From Three-Dimensional (3D)- to 6D-Printing Technology in Orthopedics: Science Fiction or Scientific Reality?

Abstract

:1. Introduction

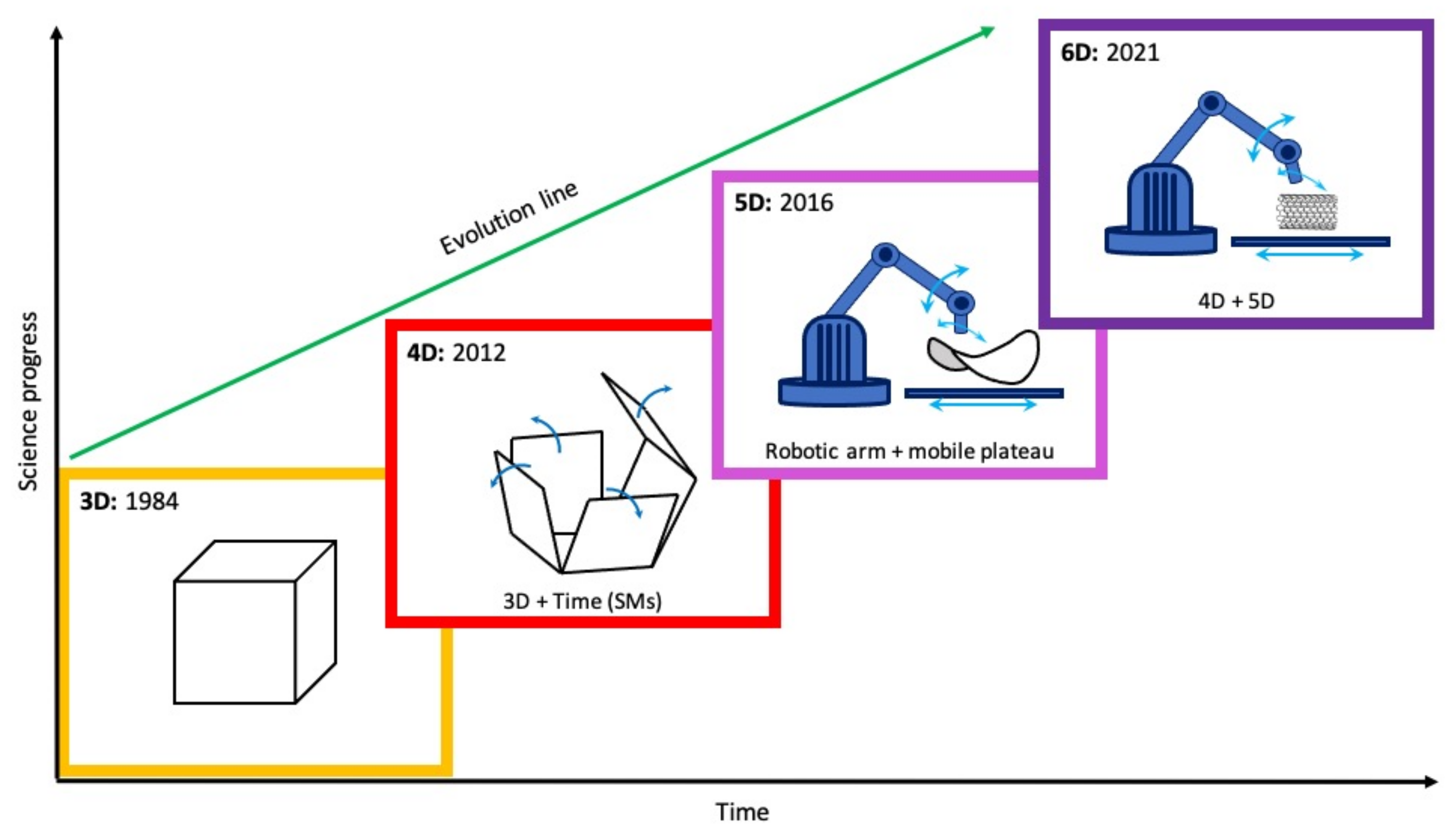

2. From 3D to 6D Printing Technology

3. 3D, 4D, 5D and 6D Printing: Key Aspects and Differences among Different Printing Technologies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghilan, A.; Chiriac, A.P.; Nita, L.E.; Rusu, A.G.; Neamtu, I.; Mihai Chiriac, V. Trends in 3D printing processes for biomedical field: Opportunities and challenges. J. Polym. Environ. 2020, 28, 1345–1367. [Google Scholar] [CrossRef] [PubMed]

- Vaish, A.; Vaish, R. 3D printing and its application in orthopedics. J. Clin. Orthop. Trauma 2018, 9, S74–S75. [Google Scholar] [CrossRef] [PubMed]

- Vasiliadis, A.V.; Koukoulias, N.; Katakalos, K. Three-dimensional-printed scaffolds for meniscus tissue engineering: Opportunity for the future in the orthopaedic world. J. Funct. Biomat. 2021, 12, 69. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufactruring (3D printing): A review of materials, methods, applications and challenges. Compos. B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Courtial, E.-J.; Colly, A.; Marquette, C. Dynamic molding: Additive manufacturing in partially ordered system. Addit. Manuf. 2022, 51, 102598. [Google Scholar] [CrossRef]

- Duan, X.; Wang, B.; Yang, L.; Kadakia, A.R. Applications of 3D printing technology in orthopedic treatment. BioMed Res. Int. 2021, 2021, 9892456. [Google Scholar] [CrossRef]

- Morgan, C.; Khatri, C.; Hanna, S.A.; Ashrafian, H.; Sarraf, K.M. Use of three-dimensional printing in preoperative planning in orthopaedic trauma surgery: A systematic review and meta-analysis. World J. Orthop. 2020, 11, 57–67. [Google Scholar] [CrossRef]

- Mazy, D.; Elbaum, R.; Beckers, G.; Matriche, C.; Vannieuwenhove, O. Orthopaedic support with 3D printing in children: Marketing effect or solution of the future? Acta. Orthop. Belg. 2020, 86, 378–382. [Google Scholar]

- Raza, M.; Murphy, D.; Gelfer, Y. The effect of three-dimensional (3D) printing on quantitative and qualitative outcomes in paediatric orthopaedic osteotomies: A systematic review. EFORT Open Rev. 2021, 6, 130–138. [Google Scholar] [CrossRef]

- Kumar, P.; Vatsya, P.; Kumar Rajnish, R.; Hooda, A.; Dhillon, M.S. Application of 3D printing in hip and knee arthroplasty: A narrative review. Indian J. Orthop. 2020, 55, 14–26. [Google Scholar] [CrossRef]

- Tserovski, S.; Georgieva, S.; Simeonov, R.; Bigdeli, A.; Rottinger, H.; Kinov, P. Advantages and disadvantages of 3D printing for pre-operative planning of revision hip surgery. J. Surg. Case Rep. 2019, 2019, rjz214. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, G.; Frisoni, T.; Spazzoli, B.; Lucchese, A.; Donati, D. Computer assisted surgery and 3D printing in orthopaedic oncology: A lesson learned by cranio-maxillo-facial surgery. Appl. Sci. 2021, 11, 8584. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Pratap Singh, R.; Suman, R. Significant roles of 4D printing using smart materials in the field of manufacturing. Adv. Ind. Eng. Polym. Res. 2021, 11, 301–311. [Google Scholar] [CrossRef]

- Zhou, W.; Qiao, Z.; Nazarzadeh Zare, E.; Huang, J.; Zheng, X.; Sun, X.; Shao, M.; Wang, H.; Wang, X.; Chen, D.; et al. 4D-printed dynamic materials in biomedical applications: Chemistry, challenges and their future perspectives in the clinical sector. J. Med. Chem. 2020, 63, 8003–8024. [Google Scholar] [CrossRef] [PubMed]

- Javaid, M.; Haleem, A. Significant advancements of 4D printing in the field of orthopaedics. J. Clin. Orthop. Trauma 2020, 11, S485–S490. [Google Scholar] [CrossRef]

- Sahafnejad-Mohammadi, I.; Karamimoghadam, M.; Zolfagharian, A.; Akrami, M.; Bodaghi, M. 4D printing technology in medical engineering: A narrative review. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 233. [Google Scholar] [CrossRef]

- Wan, Z.; Zhang, P.; Liu, Y.; Lv, L.; Zhou, Y. Four-dimensional bioprinting: Current developments and applications in bone tissue engineering. Acta. Biomater. 2020, 101, 26–42. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Vaishya, R. 4D printing and its applications in Orthopaedics. J. Clin. Orthop. Trauma 2018, 9, 275–276. [Google Scholar] [CrossRef]

- Hamza, H. Dental 4D printing: An innovative approach. Innovation 2018, 1, e17. [Google Scholar]

- Liu, G.; He, Y.; Liu, P.; Chen, Z.; Chen, X.; Wan, L.; Li, Y.; Lu, J. Development of bioimplants with 2D, 3D and 4D additive manufacturing materials. Engineering 2020, 6, 1232–1243. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Vaishya, R. 5D printing and its expected applications in orthopaedics. J. Clin. Orthop. Trauma 2019, 10, 809–810. [Google Scholar] [CrossRef] [PubMed]

- Georgantzinos, S.K.; Giannopoulos, G.I.; Bakalis, P.A. Additive manufacturing for effective smart structures: The idea of 6D printing. J. Compos. Sci. 2021, 5, 119. [Google Scholar] [CrossRef]

- Ganesan, B.; Luximon, A.; Al-Jumaily, A.; Balasankar, S.K.; Naik, G.R. Ponseti method in the management of clubfoot under 2 years of age: A systematic review. PLoS ONE 2017, 12, e0178299. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tack, P.; Victor, J.; Gemmel, P.; Annemans, L. 3D-printing techniques in a medical setting: A systematic literature review. Biomed. Eng. Online 2016, 15, 115. [Google Scholar] [CrossRef] [Green Version]

- Hada, T.; Kanazawa, M.; Iwaki, M.; Arakida, T.; Soeda, Y.; Katheng, A.; Otake, R.; Minakuchi, S. Effect of printing direction on the accuracy of 3D-printed dentures using stereolithography technology. Materials 2020, 13, 3405. [Google Scholar] [CrossRef] [PubMed]

- Chu, H.; Yang, E.; Sun, L.; Cai, S.; Yang, R.; Liang, W.; Yu, H.; Liu, L. 4D printing: A review on recent progresses. Micromachines 2020, 11, 796. [Google Scholar] [CrossRef]

- Rahman, M.; Almalki, W.H.; Alghamdi, S.; Alharbi, K.S.; Khalilullah, H.; Akhter, H.; Keshari, A.K.; Sharma, N.; Singh, T.; Soni, K.; et al. Three ‘D’s: Design approach, dimensional printing, and drug delivery systems as promising tools in healthcare applications. Drug Discov. Today 2021, 26, 2726–2733. [Google Scholar] [CrossRef]

| Characteristics | 3D Printing | 4D Printing | 5D Printing | 6D Printing |

|---|---|---|---|---|

| Building process | A programmed path fabricates a structure by a layer-by-layer fashion from bottom to top. | 4D printing is mainly based on 3D printing. | 5D printing produces objects from five directions (the print object moves while the printer head is printing). | 6D printing is a combination of 4D and 5D printing. |

| Materials used | Uses thermoplastic polycarbonate, acrylonitrile styrene, photopolymers, resins. | Uses smart materials, including shape memory polymers (SMPs) and hydrogels. | Uses same materials with 3D printing. | Uses smart materials with single or multiple intelligences. |

| Object shape and durability | Not good in the manufacturing of complex objects. | Object that changes shape due to external stimuli over time. | Object with a curved layer and three to five times stronger than a 3D-printed object. | Capable of changing its shape or properties. |

| Applications | Biomedical and pharmacological engineering, anatomical designs, medicine, dentistry, aerospace, electronics, education, entertainment, automobile, fashion, defense. | Higher accuracy in medical devices, constructions, aerospace engineering and the manufacturing industry. | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasiliadis, A.V.; Koukoulias, N.; Katakalos, K. From Three-Dimensional (3D)- to 6D-Printing Technology in Orthopedics: Science Fiction or Scientific Reality? J. Funct. Biomater. 2022, 13, 101. https://doi.org/10.3390/jfb13030101

Vasiliadis AV, Koukoulias N, Katakalos K. From Three-Dimensional (3D)- to 6D-Printing Technology in Orthopedics: Science Fiction or Scientific Reality? Journal of Functional Biomaterials. 2022; 13(3):101. https://doi.org/10.3390/jfb13030101

Chicago/Turabian StyleVasiliadis, Angelo V., Nikolaos Koukoulias, and Konstantinos Katakalos. 2022. "From Three-Dimensional (3D)- to 6D-Printing Technology in Orthopedics: Science Fiction or Scientific Reality?" Journal of Functional Biomaterials 13, no. 3: 101. https://doi.org/10.3390/jfb13030101

APA StyleVasiliadis, A. V., Koukoulias, N., & Katakalos, K. (2022). From Three-Dimensional (3D)- to 6D-Printing Technology in Orthopedics: Science Fiction or Scientific Reality? Journal of Functional Biomaterials, 13(3), 101. https://doi.org/10.3390/jfb13030101