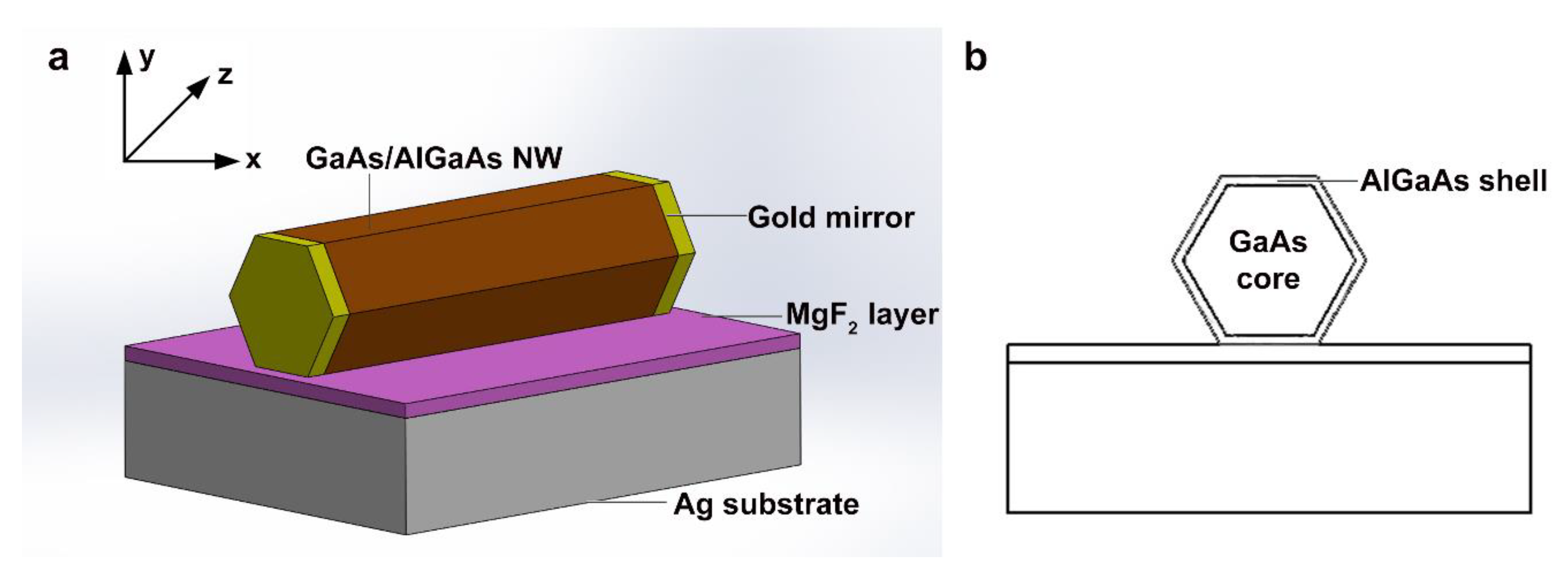

A Low-Threshold Miniaturized Plasmonic Nanowire Laser with High-Reflectivity Metal Mirrors

Abstract

:1. Introduction

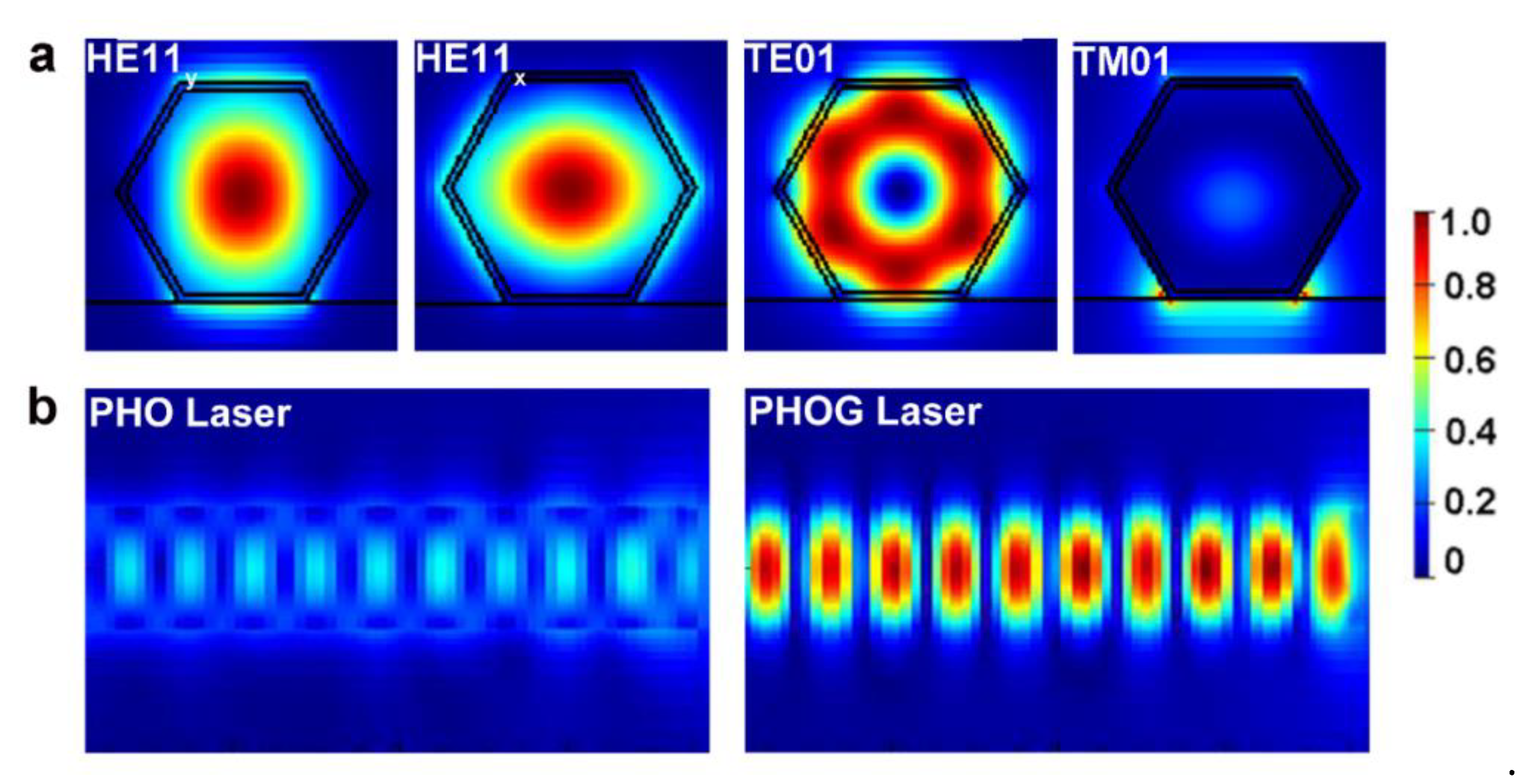

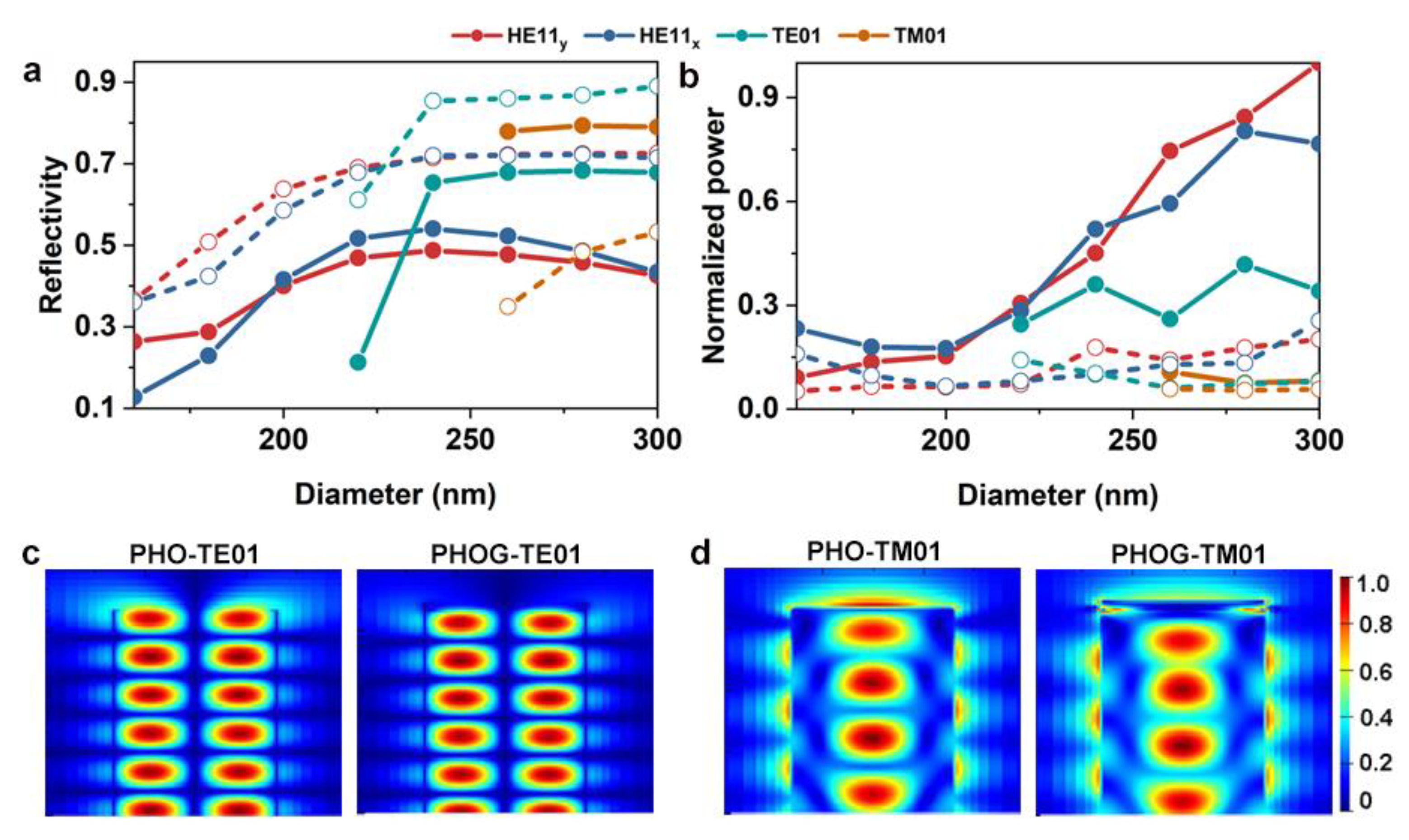

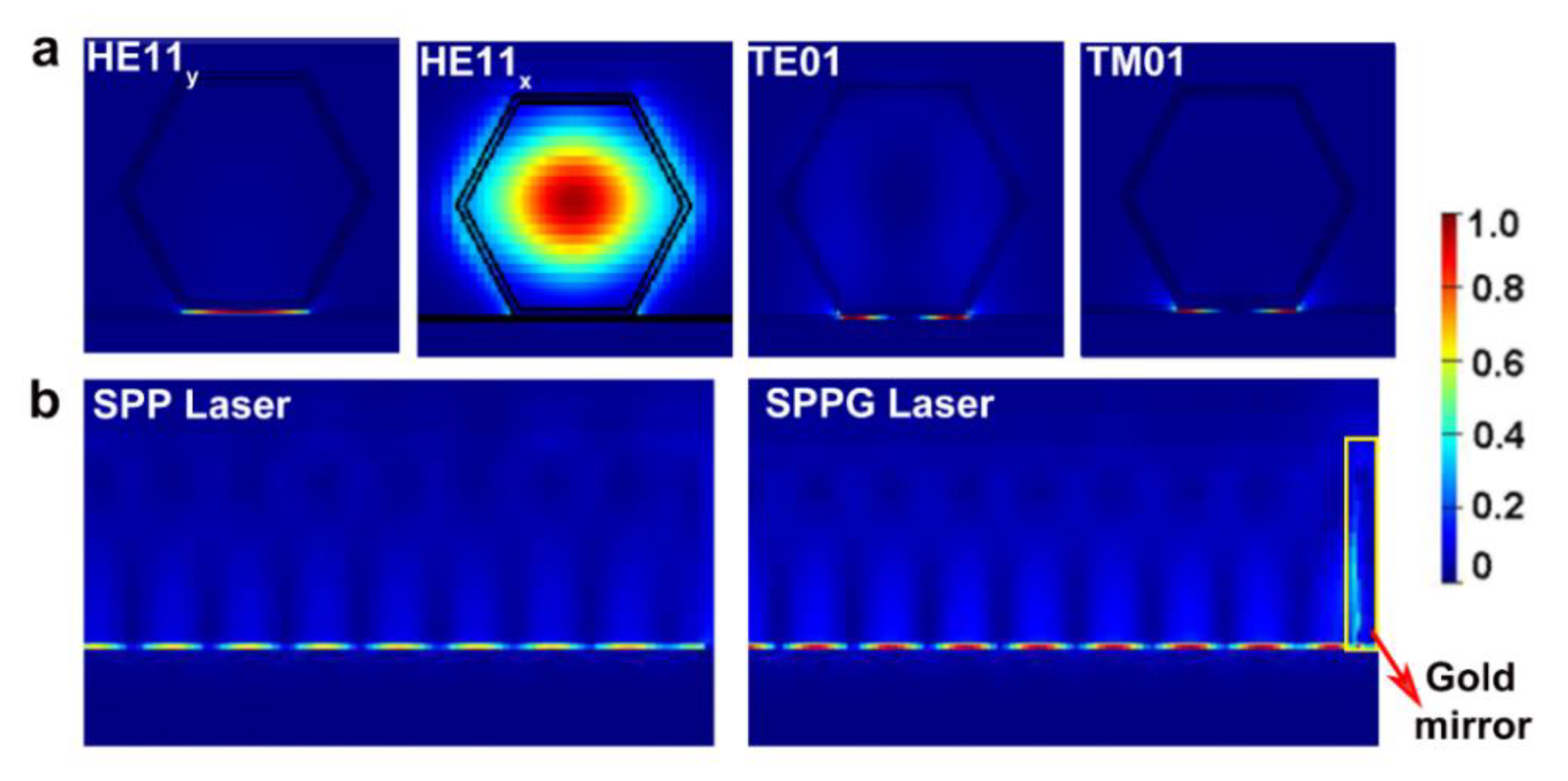

2. Methods

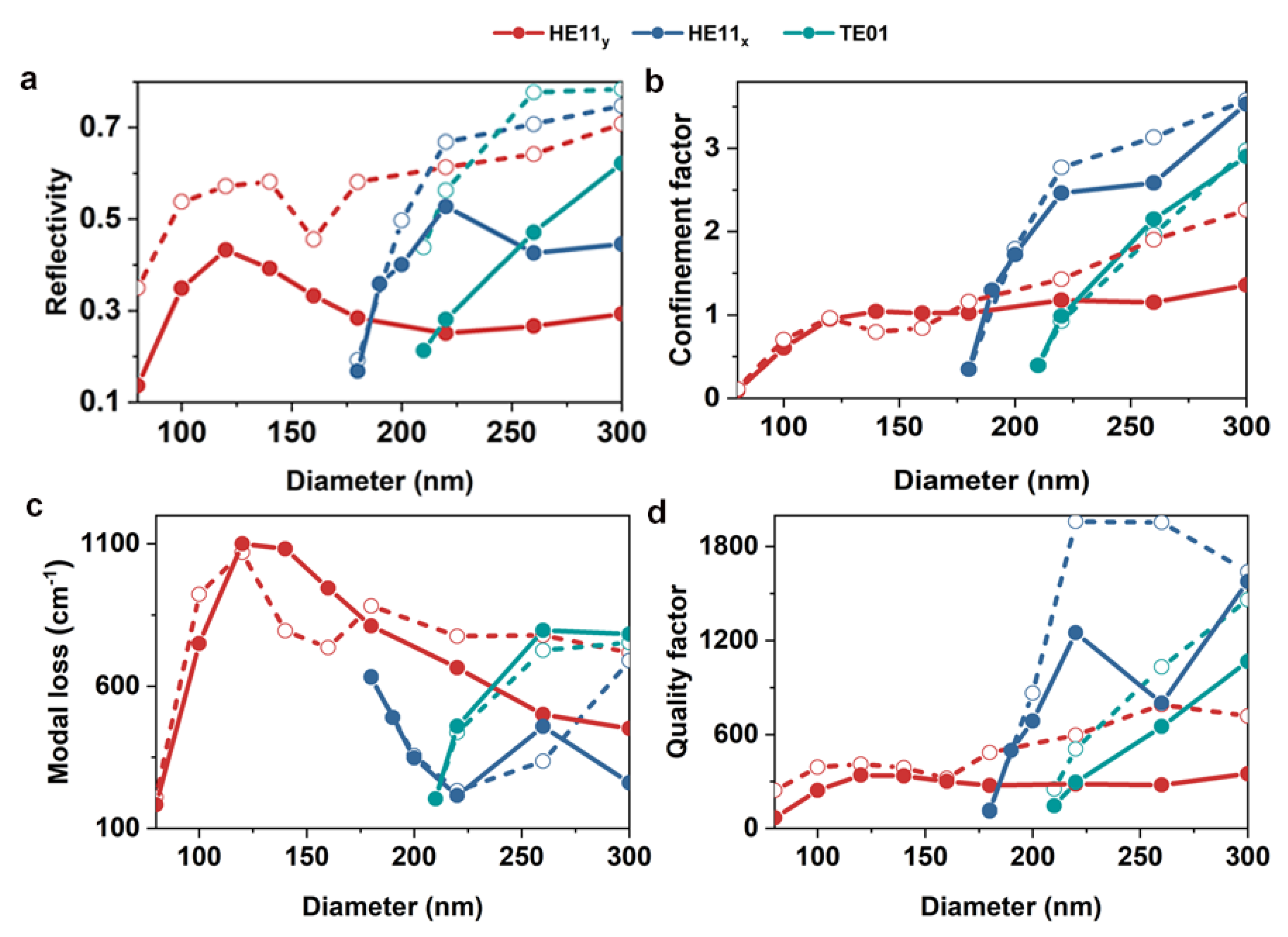

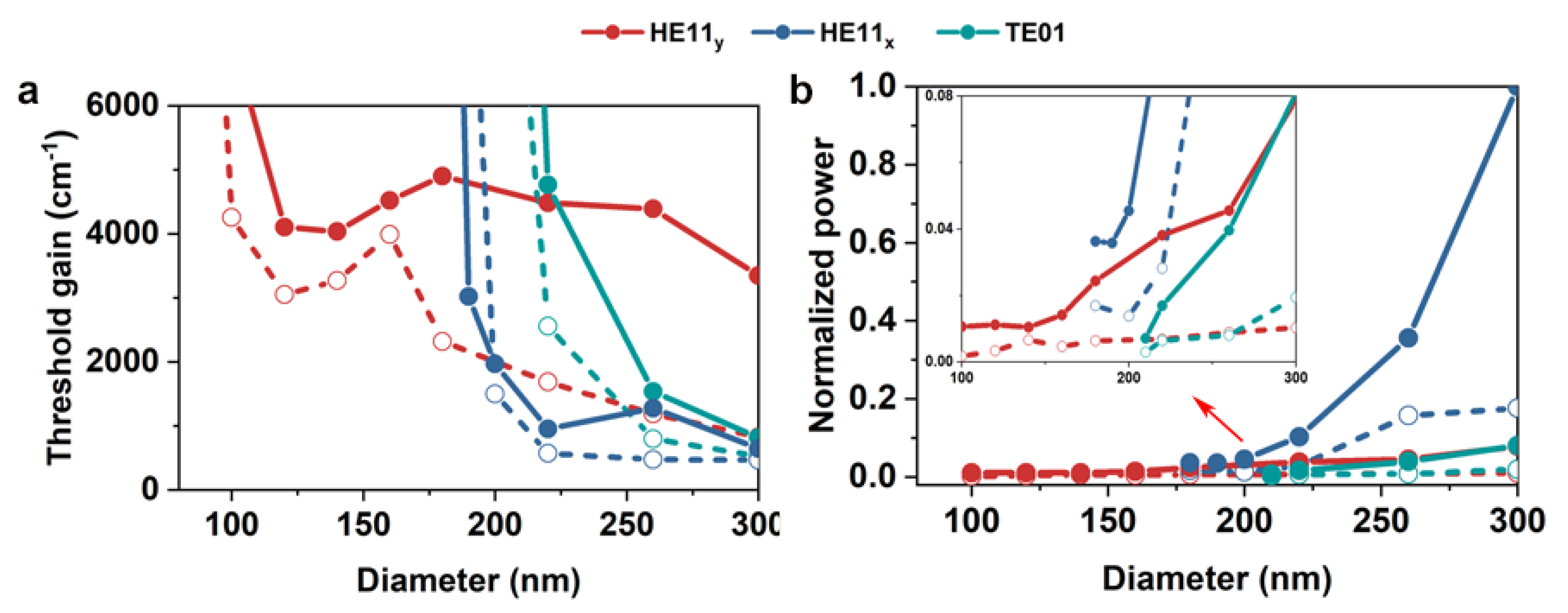

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yan, R.; Gargas, D.; Yang, P. Nanowire photonics. Nat. Photonics 2009, 3, 569–576. [Google Scholar] [CrossRef]

- Hu, J.; Odom, T.W.; Lieber, C.M. Chemistry and physics in one dimension: Synthesis and properties of nanowires and nanotubes. Acc. Chem. Res. 1999, 32, 435–445. [Google Scholar] [CrossRef]

- Duan, X.F.; Huang, Y.; Agarwal, R.; Lieber, C.M. Single-nanowire electrically driven lasers. Nature 2003, 421, 241–245. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, R.; Barrelet, C.J.; Lieber, C.M. Lasing in single cadmium sulfide nanowire optical cavities. Nano Lett. 2005, 5, 917–920. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johnson, J.C.; Yan, H.; Schaller, R.D.; Haber, L.H.; Saykally, R.J.; Yang, P. Single nanowire lasers. J. Phys. Chem. B 2001, 105, 11387–11390. [Google Scholar] [CrossRef]

- Hua, B.; Motohisa, J.; Kobayashi, Y.; Hara, S.; Fukui, T. Single GaAs/ GaAsP coaxial core-shell nanowire lasers. Nano Lett. 2008, 9, 112–116. [Google Scholar] [CrossRef] [PubMed]

- Chu, S.; Wang, G.; Zhou, W.; Lin, Y.; Chernyak, L.; Zhao, J.Z.; Kong, J.Y.; Li, L.; Ren, J.J.; Liu, J.L. Electrically pumped waveguide lasing from ZnO nanowires. Nat. Nanotechnol. 2011, 6, 506–510. [Google Scholar] [CrossRef]

- Gradecak, S.; Qian, F.; Li, Y.; Park, H.G.; Lieber, C.M. GaN nanowire lasers with low lasing thresholds. Appl. Phys. Lett. 2005, 87, 173111. [Google Scholar] [CrossRef] [Green Version]

- Eaton, S.W.; Fu, A.; Wong, A.B.; Ning, C.-Z.; Yang, P. Semiconductor nanowire lasers. Nat. Rev. Mater. 2016, 1, 1–11. [Google Scholar] [CrossRef]

- Saxena, D.; Mokkapati, S.; Parkinson, P.; Jiang, N.; Gao, Q.; Tan, H.H.; Jagadish, C. Optically pumped room-temperature GaAs nanowire lasers. Nat. Photonics 2013, 7, 963–968. [Google Scholar] [CrossRef]

- Maier, S.A.; Kik, P.G.; Atwater, H.A.; Meltzer, S.; Harel, E.; Koel, B.E.; Requicha, A.G. Local detection of electromagnetic energy transport below the diffraction limit in metal nanoparticle plasmon waveguides. Nat. Mater. 2003, 2, 229–232. [Google Scholar] [CrossRef] [PubMed]

- Oulton, R.F.; Sorger, V.J.; Zentgraf, T.; Ma, R.M.; Gladden, C.; Dai, L.; Bartal, G.; Zhang, X. Plasmon lasers at deep subwavelength scale. Nature 2009, 461, 629–632. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bergman, D.J.; Stockman, M.I. Surface plasmon amplification by stimulated emission of radiation: Quantum generation of coherent surface plasmons in nano systems. Phys. Rev. Lett. 2003, 90, 027402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ambati, M.; Nam, S.H.; Avila, E.U.; Genov, D.A.; Bartal, G.; Zhang, X. Observation of stimulated emission of surface plasmon polaritons. Nano Lett. 2008, 8, 3998–4001. [Google Scholar] [CrossRef] [PubMed]

- Noginov, M.A.; Zhu, G.; Mayy, M.F.; Ritzo, B.A.; Noginova, N.; Podolskiy, V.A. Stimulated emission of surface plasmon polaritons. Phys. Rev. Lett. 2008, 101, 226806. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Rycenga, M.; Skrabalak, S.E.; Wiley, B.; Xia, Y. Chemical synthesis of novel plasmonic nanoparticles. Annu. Rev. Phys. Chem. 2009, 60, 167–192. [Google Scholar] [CrossRef]

- Stewart, M.E.; Anderton, C.R.; Thompson, L.B.; Maria, J.; Gray, S.K.; Rogers, J.A.; Nuzzo, R.G. Nanostructured plasmonic sensors. Chem. Rev. 2008, 108, 494–521. [Google Scholar] [CrossRef]

- Gerislioglu, B.; Dong, L.; Ahmadivand, A.; Hu, H.; Nordlander, P.; Halas, N.J. Monolithic metal dimer-on-film structure: New plasmonic properties introduced by the underlying metal. Nano Lett. 2020, 20, 2087–2093. [Google Scholar] [CrossRef]

- Gerislioglu, B.; Bakan, G.; Ahuja, R.; Adam, J.; Mishra, Y.K.; Ahmadivand, A. The role of Ge2Sb2Te5 in enhancing the performance of functional plasmonic devices. Mater. Today Phys. 2020, 12, 100178. [Google Scholar] [CrossRef]

- Gerislioglu, B.; Ahmadivand, A. Functional charge transfer plasmon metadevices. Research 2019, 2020, 9468692. [Google Scholar] [CrossRef] [Green Version]

- Baida, F.I.; Belkhir, A.; Labeke, D.; Lamrous, O. Subwavelength metallic coaxial waveguides in the optical range: Role of the plasmonic modes. Phys. Rev. B 2006, 74, 205419. [Google Scholar] [CrossRef]

- Oulton, R.F.; Sorger, V.J.; Genov, D.A.; Pile, D.F.P.; Zhang, X. A hybrid plasmonic waveguide for subwavelength confinement and long-range propagation. Nat. Photonics 2008, 2, 496–500. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.S.; Kim, M.S.; Jin, Y.; Han, G.H.; Lee, Y.H.; Kim, J. Efficient exciton-plasmon conversion in Ag nanowire/ monolayer MoS2 hybrids: Direct imaging and quantitative estimation of plasmon coupling and propagation. Adv. Opt. Mater. 2015, 3, 943–947. [Google Scholar] [CrossRef]

- Wuestner, S.; Hamm, J.M.; Pusch, A.; Hess, O. Plasmonic leaky-mode lasing in active semiconductor nanowires. Laser Photonics Rev. 2015, 9, 256–262. [Google Scholar] [CrossRef]

- Ma, R.M.; Oulton, R.F.; Sorger, V.J.; Bartal, G.; Zhang, X. Room-temperature sub-diffraction-limited plasmon laser by total internal reflection. Nat. Mater. 2011, 10, 110–113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Q.; Li, G.Y.; Liu, X.F.; Qian, F.; Li, Y.; Sum, T.C.; Lieber, C.M.; Xiong, Q. A room temperature low-threshold ultraviolet plasmonic nanolaser. Nat. Commun. 2014, 5, 4953. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sidiropoulos, T.P.H.; Röder, R.; Geburt, S.; Hess, O.; Maier, S.A.; Ronning, C.; Oulton, R.F. Ultrafast plasmonic nanowire lasers near the surface plasmon frequency. Nat. Phys. 2014, 10, 870–876. [Google Scholar] [CrossRef]

- Yu, H.; Ren, K.; Wu, Q.; Wang, J.; Lin, J.; Wang, Z.; Xu, J.; Oulton, R.F.; Qu, S.C.; Jin, P. Organic–inorganic perovskite plasmonic nanowire lasers with a low threshold and a good thermal stability. Nanoscale 2016, 8, 19536–19540. [Google Scholar] [CrossRef]

- Fan, P.Y.; Colombo, C.; Huang, K.C.Y.; Krogstrup, P.; Nygård, J.; Morral, A.F.; Brongersma, M.L. An electrically-driven GaAs nanowire surface plasmon source. Nano Lett. 2012, 12, 4943–4947. [Google Scholar] [CrossRef]

- Wang, J.M.; Yan, X.; Wei, W.; Zhang, J.N.; Zhang, X.; Ren, X.M. Near-infrared hybrid plasmonic multiple quantum well nanowire lasers. Opt. Express 2017, 25, 9358–9367. [Google Scholar] [CrossRef]

- Ho, J.F.; Tatebayashi, J.; Sergent, S.; Fong, C.F.; Ota, Y.; Iwamoto, S.; Arakawa, Y. A nanowire-based plasmonic quantum dot laser. Nano Lett. 2016, 16, 2845–2850. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Sidiropoulos, T.P.H.; Liu, W.; Ronning, C.; Petrov, P.K.; Oh, S.H.; Maier, S.A.; Jin, P.; Oulton, R.F. Influence of silver film quality on the threshold of plasmonic nanowire lasers. Adv. Opt. Mater. 2017, 5, 1600856. [Google Scholar] [CrossRef]

- Wei, W.; Yan, X.; Shen, B.; Qin, J.; Zhang, X. Channel plasmon nanowire lasers with V-Groove cavities. Nanoscale Res. Lett. 2018, 13, 227. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ho, X.; Tatebayashi, J.; Sergent, S.; Fong, C.F.; Iwamoto, S.; Arakawa, Y. Low-threshold near-infrared GaAs-AlGaAs core-shell nanowire plasmon laser. ACS Photonics 2015, 2, 165–171. [Google Scholar] [CrossRef]

- Wei, W.; Yan, X.; Zhang, X. Miniaturized GaAs nanowire laser with a metal grating reflector. Nanomaterials 2020, 10, 680. [Google Scholar] [CrossRef] [Green Version]

- Hua, B.; Motohisa, J.; Ding, Y.; Hara, S.; Fukui, T. Characterization of Fabry-Pérot microcavity modes in GaAs nanowires fabricated by selective-area metal organic vapor phase epitaxy. Appl. Phys. Lett. 2007, 91, 131112. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, F.; Lysevych, M.; Tan, H.; Jagadish, C.; Fraenzl, M.; Wagner, H.P. Hybrid-plasmonic gold coated GaAs nanowire lasers. In Lasers and Electro-Optics; Optical Society of America: San Jose, CA, USA, 2018. [Google Scholar]

- Duncanson, A.; Stevenson, R.W.H. Some properties of Magnesium Fluoride crystallized from the melt. Proc. Phys. Soc. 1958, 72, 1001. [Google Scholar] [CrossRef]

- Palik, E. Handbook of Optical Constants of Solids; Academic: Orlando, FL, USA, 1998. [Google Scholar]

- Johnson, P.B.; Christy, R.W. Optical constants of the noble metals. Phys. Rev. B 1972, 6, 4370–4379. [Google Scholar] [CrossRef]

- Barnes, W.L.; Dereux, A.; Ebbesen, T.W. Surface plasmon subwavelength optics. Nature 2003, 424, 824–830. [Google Scholar] [CrossRef]

- Robinson, J.T.; Preston, K.; Painter, O.; Lipson, M. First-principle derivation of gain in high-index contrast waveguides. Opt. Express 2008, 16, 16659–16669. [Google Scholar] [CrossRef]

- Chang, S.W.; Lin, T.R.; Chuang, S.L. Theory of plasmonic Fabry-Perot nanolasers. Opt. Express 2010, 18, 15039–15053. [Google Scholar] [CrossRef] [PubMed]

- Rakić, A.D. Algorithm for the determination of intrinsic optical constants of metal films: Application to aluminum. Appl. Opt. 1995, 34, 4755–4767. [Google Scholar] [CrossRef] [PubMed]

- Fu, A.; Gao, H.; Petrov, P.; Yang, P. Widely tunable distributed Bragg Reflectors integrated into nanowire waveguides. Nano Lett. 2015, 15, 6909–6913. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Yan, X.; Wei, W.; Wu, C.; Sibirev, N.; Zhang, X.; Ren, X. A Low-Threshold Miniaturized Plasmonic Nanowire Laser with High-Reflectivity Metal Mirrors. Nanomaterials 2020, 10, 1928. https://doi.org/10.3390/nano10101928

Zheng J, Yan X, Wei W, Wu C, Sibirev N, Zhang X, Ren X. A Low-Threshold Miniaturized Plasmonic Nanowire Laser with High-Reflectivity Metal Mirrors. Nanomaterials. 2020; 10(10):1928. https://doi.org/10.3390/nano10101928

Chicago/Turabian StyleZheng, Jiahui, Xin Yan, Wei Wei, Chao Wu, Nickolay Sibirev, Xia Zhang, and Xiaomin Ren. 2020. "A Low-Threshold Miniaturized Plasmonic Nanowire Laser with High-Reflectivity Metal Mirrors" Nanomaterials 10, no. 10: 1928. https://doi.org/10.3390/nano10101928