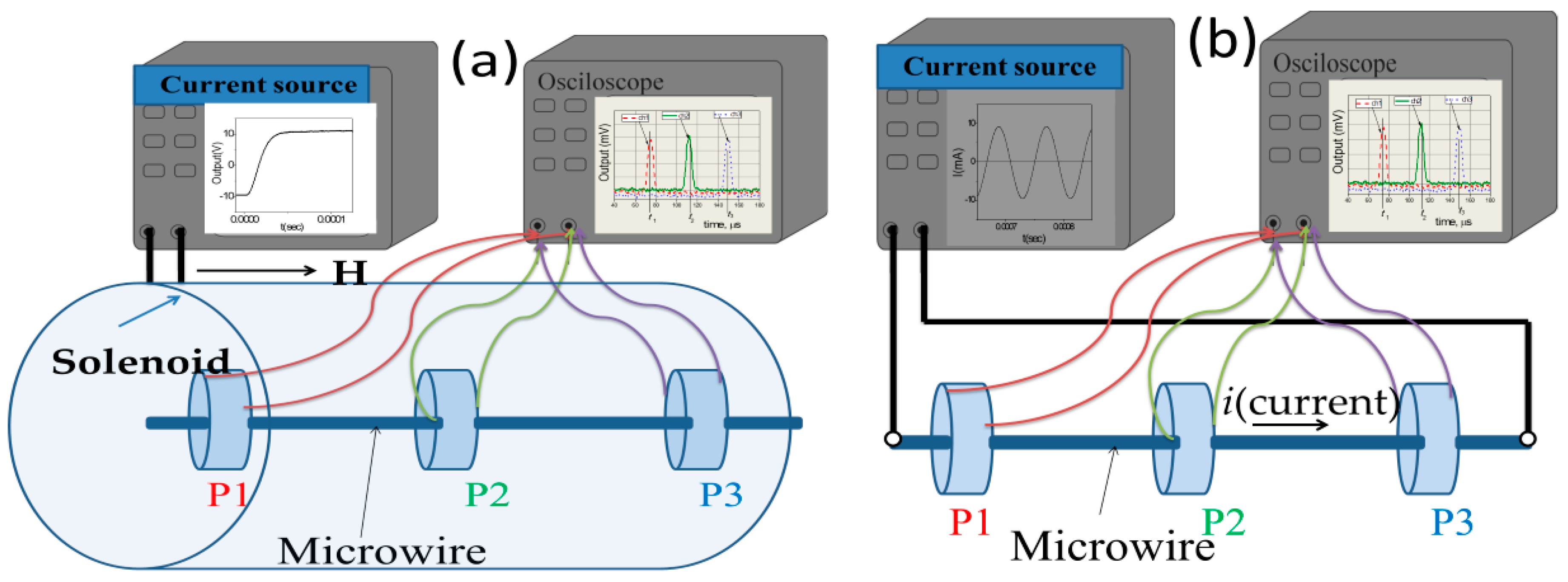

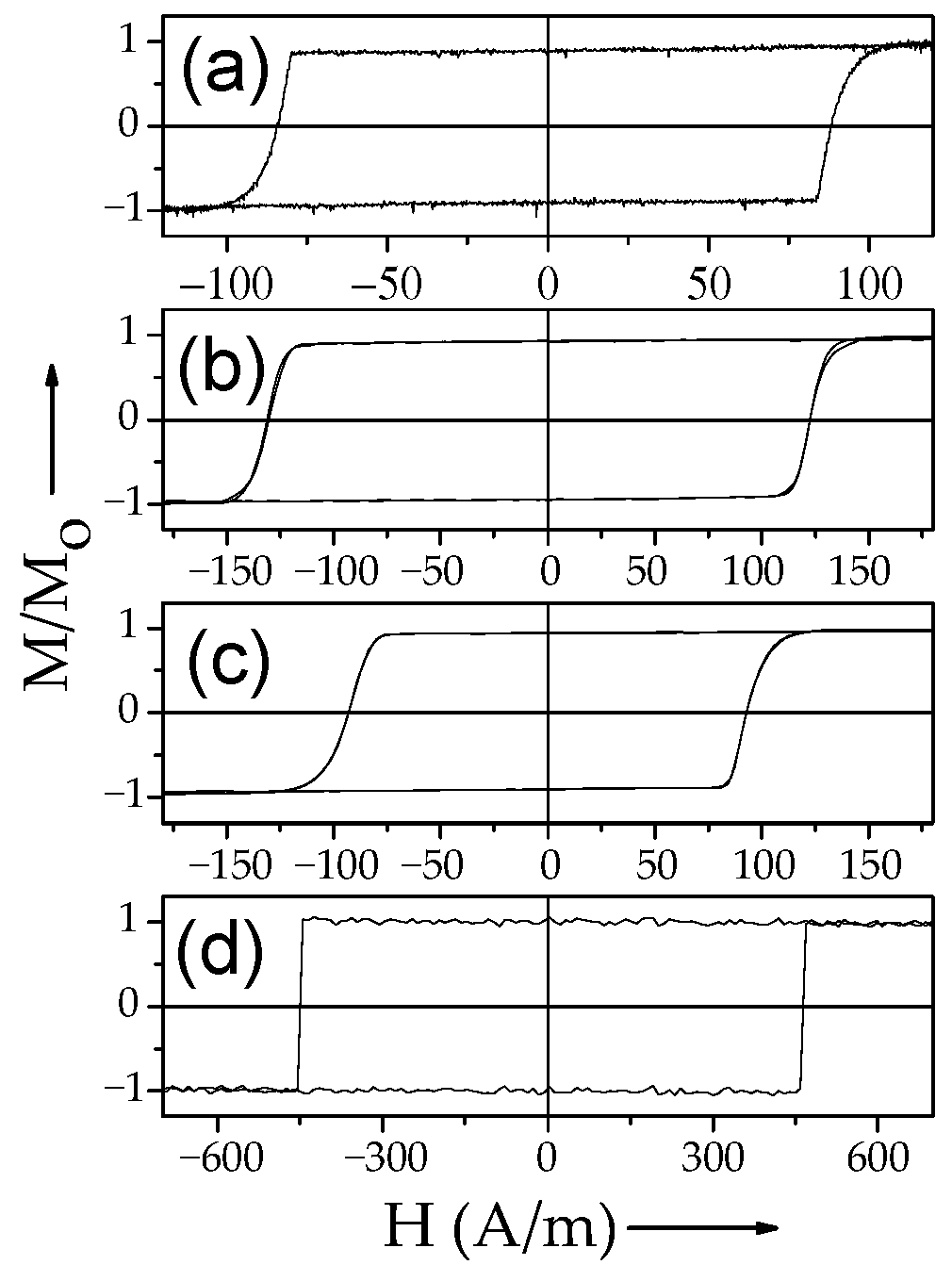

2. Materials and Methods

3. Results and Discussion

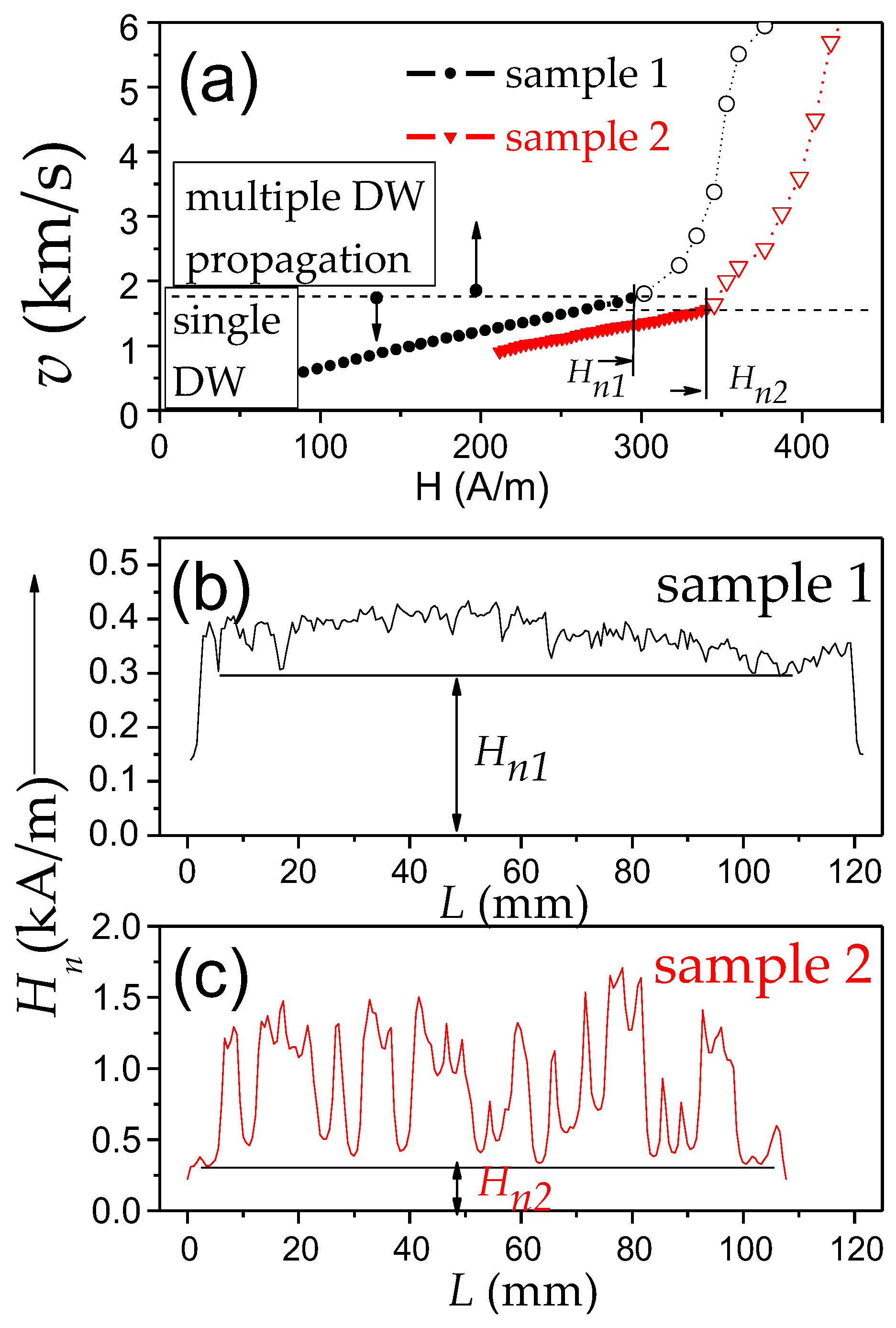

- Single and multiple DW propagation regimes: defect influence and limits of a single domain wall regime.

3.1. Single DW Propagation in Amorphous Microwires and Role of Defects

- (i)

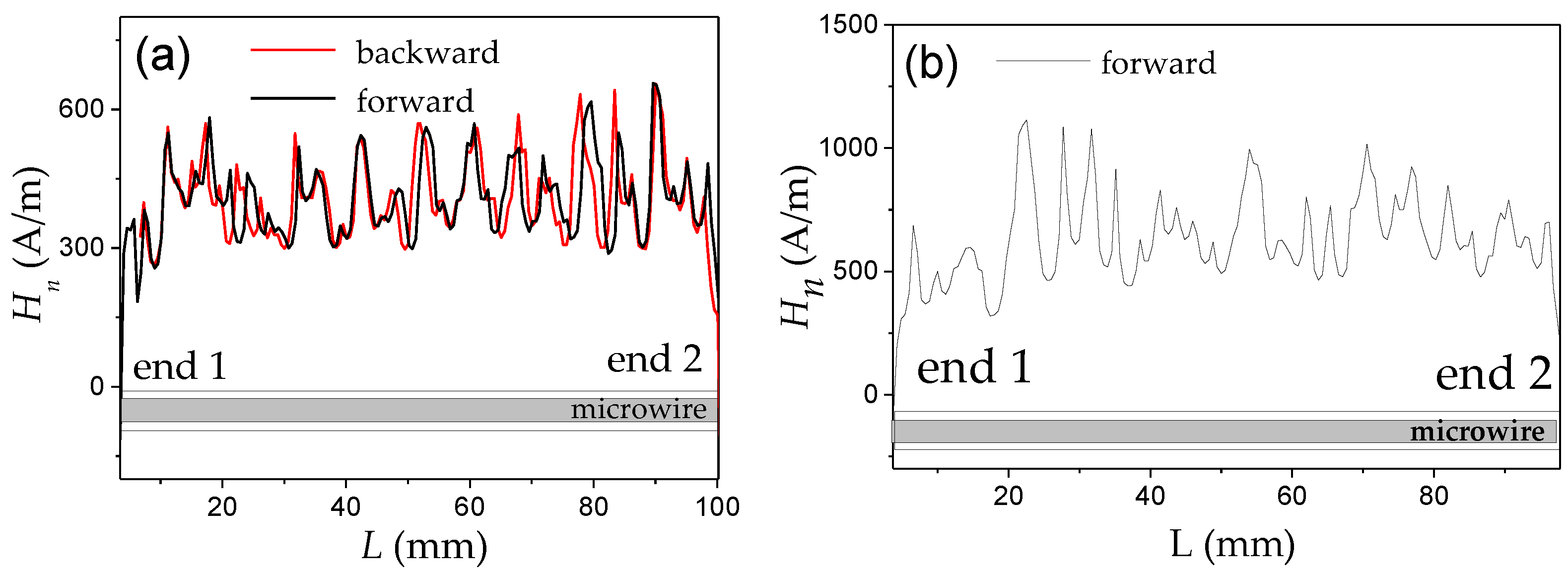

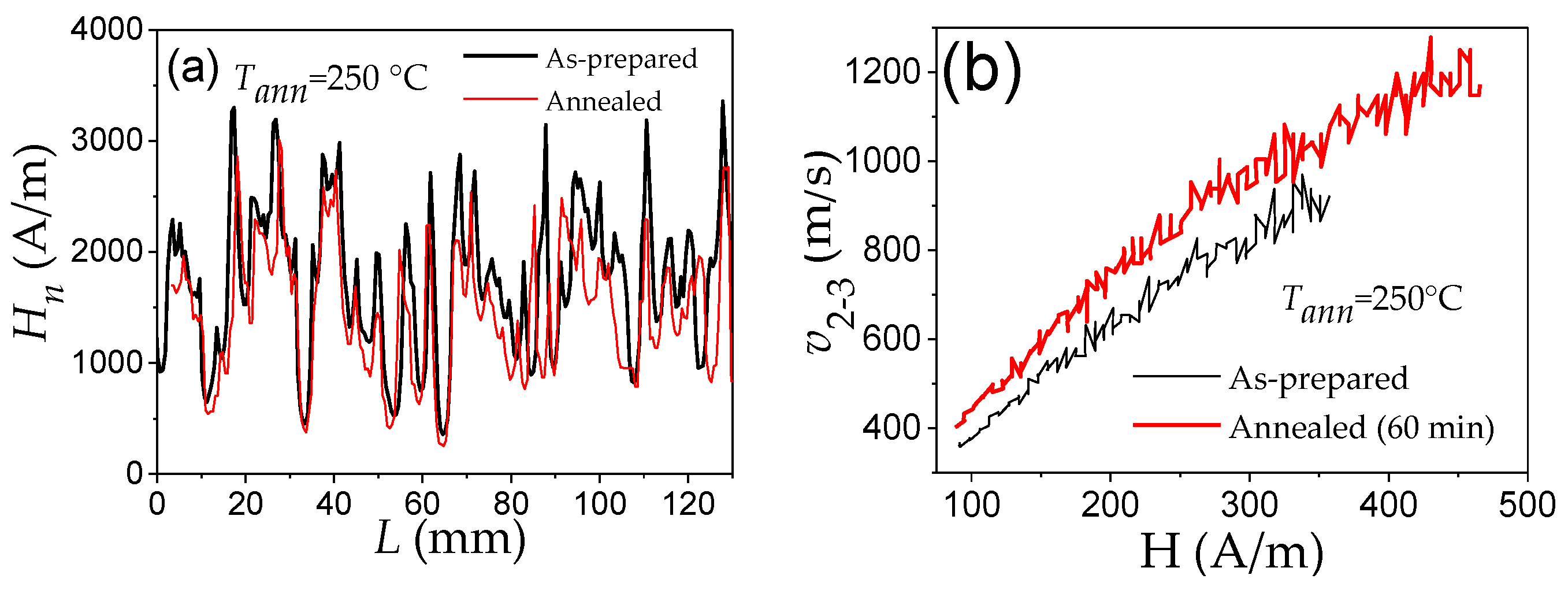

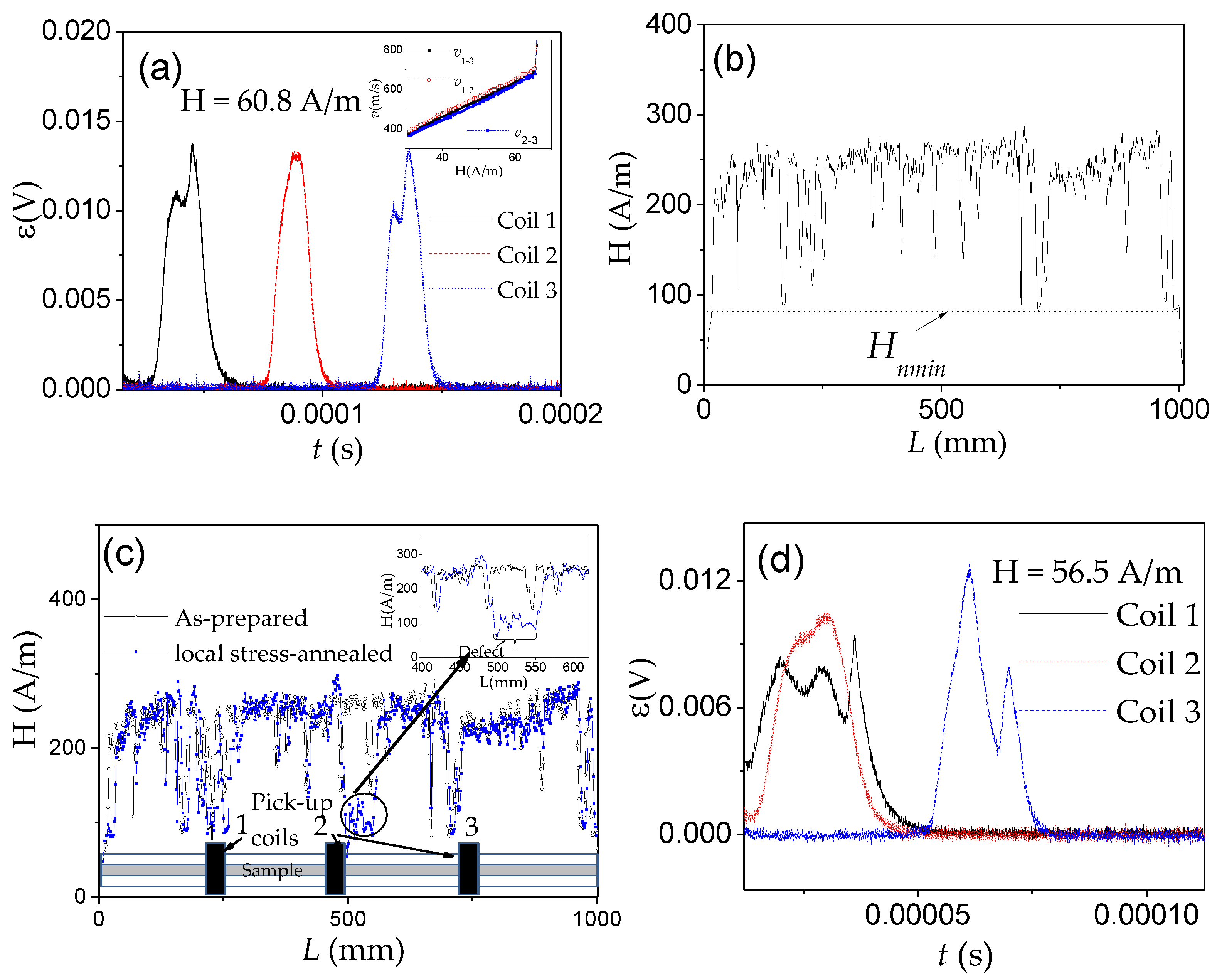

- The Hn(L) dependencies, measured by moving the same microwire forward and backward through the magnetizing coil, have the same oscillations sequence and amplitude (see Figure 3a). Accordingly, Hn(L) distributions are completely reproducible for a given sample (see Figure 3a). In some sense, Hn(L) distribution is the signature of each sample. A slight shift in the Hn(L) dependencies must be attributed to the precision of the forward and backward microwire movement.

- (ii)

- In all Hn(L) distributions Hn values near the sample ends are considerably lower than in the middle part of each sample.

- (i)

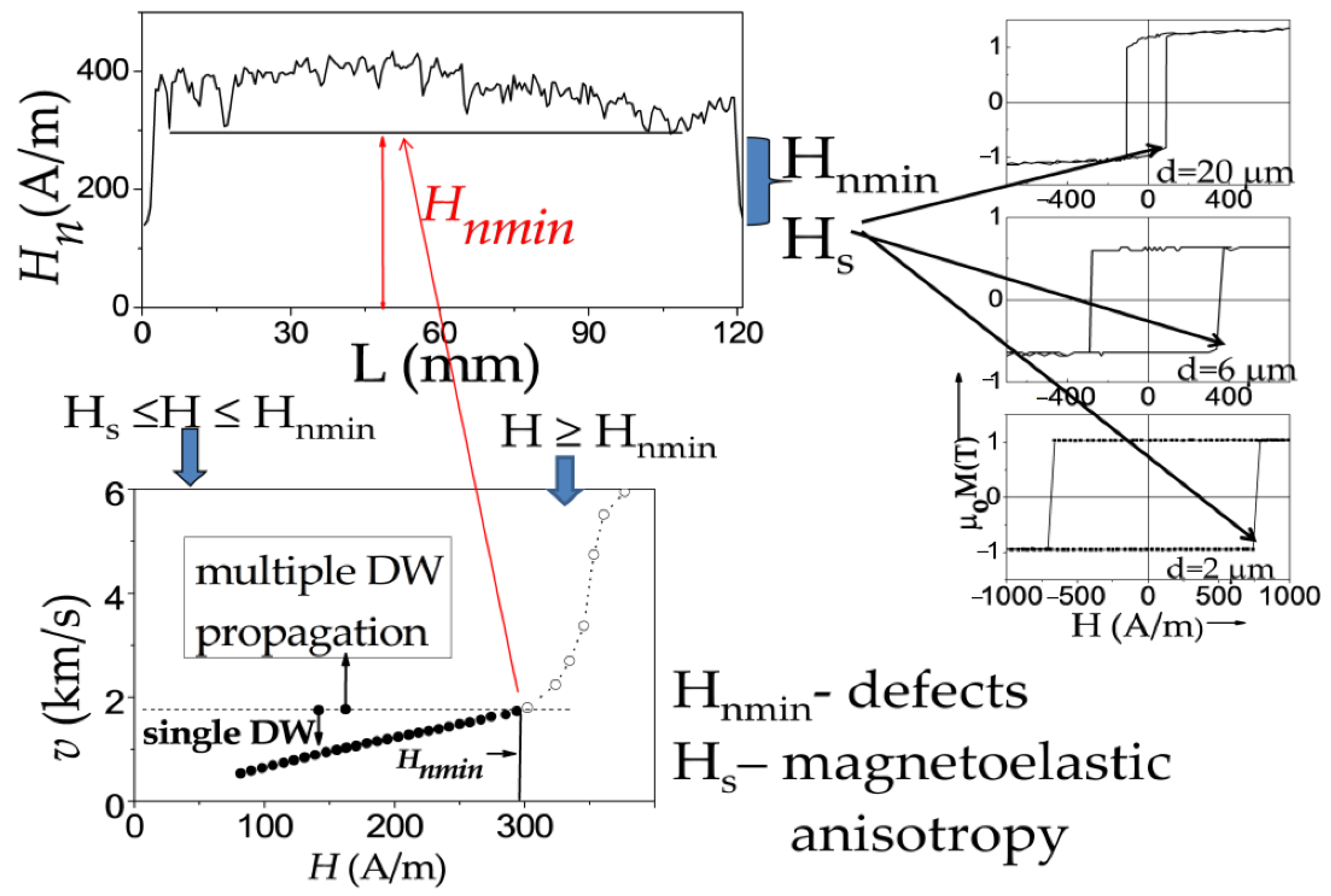

- Single DW propagation in the viscous regime can be observed in the magnetic field range between the switching field, Hs, and Hnmin, determined from the Hn(L) distribution. Therefore, the extension of a single DW regime is influenced by the factors affecting Hnmin and Hs-value.

- (ii)

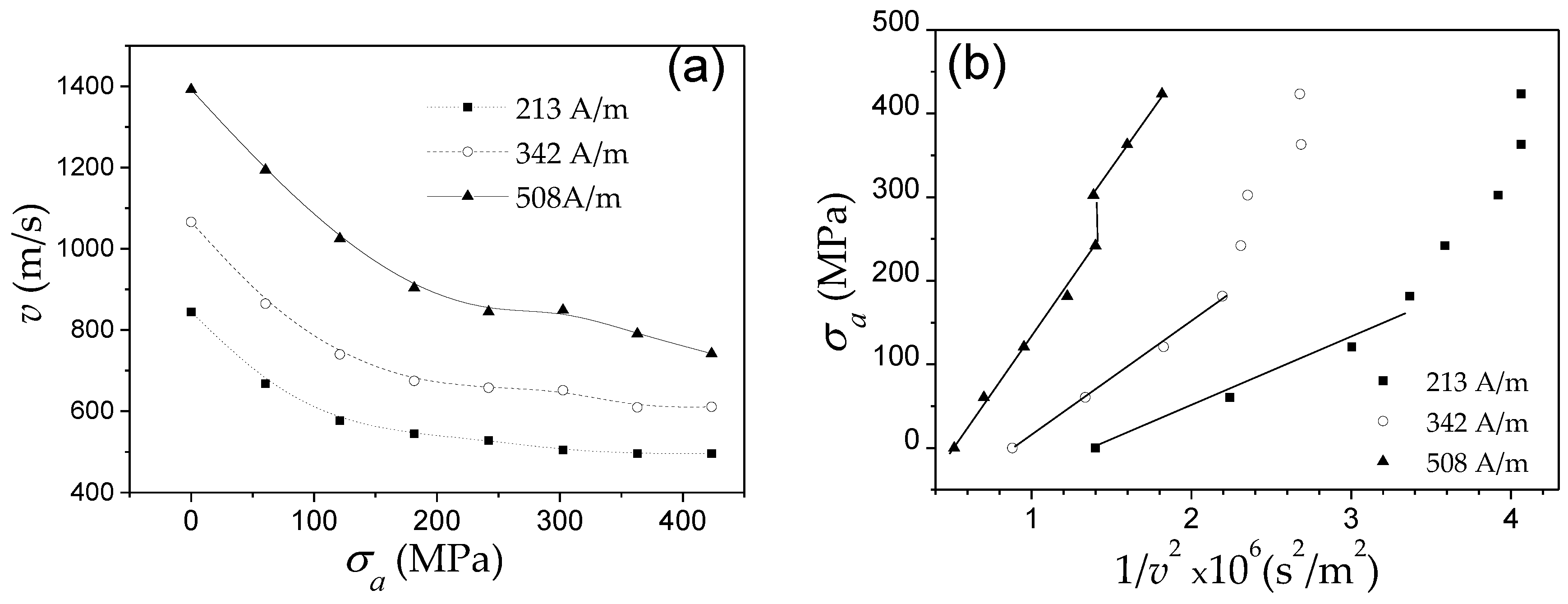

- Hs is determined as the magnetic field at which the DW depinning from the wire end takes place. Generally, the switching field magnitude is affected by the magnetoelastic and shape anisotropies.

- (iii)

- Hnmin is limited by the defects. Therefore, the extension of the linear v(H) dependence is determined by the defects and their distribution.

- Intrinsic fluctuations of exchange energies and local anisotropies,

- Clusters and chemical short ordered regions,

- Surface irregularities,

- Relaxation effects due to local structural rearrangements,

- Volume pinning of domain walls in magnetostrictive alloys,

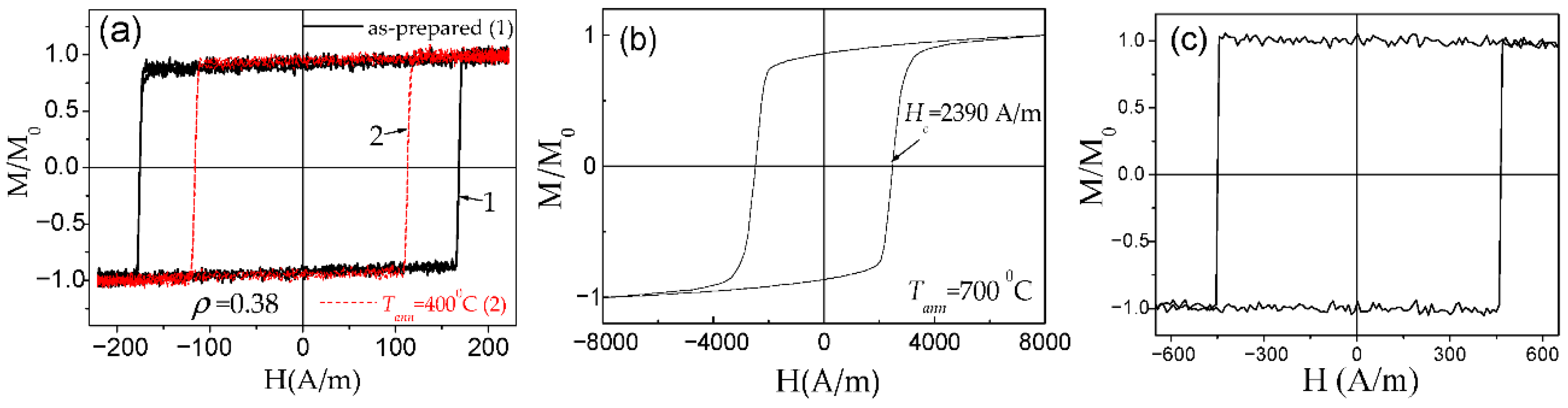

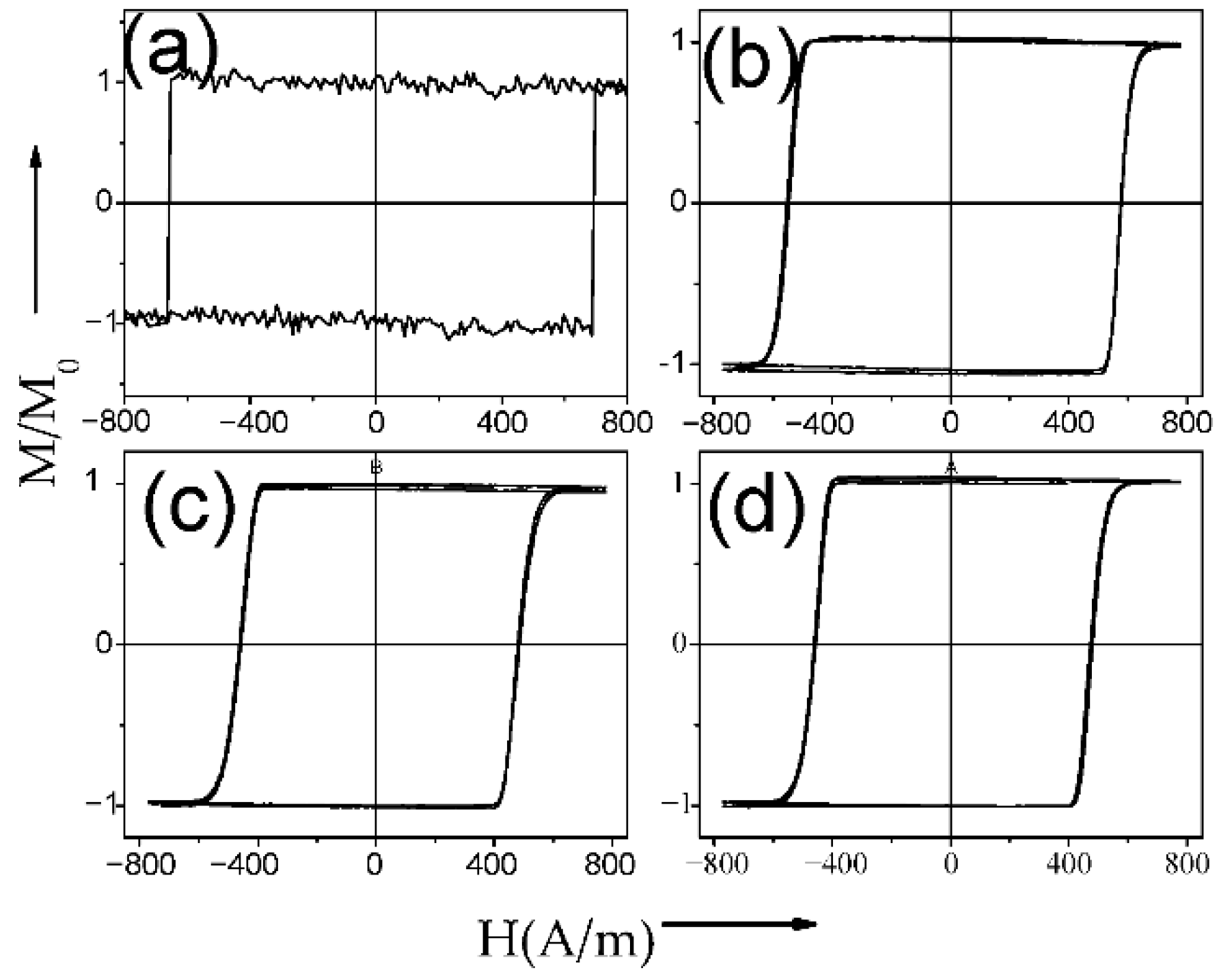

3.1.1. DW Propagation in Amorphous Microwires with Spontaneous Magnetic Bistability

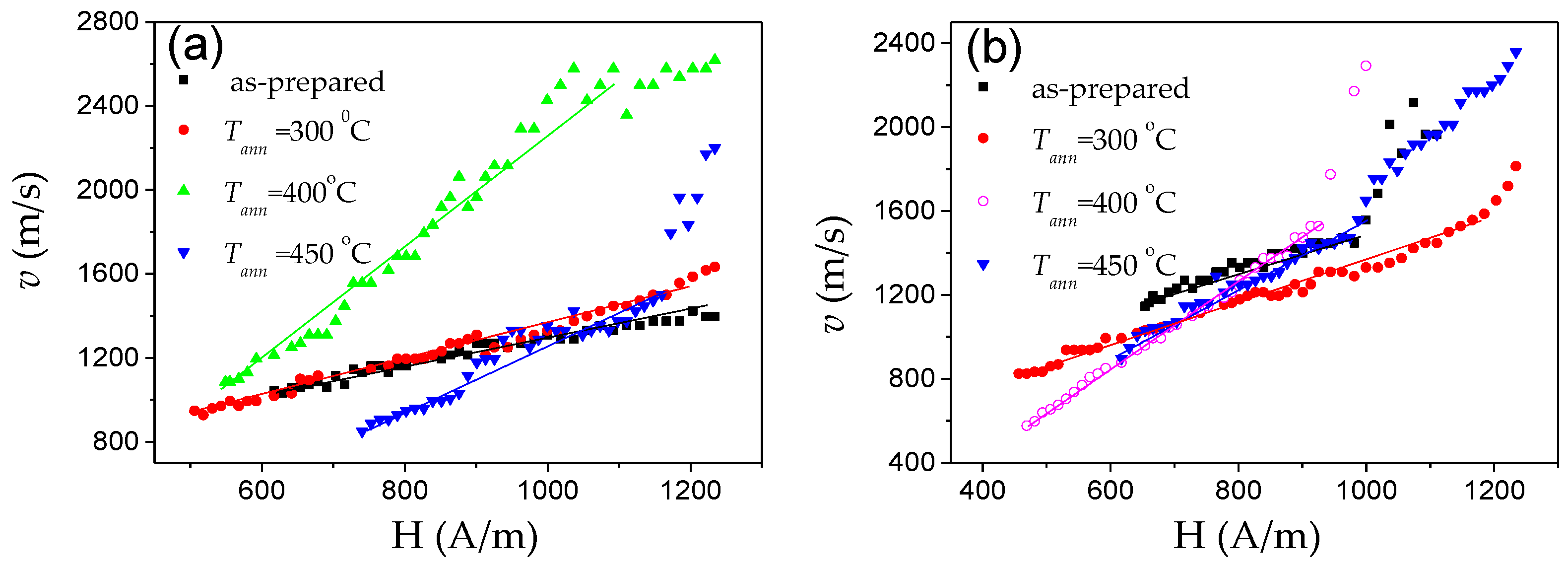

- DW propagation in as-prepared amorphous microwires

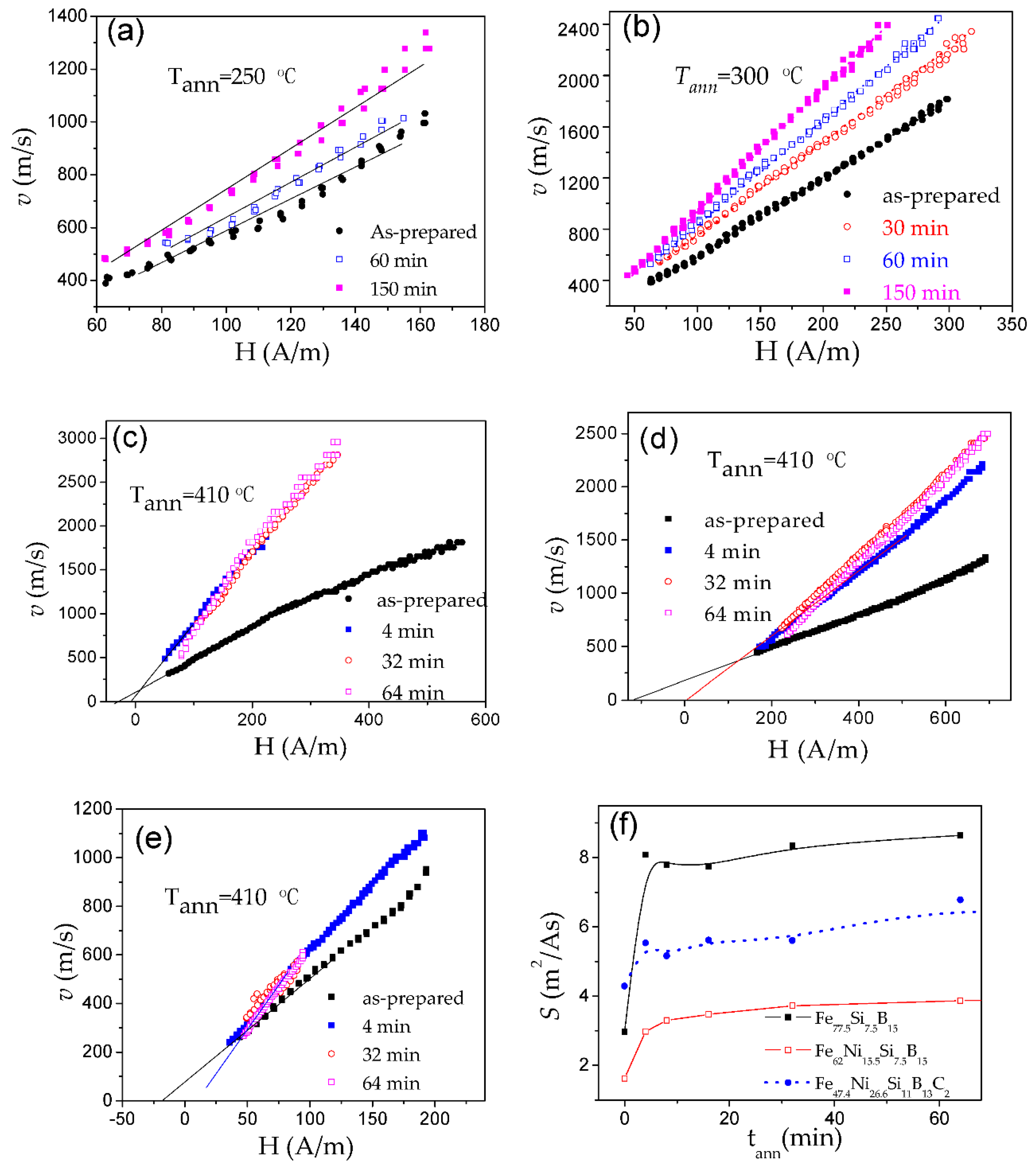

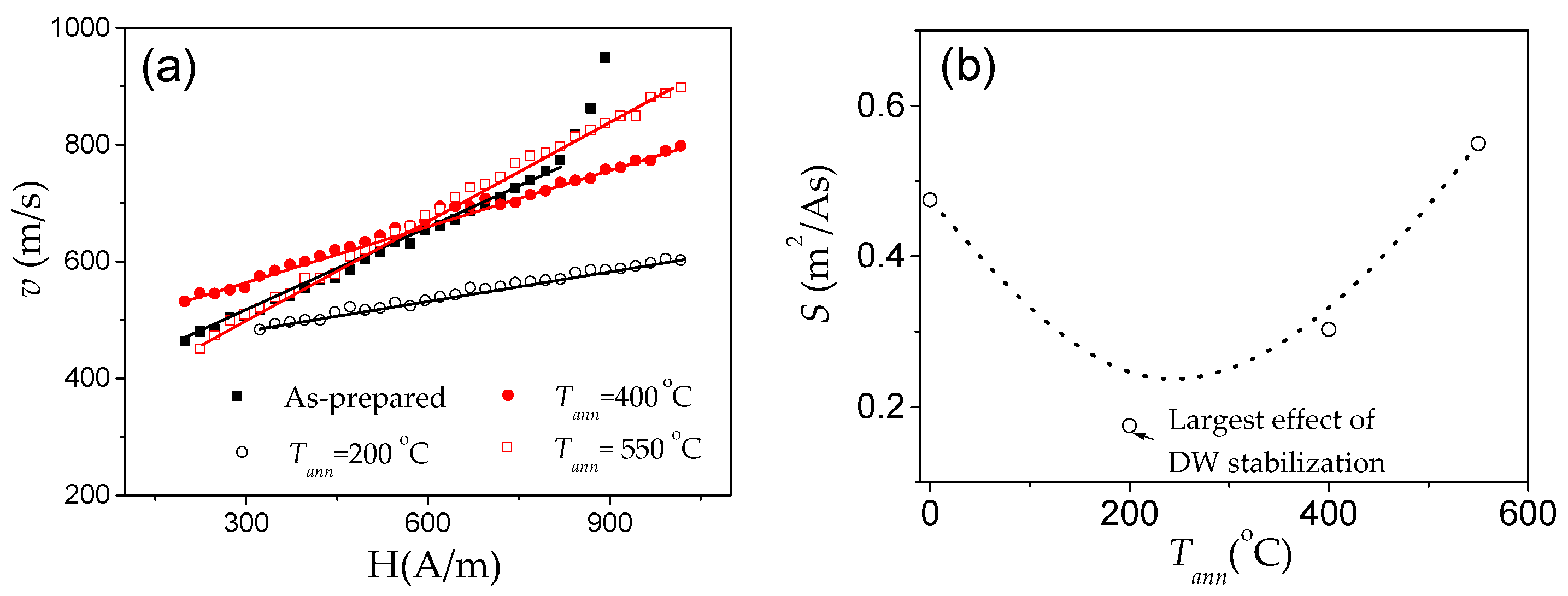

- Optimization of DW dynamics by annealing

- Effect of induced magnetic anisotropy on DW dynamics

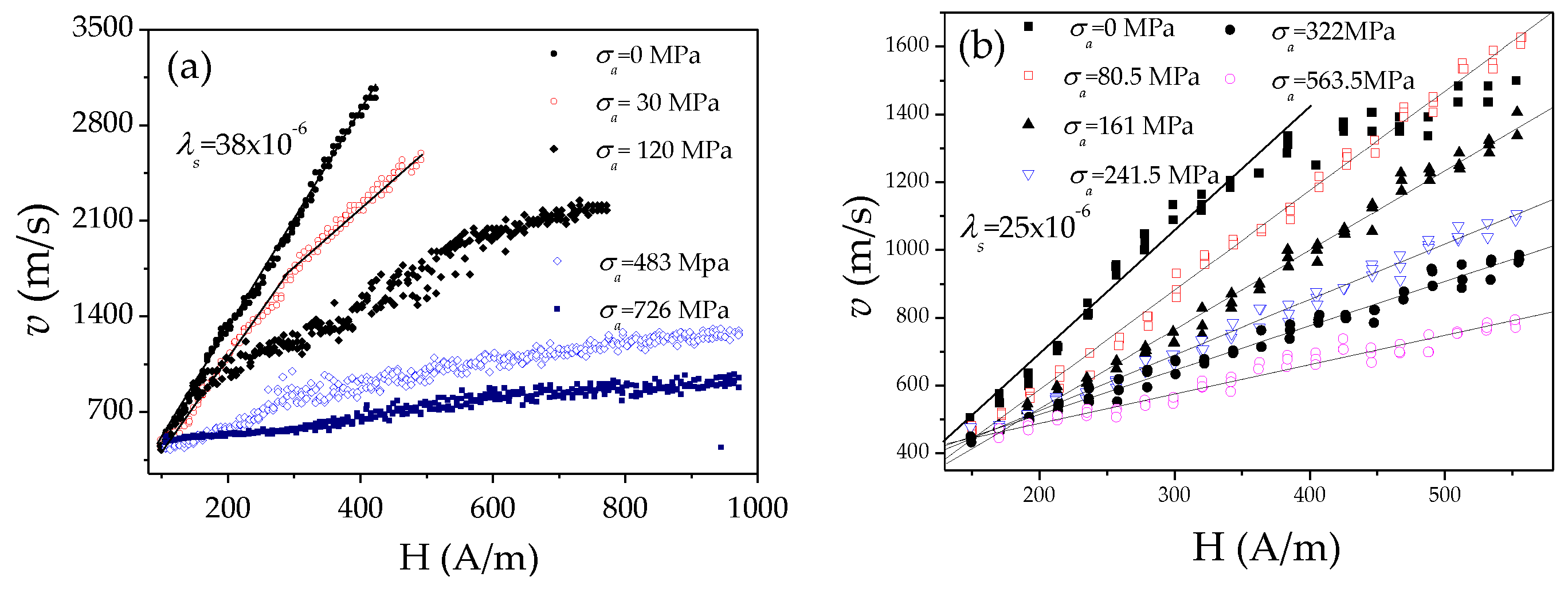

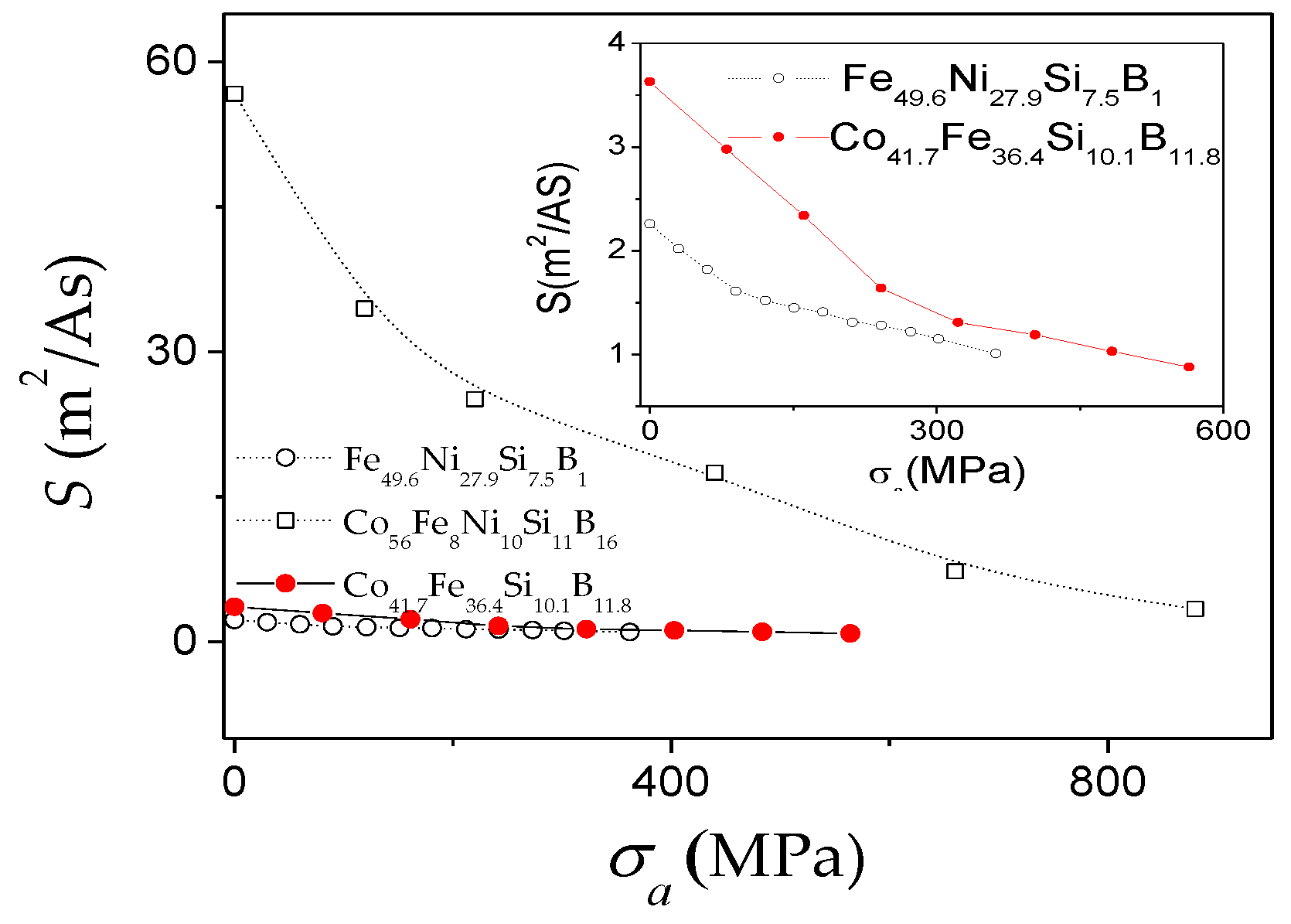

- Manipulation of DW dynamics

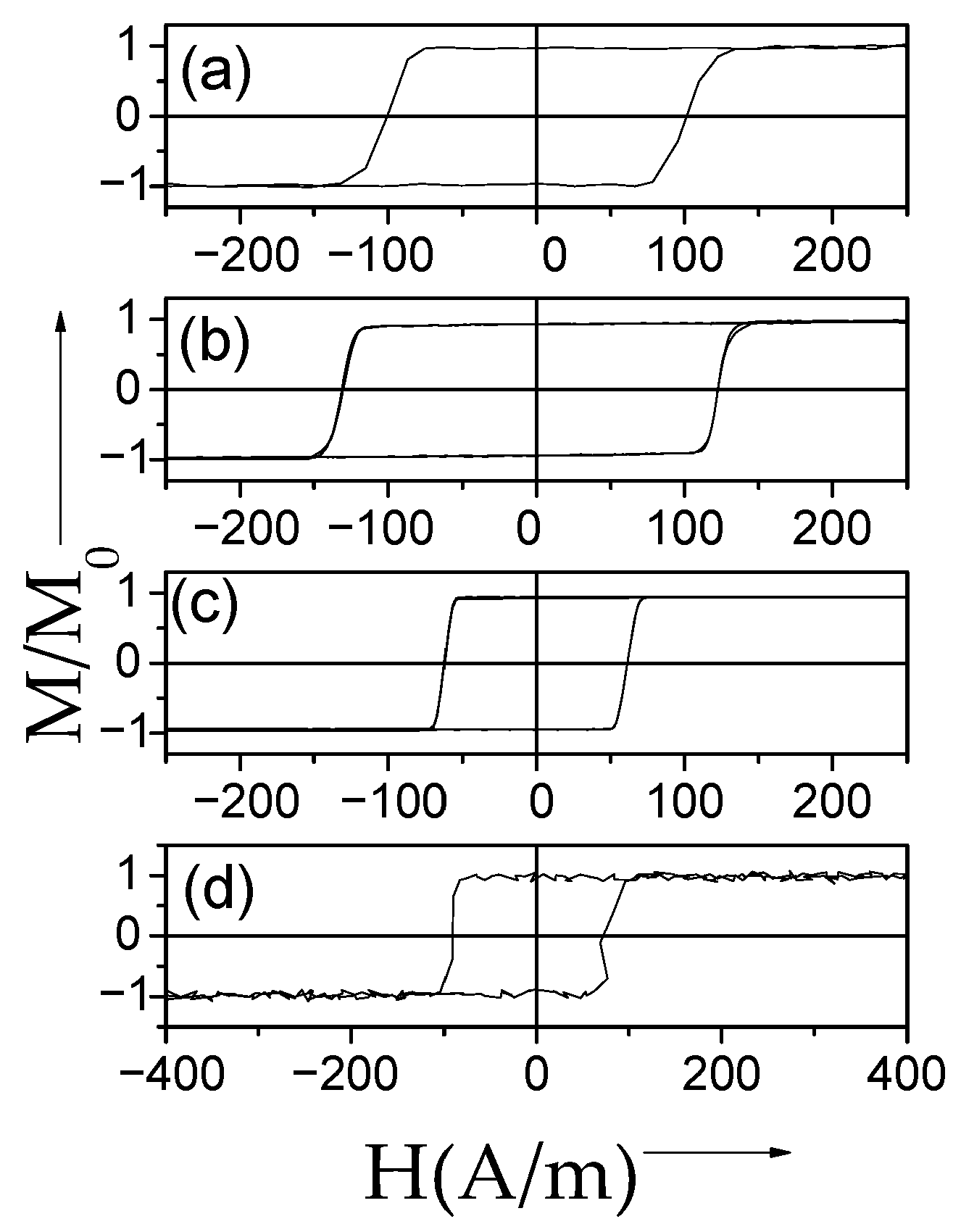

3.1.2. DW Propagation in Amorphous Microwires with Annealing-Induced Magnetic Bistability

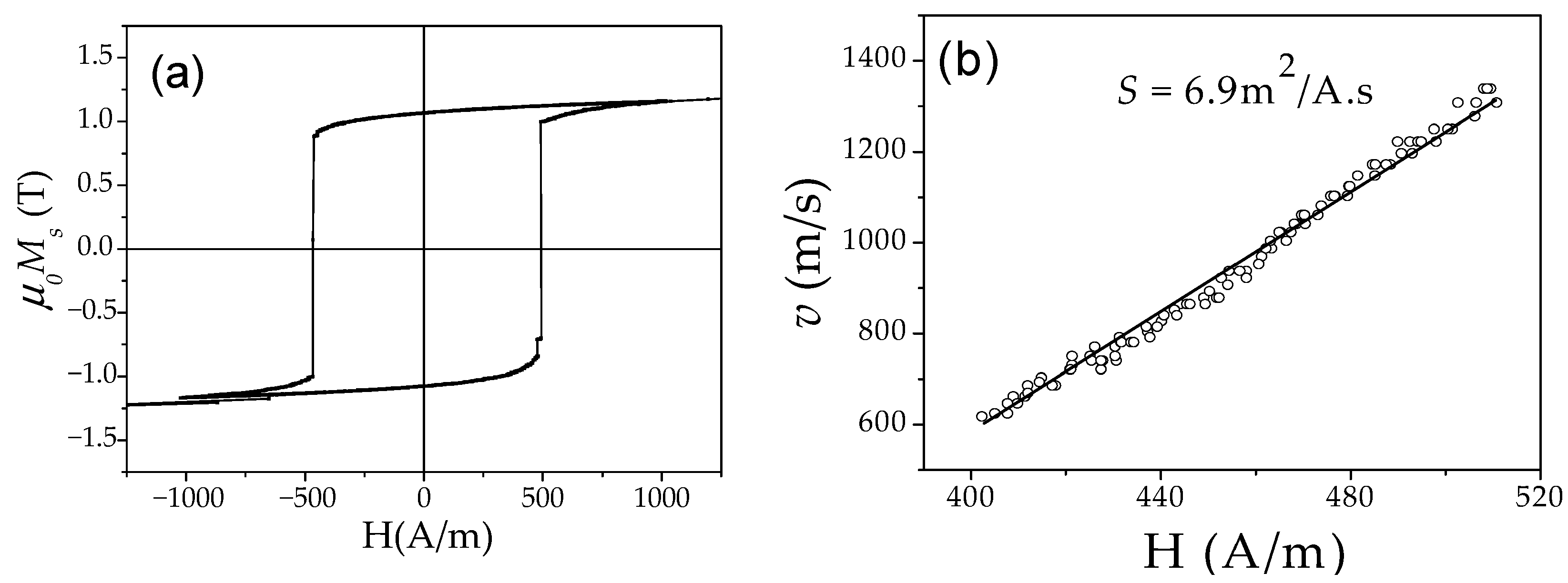

- Magnetic field driven DW propagation in Co-rich amorphous microwires

- Current driven DW propagation in Co-rich amorphous microwires

3.1.3. Single DW Propagation in Nanocrystalline Microwires

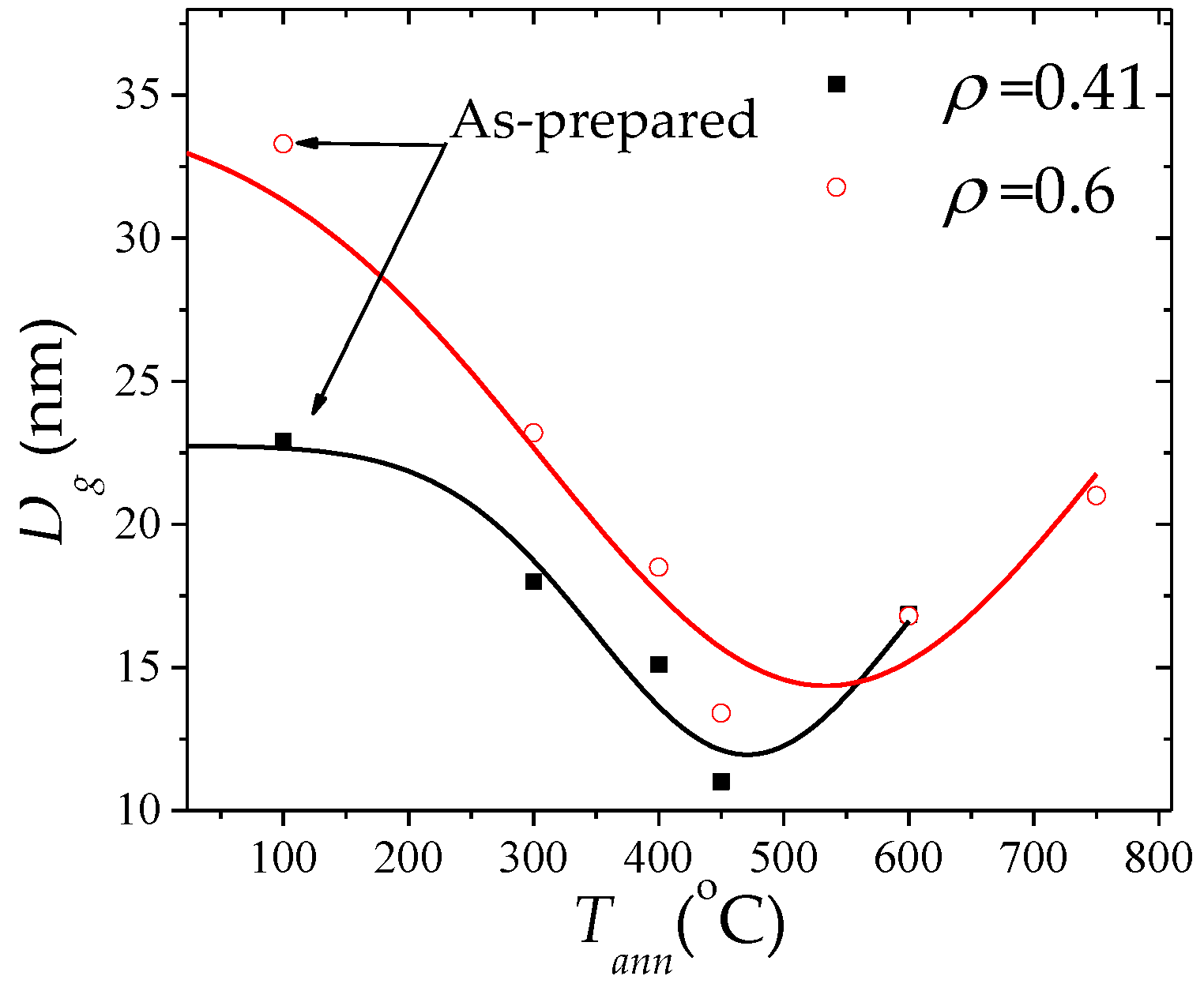

- DW propagation in Finemet-type amorphous and nanocrystalline microwires

- DW propagation in as-prepared nanocrystalline microwires

- Impact of saturation magnetization on DW mobility in nanocrystalline microwires

3.1.4. Manipulation of DW Dynamics in Magnetic Microwires

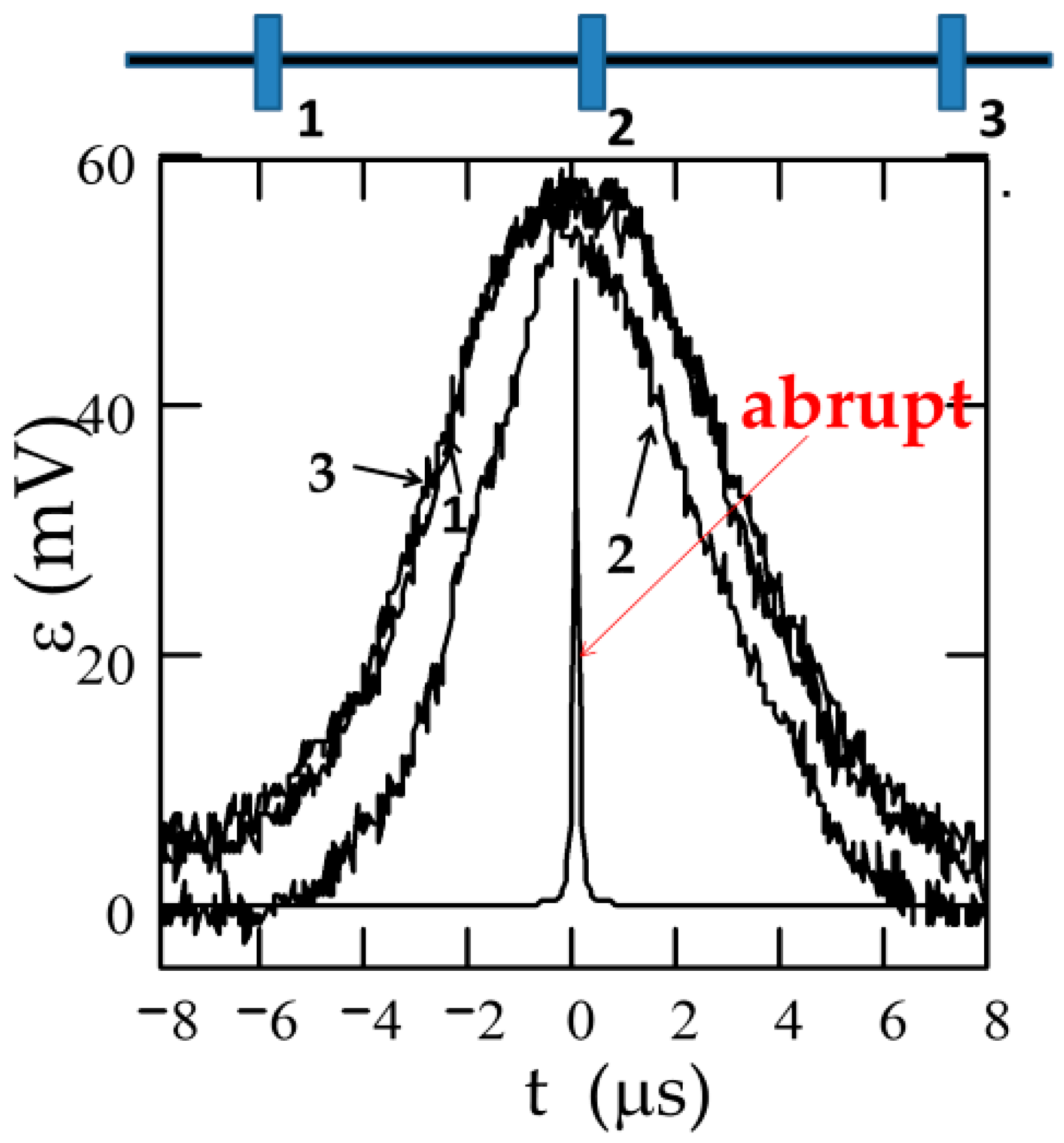

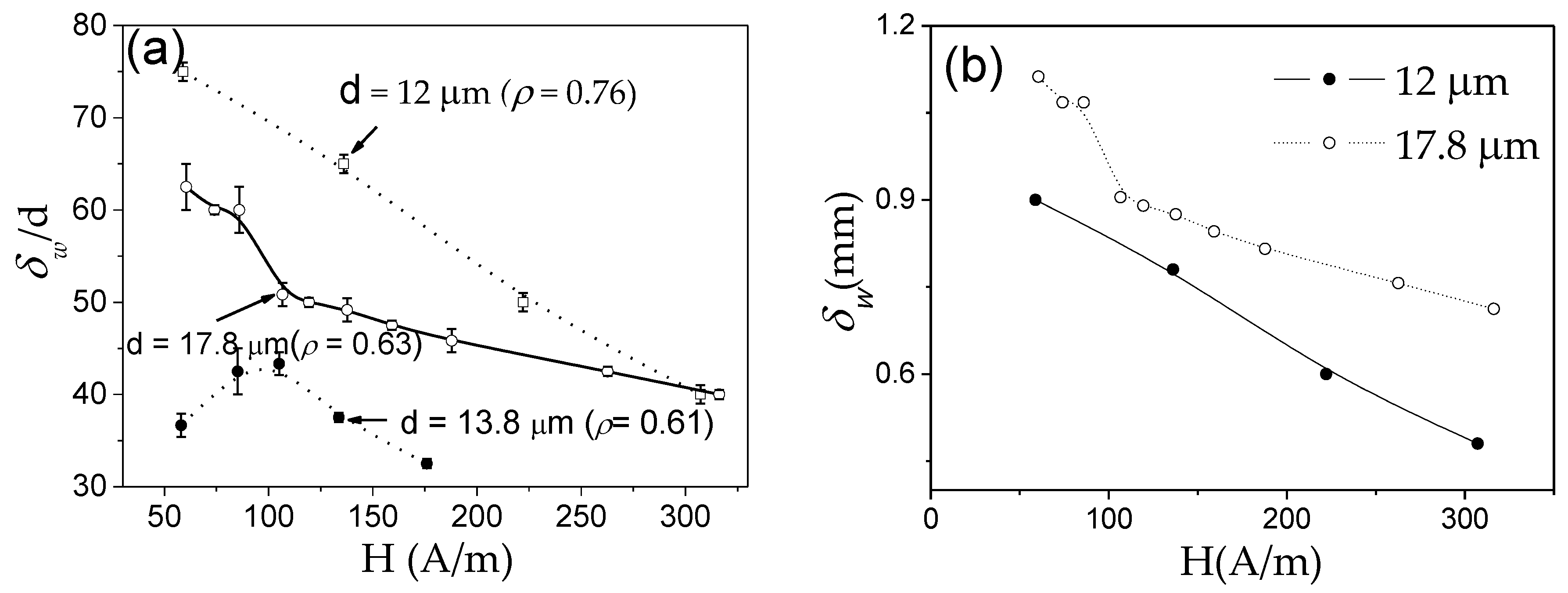

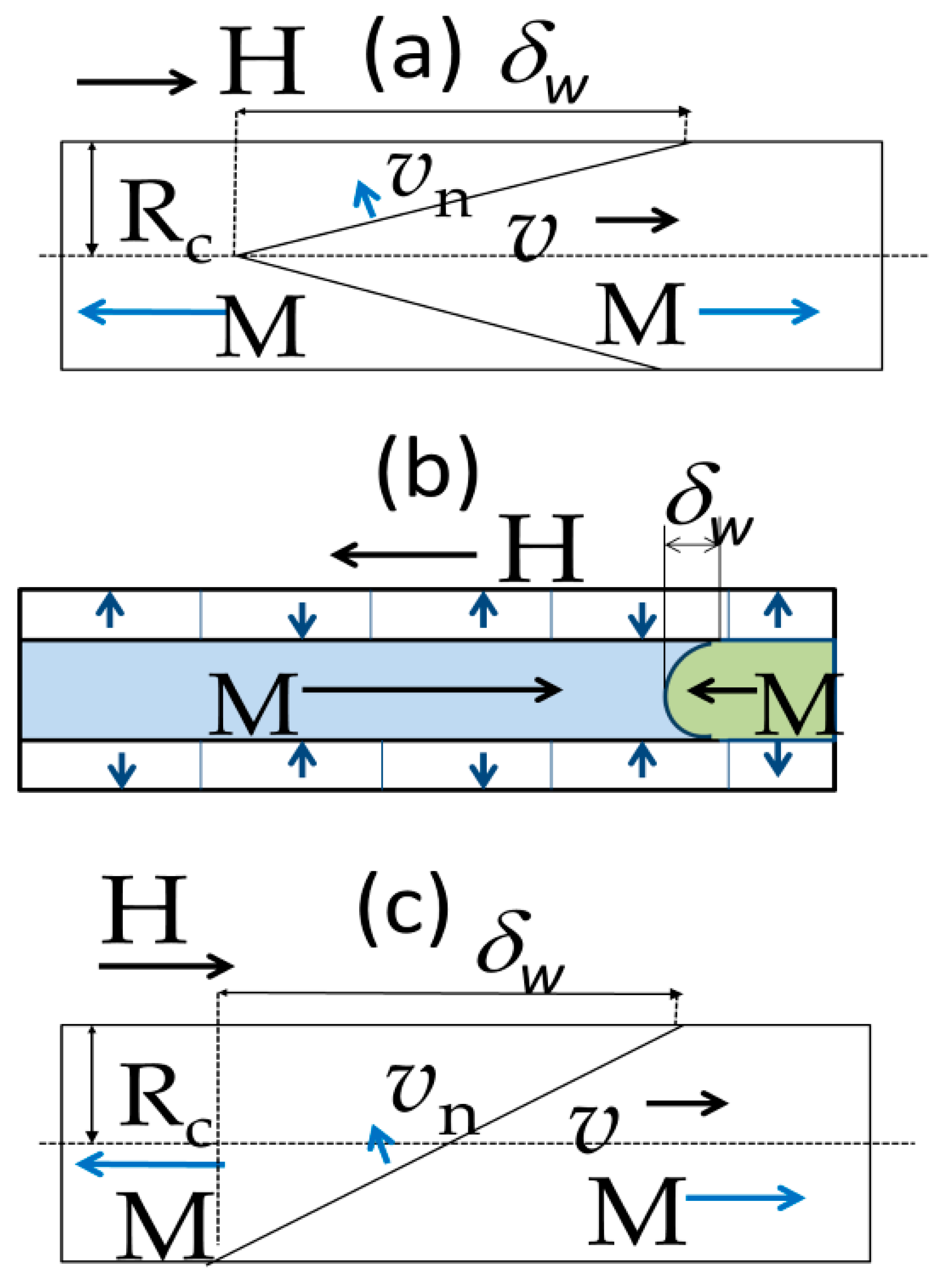

- Evaluation of DW shape and its correlation with microwire properties

- Manipulation of DW shape by control of magnetic anisotropy

- Engineering of DW propagation by local stress-annealing

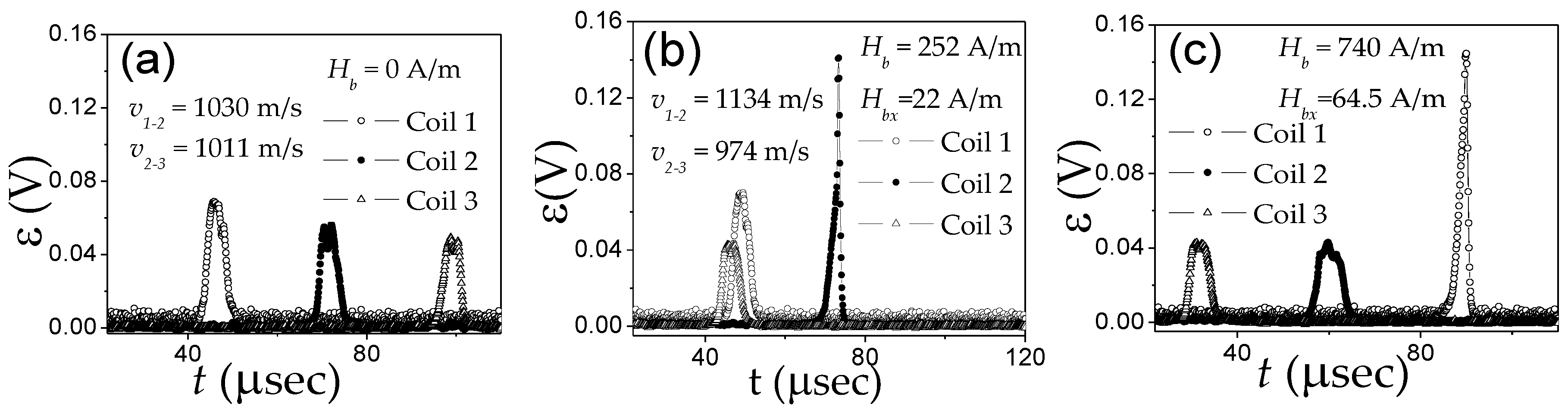

- DW collision

- -

- Appropriate annealing can be used to produce magnetically bistable microwires from initially non-magnetically bistable microwires. These magnetically bistable microwires can exhibit DW dynamics with an unusual stress.

- -

- The most appropriate magnetic anisotropy distribution can be designed using post-processing (i.e., by inducing magnetic anisotropy and design of its radial distribution).

- -

- The amorphous matrix can be devitrified, and as-prepared microwires with nanocrystalline structures can be fabricated.

- -

- The chemical composition of microwires with high saturation magnetization can be beneficial for DW dynamics improvement.

- -

- Technology improvement can be used to decrease the defect content and hence extend the single DW propagation regimes.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moriya, R.; Hayashi, M.; Thomas, L.; Rettner, C.; Parkin, S.S.P. Dependence of field driven domain wall velocity on cross-sectional area in Ni65Fe20Co15 nanowires. Appl. Phys. Lett. 2010, 97, 142506. [Google Scholar] [CrossRef]

- Knobel, M.; Vázquez, M.; Kraus, L. Giant Magnetoimpedance. In Handbook of Magnetic Materials; Elsevier: Amsterdam, The Netherlands, 2003; Volume 15, pp. 497–563. [Google Scholar]

- Zhukov, A.; Gonzalez, J.; Zhukova, V. Magnetoresistance in thin wires with granular structure. J. Magn. Magn. Mater. 2005, 294, 165–173. [Google Scholar] [CrossRef]

- Panina, L.V.; Mohri, K. Magneto-impedance effect in amorphous wires. Appl. Phys. Lett. 1994, 65, 1189–1191. [Google Scholar] [CrossRef]

- Zhukova, V.; Zhukov, A.; Blanco, J.M.; Gonzalez, J.; Ponomarev, B.K. Switching field fluctuations in a glass coated Fe-rich amorphous microwire. J. Magn. Magn. Mater. 2002, 249, 131–135. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; del Val, J.J.; Zhukova, V.; Chernenko, V.A. Magnetic and structural properties of glass-coated Heusler-type microwires exhibiting martensitic transformation. Sci. Rep. 2018, 8, 621. [Google Scholar] [CrossRef]

- Gomez-Polo, C.; Perez-Landazabal, J.I.; Recarte, V.; Sanchez-Alarcos, V.; Badini Confalonieri, G.; Vazquez, M. Ni–Mn–Ga ferromagnetic shape memory wires. J. Appl. Phys. 2010, 107, 123908. [Google Scholar] [CrossRef]

- Ripka, P.; Vértesy, G. Sensors based on soft magnetic materials Panel discussion. J. Magn. Magn. Mater. 2000, 21, 795–799. [Google Scholar] [CrossRef]

- Allwood, D.A.; Xiong, G.; Faulkner, C.C.; Atkinson, D.; Petit, D.; Cowburn, R.P. Magnetic domain-wall logic. Science 2005, 309, 1688–1692. [Google Scholar] [CrossRef]

- Parkin, S.; Yang, S.-H. Memory on the racetrack. Nat. Nanotechnol. 2015, 10, 195–198. [Google Scholar] [CrossRef]

- Uchiyama, T.; Mohri, K.; Nakayama, S. Measurement of Spontaneous Oscillatory Magnetic Field of Guinea-Pig Smooth Muscle Preparation Using Pico-Tesla Resolution Amorphous Wire Magneto-Impedance Sensor. IEEE Trans. Magn. 2011, 47, 3070–3073. [Google Scholar] [CrossRef]

- Cobeño, A.F.; Zhukov, A.; Blanco, J.M.; Larin, V.; Gonzalez, J. Magnetoelastic sensor based on GMI of amorphous microwire. Sens. Actuators Phys. 2001, 91, 95–98. [Google Scholar] [CrossRef]

- Honkura, Y.; Honkura, S. The Development of ASIC Type GSR Sensor Driven by GHz Pulse Current. Sensors 2020, 20, 1023. [Google Scholar] [CrossRef]

- Gudoshnikov, S.; Usov, N.; Zhukov, A.; Zhukova, V.; Palvanov, P.; Ljubimov, B.; Serebryakova, O.; Gorbunov, S. Evaluation of use of magnetically bistable microwires for magnetic labels. Phys. Status Solidi A 2011, 208, 526–529. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Rodionova, V.; Ipatov, M.; Zhukov, A. Domain wall propagation in micrometric wires: Limits of single domain wall regime. J. Appl. Phys. 2012, 111, 07E311. [Google Scholar] [CrossRef]

- Varga, R.; Richter, K.; Zhukov, A.; Larin, V. Domain Wall Propagation in Thin Magnetic Wires. IEEE Trans. Magn. 2008, 44, 3925–3930. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Chizhik, A.; Ipatov, M.; Zhukov, A. AC-current-induced magnetization switching in amorphous microwires. Front. Phys. 2018, 13, 137501. [Google Scholar] [CrossRef]

- Richter, K.; Varga, R.; Kováč, J.; Zhukov, A. Controlling the Domain Wall Dynamics by Induced Anisotropies. IEEE Trans. Magn. 2012, 48, 1266–1268. [Google Scholar] [CrossRef]

- Burrowes, C.; Vernier, N.; Adam, J.-P.; Herrera Diez, L.; Garcia, K.; Barisic, I.; Agnus, G.; Eimer, S.; Kim, J.-V.; Devolder, T.; et al. Low depinning fields in Ta-CoFeB-MgO ultrathin films with perpendicular magnetic anisotropy. Appl. Phys. Lett. 2013, 103, 182401. [Google Scholar] [CrossRef]

- Lei, N.; Devolder, T.; Agnus, G.; Aubert, P.; Daniel, L.; Kim, J.-V.; Zhao, W.; Trypiniotis, T.; Cowburn, R.P.; Chappert, C.; et al. Strain-controlled magnetic domain wall propagation in hybrid piezoelectric/ferromagnetic structures. Nat. Communs. 2013, 4, 1378. [Google Scholar] [CrossRef]

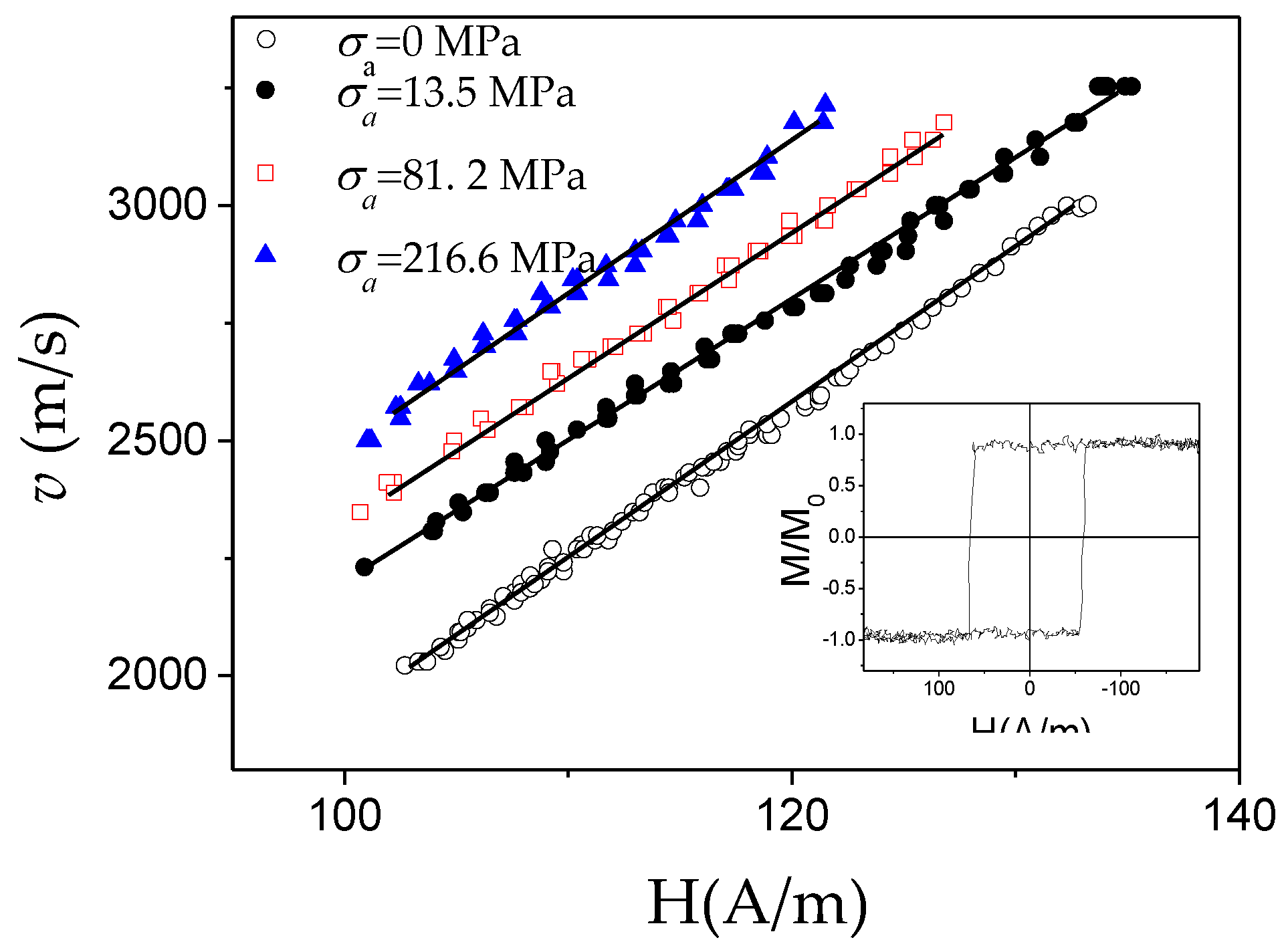

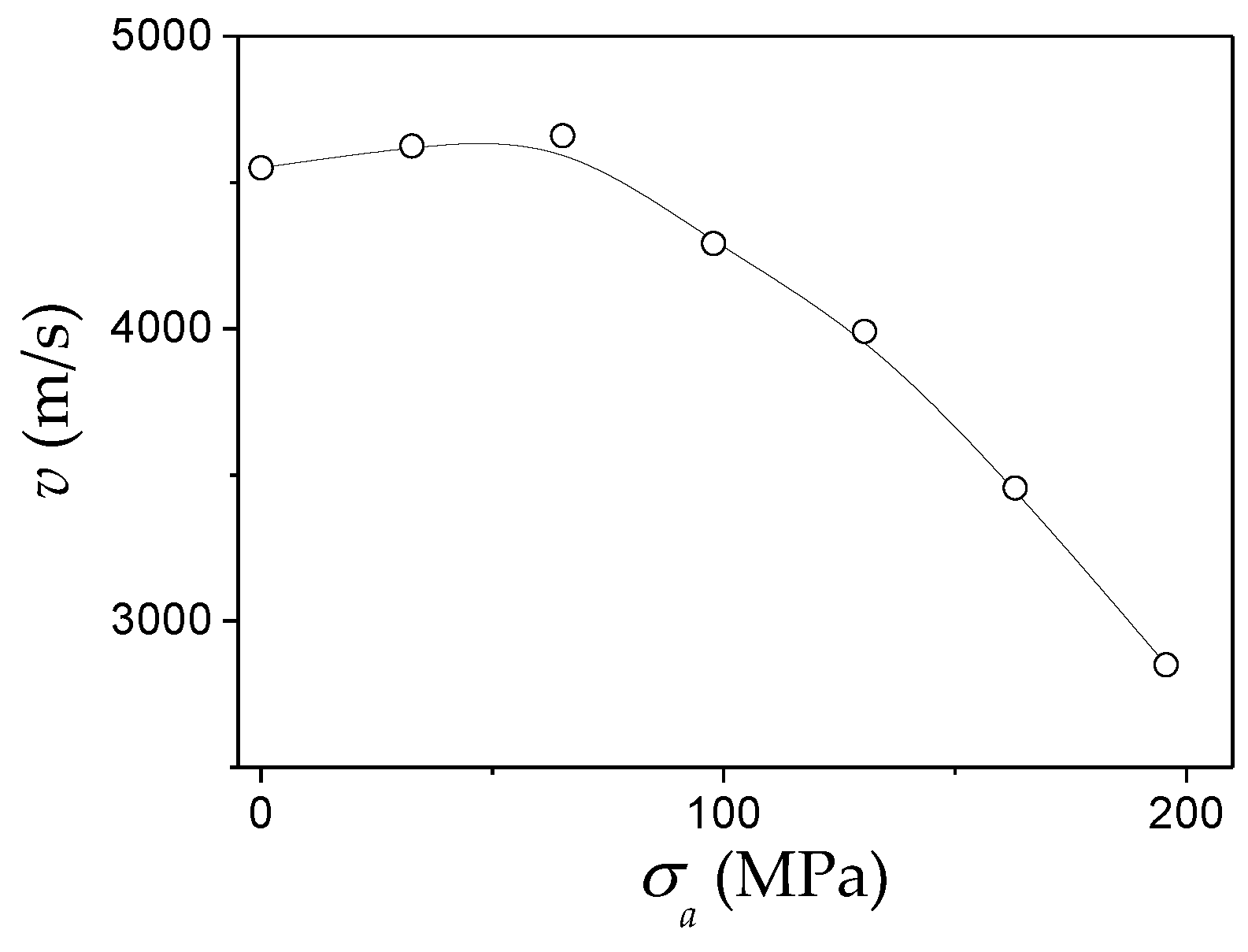

- Zhukova, V.; Blanco, J.M.; Ipatov, M.; Zhukov, A. Magnetoelastic contribution in domain wall dynamics of amorphous microwires. Physica B 2012, 407, 1450–1454. [Google Scholar] [CrossRef]

- Zhukov, A.; Blanco, J.M.; Ipatov, M.; Zhukova, V. Fast magnetization switching in thin wires: Magnetoelastic and defects contributions. IEEE Sens. Lett. 2013, 11, 170–176. [Google Scholar] [CrossRef]

- Huang, S.-H.; Lai, C.H. Domain-wall depinning by controlling its configuration at notch. Appl. Phys. Lett. 2009, 95, 032505. [Google Scholar] [CrossRef]

- Óvári, T.-A.; Corodeanu, S.; Chiriac, H. Domain wall velocity in submicron amorphous wires. J. Appl. Phys. 2011, 109, 07D502. [Google Scholar] [CrossRef]

- Zhukov, A.; Blanco, J.M.; Ipatov, M.; Talaat, A.; Zhukova, V. Engineering of domain wall dynamics in amorphous microwires by annealing. J. Alloys Compd. 2017, 707, 35–40. [Google Scholar] [CrossRef]

- Zhukov, A.; Chichay, K.; Talaat, A.; Rodionova, V.; Blanco, J.M.; Ipatov, M.; Zhukova, V. Manipulation of magnetic properties of glass-coated microwires by annealing. J. Magn. Magn. Mater. 2015, 383, 232–236. [Google Scholar] [CrossRef]

- Corte-León, P.; Blanco, J.M.; Zhukova, V.; Ipatov, M.; Gonzalez, J.; Churyukanova, M.; Taskaev, S.; Zhukov, A. Engineering of Magnetic Softness and Domain Wall Dynamics of Fe-rich Amorphous Microwires by Stress-induced Magnetic Anisotropy. Sci. Rep. 2019, 9, 12427. [Google Scholar] [CrossRef]

- Corte-León, P.; Gonzalez-Legarreta, L.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; Churyukanova, M.; Taskaev, S.; Zhukov, A. Controlling the domain wall dynamics in Fe-, Ni- and Co-based magnetic microwires. J. Alloys Compd. 2020, 834, 155170. [Google Scholar] [CrossRef]

- Bar’yakhtar, V.G.; Ivanov, B.A.; Chetkin, M.V. Dynamics of domain walls in weak ferromagnets. Sov. Phys. Uspekhi 1985, 28, 563–588. [Google Scholar] [CrossRef]

- Zvezdin, A.K.; Mukhin, A.A. Magnetoelastic solitary waves and supersonic domain-wall dynamics. Sov. Phys. JETP 1992, 75, 306–318. [Google Scholar]

- Zhukov, A.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Hernando, B.; Gonzalez-Legarreta, L.; Suñol, J.J.; Zhukova, V. Correlation of Crystalline Structure with Magnetic and Transport Properties of Glass-Coated Microwires. Crystals 2017, 7, 41. [Google Scholar] [CrossRef]

- Baranov, S.A.; Larin, V.S.; Torcunov, A.V. Technology, Preparation and Properties of the Cast Glass-Coated Magnetic Microwires. Crystals 2017, 7, 136. [Google Scholar] [CrossRef]

- Chen, D.-X.; Dempsey, N.M.; Vázquez, M.; Hernando, A. Propagating domain wall shape and dynamics in iron-rich amorphous wires. IEEE Trans. Magn. 1995, 31, 781–790. [Google Scholar] [CrossRef]

- Mohri, K.; Humphrey, F.B.; Kawashima, K.; Kimura, K.; Mizutani, M. Large Barkhausen and Matteucci effects in FeCoSiB, FeCrSiB, and FeNiSiB amorphous wires. IEEE Trans. Magn. 1990, 26, 1789–1791. [Google Scholar] [CrossRef]

- Ogasawara, I.; Ueno, S. Preparation and properties of amorphous wires. IEEE Trans. Magn. 1995, 31, 1219–1223. [Google Scholar] [CrossRef]

- Corodeanu, S.; Chiriac, H.; Óvári, T.-A. Accurate measurement of domain wall velocity in amorphous microwires, submicron wires, and nanowires. Rev. Sci. Instr. 2011, 82, 094701. [Google Scholar] [CrossRef]

- Corte-Leon, P.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; González, J.; Churyukanova, M.; Taskaev, S.; Zhukov, A. The effect of annealing on magnetic properties of “Thick” microwires. J. Alloys Compd. 2020, 831, 150992. [Google Scholar] [CrossRef]

- Ulitovsky, A.V.; Maianski, I.M.; Avramenco, A.I. Method of Continuous Casting of Glass Coated Microwire. USSR Patent No. 128427, 15 May 1960. Bulletin No. 10. [Google Scholar]

- Kraus, L.; Schneider, J.; Wiesner, H. Ferromagnetic resonance in amorphous alloys prepared by rapid quenching from the melt. Czech. J. Phys. B 1976, 26, 601–602. [Google Scholar] [CrossRef]

- Goto, T.; Nagano, M.; Wehara, N. Mechanical Properties of Amorphous Fe80P16C3B1 Filament Produced by Glass-Coated Melt Spinning. Trans. Jpn. Inst. Met. 1977, 18, 759–764. [Google Scholar] [CrossRef]

- Zhukova, V.; Cobeño, A.F.; Zhukov, A.; de Lopez, A.R.; Blanco, J.M.; Larin, V.; Gonzalez, J.; López-Pombero, S. Correlation between magnetic and mechanical properties of devitrified glass-coated Fe71.8Cu1Nb3.1Si15B9.1 microwires. J. Magn. Magn. Mater. 2002, 249, 79–84. [Google Scholar] [CrossRef]

- Talaat, A.; Alonso, J.; Zhukova, V.; Garaio, E.; García, J.A.; Srikanth, H.; Phan, M.H.; Zhukov, A. Ferromagnetic glass-coated microwires with good heating properties for magnetic hyperthermia. Sci. Rep. 2016, 6, 39300. [Google Scholar] [CrossRef]

- Mitxelena-Iribarren, O.; Campisi, J.; Martínez de Apellániz, I.; Lizarbe-Sancha, S.; Arana, S.; Zhukova, V.; Mujika, M.; Zhukov, A. Glass-coated ferromagnetic microwire-induced magnetic hyperthermia for in vitro cancer cell treatment. Mat. Sci. Eng. A Struct. C 2020, 106, 110261. [Google Scholar] [CrossRef]

- Astefanoaei, I.; Radu, D.; Chiriac, H. Internal stress distribution in DC joule-heated amorphous glass-covered microwires. J. Condens. Matter. Phys. 2006, 18, 2689–2716. [Google Scholar] [CrossRef]

- Antonov, A.S.; Borisov, V.T.; Borisov, O.V.; Prokoshin, A.F.; Usov, N.A. Residual quenching stresses in glass-coated amorphous ferromagnetic microwires. J. Phys. D Appl. Phys. 2000, 33, 1161–1168. [Google Scholar] [CrossRef]

- Zhukov, A. Domain Wall propagation in a Fe-rich glass-coated amorphous microwire. Appl. Phys. Lett. 2001, 78, 3106–3108. [Google Scholar] [CrossRef]

- Calle, E.; Vázquez, M.; del Real, R.P. Time-resolved motion of a single domain wall controlled by a local tunable barrier. J. Magn. Magn. Mater. 2020, 498, 166093. [Google Scholar] [CrossRef]

- Talaat, A.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; Gonzalez-Legarreta, L.; Hernando, B.; del Val, J.J.; Gonzalez, J.; Zhukov, A. Optimization of the giant magnetoimpedance effect of Finemet-type microwires through the nanocrystallization. J. Appl. Phys. 2014, 115, 17A313. [Google Scholar] [CrossRef]

- Zhukova, V.; Ipatov, M.; Corte-Leon, P.; Blanco, J.M.; Zanaeva, E.; Bazlov, A.I.; Jiang, J.; Louzguine-Luzgin, D.V.; Olivera, J.; Zhukov, A. Excellent magnetic properties of (Fe0.7Co0.3)83.7Si4B8P3.6Cu0.7 ribbons and microwires. Intermetallics 2020, 117, 106660. [Google Scholar] [CrossRef]

- Olivera, J.; Varga, R.; Prida, V.M.; Sanchez, M.L.; Hernando, B.; Zhukov, B. Domain wall dynamics during the devitrification of Fe73.5CuNb3Si11.5B11 magnetic microwires. Phys. Rev. B 2010, 82, 094414. [Google Scholar] [CrossRef]

- Chiriac, H.; Óvári, T.A.; Pop, G. Internal stress distribution in glass-covered amorphous magnetic wires. Phys. Rev. B 1995, 52, 10104–10113. [Google Scholar] [CrossRef]

- Zhukova, V.; Corte-Leon, P.; González-Legarreta, L.; Talaat, A.; Blanco, J.M.; Ipatov, M.; Olivera, J.; Zhukov, A. Optimization of Magnetic Properties of Magnetic Microwires by Post-Processing. Processes 2020, 8, 1006. [Google Scholar] [CrossRef]

- Zhukov, A.; Blanco, J.M.; Ipatov, M.; Zhukov, V. Magnetoelastic Contribution in Domain Wall Propagation of Micrometric Wires. J. Nanosci. Nanotechnol. 2012, 12, 7582–7586. [Google Scholar] [CrossRef]

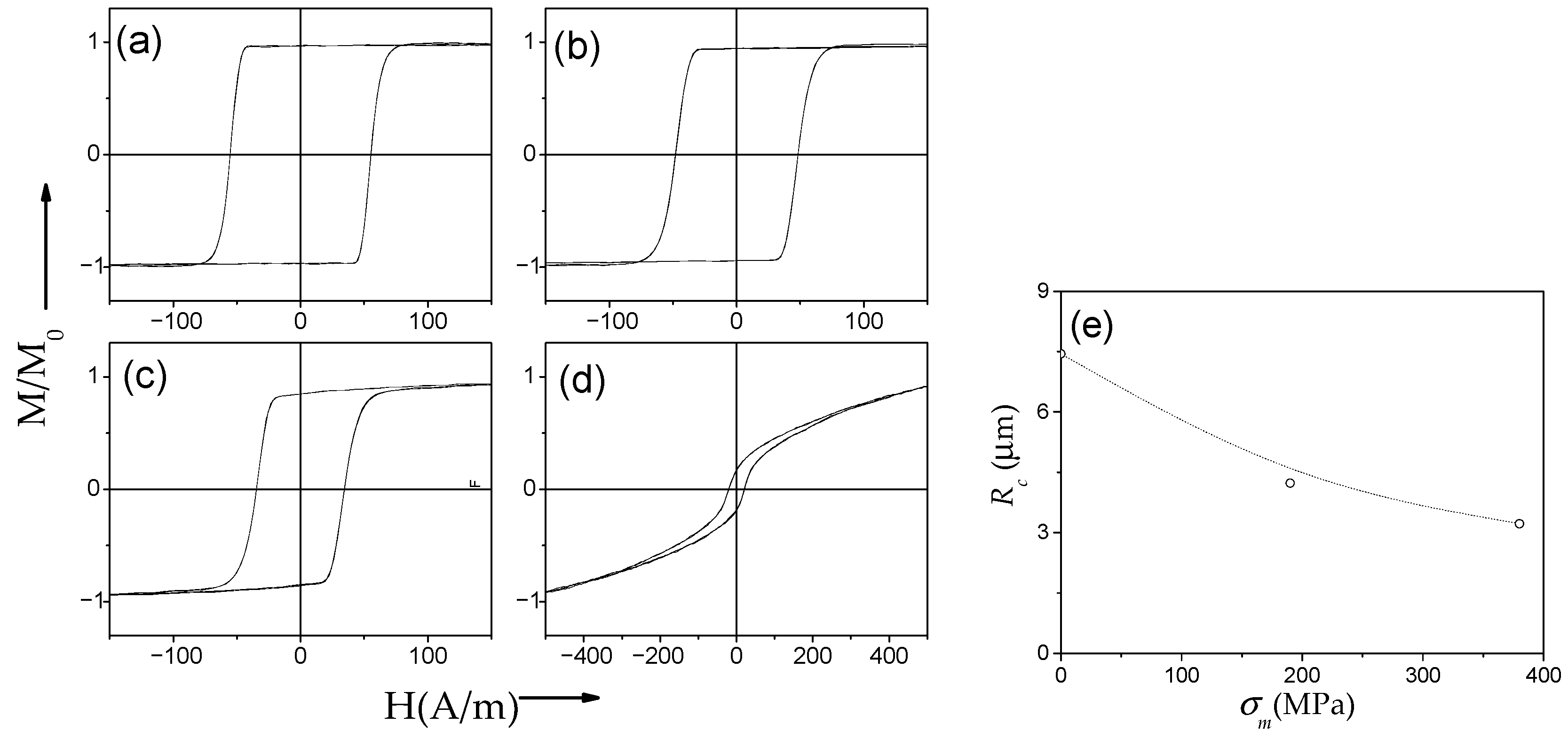

- Ipatov, M.; Usov, N.A.; Zhukov, A.; Gonzalez, J. Local nucleation fields of Fe-rich microwires and their dependence on applied stresses. Physica B 2008, 403, 379–381. [Google Scholar] [CrossRef]

- Vazquez, M.; Basheed, G.A.; Infante, G.; Del Real, R.P. Trapping and Injecting Single Domain Walls in Magnetic Wire by Local Fields. Phys. Rev. Lett. 2012, 108, 037201. [Google Scholar] [CrossRef]

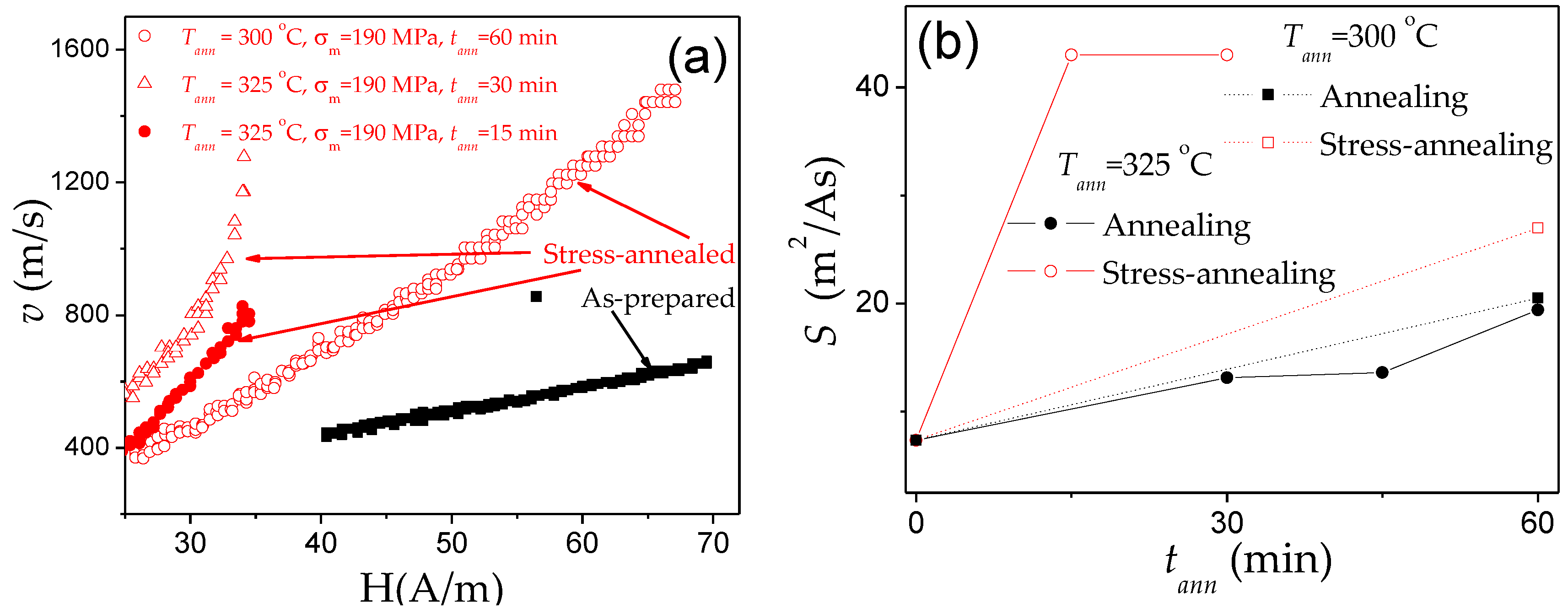

- Zhukova, V.; Blanco, J.M.; Corte-Leon, P.; Ipatov, M.; Churyukanova, M.; Taskaev, S.; Zhukov, A. Grading the magnetic anisotropy and engineering the domain wall dynamics in Fe-rich microwires by stress-annealing. Acta Mater. 2018, 155, 279–285. [Google Scholar] [CrossRef]

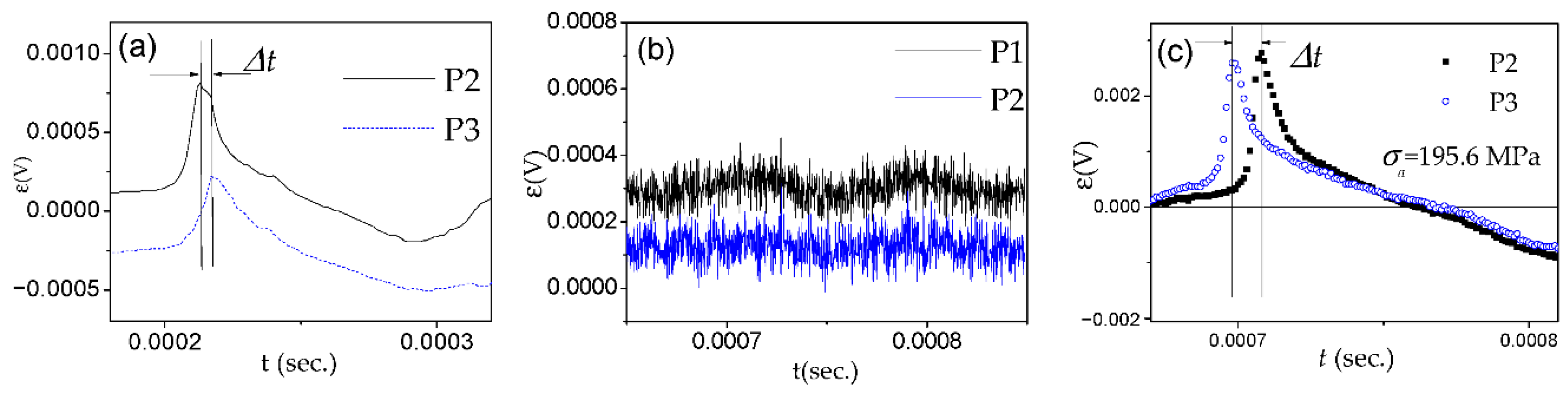

- Zhukov, A.; Blanco, J.M.; Chizhik, A.; Ipatov, M.; Rodionova, V.; Zhukova, V. Manipulation of domain wall dynamics in amorphous microwires through domain wall collision. J. Appl. Phys. 2013, 114, 043910. [Google Scholar] [CrossRef]

- Zhukova, V.; Corte-Leon, P.; Ipatov, M.; Blanco, J.M.; Gonzalez-Legarreta, L.; Zhukov, A. Development of Magnetic Microwires for Magnetic Sensor Applications. Sensors 2019, 19, 4767. [Google Scholar] [CrossRef]

- Narita, K.; Yamasaki, J.; Fukunaga, H. Measurement of saturation magnetostriction of a thin amorphous ribbon by means of small-angle magnetization rotation. IEEE Trans. Magn. 1980, 16, 435–439. [Google Scholar] [CrossRef]

- Churyukanova, M.; Semenkova, V.; Kaloshkin, S.; Shuvaeva, E.; Gudoshnikov, S.; Zhukova, V.; Shchetinin, I.; Zhukov, A. Magnetostriction investigation of soft magnetic microwires. Phys. Status Solidi A 2016, 213, 363–367. [Google Scholar] [CrossRef]

- Sixtus, K.J.; Tonks, L. Propagation of Large Barkhausen Discontinuities. II. Phys. Rev. 1932, 42, 419–435. [Google Scholar] [CrossRef]

- Zhukov, A.; Garcia-Beneytez, J.M.; Vázquez, M.; Hernandez, J.M.; Zhang, X.X.; Tejada, J. Critical behaviour of magnetic bistability in amorphous ferromagnetic materials. In Proceedings of the IV International Workshop, Santiago de Compostela, Spain, 5 July 1997; pp. 149–153. [Google Scholar]

- Fukumoto, K. Magnetization Reversal Dynamics in Magnetically Coupled Trilayer Systems. Ph.D. Thesis, Freien Universit¨at Berlin, Berlin, Germany, May 2005. [Google Scholar]

- Matsushita, A.; Abe, S.; Ishiai, S.; Jie, C.F. Magnetization Reversal and Domain Wall Propagation Characteristics of Compound Magnetic Wire. IEEE Transl. J. Magn. Jpn. 1991, 6, 415–421. [Google Scholar] [CrossRef]

- Varga, R.; Zhukov, A.; Zhukova, V.; Blanco, J.M.; Gonzalez, J. Supersonic domain wall in magnetic microwires. Phys. Rev. B 2007, 76, 132406. [Google Scholar] [CrossRef]

- Schryer, N.L.; Walker, L.R. The motion of 180° domain walls in uniform dc magnetic fields. J. Appl. Phys. 1974, 45, 5406–5421. [Google Scholar] [CrossRef]

- Ipatov, M.; Zhukova, V.; Zvezdin, A.K.; Zhukov, A. Mechanisms of the ultrafast magnetization switching in bistable amorphous microwires. J. Appl. Phys. 2009, 106, 103902. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Rodionova, V.; Ipatov, M.; Zhukov, A. Fast magnetization switching in Fe-rich amorphous microwires: Effect of magnetoelastic anisotropy and role of defects. J. Alloys Compd. 2014, 586 (Suppl. 1), S287–S290. [Google Scholar] [CrossRef]

- Rodionova, V.; Zhukova, V.; Ilyn, M.; Ipatov, M.; Perov, N.; Zhukov, A. The defects influence on domain wall propagation in bistable glass-coated microwires. Physica B 2012, 407, 1446–1449. [Google Scholar] [CrossRef]

- Chichay, K.; Zhukova, V.; Rodionova, V.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Gonzalez, J.; Zhukov, A. Tailoring of domain wall dynamics in amorphous microwires by annealing. J. Appl. Phys. 2013, 113, 17A318. [Google Scholar] [CrossRef]

- Kronmüller, H.; Fähnle, M.; Domann, M.; Grimm, H.; Grimm, R.; Gröger, B. Magnetic properties of amorphous ferromagnetic alloys. J. Magn. Magn. Mater. 1979, 13, 53–70. [Google Scholar]

- Zhukov, A.; Shuvaeva, E.; Kaloshkin, S.; Churyukanova, M.; Kostitcyna, E.; Sudarchikova, V.; Talaat, A.; Ipatov, M.; Zhukova, V. Influence of the defects on magnetic properties of glass-coated microwires. J. Appl. Phys. 2014, 115, 17A305. [Google Scholar] [CrossRef]

- Zhukov, A.; Shuvaeva, E.; Kaloshkin, S.; Churyukanova, M.; Kostitcyna, E.; Talaat, A.; Ipatov, M.; Gonzalez, J.; Zhukova, V. Studies of the Defects Influence on Magnetic Properties of Glass-Coated Microwires. IEEE Trans. Magn. 2014, 50, 2006604. [Google Scholar] [CrossRef]

- Zhukov, A.; Kostitcyna, E.; Shuvaeva, E.; Kaloshkin, S.; Churyukanova, M.; Sudarchikova, V.; Talaat, A.; Zhukova, V. Effect of composite origin on magnetic properties of glass-coated microwires. Intermetallics 2014, 44, 88–93. [Google Scholar] [CrossRef]

- Konno, Y.; Mohri, K. Magnetostriction measurements for amorphous wires. IEEE Trans. Magn. 1989, 25, 3623–3625. [Google Scholar] [CrossRef]

- Herzer, G. Amorphous and nanocrystalline soft magnets. In Proceedings of the NATO Advanced Study Insititute on Magnetic Hysteresis in Novel Materials, Mykonos, Greece, 1–12 July 1996; Hadjipanayis, G.C., Ed.; NATO ASI Series (Series E: Applied Sciences); Kluwer Academic Publishers: Dordrecht, The Netherlands, 1997; Volume 338, pp. 711–730. [Google Scholar]

- Cobeño, A.F.; Zhukov, A.; Blanco, J.M.; Gonzalez, J. Giant magneto-impedance effect in CoMnSiB amorphous microwires. J. Magn. Magn. Mater. 2001, 234, L359–L365. [Google Scholar] [CrossRef]

- Varga, R. Fast domain wall dynamics in thin magnetic wires. In Magnetic Properties of Solids; Tamayo, K.B., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2009; Chapter 6; pp. 251–272. [Google Scholar]

- Zhukov, A.; Blanco, J.M.; Ipatov, M.; Chizhik, A.; Zhukova, V. Manipulation of domain wall dynamics in amorphous microwires through the magnetoelastic anisotropy. Nanoscale Res. Lett. 2012, 7, 223. [Google Scholar] [CrossRef]

- Aragoneses, P.; Blanco, J.M.; Dominguez, L.; González, J.; Zhukov, A.; Vázquez, M. The Stress dependence of the switching field in glass-coated amorphous microwires. J. Phys. D Appl. Phys. 1998, 31, 3040–3045. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Ipatov, M.; Churyukanova, M.; Taskaev, S.; Zhukov, A. Tailoring of magnetoimpedance effect and magnetic softness of Fe-rich glass-coated microwires by stress-annealing. Sci. Rep. 2018, 8, 1–14. [Google Scholar] [CrossRef]

- Chichay, K.; Rodionova, V.; Zhukova, V.; Ipatov, M.; Perov, N.; Gorshenkov, M.; Andreev, N.; Zhukov, A. Tunable domain wall dynamics in amorphous ferromagnetic microwires. J. Alloys Compd. 2020, 835, 154843. [Google Scholar] [CrossRef]

- Zhukova, V.; Korchuganova, O.A.; Aleev, A.A.; Tcherdyntsev, V.V.; Churyukanova, M.; Medvedeva, E.V.; Seils, S.; Wagner, J.; Ipatov, M.; Blanco, J.M.; et al. Effect of annealing on magnetic properties and structure of Fe-Ni based magnetic microwires. J. Magn. Magn. Mater. 2017, 433, 278–284. [Google Scholar] [CrossRef]

- Luborsky, F.; Walter, J. Magnetic anneal anisotropy in amorphous alloys. IEEE Trans. Magn. 1977, 13, 953–956. [Google Scholar] [CrossRef]

- Haimovich, J.; Jagielinski, T.; Egami, T. Magnetic and structural effects of anelastic deformation of an amorphous alloy. J. Appl. Phys. 1985, 57, 3581–3583. [Google Scholar] [CrossRef]

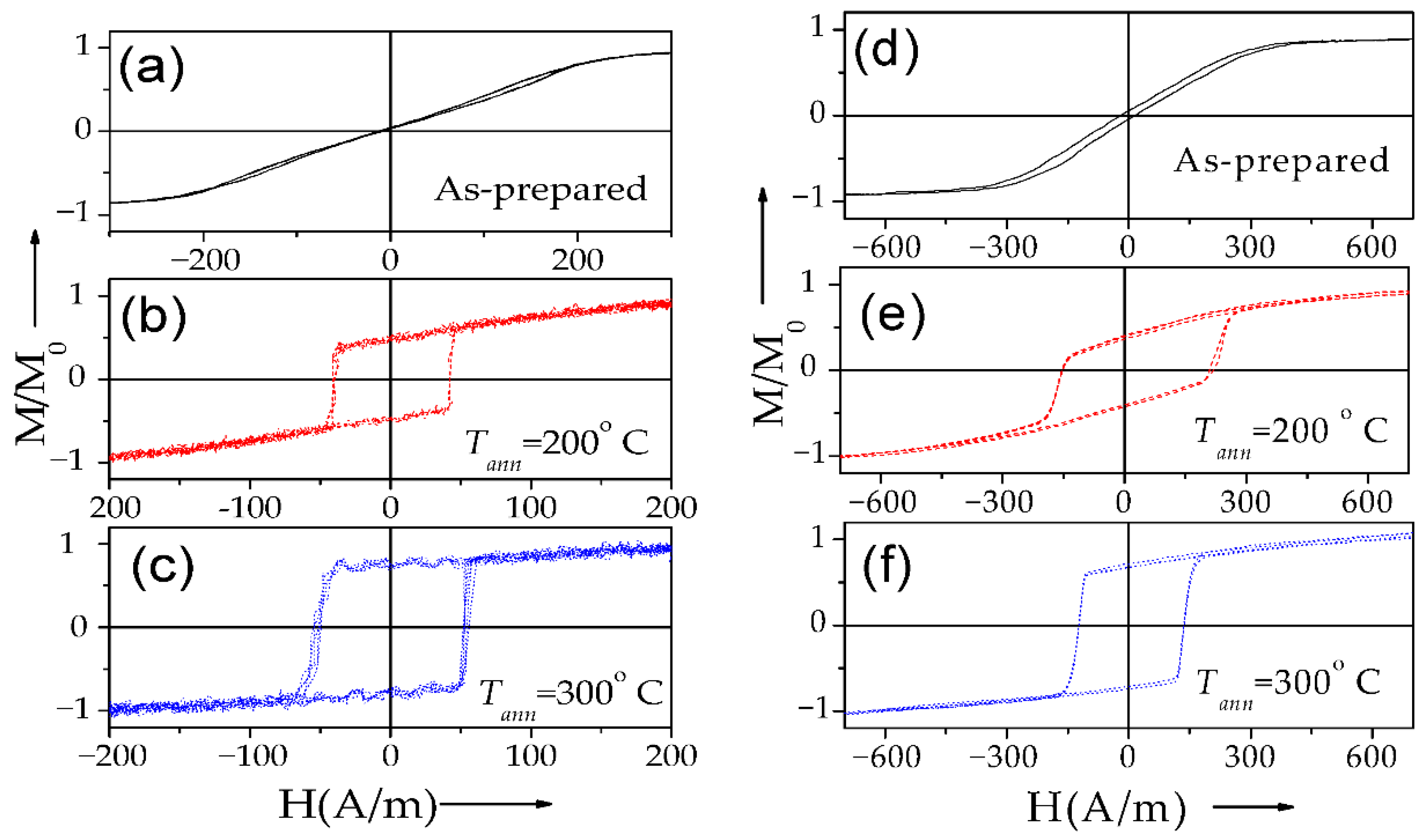

- Zhukova, V.; Talaat, A.; Corte-Leon, P.; Blanco, J.M.; Ipatov, M.; Zhukov, A. Engineering of magnetic properties and domain wall dynamics in Fe-Ni-based amorphous microwires by annealing. AIP Adv. 2020, 10, 015130. [Google Scholar] [CrossRef]

- Zhukov, A.; Churyukanova, M.; Kaloshkin, S.; Semenkova, V.; Gudoshnikov, S.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Zhukova, V. Effect of annealing on magnetic properties and magnetostriction coefficient of Fe–Ni-based amorphous microwires. J. Alloys Compd. 2015, 651, 718–723. [Google Scholar] [CrossRef]

- Kunz, A.; Reiff, S.C. Enhancing domain wall speed in nanowires with transverse magnetic fields. J. Appl. Phys. 2008, 103, 07D903. [Google Scholar] [CrossRef]

- Yang, J.; Beach, G.S.D.; Knutson, C.; Erskine, J.L. Magnetic domain-wall velocity enhancement induced by a transverse magnetic field. J. Magn. Magn. Mater. 2016, 397, 325–332. [Google Scholar] [CrossRef]

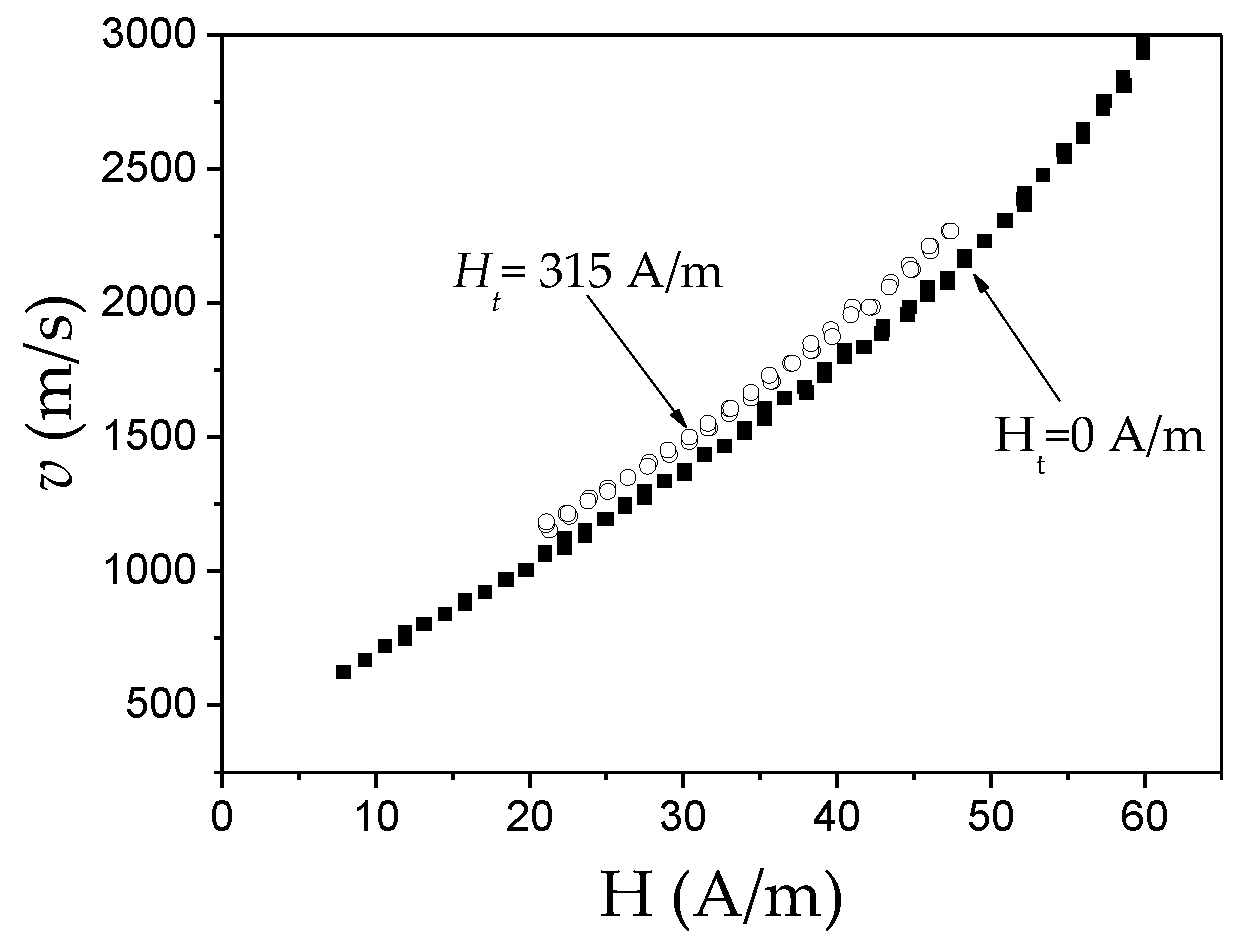

- Zhukova, V.; Blanco, J.M.; Ipatov, M.; Zhukov, A. Effect of transverse magnetic field on domain wall propagation in magnetically bistable glass-coated amorphous microwires. J. Appl. Phys. 2009, 106, 113914. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Corte-León, P.; Gonzalez-Legarreta, L.; Blanco, J.M.; Zhukova, V. Soft magnetic microwires for sensor applications. J. Magn. Magn. Mater. 2020, 498, 166180. [Google Scholar] [CrossRef]

- Takajo, M.; Yamasaki, J.; Humphrey, F.B. Domain Structure of Chemically Thinned Fe-Si-B Amorphous Wires. IEEE Trans. Magn. 1999, 35, 3904–3906. [Google Scholar] [CrossRef]

- Vazquez, M.; Chen, D.-X. The magnetization reversal process in amorphous wires. IEEE Trans. Magn. 1995, 31, 1229–1238. [Google Scholar] [CrossRef]

- Nderu, J.N.; Takajo, M.; Yamasaki, J.; Humphrey, F.B. Effect of stress on the bamboo domains and magnetization Process of CoSiB amorphous wires. IEEE Trans. Magn. 1998, 34, 1312–1314. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Ipatov, M.; Gonzalez, J.; Churyukanova, M.; Zhukov, A. Engineering of magnetic softness and giant magnetoimpedance effect in Fe-rich microwires by stress-annealing. Scr. Mater. 2018, 142, 10–14. [Google Scholar] [CrossRef]

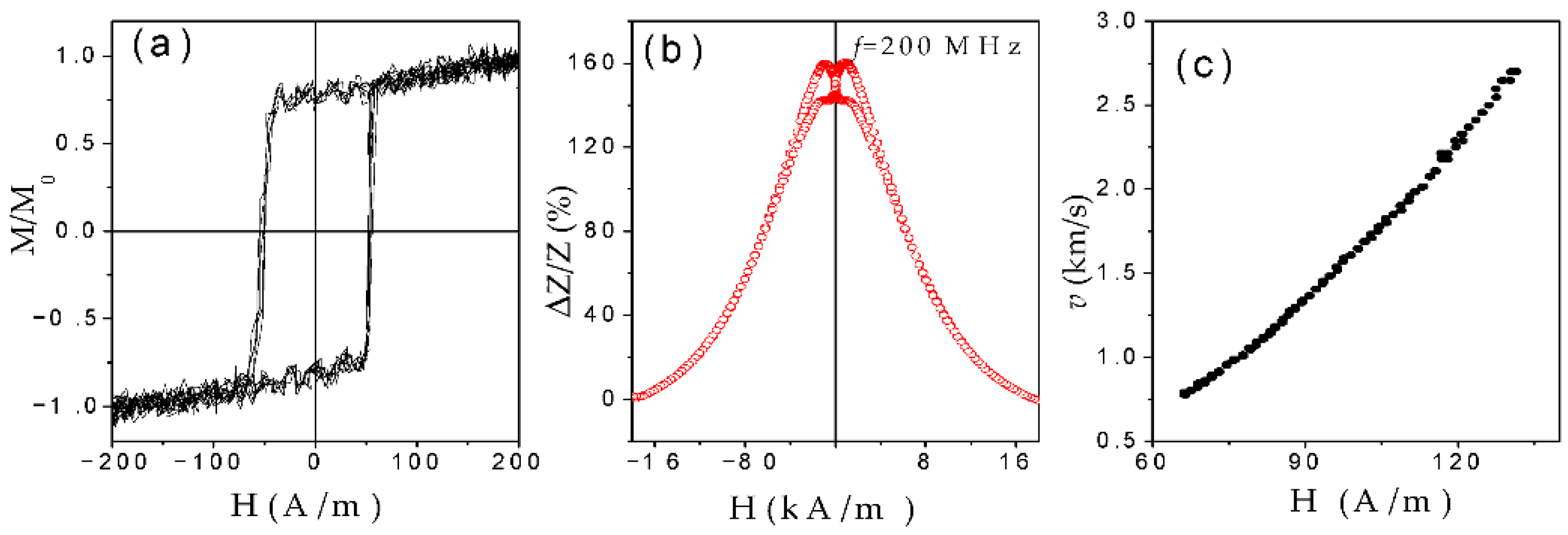

- Gonzalez-Legarreta, L.; Corte-León, P.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; Churyukanova, M.; Taskaev, S.; Zhukov, A. Route of magnetoimpedance and domain walls dynamics optimization in Co-based microwires. J. Alloys Compd. 2020, 830, 154576. [Google Scholar] [CrossRef]

- Talaat, A.; Churyukanova, M.; Blanco, J.M.; Ipatov, M.; Zhukova, V.; Zhukov, A. Simultaneous Detection of Giant Magnetoimpedance and Fast Domain Wall Propagation in Co-Based Glass-Coated Microwires. IEEE Magn. Lett. 2016, 7, 5200604. [Google Scholar] [CrossRef]

- Zhukov, A.; Talaat, A.; Churyukanova, M.; Kaloshkin, S.; Semenkova, V.; Ipatov, M.; Blanco, J.M.; Zhukova, V. Engineering of magnetic properties and GMI effect in Co-rich amorphous microwires. J. Alloys Compd. 2016, 664, 235–241. [Google Scholar] [CrossRef]

- Zhukov, A.; Talaat, A.; Ipatov, M.; Blanco, J.M.; Zhukova, V. Tailoring of magnetic properties and GMI effect of Co-rich amorphous microwires by heat treatment. J. Alloys Compd. 2014, 615, 610–615. [Google Scholar] [CrossRef]

- Ipatov, M.; Zhukova, V.; Gonzalez, J.; Zhukov, A. Magnetoimpedance hysteresis in amorphous microwires induced by core–shell interaction. Appl. Phys. Lett. 2014, 105, 122401. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Chizhik, A.; Ipatov, M.; Zhukov, A. Current induced domain wall propagation in Co-rich amorphous microwires. AIP Adv. 2017, 7, 056026. [Google Scholar] [CrossRef]

- Yoshizawa, Y.; Oguma, S.; Yamauchi, K. New Fe-based soft magnetic alloys composed of ultrafine grain structure. J. Appl. Phys. 1988, 64, 6044–6046. [Google Scholar] [CrossRef]

- McHenry, M.E.; Willard, M.A.; Laughlin, D.E. Amorphous and nanocrystalline materials for applications as soft magnets. Prog. Mater. Sci. 1999, 44, 291–433. [Google Scholar] [CrossRef]

- Herzer, G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 1990, 26, 1397–1402. [Google Scholar] [CrossRef]

- Chiriac, H.; Ovari, T.A.; Marinescu, C.S. Giant magneto-impedance effect in nanocrystalline glass-covered wires. J. Appl. Phys. 1998, 83, 6584–6586. [Google Scholar] [CrossRef]

- Dudek, C.; Adenot-Engelvin, A.L.; Bertin, F.; Acher, O. Engineering of the magnetic properties of Finemet based nanocrystalline glass-coated microwires. J. Non-Cryst. Solids 2007, 353, 925–927. [Google Scholar] [CrossRef]

- Zhukov, A.; Talaat, A.; Ipatov, M.; Blanco, J.M.; Gonzalez-Legarreta, L.; Hernando, B.; Zhukova, V. Effect of Nanocrystallization on Magnetic Properties and GMI Effect of Microwires. IEEE Trans. Magn. 2014, 50, 2501905. [Google Scholar] [CrossRef]

- Zhukova, V.; Cobeño, A.F.; Zhukov, A.; Blanco, J.M.; Larin, V.; Gonzalez, J. Coercivity of glass-coated Fe73.4 − xCu1Nb3.1Si13.4 + xB9.1 (0 ≤ x ≤ 1.6) microwires. Nanostruct. Mater. 1999, 11, 1319–1327. [Google Scholar] [CrossRef]

- Olivera, J.; Varga, R.; Vojtanik, P.; Prida, V.M.; Sanchez, M.L.; Hernando, B.; Zhukov, A. Fast domain wall dynamics in amorphous glass-coated microwires. J. Magn. Magn. Mater. 2008, 320, 2534–2537. [Google Scholar] [CrossRef]

- Klein, P.; Varga, R.; Badini-Confalonieri, G.A.; Vazquez, M. Domain Wall Dynamics in Amorphous and Nanocrystalline FeCoMoB Microwires. J. Nanosci. Nanotechnol. 2012, 12, 7464–7467. [Google Scholar] [CrossRef]

- Zhukova, V.; Talaat, A.; Ipatov, M.; del Val, J.J.; Blanco, J.M.; Gonzalez-Legarreta, L.; Hernando, B.; Varga, R.; Klein, P.; Zhukov, A. Optimization of Soft Magnetic Properties in Nanocrystalline Fe-Rich Glass-Coated Microwires. JOM 2015, 67, 2108–2116. [Google Scholar] [CrossRef]

- Talaat, A.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; Klein, P.; Varga, R.; Gonzalez-Legarreta, L.; Hernando, B.; Zhukov, A. Magnetic Properties of Nanocrystalline Microwires. J. Electr. Mater. 2016, 45, 212–218. [Google Scholar] [CrossRef]

- Zhukov, A.; Talaat, A.; Ipatov, M.; del Val, J.J.; Gonzalez-Legarreta, L.; Hernando, B.; Zhukova, V. Effect of nanocrystallization on magnetic properties and GMI effect of Fe-rich microwires. J. Electr. Mater. 2014, 43, 4540–4547. [Google Scholar] [CrossRef]

- Churyukanova, M.; Zhukova, V.; Talaat, A.; del Val, J.J.; Kaloshkin, S.; Kostitcyna, E.; Shuvaeva, E.; Sudarchikova, V.; Zhukov, A. Studies of thermal and magnetic properties of Fe-based amorphous and nanocrystalline glass coated microwires. J. Alloys Compd. 2014, 615, S256–S260. [Google Scholar] [CrossRef]

- Talaat, A.; Zhukova, V.; Ipatov, M.; del Val, J.J.; Blanco, J.M.; Gonzalez-Legarreta, L.; Hernando, B.; Churyukanova, M.; Zhukov, A. Engineering of Magnetic Softness and Magnetoimpedance in Fe-Rich Microwires by Nanocrystallization. JOM 2016, 68, 1563–1571. [Google Scholar] [CrossRef]

- Chiriac, H.; Lupu, N.; Stoian, G.; Ababei, G.; Corodeanu, S.; Óvári, T.-A. Ultrathin Nanocrystalline Magnetic Wires. Crystals 2017, 7, 48. [Google Scholar] [CrossRef]

- Kuhnt, M.; Marsilius, M.; Strache, T.; Polak, C.; Herzer, G. Magnetostriction of nanocrystalline (Fe,Co)-Si-B-P-Cu alloys. Scr. Mater. 2017, 130, 46–48. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, A.; He, A.; Yue, S.; Chang, C.; Wang, X.; Li, R.-W. Correlation between soft-magnetic properties and Tx1-Tc in high Bs FeCoSiBPC amorphous alloys. J. Alloys Compd. 2016, 659, 193–197. [Google Scholar] [CrossRef]

- García, C.; Zhukov, A.; Gonzalez, J.; Zhukova, V.; Varga, R.; del Val, J.J.; Larin, V.; Blanco, J.M. Studies of a structural and magnetic properties of glass-coated nanocrystalline Fe79Hf7B12Si2 microwires. J. Alloys Compd. 2006, 423, 116–119. [Google Scholar] [CrossRef]

- Klein, P.; Varga, R.; Vojtanik, P.; Kovac, J.; Ziman, J.; Badini-Confalonieri, G.A.; Vazquez, M. Bistable FeCoMoB microwires with nanocrystalline microstructure and increased Curie temperature. J. Phys. D Appl. Phys. 2010, 43, 045002. [Google Scholar] [CrossRef]

- Klein, P.; Varga, R.; Badini-Confalonieri, G.A.; Vazquez, M. Study of the switching field in amorphous and nanocrystalline FeCoMoB microwire. IEEE Trans. Magn. 2010, 46, 357–360. [Google Scholar] [CrossRef]

- Talaat, A.; del Val, J.J.; Zhukova, V.; Ipatov, M.; Klein, P.; Varga, R.; González, J.; Churyukanova, M.; Zhukov, A. Grain size refinement in nanocrystalline Hitperm-type glass-coated microwires. J. Magn. Magn. Mater. 2016, 406, 15–21. [Google Scholar] [CrossRef]

- Talaat, A.; del Val, J.J.; Zhukova, V.; Ipatov, M.; Klein, P.; Varga, R.; González, J.; Zhdanova, M.; Churyukanova, M.; Zhukov, A. Effect of annealing on magnetic properties of nanocrystalline Hitperm-type glass-coated microwires. J. Alloys Compd. 2016, 660, 297–303. [Google Scholar] [CrossRef]

- Ekstrom, P.A.; Zhukov, A. Spatial structure of the head-to-head propagating domain wall in glass-covered FeSiB microwire. J. Phys. D Appl. Phys. 2010, 43, 205001. [Google Scholar] [CrossRef]

- Gudoshnikov, S.A.; Grebenshchikov, Y.B.; Ljubimov, B.Y.; Palvanov, P.S.; Usov, N.A.; Ipatov, M.; Zhukov, A.; Gonzalez, J. Ground state magnetization distribution and characteristic width of head to head domain wall in Fe-rich amorphous microwire. Phys. Status Solidi A 2009, 206, 613–617. [Google Scholar] [CrossRef]

- Kladivová, M.; Ziman, J. Properties of a domain wall in a bi-stable magnetic microwire. J. Magn. Magn. Mater. 2019, 480, 193–198. [Google Scholar] [CrossRef]

- Usov, N.A.; Zhukov, A.; Gonzalez, J. Domain walls and magnetization reversal process in soft magnetic nanowires and nanotubes. J. Magn. Magn. Mater. 2007, 316, 255–261. [Google Scholar] [CrossRef]

- Zhukov, A.P.; Vázquez, M.; Velázquez, J.; Chiriac, H.; Larin, V. The remagnetization process of thin and ultrathin Fe-rich amorphous wires. J. Magn. Magn. Mater. 1995, 151, 132–138. [Google Scholar] [CrossRef]

- Panina, L.V.; Ipatov, M.; Zhukova, V.; Zhukov, A. Domain wall propagation in Fe-rich amorphous microwires. Physica B 2012, 407, 1442–1445. [Google Scholar] [CrossRef]

- Beck, F.; Rigue, J.N.; Carara, M. Effect of Electric Current on Domain Wall Dynamics. IEEE Trans. Magn. 2013, 9, 4699–4702. [Google Scholar] [CrossRef]

- Atkinson, D.; Eastwood, D.S.; Bogart, L.K. Controlling domain wall pinning in planar nanowires by selecting domain wall type and its application in a memory concept. Appl. Phys. Lett. 2008, 92, 022510. [Google Scholar] [CrossRef]

- Gawroński, P.; Zhukova, V.; Zhukov, A.; Gonzalez, J. Manipulation of domain propagation dynamics with the magnetostatic interaction in a pair of Fe-rich amorphous microwires. J. Appl. Phys. 2013, 114, 043903. [Google Scholar] [CrossRef]

- Jiménez, A.; Del Real, R.P.; Vázquez, M. Controlling depinning and propagation of single domain-walls in magnetic microwires. Eur. Phys. J. B. 2013, 86, 113. [Google Scholar] [CrossRef]

- Digiacomo, A.; Mantovan, R.; Vernier, N.; Devolder, T.; Garcia, K.; Tallarida, G.; Fanciulli, M.; Lamperti, A.; Ocker, B.; Baldi, L.; et al. Engineering Domain-Wall Motion in Co-Fe-B/MgO Ultrathin Films with Perpendicular Anisotropy Using Patterned Substrates with Subnanometer Step Modulation. Phys. Rev. Appl. 2018, 10, 064053. [Google Scholar] [CrossRef]

- Schmidt, H. Magnetization reversal by coherent rotation in single-domain magnets with arbitrary anisotropy. J. Appl. Phys. 2013, 93, 2107–2112. [Google Scholar] [CrossRef]

- Nowak, U.; Hinzke, D. Magnetization switching in small ferromagnetic particles: Nucleation and coherent rotation. J. Appl. Phys. 1999, 85, 4337–4340. [Google Scholar] [CrossRef][Green Version]

| Composition | Metallic Nucleus Diameter, d (μm) | Total Diameter, D (μm) | Ratio ρ = d/D | Magnetostriction Coefficient, λs × 10−6 |

|---|---|---|---|---|

| Fe77.5Si7.5B15 | 15.1 | 35.8 | 0.42 | 38 |

| Fe77.5Si7.5B15 | 12 | 40 | 0.3 | 38 |

| Fe75B9Si12C4 | 15.2 | 17.2 | 0.88 | 38 |

| Fe75B9Si12C4 | 13.6 | 16 | 0.85 | 38 |

| Fe74Si11B13C2 | 12 | 15.8 | 0.76 | 38 |

| Fe74Si11B13C2 | 13.8 | 22.3 | 0.62 | 38 |

| Fe74Si11B13C2 | 17.8 | 28.3 | 0.63 | 38 |

| Fe74Si11B13C2 | 16.2 | 23.8 | 0.68 | 38 |

| Fe74Si11B13C2 | 14.6 | 21.8 | 0.55 | 38 |

| Fe62Ni15.5Si7.5B15 | 14.35 | 33.25 | 0.43 | 27 |

| Fe49.6Ni27.9Si7.5B15 | 14.2 | 33.85 | 0.42 | 20 |

| Fe47.4Ni26.6Si11B13C2 | 29 | 32.2 | 0.9 | 20 |

| Co69.2Fe3.6Ni1B12.5Si11Mo1.5C1.2 | 22.8 | 23.2 | 0.98 | −1 |

| Co69.2Fe4.1B11.8Si13.8C1.1 | 25.6 | 30.2 | 0.85 | −0.03 |

| Fe71.8Cu1Nb3.1Si15B9.1 | 6.6 | 18.4 | 0.36 | 30 |

| Fe70.8Cu1Nb3.1Si14.5B10.6 | 5.8 | 15.2 | 0.38 | 30 |

| Fe38.5Co38.5B18Mo4Cu1 | 10 | 16.6 | 0.6 | 30 |

| Fe73.5Cu1Nb3Si11.5B11 | 10 | 28 | 0.36 | 30 |

| Fe8.1Co50.7Ni17.6B13.3Si10.3 | 11.6 | 14 | 0.83 | −0.9 |

| Co56Fe8Ni10Si10B16 | 22 | 26.2 | 0.84 | 0.1 |

| Fe66.7Cr11.4B12Si9Ni0.9 | 17.6 | 38.6 | 0.46 | 7 |

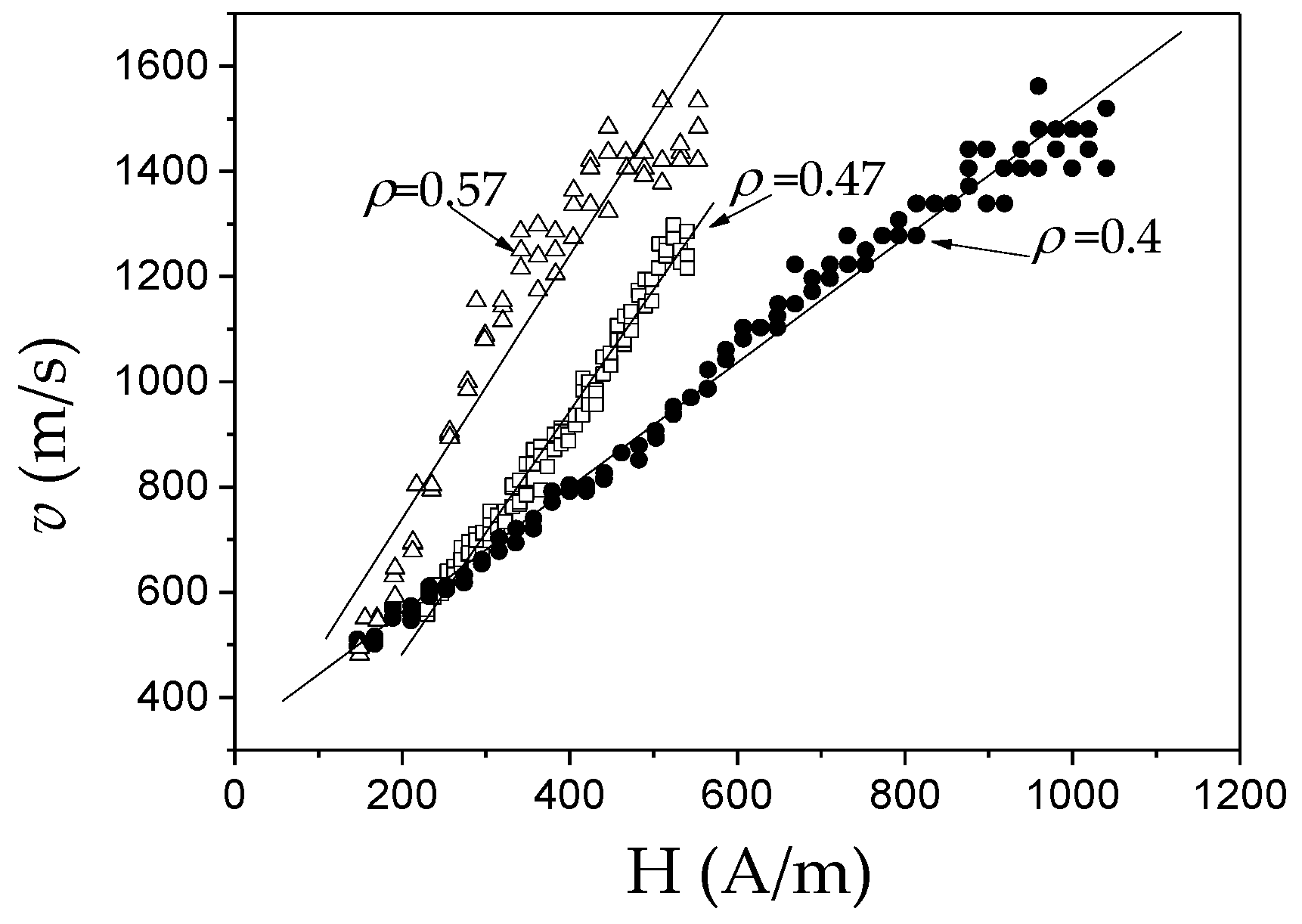

| Co41.7Fe36.4Si10.1B11.8 | 13.6 | 24 | 0.57 | 25 |

| Co41.7Fe36.4Si10.1B11.8 | 13.6 | 34 | 0.4 | 25 |

| Co41.7Fe36.4Si10.1B11.8 | 18 | 38 | 0.47 | 25 |

| Fe16Co60Si13B11 | 12 | 29 | 0.41 | 15 |

| Fe55Co23B11,8Si10.2 | 13.2 | 29.6 | 0.45 | 30 |

| Fe38.5Co38.5B18Mo4Cu1 | 9.4 | 22.5 | 0.41 | |

| Fe38.5Co38.5B18Mo4Cu1 | 10 | 16.6 | 0.6 | |

| (Fe0.7Co0.3)83.7Si4B8P3.6Cu0.7 | 15.5 | 26.5 | 0.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhukova, V.; Corte-Leon, P.; González-Legarreta, L.; Talaat, A.; Blanco, J.M.; Ipatov, M.; Olivera, J.; Zhukov, A. Review of Domain Wall Dynamics Engineering in Magnetic Microwires. Nanomaterials 2020, 10, 2407. https://doi.org/10.3390/nano10122407

Zhukova V, Corte-Leon P, González-Legarreta L, Talaat A, Blanco JM, Ipatov M, Olivera J, Zhukov A. Review of Domain Wall Dynamics Engineering in Magnetic Microwires. Nanomaterials. 2020; 10(12):2407. https://doi.org/10.3390/nano10122407

Chicago/Turabian StyleZhukova, Valentina, Paula Corte-Leon, Lorena González-Legarreta, Ahmed Talaat, Juan Maria Blanco, Mihail Ipatov, Jesus Olivera, and Arcady Zhukov. 2020. "Review of Domain Wall Dynamics Engineering in Magnetic Microwires" Nanomaterials 10, no. 12: 2407. https://doi.org/10.3390/nano10122407

APA StyleZhukova, V., Corte-Leon, P., González-Legarreta, L., Talaat, A., Blanco, J. M., Ipatov, M., Olivera, J., & Zhukov, A. (2020). Review of Domain Wall Dynamics Engineering in Magnetic Microwires. Nanomaterials, 10(12), 2407. https://doi.org/10.3390/nano10122407