3D Printing of Hierarchically Porous Lattice Structures Based on Åkermanite Glass Microspheres and Reactive Silicone Binder

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

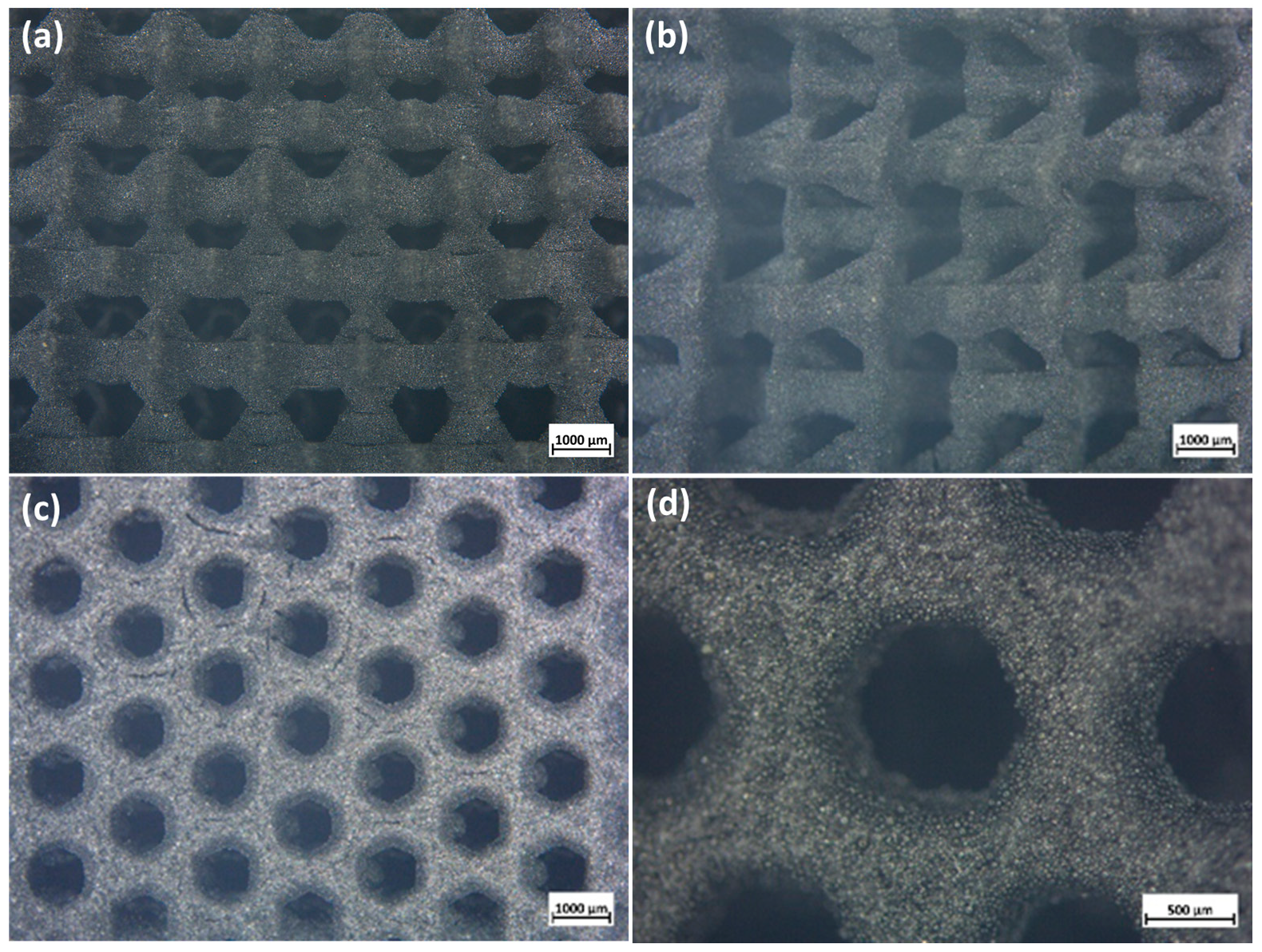

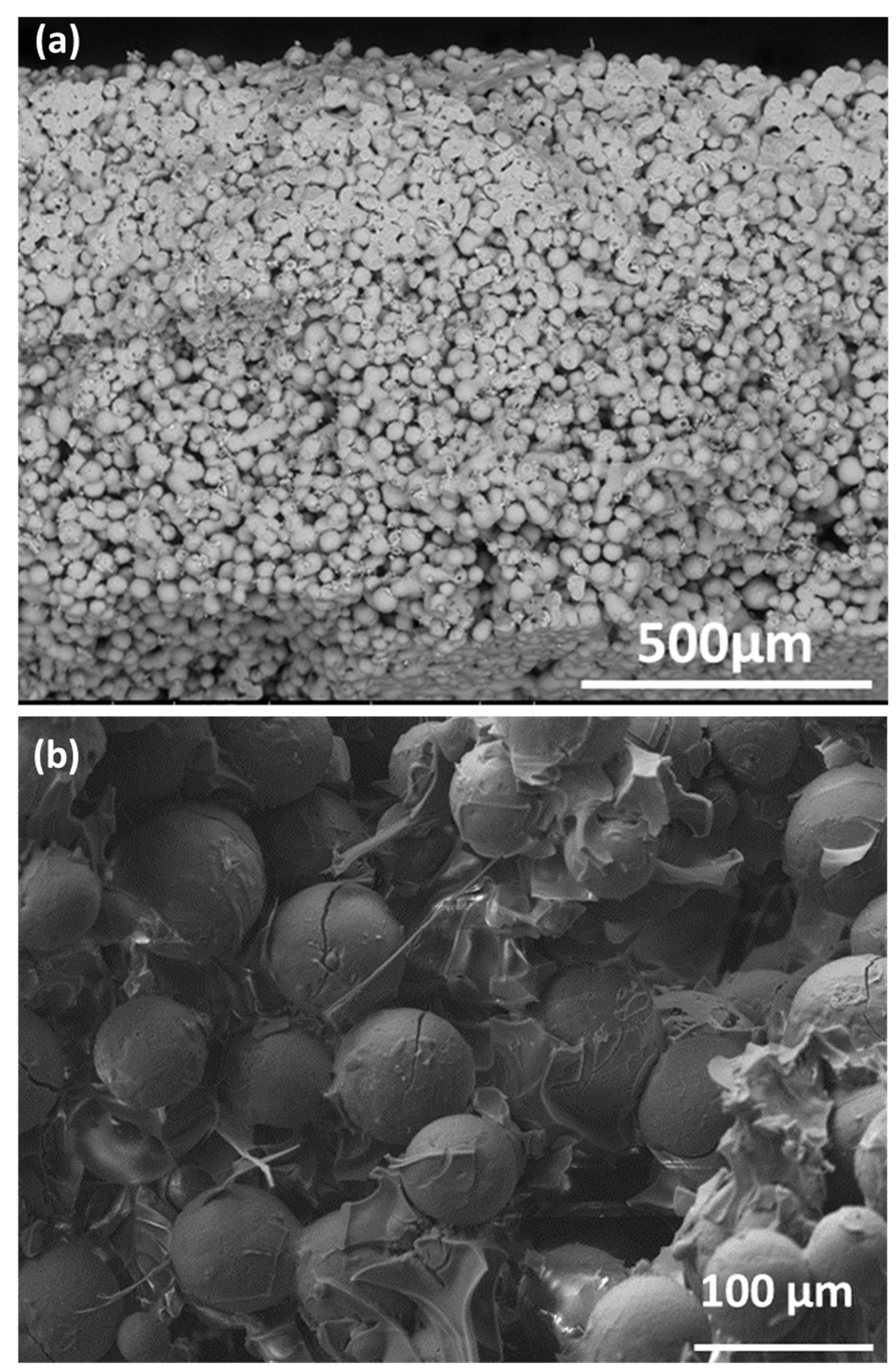

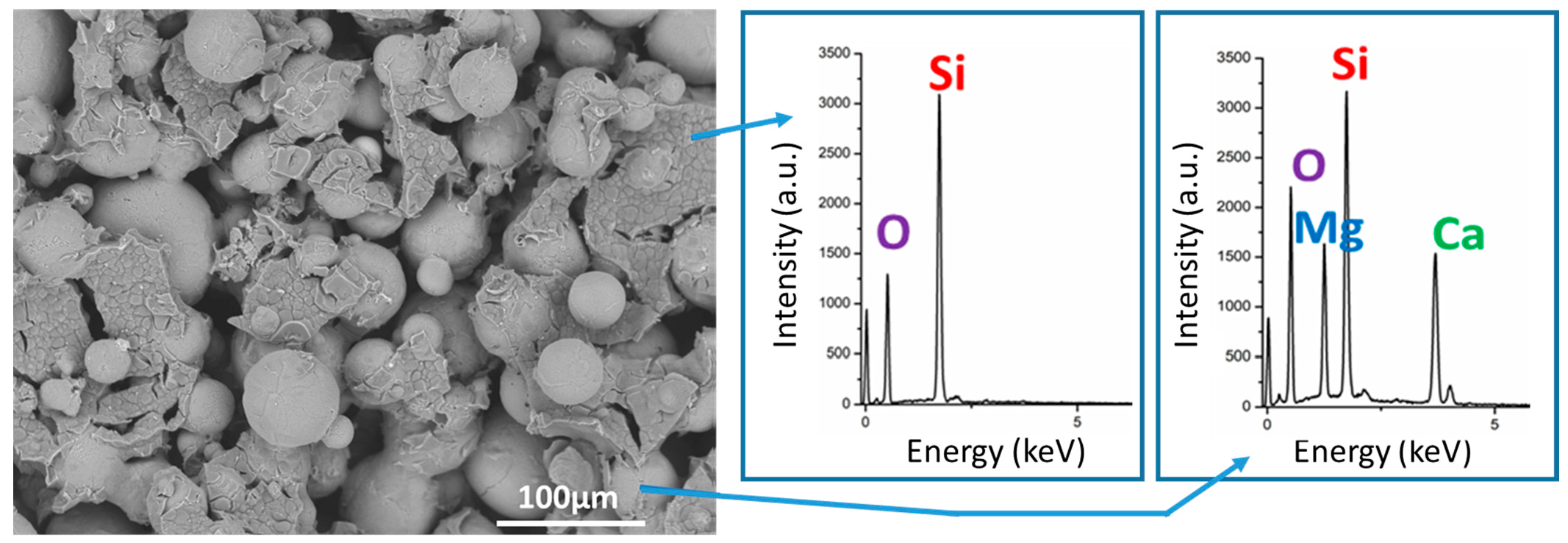

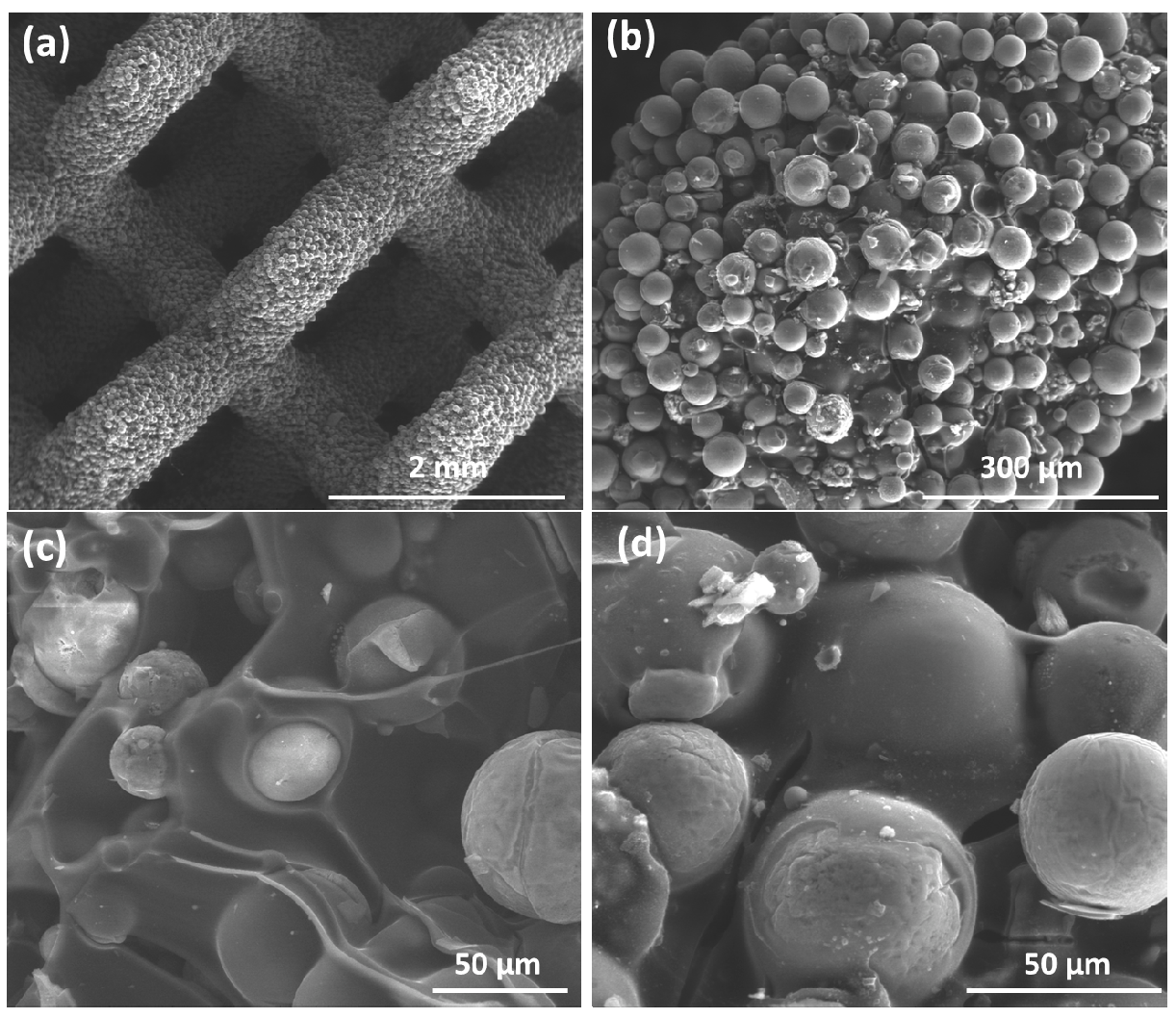

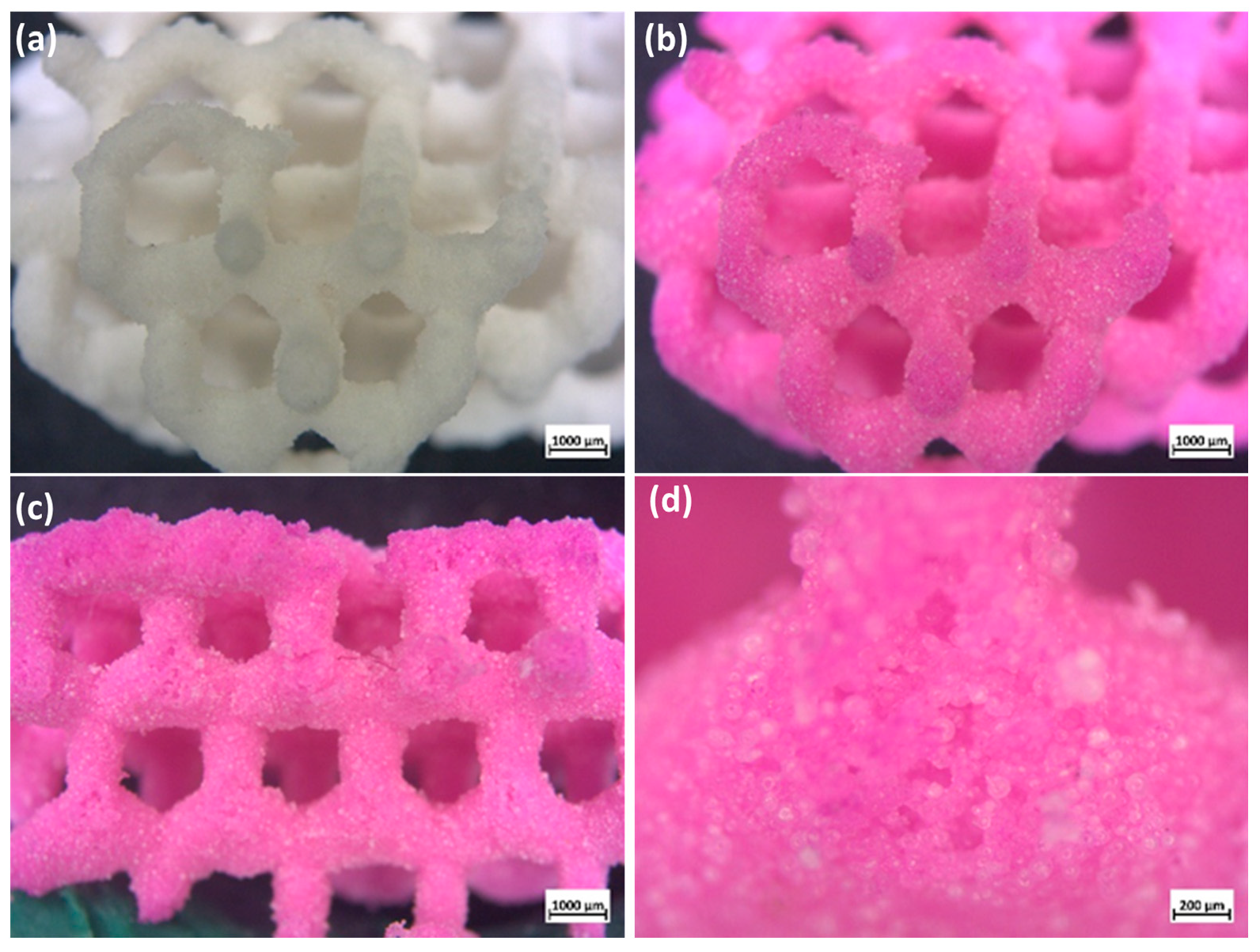

- Spherical shaped glass particles were selected to fabricate the green scaffolds. The photocurable slurry comprises photosensitive resin, 65 wt% glass microbeads, and 10 wt% silicone resin, the latter found to impart structural integrity to the scaffolds, despite poor sintering of microbeads.

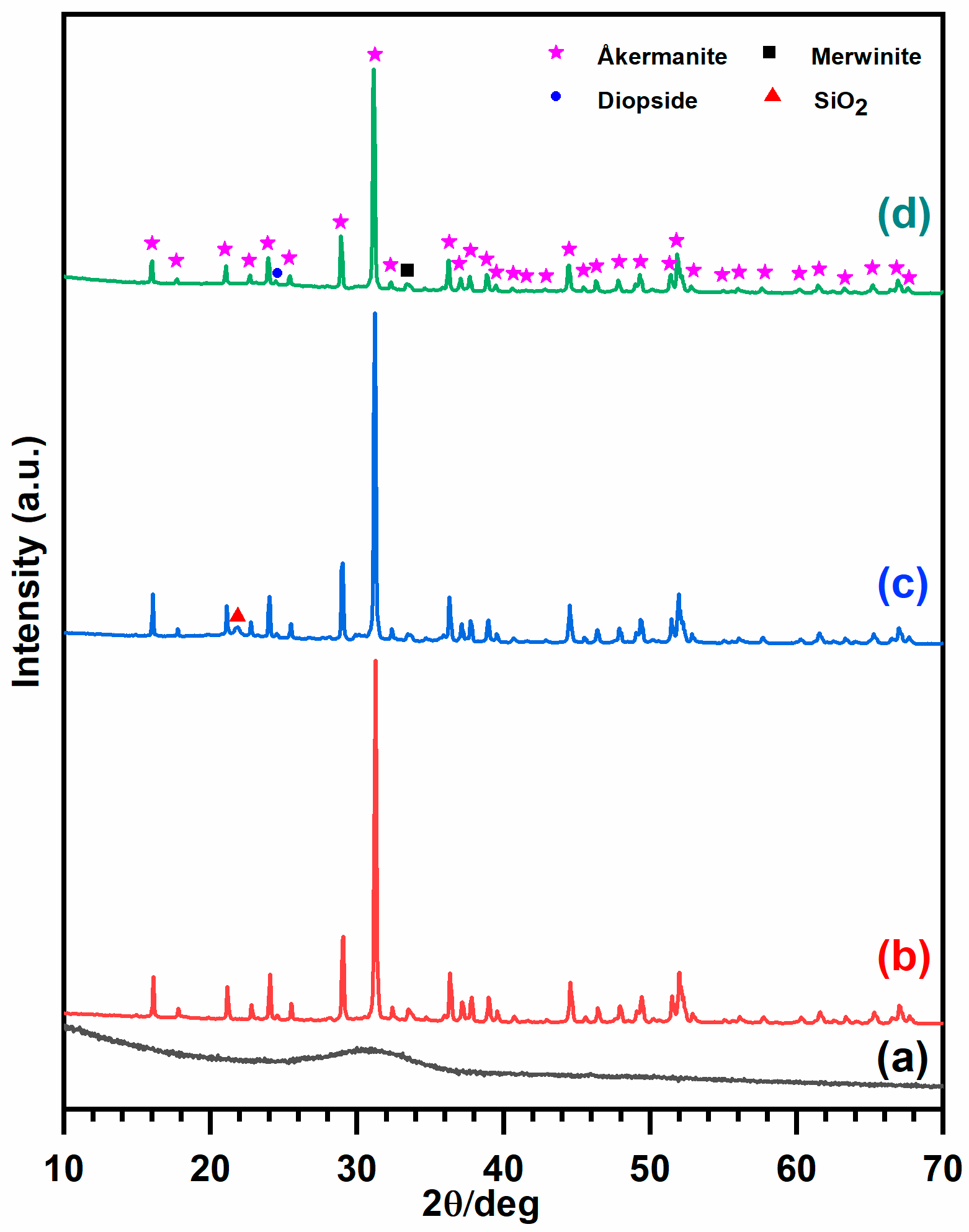

- The formation of åkermanite phase was dominant at the applied sintering temperature of 1100 °C. The firing conditions (firing in air or nitrogen) did not affect the crystallization of åkermanite, but affected the transformation of silicone resin into (partly crystallized) silica or fully amorphous SiOC.

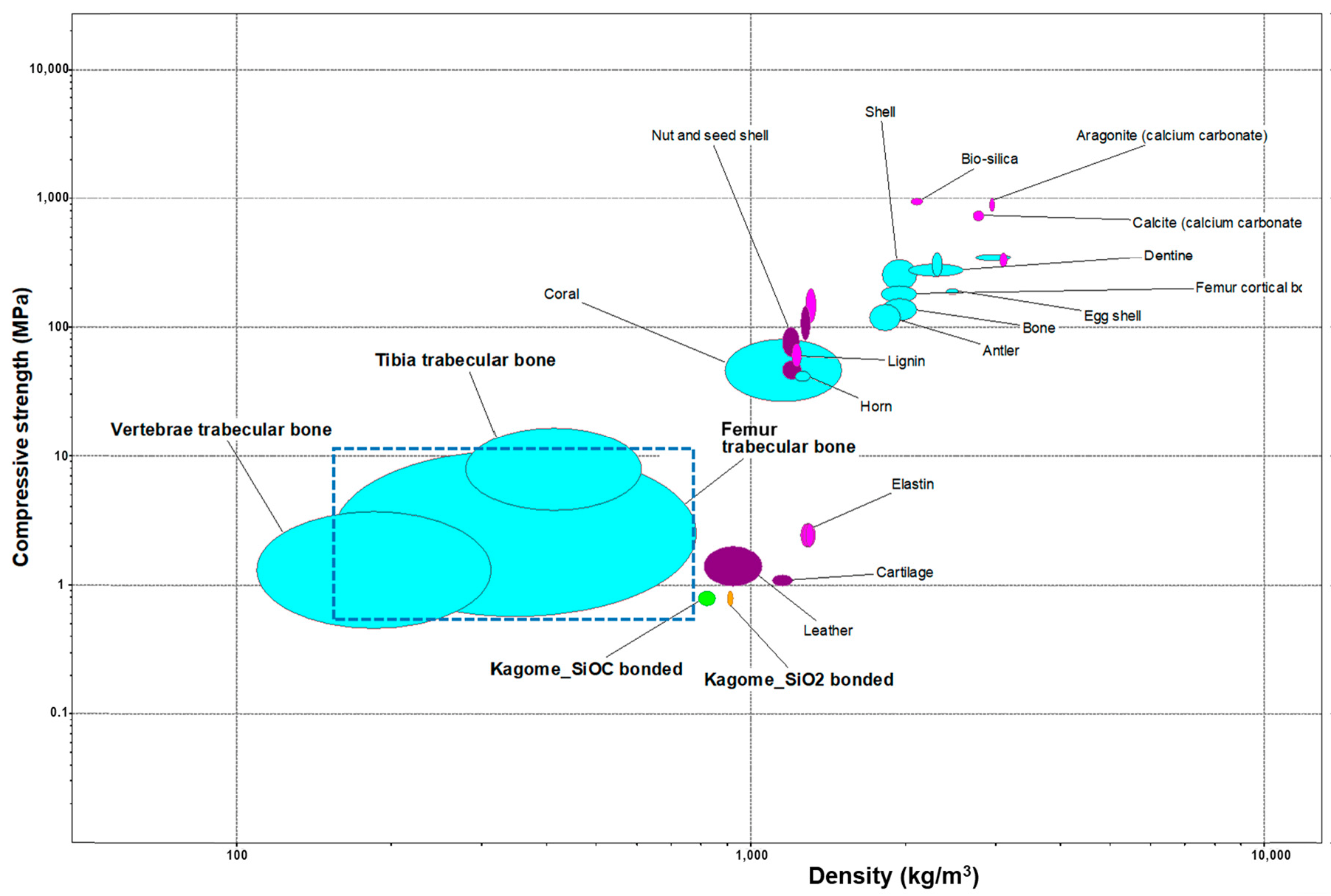

- The change from silica to SiOC binding phase had a positive effect on the strength of the prepared scaffolds, by eliminating the formation of cristobalite. A more substantial effect on the compressive strength of scaffolds is associated with the adoption of different topologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Zhang, H.; Xiong, Y.; Dong, L.; Li, X. Development of hierarchical porous bioceramic scaffolds with controlled micro/nano surface topography for accelerating bone regeneration. Mater. Sci. Eng. C 2021, 130, 112437. [Google Scholar] [CrossRef] [PubMed]

- Loh, Q.L.; Choong, C. Three-Dimensional Scaffolds for Tissue Engineering Applications: Role of Porosity and Pore Size. Tissue Eng. Part B Rev. 2013, 19, 485–502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gaharwar, A.K.; Singh, I.; Khademhosseini, A. Engineered biomaterials for in situ tissue regeneration. Nat. Rev. Mater. 2020, 5, 686–705. [Google Scholar] [CrossRef]

- Boccaccio, A.; Uva, A.E.; Fiorentino, M.; Mori, G.; Monno, G. Geometry Design Optimization of Functionally Graded Scaffolds for Bone Tissue Engineering: A Mechanobiological Approach. PLoS ONE 2016, 11, e0146935. [Google Scholar] [CrossRef] [PubMed]

- Lu, F.; Wu, R.; Shen, M.; Xie, L.; Liu, M.; Li, Y.; Xu, S.; Wan, L.; Yang, X.; Gao, C.; et al. Rational design of bioceramic scaffolds with tuning pore geometry by stereolithography: Microstructure evaluation and mechanical evolution. J. Eur. Ceram. Soc. 2021, 41, 1672–1682. [Google Scholar] [CrossRef]

- Gupta, D.; Singh, A.K.; Dravid, A.; Bellare, J. Multiscale Porosity in Compressible Cryogenically 3D Printed Gels for Bone Tissue Engineering. ACS Appl. Mater. Interfaces 2019, 11, 20437–20452. [Google Scholar] [CrossRef] [PubMed]

- Dasan, A.; Elsayed, H.; Kraxner, J.; Galusek, D.; Colombo, P.; Bernardo, E. Engineering of silicone-based mixtures for the digital light processing of Åkermanite scaffolds. J. Eur. Ceram. Soc. 2020, 40, 2566–2572. [Google Scholar] [CrossRef]

- Zadehnajar, P.; Mirmusavi, M.H.; Bakhtiari, S.S.E.; Bakhsheshi-Rad, H.R.; Karbasi, S.; RamaKrishna, S.; Berto, F. Recent advances on akermanite calcium-silicate ceramic for biomedical applications. Int. J. Appl. Ceram. Technol. 2021, 18, 1901–1920. [Google Scholar] [CrossRef]

- Xia, L.; Yin, Z.; Mao, L.; Wang, X.; Liu, J.; Jiang, X.; Zhang, Z.; Lin, K.; Chang, J.; Fang, B. Akermanite bioceramics promote osteogenesis, angiogenesis and suppress osteoclastogenesis for osteoporotic bone regeneration. Sci. Rep. 2016, 6, 22005. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Li, H.; Ea, L.; Cao, J.; Guo, B. Bioceramic akermanite enhanced vascularization and osteogenic differentiation of human induced pluripotent stem cells in 3D scaffolds in vitro and vivo. RSC Adv. 2019, 9, 25462–25470. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Wu, C.; Zhang, X.; Chang, J.; Dai, K. Regulation of immune response by bioactive ions released from silicate bioceramics for bone regeneration. Acta Biomater. 2018, 66, 81–92. [Google Scholar] [CrossRef] [PubMed]

- Fiocco, L.; Li, S.; Stevens, M.M.; Bernardo, E.; Jones, J.R. Biocompatibility and bioactivity of porous polymer-derived Ca-Mg silicate ceramics. Acta Biomater. 2017, 50, 56–67. [Google Scholar] [CrossRef] [PubMed]

- Dasan, A.; Talimian, A.; Kraxner, J.; Galusek, D.; Elsayed, H.; Bernardo, E. Åkermanite glass microspheres: Preparation and perspectives of sinter-crystallization. Int. J. Appl. Glass Sci. 2021, 12, 551–561. [Google Scholar] [CrossRef]

- Elsayed, H.; Picicco, M.; Dasan, A.; Kraxner, J.; Galusek, D.; Bernardo, E. Glass powders and reactive silicone binder: Interactions and application to additive manufacturing of bioactive glass-ceramic scaffolds. Ceram. Int. 2019, 45, 13740–13746. [Google Scholar] [CrossRef]

- Elsayed, H.; Picicco, M.; Dasan, A.; Kraxner, J.; Galusek, D.; Bernardo, E. Glass powders and reactive silicone binder: Application to digital light processing of bioactive glass-ceramic scaffolds. Ceram. Int. 2020, 46, 25299–25305. [Google Scholar] [CrossRef]

- Sharafabadi, A.K.; Abdellahi, M.; Kazemi, A.; Khandan, A.; Ozada, N. A novel and economical route for synthesizing akermanite (Ca2MgSi2O7) nano-bioceramic. Mater. Sci. Eng. C 2017, 71, 1072–1078. [Google Scholar] [CrossRef] [PubMed]

- Bernardino, R.M.; Wirth, C.; Stares, S.L.; Salmoria, G.V.; Hotza, D.; Günster, J. Manufacturing of SiO2-Coated b-TCP Structures by 3D Printing using a Preceramic Polymer as Printing Binder and Silica Source. J. Ceram. Sci. Technol. 2018, 9, 37–42. [Google Scholar] [CrossRef]

- Fiocco, L.; Elsayed, H.; Badocco, D.; Pastore, P.; Bellucci, D.; Cannillo, V.; Detsch, R.; Boccaccini, A.R.; Bernardo, E. Direct ink writing of silica-bonded calcite scaffolds from preceramic polymers and fillers. Biofabrication 2017, 9, 025012. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, H.; Carraro, F.; Agnoli, S.; Bellucci, D.; Cannillo, V.; Ferroni, L.; Gardin, C.; Zavan, B.; Bernardo, E. Direct ink writing of silica-carbon-calcite composite scaffolds from a silicone resin and fillers. J. Eur. Ceram. Soc. 2018, 38, 5200–5207. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Höland, W.; Beall, G.H. Glass-Ceramic Technology; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Ansys Granta Selector, Granta EduPack 2021 R1. https://www.ansys.com/products/materials/granta-selector/.

- Desimone, D.; Li, W.; Roether, J.A.; Schubert, D.W.; Crovace, M.C.; Rodrigues, A.C.M.; Zanotto, E.D.; Boccaccini, A.R. Biosilicate®–gelatine bone scaffolds by the foam replica technique: Development and characterization. Sci. Technol. Adv. Mater. 2013, 14, 045008. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| 3D Lattice Structures | Atm | Geometrical Density, ρ (g/cm3) | Total Porosity, P (vol %) [ρrel = 1 − P/100] | Open Porosity (vol %) | Compressive Strength, σc (MPa) [σbend* (MPa)] |

|---|---|---|---|---|---|

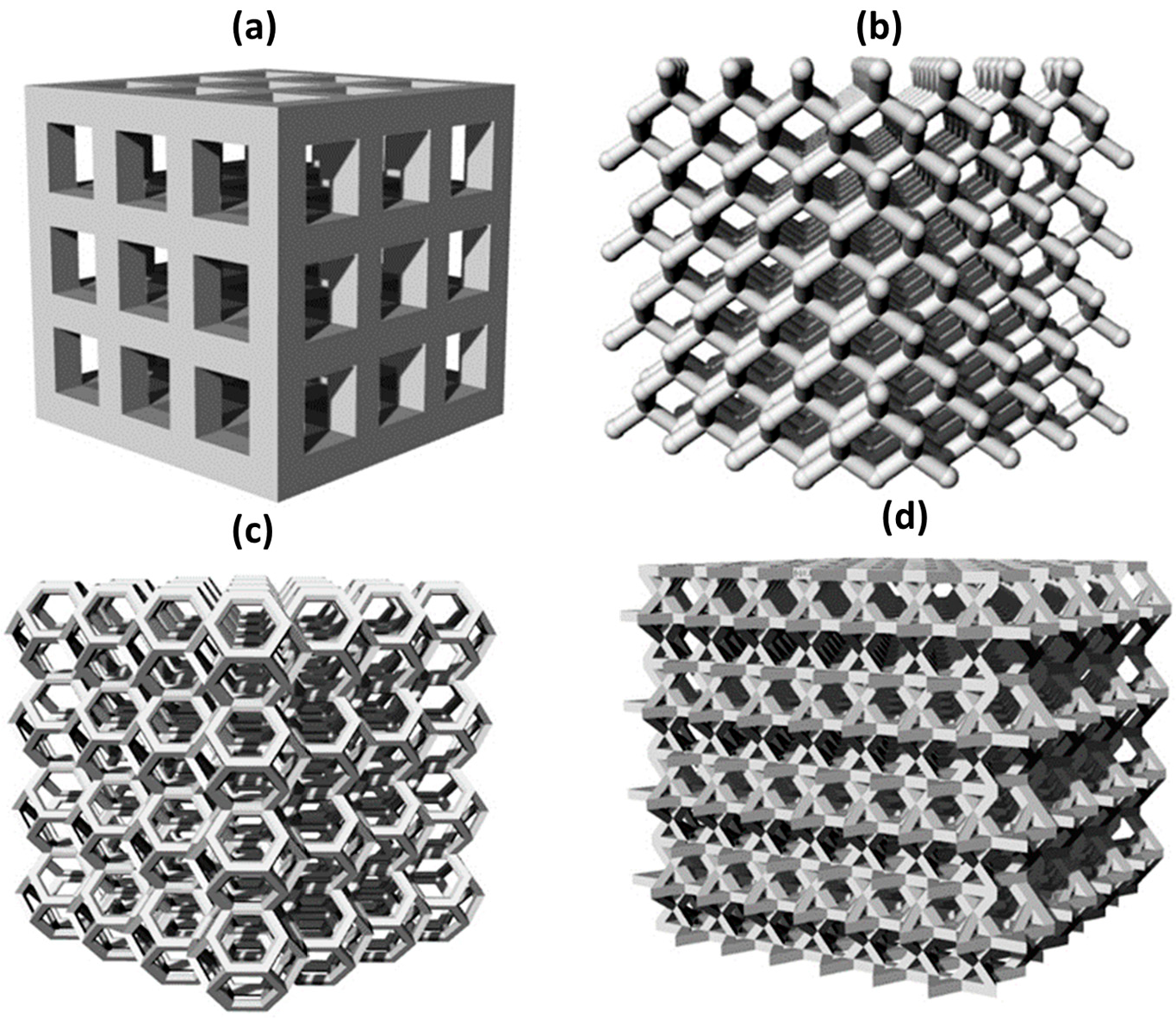

| Diamond | air | 0.46 ± 0.01 | 83.6 ± 0.3 [0.164] | 83.5 ± 0.3 | 0.07 ± 0.01 [~6] |

| N2 | 0.49 ± 0.01 | 84.1 ± 0.1 [0.159] | 83.6 ± 0.1 | 0.08 ± 0.01 [~6] | |

| Cubic | air | 0.80 ± 0.09 | 72 ± 1 [0.229] | 71.6 ± 0.1.4 | 0.5 ± 0.1 [~18] |

| N2 | 0.75 ± 0.01 | 75.7 ± 0.8 [0.243] | 75.3 ± 0.8 | 0.58 ± 0.05 [~24] | |

| Kagome | air | 0.91 ± 0.01 | 68 ± 2 [0.318] | 67.9 ± 1.0 | 0.8 ± 0.1 [~21] |

| N2 | 0.82 ± 0.03 | 73 ± 1 [0.269] | 72.7 ± 1.0 | 0.8 ± 0.1 [~28] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dasan, A.; Kraxner, J.; Grigolato, L.; Savio, G.; Elsayed, H.; Galusek, D.; Bernardo, E. 3D Printing of Hierarchically Porous Lattice Structures Based on Åkermanite Glass Microspheres and Reactive Silicone Binder. J. Funct. Biomater. 2022, 13, 8. https://doi.org/10.3390/jfb13010008

Dasan A, Kraxner J, Grigolato L, Savio G, Elsayed H, Galusek D, Bernardo E. 3D Printing of Hierarchically Porous Lattice Structures Based on Åkermanite Glass Microspheres and Reactive Silicone Binder. Journal of Functional Biomaterials. 2022; 13(1):8. https://doi.org/10.3390/jfb13010008

Chicago/Turabian StyleDasan, Arish, Jozef Kraxner, Luca Grigolato, Gianpaolo Savio, Hamada Elsayed, Dušan Galusek, and Enrico Bernardo. 2022. "3D Printing of Hierarchically Porous Lattice Structures Based on Åkermanite Glass Microspheres and Reactive Silicone Binder" Journal of Functional Biomaterials 13, no. 1: 8. https://doi.org/10.3390/jfb13010008

APA StyleDasan, A., Kraxner, J., Grigolato, L., Savio, G., Elsayed, H., Galusek, D., & Bernardo, E. (2022). 3D Printing of Hierarchically Porous Lattice Structures Based on Åkermanite Glass Microspheres and Reactive Silicone Binder. Journal of Functional Biomaterials, 13(1), 8. https://doi.org/10.3390/jfb13010008