A Simulated-Annealing-Quasi-Oppositional-Teaching-Learning-Based Optimization Algorithm for Distributed Generation Allocation

Abstract

:1. Introduction

1.1. Motivation

1.2. Literature Review

1.3. Contributions, Gap, and Novelty

- This paper presents a novel modified algorithm for DG sizing and placement in a test distribution grid. This modification improves the TLBO method proficiency.

- This paper presents a multi-objective optimal solutions clustering method using suggested weight factors to avoid the human decision-making interface for selecting the best-compromised solution.

- This paper compares the proposed algorithm’s optimal solutions and the best-reported optimization algorithms for DG placement in the distribution system to prove the superiority.

- This paper compares the optimal solutions of DG placement in the cases of a similar type of DG for fuel cells, photovoltaic units, wind turbines, and a combination of all the mentioned DGs.

- This paper presents a methodology for integrating DG to improve the power quality issues of the distribution system.

2. Multi-Objective Formulation for Placement of Distributed Generators

2.1. Objective Functions

2.1.1. Total Electricity Generation Cost

2.1.2. The Bus Voltage Deviation

2.1.3. Power Losses

2.1.4. Emission

2.2. Constraints

2.2.1. Limitation of Voltage

2.2.2. DG Unit’s Number

2.2.3. Size of DG

2.2.4. Other Limitations

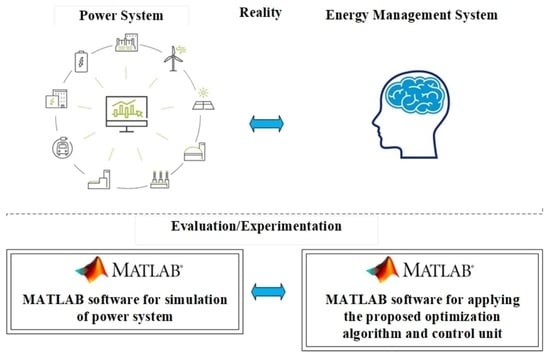

3. Proposed MOQTLBO Method

3.1. Modification of the Original TLBO

3.2. Quasi-Opposition-Based Learning

- Opposite number

- Quasi opposite number:

- Quasi opposite point:

- Quasi opposite point:

3.3. Quasi-Oppositional Based Optimization

3.4. The Implementation of the Proposed MOQTLBO

4. Conventional Optimization Approaches

5. Simulation Results

5.1. Case Study1: Part1—Single-Objective Results

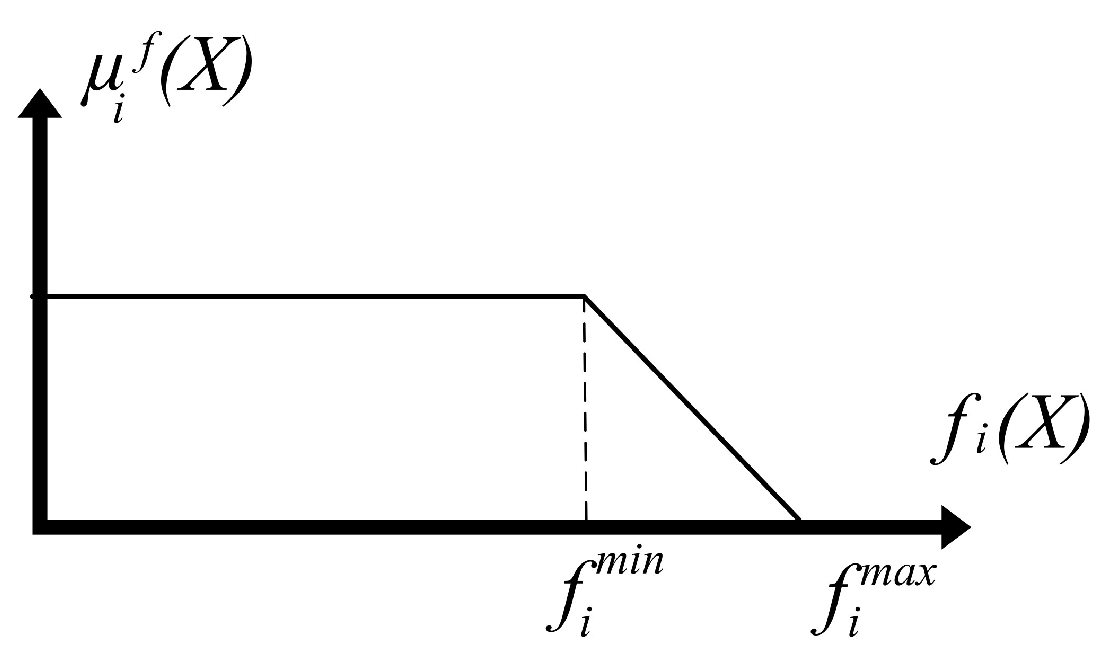

5.2. Case Study1: Part2—Multi-Objective Results

- Case V-assumed objectives: cost, power losses, and voltage deviation (i.e., f1, f2, and f3).

- Case VI-assumed objectives: cost, voltage deviation, and emission (i.e., f1, f2, and f4).

- Case VII-assumed objectives: power losses, voltage deviation, and emission (i.e., f2, f3, and f4).

- Case VIII-assumed objectives: cost, power losses, and emission (i.e., f1, f3, and f4).

- Case IX-assumed objectives: all objective functions (i.e., f1, f2, f3, and f4).

- -

- Comparing the obtained values of objective functions in Cases IV and IX-I shows that the voltage deviation value of Case IX-I (i.e., 1.4031) is lower than the voltage deviation of Case IV (i.e., 2.5059). Still, three other objective functions (i.e., cost, power loss, and emission) of Case IV are lower than Case IX–I. It means that the three objective functions’ worsened values in Case IV occur due to the reduction of voltage deviation in Case IX-I.

- -

- The first and second objective functions in case V have no conflict because when w1 and w2 are altered (decreased or increased), the objective functions do not change.

- -

- The objectives related to cost or power losses have the same behavior. The results of Cases I, II, III, IV, and V have proved this claim. In Cases I and III, cost and power losses have the same behavior. It means that when we minimize either cost or power loss individually, the other one is also minimized.

- -

- The cost and emission objective functions are conflicting with others. In Cases I, II, III, and IV, when the cost function is improved, the emission function is worsened and vice versa.

5.3. Case Study2: Part1—SAME Generators

5.4. Case Study2: Part2—The Combination of Generators

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Rate of annual interest | |

| Two real numbers ( is bigger than ) | |

| The capacity of the generator [kW] | |

| Summation and when the generator is a fuel cell unit | |

| Capital cost [$/kW] | |

| The capital cost of the generator in the lifetime based on capacity, annual interest, and load factor | |

| Summation of fuel cost and operation and maintenance cost | |

| Cost function | |

| Summation and when a generator is a photovoltaic unit | |

| Cost of substation | |

| Summation and when the generator is a wind turbine | |

| Emission of nth DG | |

| The total emission of greenhouse gases from one kind of DG unit | |

| The total emission of greenhouse gases from fuel cell units | |

| The total emission of greenhouse gases from photovoltaic units | |

| The total emission of greenhouse gases from wind turbines | |

| , | Total electricity generation cost, bus voltage deviation, power loss, and emission functions (objective functions) |

| ,, | Minimized total electricity generation cost, bus voltage deviation, power loss, and emission functions |

| Fuel cost [$/kWh] | |

| , | pth and qth objective functions |

| , | Upper and lower limits of |

| The xth objective function | |

| A constant between 0 and 1 | |

| Actual current mth branch of the distribution system | |

| Jumping rate | |

| The capacity of the nth DG | |

| Number of objective functions in multi-objective problems | |

| Load factor | |

| Lifetime [year] | |

| Any value for which the normal distribution function is required | |

| Minimum of membership function of ith feasible solution | |

| Minimum of membership function of the new feasible solution | |

| ,,,, | Emission characteristics coefficient of nth DG |

| Time step [year] | |

| Membership function | |

| Maximum number of buses | |

| Number of fuel cell units | |

| The lifetime of DG units | |

| Number of distribution system branches | |

| Number of photovoltaic units | |

| Number of wind units | |

| Operation and maintenance cost of DG units | |

| Active power [kW] | |

| The power generated by the fuel cell unit | |

| Total load power | |

| The electrical output of the nth generator | |

| The power generated by the photovoltaic unit | |

| Value of injected active power to the distribution system | |

| The power generated by the wind turbine | |

| Price of injected active power to the distribution system | |

| Resistance mth branch of the distribution system | |

| Variance | |

| The magnitude of the voltage at mth bus | |

| , | Upper and lower voltage limits |

| The nominal voltage of the mth bus of the distribution system | |

| Voltage magnitude of the mth bus of the distribution system | |

| Vector of location and power for DG units | |

| New learner (new member of the population) | |

| Old learner (an old member of the population) | |

| the contrast between the teacher’s learning Level and the mean of the class at any iteration | |

| New teacher’s learning level in iteration r + 1 | |

| Teacher’s learning level in iteration r | |

| Matrix of location (discrete numbers) and size (continuous numbers) of DG units | |

| Learner x (feasible solution x) | |

| Learner z (feasible solution z) | |

| SA vector (with K vector component for vth member of population) | |

| Feasible solution vector (with K vector component for vth member of population) | |

| New generated members of the population | |

| Equal to or based on the mentioned conditions | |

| Any real number between [a,b] | |

| Opposite number | |

| Quasi opposite point |

Appendix A. Optimization Techniques

Appendix B. Original TLBO Algorithm

Appendix C. Test System Specification

| Branch Number | Sending Bus | Receiving Bus | R (Ω) | X (Ω) | p (kW) | Q (kVAr) |

|---|---|---|---|---|---|---|

| 1 | 1 | 2 | 1.097 | 1.074 | 100.0 | 90.0 |

| 2 | 2 | 3 | 1.463 | 1.432 | 60.0 | 40.0 |

| 3 | 3 | 4 | 0.731 | 0.716 | 150.0 | 130.0 |

| 4 | 4 | 5 | 0.366 | 0.358 | 75.0 | 50.0 |

| 5 | 5 | 6 | 1.828 | 1.790 | 15.0 | 9.0 |

| 6 | 6 | 7 | 1.097 | 1.074 | 18.0 | 14.0 |

| 7 | 7 | 8 | 0.731 | 0.716 | 13.0 | 10.0 |

| 8 | 8 | 9 | 0.731 | 0.716 | 16.0 | 11.0 |

| 9 | 4 | 10 | 1.080 | 0.734 | 20.0 | 10.0 |

| 10 | 10 | 11 | 1.620 | 1.101 | 16.0 | 9.0 |

| 11 | 11 | 12 | 1.080 | 0.734 | 50.0 | 40.0 |

| 12 | 12 | 13 | 1.350 | 0.917 | 105.0 | 90.0 |

| 13 | 13 | 14 | 0.810 | 0.550 | 25.0 | 15.0 |

| 14 | 14 | 15 | 1.944 | 1.321 | 40.0 | 25.0 |

| 15 | 7 | 68 | 1.080 | 0.734 | 100.0 | 60.0 |

| 16 | 68 | 69 | 1.620 | 1.101 | 40.0 | 30.0 |

| 17 | 1 | 16 | 1.097 | 1.074 | 60.0 | 30.0 |

| 18 | 16 | 17 | 0.366 | 0.358 | 40.0 | 25.0 |

| 19 | 17 | 18 | 1.463 | 1.432 | 15.0 | 9.0 |

| 20 | 18 | 19 | 0.914 | 0.895 | 13.0 | 7.0 |

| 21 | 19 | 20 | 0.804 | 0.787 | 30.0 | 20.0 |

| 22 | 20 | 21 | 1.133 | 1.110 | 90.0 | 50.0 |

| 23 | 21 | 22 | 0.475 | 0.465 | 50.0 | 30.0 |

| 24 | 17 | 23 | 2.214 | 1.505 | 60.0 | 40.0 |

| 25 | 23 | 24 | 1.620 | 1.110 | 100.0 | 80.0 |

| 26 | 24 | 25 | 1.080 | 0.734 | 80.0 | 65.0 |

| 27 | 25 | 26 | 0.540 | 0.367 | 100.0 | 60.0 |

| 28 | 26 | 27 | 0.540 | 0.367 | 100.0 | 55.0 |

| 29 | 27 | 28 | 1.080 | 0.734 | 120.0 | 70.0 |

| 30 | 28 | 29 | 1.080 | 0.734 | 105.0 | 70.0 |

| 31 | 70 | 30 | 0.366 | 0.358 | 80.0 | 50.0 |

| 32 | 30 | 31 | 0.731 | 0.716 | 60.0 | 40.0 |

| 33 | 31 | 32 | 0.731 | 0.716 | 13.0 | 8.0 |

| 34 | 32 | 33 | 0.804 | 0.787 | 16.0 | 9.0 |

| 35 | 33 | 34 | 1.170 | 1.145 | 50.0 | 30.0 |

| 36 | 34 | 35 | 0.768 | 0.752 | 40.0 | 28.0 |

| 37 | 35 | 36 | 0.731 | 0.716 | 60.0 | 40.0 |

| 38 | 36 | 37 | 1.097 | 1.074 | 40.0 | 30.0 |

| 39 | 37 | 38 | 1.463 | 1.432 | 30.0 | 25.0 |

| 40 | 32 | 39 | 1.080 | 0.734 | 150.0 | 100.0 |

| 41 | 39 | 40 | 0.540 | 0.367 | 60.0 | 35.0 |

| 42 | 40 | 41 | 1.080 | 0.734 | 120.0 | 70.0 |

| 43 | 41 | 42 | 1.836 | 1.248 | 90.0 | 60.0 |

| 44 | 42 | 43 | 1.296 | 0.881 | 18.0 | 10.0 |

| 45 | 40 | 44 | 1.188 | 0.807 | 16.0 | 10.0 |

| 46 | 44 | 45 | 0.540 | 0.367 | 100.0 | 50.0 |

| 47 | 42 | 46 | 1.080 | 0.734 | 60.0 | 40.0 |

| 48 | 35 | 47 | 0.540 | 0.367 | 90.0 | 70.0 |

| 49 | 47 | 48 | 1.080 | 0.734 | 85.0 | 55.0 |

| 50 | 48 | 49 | 1.080 | 0.734 | 100.0 | 70.0 |

| 51 | 49 | 50 | 1.080 | 0.734 | 140.0 | 90.0 |

| 52 | 70 | 51 | 0.366 | 0.358 | 60.0 | 40.0 |

| 53 | 51 | 52 | 1.463 | 1.432 | 20.0 | 11.0 |

| 54 | 52 | 53 | 1.463 | 1.432 | 40.0 | 30.0 |

| 55 | 53 | 54 | 0.914 | 0.895 | 36.0 | 24.0 |

| 56 | 54 | 55 | 1.097 | 1.074 | 30.0 | 20.0 |

| 57 | 55 | 56 | 1.097 | 1.074 | 43.0 | 30.0 |

| 58 | 52 | 57 | 0.270 | 0.183 | 80.0 | 50.0 |

| 59 | 57 | 58 | 0.270 | 0.183 | 240.0 | 120.0 |

| 60 | 58 | 59 | 0.810 | 0.550 | 125.0 | 110.0 |

| 61 | 59 | 60 | 1.296 | 0.881 | 25.0 | 10.0 |

| 62 | 55 | 61 | 1.188 | 0.807 | 10.0 | 5.0 |

| 63 | 61 | 62 | 1.188 | 0.807 | 150.0 | 130.0 |

| 64 | 62 | 63 | 0.810 | 0.550 | 50.0 | 30.0 |

| 65 | 63 | 64 | 1.620 | 1.0101 | 30.0 | 20.0 |

| 66 | 62 | 65 | 1.080 | 0.734 | 130.0 | 120.0 |

| 67 | 65 | 66 | 0.540 | 0.367 | 150.0 | 130.0 |

| 68 | 66 | 67 | 1.080 | 0.734 | 25.0 | 15.0 |

References

- Taheri, S.I.; Salles, M.B.C.; Kagan, N. A New Modified TLBO Algorithm for Placement of AVRs in Distribution System. In Proceedings of the 2019 IEEE PES Conference on Innovative Smart Grid Technologies, ISGT Latin America 2019, Gramado, Brazil, 15–18 September 2019. [Google Scholar]

- Sabir, A.; Ibrir, S. A Robust Control Scheme for Grid-Connected Photovoltaic Converters with Low-Voltage Ride-through Ability without Phase-Locked Loop. ISA Trans. 2020, 96, 287–298. [Google Scholar] [CrossRef] [PubMed]

- Güler, N.; Irmak, E. Design, Implementation and Model Predictive Based Control of a Mode-Changeable DC/DC Converter for Hybrid Renewable Energy Systems. ISA Trans. 2021, 114, 485–498. [Google Scholar] [CrossRef] [PubMed]

- Sepehrzad, R.; Moridi, A.R.; Hassanzadeh, M.E.; Seifi, A.R. Intelligent Energy Management and Multi-Objective Power Distribution Control in Hybrid Micro-Grids Based on the Advanced Fuzzy-PSO Method. ISA Trans. 2021, 112, 199–213. [Google Scholar] [CrossRef] [PubMed]

- Gazijahani, F.S.; Ravadanegh, S.N.; Salehi, J. Stochastic Multi-Objective Model for Optimal Energy Exchange Optimization of Networked Microgrids with Presence of Renewable Generation under Risk-Based Strategies. ISA Trans. 2018, 73, 100–111. [Google Scholar] [CrossRef] [PubMed]

- Esmaeili, M.; Sedighizadeh, M.; Esmaili, M. Multi-Objective Optimal Reconfiguration and DG (Distributed Generation) Power Allocation in Distribution Networks Using Big Bang-Big Crunch Algorithm Considering Load Uncertainty. Energy 2016, 103, 86–99. [Google Scholar] [CrossRef]

- El-Fergany, A. Study Impact of Various Load Models on DG Placement and Sizing Using Backtracking Search Algorithm. Appl. Soft Comput. J. 2015, 30, 803–811. [Google Scholar] [CrossRef]

- Fu, G. An Explicit Divergence-Free DG Method for Incompressible Flow. Comput. Methods Appl. Mech. Eng. 2019, 345, 502–517. [Google Scholar] [CrossRef]

- Hadidian-Moghaddam, M.J.; Arabi-Nowdeh, S.; Bigdeli, M.; Azizian, D. A Multi-Objective Optimal Sizing and Siting of Distributed Generation Using Ant Lion Optimization Technique. Ain Shams Eng. J. 2018, 9, 2101–2109. [Google Scholar] [CrossRef]

- Das, B.; Mukherjee, V.; Das, D. Optimum DG Placement for Known Power Injection from Utility/Substation by a Novel Zero Bus Load Flow Approach. Energy 2019, 175, 228–249. [Google Scholar] [CrossRef]

- Niknam, T.; Taheri, S.I.; Mohammadi, M. Improvement and Revision of Polymer Electrolyte Membrane Fuel Cell Dynamic Model. Electr. Power Compon. Syst. 2010, 38, 1353–1369. [Google Scholar] [CrossRef]

- Ravindran, S.; Victoire, T.A.A. A Bio-Geography-Based Algorithm for Optimal Siting and Sizing of Distributed Generators with an Effective Power Factor Model. Comput. Electr. Eng. 2018, 72, 482–501. [Google Scholar] [CrossRef]

- Molver, I.; Chowdhury, S. Alternative Approaches for Analysing the Impact of Distributed Generation on Shunt Compensated Radial Medium Voltage Networks. Comput. Electr. Eng. 2020, 85, 106676. [Google Scholar] [CrossRef]

- Bayat, A.; Bagheri, A.; Noroozian, R. Optimal Siting and Sizing of Distributed Generation Accompanied by Reconfiguration of Distribution Networks for Maximum Loss Reduction by Using a New UVDA-Based Heuristic Method. Int. J. Electr. Power Energy Syst. 2016, 77, 360–371. [Google Scholar] [CrossRef]

- Iqbal, F.; Khan, M.T.; Siddiqui, A.S. Optimal Placement of DG and DSTATCOM for Loss Reduction and Voltage Profile Improvement. Alex. Eng. J. 2018, 57, 755–765. [Google Scholar] [CrossRef]

- Niknam, T.; Azizipanah-Abarghooee, R.; Aghaei, J. A New Modified Teaching-Learning Algorithm for Reserve Constrained Dynamic Economic Dispatch. IEEE Trans. Power Syst. 2013, 28, 749–763. [Google Scholar] [CrossRef]

- Kumar, S.; Mandal, K.K.; Chakraborty, N. Optimal DG Placement by Multi-Objective Opposition Based Chaotic Differential Evolution for Techno-Economic Analysis. Appl. Soft Comput. J. 2019, 78, 70–83. [Google Scholar] [CrossRef]

- ChithraDevi, S.A.; Lakshminarasimman, L.; Balamurugan, R. Stud Krill Herd Algorithm for Multiple DG Placement and Sizing in a Radial Distribution System. Eng. Sci. Technol. Int. J. 2017, 20, 748–759. [Google Scholar] [CrossRef]

- Kasaei, M.J.; Gandomkar, M.; Nikoukar, J. Optimal Management of Renewable Energy Sources by Virtual Power Plant. Renew. Energy 2017, 114, 1180–1188. [Google Scholar] [CrossRef]

- Bahmanifirouzi, B.; Niknam, T.; Taheri, S.I. A New Evolutionary Algorithm for Placement of Distributed Generation. In Proceedings of the 2011 IEEE Power Engineering and Automation Conference, Wuhan, China, 8–9 September 2011; Volume 1, pp. 104–107. [Google Scholar] [CrossRef]

- Niknam, T.; Taheri, S.I.; Aghaei, J.; Tabatabaei, S.; Nayeripour, M. A Modified Honey Bee Mating Optimization Algorithm for Multiobjective Placement of Renewable Energy Resources. Appl. Energy 2011, 88, 4817–4830. [Google Scholar] [CrossRef]

- Miao, D.; Hossain, S. Improved Gray Wolf Optimization Algorithm for Solving Placement and Sizing of Electrical Energy Storage System in Micro-Grids. ISA Trans. 2020, 102, 376–387. [Google Scholar] [CrossRef] [PubMed]

- Ayoubi, M.; Hooshmand, R.A. A New Fuzzy Optimal Allocation of Detuned Passive Filters Based on a Nonhomogeneous Cuckoo Search Algorithm Considering Resonance Constraint. ISA Trans. 2019, 89, 186–197. [Google Scholar] [CrossRef] [PubMed]

- Ramirez-Rosado, I.J.; Dominguez-Navarro, J.A. New Multiobjective Tabu Search Algorithm for Fuzzy Optimal Planning of Power Distribution Systems. IEEE Trans. Power Syst. 2006, 21, 224–233. [Google Scholar] [CrossRef]

- Khare, R.; Kumar, Y. A Novel Hybrid MOL-TLBO Optimized Techno-Economic-Socio Analysis of Renewable Energy Mix in Island Mode. Appl. Soft Comput. J. 2016, 43, 187–198. [Google Scholar] [CrossRef]

- Zou, F.; Chen, D.; Xu, Q. A Survey of Teaching–Learning-Based Optimization. Neurocomputing 2019, 335, 366–383. [Google Scholar] [CrossRef]

- Joshi, P.M.; Verma, H.K. An Improved TLBO Based Economic Dispatch of Power Generation through Distributed Energy Resources Considering Environmental Constraints. Sustain. Energy Grids Netw. 2019, 18, 100207. [Google Scholar] [CrossRef]

- Sahu, S.; Barisal, A.K.; Kaudi, A. Multi-Objective Optimal Power Flow with DG Placement Using TLBO and MIPSO: A Comparative Study. Energy Procedia 2017, 117, 236–243. [Google Scholar] [CrossRef]

- Elsisi, M.; Soliman, M. Optimal Design of Robust Resilient Automatic Voltage Regulators. ISA Trans. 2021, 108, 257–268. [Google Scholar] [CrossRef]

- Srikanth, M.V.; Yadaiah, N. An AHP Based Optimized Tuning of Modified Active Disturbance Rejection Control: An Application to Power System Load Frequency Control Problem. ISA Trans. 2018, 81, 286–305. [Google Scholar] [CrossRef]

- Biswas, P.P.; Mallipeddi, R.; Suganthan, P.N.; Amaratunga, G.A.J. A Multiobjective Approach for Optimal Placement and Sizing of Distributed Generators and Capacitors in Distribution Network. Appl. Soft Comput. J. 2017, 60, 268–280. [Google Scholar] [CrossRef]

- Mandal, B.; Roy, P.K. Optimal Reactive Power Dispatch Using Quasi-Oppositional Teaching Learning Based Optimization. Int. J. Electr. Power Energy Syst. 2013, 53, 123–134. [Google Scholar] [CrossRef]

- Taheri, S.I.; Vieira, G.G.T.T.; Salles, M.B.C.; Avila, S.L. A Trip-Ahead Strategy for Optimal Energy Dispatch in Ship Power Systems. Electr. Power Syst. Res. 2020, 192, 106917. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Wang, B. Within-Day Rolling Optimal Scheduling Problem for Active Distribution Networks by Multi-Objective Evolutionary Algorithm Based on Decomposition Integrating with Thought of Simulated Annealing. Energy 2021, 223, 120027. [Google Scholar] [CrossRef]

- Taheri, S.I.; Salles, M.B.C.; Nassif, A.B. Distributed Energy Resource Placement Considering Hosting Capacity by Combining Teaching-Learning-Based and Honey-Bee-Mating Optimisation Algorithms. Appl. Soft Comput. 2021, 113, 107953. [Google Scholar] [CrossRef]

- Das, D. A Fuzzy Multiobjective Approach for Network Reconfiguration of Distribution Systems. IEEE Trans. Power Deliv. 2005, 21, 202–209. [Google Scholar] [CrossRef]

- Taheri, S.I.; Salles, M.B.C. A New Modification for TLBO Algorithm to Placement of Distributed Generation. In Proceedings of the 2019 International Conference on Clean Electrical Power (ICCEP), Otranto, Italy, 2–4 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 593–598. [Google Scholar]

- Singh, B.; Mukherjee, V.; Tiwari, P. Genetic Algorithm Optimized Impact Assessment of Optimally Placed DGs and FACTS Controller with Different Load Models from Minimum Total Real Power Loss Viewpoint. Energy Build. 2016, 126, 194–219. [Google Scholar] [CrossRef]

- Das, B.; Mukherjee, V.; Das, D. DG Placement in Radial Distribution Network by Symbiotic Organisms Search Algorithm for Real Power Loss Minimization. Appl. Soft Comput. J. 2016, 49, 920–936. [Google Scholar] [CrossRef]

- Taheri, S.I.; Rodrigues, L.L.; Salles, M.B.; Sguarezi Filho, A.J. A Day-Ahead Hybrid Optimization Algorithm for Finding the Dispatch Schedule of VPP in a Distribution System. Simpósio Bras. Sist. Elétricos-SBSE 2020, 1, 1–6. [Google Scholar] [CrossRef]

- Taheri, S.I.; Salles, M.B.C.; Costa, E.C.M. Optimal Cost Management of Distributed Generation Units and Microgrids for Virtual Power Plant Scheduling. IEEE Access 2020, 8, 208449–208461. [Google Scholar] [CrossRef]

- Niknam, T.; Azizipanah-Abarghooee, R.; Rasoul Narimani, M. A New Multi Objective Optimization Approach Based on TLBO for Location of Automatic Voltage Regulators in Distribution Systems. Eng. Appl. Artif. Intell. 2012, 25, 1577–1588. [Google Scholar] [CrossRef]

- Hosseinpour, H.; Bastaee, B. Optimal Placement of On-Load Tap Changers in Distribution Networks Using SA-TLBO Method. Int. J. Electr. Power Energy Syst. 2015, 64, 1119–1128. [Google Scholar] [CrossRef]

- Sultana, S.; Roy, P.K. Multi-Objective Quasi-Oppositional Teaching Learning Based Optimization for Optimal Location of Distributed Generator in Radial Distribution Systems. Int. J. Electr. Power Energy Syst. 2014, 63, 534–545. [Google Scholar] [CrossRef]

- Frey, B.B. Friedman Test. In The SAGE Encyclopedia of Educational Research, Measurement, and Evaluation; SAGE: Sauzend Oaks, CA, USA, 2018. [Google Scholar]

- Rathore, A.; Patidar, N.P. Optimal Sizing and Allocation of Renewable Based Distribution Generation with Gravity Energy Storage Considering Stochastic Nature Using Particle Swarm Optimization in Radial Distribution Network. J. Energy Storage 2021, 35, 102282. [Google Scholar] [CrossRef]

- Hemeida, A.M.; Bakry, O.M.; Mohamed, A.-A.A.; Mahmoud, E.A. Genetic Algorithms and Satin Bowerbird Optimization for Optimal Allocation of Distributed Generators in Radial System. Appl. Soft Comput. 2021, 111, 107727. [Google Scholar] [CrossRef]

- Ferrer, J.; Chicano, F.; Alba, E. Estimating Software Testing Complexity. Inf. Softw. Technol. 2013, 55, 2125–2139. [Google Scholar] [CrossRef]

- Kianmehr, E.; Nikkhah, S.; Rabiee, A. Multi-Objective Stochastic Model for Joint Optimal Allocation of DG Units and Network Reconfiguration from DG Owner’s and DisCo’s Perspectives. Renew. Energy 2019, 132, 471–485. [Google Scholar] [CrossRef]

- Alva, S.; Manjunath, V. Strategy-Proof Pareto-Improvement. J. Econ. Theory 2019, 181, 121–142. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.J.; Vakharia, D.P. Teaching-Learning-Based Optimization: A Novel Method for Constrained Mechanical Design Optimization Problems. Comput. Aided Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Venkata Rao, R. Review of Applications of Tlbo Algorithm and a Tutorial for Beginners to Solve the Unconstrained and Constrained Optimization Problems. Decis. Sci. Lett. 2016, 5, 1–30. [Google Scholar] [CrossRef]

| Method | Pseudocode |

|---|---|

| Quasi-oppositional based initialization | Begin For d = 1: ( = population size) For l = 1: ( = controlvariable) End End End |

| Quasi-oppositional based generation jumping | Begin If rand (0,1) For d = 1: For l = 1: End End End End |

| Steps | Description |

|---|---|

| Step 1 | The first step defines the algorithm’s inputs, such as population size, the iterations number, DG numbers, DG characteristics, constraints, and network data. |

| Step 2 | This step calculates the initial population by using Equation (26). |

| Step 3 | The third step firstly calculates the objective functions vectors (i.e., Equations (6), (8), (10) and (13)) by using the backward-forward distribution load flow [10] (this paper obtains all calculations of objective functions by using the results of backward-forward load flow). Secondly, this step normalizes them by Equation (A4). |

| Step 4 | This step calculates Pareto optimal solutions by normalized objective function vectors of Step 3, and it saves them in the external cache. |

| Step 5 | This step computes the population mean column-wise, such as in Equation (27). The algorithm randomly selects a Pareto optimal solution of the external cache as a teacher (). Then, it calculates Xnew according to Equation (A7) using Xdiffk obtained from Equation (A6). |

| Step 6 | This step is the Learner phase. The algorithm checks the limitations of the considered elements. If an independent variable is higher than the maximum level, the algorithm makes it similar to the top level. If it is less than the minimum level, the algorithm changes identically to the minimum value. This step calculates the new vector’s objective functions (i.e., ) and compares them with the existing vectors in the external cache. The algorithm approves it () by Equation (19) or Equation (20). |

| Step 7 | This step obtains a new population member (SA vector) by Equation (17) and then calculates Xk+1new y Equation (20) and, after that, compares it with the existing vectors in the external cache. Finally, this step adds Pareto optimal solutions to the external cache. |

| Step 8 | This step is Quasi-opposition-based learning modification. This step generates the QOP set and calculates the corresponding fitness values. |

| Step 9 | This step chooses the required fittest vector number from Xi and QOP as a new population set. |

| Step 10 | Firstly, this step classifies the solutions to find the best one. Secondly, it assigns that solution to the new teacher. Thirdly, this step modifies each student’s grade based on the new teacher’s knowledge (i.e., modifying Xi). Lastly, the algorithm obtains Pareto optimal solutions and adds them to the external cache. |

| Step 11 | This step specifies the non-dominated solutions of the external cache. The algorithm added some solutions in steps 7 and 10, and they might dominate existing solutions. Consequently, the algorithm needs to apply the Pareto method to find the non-dominated answers among the old and new external cache members. |

| Step 12 | This step makes a loop by going back to Step 5 until the present iteration number equals the maxi-mum iteration number. |

| Algorithm | Principle | Strengths | Weaknesses |

|---|---|---|---|

| GA | Based on the process of natural selection, involving selection, crossover, and mutation operations on a population of potential solutions. | Effective for exploring large solution spaces, suitable for complex, multimodal, and nonlinear optimization problems. | Can get stuck in local optima, requires tuning of parameters, and may have slow convergence rates for some problems. |

| PSO | Mimics the social behavior of birds flocking, where particles adjust their positions based on their own best experience and the swarm’s collective knowledge. | Fast convergence, easy implementation, and good at escaping local optima. Suitable for continuous and discrete optimization problems. | Convergence to global optimum is not always guaranteed; performance highly depends on parameters and initialization. |

| HBMO | Inspired by the mating behavior of honey bees. | Suitable for both continuous and discrete problems, capable of escaping local optima, and often effective for complex, multimodal functions. | Requires careful parameter tuning, might have longer convergence times for some problems, and could be sensitive to initializations. |

| TLBO | Simulates the teaching and learning processes in a classroom, where learners (solutions) improve over iterations by learning from each other and a teacher (best solution). | Simplicity in implementation, less parameter tuning, and robust performance for various problem types. It’s particularly effective in continuous optimization. | Can be sensitive to the initial population, might struggle with discrete or combinatorial problems, and might require more iterations for convergence in certain cases. |

| Objective | Algorithm | Average | Best Result | Worst Result |

|---|---|---|---|---|

| GA [46] | 6.531 × 107 | 6.512 × 107 | 6.568 × 107 | |

| PSO [45] | 6.526 × 107 | 6.501 × 107 | 6.555 × 107 | |

| HBMO [35] | 6.517 × 107 | 6.499 × 107 | 6.540 × 107 | |

| TLBO [35] | 6.493 × 107 | 6.474 × 107 | 6.511 × 107 | |

| MQOTLBO | 6.453 × 107 | 6.433 × 107 | 6.502 × 107 | |

| GA [46] | 2.55847 | 2.56384 | 2.58964 | |

| PSO [45] | 2.56217 | 2.55554 | 2.57894 | |

| HBMO [35] | 2.55784 | 2.54194 | 2.56985 | |

| TLBO [35] | 2.52719 | 2.51515 | 2.54573 | |

| MQOTLBO | 2.51102 | 2.50598 | 2.53169 | |

| GA [46] | 132.7814 | 129.5982 | 135.8975 | |

| PSO [45] | 130.1585 | 128.9817 | 132.2548 | |

| HBMO [35] | 128.4562 | 128.0254 | 129.8372 | |

| TLBO [35] | 127.0255 | 126.2418 | 128.2651 | |

| MQOTLBO | 126.0288 | 125.0252 | 127.2222 | |

| GA [46] | 1.22908 × 106 | 1.21003 × 106 | 1.25609 × 106 | |

| PSO [45] | 1.08601 × 106 | 1.08002 × 106 | 1.08928 × 106 | |

| HBMO [35] | 1.08250 × 106 | 1.07382 × 106 | 1.08530 × 106 | |

| TLBO [35] | 1.07601 × 106 | 1.07225 × 106 | 1.07912 × 106 | |

| MQOTLBO | 1.07559 × 106 | 1.07204 × 106 | 1.07906 × 106 |

| DG Type | Fuel Cell | Photovoltaic Units | Wind Turbine (Small) | Wind Turbine (Big) |

|---|---|---|---|---|

| Rated capacity (kW) | 100 | 100 | 10 | 100 |

| Capital cost ($/kW) | 3674 | 6675 | 3866 | 1500 |

| Fuel cost ($/kWh) | 0.029 | 0 | 0 | 0 |

| Operation and Maintenance cost ($/kWh) | 0.01 | 0.005 | 0.005 | 0.005 |

| Lifetime (year) | 10 | 20 | 20 | 20 |

| Method | Cost ($) | DG Placement (Bus Number) | CPU Time (s) |

|---|---|---|---|

| GA [46] | 6.508 × 107 | 1, 2, 3, 13, 21, 29, 31, 33, 34, 44, 52, 53 | 572.63 |

| PSO [45] | 6.480 × 107 | 1, 2, 3, 14, 21, 29, 31, 33, 34, 44, 52, 53 | 354.2 |

| HBMO [35] | 6.489 × 107 | 1, 2, 3, 14, 21, 29, 31, 33, 34, 44, 52, 53 | 102.3 |

| TLBO | 6.471 × 107 | 1, 2, 3, 14, 21, 29, 31, 33, 34, 44, 52, 53 | 75.26 |

| MQOTLBO | 6.432 × 107 | 1, 2, 3, 14, 21, 29, 31, 33, 34, 44, 52, 53 | 70.32 |

| Method | Voltage Deviation (pu) | DG Placement (Bus Number) | CPU Time (s) |

|---|---|---|---|

| GA [46] | 2.54787 | 10, 12, 13, 18, 28, 34, 35, 44, 51, 53, 66, 67 | 445.12 |

| PSO [45] | 2.52588 | 11, 12, 13, 18, 28, 34, 35, 44, 51, 53, 66, 67 | 226.18 |

| HBMO [35] | 2.52325 | 11, 12, 13, 18, 28, 34, 35, 44, 51, 53, 66, 67 | 124.1 |

| TLBO | 2.51255 | 11, 12, 13, 18, 28, 34, 35, 44, 51, 53, 66, 67 | 115.67 |

| MQOTLBO | 2.50598 | 11, 12, 13, 18, 28, 34, 35, 44, 51, 53, 66, 67 | 110.52 |

| Method | Power Losses (KWh) | DG Placement (Bus Number) | CPU Time (s) |

|---|---|---|---|

| GA [46] | 128.3258 | 6, 7, 8, 23, 30, 31, 41, 44, 58, 59, 66, 67 | 147.21 |

| PSO [45] | 127.1574 | 7, 8, 9, 23, 30, 31, 41, 44, 58, 59, 66, 69 | 306.81 |

| HBMO [35] | 126.2312 | 6, 8, 9, 23, 30, 31, 41, 44, 58, 59, 66, 67 | 123.89 |

| TLBO | 126.2258 | 6, 8, 9, 23, 30, 31, 41, 44, 58, 59, 66, 67 | 110.56 |

| MQOTLBO | 125.0184 | 6, 8, 9, 23, 30, 31, 41, 44, 58, 59, 66, 67 | 104.74 |

| Method | Emission (Kg/h) | DG Placement (Bus Number) | CPU Time (s) |

|---|---|---|---|

| GA [46] | 6, 7, 8, 23, 30, 31, 41, 44, 58, 59, 66, 67 | 444.46 | |

| PSO [45] | 7, 9, 10, 23, 30, 31, 41, 44, 58, 59, 66, 67 | 252.49 | |

| HBMO [36] | 7, 9, 10, 23, 30, 31, 41, 44, 58, 59, 66, 67 | 122.78 | |

| TLBO | 7, 9, 10, 23, 30, 31, 41, 44, 58, 59, 66, 67 | 115.52 | |

| MQOTLBO | 7, 9, 10, 23, 30, 31, 41, 44, 58, 59, 66, 67 | 110.29 |

| Cases | Importance | Cost ($) | Power Losses (KWh) | Voltage Deviation (PU) | Emission (Kgr/h) | |||

|---|---|---|---|---|---|---|---|---|

| W1 | W2 | W3 | W4 | |||||

| Case I | - | - | - | - | 6.432 × 107 | 125.6982 | 2.5289 | 1.07903 × 106 |

| Case II | - | - | - | - | 6.501 × 107 | 127.4935 | 2.5801 | 1.07204 × 106 |

| Case III | - | - | - | - | 6.433 × 107 | 125.0184 | 2.5257 | 1.07542 × 106 |

| Case IV | - | - | - | - | 6.457 × 107 | 126.8010 | 2.5059 | 1.07447 × 106 |

| Case V | 0.33 | 0.33 | 0.33 | - | 6.4660 × 107 | 128.8938 | 2.3800 | - |

| 0.2 | 0.4 | 0.4 | - | 6.4443 × 107 | 125.5460 | 0.1775 | - | |

| 0.4 | 0.2 | 0.4 | - | 6.4443 × 107 | 125.5460 | 0.3732 | - | |

| 0.4 | 0.4 | 0.2 | - | 6.4443 × 107 | 125.5460 | 0.3732 | - | |

| Case VI | 0.33 | - | 0.33 | 0.33 | 6.4820 × 107 | - | 2.5098 | 1.5100 × 106 |

| 0.2 | - | 0.4 | 0.4 | 6.4725 × 107 | - | 0.3691 | 1.0772 × 106 | |

| 0.4 | - | 0.2 | 0.4 | 6.4725 × 107 | - | 0.3691 | 1.0752 × 106 | |

| 0.4 | - | 0.4 | 0.2 | 6.4725 × 107 | - | 0.1746 | 1.0762 × 106 | |

| Case VII | - | 0.33 | 0.33 | 0.33 | - | 135.9335 | 0.3024 | 1.0785 × 106 |

| - | 0.2 | 0.4 | 0.4 | - | 135.9335 | 0.3808 | 1.0785 × 106 | |

| - | 0.4 | 0.2 | 0.4 | - | 135.9335 | 0.3708 | 1.0785 × 106 | |

| - | 0.4 | 0.4 | 0.2 | - | 133.5985 | 0.1561 | 1.0808 × 106 | |

| Case VIII | 0.33 | 0.33 | - | 0.33 | 7.6062 × 107 | 150.4555 | - | 1.0757 × 106 |

| 0.2 | 0.4 | - | 0.4 | 6.8058 × 107 | 148.2527 | - | 1.0807 × 106 | |

| 0.4 | 0.2 | - | 0.4 | 6.8059 × 107 | 126.2527 | - | 1.0807 × 106 | |

| 0.4 | 0.4 | - | 0.2 | 6.8057 × 107 | 130.0764 | - | 1.0807 × 106 | |

| Case IX | 0.25 | 0.25 | 0.25 | 0.25 | 7.6813 × 107 | 141.9335 | 1.4031 | 1.2657 × 106 |

| 0.1 | 0.3 | 0.3 | 0.3 | 7.7172 × 107 | 139.2145 | 1.3051 | 1.1659 × 106 | |

| 0.3 | 0.1 | 0.3 | 0.3 | 7.6063 × 107 | 140.7865 | 1.2747 | 1.2554 × 106 | |

| 0.3 | 0.3 | 0.1 | 0.3 | 7.5772 × 107 | 138.8321 | 1.7014 | 1.2453 × 106 | |

| 0.3 | 0.3 | 0.3 | 0.1 | 7.6270 × 107 | 133.3472 | 0.3909 | 1.2873 × 106 | |

| DG Type | Cost ($) | Voltage Deviation (pu) | Power Losses (kWh) | Emission (kg/h) |

|---|---|---|---|---|

| 10 kW Wind Turbine | 6.884 × 107 | 2.885497 | 91.1902 | 0 |

| 100 kW Wind Turbine | 300.361 × 107 | 2.124123 | 144.9812 | 0 |

| Photovoltaic | 12.919 × 107 | 2.169854 | 121.6812 | 0 |

| Fuel cell with CHP | 6.437 × 107 | 2.3854 | 111.1562 | 1.07305 × 106 |

| Cost ($) | Voltage Deviation (per unit) | Power Losses (kWh) | Emission (ton/h) | Location of Fuel Cell Units | Location of Photovoltaic Units | Location of Wind Units |

|---|---|---|---|---|---|---|

| 8.426 × 107 | 2.569853 | 134.6857 | 1.024 × 106 | 4,7,12,14,21,29,31,33 | 22,69 | 56,57 |

| 8.487 × 107 | 2.552981 | 135.7412 | 1.072 × 106 | 5,11,22,34,35,44,47,49 | 15,66 | 56,60 |

| 8.506 × 107 | 2.694219 | 119.5599 | 1.065 × 106 | 6,8,18,23,31,33,39,48 | 66,69 | 5,26 |

| 8.518 × 107 | 2.727727 | 116.9998 | 1.03 × 106 | 9,23,30,31,41,44,58,59 | 22,45 | 57,60 |

| 8.525 × 107 | 2.457199 | 126.7923 | 1.069 × 106 | 11,18,40,47,50,59,62,64 | 45,66 | 32,35 |

| 8.510 × 107 | 2.777587 | 127.1248 | 1.066 × 106 | 11,19,40,44,56,57,60,64 | 15,45 | 54,60 |

| 8.522 × 107 | 2.565555 | 128.7498 | 1.014 × 106 | 11,17,43,44,52,57,62,64 | 15,22 | 5,60 |

| 8.527 × 107 | 2.647498 | 129.7459 | 1.061 × 106 | 8,9,11,13,50,59,65,69 | 22,45 | 60,64 |

| 8.533 × 107 | 2.384455 | 135.1289 | 1.051 × 106 | 4,8,11,22,41,46,58,66 | 45,69 | 32,57 |

| 8.542 × 107 | 2.484489 | 129.3355 | 1.075 × 106 | 7,12,25,33,44,52,67,69 | 22,66 | 54,56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taheri, S.I.; Davoodi, M.; Ali, M.H. A Simulated-Annealing-Quasi-Oppositional-Teaching-Learning-Based Optimization Algorithm for Distributed Generation Allocation. Computation 2023, 11, 214. https://doi.org/10.3390/computation11110214

Taheri SI, Davoodi M, Ali MH. A Simulated-Annealing-Quasi-Oppositional-Teaching-Learning-Based Optimization Algorithm for Distributed Generation Allocation. Computation. 2023; 11(11):214. https://doi.org/10.3390/computation11110214

Chicago/Turabian StyleTaheri, Seyed Iman, Mohammadreza Davoodi, and Mohd. Hasan Ali. 2023. "A Simulated-Annealing-Quasi-Oppositional-Teaching-Learning-Based Optimization Algorithm for Distributed Generation Allocation" Computation 11, no. 11: 214. https://doi.org/10.3390/computation11110214

APA StyleTaheri, S. I., Davoodi, M., & Ali, M. H. (2023). A Simulated-Annealing-Quasi-Oppositional-Teaching-Learning-Based Optimization Algorithm for Distributed Generation Allocation. Computation, 11(11), 214. https://doi.org/10.3390/computation11110214