Bioinspired Soft Machines: Engineering Nature’s Grace into Future Innovations

Abstract

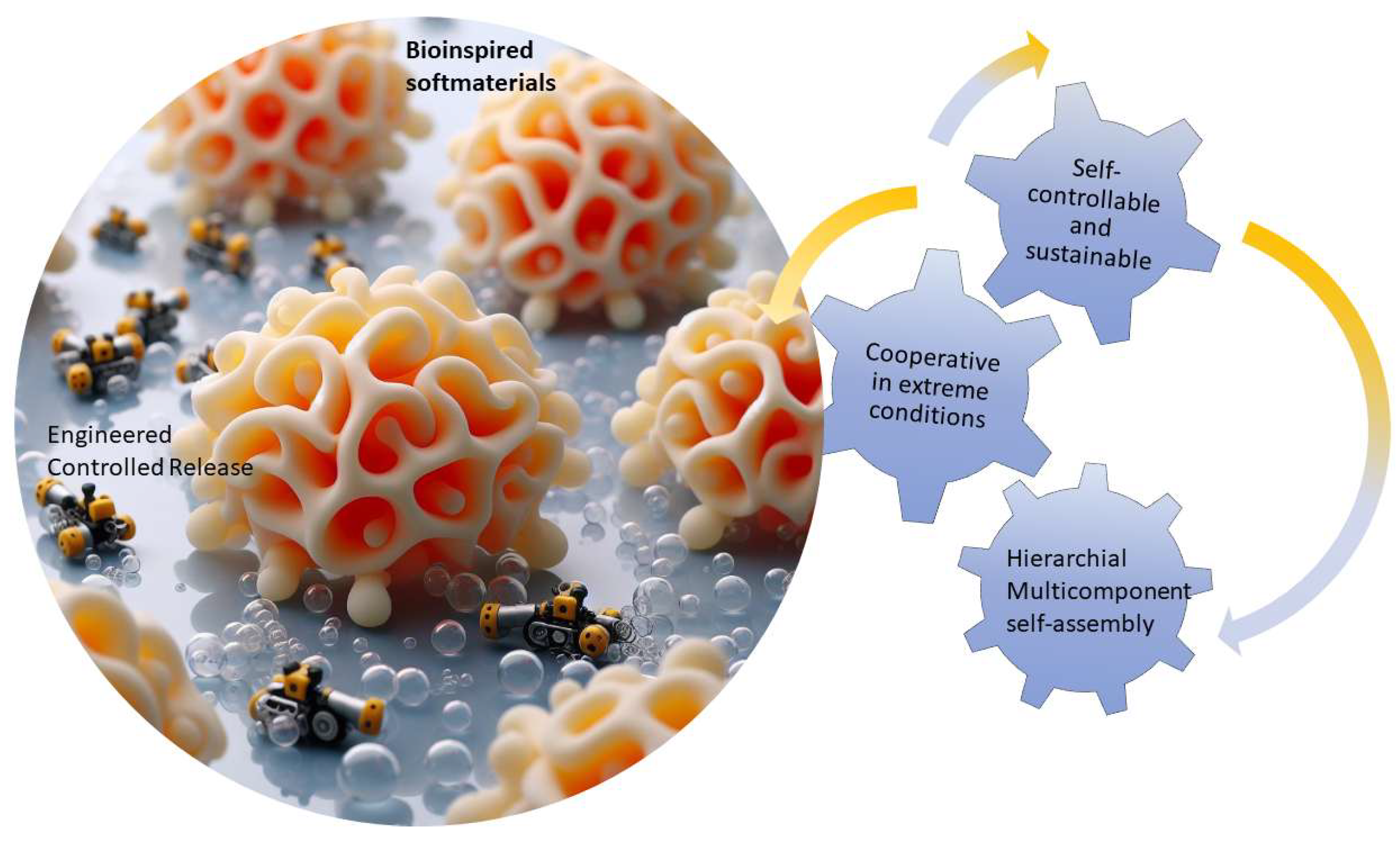

1. Introduction to Bioinspired Soft Machines

2. Understanding Biological Inspiration

3. Materials Selection in Soft Machines

| Company/Group Name | Bioinspired Theme | Product Name | Usage | Reference |

|---|---|---|---|---|

| Fusion Bionic | Nano-scale surface texture | Bioinspired nanotexture | Surface applications in various fields like medical and aerospace | [46] |

| GreenPod Labs | Plant-based volatiles | Packaging sachets | Sustainable packaging | [47] |

| Intropic Materials | Enzymatic processes | Plastic degradation | Plastic waste management | [48] |

| Biohm | Biomimicry | Circular construction | Sustainable construction | [49] |

| Terrapin Bright Green | Biomimicry in transportation | Biomimicry-inspired transportation solutions | Sustainable transportation systems | [50] |

| TISSIUM | Gecko adhesion | Surgical adhesive | Medical surgeries (tissue reconstruction) | [51] |

| SoftGripping | Soft grippers | GorillaFingers | Pick and place | [52] |

4. Actuation Mechanisms in Bioinspired Soft Machines

4.1. Actuation Mechanisms

- (a)

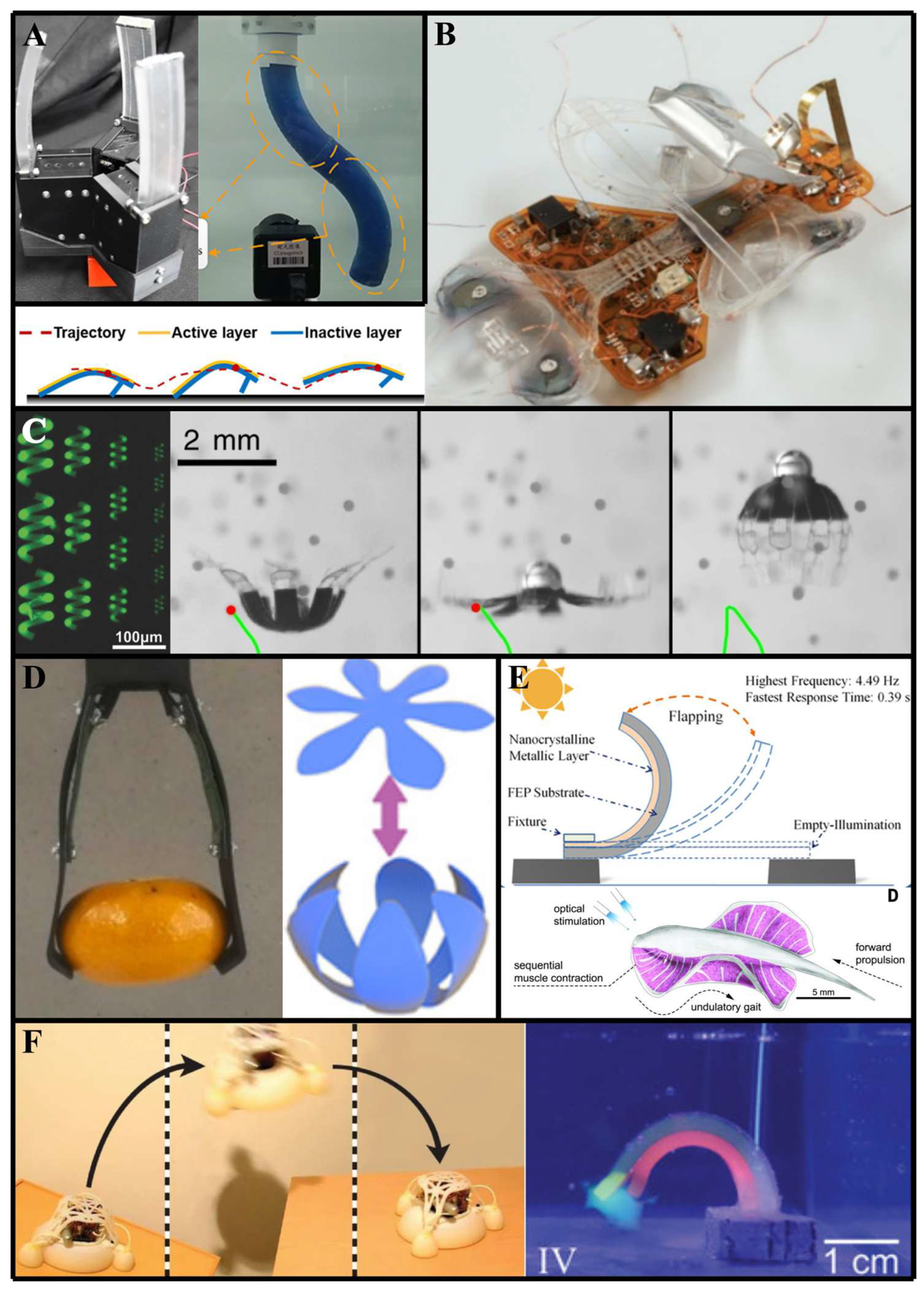

- Pneumatic actuation relies on the use of pressurized air or gas to deform soft structures, enabling smooth and versatile movements [54]. Additionally, pneumatic networks represent a bioinspired approach to actuation, mimicking the distributed network of muscles and tendons found in biological organisms. By embedding channels within soft structures and selectively pressurizing them, soft machines can achieve complex movements and deformations, reminiscent of natural locomotion [55]. Hydraulic actuation, similar in principle to pneumatic actuation, uses pressurized liquid instead of gas, offering increased power and precision in certain applications [56]. Applications include grippers mimicking octopus tentacles (Figure 5A), where selective pressurization replicates muscular hydrostat dynamics [57,58].

- (b)

- Electric actuation, on the other hand, involves the use of electrically driven components such as shape memory alloys or electroactive polymers to induce deformations in soft materials, providing precise control and responsiveness [59]. Shape memory alloys (SMAs), such as NiTi, exhibit a martensitic–austenitic phase transformation when heated, leading to substantial contraction forces and repeatable shape recovery [60]. Electroactive polymers (EAPs), including dielectric elastomers and ionic polymer–metal composites, deform under electric fields via Maxwell stress or ion migration, offering large strain outputs and muscle-like actuation profiles [61]. Applications include small-scale actuators with a fast response [62,63] (Figure 5B).

- (c)

- Muscle-like actuators, for example, emulate the contractile properties of biological muscles, enabling soft machines to exhibit dynamic and adaptive movements [64]. These actuators can be fabricated using materials such as dielectric elastomers or pneumatic artificial muscles, offering a high degree of compliance and controllability [65].

- (d)

- Magnetic actuation involves the use of magnetic fields and gradients to manipulate soft composites embedded with ferromagnetic or superparamagnetic particles. Hard magnetic materials enable programmed deformation through spatially varying magnetization profiles, while soft magnetic materials exhibit torques and forces due to field-induced magnetization, enabling rapid, wireless, and untethered actuation with complex spatiotemporal control [34,66]. Applications include µm or mm scale remotely actuated robots with multiple functionalities [67,68] (Figure 5C).

- (e)

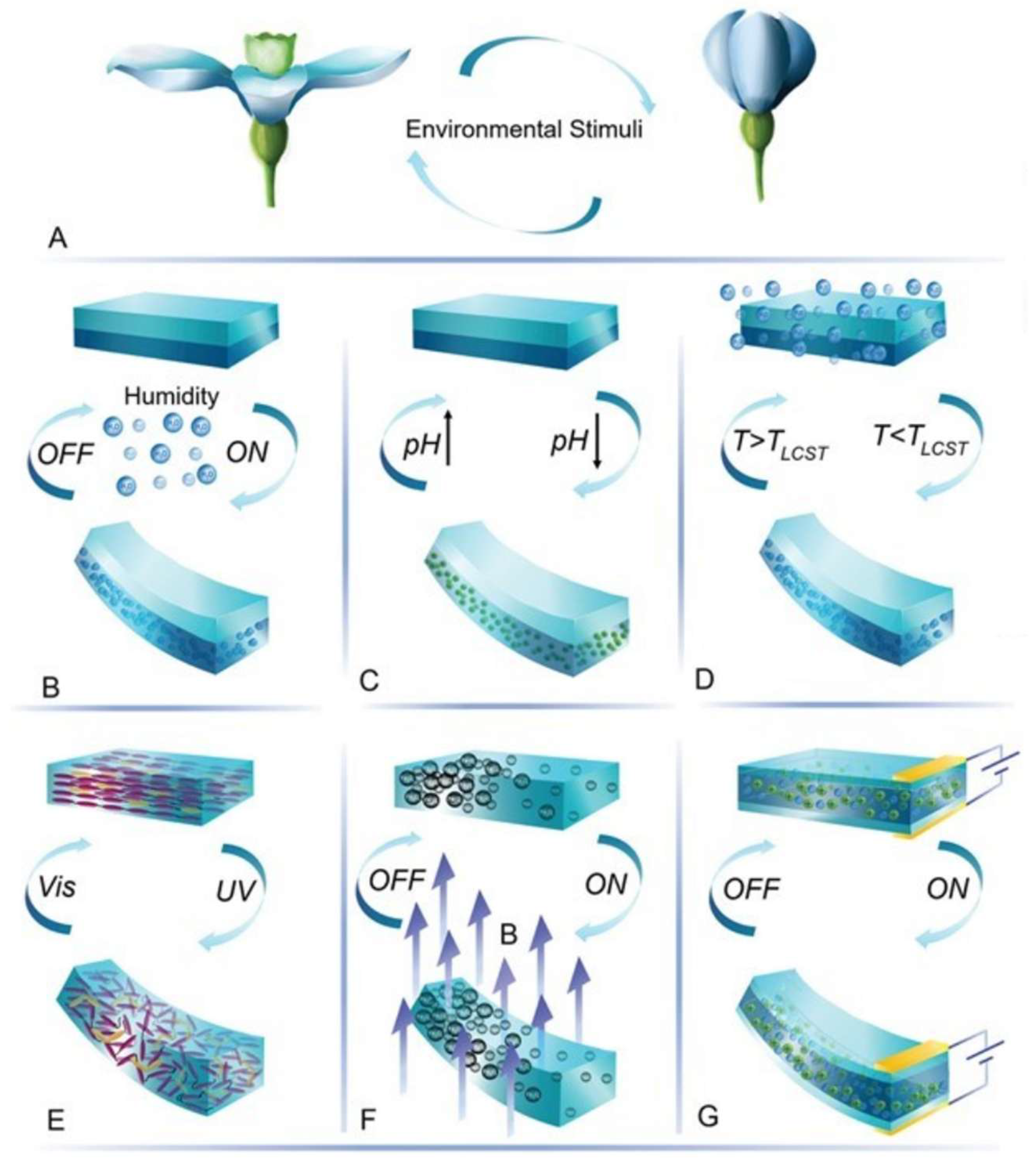

- Thermally responsive actuation employs materials that undergo volumetric or mechanical transitions upon heating, triggered via infrared (IR) or near-infrared (NIR) radiation, thermal conduction, or Joule heating through conductive networks. Examples include hydrogels, thermoplastic elastomers, and liquid crystal elastomers, where thermal input modulates phase behavior, stiffness, or swelling, resulting in controlled morphological transformations [69,70,71] (Figure 5D).

- (f)

- (g)

4.2. Control Strategies

- (a)

- Reduced-order modeling: Finite element methods (FEM) approximate soft body dynamics. For instance, Ye et al. modeled octopus-inspired arms using Cosserat rod theory, reducing computational load by 70% [11].

- (b)

- Proprioceptive feedback: Stretchable sensors can be used to enable real-time strain mapping. For example, the SoftSCREEN colonoscope uses curvature feedback for closed-loop navigation [4]. Sujit et al. demonstrated inductive sensing for precise, low-hysteresis strain measurement and closed-loop control in soft robots [82]. Polykretis et al. demonstrated adaptive neural network-based control of DEAs [83].

- (c)

- Feedforward control: Simple repetitive tasks like soft gripper actuation can be performed using preprogrammed pressure sequences [84].

- (d)

- Embodied intelligence: Control can be offloaded to material properties. For example, the continuous deformability of octopus-inspired arms is utilized for complex manipulation [85].

5. Embodied Intelligence in Bioinspired Soft Machines

6. Applications and Future Directions of Bioinspired Soft Machines

6.1. Current Applications

6.2. Future Directions and Advancements

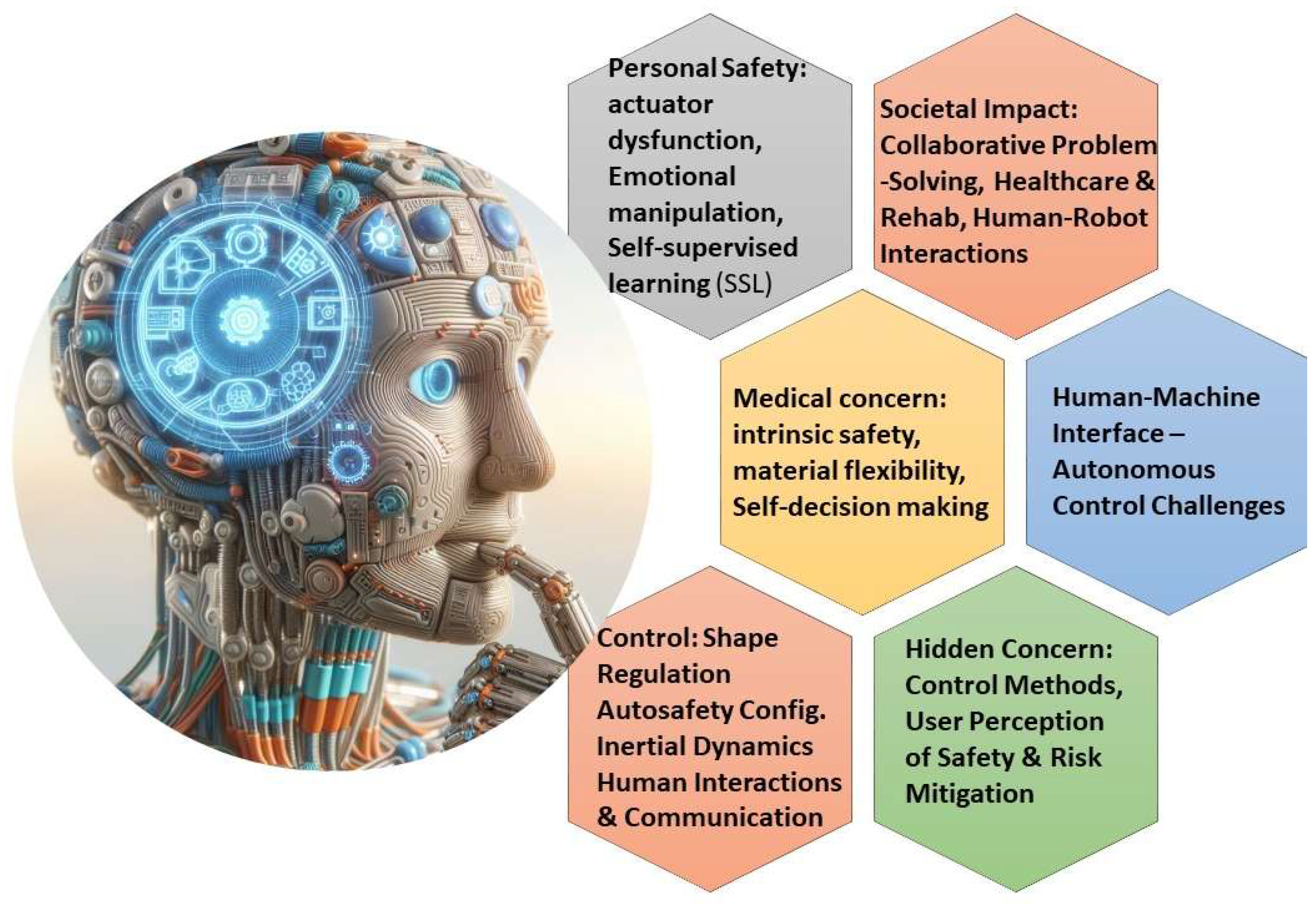

7. Ethical Considerations and Societal Impacts

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ER | electrorheological |

| MR | magnetorheological |

| SMA | shape memory alloy |

| IPMC | ionic polymer–metal composite |

| DEA | dielectric elastomer |

| AI | artificial intelligence |

| E | elastic modulus |

| ultimate tensile strength | |

| strain at failure | |

| ML | machine learning |

| QSAR | quantitative structure–activity relationship |

| NAM | new approach methodology |

References

- Cianchetti, M.; Laschi, C.; Menciassi, A.; Dario, P. Biomedical applications of soft robotics. Nat. Rev. Mater. 2018, 3, 143–153. [Google Scholar] [CrossRef]

- Gariya, N.; Kumar, P. A review on soft materials utilized for the manufacturing of soft robots. Mater. Today Proc. 2021, 46, 11177–11181. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B. Bioinspired materials and approaches for soft robotics. MRS Bull. 2021, 46, 345–349. [Google Scholar] [CrossRef]

- Consumi, V.; Lindenroth, L.; Merlin, J.; Stoyanov, D.; Stilli, A. Design and Evaluation of the SoftSCREEN Capsule for Colonoscopy. IEEE Robot. Autom. Lett. 2023, 8, 1659–1666. [Google Scholar] [CrossRef]

- Feinberg, A.W. Biological Soft Robotics. Annu. Rev. Biomed. Eng. 2015, 17, 243–265. [Google Scholar] [CrossRef]

- Ren, L.; Li, B.; Wei, G.; Wang, K.; Song, Z.; Wei, Y.; Ren, L.; Qingping, L. Biology and bioinspiration of soft robotics: Actuation, sensing, and system integration. iScience 2021, 24, 103075. [Google Scholar] [CrossRef]

- Zullo, L.; Di Clemente, A.; Maiole, F. How octopus arm muscle contractile properties and anatomical organization contribute to arm functional specialization. J. Exp. Biol. 2022, 225, jeb243163. [Google Scholar] [CrossRef]

- Alici, G. Robotics—Soft Robotics. In Encyclopedia of Biomedical Engineering; Narayan, R., Ed.; Elsevier: Oxford, UK, 2019; pp. 652–659. [Google Scholar]

- Roh, Y.; Lee, Y.; Lim, D.; Gong, D.; Hwang, S.; Kang, M.; Kim, D.; Cho, J.; Kwon, G.; Kang, D.; et al. Nature’s Blueprint in Bioinspired Materials for Robotics. Adv. Funct. Mater. 2024, 34, 2306079. [Google Scholar] [CrossRef]

- Walker, I.; Dawson, D.; Flash, T.; Grasso, F.; Hanlon, R.; Hochner, B.; Kier, W.; Pagano, C.; Rahn, C.; Zhang, Q. Continuum Robot Arms Inspired by Cephalopods; SPIE: Washington, DC, USA, 2005; Volume 5804. [Google Scholar]

- Ye, T.; Wang, Y.; Xu, S.; Wang, Y.; Li, J. Modeling and motion control of an octopus-like flexible manipulator actuated by shape memory alloy wires. J. Intell. Mater. Syst. Struct. 2021, 33, 3–16. [Google Scholar] [CrossRef]

- Calisti, M.; Giorelli, M.; Levy, G.; Mazzolai, B.; Hochner, B.; Laschi, C.; Dario, P. An octopus-bioinspired solution to movement and manipulation for soft robots. Bioinspiration Biomim. 2011, 6, 036002. [Google Scholar] [CrossRef]

- Kumar, S.R.S. How Elephant’s Flexible Trunk Can Improve Robots; Hindustan Times; HT Media Limited: Delhi, India, 25 July 2022. [Google Scholar]

- Tang, C. Soft Robotic Gripper Modeled after an Elephant’s Trunk. Ph.D. Thesis, UNSW Sydney, Sydney, Australia, 2020. [Google Scholar]

- Leanza, S.; Lu-Yang, J.; Kaczmarski, B.; Wu, S.; Kuhl, E.; Zhao, R.R. Elephant Trunk Inspired Multimodal Deformations and Movements of Soft Robotic Arms. Adv. Funct. Mater. 2024, 34, 2400396. [Google Scholar] [CrossRef]

- Ashuri, T.; Armani, A.; Jalilzadeh Hamidi, R.; Reasnor, T.; Ahmadi, S.; Iqbal, K. Biomedical soft robots: Current status and perspective. BioMed Eng. Lett. 2020, 10, 369–385. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, H.; Tse, Z. Soft robotics with compliance and adaptation for biomedical applications and forthcoming challenges. Int. J. Robot. Autom. 2018, 33, 68–80. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Sci. Robot. 2016, 1, eaah3690. [Google Scholar] [CrossRef]

- Truby, R.L. Designing Soft Robots as Robotic Materials. Acc. Mater. Res. 2021, 2, 854–857. [Google Scholar] [CrossRef]

- Hegde, C.; Su, J.; Tan, J.M.R.; He, K.; Chen, X.; Magdassi, S. Sensing in Soft Robotics. ACS Nano 2023, 17, 15277–15307. [Google Scholar] [CrossRef]

- Ang, B.W.K.; Yeow, C.-H.; Lim, J.H. A Critical Review on Factors Affecting the User Adoption of Wearable and Soft Robotics. Sensors 2023, 23, 3263. [Google Scholar] [CrossRef]

- Wang, Y.; Gregory, C.; Minor, M.A. Improving Mechanical Properties of Molded Silicone Rubber for Soft Robotics Through Fabric Compositing. Soft Robot. 2018, 5, 272–290. [Google Scholar] [CrossRef]

- Tasić, P.; Hajro, I.; Hodzic, D.; Pandžić, A. Selection Charts for Structural Steels Regarding Design Criteria and Trending Properties. In Proceedings of the 31st International DAAAM Symposium 2020; DAAAM International: Vienna, Austria, 2020; pp. 0453–0458. [Google Scholar]

- Marchese, A.D.; Katzschmann, R.K.; Rus, D. A Recipe for Soft Fluidic Elastomer Robots. Soft Robot. 2015, 2, 7–25. [Google Scholar] [CrossRef]

- Coyle, S.; Majidi, C.; LeDuc, P.; Hsia, K.J. Bio-inspired soft robotics: Material selection, actuation, and design. Extrem. Mech. Lett. 2018, 22, 51–59. [Google Scholar] [CrossRef]

- Khandan, A.; Jazayeri, H.; Fahmy, M.D.; Razavi, M. Hydrogels: Types, structure, properties, and applications. Biomat. Tiss. Eng. 2017, 4, 143–169. [Google Scholar]

- Deligkaris, K.; Tadele, T.S.; Olthuis, W.; van den Berg, A. Hydrogel-based devices for biomedical applications. Sens. Actuators B Chem. 2010, 147, 765–774. [Google Scholar] [CrossRef]

- Schönfeld, D.; Chalissery, D.; Wenz, F.; Specht, M.; Eberl, C.; Pretsch, T. Actuating Shape Memory Polymer for Thermoresponsive Soft Robotic Gripper and Programmable Materials. Molecules 2021, 26, 522. [Google Scholar] [CrossRef] [PubMed]

- Boyraz, P.; Runge, G.; Raatz, A. An overview of novel actuators for soft robotics. Proc. Actuators 2018, 7, 48. [Google Scholar] [CrossRef]

- Bilodeau, R.A.; Kramer, R.K. Self-Healing and Damage Resilience for Soft Robotics: A Review. Front. Robot. AI 2017, 4, 48. [Google Scholar] [CrossRef]

- Biological Robots: Perspectives on an Emerging Interdisciplinary Field. Soft Robot. 2023, 10, 674–686. [CrossRef]

- de Avila, L.; Plutnar, J.; Sofer, Z.; Neves, B.R.A. PDMS—A simple and effective platform for determining Young’s modulus of ultrathin 2D materials. Appl. Phys. Lett. 2024, 125, 253104. [Google Scholar] [CrossRef]

- Ansari, M.H.D.; Iacovacci, V.; Pane, S.; Ourak, M.; Borghesan, G.; Tamadon, I.; Vander Poorten, E.; Menciassi, A. 3D Printing of Small-Scale Soft Robots with Programmable Magnetization. Adv. Funct. Mater. 2023, 33, 2211918. [Google Scholar] [CrossRef]

- Garai, A.; Haldar, K. Experiments and modeling of magneto-stiffening effects for magnetoactive polymer. Int. J. Mech. Sci. 2025, 286, 109860. [Google Scholar] [CrossRef]

- Singh, A.V.; Ansari, M.H.D.; Mahajan, M.; Srivastava, S.; Kashyap, S.; Dwivedi, P.; Pandit, V.; Katha, U. Sperm Cell Driven Microrobots-Emerging Opportunities and Challenges for Biologically Inspired Robotic Design. Micromachines 2020, 11, 448. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.V.; Dad Ansari, M.H.; Dayan, C.B.; Giltinan, J.; Wang, S.; Yu, Y.; Kishore, V.; Laux, P.; Luch, A.; Sitti, M. Multifunctional magnetic hairbot for untethered osteogenesis, ultrasound contrast imaging and drug delivery. Biomaterials 2019, 219, 119394. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Bai, H.; Shepherd, R.F.; Zhao, H. Bio-inspired design and additive manufacturing of soft materials, machines, robots, and haptic interfaces. Angew. Chem. Int. Ed. 2019, 58, 11182–11204. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.V.; Ansari, M.H.D.; Laux, P.; Luch, A. Micro-nanorobots: Important considerations when developing novel drug delivery platforms. Expert Opin. Drug Deliv. 2019, 16, 1259–1275. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Pei, Q.; Joseph, J. High-Speed Electrically Actuated Elastomers with Strain Greater Than 100%. Science 2000, 287, 836–839. [Google Scholar] [CrossRef]

- Calvert, P. Hydrogels for Soft Machines. Adv. Mater. 2009, 21, 743–756. [Google Scholar] [CrossRef]

- Oh, S.-W.; Guo, T.; Kuenstler, A.; Hayward, R.; Palffy-Muhoray, P.; Zheng, X. Measuring the five elastic constants of a nematic liquid crystal elastomer. Liq. Cryst. 2020, 48, 511–520. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Baxevanis, T.; Lagoudas, D.C. Fracture mechanics of shape memory alloys: Review and perspectives. Int. J. Fract. 2015, 191, 191–213. [Google Scholar] [CrossRef]

- Case, J.C.; White, E.L.; Kramer, R.K. Soft Material Characterization for Robotic Applications. SOFT Robot. 2015, 2, 80–87. [Google Scholar] [CrossRef]

- Jiang, H.Y.; Kelch, S.; Lendlein, A. Polymers Move in Response to Light. Adv. Mater. 2006, 18, 1471–1475. [Google Scholar] [CrossRef]

- Meng, Q.; Hu, J.; Ho, K.; Ji, F.; Chen, S. The Shape Memory Properties of Biodegradable Chitosan/Poly(l-lactide) Composites. J. Polym. Environ. 2009, 17, 212–224. [Google Scholar] [CrossRef]

- Zhang, Y.-F.; Zhang, N.; Hingorani, H.; Ding, N.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.; Ge, Q. Fast-Response, Stiffness-Tunable Soft Actuator by Hybrid Multimaterial 3D Printing. Adv. Funct. Mater. 2019, 29, 1806698. [Google Scholar] [CrossRef]

- Yang, J.; Cao, P.; Gao, K.; Ding, C.; Chen, S.; Zhang, X.; Wang, T.; Wang, Q.; Zhang, Y. Thermal Tunable Tribological Behavior of Shape Memory Biphenyl Epoxy Resin. Coatings 2023, 13, 166. [Google Scholar] [CrossRef]

- Capadona, J.R.; Shanmuganathan, K.; Tyler, D.J.; Rowan, S.J.; Weder, C. Stimuli-Responsive Polymer Nanocomposites Inspired by the Sea Cucumber Dermis. Science 2008, 319, 1370–1374. [Google Scholar] [CrossRef]

- Trotter, J.A.; Tipper, J.; Lyons-Levy, G.; Chino, K.; Heuer, A.H.; Liu, Z.; Mrksich, M.; Hodneland, C.; Dillmore, W.S.; Koob, T.J.; et al. Towards a fibrous composite with dynamically controlled stiffness: Lessons from echinoderms. Biochem. Soc. Trans. 2000, 28, 357–362. [Google Scholar] [CrossRef]

- Rokaya, D.; Skallevold, H.E.; Srimaneepong, V.; Marya, A.; Shah, P.K.; Khurshid, Z.; Zafar, M.S.; Sapkota, J. Shape Memory Polymeric Materials for Biomedical Applications: An Update. J. Compos. Sci. 2023, 7, 24. [Google Scholar] [CrossRef]

- Yasa, O.; Toshimitsu, Y.; Michelis, M.Y.; Jones, L.S.; Filippi, M.; Buchner, T.; Katzschmann, R.K. An overview of soft robotics. Annu. Rev. Control Robot. Auton. Syst. 2023, 6, 1–29. [Google Scholar] [CrossRef]

- Huang, W.; Xiao, J.; Xu, Z. A variable structure pneumatic soft robot. Sci. Rep. 2020, 10, 18778. [Google Scholar] [CrossRef]

- Su, H.; Hou, X.; Zhang, X.; Qi, W.; Cai, S.; Xiong, X.; Guo, J. Pneumatic Soft Robots: Challenges and Benefits. Actuators 2022, 11, 92. [Google Scholar] [CrossRef]

- Pawar, P.B. Industrial Hydraulics and Pneumatics; Sankalp Publication: Pune, India, 2020. [Google Scholar]

- Lee, J.-H.; Chung, Y.S.; Rodrigue, H. Long Shape Memory Alloy Tendon-based Soft Robotic Actuators and Implementation as a Soft Gripper. Sci. Rep. 2019, 9, 11251. [Google Scholar] [CrossRef] [PubMed]

- Xie, Q.; Wang, T.; Yao, S.; Zhu, Z.; Tan, N.; Zhu, S. Design and modeling of a hydraulic soft actuator with three degrees of freedom. Smart Mater. Struct. 2020, 29, 125017. [Google Scholar] [CrossRef]

- Ankit; Ho, T.Y.K.; Nirmal, A.; Kulkarni, M.R.; Accoto, D.; Mathews, N. Soft actuator materials for electrically driven haptic interfaces. Adv. Intell. Syst. 2022, 4, 2100061. [Google Scholar] [CrossRef]

- Kim, M.-S.; Heo, J.-K.; Rodrigue, H.; Lee, H.-T.; Pané, S.; Han, M.-W.; Ahn, S.-H. Shape Memory Alloy (SMA) Actuators: The Role of Material, Form, and Scaling Effects. Adv. Mater. 2023, 35, 2208517. [Google Scholar] [CrossRef] [PubMed]

- Maksimkin, A.V.; Dayyoub, T.; Telyshev, D.V.; Gerasimenko, A.Y. Electroactive Polymer-Based Composites for Artificial Muscle-like Actuators: A Review. Nanomaterials 2022, 12, 2272. [Google Scholar] [CrossRef]

- Ji, X.; Liu, X.; Cacucciolo, V.; Imboden, M.; Civet, Y.; El Haitami, A.; Cantin, S.; Perriard, Y.; Shea, H. An autonomous untethered fast soft robotic insect driven by low-voltage dielectric elastomer actuators. Sci. Robot. 2019, 4, eaaz6451. [Google Scholar] [CrossRef]

- Wu, Y.; Yim, J.K.; Liang, J.; Shao, Z.; Qi, M.; Zhong, J.; Luo, Z.; Yan, X.; Zhang, M.; Wang, X.; et al. Insect-scale fast moving and ultrarobust soft robot. Sci. Robot. 2019, 4, eaax1594. [Google Scholar] [CrossRef] [PubMed]

- Higueras-Ruiz, D.R.; Nishikawa, K.; Feigenbaum, H.; Shafer, M. What is an artificial muscle? A comparison of soft actuators to biological muscles. Bioinspiration Biomim. 2021, 17, 011001. [Google Scholar] [CrossRef]

- Ramdya, P.; Ijspeert, A.J. The neuromechanics of animal locomotion: From biology to robotics and back. Sci. Robot. 2023, 8, eadg0279. [Google Scholar] [CrossRef]

- Bayaniahangar, R.; Bayani Ahangar, S.; Zhang, Z.; Lee, B.P.; Pearce, J.M. 3-D printed soft magnetic helical coil actuators of iron oxide embedded polydimethylsiloxane. Sens. Actuators B Chem. 2021, 326, 128781. [Google Scholar] [CrossRef]

- Ren, Z.; Hu, W.; Dong, X.; Sitti, M. Multi-functional soft-bodied jellyfish-like swimming. Nat. Commun. 2019, 10, 2703. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Qin, X.-H.; Hu, C.; Terzopoulou, A.; Chen, X.-Z.; Huang, T.-Y.; Maniura-Weber, K.; Pané, S.; Nelson, B.J. 3D Printed Enzymatically Biodegradable Soft Helical Microswimmers. Adv. Funct. Mater. 2018, 28, 1804107. [Google Scholar] [CrossRef]

- Zhao, Y.; Hua, M.; Yan, Y.; Wu, S.; Alsaid, Y.; He, X. Stimuli-Responsive Polymers for Soft Robotics. Annu. Rev. Control Robot. Auton. Syst. 2022, 5, 515–545. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Bodaghi, M.; Serjouei, A.; Afazov, S.; Zolfagharian, A. Adaptive reversible composite-based shape memory alloy soft actuators. Sens. Actuators A Phys. 2022, 345, 113779. [Google Scholar] [CrossRef]

- Yang, Y.; Pei, Z.; Li, Z.; Wei, Y.; Ji, Y. Making and Remaking Dynamic 3D Structures by Shining Light on Flat Liquid Crystalline Vitrimer Films without a Mold. J. Am. Chem. Soc. 2016, 138, 2118–2121. [Google Scholar] [CrossRef]

- Dong, X.; Xu, J.; Xu, X.; Dai, S.; Zhou, X.; Ma, C.; Cheng, G.; Yuan, N.; Ding, J. Sunlight-Driven Continuous Flapping-Wing Motion. ACS Appl. Mater. Interfaces 2020, 12, 6460–6470. [Google Scholar] [CrossRef]

- Park, S.-J.; Gazzola, M.; Park, K.S.; Park, S.; Di Santo, V.; Blevins, E.L.; Lind, J.U.; Campbell, P.H.; Dauth, S.; Capulli, A.K.; et al. Phototactic guidance of a tissue-engineered soft-robotic ray. Science 2016, 353, 158. [Google Scholar] [CrossRef]

- El-Atab, N.; Mishra, R.B.; Al-Modaf, F.; Joharji, L.; Alsharif, A.A.; Alamoudi, H.; Diaz, M.; Qaiser, N.; Hussain, M.M. Soft Actuators for Soft Robotic Applications: A Review. Adv. Intell. Syst. 2020, 2, 2000128. [Google Scholar] [CrossRef]

- Fusi, G.; Del Giudice, D.; Skarsetz, O.; Di Stefano, S.; Walther, A. Autonomous Soft Robots Empowered by Chemical Reaction Networks. Adv. Mater. 2023, 35, 2209870. [Google Scholar] [CrossRef]

- Bartlett, N.W.; Tolley, M.T.; Overvelde, J.T.B.; Weaver, J.C.; Mosadegh, B.; Bertoldi, K.; Whitesides, G.M.; Wood, R.J. A 3D-printed, functionally graded soft robot powered by combustion. Science 2015, 349, 161–165. [Google Scholar] [CrossRef]

- Li, M.; Pal, A.; Aghakhani, A.; Pena-Francesch, A.; Sitti, M. Soft actuators for real-world applications. Nat. Rev. Mater 2022, 7, 235–249. [Google Scholar] [CrossRef] [PubMed]

- Ansari, M.H.; Ha, X.T.; Ourak, M.; Borghesan, G.; Iacovacci, V.; Vander Poorten, E.; Menciassi, A. Characterization of a 3D Printed Endovascular Magnetic Catheter. Actuators 2023, 12, 409. [Google Scholar] [CrossRef]

- Carpi, F.; Pappone, C. Stereotaxis Niobe magnetic navigation system for endocardial catheter ablation and gastrointestinal capsule endoscopy. Expert Rev. Med. Devices 2009, 6, 487–498. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, F.; Waqas, M.; Jawed, B.; Soomro, A.M.; Kumar, S.; Hina, A.; Khan, U.; Kim, K.H.; Choi, K.H. Decade of bio-inspired soft robots: A review. Smart Mater. Struct. 2022, 31, 073002. [Google Scholar] [CrossRef]

- Roche, E.T.; Wohlfarth, R.; Overvelde, J.T.; Vasilyev, N.V.; Pigula, F.A.; Mooney, D.J.; Bertoldi, K.; Walsh, C.J. A bioinspired soft actuated material. Adv. Mater 2014, 26, 1200–1206. [Google Scholar] [CrossRef]

- Sahu, S.K.; Tamadon, I.; Rosa, B.; Renaud, P.; Menciassi, A. A Spring-Based Inductive Sensor for Soft and Flexible Robots. IEEE Sens. J. 2022, 22, 19931–19940. [Google Scholar] [CrossRef]

- Polykretis, I.; Supic, L.; Danielescu, A. Bioinspired smooth neuromorphic control for robotic arms. Neuromorphic Comput. Eng. 2023, 3, 014013. [Google Scholar] [CrossRef]

- Wang, T.; Jin, T.; Lin, W.; Lin, Y.; Liu, H.; Yue, T.; Tian, Y.; Li, L.; Zhang, Q.; Lee, C. Multimodal Sensors Enabled Autonomous Soft Robotic System with Self-Adaptive Manipulation. ACS Nano 2024, 18, 9980–9996. [Google Scholar] [CrossRef] [PubMed]

- Laschi, C.; Matteo, C.; Barbara, M.; Laura, M.; Maurizio, F.; and Dario, P. Soft Robot Arm Inspired by the Octopus. Adv. Robot. 2012, 26, 709–727. [Google Scholar] [CrossRef]

- Cianchetti, M. Embodied Intelligence in Soft Robotics Through Hardware Multifunctionality. Front. Robot. AI 2021, 8, 724056. [Google Scholar] [CrossRef]

- Sun, J.; Lerner, E.; Tighe, B.; Middlemist, C.; Zhao, J. Embedded shape morphing for morphologically adaptive robots. Nat. Commun. 2023, 14, 6023. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B. Lessons from animals and plants: The symbiosis of morphological computation and soft robotics. IEEE Robot. Autom. Mag. 2016, 23, 107–114. [Google Scholar] [CrossRef]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef] [PubMed]

- Cangelosi, A.; Bongard, J.; Fischer, M.H.; Nolfi, S. Embodied intelligence. In Springer Handbook of Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2015; pp. 697–714. [Google Scholar]

- Floreano, D.; Mondada, F.; Perez-Uribe, A.; Roggen, D. Evolution of embodied intelligence. In Proceedings of the Embodied Artificial Intelligence: International Seminar, Dagstuhl Castle, Germany, 7–11 July 2003; Revised Papers. 2004; pp. 293–311. [Google Scholar]

- Sitti, M. Physical intelligence as a new paradigm. Extrem. Mech. Lett. 2021, 46, 101340. [Google Scholar] [CrossRef]

- Harvey, K. Embodied Intelligence through Coordination Dynamics in the Brain-Body Complex. Int. J. Basic Appl. Sci. 2019, 3, 37–54. [Google Scholar]

- Tauber, F.; Desmulliez, M.; Piccin, O.; Stokes, A.A. Perspective for soft robotics: The field’s past and future. Bioinspiration Biomim. 2023, 18, 035001. [Google Scholar] [CrossRef]

- Mengaldo, G.; Renda, F.; Brunton, S.L.; Bächer, M.; Calisti, M.; Duriez, C.; Chirikjian, G.S.; Laschi, C. A concise guide to modelling the physics of embodied intelligence in soft robotics. Nat. Rev. Phys. 2022, 4, 595–610. [Google Scholar] [CrossRef]

- Laschi, C. Embodied Intelligence in soft robotics: Joys and sorrows. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1261, 012002. [Google Scholar] [CrossRef]

- Lara, B.; Astorga, D.; Mendoza-Bock, E.; Pardo, M.; Escobar, E.; Ciria, A. Embodied Cognitive Robotics and the learning of sensorimotor schemes. Adapt. Behav. 2018, 26, 225–238. [Google Scholar] [CrossRef]

- Hartmann, F.; Baumgartner, M.; Kaltenbrunner, M. Becoming Sustainable, The New Frontier in Soft Robotics. Adv. Mater. 2021, 33, 2004413. [Google Scholar] [CrossRef]

- Wang, Z.; Or, K.; Hirai, S. A dual-mode soft gripper for food packaging. Robot. Auton. Syst. 2020, 125, 103427. [Google Scholar] [CrossRef]

- Hao, Y.; Gong, Z.; Xie, Z.; Guan, S.; Yang, X.; Wang, T.; Wen, L. A Soft Bionic Gripper with Variable Effective Length. J. Bionic Eng. 2018, 15, 220–235. [Google Scholar] [CrossRef]

- Fusco, S.; Sakar, M.S.; Kennedy, S.; Peters, C.; Bottani, R.; Starsich, F.; Mao, A.; Sotiriou, G.A.; Pané, S.; Pratsinis, S.E.; et al. An Integrated Microrobotic Platform for On-Demand, Targeted Therapeutic Interventions. Adv. Mater. 2014, 26, 952–957. [Google Scholar] [CrossRef]

- Mohammadi, A.; Lavranos, J.; Zhou, H.; Mutlu, R.; Alici, G.; Tan, Y.; Choong, P.; Oetomo, D. A practical 3D-printed soft robotic prosthetic hand with multi-articulating capabilities. PLoS ONE 2020, 15, e0232766. [Google Scholar] [CrossRef]

- Das, R.; Babu, S.P.M.; Visentin, F.; Palagi, S.; Mazzolai, B. An earthworm-like modular soft robot for locomotion in multi-terrain environments. Sci. Rep. 2023, 13, 1571. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Ilievski, F.; Choi, W.; Morin, S.A.; Stokes, A.A.; Mazzeo, A.D.; Chen, X.; Wang, M.; Whitesides, G.M. Multigait soft robot. Proc. Natl. Acad. Sci. USA 2011, 108, 20400–20403. [Google Scholar] [CrossRef] [PubMed]

- Hammond, M.; Cichella, V.; Lamuta, C. Bioinspired Soft Robotics: State of the Art, Challenges, and Future Directions. Curr. Robot. Rep. 2023, 4, 65–80. [Google Scholar] [CrossRef]

- Isaka, K.; Tsumura, K.; Watanabe, T.; Toyama, W.; Sugesawa, M.; Yamada, Y.; Yoshida, H.; Nakamura, T. Development of underwater drilling robot based on earthworm locomotion. IEEE Access 2019, 7, 103127–103141. [Google Scholar] [CrossRef]

- Zhu, J.; Lyu, L.; Xu, Y.; Liang, H.; Zhang, X.; Ding, H.; Wu, Z. Intelligent soft surgical robots for next-generation minimally invasive surgery. Adv. Intell. Syst. 2021, 3, 2100011. [Google Scholar] [CrossRef]

- Tse, Z.; Chen, Y.; Hovet, S.; Monfaredi, R.; Xu, S.; Wood, B.; Cleary, K. Soft Robotics in Medical Applications. J. Med. Robot. Res. 2018, 3, 1841006. [Google Scholar] [CrossRef]

- Tauber, F.J.; Slesarenko, V. Early career scientists converse on the future of soft robotics. Front. Robot. AI 2023, 10, 1129827. [Google Scholar] [CrossRef] [PubMed]

- Pan, M.; Yuan, C.; Liang, X.; Dong, T.; Liu, T.; Zhang, J.; Zou, J.; Yang, H.; Bowen, C. Soft Actuators and Robotic Devices for Rehabilitation and Assistance. Adv. Intell. Syst. 2022, 4, 2100140. [Google Scholar] [CrossRef]

- Delmerico, J.; Mintchev, S.; Giusti, A.; Gromov, B.; Melo, K.; Horvat, T.; Cadena, C.; Hutter, M.; Ijspeert, A.; Floreano, D.; et al. The current state and future outlook of rescue robotics. J. Field Robot. 2019, 36, 1171–1191. [Google Scholar] [CrossRef]

- Aracri, S.; Giorgio-Serchi, F.; Suaria, G.; Sayed, M.E.; Nemitz, M.P.; Mahon, S.; Stokes, A.A. Soft robots for ocean exploration and offshore operations: A perspective. Soft Robot. 2021, 8, 625–639. [Google Scholar] [CrossRef]

- Hughes, J.; Culha, U.; Giardina, F.; Guenther, F.; Rosendo, A.; Iida, F. Soft manipulators and grippers: A review. Front. Robot. AI 2016, 3, 69. [Google Scholar] [CrossRef]

- Wegener, K.; Damm, O.; Harst, S.; Ihlenfeldt, S.; Monostori, L.; Teti, R.; Wertheim, R.; Byrne, G. Biologicalisation in manufacturing–Current state and future trends. CIRP Ann. 2023, 72, 781–807. [Google Scholar] [CrossRef]

- Gao, S.; Dai, Y.; Nathan, A. Tactile and Vision Perception for Intelligent Humanoids. Adv. Intell. Syst. 2022, 4, 2100074. [Google Scholar] [CrossRef]

- Xiong, J.; Chen, J.; Lee, P.S. Functional Fibers and Fabrics for Soft Robotics, Wearables, and Human–Robot Interface. Adv. Mater. 2021, 33, 2002640. [Google Scholar] [CrossRef]

- Islam, M.A.; Talukder, L.; Al, M.F.; Sarker, S.K.; Muyeen, S.M.; Das, P.; Hasan, M.M.; Das, S.K.; Islam, M.M.; Islam, M.R.; et al. A review on self-healing featured soft robotics. Front. Robot. AI 2023, 10, 1202584. [Google Scholar] [CrossRef]

- Roels, E.; Terryn, S.; Iida, F.; Bosman, A.; Norvez, S.; Clemens, F.; Van Assche, G.; Vanderborght, B.; Brancart, J. Processing of Self-Healing Polymers for Soft Robotics. Adv. Mater. 2021, 34, e2104798. [Google Scholar] [CrossRef]

- Horvath, M.A.; Hu, L.; Mueller, T.; Hochstein, J.; Rosalia, L.; Hibbert, K.A.; Hardin, C.C.; Roche, E.T. An organosynthetic soft robotic respiratory simulator. APL Bioeng. 2020, 4, 026108. [Google Scholar] [CrossRef] [PubMed]

- Duggal, A.S.; Malik, P.K.; Gehlot, A.; Singh, R.; Gaba, G.S.; Masud, M.; Al-Amri, J.F. A sequential roadmap to Industry 6.0: Exploring future manufacturing trends. IET Commun. 2022, 16, 521–531. [Google Scholar] [CrossRef]

- Berrueta, T.A.; Murphey, T.D.; Truby, R.L. Materializing Autonomy in Soft Robots across Scales. Adv. Intell. Syst. 2024, 6, 2300111. [Google Scholar] [CrossRef]

- Li, P.; Yin, R.; Cheng, J.; Lin, J. Bacterial Biofilm Formation on Biomaterials and Approaches to Its Treatment and Prevention. Int. J. Mol. Sci. 2023, 24, 11680. [Google Scholar] [CrossRef]

- Lam, M.; Migonney, V.; Falentin-Daudre, C. Review of silicone surface modification techniques and coatings for antibacterial/antimicrobial applications to improve breast implant surfaces. Acta Biomater. 2021, 121, 68–88. [Google Scholar] [CrossRef]

- Li, D.; Dornadula, V.; Lin, K.; Wehner, M. Position Control for Soft Actuators, Next Steps toward Inherently Safe Interaction. Electronics 2021, 10, 1116. [Google Scholar] [CrossRef]

- Eiben, Á.E.; Ellers, J.; Meynen, G.; Nyholm, S. Robot Evolution: Ethical Concerns. Front. Robot. AI 2021, 8. [Google Scholar] [CrossRef]

- Wachter, S.; Mittelstadt, B.; Floridi, L. Transparent, Explainable, and Accountable AI for Robotics. Sci. Robot. 2017, 2, eaan6080. [Google Scholar] [CrossRef] [PubMed]

- Daniel, S. The Impact of Artificial Intelligence on Employment and Workforce Dynamics in Contemporary Society Author(s); Ladoke Akintola University of Technology: Ogbomosho, Nigeria, 2023. [Google Scholar] [CrossRef]

- Elendu, C.; Amaechi, D.C.; Elendu, T.C.; Jingwa, K.A.; Okoye, O.K.; John Okah, M.; Ladele, J.A.; Farah, A.H.; Alimi, H.A. Ethical implications of AI and robotics in healthcare: A review. Medicine 2023, 102, e36671. [Google Scholar] [CrossRef]

- Lin, Z.; Jiang, T.; Shang, J. The emerging technology of biohybrid micro-robots: A review. Bio-Des. Manuf. 2022, 5, 107–132. [Google Scholar] [CrossRef]

- Mousa, M.; Soliman, M.; Saleh, M.; Radwan, A. Biohybrid Soft Robots, E-Skin, and Bioimpedance Potential to Build Up Their Applications: A Review. IEEE Access 2020, 8, 184524–184539. [Google Scholar] [CrossRef]

- Sohn, S.; Buskirk, M.V.; Buckenmeyer, M.J.; Londono, R.; Faulk, D. Whole organ engineering: Approaches, challenges, and future directions. Appl. Sci. 2020, 10, 4277. [Google Scholar] [CrossRef]

- Singh, A.V.; Varma, M.; Rai, M.; Pratap Singh, S.; Bansod, G.; Laux, P.; Luch, A. Advancing Predictive Risk Assessment of Chemicals via Integrating Machine Learning, Computational Modeling, and Chemical/Nano-Quantitative Structure-Activity Relationship Approaches. Adv. Intell. Syst. 2024, 6, 2300366. [Google Scholar] [CrossRef]

- Singh, A.V.; Shelar, A.; Rai, M.; Laux, P.; Thakur, M.; Dosnkyi, I.; Santomauro, G.; Singh, A.K.; Luch, A.; Patil, R.; et al. Harmonization Risks and Rewards: Nano-QSAR for Agricultural Nanomaterials. J. Agric. Food Chem. 2024, 72, 2835–2852. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.V.; Bansod, G.; Mahajan, M.; Dietrich, P.; Singh, S.P.; Rav, K.; Thissen, A.; Bharde, A.M.; Rothenstein, D.; Kulkarni, S.; et al. Digital Transformation in Toxicology: Improving Communication and Efficiency in Risk Assessment. ACS Omega 2023, 8, 21377–21390. [Google Scholar] [CrossRef]

- Rai, M.; Singh, A.V.; Paudel, N.; Kanase, A.; Falletta, E.; Kerkar, P.; Heyda, J.; Barghash, R.F.; Pratap Singh, S.; Soos, M. Herbal concoction Unveiled: A computational analysis of phytochemicals’ pharmacokinetic and toxicological profiles using novel approach methodologies (NAMs). Curr. Res. Toxicol. 2023, 5, 100118. [Google Scholar] [CrossRef]

- Singh, A.V.; Bansod, G.; Schumann, A.; Bierkandt, F.S.; Laux, P.; Nakhale, S.V.; Shelar, A.; Patil, R.; Luch, A. Analyzing Tattoo Pigments in a Laboratory Setting: Application of UV-Vis and FTIR Spectroscopy Methods supported with Chemometric Modelling. Researchsquare 2023, Preprint. [Google Scholar] [CrossRef]

| Material Type | E | Material Selection: Application | Actuation Criteria: Application | References | ||

|---|---|---|---|---|---|---|

| Electroactive polymers | 0.01–10 MPa | >200% | Flexibility, responsiveness, durability | Electrical stimulation, mechanical deformation | [40] | |

| Magnetic soft composites | ~0.1–10 MPa | ~2 MPa | >200% | Magnetic responsiveness, structural integrity | Magnetic fields | [34,35] |

| Stimuli-responsive hydrogels | 10–100 kPa | 1 kPa–1 MPa | 2–100% | Swelling behavior, mechanical properties | Various stimuli (e.g., temperature, pH) | [41] |

| Liquid crystal elastomers | 0.1–100 MPa | 1–10 MPa | >200% | Mechanical properties | Various stimuli (e.g., heat, light, electricity) | [42] |

| Shape memory alloys | 50–100 GPa | Up to 1.5 GPa | Up to 15% | Shape recovery, biocompatibility | Thermal activation | [43,44] |

| Robot Characteristics | Soft Machines | Conventional Hard Robotics |

|---|---|---|

| Compliance | Able to bend and twist with high curvatures and exhibit unprecedented adaptation, sensitivity, and agility. Soft materials are elastic and can deform and absorb much of the energy arising from a collision, so large degrees of freedom (DoFs). | Poor grasping power and mobility over soft surfaces. Hard materials perform single tasks efficiently, but often with limited compliance due to rigid links and joints. |

| Adaptability | Soft machines can adapt their shape to the environment, enabling their use in confined spaces. | Hard robots have limited adaptability due to rigid links and joints, restricting their use in confined spaces. |

| Material’s Young’s modulus | Soft materials like skin or muscle tissue have a Young’s modulus ranging from 104 to 109 Pa. | Hard materials like metals or hard plastics have a Young’s modulus ranging from 109 to 1012 Pa. |

| Actuation force | Soft structures are usually able to apply weak forces and torques. | Conventional actuators can apply high forces and torques. |

| Ease of integrating subsystems | Integrating sensing, actuation, computation, power storage, and communication into controllable soft-bodied material is difficult. Subsystems may move with respect to each other. | Subsystems can be attached firmly to the body. |

| Ease of fabrication | Soft machines are usually fabricated using multimaterial 3D printing, soft lithography, and molding and casting. | Hard robots are usually fabricated using 3D printing, machining, and injection molding. |

| Ease of control | Soft machines have an infinite number of degrees of freedom due to their ability to bend, twist, stretch, compress, buckle, wrinkle, and exhibit elasticity. Control is challenging and requires new approaches to modeling, control, dynamics, and high-level planning. | Hard robots generally have 6 degrees of freedom (DoFs) (three rotations and three translations about the x, y, and z axes). |

| Actuation principle | Soft machines utilize fluidic, electrical, light-based, magnetic, chemical, or thermal actuation. | Hard robots usually utilize electric or fluidic actuation. |

| Sensing | Soft machines use piezoelectric polymers, stretchable electronics, and various strains, including tensile, shear, or curvature, measured with layered channel geometries for sensing environmental signals. | Hard robots use encoders, metal or semiconductor strain gauges, or inertial measurement units (IMUs) for sensing. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, A.V.; Ansari, M.H.D.; Dey, A.K.; Laux, P.; Samal, S.K.; Malgaretti, P.; Mohapatra, S.R.; Busse, M.; Suar, M.; Tisato, V.; et al. Bioinspired Soft Machines: Engineering Nature’s Grace into Future Innovations. J. Funct. Biomater. 2025, 16, 158. https://doi.org/10.3390/jfb16050158

Singh AV, Ansari MHD, Dey AK, Laux P, Samal SK, Malgaretti P, Mohapatra SR, Busse M, Suar M, Tisato V, et al. Bioinspired Soft Machines: Engineering Nature’s Grace into Future Innovations. Journal of Functional Biomaterials. 2025; 16(5):158. https://doi.org/10.3390/jfb16050158

Chicago/Turabian StyleSingh, Ajay Vikram, Mohammad Hasan Dad Ansari, Arindam K. Dey, Peter Laux, Shailesh Kumar Samal, Paolo Malgaretti, Soumya Ranjan Mohapatra, Madleen Busse, Mrutyunjay Suar, Veronica Tisato, and et al. 2025. "Bioinspired Soft Machines: Engineering Nature’s Grace into Future Innovations" Journal of Functional Biomaterials 16, no. 5: 158. https://doi.org/10.3390/jfb16050158

APA StyleSingh, A. V., Ansari, M. H. D., Dey, A. K., Laux, P., Samal, S. K., Malgaretti, P., Mohapatra, S. R., Busse, M., Suar, M., Tisato, V., & Gemmati, D. (2025). Bioinspired Soft Machines: Engineering Nature’s Grace into Future Innovations. Journal of Functional Biomaterials, 16(5), 158. https://doi.org/10.3390/jfb16050158