Quo Vadis LIPSS?—Recent and Future Trends on Laser-Induced Periodic Surface Structures

Abstract

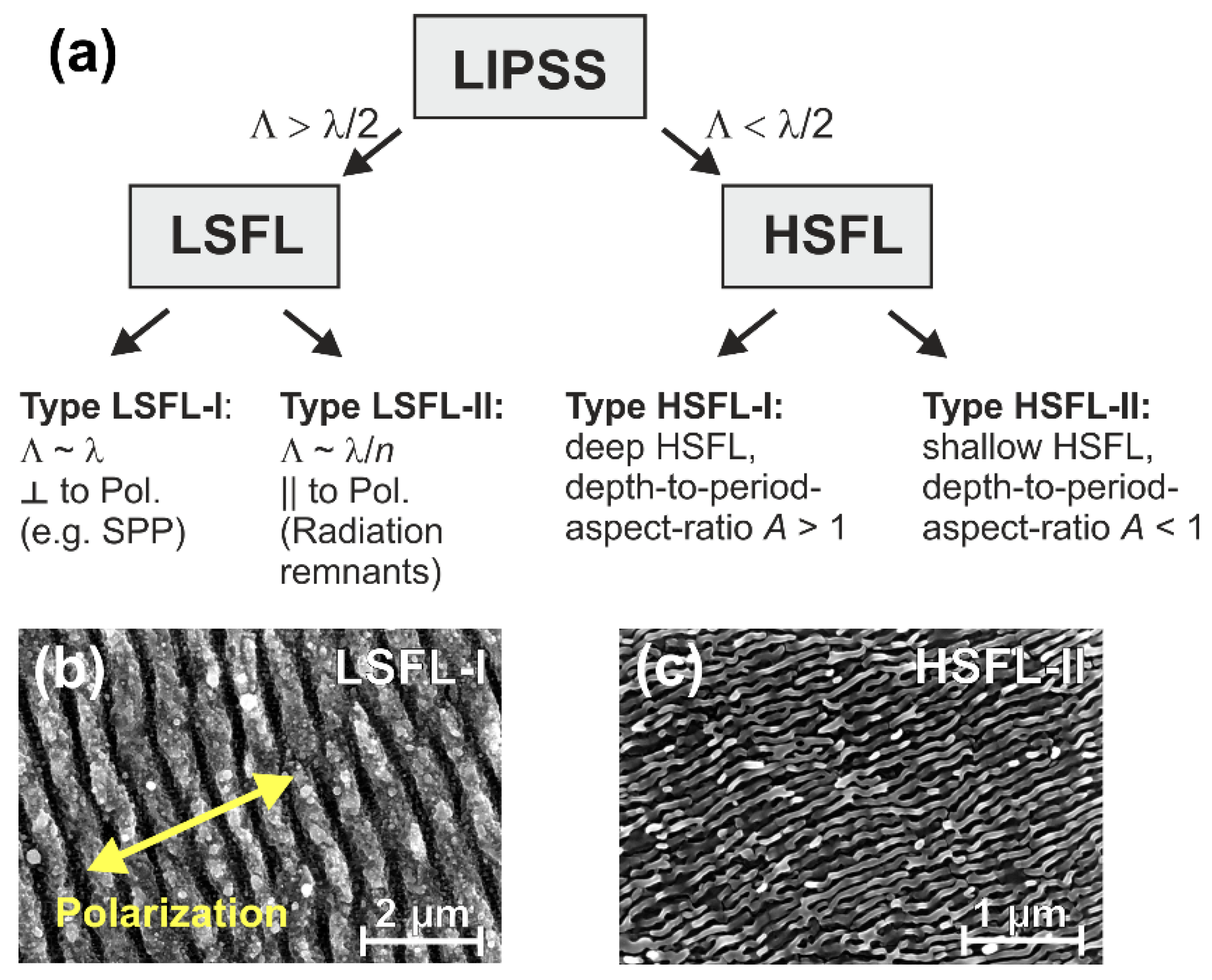

:1. Introduction

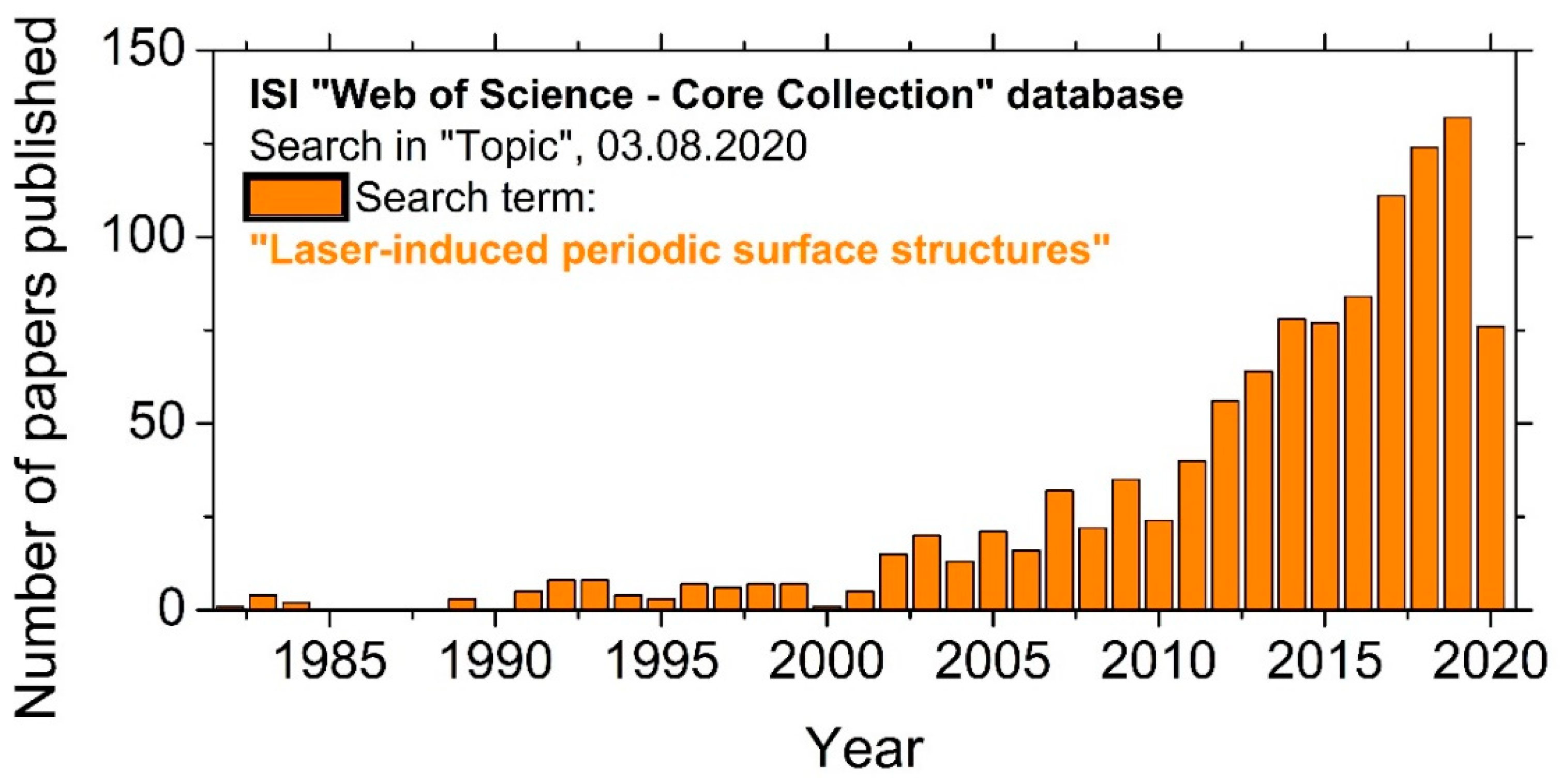

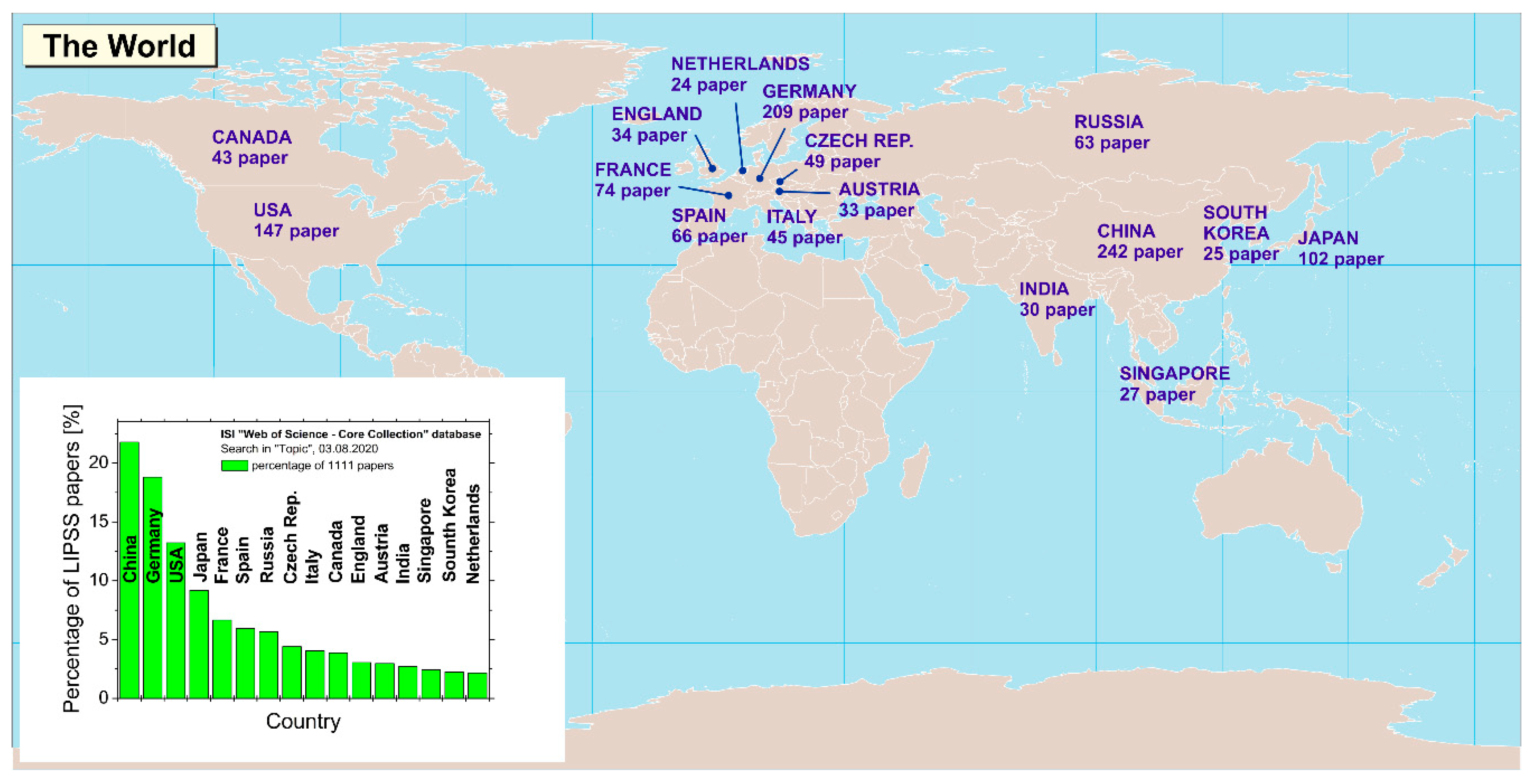

2. Analysis of the Research Area of LIPSS

2.1. Available Literature

2.1.1. Peer Reviewed Articles (1982–2020)

2.1.2. Review Articles

2.1.3. Special Issues

2.2. Scientific Conferences and Workshops

3. Recent (Ongoing) Trends

3.1. Electromagnetics vs. Matter Reorganization

3.2. Topography vs. Chemistry

3.3. LIPSS vs. DLIP

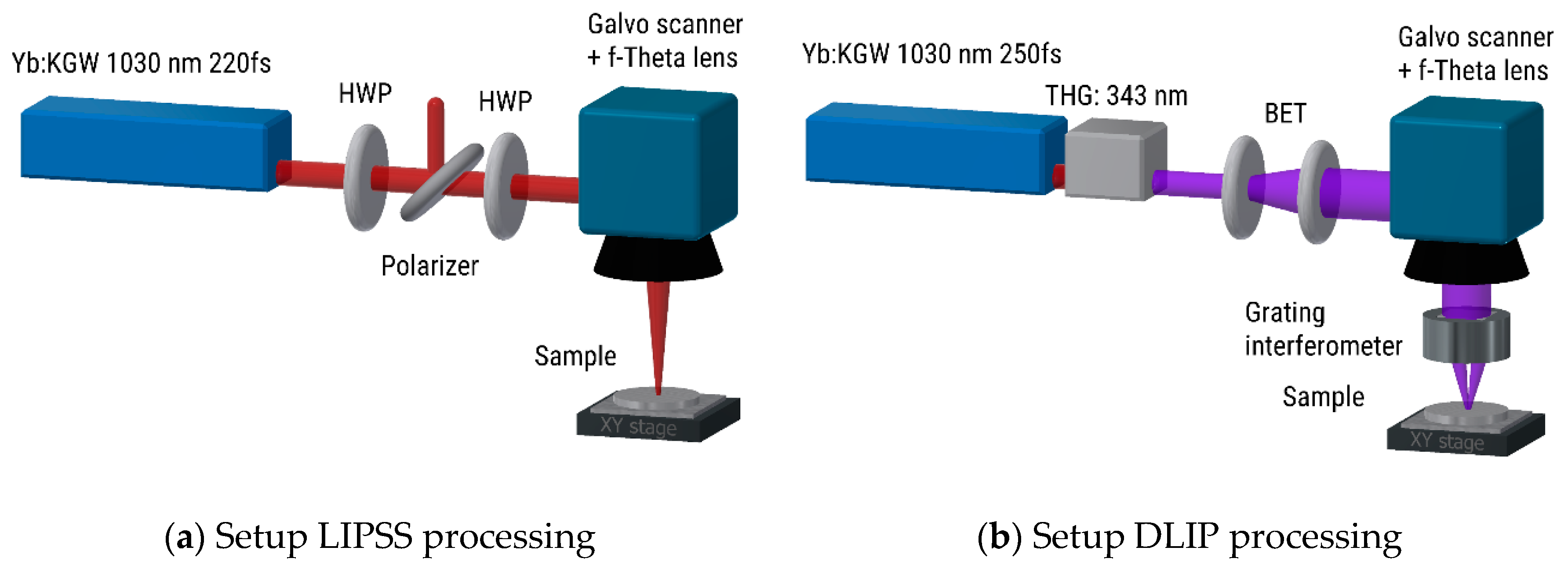

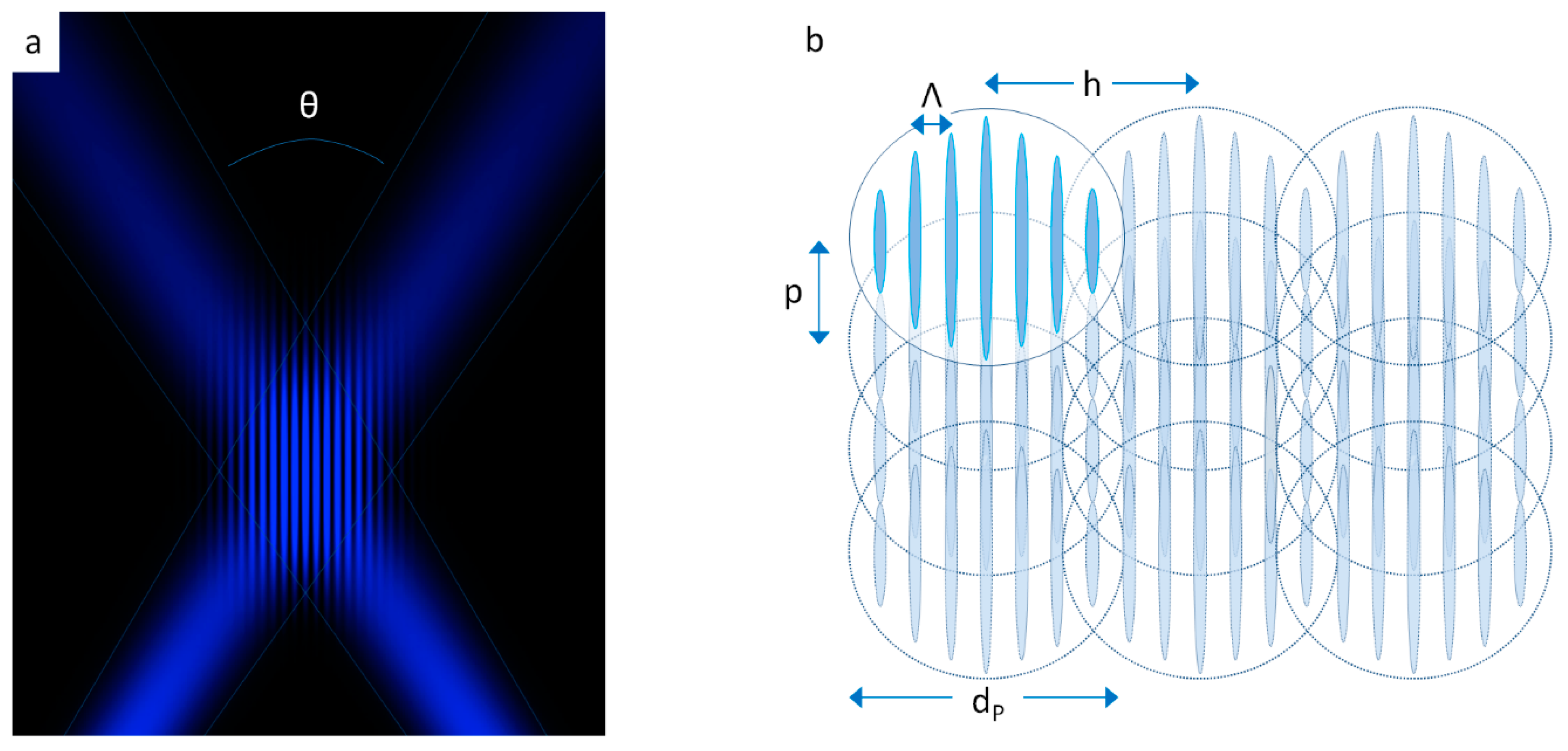

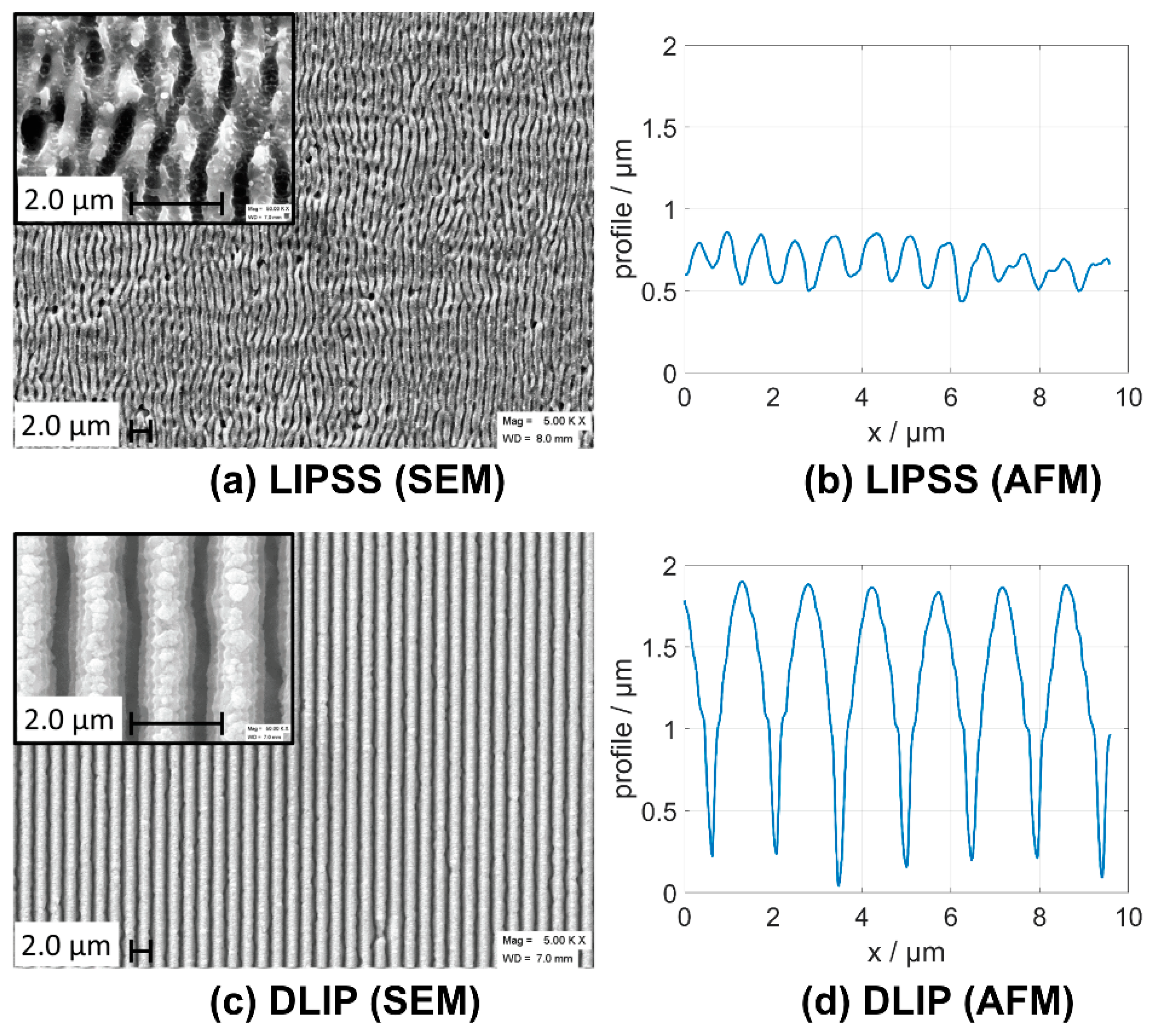

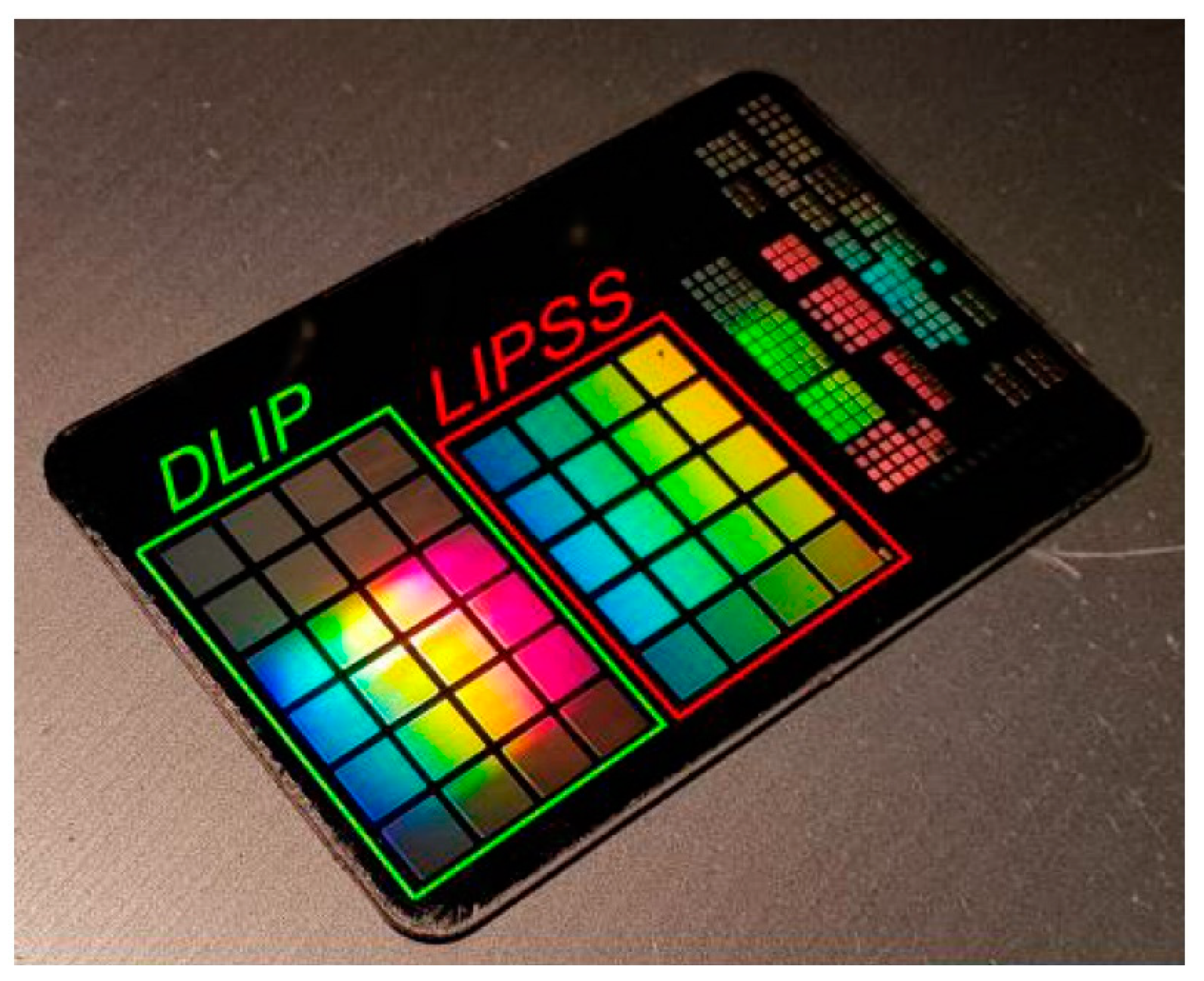

3.4. Exploration of Other Applications

- Biomimetic surfaces: Nature provides many highly optimized surface functionalities that may be transferred to technical applications via tailored laser-processing, including LIPSS. Examples are dirt-repellent surfaces through the well-known lotus effect, anti-icing [57,58], the directional transport of liquids inspired by moisture-harvesting lizards [59] and bark bugs [60], antiadhesive surfaces inspired by cribellating spiders [61], or antibacterial [62,63,64,65,66,67], cell-repellent [68], and cell-stimulating/-adapting surfaces [69,70,71] for medical applications [72]. A detailed review of the laser engineering of biomimetic surfaces is provided in [6].

- Combined processing strategies: Currently, several research groups are exploring the combination of LIPSS with additional surface treatment techniques—either “in situ” during the laser processing, or “ex situ” after the laser-processing. Examples are: (i) combined laser processing strategies (such as in situ double-pulse treatments [20,73,74] or ex situ LIPSS + DLIP, see Section 3.3), or a two-step laser processing of microstructures (e.g., lines, grids, or more complex microfluidic channels) patterned additionally with nanostructures (LIPSS) [59,75]; (ii) the combination of LIPSS processing with thermal heat during [76,77] or after [78,79] laser irradiation; (iii) electrochemical post-processing, such as anodization [67,80]; or (iv) ion beam post-processing for altering the electrical conductivity [81].

- Improved regularity of LIPSS through surface overlayers: On dielectrics, the generation of large surface areas covered homogeneously with LIPSS is often very difficult when the single photon energy is significantly smaller than the band gap energy, i.e., when nonlinear absorption is required to couple the laser beam energy with the solid. Apart from the strategy to reduce the nonlinearity via the irradiation wavelength [82], another way to overcome this difficulty can lie in adding a very thin strongly-absorbing surface overlayer on the dielectric in order to facilitate resonant coupling effects of the laser radiation to the material underneath. For hexagonally arranged ablative nanobumps on glass, tens of nanometer thick copper and silver coatings were shown to be suitable [83,84]. Later, Kunz et al. demonstrated that large surface areas homogeneously covered by HSFL can be processed on fused silica by the help of an additional 20 nm-thick gold layer [85].

- LIPSS on thin films: Often, the selective structuring of thin film coatings is necessary for creating specific surface functionalities. Conventional surface structuring techniques are, however, often limited by small film thicknesses in the sub-micrometer range and high hardness or brittleness of the film materials. Hence, several groups are exploring the (contactless) formation of LIPSS on various overlayer materials [86,87]. Furthermore, following the general trend of research on graphene (triggered by the Nobel prize awarded in 2010), several authors studied the formation of LIPSS on graphene or graphene oxide-covered substrates [88,89,90,91,92]. It was demonstrated that LIPSS manifesting via structural modifications of the graphene or the material underneath can be used as local probe of plasmonic resonances [91,92].

- LIPSS for sensing applications: One of the first applications of LIPSS came up in the context of black silicon that can be generated upon ultrashort laser processing of silicon as hierarchical surface morphology consisting of micrometric Spikes [93] covered with nanometric LIPSS. It was recognized by Mazur and his co-workers at Harvard University (USA) that these surface structures can be used for building silicon-based photodetector devices with an enhanced optical sensitivity in the (near) infrared spectral region. Later, this idea was commercialized and is already being used for night vision cameras [94]. Another sensing application of LIPSS used in chemical analytics is based on surface-enhanced Raman spectroscopy (SERS). The effect is based on electromagnetic near-field enhancement in the vicinity of very sharp surface topographic features and may be further enlarged by resonant effects, such as the excitation of SPPs. It was demonstrated that the SERS effect on LIPSS on polymers that were overcoated with gold can increase the detection sensitivity of specific analyte molecules by several orders of magnitude [95,96]. Additionally, the localized laser surface processing could help to spatially confine the analyte solution during an additional evaporation-based concentration enhancement step [97,98].

3.5. Funding Stratgies for LIPSS: The European H2020 Perspective

4. Future Trends and Open Questions

Funding

Acknowledgments

Conflicts of Interest

References

- Bonse, J.; Höhm, S.; Kirner, S.V.; Rosenfeld, A.; Krüger, J. Laser-induced periodic surface structures—A scientific evergreen. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 9000615. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Direct femtosecond laser surface nano/microstructuring and its applications. Laser Photonics Rev. 2013, 7, 385–407. [Google Scholar] [CrossRef]

- Florian, C.; Kirner, S.V.; Krüger, J.; Bonse, J. Surface functionalization by laser-induced periodic surface structures. J. Laser Appl. 2020, 32, 022063. [Google Scholar] [CrossRef]

- Gräf, S. Formation of laser-induced periodic surface structures on different materials: Fundamentals, properties and applications. Adv. Opt. Technol. 2020, 9, 11–39. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Krüger, J. Laser-Induced Periodic Surface Structures (LIPSS). In Handbook of Laser Micro- and Nano-Engineering; Sugioka, K., Ed.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Stratakis, E.; Bonse, J.; Heitz, J.; Siegel, J.; Tsibidis, G.D.; Skoulas, E.; Papadopoulos, A.; Mimidis, A.; Joel, A.C.; Comanns, P.; et al. Laser engineering of biomimetic surfaces. Mater. Sci. Eng. R 2020, 141, 100562. [Google Scholar] [CrossRef]

- Ahmmed, K.M.T.; Grambow, C.; Kietzig, A.-M. Fabrication of micro/nano structures on metals by femtosecond laser micromachining. Micromachines 2014, 5, 1219. [Google Scholar] [CrossRef]

- Rudenko, A.; Colombier, J.-P.; Höhm, S.; Rosenfeld, A.; Krüger, J.; Bonse, J.; Itina, T.E. Spontaneous periodic ordering on the surface and in the bulk of dielectrics irradiated by ultrafast laser: A shared electromagnetic origin. Sci. Rep. 2017, 7, 12306. [Google Scholar] [CrossRef]

- Kirner, S.V.; Wirth, T.; Sturm, H.; Krüger, J.; Bonse, J. Nanometer-resolved chemical analyses of femtosecond laser-induced periodic surface structures on titanium. J. Appl. Phys. 2017, 122, 10490. [Google Scholar] [CrossRef]

- van Driel, H.M.; Sipe, J.E.; Young, J.F. Laser-induced periodic surface structures on solids: A universal phenomenon. Phys. Rev. Lett. 1982, 49, 1955–1958. [Google Scholar] [CrossRef]

- Sipe, J.E.; Young, J.F.; Preston, J.S.; van Driel, H.M. Laser-induced periodic surface structure. I. Theory. Phys. Rev. B 1983, 27, 1141–1154. [Google Scholar] [CrossRef]

- Young, J.F.; Preston, J.S.; van Driel, H.M.; Sipe, J.E. Laser-induced periodic surface structure. II. Experiments on Ge, Si, Al, and brass. Phys. Rev. B 1983, 27, 1155–1172. [Google Scholar] [CrossRef]

- Young, J.F.; Sipe, J.E.; van Driel, H.M. Laser-induced periodic surface structure. III. Fluence regimes, the role of feedback, and details of the induced topography in germanium. Phys. Rev. B 1984, 30, 2001–2015. [Google Scholar] [CrossRef]

- Guosheng, Z.; Fauchet, P.M.; Siegman, A. Growth of spontaneous periodic surface structures on solids during laser illumination. Phys. Rev. B 1982, 26, 5366–5381. [Google Scholar] [CrossRef]

- Fauchet, P.M.; Siegman, A. Surface ripples on silicon and gallium arsenide under picosecond laser illumination. Appl. Phys. Lett. 1982, 40, 824–826. [Google Scholar] [CrossRef]

- van Driel, H.M.; Sipe, J.E.; Young, J.F. Laser-induced coherent modulation of solid and liquid surfaces. J. Lumin. 1985, 30, 446–471. [Google Scholar] [CrossRef]

- Siegman, A.E.; Fauchet, P.M. Stimulated Wood’s anomaly on laser-illuminated surfaces. IEEE J. Quantum Electron. 1986, 22, 1384–1403. [Google Scholar] [CrossRef]

- Akhmanov, S.A.; Emel’yanov, V.I.; Koroteev, N.I.; Seminogov, V.N. Interaction of powerful laser radiation with the surfaces of semiconductors and metals: Nonlinear optical effects and nonlinear optical diagnostics. Sov. Phys. Usp. 1985, 28, 1084–1124. [Google Scholar] [CrossRef]

- Bonch-Bruevich, A.M.; Libenson, M.N.; Makin, V.S.; Trubaev, V.V. Surface electromagnetic waves in Optics. Opt. Eng. 1992, 31, 718–730. [Google Scholar] [CrossRef]

- Höhm, S.; Herzlieb, M.; Rosenfeld, A.; Krüger, J.; Bonse, J. Dynamics of the formation of laser-induced periodic surface structures (LIPSS) upon femtosecond two-color double-pulse irradiation of metals, semiconductors, and dielectrics. Appl. Surf. Sci. 2016, 374, 331–338. [Google Scholar] [CrossRef]

- Sokolowski-Tinten, K.; Barty, A.; Boutet, S.; Shymanovich, U.; Chapman, H.; Bogan, M.; Marchesini, S.; Hau-Riege, S.; Stojanovic, N.; Bonse, J.; et al. Short-pulse laser induced transient structure formation and ablation studied with time-resolved coherent XUV-scattering. AIP Conf. Proc. 2010, 1278, 373–379. [Google Scholar]

- Bonse, J. Scattering on scattering. Light: Sci. Appl. 2017, 6, e17088. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Höhm, S.; Rosenfeld, A.; Krüger, J.; Bonse, J. Femtosecond diffraction dynamics of laser-induced periodic surface structures on fused silica. Appl. Phys. Lett. 2013, 102, 054102. [Google Scholar] [CrossRef]

- Garcia-Lechuga, M.; Puerto, D.; Fuentes-Edfuf, Y.; Solis, J.; Siegel, J. Ultrafast moving-spot microscopy: Birth and growth of laser-induced periodic surface structures. ACS Photonics 2016, 3, 1961–1967. [Google Scholar] [CrossRef] [Green Version]

- Her, T.-H. Femtosecond-Laser-Induced Periodic Self-Organized Nanostructures. In Comprehensive Nanoscience and Technology: Nanofabrication and Devices; Andrews, D., Scholes, G., Wiederrecht, G., Eds.; Academic Press: New York, NY, USA, 2011; Volume 4, pp. 277–314. [Google Scholar]

- Buividas, R.; Mikutis, M.; Juodkazis, S. Surface and bulk structuring of materials by ripples with long and short laser pulses: Recent advances. Prog. Quantum Electron. 2014, 38, 119–156. [Google Scholar] [CrossRef]

- Shimotsuma, Y.; Kazanski, P.G.; Qiu, J.; Hirao, K. Self-organized nanogratings in glass irradiated by ultrashort light pulses. Phys. Rev. Lett. 2003, 91, 247405. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bonse, J.; Gräf, S. Maxwell meets Marangoni—A review of theories on laser-induced periodic surface structures. Laser Photonics Rev. 2020, 14, 2000215. [Google Scholar] [CrossRef]

- Rudenko, A.; Abou-Saleh, A.; Pigeon, F.; Mauclair, C.; Garrelie, F.; Stoian, R.; Colombier, J.-P. High-frequency periodic patterns driven by non-radiative fields coupled with Marangoni convection instabilities on laser-excited metal surfaces. Acta Mater. 2020, 194, 93–105. [Google Scholar] [CrossRef]

- Müller, F.A.; Kunz, C.; Gräf, S. Bio-inspired functional surfaces based on laser-induced periodic surface structures. Materials 2016, 9, 476. [Google Scholar] [CrossRef]

- Skolski, J.Z.P.; Römer, G.R.B.E.; Obona, J.V.; Ocelik, V.; Huis in ’t Veld, A.J.; De Hosson, J.T.M. Laser-induced periodic surface structures: Fingerprints of light localization. Phys. Rev. B 2012, 85, 075320. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Colombier, J.-P.; Faure, N.; Cheng, G.; Stoian, R. Coherence in ultrafast laser-induced periodic surface structures. Phys. Rev. B 2015, 92, 174109. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Barberoglou, M.; Loukakos, P.A.; Stratakis, E.; Fotakis, C. Dynamics of ripple formation on silicon surfaces by ultrashort laser pulses in subablation conditions. Phys. Rev. B 2012, 86, 115316. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, D.S.; Lipp, V.P.; Blumenstein, A.; Kleinwort, F.; Veiko, V.P.; Yakovlev, E.; Roddatis, V.; Garcia, M.E.; Rethfeld, B.; Ihlemann, J.; et al. Experimental and theoretical investigation of periodic nanostructuring of Au with ultrashort UV laser pulses near the damage threshold. Phys. Rev. Appl. 2015, 4, 064006. [Google Scholar] [CrossRef]

- Shugaev, M.V.; Gnilitskyi, I.; Bulgakova, N.M.; Zhigilei, L.V. Mechanism of single-pulse ablative generation of laser-induced periodic surface structures. Phys. Rev. B 2017, 96, 205429. [Google Scholar] [CrossRef] [Green Version]

- Landis, E.C.; Phillips, K.C.; Mazur, E.; Friend, C.M. Formation of nanostructured TiO2 by femtosecond laser irradiation of titanium in O2. J. Appl. Phys. 2012, 112, 063108. [Google Scholar] [CrossRef]

- Öktem, B.; Pavlov, I.; Ilday, S.; Kalaycıoğlu, H.; Rybak, A.; Yavaş, S.; Erdoğan, M.; Ilday, F.Ö. Nonlinear laser lithography for indefinitely large-area nanostructuring with femtosecond pulses. Nat. Photonics 2013, 7, 897–901. [Google Scholar] [CrossRef]

- Dostovalov, A.V.; Korolkov, V.P.; Okotrub, K.A.; Bronnikov, K.A.; Babin, S.A. Oxide composition and period variation of thermochemical LIPSS on chromium films with different thickness. Opt. Express 2018, 26, 7712–7723. [Google Scholar] [CrossRef]

- Florian, C.; Déziel, J.L.; Kirner, S.V.; Siegel, J.; Bonse, J. The role of the laser-induced oxide layer in the formation of laser-induced periodic surface structures. Nanomaterials 2020, 10, 147. [Google Scholar] [CrossRef] [Green Version]

- Zwahr, C.; Welle, A.; Weingärtner, T.; Heinemann, C.; Kruppke, B.; Gulow, N.; Holthaus, M.G.; Lasagni, A.F. Ultrashort pulsed laser surface patterning of titanium to improve osseointegration of dental implants. Adv. Eng. Mater. 2019, 21, 1900639. [Google Scholar] [CrossRef] [Green Version]

- Florian, C.; Wonneberger, R.; Undisz, A.; Kirner, S.V.; Wasmuth, K.; Spaltmann, D.; Krüger, J.; Bonse, J. Chemical effects during the formation of various types of femtosecond laser-generated surface structures on titanium alloy. Appl. Phys. A 2020, 126, 266. [Google Scholar] [CrossRef] [Green Version]

- Kirner, S.V.; Slachciak, N.; Elert, A.M.; Griepentrog, M.; Fischer, D.; Hertwig, A.; Sahre, M.; Dörfel, I.; Sturm, H.; Pentzien, S.; et al. Tribological performance of titanium samples oxidized by fs-laser radiation, thermal heating, or electrochemical anodization. Appl. Phys. A 2018, 124, 326. [Google Scholar] [CrossRef]

- Ayerdi, J.J.; Slachciak, N.; Llavori, I.; Zabala, A.; Aginagalde, A.; Bonse, J.; Spaltmann, D. On the role of a ZDDP in the tribological performance of femtosecond laser-induced periodic surface structures on titanium alloy against different counterbody materials. Lubricants 2019, 7, 79. [Google Scholar] [CrossRef] [Green Version]

- Kietzig, A.M.; Hatzikiriakos, S.G.; Englezos, P. Patterned superhydrophobic metallic surfaces. Langmuir 2009, 25, 4821–4827. [Google Scholar] [CrossRef] [PubMed]

- Yasumaru, N.; Sentoku, E.; Kiuchi, J. Formation of organic layer on femtosecond laser-induced periodic surface structures. Appl. Surf. Sci. 2017, 405, 267–272. [Google Scholar] [CrossRef]

- Gregorčič, P. Comment on “Bioinspired reversible switch between underwater superoleophobicity/superaerophobicity and oleophilicity/aerophilicity and improved antireflective property on the nanosecond laser-ablated superhydrophobic titanium surfaces”. ACS Appl. Mater. Interfaces 2020. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rung, S.; Bokan, K.; Kleinwort, F.; Schwarz, S.; Simon, P.; Klein-Wiele, J.-H.; Esen, C.; Hellmann, R. Possibilities of dry and lubricated friction modification enabled by different ultrashort laser-based surface structuring methods. Lubricants 2019, 7, 43. [Google Scholar] [CrossRef] [Green Version]

- Mezera, M.; Alamri, S.; Hendriks, W.A.P.M.; Hertwig, A.; Elert, A.M.; Bonse, J.; Kunze, T.; Lasagni, A.F.; Römer, G.R.B.E. Hierarchical micro-/nano-structures on polycarbonate via UV pulsed laser processing. Nanomaterials 2020, 10, 1184. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Griepentrog, M.; Spaltmann, D.; Krüger, J. Femtosecond laser texturing of surfaces for tribological applications. Materials 2018, 11, 801. [Google Scholar] [CrossRef] [Green Version]

- Soldera, M.; Fortuna, F.; Teutoburg-Weiss, S.; Milles, S.; Taretto, K.; Lasagni, A.F. Comparison of structural colors achieved by laser-induced periodic surface structures and direct laser interference patterning. J. Laser Micro/Nanoeng. 2020, 15, 97–103. [Google Scholar]

- Mincuzzi, M.; Gemini, L.; Faucon, M.; Kling, R. Extending ultra-short pulse laser texturing over large area. Appl. Surf. Sci. 2016, 386, 65–71. [Google Scholar] [CrossRef]

- Lang, V.; Roch, T.; Lasagni, A.F. High-speed surface structuring of polycarbonate using direct laser interference patterning: Toward 1 m2min−1 fabrication speed barrier. Adv. Eng. Mater. 2016, 18, 1342–1348. [Google Scholar] [CrossRef]

- Faas, S.; Bielke, U.; Weber, R.; Graf, T. Scaling the productivity of laser structuring processes using picosecond laser pulses at average powers of up to 420 W to produce superhydrophobic surfaces on stainless steel AISI 316L. Sci. Rep. 2019, 9, 1933. [Google Scholar] [CrossRef] [PubMed]

- Schille, J.; Schneider, L.; Mauersberger, S.; Szokup, S.; Höhn, S.; Pötschke, J.; Reiß, F.; Leidich, E.; Löschner, U. High-rate laser surface texturing for advanced tribological functionality. Lubricants 2020, 8, 33. [Google Scholar] [CrossRef] [Green Version]

- Alamri, S.; Fraggelakis, F.; Kunze, T.; Krupop, B.; Mincuzzi, G.; Kling, R.; Lasagni, A.F. On the interplay of DLIP and LIPSS upon ultra-short laser pulse irradiation. Materials 2019, 12, 1018. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ehrhardt, M.; Lai, S.; Lorenz, P.; Zimmer, K. Guiding of LIPSS formation by excimer laser irradiation of pre-patterned polymer films for tailored hierarchical structures. Appl. Surf. Sci. 2020, 506, 144785. [Google Scholar] [CrossRef]

- Römer, G.; del Cerro, D.A.; Sipkema, R.C.J.; Groenendijk, M.N.W.; Huis in‘t Veld, A.J. Ultra short pulse laser generated surface textures for anti-ice applications in aviation. In Proceedings of the 28th International Congress on Applications of Lasers & Electro-Optics, ICALEO 2009, Orlando, FL, USA, 2–5 November 2009; Laser Institute of America: Orlando, FL, USA, 2009; pp. 30–37. [Google Scholar]

- Vercillo, V.; Tonnicchia, S.; Romano, J.; García-Girón, A.; Aguilar-Morales, A.I.; Alamri, S.; Dimov, S.S.; Kunze, T.; Lasagni, A.F.; Bonaccurso, E. Design rules for laser-treated icephobic metallic surfaces for aeronautic applications. Adv. Funct. Mater. 2020, 30, 1910268. [Google Scholar] [CrossRef]

- Hermens, U.; Kirner, S.V.; Emonts, C.; Comanns, P.; Skoulas, E.; Mimidis, A.; Mescheder, H.; Winands, K.; Krüger, J.; Stratakis, E.; et al. Mimicking lizard-like surface structures upon ultrashort laser pulse irradiation of inorganic materials. Appl. Surf. Sci. 2017, 418, 499–507. [Google Scholar] [CrossRef]

- Kirner, S.V.; Hermens, U.; Mimidis, A.; Skoulas, E.; Florian, C.; Hischen, F.; Plamadeala, C.; Baumgartner, W.; Winands, K.; Mescheder, H.; et al. Mimicking bug-like surface structures and their fluid transport produced by ultrashort laser pulse irradiation of steel. Appl. Phys. A 2017, 123, 754. [Google Scholar] [CrossRef] [Green Version]

- Joel, A.-C.; Meyer, M.; Heitz, J.; Heiss, A.; Park, D.; Adamova, H.; Baumgartner, W. Biomimetic combs as antiadhesive tools to manipulate nanofibers. ACS Appl. Nano Mater. 2020, 3, 3395–3401. [Google Scholar] [CrossRef]

- Cunha, A.; Elie, A.-M.; Plawinski, L.; Serro, A.P.; Botelho do Rego, A.M.; Almeida, A.; Urdaci, M.C.; Durrieu, M.-C.; Vilar, R. Femtosecond laser surface texturing of titanium as a method to reduce the adhesion of Staphylococcus aureus and biofilm formation. Appl. Surf. Sci. 2016, 360, 485–493. [Google Scholar] [CrossRef]

- Epperlein, N.; Menzel, F.; Schwibbert, K.; Koter, R.; Bonse, J.; Sameith, J.; Krüger, J.; Toepel, J. Influence of femtosecond laser produced nanostructures on biofilm growth on steel. Appl. Surf. Sci. 2017, 418, 420–424. [Google Scholar] [CrossRef]

- Schwibbert, K.; Menzel, F.; Epperlein, N.; Bonse, J.; Krüger, J. Bacterial adhesion on femtosecond laser-modified polyethylene. Materials 2019, 12, 3107. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Slepička, P.; Siegel, J.; Lyutakov, O.; Slepičková Kasálková, N.; Kolská, Z.; Bačáková, L.; Švorčík, V. Polymer nanostructures for bioapplications induced by laser treatment. Biotechnol. Adv. 2018, 36, 839–855. [Google Scholar] [CrossRef] [PubMed]

- Neděla, O.; Slepička, P.; Slepickova Kasalkova, N.; Sajdl, P.; Kolská, Z.; Rimpelová, S.; Švorčík, V. Antibacterial properties of angle-dependent nanopatterns on polystyrene. React. Funct. Polymer 2019, 136, 173–180. [Google Scholar] [CrossRef]

- Fajstavr, D.; Neznalová, K.; Slepičková Kasálková, N.; Rimpelová, S.; Kubičíková, K.; Švorčík, V.; Slepička, P. Nanostructured Polystyrene Doped with Acetylsalicylic Acid and Its Antibacterial Properties. Materials 2020, 13, 3609. [Google Scholar] [CrossRef]

- Heitz, J.; Plamadeala, C.; Muck, M.; Armbruster, O.; Baumgartner, W.; Weth, A.; Steinwender, C.; Blessberger, H.; Kellermair, J.; Kirner, S.V.; et al. Femtosecond laser-induced microstructures on Ti substrates for reduced cell adhesion. Appl. Phys. A 2017, 123, 734. [Google Scholar] [CrossRef] [Green Version]

- Rebollar, E.; Pérez, S.; Hernández, M.; Domingo, C.; Martín, M.; Ezquerra, T.A.; García-Ruiz, J.P.; Castillejo, M. Physicochemical modifications accompanying UV laser induced surface structures on poly(ethyleneterephthalate) and their effect on adhesion of mesenchymal cells. Phys. Chem. Chem. Phys. 2014, 16, 17551–17559. [Google Scholar] [CrossRef]

- Barb, R.-A.; Hrelescu, C.; Dong, L.; Heitz, J.; Siegel, J.; Slepicka, P.; Vosmanska, V.; Svorcik, V.; Magnus, B.; Marksteiner, R.; et al. Laser-induced periodic surface structures on polymers for formation of gold nanowires and activation of human cells. Appl. Phys. A 2014, 117, 295–300. [Google Scholar] [CrossRef]

- Michaljaničová, I.; Slepička, P.; Rimpelová, S.; Slepičková Kasálková, N.; Švorčík, V. Regular pattern formation on surface of aromatic polymers and its cytocompatibility. Appl. Surf. Sci. 2016, 370, 131–141. [Google Scholar] [CrossRef]

- Fosodeder, P.; Baumgartner, W.; Steinwender, C.; Hassel, A.W.; Florian, C.; Bonse, J.; Heitz, J. Repellent rings at titanium cylinders against overgrowth by fibroblasts. Adv. Opt. Technol. 2020, 9, 113–120. [Google Scholar] [CrossRef]

- Fraggelakis, F.; Mincuzzi, G.; Lopez, J.; Manek-Hönninger, I.; Kling, R. Controlling 2D laser nano structuring over large area with double femtosecond pulses. Appl. Surf. Sci. 2019, 470, 677–686. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, A.-D.; Li, B.; Cui, T.-H.; Lu, Y.-F. Electrons dynamics control by shaping femtosecond laser pulses in micro/nanofabrication: Modeling, method, measurement and application. Light: Sci. Appl. 2018, 7, 171134. [Google Scholar] [CrossRef] [Green Version]

- Martinez-Calderon, M.; Rodriguez, A.; Dias-Ponte, A.; Morant-Minana, M.C.; Gómez-Aranzadi, M.; Olaizola, S.M. Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Appl. Surf. Sci. 2016, 374, 81–89. [Google Scholar] [CrossRef]

- Deng, G.; Feng, G.; Zhou, S. Experimental and FDTD study of silicon surface morphology induced by femtosecond laser irradiation at a high substrate temperature. Opt. Express 2017, 25, 7818–7827. [Google Scholar] [CrossRef] [PubMed]

- Gräf, S.; Kunz, C.; Engel, S.; Derrien, T.J.-Y.; Müller, F.A. Femtosecond laser-induced periodic surface structures on fused silica: The impact of the initial substrate temperature. Materials 2018, 11, 1340. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fan, P.; Zhong, M. Laser Surface Micro-Nano Structuring via Hybrid Process. In Handbook of Laser Micro- and Nano-Engineering; Sugioka, K., Ed.; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Sotillo, B.; Ariza, R.; Siegel, J.; Solis, J.; Fernandez, P. Preferential growth of ZnO micro- and nanostructure assemblies on fs-laser-induced periodic structures. Nanomaterials 2020, 10, 731. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lone, S.A.; Muck, M.; Fosodeder, P.; Mardare, C.C.; Florian, C.; Weth, A.; Krüger, J.; Steinwender, C.; Baumgartner, W.; Heitz, J.; et al. Impact of femtosecond laser treatment accompanied with anodization of titanium alloy on fibroblast cell growth. Phys. Stat. Sol. (a) 2020, 217, 1900838. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.Z.; Wang, W.J.; Jiang, G.D.; Mei, X.S.; Pan, A.F.; Chen, T. Nanostructures with good photoelectric properties fabricated by femtosecond laser and secondary sputtering on ITO films. Opt. Mater. 2020, 109, 110302. [Google Scholar] [CrossRef]

- Martínez-Calderon, M.; Azkona, J.J.; Casquero, N.; Rodríguez, A.; Domke, M.; Gómez-Aranzadi, M.; Olaizola, S.M.; Granados, E. Tailoring diamond’s optical properties via direct femtosecond laser nanostructuring. Sci. Rep. 2018, 8, 14262. [Google Scholar] [CrossRef]

- He, Y.; Zhang, J.; Singh, S.; Garcell, E.; Vorobyev, A.Y.; Lam, B.; Zhan, Z.; Yang, J.; Guo, C. Maskless laser nano-lithography of glass through sequential activation of multi-threshold ablation. Appl. Phys. Lett. 2019, 114, 133107. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Cong, C.; Guo, C. Single-step maskless nano-lithography on glass by femtosecond laser processing. J. Appl. Phys. 2020, 127, 163102. [Google Scholar] [CrossRef] [Green Version]

- Kunz, C.; Engel, S.; Müller, F.A.; Gräf, S. Large-area fabrication of laser-induced periodic surface structures on fused silica using thin gold layers. Nanomaterials 2020, 10, 1187. [Google Scholar] [CrossRef] [PubMed]

- Bonse, J.; Kirner, S.V.; Koter, R.; Pentzien, S.; Spaltmann, D.; Krüger, J. Femtosecond laser-induced periodic surface structures on titanium nitride coatings for tribological applications. Appl. Surf. Sci. 2017, 418, 572–579. [Google Scholar] [CrossRef]

- Rodríguez, A.; Morant-Miñana, M.C.; Dias-Ponte, A.; Martínez-Calderón, M.; Gómez-Aranzadi, M.; Olaizola, S.M. Femtosecond laser-induced periodic surface nanostructuring of sputtered platinum thin films. Appl. Surf. Sci. 2015, 351, 135–139. [Google Scholar] [CrossRef]

- Beltaos, A.; Kovacevic, A.G.; Matkovic, A.; Ralevic, U.; Savic-Sevic, S.; Jovanovic, D.; Jelenkovic, B.M.; Gajic, R. Femtosecond laser induced periodic surface structures on multi-layer graphene. J. Appl. Phys. 2014, 116, 204306. [Google Scholar] [CrossRef]

- Kasischke, M.; Maragkaki, S.; Volz, S.; Ostendorf, A.; Gurevich, E.L. Simultaneous nanopatterning and reduction of graphene oxide by femtosecond laser pulses. Appl. Surf. Sci. 2018, 445, 197–203. [Google Scholar] [CrossRef] [Green Version]

- Kovalska, E.; Pavlov, I.; Deminskyi, P.; Baldycheva, A.; OÖmer Ilday, F.; Kocabas, C. NLL-assisted multilayer graphene patterning. ACS Omega 2018, 3, 1546–1554. [Google Scholar] [CrossRef] [PubMed]

- Zou, T.; Zhao, B.; Xin, W.; Wang, Y.; Wang, B.; Zheng, X.; Xie, H.; Zhang, Z.; Yang, J.; Guo, C. High-speed femtosecond laser plasmonic lithography and reduction of graphene oxide for anisotropic photoresponse. Light: Sci. Appl. 2020, 9, 69. [Google Scholar] [CrossRef] [Green Version]

- Dragowska-Horna, K.A.; Mirza, I.; Rodriguez, A.; Kovaříček, P.; Sládek, J.; Derrien, T.J.-Y.; Gedvilas, M.; Račiukaitis, G.; Frank, O.; Bulgakova, N.M.; et al. Periodic surface functional group density on graphene via laser-induced substrate patterning at Si/SiO2 interface. Nano Research 2020, 13, 2332–2339. [Google Scholar] [CrossRef]

- Her, T.-H.; Finlay, R.J.; Wu, C.; Deliwala, S.; Mazur, E. Microstructuring of silicon with femtosecond laser pulses. Appl. Phys. Lett. 1998, 73, 1673–1675. [Google Scholar] [CrossRef]

- Crawford, M. Black Silicon: 23 Years Later. SPIE Prof. 2019, 14, 26–29. [Google Scholar]

- Rebollar, E.; Sanz, M.; Pérez, S.; Hernández, M.; Martín-Fabiani, I.; Rueda, D.R.; Ezquerra, T.A.; Domingo, C.; Castillejo, M. Gold coatings on polymer laser induced periodic surface structures: Assessment as substrates for surface-enhanced Raman scattering. Phys. Chem. Chem. Phys. 2012, 14, 15699–15705. [Google Scholar] [CrossRef] [PubMed]

- Rebollar, E.; Castillejo, M.; Ezquerra, T.A. Laser Induced Periodic Surface Structures on Polymer Films: From Fundamentals to Applications. Eur. Polym. J. 2015, 73, 162–174. [Google Scholar] [CrossRef] [Green Version]

- Pavliuk, G.; Pavlov, D.; Mitsai, E.; Vitrik, O.; Mironenko, A.; Zakharenko, A.; Kulinich, S.; Juodkazis, S.; Bratskaya, S.; Zhizhchenko, A. Ultrasensitive SERS-Based Plasmonic Sensor with Analyte Enrichment System Produced by Direct Laser Writing. Nanomaterials 2019, 10, 49. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, X.; Pan, R.; Cai, M.; Liu, W.; Luo, X.; Chen, C.; Jiang, G.; Zhong, M. Ultrafast laser micro-nano structured superhydrophobic teflon surfaces for enhanced SERS detection via evaporation concentration. Adv. Opt. Technol. 2020, 9, 89–100. [Google Scholar] [CrossRef]

- Czajkowski, K.; Ratzke, M.; Varlamova, O.; Reif, J. Femtosecond-laser-induced periodic surface structures on magnetic layer targets: The roles of femtosecond-laser interaction and of magnetization. Appl. Surf. Sci. 2017, 418, 84–87. [Google Scholar] [CrossRef]

- Arranz, M.A.; Sánchez, E.H.; Rebollar, E.; Castillejo, M.; Colino, J.M. Form and magnetic birefringence in undulated permalloy/PET films. Opt. Express 2019, 27, 21285–21294. [Google Scholar] [CrossRef]

- Sánchez, E.H.; Rodriguez-Rodriguez, G.; Aragón, R.; Arranz, M.A.; Rebollar, E.; Castillejo, M.; Colino, J.M. Anisotropy engineering of soft thin films in the undulated magnetic state. J. Magn. Magn. Mater. 2020, 514, 167149. [Google Scholar] [CrossRef]

- Cubero, A.; Martínez, E.; Angurel, L.A.; de la Fuente, G.F.; Navarro, R.; Legall, H.; Krüger, J.; Bonse, J. Effects of laser-induced periodic surface structures on the superconducting properties of niobium. Appl. Surf. Sci. 2020, 508, 145140. [Google Scholar] [CrossRef]

- Velli, M.-C.; Tsibidis, G.D.; Mimidis, A.; Skoulas, E.; Pantazis, V.; Stratakis, E. Predictive modeling approaches in laser-based material processing. arXiv 2020, arXiv:2006.07686. Available online: https://arxiv.org/abs/2006.07686 (accessed on 23 September 2020).

| Institution | Country | Number of Papers 1 | Percentage 1 |

|---|---|---|---|

| Centre National de la Recherche Scientifique, CNRS | FR | 60 | 5.4% |

| Chinese Academy of Sciences | CN | 54 | 4.9% |

| Consejo Superior de Investigaciones Científicas, CSIC | ES | 53 | 4.8% |

| Bundesanstalt für Materialforschung und -prüfung, BAM | DE | 49 | 4.4% |

| Max-Born-Institut für Nichtlineare Optik und Kurzzeitspektroskopie, MBI | DE | 40 | 3.6% |

| Russian Academy of Sciences, RAS | RU | 36 | 3.2% |

| University of Rochester | USA | 34 | 3.1% |

| Czech Academy of Sciences, CAS | CZ | 31 | 2.8% |

| CNRS Institute for Engineering Systems Sciences, INSIS | FR | 30 | 2.7% |

| Université Jean Monnet Saint-Étienne | FR | 30 | 2.7% |

| Journal | Publisher | Number of Papers 1 | Percentage 1 |

|---|---|---|---|

| Applied Surface Science | Elsevier | 167 | 15.0% |

| Proceedings of SPIE | SPIE 2 | 95 | 8.6% |

| Applied Physics A | Springer Nature | 69 | 6.2% |

| Journal of Applied Physics | AIP 3 | 48 | 4.3% |

| Applied Physics Letters | AIP 3 | 40 | 3.6% |

| Optics Express | OSA 4 | 40 | 3.6% |

| Journal of Laser Micro/Nanoengineering | JLPS 5 | 25 | 2.3% |

| Physical Review B | APS 6 | 19 | 1.7% |

| Optics and Laser Technology | Elsevier | 18 | 1.6% |

| Optics Letters | OSA 4 | 18 | 1.6% |

| Journal | Publisher | Special Issue | Date |

|---|---|---|---|

| Journal of Laser Applications | LIA 1 | “Generation of sub-100 nm Structures by Nonlinear Laser Material Interaction” | 2012 |

| Optical Materials Express | OSA 2 | “Ultrafast Laser Modification of Materials (ULM)” | 2013 |

| MRS Bulletin | MRS 3 | “Ultrafast Laser Synthesis and Processing of Materials” | 2016 |

| Nanomaterials | MDPI 4 | “Laser-Based Nano Fabrication and Nano Lithography” | 2018 |

| Opto-Electronic Advances | IOE-CAS 5 | “IAPLE Special Issue of Opto-Electronic Advances” | 2019 |

| Optical Materials Express | OSA 2 | “Laser Writing” | 2019 |

| Lubricants | MDPI 4 | “Laser-Induced Periodic Surface Nano- and Microstructures for Tribological Applications” | 2020 |

| Advanced Optical Technologies | De Gruyter | “Laser Micro- and Nano-Material Processing” | 2020 |

| Nanomaterials | MDPI 4 | “Laser-Generated Periodic Nanostructures” | 2020 |

| Nanomaterials | MDPI 4 | “Laser Synthesis and Modification of Materials at the Nanoscale” | 2020 |

| Nanomaterials | MDPI 4 | “Laser Printing of Nanophotonic Structures” | 2020 |

| Photonics | MDPI 4 | “Femtosecond Laser Micro/Nanofabrication” | 2020 |

| Nanomaterials | MDPI 4 | “Laser Surface Functionalization on Nanomaterials” | 2021 |

| Nanomaterials | MDPI 4 | “Nanopatterning of Bionic Materials” | 2021 |

| Year | Date | Host | Country |

|---|---|---|---|

| 2011 | 10–11 October | University of Twente | NL |

| 2012 | 3–4 October | Brandenburgische Technische Universität Cottbus | DE |

| 2013 | 7 November | Bundesanstalt für Materialforschung und -prüfung (BAM), Berlin | DE |

| 2014 | 11 November | HiLASE Centre, Dolní Břežany | CZ |

| 2015 | 5 December | Laboratoire Hubert Curien, Saint-Étienne | FR |

| 2016 | 24–25 November | Foundation of Research and Technology Hellas (FORTH), Heraklion | GR |

| 2017 | 28–29 September | Brandenburgische Technische Universität Cottbus | DE |

| 2018 | 27–28 September | Ruhr-Universität Bochum | DE |

| 2019 | 26–27 September | University of Ljubljana | SL |

| 2020/2021 | To be decided | CNRS/Université d’Orléans | FR |

| Property | DLIP (Two Beams) | LIPSS (One Beam) |

|---|---|---|

| Spatial period | >λ/2 1 | ~λ/10 (HSFL)–~λ (LSFL) |

| Modulation depth [nm] | 0–2000 [47] | <1000 (HSFL) [5] |

| <400 (LSFL) [47] | ||

| Regularity of grating | ++ 2 | + 3/o 4 |

| Flexibility of processing | pixelwise during scanning | continuous scanning |

| Control of periods/depths | ++ 2, independent | o 4, dependent |

| Complexity of setup | ++ 2/+ 3 | – 5 |

| Areal processing rate (current state) | <m2/min | <1.5 m2/min [54] |

| Required beam coherence | global | local |

| Pulse duration | ps-cw | fs-cw |

| Acronym | Name | Duration | Website |

|---|---|---|---|

| LASERLAB-EUROPE | The Integrated Initiative of European Laser Research Infrastructures | 2019–2023 | https://cordis.europa.eu/project/id/871124 |

| LiNaBioFluid | Laser-induced Nanostructures as Biomimetic Model of Fluid Transport in the Integument of Animals | 2015–2018 | https://cordis.europa.eu/project/id/665337 |

| Laser4Fun | European ESRs 1 Network on short pulsed laser Micro/Nanostructuring of Surfaces | 2015–2019 | https://cordis.europa.eu/project/id/675063/ |

| TresClean | High throughput laser texturing of self-cleaning and antibacterial surfaces | 2016–2020 | https://cordis.europa.eu/project/id/687613/ |

| LASER4SURF | Laser for mass production of functionalized metallic surfaces | 2017–2021 | https://cordis.europa.eu/project/id/768636 |

| CellFreeImplant | Cell-free Ti-based Medical Implants due to Laser-induced Microstructures | 2018–2019 | https://cordis.europa.eu/project/id/800832/ |

| LaBionicS | Laser Bionic Surfaces | 2018–2020 | https://cordis.europa.eu/project/id/801250/ |

| LAMPAS | High throughput Laser structuring with Multiscale Periodic feature sizes for Advanced Surface Functionalities | 2019–2021 | https://cordis.europa.eu/project/id/825132/ |

| FemtoSurf | Functional surface treatments using ultra-short pulse laser system | 2019–2021 | https://cordis.europa.eu/project/id/825512/ |

| BioProMarL | Bio-inspired Protection of Marble with Lasers | 2019–2021 | https://cordis.europa.eu/project/id/852048/ |

| BioCombs4Nanofibers | Antiadhesive Bionic Combs for Handling of Nanofibers | 2019–2022 | https://cordis.europa.eu/project/id/862016/ |

| LaserImplant | Laser-induced hierarchical micro-/nano-structures for controlled cell adhesion at implants | 2021–2022 | https://cordis.europa.eu/project/id/951730 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonse, J. Quo Vadis LIPSS?—Recent and Future Trends on Laser-Induced Periodic Surface Structures. Nanomaterials 2020, 10, 1950. https://doi.org/10.3390/nano10101950

Bonse J. Quo Vadis LIPSS?—Recent and Future Trends on Laser-Induced Periodic Surface Structures. Nanomaterials. 2020; 10(10):1950. https://doi.org/10.3390/nano10101950

Chicago/Turabian StyleBonse, Jörn. 2020. "Quo Vadis LIPSS?—Recent and Future Trends on Laser-Induced Periodic Surface Structures" Nanomaterials 10, no. 10: 1950. https://doi.org/10.3390/nano10101950

APA StyleBonse, J. (2020). Quo Vadis LIPSS?—Recent and Future Trends on Laser-Induced Periodic Surface Structures. Nanomaterials, 10(10), 1950. https://doi.org/10.3390/nano10101950