Multi-Criteria Analysis in Circular Economy Principles: Using AHP Model for Risk Assessment in Sustainable Whisky Production

Abstract

1. Introduction

1.1. Sustainable Whisky Production

1.2. Analytical Hierarchy Process Model Used for Risk Assessment

2. Materials and Methods

2.1. Qualitative Analysis—Identify Common Risk Factors from Case Studies

2.2. Quantitative Analysis—Using AHP Model to Assess Risks in Whisky Industry

2.2.1. Step 1. Hierarchy Construction

2.2.2. Step 2. Pairwise Comparison

- means that Criterion 1 is moderately more important than Criterion 2.

- means that Criterion 2 is less important than Criterion 1.

2.2.3. Step 3. Checking the Consistency Ratio

3. Results

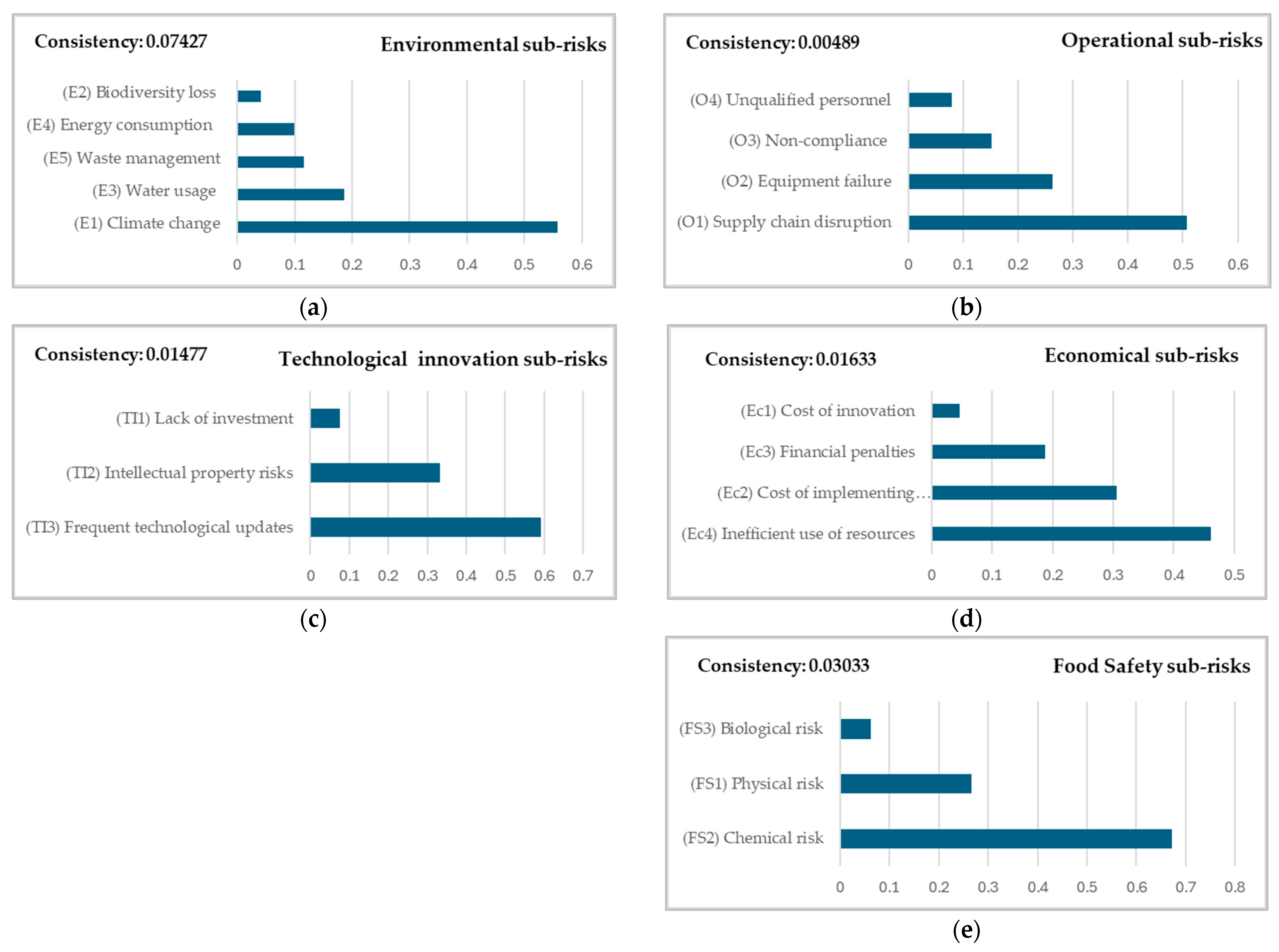

- (a)

- The sub-criteria with the highest environmental risk were determined to be climate change affecting ingredient availability (0.558), and water usage (0.186), while the lowest environmental risk was biodiversity risk (0.041). Waste management (0.116) and energy consumption (0.098) are very closely ranked. These findings explain the extensive focus in research literature on developing new technological alternatives that mitigate these risks. The CR value of 0.074 (the highest among other risk categories results from this study) implies that the prioritization may change, depending on the unique context under which certain distilleries may operate.

- (b)

- In the operational risk class, supply chain disruption (0.507) is perceived to hold the highest impact towards sustainable whisky production, followed by equipment failure leading to production delays (0.263) and non-compliance with technological parameters during manufacturing phases (0.152). Based on the experts’ experience, unqualified personnel (0.078) had the lowest perceived contribution to operational risk. The consistency ratio CR of 0.004 indicates excellent consensus on the impact and priority of the sub-risks that were assessed.

- (c)

- The weights of the sub-criteria in the technological innovation risk category have been determined to be frequent technological updates (0.591) and intellectual property risks related to new technologies (0.333). Since the distilleries that participated in this study were built after the 2000s, the majority of them rely on newer technology and adhere to ISO guidelines. Therefore, the sub-risk lack of investment in circular technologies (0.075) is ranked relatively low for the selected target group. However, there are many frequent technological advances that can be adopted to address water usage, waste management, and other environmental risks. The intellectual property implications of such solutions are often the driving factors of successful marketing strategies that satisfy customer preferences for reduced carbon footprint technologies, increase brand awareness of being sustainable, and help distilleries gain competitive advantage. The consistency ratio CR of 0.014 indicates consensus on the impact and priority of the sub-risks that were assessed.

- (d)

- In the economic risk class, inefficient use of resources (0.461) is by far the most important sub-criteria impacting sustainable whisky production, closely followed by the cost of implementing sustainable practices (0.305) and financial penalties for non-compliance with standards and regulations (0.187). The cost of innovation (0.046) is ranked lower than other economic sub-criteria since the sample population has less of an innovation and technological gap to address compared to traditional whisky distilleries that, for example, would need to buy equipment to modernize their production facilities. The consistency ratio CR of 0.016 indicates consensus on the impact and priority of the sub-risks that were assessed.

- (e)

- The main food safety risks associated with sustainable whisky production are chemical risks (0.671) such as contamination of grains—raw material with mycotoxins, pesticides, residual chemicals, from cleaning processes—followed by physical risks (0.265)—entry of foreign objects during technological process and biological risks (0.063)—contamination of grains with bacteria, fungi, etc. Biological risk has the lowest weight because of the nature of alcoholic beverage production, as the pathogenic microorganisms cannot survive the high alcohol content (min. 40% alc. vol.) present in whiskies. The consistency ratio CR of 0.030 indicates consensus on the impact and priority of the sub-risks that were assessed.

4. Discussion

4.1. Limitations of the AHP Research

4.2. Recommendations for Future Research

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dabija, D.; Năstase, C. Exploring the Evolution of Sustainability Paradigms: From Linear to Circular Economy Models. Proc. Int. Conf. Bus. Excell. 2024, 18, 754–769. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- MahmoumGonbadi, A.; Genovese, A.; Sgalambro, A. Closed-Loop Supply Chain Design for the Transition towards a Circular Economy: A Systematic Literature Review of Methods, Applications and Current Gaps. J. Clean. Prod. 2021, 323, 129101. [Google Scholar] [CrossRef]

- Duffy, C.; Styles, D.; Schestak, I.; Macgregor, K.; Jack, F.; Henn, D.; Black, K.; Iannetta, P.P.M. Optimising Sustainability: Circular Pathways for Scotch Whisky Distillery Co-Products. J. Clean. Prod. 2023, 395, 136436. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Halog, A.; Cloutier, S. Systems Thinking for Life Cycle Sustainability Assessment: A Review of Recent Developments, Applications, and Future Perspectives. Sustainability 2017, 9, 706. [Google Scholar] [CrossRef]

- Dieckmann, E.; Sheldrick, L.; Tennant, M.; Myers, R.; Cheeseman, C. Analysis of Barriers to Transitioning from a Linear to a Circular Economy for End of Life Materials: A Case Study for Waste Feathers. Sustainability 2020, 12, 1725. [Google Scholar] [CrossRef]

- Wang, Z.; Luo, P.; Zha, X.; Xu, C.; Kang, S.; Zhou, M.; Nover, D.; Wang, Y. Overview Assessment of Risk Evaluation and Treatment Technologies for Heavy Metal Pollution of Water and Soil. J. Clean. Prod. 2022, 379, 134043. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R. Sustainability in the Circular Economy: Insights and Dynamics of Designing Circular Business Models. Appl. Sci. 2022, 12, 1521. [Google Scholar] [CrossRef]

- Golinska-dawson, P.; Werner-lewandowska, K.; Kosacka-olejnik, M. Responsible Resource Management in Remanufactur-Ing—Framework for Qualitative Assessment in Small and Medium-sized Enterprises. Resources 2021, 10, 19. [Google Scholar] [CrossRef]

- Gedam, V.V.; Raut, R.D.; Lopes de Sousa Jabbour, A.B.; Tanksale, A.N.; Narkhede, B.E. Circular Economy Practices in a Developing Economy: Barriers to Be Defeated. J. Clean. Prod. 2021, 311, 127670. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; Chowdhury, S.; Saha, K.; Budhwar, P.; De, D. Adoption of Circular Economy Practices in Small and Medium-Sized Enterprises: Evidence from Europe. Int. J. Prod. Econ. 2022, 248, 108496. [Google Scholar] [CrossRef]

- Walzberg, J.; Lonca, G.; Hanes, R.J.; Eberle, A.L.; Carpenter, A.; Heath, G.A. Do We Need a New Sustainability Assessment Method for the Circular Economy? A Critical Literature Review. Front. Sustain. 2020, 1, 620047. [Google Scholar] [CrossRef]

- Kirchherr, J.; Yang, N.H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- MacKenzie, N.G.; Perchard, A.; Mackay, D.; Burt, G. Unlocking Dynamic Capabilities in the Scotch Whisky Industry, 1945–Present. Bus. Hist. 2022, 66, 1082–1102. [Google Scholar] [CrossRef]

- Ambrosini, V.; Bowman, C.; Collier, N. Dynamic Capabilities: An Exploration of How Firms Renew Their Resource Base. Br. J. Manag. 2009, 20, S9–S24. [Google Scholar] [CrossRef]

- Gennari, F. The Transition towards a Circular Economy. A Framework for SMEs. J. Manag. Gov. 2023, 27, 1423–1457. [Google Scholar] [CrossRef]

- Schulte, J.; Villamil, C.; Hallstedt, S.I. Strategic Sustainability Risk Management in Product Development Companies: Key Aspects and Conceptual Approach. Sustainability 2020, 12, 10531. [Google Scholar] [CrossRef]

- Bigdeloo, M.; Teymourian, T.; Kowsari, E.; Ramakrishna, S.; Ehsani, A. Sustainability and Circular Economy of Food Wastes: Waste Reduction Strategies, Higher Recycling Methods, and Improved Valorization. Mater. Circ. Econ. 2021, 3, 1–9. [Google Scholar] [CrossRef]

- De Pascale, A.; Di Vita, G.; Giannetto, C.; Ioppolo, G.; Lanfranchi, M.; Limosani, M.; Szopik-Depczyńska, K. The Circular Economy Implementation at the European Union Level. Past, Present and Future. J. Clean. Prod. 2023, 423, 138658. [Google Scholar] [CrossRef]

- Weber, C.T.; Trierweiler, L.F.; Trierweiler, J.O. Food Waste Biorefinery Advocating Circular Economy: Bioethanol and Distilled Beverage from Sweet Potato. J. Clean. Prod. 2020, 268, 121788. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Spent Grain: A Functional Ingredient for Food Applications. Foods 2023, 12, 1533. [Google Scholar] [CrossRef] [PubMed]

- Chetrariu, A.; Dabija, A. Brewer’s Spent Grains: Possibilities of Valorization, a Review. Appl. Sci. 2020, 10, 5619. [Google Scholar] [CrossRef]

- Klein, S.P.; Liszt-Rohlf, V.; Spieth, P. Value-based Bricolage: Resource Mobilization in the Circular Economy. J. Ind. Ecol. 2023, 27, 1476–1487. [Google Scholar] [CrossRef]

- Arijeniwa, V.F.; Akinsemolu, A.A.; Chukwugozie, D.C.; Onawo, U.G.; Ochulor, C.E.; Nwauzoma, U.M.; Kawino, D.A.; Onyeaka, H. Closing the Loop: A Framework for Tackling Single-Use Plastic Waste in the Food and Beverage Industry through Circular Economy- a Review. J. Environ. Manag. 2024, 359, 120816. [Google Scholar] [CrossRef]

- Schestak, I.; Styles, D.; Black, K.; Williams, A.P. Circular Use of Feed By-Products from Alcohol Production Mitigates Water Scarcity. Sustain. Prod. Consum. 2022, 30, 158–170. [Google Scholar] [CrossRef]

- Yu, T.; Kowalski, M.P.; Shackelford, L.T.; Brooks, D.C.; Ennis, J.M. Using Web3 Technologies to Represent Personalized Consumer Taste Preferences in Whiskies. Food Qual. Prefer. 2024, 118, 105201. [Google Scholar] [CrossRef]

- Mordor Intelligence. Whiskey Market Size & Share Analysis—Growth Trends & Forecasts (2024–2029). 2024. Available online: https://www.mordorintelligence.com/industry-reports/whisky-market (accessed on 8 August 2024).

- Urbinati, A.; Shams Esfandabadi, Z.; Messeni Petruzzelli, A. Assessing the Interplay between Open Innovation and Sustainability-Oriented Innovation: A Systematic Literature Review and a Research Agenda. Bus. Ethics Environ. Responsib. 2023, 32, 1078–1095. [Google Scholar] [CrossRef]

- Edwards, C.; McNerney, C.C.; Lawton, L.A.; Palmer, J.; Macgregor, K.; Jack, F.; Cockburn, P.; Plummer, A.; Lovegrove, A.; Wood, A. Recoverable Resources from Pot Ale & Spent Wash from Scotch Whisky Production. Resour. Conserv. Recycl. 2022, 179, 106114. [Google Scholar] [CrossRef]

- Page, I.B. Why Do Distilleries Produce Multiple Ages of Whisky? J. Wine Econ. 2019, 14, 26–47. [Google Scholar] [CrossRef]

- The Whisky Yardvark. Distilleries. 2024. Available online: https://www.thewhiskyardvark.com/distilleries (accessed on 8 August 2024).

- Ubando, A.T.; Felix, C.B.; Chen, W.-H. Biorefineries in Circular Bioeconomy: A Comprehensive Review. Bioresour. Technol. 2020, 299, 122585. [Google Scholar] [CrossRef] [PubMed]

- Scotch Whisky Association. Insights. 2024. Available online: https://www.scotch-whisky.org.uk/insights (accessed on 8 August 2024).

- Bower, J. Scotch Whisky: History, Heritage and the Stock Cycle. Beverages 2016, 2, 11. [Google Scholar] [CrossRef]

- Olanrewaju, F.O.; Andrews, G.E.; Phylaktou, H.N.; Li, H.; Smith, S.; Maxfield, J.D.; Wakeman, R. Renewable Energy from Whisky Distillery By-Products. Chem. Eng. Trans. 2023, 105, 211–216. [Google Scholar] [CrossRef]

- Roberts, C.; Maslin, M. How Might Climate Change Impact Scotch Whisky Production in the Next 50–100 Years? UCL Environmental Change Research Centre: London, UK, 2021. [Google Scholar]

- Bringhurst, T.; Brosnan, J.; Russell, I.; Stewart, G. Water: An Essential Raw Material for Whisk(e)y Production. In Whisky; Elsevier: Amsterdam, The Netherlands, 2014; pp. 291–298. [Google Scholar]

- Nicol, D.A. Batch Distillation. In Whisky; Elsevier: Amsterdam, The Netherlands, 2014; pp. 155–178. [Google Scholar]

- Pecchioli, B.; Moroz, D. Do Geographical Appellations Provide Useful Quality Signals? The Case of Scotch Single Malt Whiskies. Econ. Model. 2023, 124, 106331. [Google Scholar] [CrossRef]

- Harkness, C.; Semenov, M.A.; Areal, F.; Senapati, N.; Trnka, M.; Balek, J.; Bishop, J. Adverse Weather Conditions for UK Wheat Production under Climate Change. Agric. Meteorol. 2020, 282–283, 107862. [Google Scholar] [CrossRef] [PubMed]

- Mcgrane, S.J.; Allan, G.J.; Roy, G. Water as an Economic Resource and the Impacts of Climate Change on the Hydrosphere, Regional Economies and Scotland. Fraser Allander Econ. Comment. 2018, 42, 53–74. [Google Scholar]

- Maximize Market Research. Whiskey Market: Global Industry Analysis by Market Share, Trend, Size, Competitive Landscape, Regional Outlook and Forecast (2024–2030). 2024. Available online: https://www.maximizemarketresearch.com/market-report/global-whiskey-market/27265/ (accessed on 8 August 2024).

- Chetrariu, A.; Dabija, A. Spent Grain from Malt Whisky: Assessment of the Phenolic Compounds. Molecules 2021, 26, 3236. [Google Scholar] [CrossRef]

- Klein, O.; Nier, S.; Tamásy, C. Towards a Circular Bioeconomy? Pathways and Spatialities of Agri-Food Waste Valorisation. Tijdschr. Voor Econ. Soc. Geogr. 2022, 113, 194–210. [Google Scholar] [CrossRef]

- Jahandideh, H.; McCardle, K.; Tang, C.; Fahimnia, B. Capacity Allocation for Producing Age-Based Products. Decis. Sci. 2023, 54, 473–493. [Google Scholar] [CrossRef]

- Fromentin, V.; Pecchioli, B.; Moroz, D. Time-Varying Causality among Whisky, Wine, and Equity Markets. Financ. Res. Lett. 2024, 63, 105345. [Google Scholar] [CrossRef]

- Bomba, M.Y.; Susol, N.Y. Main Requirements for Food Safety Management Systems under International Standards: BRC, IFS, FSSC 22000, ISO 22000, Global GAP, SQF. Sci. Messenger LNU Vet. Med. Biotechnol. 2020, 22, 18–25. [Google Scholar] [CrossRef]

- Zimon, D.; Madzik, P.; Domingues, P. Development of Key Processes along the Supply Chain by Implementing the ISO 22000 Standard. Sustainability 2020, 12, 6176. [Google Scholar] [CrossRef]

- Mamalis, S.; Kafetzopoulos, D.P.; Aggelopoulos, S. The New Food Safety Standard ISO 22000. Assessment, Comparison and Correlation with HACCP and ISO 9000:2000. The Practical Implementation in Victual Business. In Proceedings of the 113th EAAE Seminar A Resilient European Food Industry and Food Chain in a Challenging World, Chania, Greece, 3–6 September 2009. [Google Scholar]

- Condrea, E.; Constantinescu, G.; Stanciu, A.C.; Constandache, M. Particularities of fssc 22000-food safety management system. J. Environ. Prot. Ecol. 2015, 16, 274–279. [Google Scholar]

- Darabont, D.C.; Antonov, A.E.; Bejinariu, C. Key Elements on Implementing an Occupational Health and Safety Management System Using ISO 45001 Standard. MATEC Web Conf. 2017, 121, 11007. [Google Scholar] [CrossRef]

- Darabont, D.-C.; Moraru, R.I.; Antonov, A.E.; Bejinariu, C. 7th International Multidisciplinary Symposium “Sustainable Development Through Quality and Innovation in Engineering and Research” Managing New and Emerging Risks in the Context of ISO 45001 Standard; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Tarí, J.J.; Molina-Azorín, J.F.; Heras, I. Benefits of the ISO 9001 and ISO 14001 Standards: A Literature Review. J. Ind. Eng. Manag. 2012, 5, 297–322. [Google Scholar] [CrossRef]

- Rampasso, I.S.; Filho, G.P.M.; Anholon, R.; de Araujo, R.A.; Lima, G.B.A.; Zotes, L.P.; Filho, W.L. Challenges Presented in the Implementation of Sustainable Energy Management via ISO 50001:2011. Sustainability 2019, 11, 6321. [Google Scholar] [CrossRef]

- Fuchs, H.; Aghajanzadeh, A.; Therkelsen, P. Identification of Drivers, Benefits, and Challenges of ISO 50001 through Case Study Content Analysis. Energy Policy 2020, 142, 111443. [Google Scholar] [CrossRef]

- Parviainen, T.; Goerlandt, F.; Helle, I.; Haapasaari, P.; Kuikka, S. Implementing Bayesian Networks for ISO 31000:2018-Based Maritime Oil Spill Risk Management: State-of-Art, Implementation Benefits and Challenges, and Future Research Directions. J Environ. Manag. 2021, 278, 111520. [Google Scholar] [CrossRef]

- Sine, M.M.; Maria, E. Analisis Manajemen Risiko Pada Penerapan Sistem Informasi Pembangunan Daerah (SIPD) Menggunakan IEC/ISO 31010:2019. Build. Inform. Technol. Sci. (BITS) 2022, 4, 96–105. [Google Scholar] [CrossRef]

- Kokangül, A.; Polat, U.; Dağsuyu, C. A New Approximation for Risk Assessment Using the AHP and Fine Kinney Methodologies. Saf. Sci. 2017, 91, 24–32. [Google Scholar] [CrossRef]

- Božanić, D.; Tešić, D.; Komazec, N.; Marinković, D.; Puška, A. Interval Fuzzy AHP Method in Risk Assessment. Rep. Mech. Eng. 2023, 4, 131–140. [Google Scholar] [CrossRef]

- Unver, S.; Ergenc, I. Safety Risk Identification and Prioritize of Forest Logging Activities Using Analytic Hierarchy Process (AHP). Alex. Eng. J. 2021, 60, 1591–1599. [Google Scholar] [CrossRef]

- Gheorghita, R.E.; Lupaescu, A.V.; Gâtlan, A.M.; Dabija, D.; Lobiuc, A.; Iatcu, O.C.; Buculei, A.; Andriesi, A.; Dabija, A. Biopolymers-Based Macrogels with Applications in the Food Industry: Capsules with Berry Juice for Functional Food Products. Gels 2024, 10, 71. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Kumar, D.T.; Shankar, K.M.; Kannan, D.; Chen, G. Analyzing Criteria and Sub-Criteria for the Corporate Social Responsibility-Based Supplier Selection Process Using AHP. Int. J. Adv. Manuf. Technol. 2013, 68, 907–916. [Google Scholar] [CrossRef]

- Ioan Ban, A.; Iuliana Ban, O.; Bogdan, V.; Sabau Popa, D.C.; Tuse, D. Performance Evaluation Model of Romanian Manufacturing Listed Companies by Fuzzy Ahp and Topsis. Technol. Econ. Dev. Econ. 2020, 26, 808–836. [Google Scholar] [CrossRef]

- Canco, I.; Kruja, D.; Iancu, T. Ahp, a Reliable Method for Quality Decision Making: A Case Study in Business. Sustainability 2021, 13, 13932. [Google Scholar] [CrossRef]

- Saaty, T.L. Some Mathematical Concepts of the Analytic Hierarchy Process. Behaviormetrika 1991, 18, 1–9, Correction in Behaviormetrika 2021, 48, 193–194. [Google Scholar] [CrossRef]

- Vivek, K.; Subbarao, K.V.; Routray, W.; Kamini, N.R.; Dash, K.K. Application of Fuzzy Logic in Sensory Evaluation of Food Products: A Comprehensive Study. Food Bioprocess Technol. 2019, 13, 1–29. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy and Analytic Network Processes for the Measurement of Intangible Criteria and for Decision-Making; Springer: Berlin/Heidelberg, Germany, 2016; pp. 363–419. [Google Scholar]

- Ayyildiz, E.; Gumus, A.T. Pythagorean Fuzzy AHP Based Risk Assessment Methodology for Hazardous Material Transportation: An Application in Istanbul. Environ. Sci. Pollut. Res. 2021, 28, 35798–35810. [Google Scholar] [CrossRef]

- Zuraidi, S.N.F.; Rahman, M.A.A.; Akasah, Z.A. A Study of Using AHP Method to Evaluate the Criteria and Attribute of Defects in Heritage Building. E3S Web Conf. 2018, 65, 01005. [Google Scholar]

- Dabija, A.; Ciocan, M.E.; Chetrariu, A.; Dabija, D. Research on the use of the ahp method in the sensory analysis of buckwheat and sorghum beer. Sci. Study Research. Chem. Chem. Eng. Biotechnol. Food Ind. 2023, 24, 291–300. [Google Scholar]

- Kumar Sharma, Y.; Kumar Yadav, A.; Kumar Mangla, S.; Patil, P.P. Ranking the Success Factors to Improve Safety and Security in Sustainable Food Supply Chain Management Using Fuzzy AHP. Mater. Today Proc. 2018, 5, 12187–12196. [Google Scholar] [CrossRef]

- Serpa, N.P.; da Silva, D.J.C.; Wegner, R.D.S.; Stertzr, E.; Teixeira, C.S.; Lopes, L.F.D. Quality and Sustainability in the Production Process: A Study of Bakeries Using an Integrated Multi-Criteria Method Based on Fuzzy AHP and Fuzzy TOPSIS. Environ. Qual. Manag. 2023, 32, 251–262. [Google Scholar] [CrossRef]

- Ali, B.M.; Andersson, M.G.; van den Borne, B.H.P.; Focker, M.; van der Fels-Klerx, H.J. Multi-Criteria Decision Analysis in Food Safety Risk Management: The Case of Dioxins in Baltic Fish. Foods 2022, 11, 1059. [Google Scholar] [CrossRef] [PubMed]

- Yazdani, M.; Gonzalez, E.D.R.S.; Chatterjee, P. A Multi-Criteria Decision-Making Framework for Agriculture Supply Chain Risk Management under a Circular Economy Context. Manag. Decis. 2019, 59, 1801–1826. [Google Scholar] [CrossRef]

- Agapie, A. Consistency in the Context of AHP: Half Friend, Half Foe. In Proceedings of the International Symposium of the Analytic Hierarchy Process, Washington, DC, USA, 29 June 2014. [Google Scholar]

- Pino, M.E.M.; Ordoñez, F.R.R.; Ysa, R.A.S.; Llanos, D.M.J.; Cruz, M.M.T.; Calderón, B.A.C. Role of Expert in Validation of Information Collection Instruments for Business Purposes. Int. J. Prof. Bus. Rev. 2023, 8, e03122. [Google Scholar] [CrossRef]

| Country | Year Opened | Whisky Type (Grain Type) | Production (Liters) |

|---|---|---|---|

| Austria | 2009 | Single Malt Whisky (Barley) | ~90,000 |

| Belgium | 2004 | Single Malt Whisky (Barley) | ~60,000 |

| Czech Republic | 2008 | Single Malt Whisky (Barley) | ~70,000 |

| Estonia | 2015 | Single Malt Whisky (Barley) | ~30,000 |

| Finland | 2014 | Rye Whisky (Rye) | ~100,000 |

| France | 2015 | Malt Whisky (Barley), and Experimental (various grains) | ~100,000 |

| Germany | 2016 | Single Malt Whisky (Barley) | ~200,000 |

| Hungary | 2002 | Malt Whisky (Barley) | ~30,000 |

| Italy | 2012 | Malt Whisky (Barley), Rye Whisky | ~90,000 |

| Lithuania | 2010 | Grain Whisky (Rye, Wheat) | ~50,000 |

| Luxembourg | 2004 | Single Malt Whisky (Barley) | ~20,000 |

| Netherlands | 2000 | Single Malt Whisky (Barley), Rye Whisky, and Corn Whisky (Maize) | ~150,000 |

| Norway | 2014 | Single Malt Whisky (Barley) | ~30,000 |

| Poland | 2005 | Single Malt Whisky (Barley) | ~50,000 |

| Portugal | 2018 | Malt Whisky (Barley) | ~20,000 |

| Slovakia | 2001 | Grain Whisky (Corn, Wheat, Barley) | ~100,000 |

| Spain | 2002 | Malt Whisky (Barley) | ~100,000 |

| Switzerland | 2005 | Single Malt Whisky (Barley) | ~100,000 |

| Intensity Scale | Definition |

|---|---|

| 1 | indicates equal importance |

| 3 | indicates moderate importance |

| 5 | indicates strong importance |

| 7 | indicates very strong importance |

| 9 | indicates extreme importance |

| 2, 4, 6, 8 | intermediate values between the two adjacent judgments. |

| Size of Matrix (n) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Random Average CI (RI) | 0 | 0 | 0.52 | 0.89 | 1.11 | 1.24 | 1.35 | 1.40 | 1.45 | 1.49 |

| Main Risk | Local Weight (LW) | Sub-Criteria | Local Weight (LW) | Global Weight (GW) | Rank |

|---|---|---|---|---|---|

| Environmental (E) | 0.369 | (E1) Climate change 1 | 0.558 | 0.247 | 1 |

| (E2) Biodiversity loss | 0.041 | 0.018 | 13 | ||

| (E3) Water usage | 0.186 | 0.082 | 4 | ||

| (E4) Energy consumption | 0.098 | 0.044 | 8 | ||

| (E5) Waste management | 0.116 | 0.051 | 7 | ||

| Operational (O) | 0.253 | (O1) Supply chain disruption | 0.507 | 0.139 | 2 |

| (O2) Equipment failure 2 | 0.263 | 0.072 | 5 | ||

| (O3) Non-compliance 3 | 0.152 | 0.041 | 9 | ||

| (O4) Unqualified personnel | 0.078 | 0.021 | 12 | ||

| Technological innovation (TI) | 0.181 | (TI1) Lack of investment 4 | 0.075 | 0.015 | 15 |

| (TI2) Intellectual property risks 5 | 0.333 | 0.065 | 6 | ||

| (TI3) Frequent technological updates | 0.592 | 0.115 | 3 | ||

| Economical (Ec) | 0.101 | (Ec1) Cost of innovation | 0.047 | 0.003 | 18 |

| (Ec2) Cost of implementing sustainable practices | 0.305 | 0.017 | 14 | ||

| (Ec3) Financial penalties 6 | 0.187 | 0.010 | 16 | ||

| (Ec4) Inefficient use of resources | 0.461 | 0.025 | 10 | ||

| Food safety (FS) | 0.096 | (FS1) Physical risk 7 | 0.265 | 0.009 | 17 |

| (FS2) Chemical risk 8 | 0.672 | 0.023 | 11 | ||

| (FS3) Biological risk 9 | 0.063 | 0.002 | 19 |

| Main Risk Categories | CI | CR | Decision (CR ≤ 0.1) | |

|---|---|---|---|---|

| Environmental (E) | 5.334081 | 0.083520 | 0.074270 | Consistent |

| Operational (O) | 4.013335 | 0.004445 | 0.004888 | Consistent |

| Technological innovation (TI) | 3.014153 | 0.007077 | 0.014767 | Consistent |

| Economical (Ec) | 4.044563 | 0.014854 | 0.016333 | Consistent |

| Food safety (FS) | 3.029071 | 0.014536 | 0.030330 | Consistent |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dabija, D.; Nastase, C.-E.; Chetrariu, A.; Dabija, A. Multi-Criteria Analysis in Circular Economy Principles: Using AHP Model for Risk Assessment in Sustainable Whisky Production. Computation 2024, 12, 206. https://doi.org/10.3390/computation12100206

Dabija D, Nastase C-E, Chetrariu A, Dabija A. Multi-Criteria Analysis in Circular Economy Principles: Using AHP Model for Risk Assessment in Sustainable Whisky Production. Computation. 2024; 12(10):206. https://doi.org/10.3390/computation12100206

Chicago/Turabian StyleDabija, Dadiana, Carmen-Eugenia Nastase, Ancuţa Chetrariu, and Adriana Dabija. 2024. "Multi-Criteria Analysis in Circular Economy Principles: Using AHP Model for Risk Assessment in Sustainable Whisky Production" Computation 12, no. 10: 206. https://doi.org/10.3390/computation12100206

APA StyleDabija, D., Nastase, C.-E., Chetrariu, A., & Dabija, A. (2024). Multi-Criteria Analysis in Circular Economy Principles: Using AHP Model for Risk Assessment in Sustainable Whisky Production. Computation, 12(10), 206. https://doi.org/10.3390/computation12100206