Analysis of Liquid Quantity Measurement in Loading/Unloading Processes in Cylindrical Tanks

Abstract

:1. Introduction

- -

- Determination of the main factors of absolute quantity measurement uncertainty, using static volumetric assessments of the tank;

- -

- Determination of the main factors of measurement uncertainty for the quantity change resulting from the loading/unloading processes;

- -

- Modeling and comparison of absolute mass and mass difference measurement processes at the tank;

- -

- Formulation of recommendations for improving the efficiency of fuel control and sales processes in a company related to quantity measurements in the tank.

2. Modeling of Material Mass Estimation in Vertical Tanks

- Estimation of the absolute mass of the product in the tank;

- Estimation of product mass transfer (loading/unloading).

2.1. Evaluation of the Product Mass in the Tank

- Measured indirectly, using a level measuring system, at the actual temperature, Tact;

- Estimated at the laboratory at a temperature, T0, and then used for further calculations when the level measuring system does not have a density measurement function.

2.2. Evaluation of the Uncertainty of Product Volume in the Tank Estimation

- Tank calibration procedure, i.e., the uncertainty of the tank graduation table;

- Level measurement: Even with an ideal tank graduation table, the level measurement is the variable that determines which row is considered as a volume estimation outcome.

2.3. Evaluation of the Uncertainty of Product Mass in the Tank Estimation

3. Estimation of the Uncertainty of Subtractive Measurements: Discussion

- (1)

- Use additional measuring instruments, e.g., flow meters;

- (2)

- Perform two measurements of the product mass in the tank, namely before and after the transfer operation.

- Custody and inventory transfer operations should be differentiated from those that measure the absolute inventory in a tank in real time. It is recommended to use mathematical expressions for the calculation of the change in mass between the two measuring points and the calculation of the uncertainty (Formulas (12), (13) and (14), respectively). The total standard uncertainty should be estimated from the standard uncertainties of the individual components of the mass difference. Note that the above formulas apply to the calibration results of the tanks at the normalized temperature. When measuring the volume of the tank, it is necessary to introduce temperature corrections for the specific case, owing to the thermal expansion. Otherwise, the temperature estimation uncertainty component can have a strong impact on the expanded system uncertainty [10,28,38].

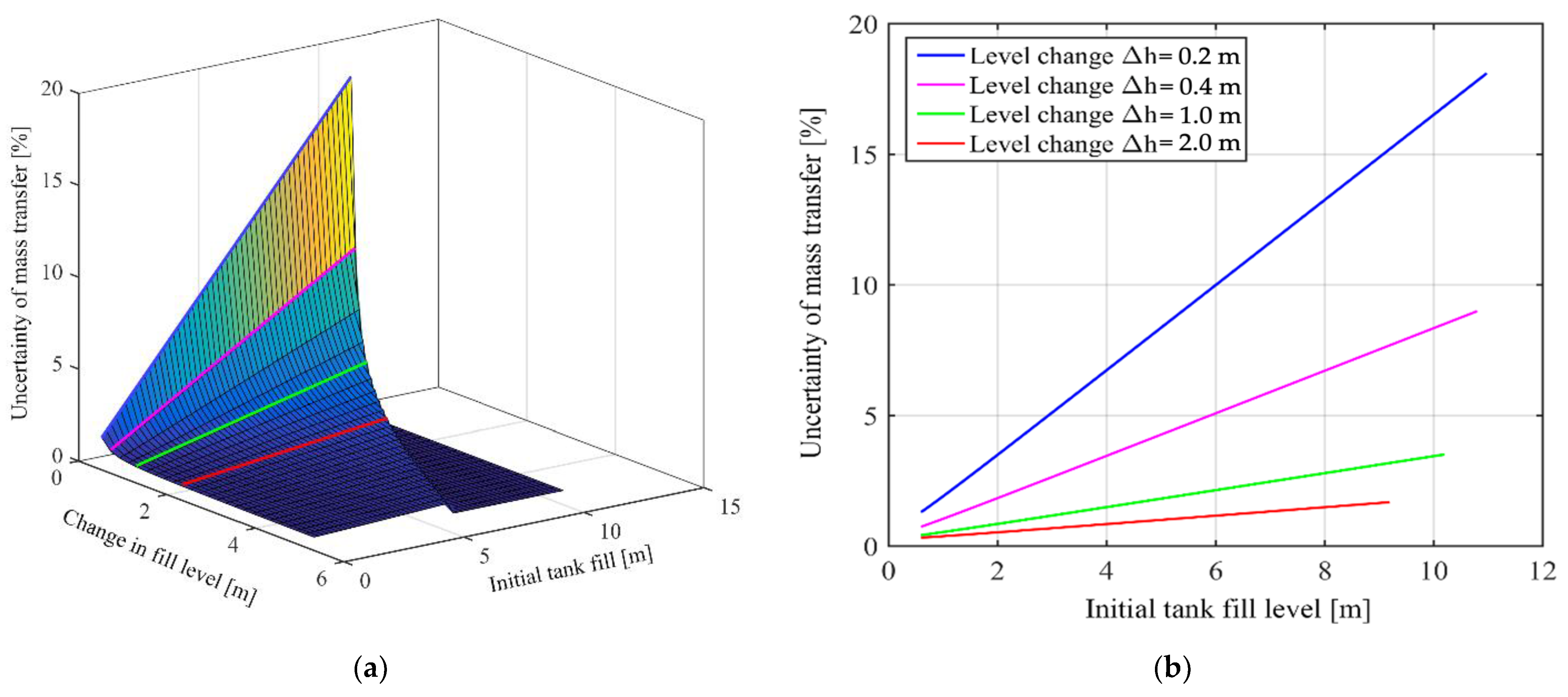

- The filling/emptying processes of the existing tanks should be controlled, considering that the uncertainty of the measuring system is influenced by the workflow: (1) the fuller the tank, the higher the resulting measurement uncertainty; and (2) the higher the filling quantity, the lower the measurement uncertainty. The product transfer process must be organized in such a way that the one-time received and dispensed quantity at the same level of the tank would compensate each other. The product should be distributed on a tank farm based on the level at which the difference in mass is measured. If the amount of product transferred during an operation affects the level change in the tank by 0.2 m, the uncertainty of the mass of such a transaction changes linearly from 2% to 20% when the initial filling is 1 m < h < 12 m. In the case of 2 m, the mass uncertainty in such a transaction changes linearly from 0.4% to 2.3% when the initial filling is 1 m < h < 12 m.

- Mass and volume measurement uncertainties derived from absolute volume data are often overly optimistic. The uncertainty of the mass differential measurements is greater than it would be expected from the inventory measurements within the tank. This needs to be considered when determining the maximum measurement errors for all measuring instruments and/or measuring systems used in the accounting chain when designing and selecting measurement systems/equipment when forecasting worst-case scenarios.

4. Conclusions

- -

- The tank calibration uncertainty is the dominant term in mass evaluation in fuel tanks. Therefore, tanks, as part of the product amount evaluation system, must be maintained regularly and inspected. Other constituents in the uncertainty budget, namely density determination and level measurement, were relatively small. However, at extremely low product levels in the tank, the density and level measurement errors have a greater influence. This assumes that the weight in the tank is always corrected for temperature fluctuations if the product properties are set at a fixed (normalized) temperature.

- -

- The uncertainty of the mass measurement transferred to/from the tank becomes highly dependent on the tank’s initial fill level (i.e., before the transaction) and the amount of product transferred. If the tank is almost full and a small amount of product is transferred during operation, the uncertainty of the mass of such a transaction can be up to 20%. However, as the amount of transferred product increased, this uncertainty decreased sharply (up to 2% or less). For comparison, other authors have reported that typical manual tank gauging uncertainties range from 0.6% to 2.5% [28,45].

- -

- Custody transfer operations should be separated from those intended to measure the absolute inventory in the tank, and a mathematical model related to the mass difference calculation was used. The mass of the contained product was evaluated indirectly by measuring the fill level, tank geometric parameters, liquid temperature, and density.

- -

- Although static tank measurements are less efficient than dynamic measurements realized with counters [28], the formulated recommendations allow for the management of custody transfer and can play a serious role in the amount of trust the operator can place in his inventory management system. This will help us understand that inventory management can indirectly control inventory accuracy. Larger measurement uncertainties in custody transfer result in higher losses and finances.

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- OIML R 71; Fixed Storage Tanks. General Requirements, TC 8/SC 1 Static Volume and Mass Measurement. 2008 ed.; Bureau International de Métrologie Légale: Paris, France, 2014.

- ISO 7507-4: 2010; Petroleum and Liquid Petroleum Products—Calibration of Vertical Cylindrical Tanks—Part 4: Internal Electro-Optical Distance-Ranging Method. ISO/TC 28/SC 2 Measurement of Petroleum and Related Products: London, UK, 2010.

- API MPMS 2.2A; Manual of Petroleum Measurement Standards Chapter 2.2A Measurement and Calibration of Upright Cylindrical Tanks by the Manual Tank Strapping Method. 2nd ed. American Petroleum Institute (API): Washington, DC, USA, 2019.

- Filho, B.R.; Gonçalves, R. Legal metrology, the economy and society: A systematic literature review. Measurement 2015, 69, 155–163. [Google Scholar] [CrossRef]

- Timothy Shea, J. Market Levels Rising in the Process Level Measurement and Inventory Tank Gauging Segments. Fierce Electronics: New York, NY, USA, 2012. Available online: https://www.fierceelectronics.com/components/market-levels-rising-process-level-measurement-and-inventory-tank-gauging-segments (accessed on 2 November 2021).

- Safety and Environmental Standards for Fuel Storage Sites; Process Safety Leadership Group Final Report; Health and Safety Executive: London, UK, 2009.

- Okeke, A. Towards sustainability in the global oil and gas industry: Identifying where the emphasis lies. Environ. Sustain. Indic. 2021, 12, 100145. [Google Scholar] [CrossRef]

- Fisher, W.P.; Pendrill, L.; da Cruz, A.L.; Felin, A. Why metrology? Fair dealing and efficient markets for the United Nations’ Sustainable Development Goals. J. Phys. Conf. Ser. 2019, 1379, 012023. [Google Scholar] [CrossRef]

- Agboola, O.O.; Akinnuli, O.B.; Akintunde, A.M.; Kareem, B. Modelling of Cost Estimates for the Geometrical Calibration of Upright Oil Storage Tanks. Int. J. Energy Econ. Policy 2020, 10, 464–470. [Google Scholar] [CrossRef]

- Inventory Management. Fuels Manager 2000 Inventory Management Software for Bulk Storage, Pipeline and Terminal Applications in the Oil and Gas Industry. Endress+Hauser GmbH+Co. Instruments International. Technical Information TI 408V/00/en. Available online: http://www.merteh.lv/eh/pdf/TI408VEN.PDF (accessed on 2 November 2021).

- Inventory Control Solutions. Integrate Field Instruments and Software for Complete Asset Management. Varec, Inc., a Leidos Company, 2020. Available online: https://www.varec.com/web/wp-content/uploads/2018/10/PRO157_Inventory-Control_brochure_web.pdf (accessed on 2 November 2021).

- Abby Jenkins. Just-in-Time Inventory (JIT) Explained: A Guide. Oracle, 2020. Available online: https://www.netsuite.com/portal/resource/articles/inventory-management/just-in-time-inventory.shtml (accessed on 2 November 2021).

- Abby Jenkins. Ultimate Lean Inventory Management Guide for Businesses. Oracle, 2021. Available online: https://www.netsuite.com/portal/resource/articles/inventory-management/lean-inventory-management.shtml (accessed on 2 November 2021).

- API MPMS Chapter 18.2. Custody Transfer of Crude Oil from Lease Tanks Using Alternative Measurement Methods. American Petroleum Institute (API), 2016; p. 36. Available online: https://pdf4pro.com/view/api-mpms-chapter-18-2-custody-transfer-of-crude-4e60.html (accessed on 2 November 2021).

- Meškuotienė, A.; Kaškonas, P.; Urbonavičius, B.G. Analysis of Fuel’s Amount Measurement Process and Its Reliability in Commercial Transaction. MAPAN 2020, 36, 175–185. [Google Scholar] [CrossRef]

- Braddock, R.; Chambers, C. Tank Gauging Systems Used for Bulk Storage of Gasoline; Health and Safety Laboratory: Buxton, Derbyshire, UK, 2011; Available online: https://www.icheme.org/media/9288/xxii-paper-77.pdf (accessed on 17 January 2022).

- Knyva, V.; Knyva, M.; Rainys, J. New Approach to Calibration of Vertical Fuel Tanks. Electron. Electr. Eng. 2013, 19, 37–40. [Google Scholar] [CrossRef]

- Chen, G.; Wan, Y.; Lin, H.; Hu, H.; Liu, G.; Peng, Y. Vertical tank capacity measurement based on Monte Carlo method. PLoS ONE 2021, 16, e0250207. [Google Scholar] [CrossRef]

- Agboola, O.O.; Akinnuli, B.O.; Akintunde, M.A.; Ikubanni, P.; Adeleke, A.A. Comparative Analysis of Manual Strapping Method (MSM) and Electro-Optical Distance Ranging (EODR) Method of Tank Calibration. J. Phys. Conf. Ser. 2019, 1378, 022062. [Google Scholar] [CrossRef] [Green Version]

- Agboola, O.; Ikubanni, P. Application of statistical quality control (sqc) in the calibration of oil storage tanks. J. Prod. Eng. 2017, 20, 127–132. [Google Scholar] [CrossRef]

- The Engineer’s Guide to Tank Gauging. Emerson Electric Co., 2021. Available online: https://www.emerson.com/documents/automation/-engineer-s-guide-to-tank-gauging-en-175314.pdf (accessed on 17 January 2022).

- Yahya, S.I. A Multi-Level Storage Tank Gauging and Monitoring System Using a Nanosecond Pulse. Int. J. Eng. Trends Technol. (IJETT) 2013, 5, 17. Available online: http://www.ijettjournal.org (accessed on 17 January 2022).

- Samoilenko, O.; Zaets, V. Calibration of Tanks and Ships’ Tanks for Storage and Transportation of Liquids by Laser Scanning. Open access peer-reviewed chapter. Appl. Asp. Mod. Metrol. 2021. [Google Scholar] [CrossRef]

- Sholette, B.; Howsare, B. Level Measurement: General Process vs. Inventory Tank Gauging. 2015. Available online: https://www.controleng.com/articles/level-measurement-general-process-vs-inventory-tank-gauging/ (accessed on 17 January 2022).

- Comstock, D. Measurement Accuracy and Sources of Error in Tank Gauging. Technical Library as A Service to the Hydro Carbon Measurement Industry. Available online: https://pdfcoffee.com/measurement-accuracy-and-sources-of-error-in-tank-gauging-2270-2-pdf-free.html (accessed on 17 January 2022).

- Makushkin, S.G.; Kuz’Min, S.A.; Kalashnik, G.G. Tank Deformation and Accuracy in Measuring Oil Product Mass. Chem. Pet. Eng. 2001, 37, 278–281. [Google Scholar] [CrossRef]

- Sreenevasan, R. Tank Gauges for Oil and Gas. In Volume I Measurement and Safety; CRC Press: Boca Raton, FL, USA, 2016; Volume I, pp. 665–679. Available online: https://books.google.lt/books?id=syINDgAAQBAJ&pg=PA665&lpg=PA665&dq=fuel+custody+transfer+and+inventory+control&source=bl&ots=6Zv_4pqq-3&sig=ACfU3U1-WqKEX3cLuS3gvHLASNtER9x7Dw&hl=en&sa=X&ved=2ahUKEwi3m9-Zg9r3AhUEDewKHVAqDdMQ6AF6BAgeEAM#v=onepage&q=fuel%20custody%20transfer%20and%20inventory%20control&f=false (accessed on 17 January 2022).

- Shunashu, I.L.; Casmir, R. Assessing the impact of measurement uncertainty in custody transfer to the development of oil & gas industry in Tanzania. Bus. Educ. 2020, 4, 16. Available online: http://dspace.cbe.ac.tz:8080/xmlui/bitstream/handle/123456789/498/222-588-1-SM.pdf?sequence=1&isAllowed=y (accessed on 24 January 2022).

- Adekitan, A.I.; Omoruyi, O. Stock keeping accuracy: A data based investigation of storage tank calibration challenges. Data Brief 2018, 19, 2155–2162. [Google Scholar] [CrossRef] [PubMed]

- Enraf, B.V. The Art of Tank Gauging; For Safety and Precision; Enraf B.V.: Delft, The Netherlands; Available online: http://satengin.com/Honeywell%20Enraf/4416650%20Art%20of%20Tank%20Gaugin.pdf (accessed on 24 January 2022).

- Directive 017: Measurement Requirements for Oil and Gas Operations; Alberta Energy Regulator: Calgary, Canada, 2022; Available online: https://static.aer.ca/prd/documents/directives/Directive017.pdf (accessed on 24 January 2022).

- Spisbury, B.; Hofstede, H. Uncertainties in shore tank measurement. KROHNE Oil Gas 2006, 42–43. Available online: https://root.krohne.com/fileadmin/content/media-lounge/PDF-Download/Oil_and_Gas/Reprint_TankStorageMagazine_20061_lowres_fromdescreened_scan.pdf (accessed on 24 January 2022).

- Johannesson, U. Solving the seven most common tank gauging problems. Tank Storage Mag. 2016, 12, 3. Available online: https://www.emerson.com/documents/automation/article-solving-seven-most-common-tank-gauging-problems-article-rosemount-en-176542.pdf (accessed on 24 January 2022).

- Cahill, J. Cures for Common Tank Gauging Problem. Measurement Instrumentation. Tank Gauging, 2016. Available online: https://www.emersonautomationexperts.com/2016/measurement-instrumentation/cures-common-tank-gauging-problems/ (accessed on 24 January 2022).

- OIML R 85-1/2: 2008; Automatic Level Gauges for Measuring the Level of Liquid in Stationary Storage Tanks, TC 8/SC 1 Static Volume and Mass Measurement. Bureau International de Métrologie Légale: Paris, France, 2008.

- ASTM D5002-19; Standard Test Method for Density and Relative Density of Crude Oils by Digital Density Analyzer. ASTM International: West Conshohocken, PA, USA, 2019.

- OIML G 14: 2011; Density Measurement. Bureau International de Métrologie Légale: Paris, France, 2011.

- Kolbjørnsen, H.; Lucas, P.; Mortensen, T.; Poder, L. Evaluation Uncertainty in Transferred LNG Volume; European Metrology Research Program: Braunschweig, Germany, 2011; Available online: https://lngmetrology.info/wp-content/uploads/2015/04/01-UncertaintyVolumeLNG_V22.pdf (accessed on 24 January 2022).

- EURAMET Calibration Guide No. 21 Version 2.0. Guidelines on the Calibration of Standard Capacity Measures Using the Volumetric Method. EURAMET e.V.; Technical Committee for Flow: Braunschweig, Germany, 2020; p. 31. Available online: http://www.eim.gr/wp-content/uploads/2020/06/I-CAL-GUI-021-Calibration-Guideline-No.-21-web.pdf (accessed on 24 January 2022).

- OpenStax. OpenStax, College Physics. 2016. Available online: https://openstax.org/books/college-physics/pages/13-2-thermal-expansion-of-solids-and-liquids (accessed on 24 January 2022).

- Santos, D.Q.; de Lima, A.L.; de Lima, A.P.; Neto, W.B.; Fabris, J.D. Thermal expansion coefficient and algebraic models to correct values of specific mass as a function of temperature for corn biodiesel. Fuel 2013, 106, 646–650. [Google Scholar] [CrossRef] [Green Version]

- ISO/TR 19441: 2018(en); Petroleum Products—Density Versus Temperature Relationships of Current Fuels, Biofuels and Biofuel Components. ISO/TC 28 Petroleum and Related Products, Fuels, and Lubricants from Natural or Synthetic Sources. ISO: Delft, The Netherlands, 2018.

- Wolf, H. Transport Properties of Fuels; Online Version of the PTB-Bericht PTB-Th-5en; Physikalisch-Technische Bundesanstalt (PTB): Braunschweig, Germany, 2015. [Google Scholar] [CrossRef]

- JCGM GUM-6: 2020; Guide to the Expression of Uncertainty in Measurement—Part 6: Developing and Using Measurement Models. Joint Committee for Guides in Metrology. Bureau International de Métrologie Légale: Paris, France, 2020.

- Stewart Ash, P.E. Measurement accuracy and sources of error in tank gauging. Meas. Eng. BP Pipe 2014, 325–329. Available online: https://pdfcoffee.com/tank-measurement-errors-pdf-free.html (accessed on 24 January 2022).

| Parameter | Value |

|---|---|

| tank filling level | (0.6–11.2) m |

| tank volume | (690–18,000) m3 |

| density of stored product | 840 kg/m3 |

| pressure sensor measurement error | 0.1% |

| level measurement error | 0.5 mm |

| Parameter | Value |

|---|---|

| tank filling level | (0.6–11.2) m |

| tank volume | (690–18,000) m3 |

| level change | (0.2–5) m |

| density of stored product | 840 kg/m3 |

| pressure sensor measurement error | 0.1% |

| level measurement error | 0.5 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meškuotienė, A.; Kaškonas, P.; Urbonavičius, B.G.; Balčiūnas, G.; Dobilienė, J. Analysis of Liquid Quantity Measurement in Loading/Unloading Processes in Cylindrical Tanks. Computation 2022, 10, 122. https://doi.org/10.3390/computation10070122

Meškuotienė A, Kaškonas P, Urbonavičius BG, Balčiūnas G, Dobilienė J. Analysis of Liquid Quantity Measurement in Loading/Unloading Processes in Cylindrical Tanks. Computation. 2022; 10(7):122. https://doi.org/10.3390/computation10070122

Chicago/Turabian StyleMeškuotienė, Asta, Paulius Kaškonas, Benas Gabrielis Urbonavičius, Gintautas Balčiūnas, and Justina Dobilienė. 2022. "Analysis of Liquid Quantity Measurement in Loading/Unloading Processes in Cylindrical Tanks" Computation 10, no. 7: 122. https://doi.org/10.3390/computation10070122

APA StyleMeškuotienė, A., Kaškonas, P., Urbonavičius, B. G., Balčiūnas, G., & Dobilienė, J. (2022). Analysis of Liquid Quantity Measurement in Loading/Unloading Processes in Cylindrical Tanks. Computation, 10(7), 122. https://doi.org/10.3390/computation10070122