Fast Degradation of Bisphenol A in Water by Nanostructured CuNPs@CALB Biohybrid Catalysts

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

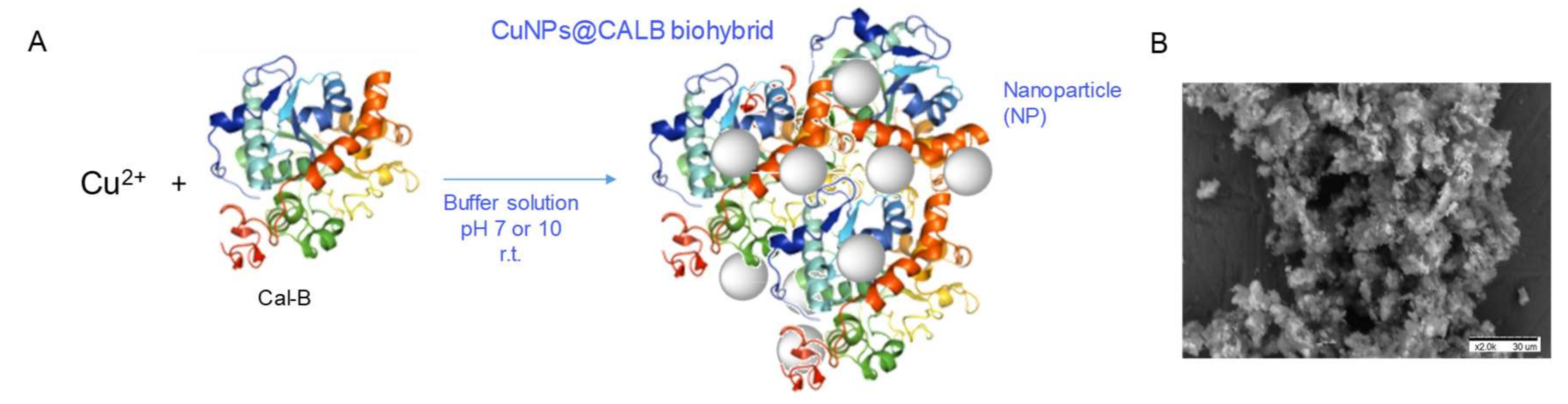

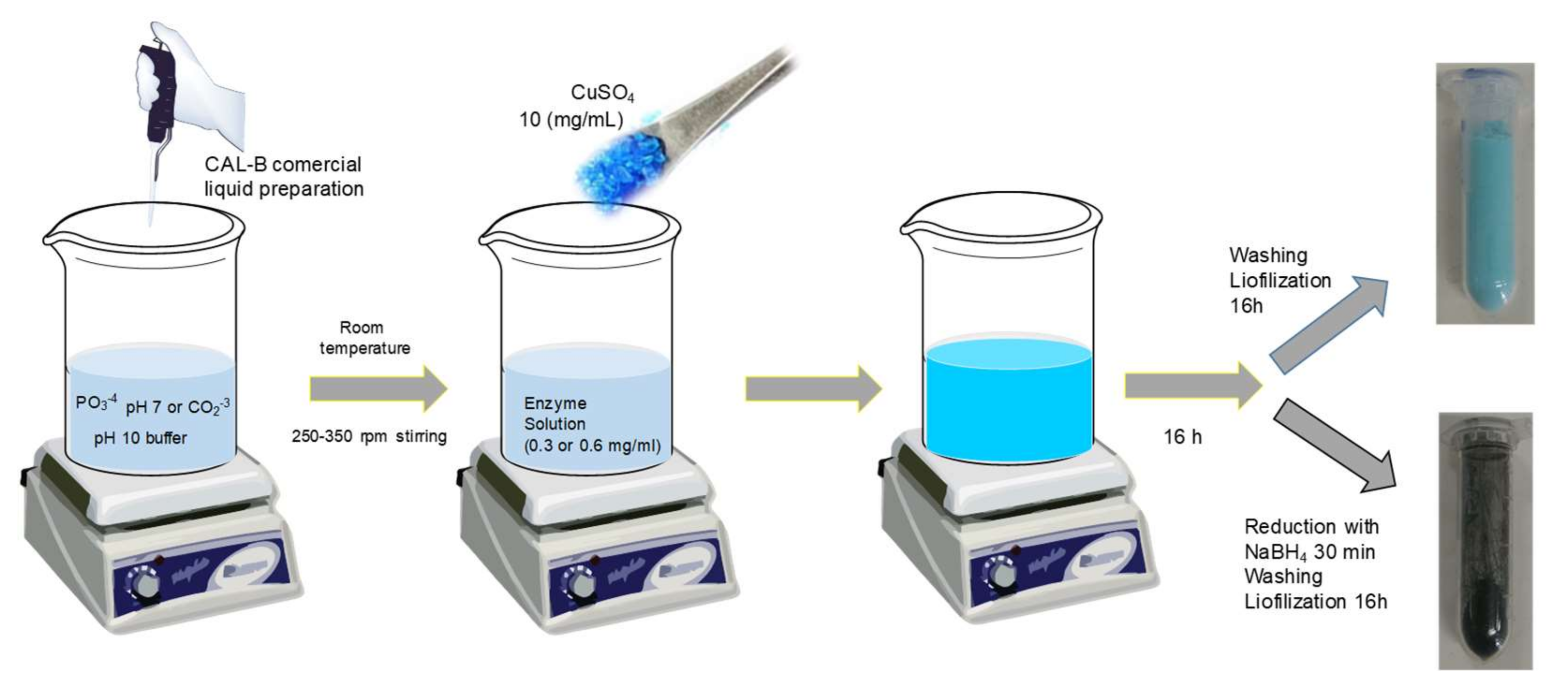

2.2. Fabrication of CuNPs@CAL-B Nanobiohybrids

2.3. Characterization Techniques

2.4. Water Treatment: Active CuNPs@CAL-B Nanobiohybrids Catalyzing the Degradation of Bisphenol A (BPA)

2.5. Reuse of CuNPs@CALB-3 Nanobiohybrids in the Degradation of Bisphenol A (BPA)

2.6. Catalase-Like Activity of Cu Nanobiohybrids

3. Results

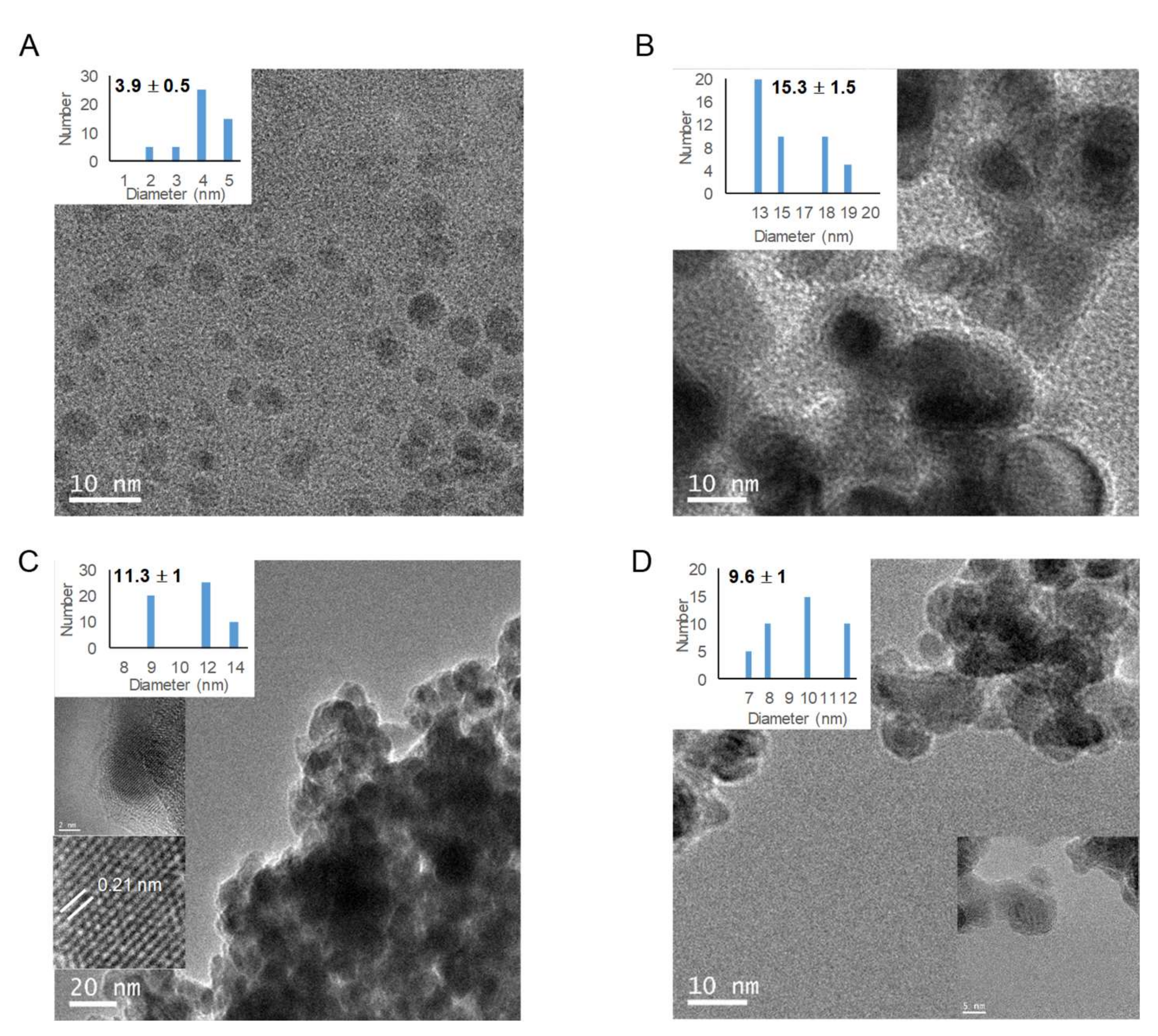

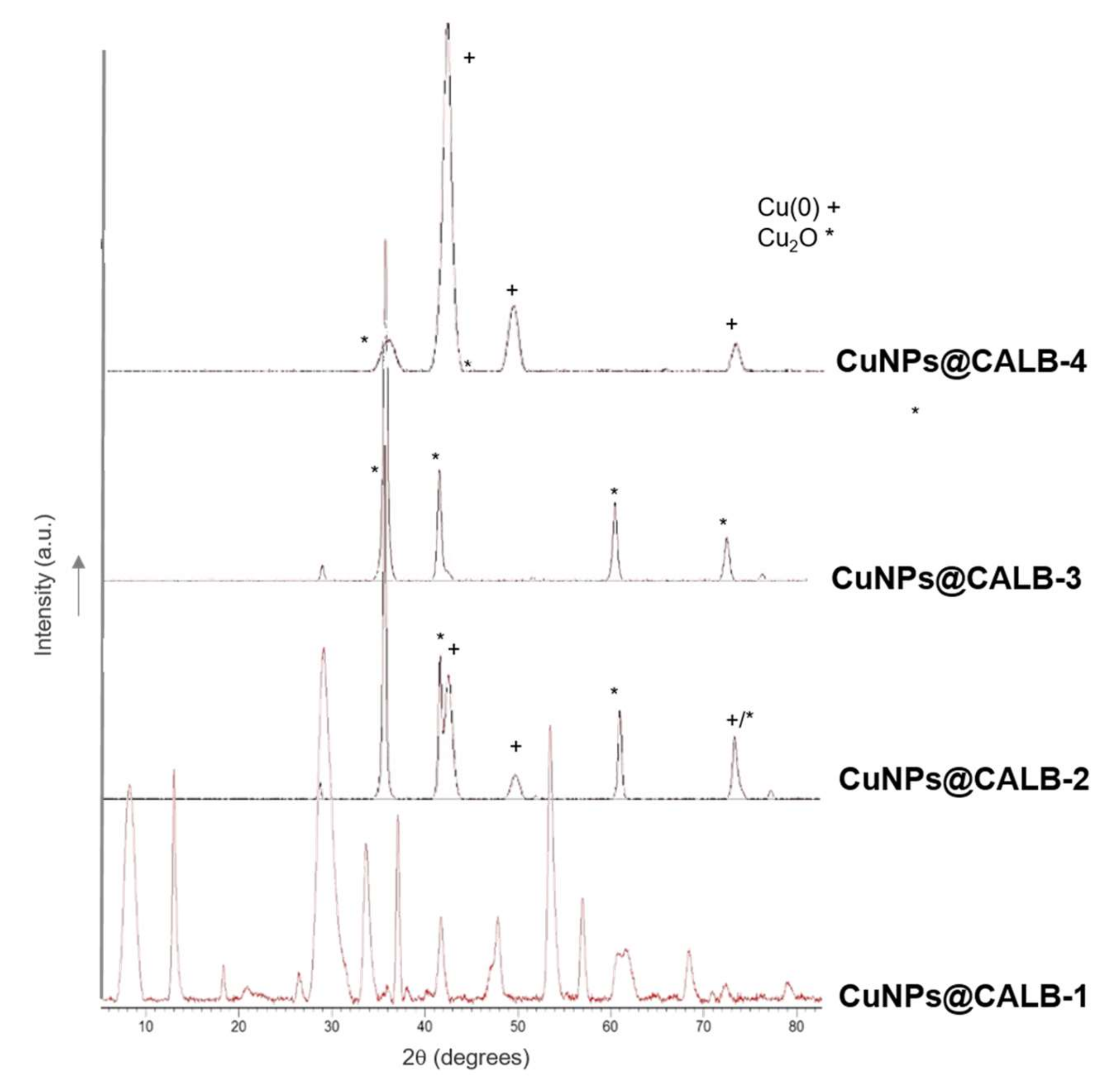

3.1. Synthesis and Caractherization of Nanostructured CuNPs@CAL-B Nanobiohybrids Catalysts

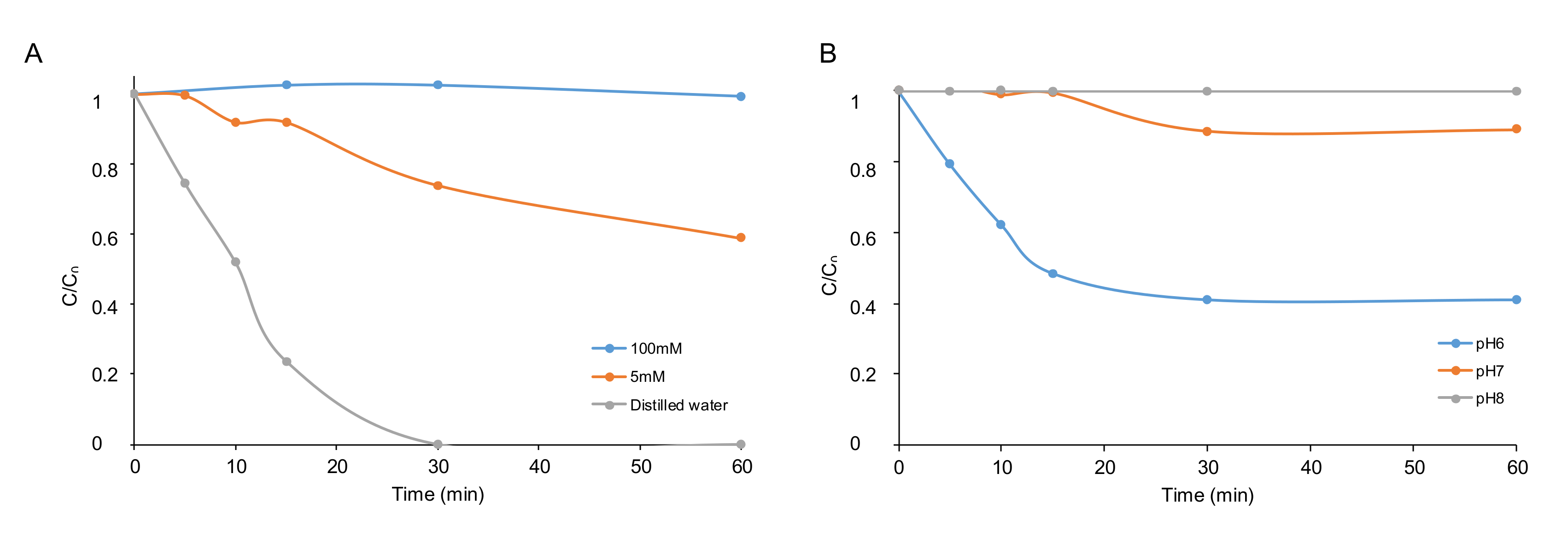

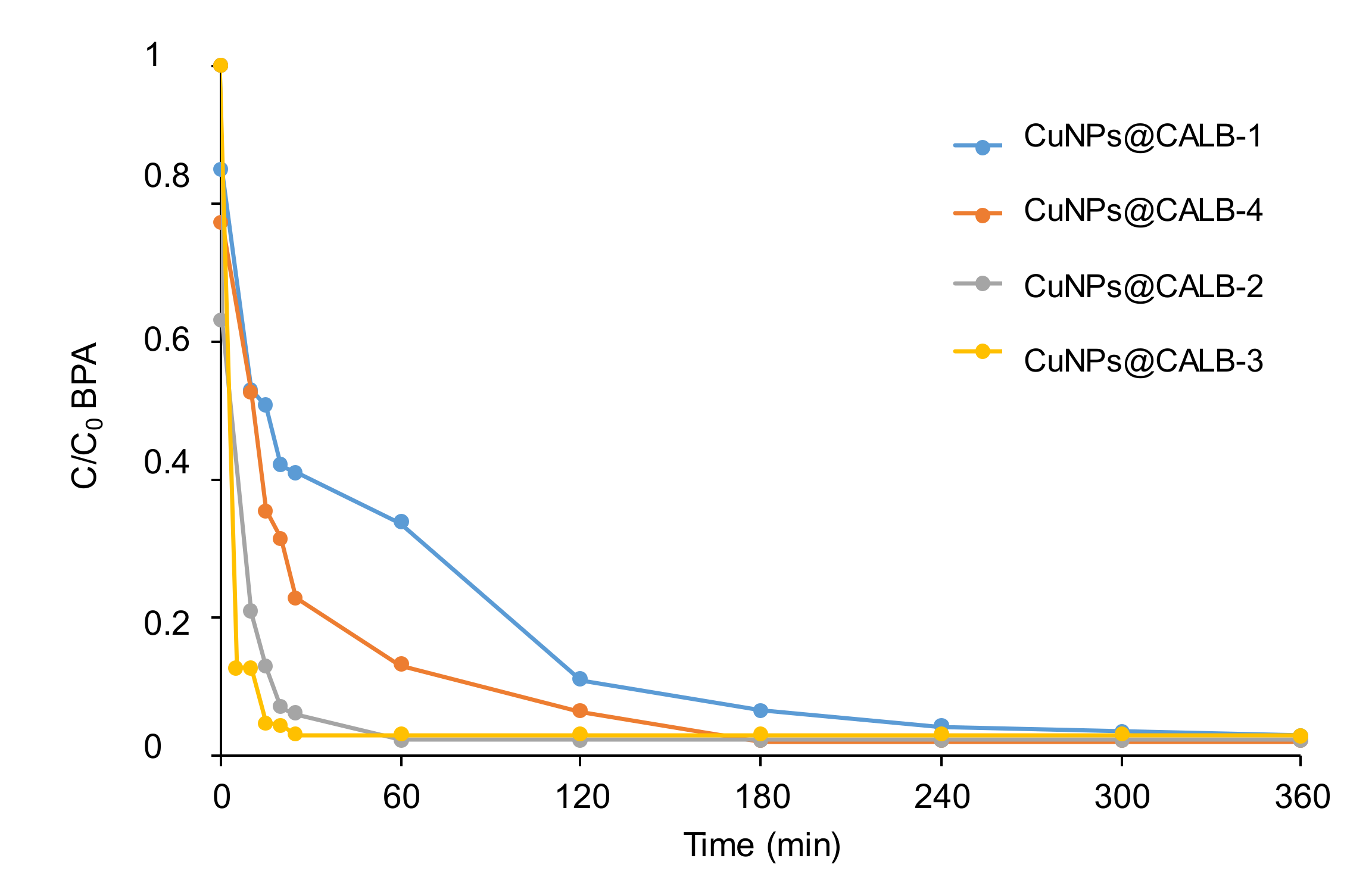

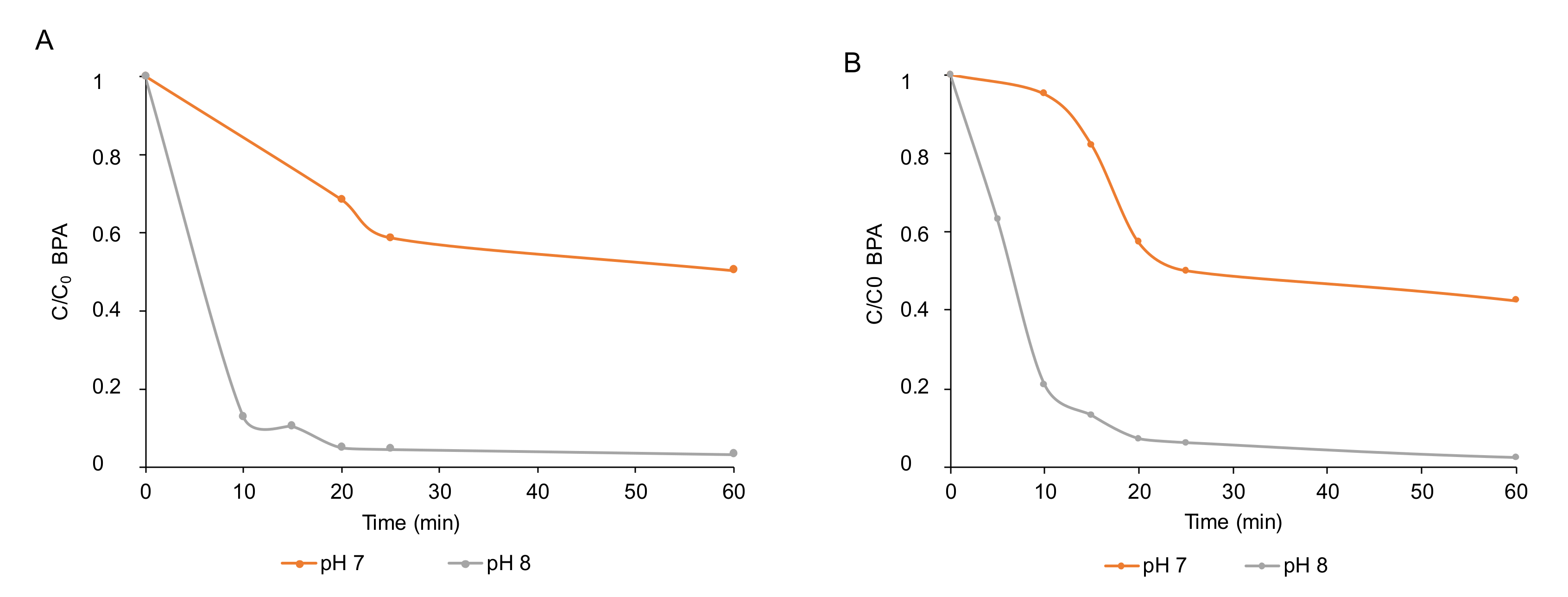

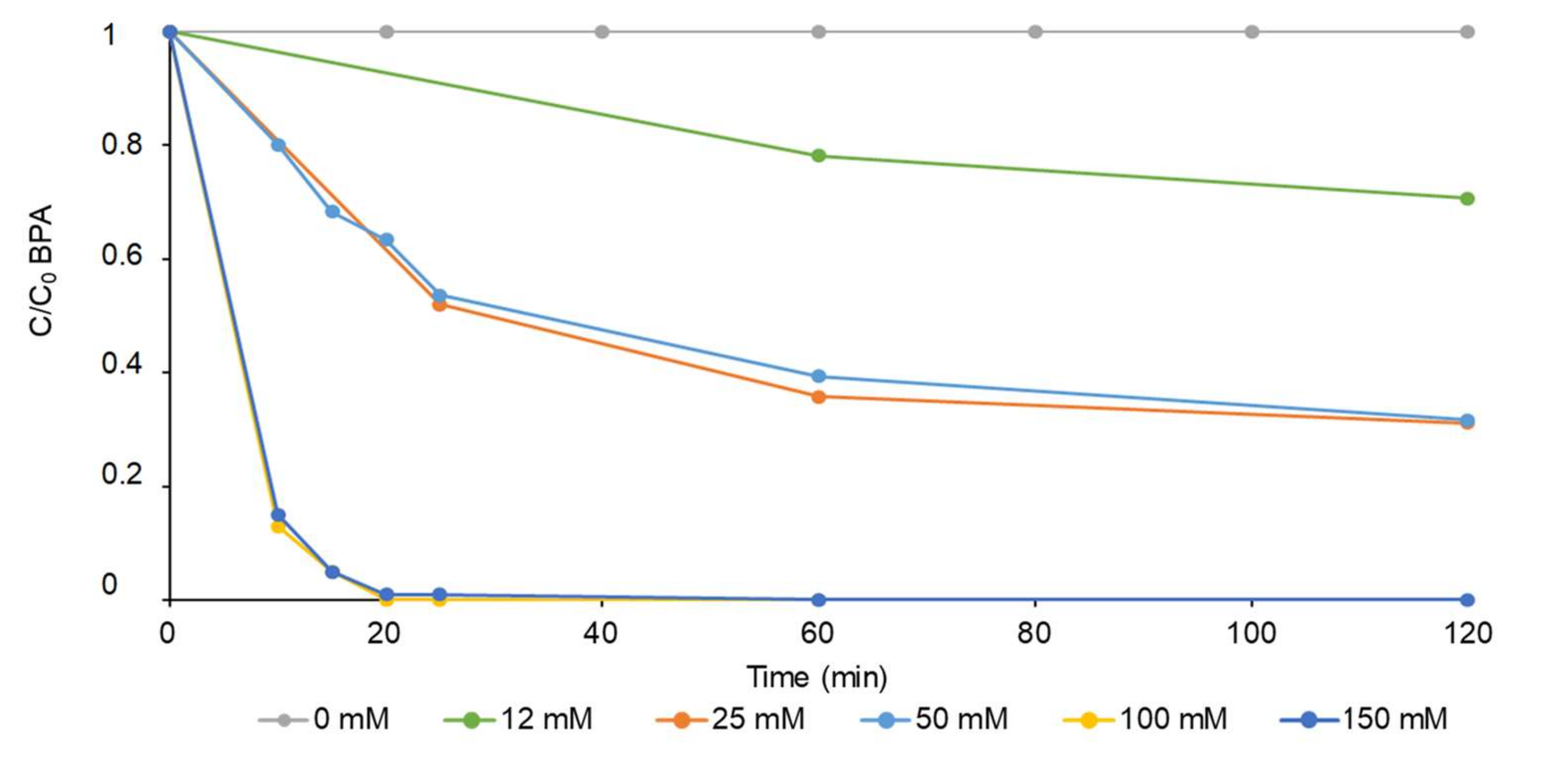

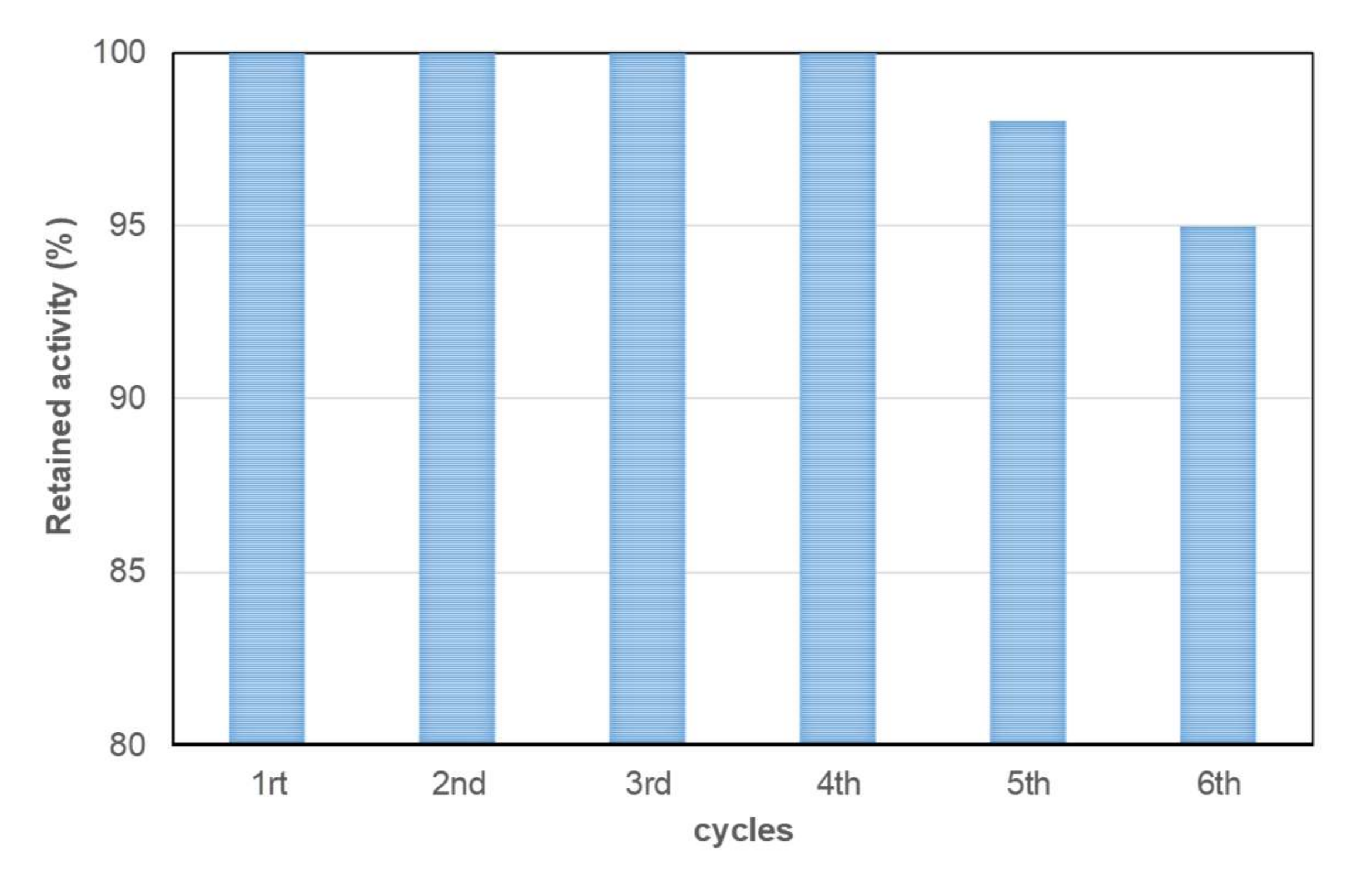

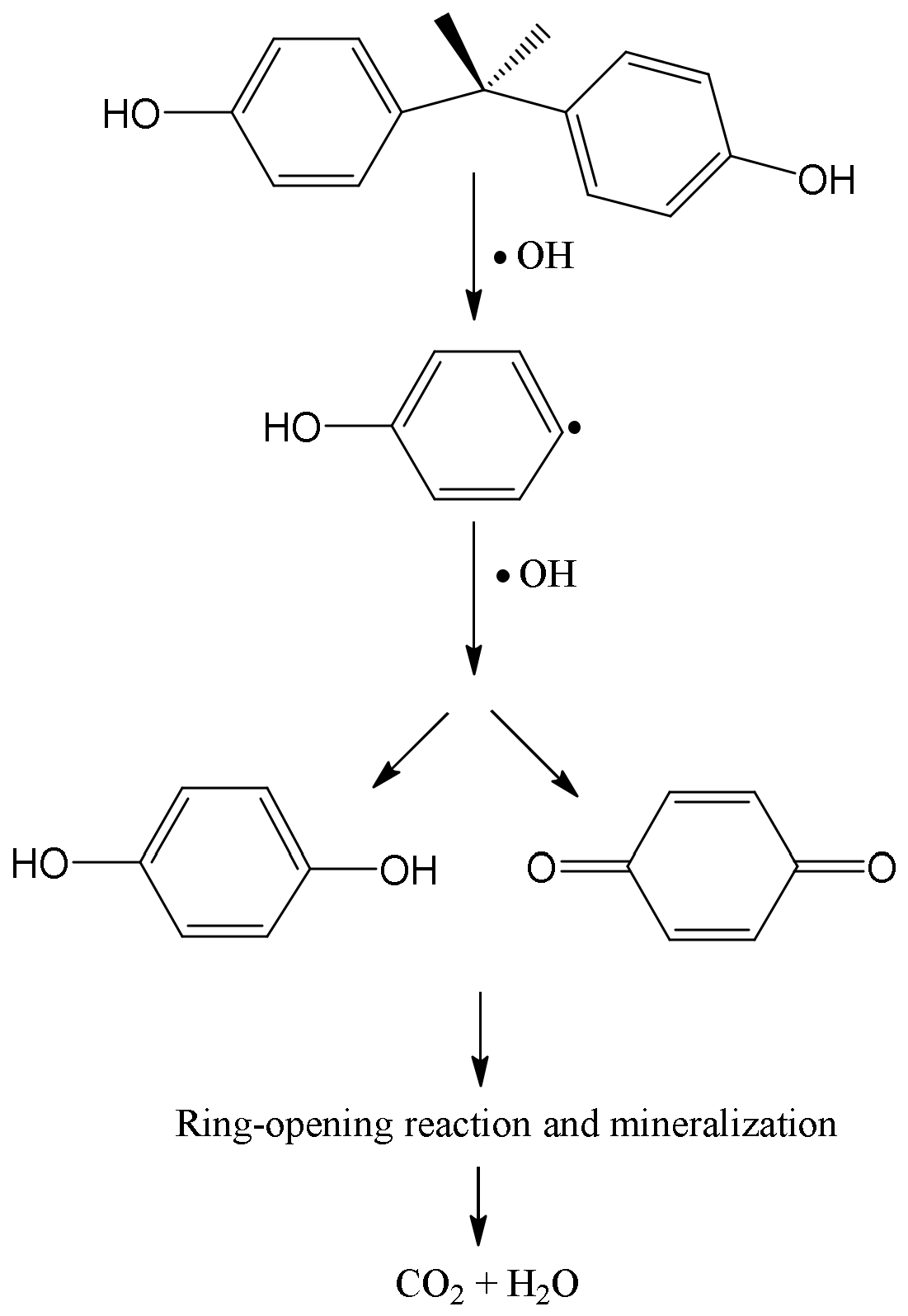

3.2. Bisphenol A (BPA) Degradation by Cu Nanobiohybrids

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sajid, M.; Basheer, C.; Narasimhan, K.; Buhmeida, A.; Qahtani, A.; Al-ahwal, M.S. Persistent and Endocrine Disrupting Organic Pollutants: Advancements and Challenges in Analysis, Health Concerns and Clinical Correlates. Nat. Environ. Pollut. Technol. 2016, 15, 733–746. [Google Scholar]

- Fu, F.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef] [PubMed]

- Hoepner, L.A. Bisphenol a: A narrative review of prenatal exposure effects on adipogenesis and childhood obesity via peroxisome proliferator-activated receptor gamma. Environ. Res. 2019, 173, 54–68. [Google Scholar] [CrossRef] [PubMed]

- Makris, K.C.; Andra, S.S.; Jia, A.; Herrick, L.; Christophi, C.A.; Snyder, S.A.; Hauser, R. Association between water consumption from polycarbonate containers and bisphenol A intake during harsh environmental conditions in summer. Environ. Sci. Technol. 2013, 47, 3333–3343. [Google Scholar] [CrossRef] [PubMed]

- Schecter, A.; Malik, N.; Haffner, D.; Smith, S.; Harris, T.R.; Paepke, O.; Brinbaum, L. Bisphenol A (BPA) in U.S. Food. Environ. Sci. Technol. 2010, 44, 9425–9430. [Google Scholar] [CrossRef]

- Kuo, H.W.; Ding, W.H. Trace determination of bisphenol A and phytoestrogens in infant formula powders by gas chromatography-mass spectrometry. J. Chromatrogr. A 2004, 1027, 67–74. [Google Scholar] [CrossRef]

- Ulutao, O.K.; Yildiz, N.; Durmaz, E.; Ahbab, M.A.; Barlas, N.; Çok, Ã. An in vivo assessment of the genotoxic potential of bisphenol A and 4-tert-octylphenol in rats. Arch. Toxicol. 2011, 85, 995–1001. [Google Scholar] [CrossRef]

- Commission Regulation (EU) 2018/213 of 12 February 2018 on the use of Bisphenol A in Varnishes and Coatings Intended to Come Into Contact with Food and Amending Regulation (EU) No 10/2011 as Regards the Use of That Substance in Plastic Food Contact Materials. Available online: Https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.041.01.0006.01.ENG&toc=OJ:L: 2018:041:TOC (accessed on 1 September 2018).

- Hua, Z.; Ma, W.; Bai, X.; Feng, R.; Yu, L.; Zhang, X.; Dai, Z. Heterogeneous Fenton degradation of bisphenol A catalyzed by efficient adsorptive Fe3O4/GO nanocomposites. Environ. Sci. Pollut. Res. 2014, 21, 7737–7745. [Google Scholar] [CrossRef]

- Ma, L.; He, H.; Zhu, R.; Zhu, J.; Mackinnonc, I.D.R.; Xiet, Y. Bisphenol A degradation by a new acidic nano zero-valent iron diatomite composite. Catal. Sci. Technol. 2016, 6, 6066–6075. [Google Scholar] [CrossRef]

- Outsiou, A.; Frontistis, Z.; Ribeiro, R.S.; Antonopoulou, M.; Konstantinou, I.K.; Silva, A.M.T.; Faria, J.L.; Gomes, H.T.; Mantzavinos, D. Activation of sodium persulfate by magnetic carbon xerogels (CX/CoFe) for the oxidation of bisphenol A: Process variables effects, matrix effects and reaction pathways. Water Res. 2017, 124, 97–107. [Google Scholar] [CrossRef]

- Liu, R.; Xu, Y.; Chen, B. Self-Assembled Nano-FeO(OH)/Reduced Graphene Oxide Aerogel as a Reusable Catalyst for Photo-Fenton Degradation of Phenolic Organics. Environ. Sci. Technol. 2018, 52, 7043–7053. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Ren, B.; Sun, Z.; Li, C.; Zhang, X.; Kong, M.; Zheng, S.; Dionysiou, D.D. Monodispersed CuFe2O4 nanoparticles anchored on natural kaolinite as highly efficient peroxymonosulfate catalyst for bisphenol A degradation. Appl. Catal. B Environ. 2019, 253, 206–217. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Sun, J.; Wang, Y.; Zhao, X. Electrospun flexible self-standing Cu–Al2O3 fibrous membranes as Fenton catalysts for bisphenol A degradation. J. Mat. Chem. A 2017, 36, 19151–19158. [Google Scholar] [CrossRef]

- Pachamuthu, M.P.; Karthikeyan, S.; Maheswari, R.; Lee, A.F.; Ramanathan, A. Fenton-like degradation of Bisphenol A catalyzed by mesoporous Cu/TUD-1. Appl. Surf. Sci. 2017, 393, 67–73. [Google Scholar] [CrossRef]

- Lyu, L.; Yan, D.; Yu, G.; Cao, W.; Hu, C. Efficient Destruction of Pollutants in Water by a Dual-Reaction-Center Fenton-like Process over Carbon Nitride Compounds-Complexed Cu(II)-CuAlO2. Environ. Sci Technol. 2018, 52, 4294–4304. [Google Scholar] [CrossRef] [PubMed]

- Shylesh, S.; Schnemann, V.; Thiel, W.R. Magnetically separable nanocatalysts: Bridges between homogeneous and heterogeneous catalysis. Angew. Chem. Int. Ed. 2010, 49, 3428–3459. [Google Scholar] [CrossRef]

- Ben Aissa, M.A.; Tremblay, B.; Andrieux-Ledier, A.; Maisonhaute, E.; Raouafi, N.; Courty, A. Copper nanoparticles of well-controlled size and shape: A new advance in synthesis and self-organization. Nanoscale 2015, 7, 3189–3195. [Google Scholar] [CrossRef]

- Tripathi, K.M.; Ameerunisha Begum, A.; Sonkara, S.K.; Sarkar, S. Nanospheres of copper(iii) 1,2-dicarbomethoxy-1,2-dithiolate and its composite with water soluble carbon nanotubes. New. J. Chem. 2013, 37, 2708–2715. [Google Scholar] [CrossRef]

- Das, G.S.; Sarkar, S.; Aggarwal, R.; Sonkar, S.K.; Park, J.-W.; Tripathi, K.M.; Kim, T.Y. Fluorescent microspheres of zinc 1,2-dicarbomethoxy-1,2-dithiolate complex decorated with carbon nanotubes. Carbon Lett. 2019, 29, 595–603. [Google Scholar]

- Uppenberg, J.; Hansen, M.T.; Patkar, S.; Jones, T.A. The sequence, crystal structure determination and refinement of two crystal forms of lipase B fromCandida Antarctica. Structure 1994, 2, 293–308. [Google Scholar] [CrossRef]

- Benavente, R.; Lopez-Tejedor, D.; Palomo, J.M. Synthesis of a superparamagnetic ultrathin FeCO3 nanorods-enzyme bionanohybrid as a novel heterogeneous catalyst. Chem. Commun. 2018, 54, 6256–6259. [Google Scholar] [CrossRef] [PubMed]

- Gui, L.; Jin, H.; Zheng, Y.; Peng, R.; Luo, Y.; Yu, P. Electrochemical Degradation of Bisphenol A Using Different Modified Anodes Based on Titanium in Aqueous Solution. Int. J. Electrochem. Sci. 2018, 13, 7141–7156. [Google Scholar] [CrossRef]

| Entry | Nanocatalyst | pH | BPA Degradation at 10 min (%) | TOF b (h−1) | tconv >99% c (min) |

|---|---|---|---|---|---|

| 1 | CuNPs@CALB-1 | 7 | 20.63 | 240 | 1140 |

| 2 | CuNPs@CALB-1 | 8 | 11.30 | 126 | 1020 |

| 3 | CuNPs@CALB-2 | 7 | 18.00 | 60 | >1500 |

| 4 | CuNPs@CALB-2 | 8 | 79.10 | 246 | 60 |

| 5 | CuNPs@CALB-3 | 7 | 31.53 | 66 | >1500 |

| 6 | CuNPs@CALB-3 | 8 | 87.13 | 366 | 60 |

| 7 | CuNPs@CALB-4 | 7 | 39.96 | 120 | 1020 |

| 8 | CuNPs@CALB-4 | 8 | 47.33 | 144 | 1020 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Losada-Garcia, N.; Rodriguez-Otero, A.; Palomo, J.M. Fast Degradation of Bisphenol A in Water by Nanostructured CuNPs@CALB Biohybrid Catalysts. Nanomaterials 2020, 10, 7. https://doi.org/10.3390/nano10010007

Losada-Garcia N, Rodriguez-Otero A, Palomo JM. Fast Degradation of Bisphenol A in Water by Nanostructured CuNPs@CALB Biohybrid Catalysts. Nanomaterials. 2020; 10(1):7. https://doi.org/10.3390/nano10010007

Chicago/Turabian StyleLosada-Garcia, Noelia, Alba Rodriguez-Otero, and Jose M. Palomo. 2020. "Fast Degradation of Bisphenol A in Water by Nanostructured CuNPs@CALB Biohybrid Catalysts" Nanomaterials 10, no. 1: 7. https://doi.org/10.3390/nano10010007

APA StyleLosada-Garcia, N., Rodriguez-Otero, A., & Palomo, J. M. (2020). Fast Degradation of Bisphenol A in Water by Nanostructured CuNPs@CALB Biohybrid Catalysts. Nanomaterials, 10(1), 7. https://doi.org/10.3390/nano10010007