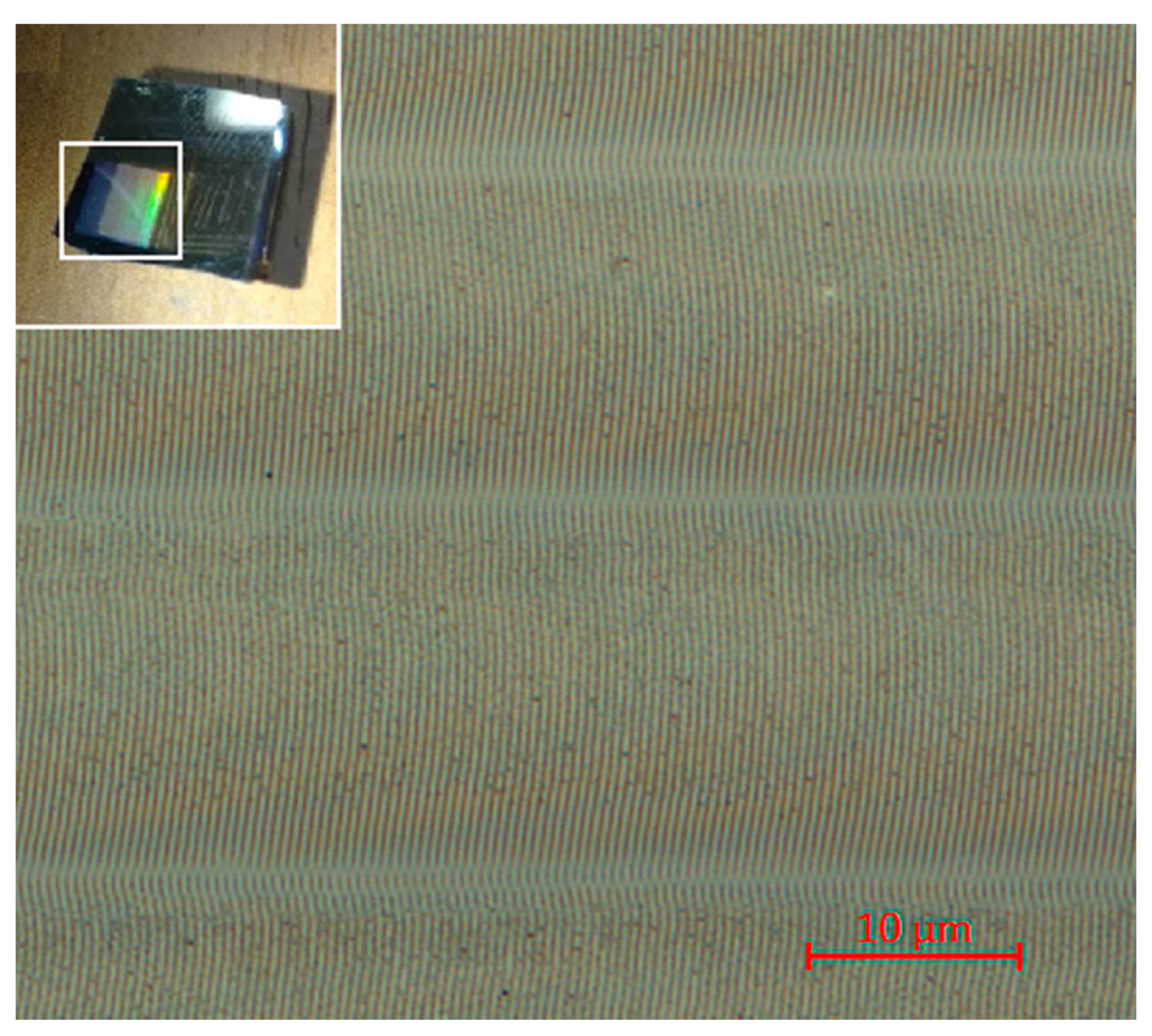

Formation of the Submicron Oxidative LIPSS on Thin Titanium Films During Nanosecond Laser Recording

Abstract

1. Introduction

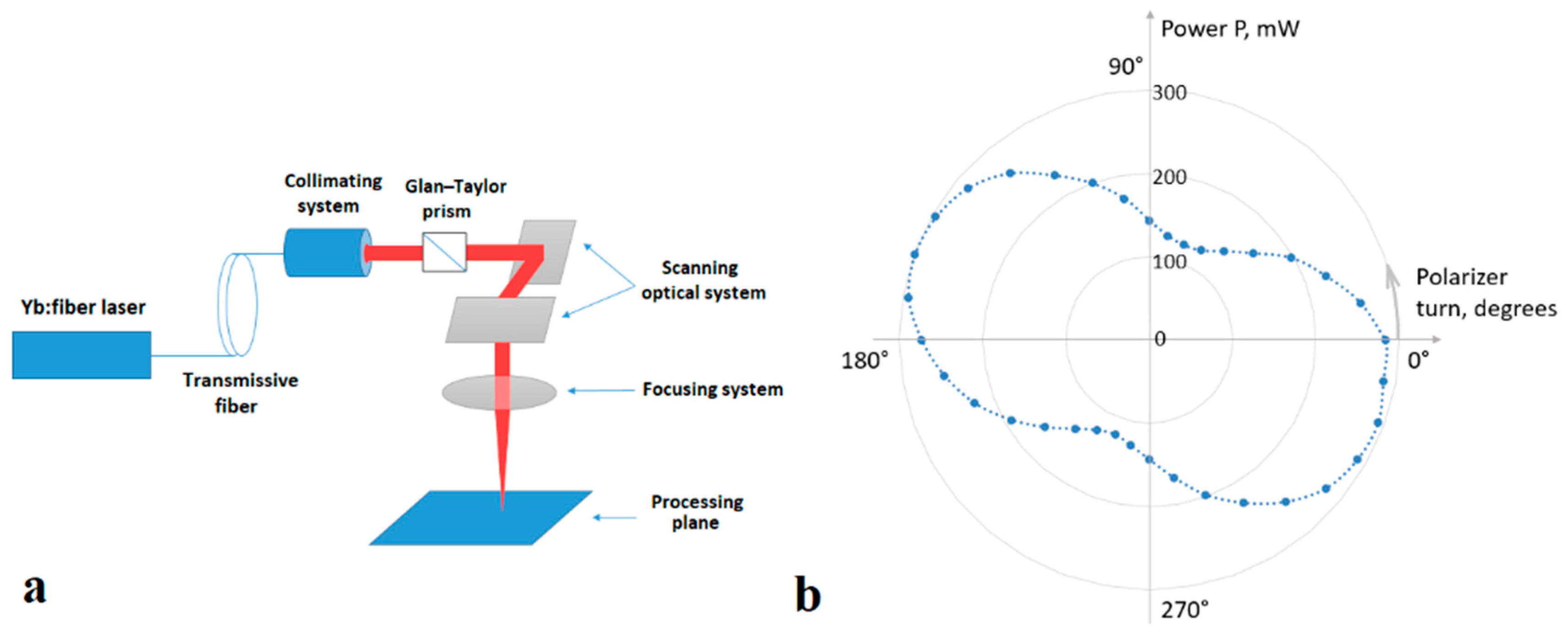

2. Materials and Methods

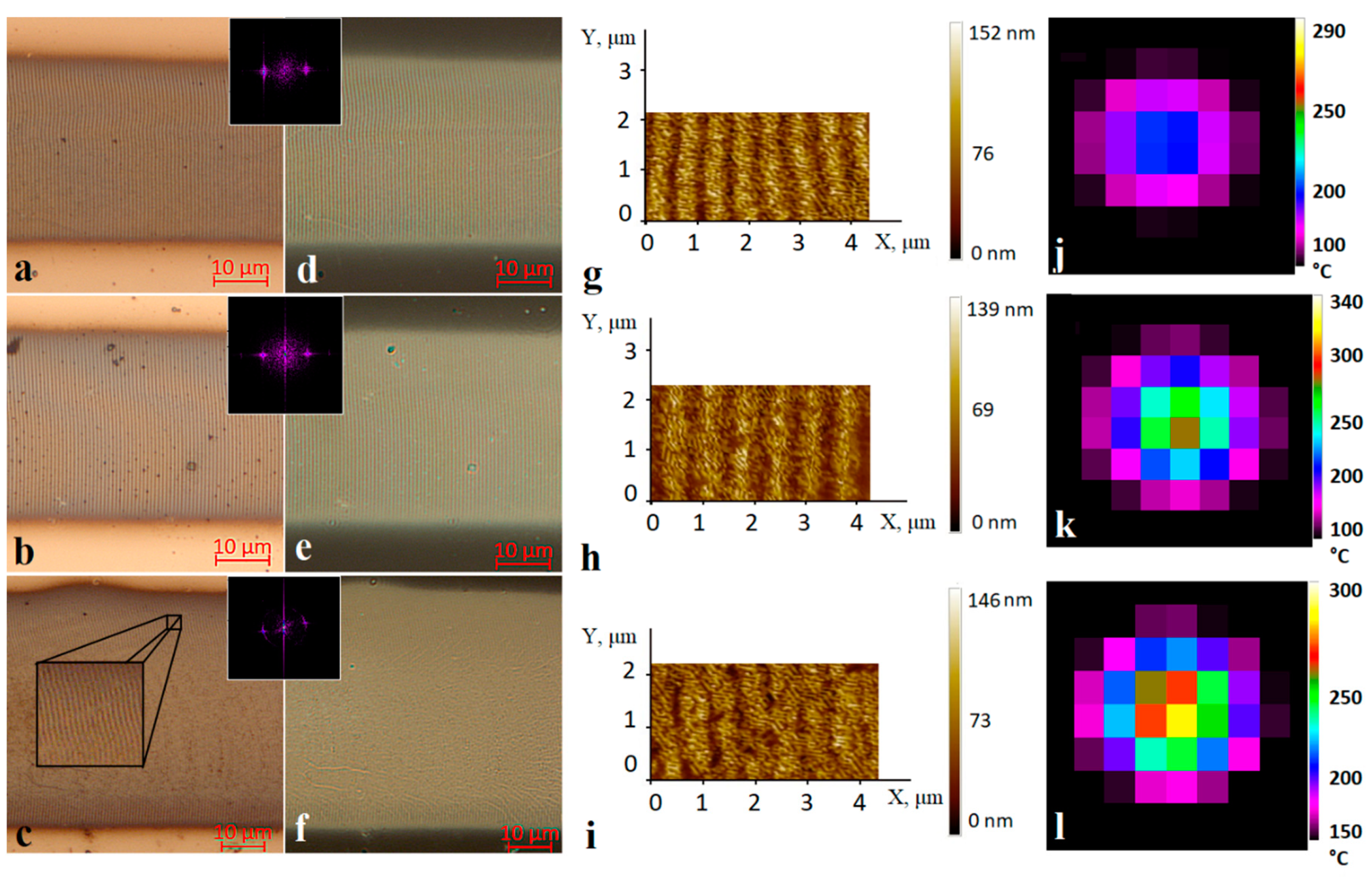

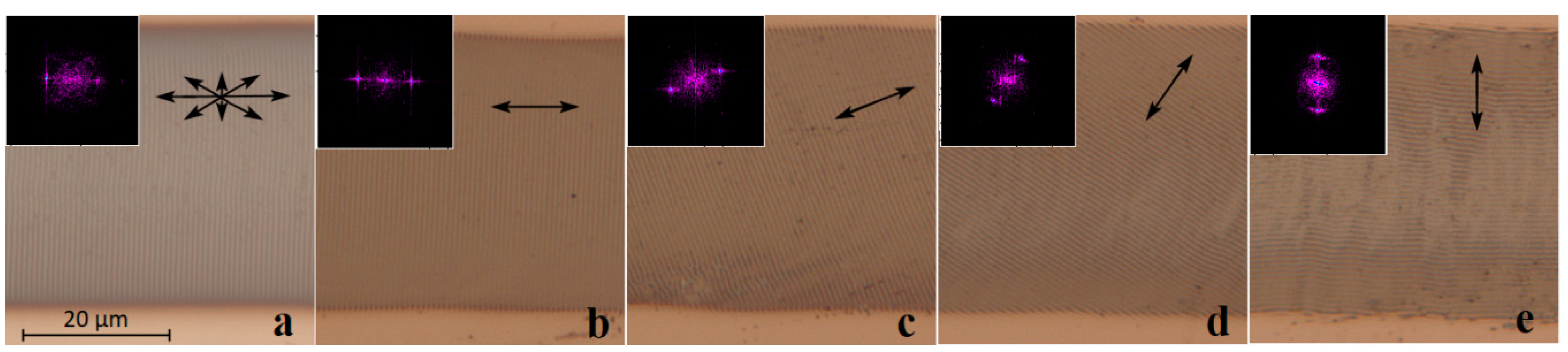

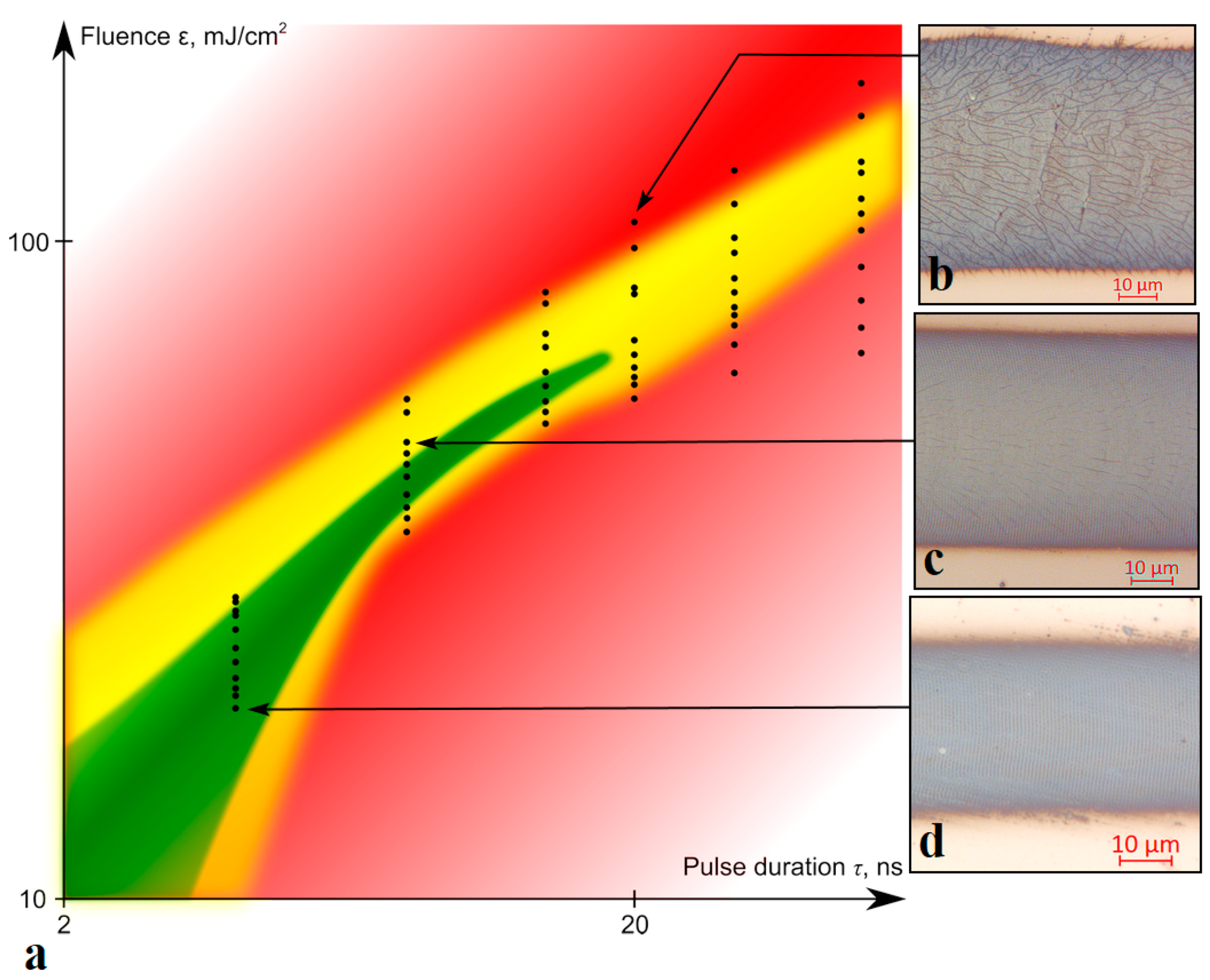

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Veiko, V.; Karlagina, Y.; Moskvin, M.; Mikhailovskii, V.Y.; Одинцoва, Г.; Olshin, P.; Pankin, D.; Romanov, V.; Yatsuk, R. Metal surface coloration by oxide periodic structures formed with nanosecond laser pulses. Opt. Lasers Eng. 2017, 96, 63–67. [Google Scholar] [CrossRef]

- Ageev, E.I.; Veiko, V.P.; Vlasova, E.A.; Karlagina, Y.Y.; Krivonosov, A.; Moskvin, M.K.; Odintsova, G.V.; Pshenichnov, V.E.; Romanov, V.V.; Yatsuk, R.M. Controlled nanostructures formation on stainless steel by short laser pulses for products protection against falsification. Opt. Express 2018, 26, 2117–2122. [Google Scholar] [CrossRef] [PubMed]

- Kunz, C.; Engel, S.; Müller, F.A.; Gräf, S. Large-Area Fabrication of Laser-Induced Periodic Surface Structures on Fused Silica Using Thin Gold Layers. Nanomaterials 2020, 10, 1187. [Google Scholar] [CrossRef] [PubMed]

- San-Blas, A.; Martinez-Calderon, M.; Buencuerpo, J.; Sanchez-Brea, L.; Del Hoyo, J.; Gómez-Aranzadi, M.; Rodríguez, A.; Olaizola, S. Femtosecond laser fabrication of LIPSS-based waveplates on metallic surfaces. Appl. Surf. Sci. 2020, 520, 146328. [Google Scholar] [CrossRef]

- Vorobyev, A.; Guo, C. Femtosecond laser structuring of titanium implants. Appl. Surf. Sci. 2007, 253, 7272–7280. [Google Scholar] [CrossRef]

- Klos, A.; Sedao, X.; Itina, T.E.; Helfenstein-Didier, C.; Donnet, C.; Peyroche, S.; Vico, L.; Guignandon, A.; Dumas, V. Ultrafast Laser Processing of Nanostructured Patterns for the Control of Cell Adhesion and Migration on Titanium Alloy. Nanomaterials 2020, 10, 864. [Google Scholar] [CrossRef]

- Martínez-Calderon, M.; Rodríguez, A.; Dias-Ponte, A.; Morant-Miñana, M.; Gómez-Aranzadi, M.; Olaizola, S. Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Appl. Surf. Sci. 2016, 374, 81–89. [Google Scholar] [CrossRef]

- Long, J.; Fan, P.; Zhong, M.; Zhang, H.; Xie, Y.; Lin, C. Superhydrophobic and colorful copper surfaces fabricated by picosecond laser induced periodic nanostructures. Appl. Surf. Sci. 2014, 311, 461–467. [Google Scholar] [CrossRef]

- Nathala, C.S.; Ajami, A.; Ionin, A.A.; Kudryashov, S.I.; Makarov, S.V.; Ganz, T.; Assion, A.; Husinsky, W. Experimental study of fs-laser induced sub-100-nm periodic surface structures on titanium. Opt. Express 2015, 23, 5915–5929. [Google Scholar] [CrossRef]

- Han, W.; Jiang, L.; Li, X.; Liu, P.; Xu, L.; Guo, L. Continuous modulations of femtosecond laser-induced periodic surface structures and scanned line-widths on silicon by polarization changes. Opt. Express 2013, 21, 15505–15513. [Google Scholar] [CrossRef]

- Bonse, J.; Höhm, S.; Rosenfeld, A.; Kruger, J. Sub-100-nm laser-induced periodic surface structures upon irradiation of titanium by Ti:sapphire femtosecond laser pulses in air. Appl. Phys. A 2012, 110, 547–551. [Google Scholar] [CrossRef]

- Öktem, B.; Pavlov, I.; Ilday, S.; Kalaycıoğlu, H.; Rybak, A.; Yavaş, S.; Erdoğan, M.; Ilday, F. Ömer Nonlinear laser lithography for indefinitely large-area nanostructuring with femtosecond pulses. Nat. Photon. 2013, 7, 897–901. [Google Scholar] [CrossRef]

- Bonse, J.; Hohm, S.; Kirner, S.V.; Rosenfeld, A.; Kruger, J. Laser-Induced Periodic Surface Structures— A Scientific Evergreen. IEEE J. Sel. Top. Quantum Electron. 2016, 23, 1–15. [Google Scholar] [CrossRef]

- Dostovalov, A.V.; Derrien, T.J.-Y.; Lizunov, S.A.; Přeučil, F.; Okotrub, K.A.; Mocek, T.; Korolkov, V.P.; Babin, S.A.; Bulgakova, N.M. LIPSS on thin metallic films: New insights from multiplicity of laser-excited electromagnetic modes and efficiency of metal oxidation. Appl. Surf. Sci. 2019, 491, 650–658. [Google Scholar] [CrossRef]

- Одинцoва, Г.; Andreeva, Y.M.; Salminen, A.; Roozbahani, H.; Van Cuong, L.; Yatsuk, R.; Golubeva, V.; Romanov, V.; Veiko, V.; Luong, V.C. Investigation of production related impact on the optical properties of color laser marking. J. Mater. Process. Technol. 2019, 274, 116263. [Google Scholar] [CrossRef]

- Kang, M.J.; Park, T.S.; Kim, M.; Hwang, E.S.; Kim, S.H.; Shin, S.T.; Cheong, B.-H. Periodic surface texturing of amorphous-Si thin film irradiated by UV nanosecond laser. Opt. Mater. Express 2019, 9, 4247–4255. [Google Scholar] [CrossRef]

- Reyes-Contreras, A.; Camacho-López, M.A.; Camacho-López, S.; Olea-Mejía, O.; Esparza-García, A.; Bañuelos-Muñetón, J.G. Laser-induced periodic surface structures on bismuth thin films with ns laser pulses below ablation threshold. Opt. Mater. Express 2017, 7, 1777. [Google Scholar] [CrossRef]

- Dusser, B.; Sagan, S.; Soder, H.; Faure, N.; Colombier, J.-P.; Jourlin, M.; Audouard, E. Controlled nanostructrures formation by ultra fast laser pulses for color marking. Opt. Express 2010, 18, 2913–2924. [Google Scholar] [CrossRef]

- Makin, V.S.; Logacheva, E.I.; Makin, R.S. Localized surface plasmon polaritons and nonlinear overcoming of the diffraction optical limit. Opt. Spectrosc. 2016, 120, 610–614. [Google Scholar] [CrossRef]

- Ehrhardt, M.; Han, B.; Frost, F.; Lorenz, P.; Zimmer, K. Generation of laser-induced periodic surface structures (LIPSS) in fused silica by single NIR nanosecond laser pulse irradiation in confinement. Appl. Surf. Sci. 2019, 470, 56–62. [Google Scholar] [CrossRef]

- Andreeva, Y.M.; Luong, V.C.; Lutoshina, D.S.; Medvedev, O.S.; Mikhailovskii, V.Y.; Moskvin, M.K.; Одинцoва, Г.; Romanov, V.V.; Shchedrina, N.N.; Veiko, V.P. Laser coloration of metals in visual art and design. Opt. Mater. Express 2019, 9, 1310–1319. [Google Scholar] [CrossRef]

- Florian, C.; Déziel, J.-L.; Kirner, S.V.; Siegel, J.; Bonse, J. The Role of the Laser-Induced Oxide Layer in the Formation of Laser-Induced Periodic Surface Structures. Nanomaterials 2020, 10, 147. [Google Scholar] [CrossRef] [PubMed]

- Veiko, V.P.; Shakhno, E.A.; Sinev, D.A. Laser thermochemical writing: Pursuing the resolution. Opt. Quantum Electron. 2016, 48, 322. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, R.; Guo, C.F.; Miao, J.; Tian, Y.; Ren, T.; Liu, Q. Path-directed and maskless fabrication of ordered TiO2 nanoribbons. Nanoscale 2012, 4, 1545–1548. [Google Scholar] [CrossRef]

- Veiko, V.P.; Zakoldaev, R.A.; Shakhno, E.A.; Sinev, D.A.; Nguyen, Z.K.; Baranov, A.V.; Bogdanov, K.V.; Gedvilas, M.; Raciukaitis, G.; Vishnevskaya, L.V.; et al. Thermochemical writing with high spatial resolution on Ti films utilising picosecond laser. Opt. Mater. Express 2019, 9, 2729–2737. [Google Scholar] [CrossRef]

- Veiko, V.P.; Nguyen, Q.D.; Shakhno, E.A.; Sinev, D.A.; Lebedeva, E.V. Physical similarity of the processes of laser thermochemical recording on thin metal films and modeling the recording of submicron structures. Opt. Quantum Electron. 2019, 51, 348. [Google Scholar] [CrossRef]

- Shakhno, E.A.; Sinev, D.A.; Kulazhkin, A.M. Features of laser oxidation of thin films of titanium. J. Opt. Technol. 2014, 81, 298. [Google Scholar] [CrossRef]

- Guo, C.F.; Cao, S.; Jiang, P.; Fang, Y.; Zhang, J.; Fan, Y.; Wang, Y.; Xu, W.; Zhao, Z.; Liu, Q. Grayscale photomask fabricated by laser direct writing in metallic nano-films. Opt. Express 2009, 17, 19981–19987. [Google Scholar] [CrossRef]

- Korolkov, V.P.; Sedukhin, A.G.; Mikerin, S.L. Technological and optical methods for increasing the spatial resolution of thermochemical laser writing on thin metal films. Opt. Quantum Electron. 2019, 51, 389. [Google Scholar] [CrossRef]

- Veiko, V.P.; Korolkov, V.P.; Poleshchuk, A.G.; Sinev, D.A.; Shakhno, E.A. Laser technologies in micro-optics. Part 1. Fabrication of diffractive optical elements and photomasks with amplitude transmission. Optoelectron. Instrum. Data Process. 2017, 53, 474–483. [Google Scholar] [CrossRef]

- Laser Center. Available online: https://www.newlaser.ru/laser/lc/minimarker2.php (accessed on 27 September 2020).

- Metev, S.M.; Veiko, V.P. Laser-Assisted Microtechnology; Springer: Berlin, Germany, 1998; p. 180. [Google Scholar]

- Kikoin, I.K. Tables of Physical Quantities; Atomizdat: Moscow, Russia, 1976. [Google Scholar]

- Ordal, M.A.; Bell, R.J.; Alexander, R.W.; Newquist, L.A.; Querry, M.R. Optical properties of Al, Fe, Ti, Ta, W, and Mo at submillimeter wavelengths. Appl. Opt. 1988, 27, 1203–1209. [Google Scholar] [CrossRef]

- Gedvilas, M.; Voisiat, B.; Indrisiunas, S.; Raciukaitis, G.; Veiko, V.; Zakoldaev, R.A.; Sinev, D.; Shakhno, E. Thermo-chemical microstructuring of thin metal films using multi-beam interference by short (nano- & picosecond) laser pulses. Thin Solid Films 2017, 634, 134–140. [Google Scholar] [CrossRef]

| Titanium [33,34] | |

| Density, p1 | 4.5 × 103 kg/m3 |

| Thermal capacity, c1 | 530.8 J/(kg·K) |

| Absorbance coefficient A1 at λ = 1.07 μm | 0.42 |

| BK7 glass [35] | |

| Density, p1 | 2.5 × 103 kg/m3 |

| Thermal capacity, c2 | 720 J/(kg·K) |

| Thermal diffusivity, a2 | 0.6 × 10−6 m2/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sinev, D.A.; Yuzhakova, D.S.; Moskvin, M.K.; Veiko, V.P. Formation of the Submicron Oxidative LIPSS on Thin Titanium Films During Nanosecond Laser Recording. Nanomaterials 2020, 10, 2161. https://doi.org/10.3390/nano10112161

Sinev DA, Yuzhakova DS, Moskvin MK, Veiko VP. Formation of the Submicron Oxidative LIPSS on Thin Titanium Films During Nanosecond Laser Recording. Nanomaterials. 2020; 10(11):2161. https://doi.org/10.3390/nano10112161

Chicago/Turabian StyleSinev, Dmitry A., Daria S. Yuzhakova, Mikhail K. Moskvin, and Vadim P. Veiko. 2020. "Formation of the Submicron Oxidative LIPSS on Thin Titanium Films During Nanosecond Laser Recording" Nanomaterials 10, no. 11: 2161. https://doi.org/10.3390/nano10112161

APA StyleSinev, D. A., Yuzhakova, D. S., Moskvin, M. K., & Veiko, V. P. (2020). Formation of the Submicron Oxidative LIPSS on Thin Titanium Films During Nanosecond Laser Recording. Nanomaterials, 10(11), 2161. https://doi.org/10.3390/nano10112161