Abstract

In aluminum electrolysis workshops, real-time pose perception of shelling heads is crucial to process accuracy and equipment safety. However, due to high temperatures, smoke, dust, and metal obstructions, traditional pose estimation methods struggle to achieve high accuracy and robustness. At the same time, the continuous movement of the shelling head and the similar geometric structures around it make it hard to match point-clouds, which makes it even harder to track the position and orientation. In response to the above challenges, we propose a multi-stage optimization pose estimation algorithm based on point-cloud processing. This method is designed for dynamic perception tasks of three-dimensional components in complex industrial scenarios. First stage improves the accuracy of initial matching by combining a weighted 3D Hough voting and adaptive threshold mechanism with an improved FPFH feature matching strategy. In the second stage, by integrating FPFH and PCA feature information, a stable initial registration is achieved using the RANSAC-IA coarse registration framework. In the third stage, we designed an improved ICP algorithm that effectively improved the convergence of the registration process and the accuracy of the final pose estimation. The experimental results show that the proposed method has good robustness and adaptability in a real electrolysis workshop environment, and can achieve pose estimation of the shelling head in the presence of noise, occlusion, and complex background interference.

1. Introduction

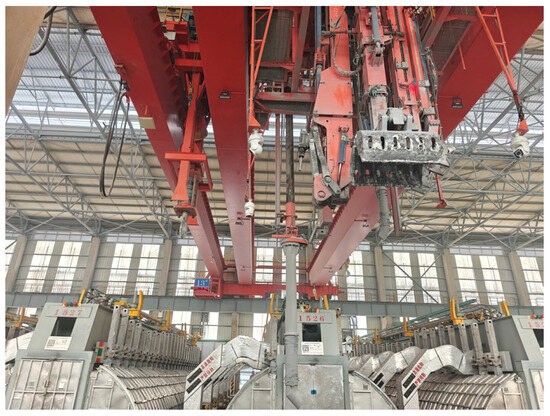

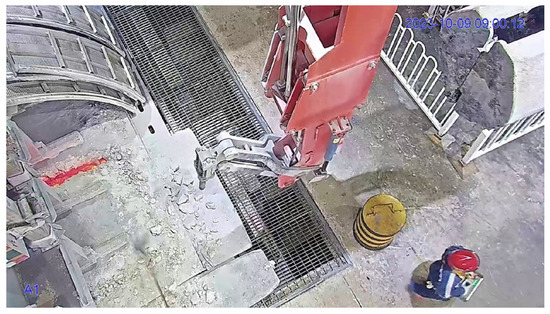

Aluminum electrolysis is a key step in industrial aluminum production. In 1886, American chemist Charles Martin Hall and French chemist Paul Héroult independently developed the Hall–Héroult process. This method converts aluminum oxide () into liquid aluminum through electrolysis at high temperatures between °C and °C [1,2,3]. With the advancement of the “carbon peaking and neutrality” goals, achieving automation and intelligent management of the electrolysis process, as well as improving energy efficiency, have become key industry priorities [4]. In this context, the operation sequence of the bridge cranes is crucial for maintaining the stability and efficiency of the electrolysis process. Specifically, the process begins with the entry of alumina into the electrolyzer, followed by the decrustation stage (separation of the cell wall from the basal shell), the deslagging step (removal of accumulated sludge), and ends with the replacement of the old electrode with a new one. The entire aluminum electrolysis workshop involves a complex process and harsh environment, as shown in Figure 1, with various unfavorable factors such as high temperature, dust, strong magnetic fields, and corrosive gases. Currently, aluminum electrolysis workshops mainly rely on manual labor with low automation, which not only increases workers’ workload but may also lead to lower productivity and inconsistent product quality. Traditional manual operations are prone to human factors like fatigue and mistakes, which can disrupt the continuity and stability of production. Studies have shown that a deviation of more than in the sheller head’s angle will lead to inadequate crushing of the shell layer, increasing the occurrence of the anode effect by 15–20% [5]. Additionally, the lack of suitable sensors to detect the real-time position of the end tool during shelling, due to exposure to high-temperature aluminum, presents a challenge for automation. Therefore, to automate the entire aluminum electrolysis workshop, it’s crucial to accurately estimate the end tool’s position and provide feedback for effective control [6].

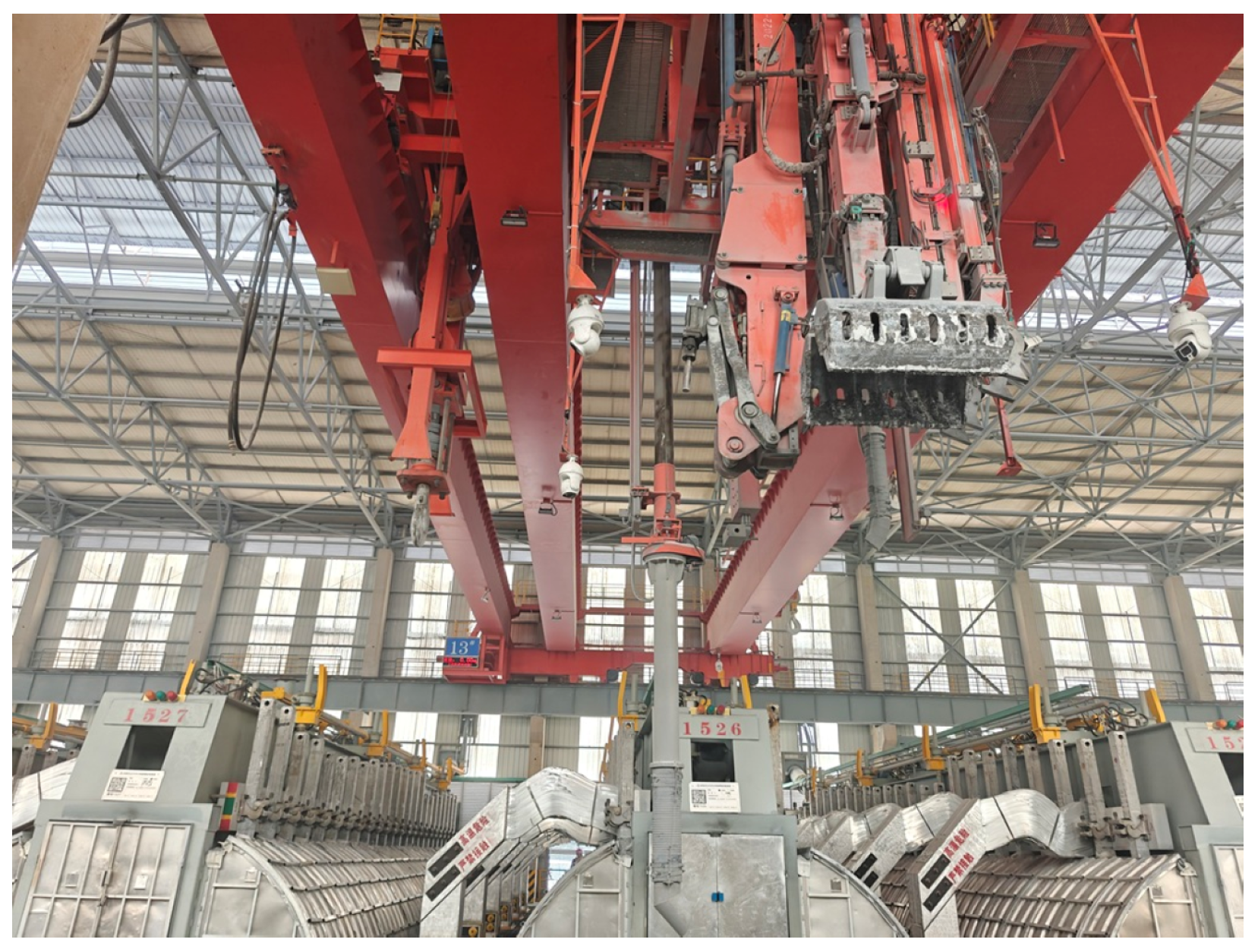

Figure 1.

Schematic diagram of the aluminum electrolysis workshop.

Traditional image pose estimation methods are mainly based on visual measurement techniques using calibration plates [7] or template matching algorithms based on CAD models [8]. Wang et al. [9] achieved a positioning accuracy of 0.5 mm under laboratory conditions by improving the SURF feature matching. However, this method faces several challenges when applied to the aluminum electrolysis industry. First, complex lighting conditions and frequent lighting changes significantly affect the reliability and precision of image feature extraction [10,11]; second, the complex kinematic characteristics of the shell-hitting mechanism can easily obscure or deform key features in the image, reducing the accuracy of feature matching [12,13]. Additionally, fluoride aerosols generated on the surface of the electrolyzer can cause foggy interference in the image, significantly reducing image quality and leading to partial loss of feature information [14]. These factors make it difficult for traditional two-dimensional pose estimation algorithms to meet the production process requirements.

Although traditional algorithms such as Iterative Closest Point (ICP) [15], Normal Distributions Transform (NDT) [16], Random Sample Consensus (RANSAC) [17,18], and feature-based point-cloud registration methods (e.g., SHOT [19]) perform well in laboratory settings; their registration errors in complex industrial environments such as aluminum electrolysis workshops often exceed 5 mm, making them insufficient for the high-precision demands of industrial processes. Recently, feature descriptor-based point-cloud registration techniques have offered new insights into solving complex pose estimation problems in industrial settings. The Fast Point Feature Histogram (FPFH) proposed by Rusu et al. [20] builds a 3D feature space and shows superior robustness compared to traditional methods in robotic grasping tasks.

Zhou et al. [21,22,23,24] introduced deep learning into point-cloud registration using the PointNet++ architecture [25,26], achieving high matching success rates under noisy conditions. More recently, deep learning-based methods have made notable progress. For instance, HybridReg leverages uncertainty masks to handle hybrid rigid and non-rigid motions, showing strong performance in dynamic scenes [27]; BiEquiFormer adopts a bi-equivariant architecture to ensure robustness under arbitrary initial poses [28]; and CoFF fuses RGB and geometric features to resolve ambiguities in symmetric or planar regions [29,30]. These approaches demonstrate impressive accuracy and robustness on public datasets, providing valuable insights for registration research. Nevertheless, applying these deep learning techniques to specialized industrial environments, such as aluminum electrolysis workshops, still faces significant challenges. Sensor selection issues hinder the acquisition of reliable initial point-clouds, and high-temperature conditions produce uneven point-cloud density, reducing the discriminative ability of traditional feature descriptors [31] and compromising registration accuracy [32]. Moreover, the multi-link configuration of the crust-breaking mechanism causes complex non-rigid deformations, making rigid-assumption-based registration algorithms ineffective [33]. Additionally, strict real-time requirements and harsh conditions such as dust and occlusions limit the practical deployment of computationally intensive deep learning models. Deep learning methods also rely heavily on large-scale annotated training data, which are difficult to obtain in these industrial settings.

By contrast, traditional optimization-based methods, while less expressive than deep models, offer advantages of being training-free, computationally efficient, and interpretable, making them more suitable for industrial deployment. Motivated by these considerations, we propose a multistage optimization framework for pose estimation, which improves pose estimation performance through feature space reconstruction and multi-stage alignment strategies.The main contributions of this paper are as follows:

- We design an error compensation mechanism for end pose estimation in aluminum electrolysis workshops, which mitigates the influence of noise masking and improves robustness under harsh industrial conditions;

- We develop an improved ICP algorithm with bi-directional error constraints, which reduces alignment inaccuracies and convergence difficulties, while avoiding local optima during the fine alignment stage;

- We integrate multi-stage point-cloud alignment into a unified framework, enabling reliable and accurate pose estimation in complex industrial scenarios, with potential extension to other application domains such as robotics, augmented reality, and digital twins.

2. Challenges of the Moment

As shown in Figure 2, the aluminum electrolysis workshop’s shelling mechanism features a typical four-link mechanical structure, whose kinematic characteristics directly influence the thermal equilibrium of the electrolysis tank and the distribution of alumina concentration. The mechanism consists of a fixed frame, a movable frame, a connecting frame, an upper connecting rod, a lower connecting rod, and a shell beater head, all of which are driven by double hydraulic cylinders to enable both lifting and tilting compound motion. Currently, the aluminum electrolysis industry predominantly uses pose estimation based on two-dimensional vision. However, the accuracy of this method is limited by the complex industrial environment, making it challenging to meet the precise requirements of the production process.

Figure 2.

Shelling mechanism under working condition.

2.1. Characterization of Aluminum Electrolysis Workshop Shelling Mechanism Working Conditions

The mechanical structure of the four-link shell-hitting mechanism is characterized as follows.

- Multi-degree-of-freedom motion: the tilting hydraulic cylinder provides a continuous tilting range of –, and the lifting hydraulic cylinder can realize a vertical stroke of 0.5–1.2 m. This composite motion leads to significant nonlinear features in the point-cloud distribution, which increases the alignment difficulty.

- Structural symmetry: the upper and lower connecting rods and the connecting frame are geometrically symmetrical. Although this characteristic is beneficial to the mechanical balance of the mechanism, it is easy to produce ambiguity in the matching of the point-cloud features, which leads to a decrease in the accuracy of the alignment.

Due to the use of hydraulic cylinders and their installation location close to the aluminum electrolysis reactors, the high temperatures and strong magnetic field environment in the area made it possible for no sensors to achieve stable pose estimation. In addition, dust and vibration in the aluminum electrolysis workshop environment can interfere with the point-cloud acquisition.

2.2. Engineering Adaptability Issues of Current Pose Estimation Methods

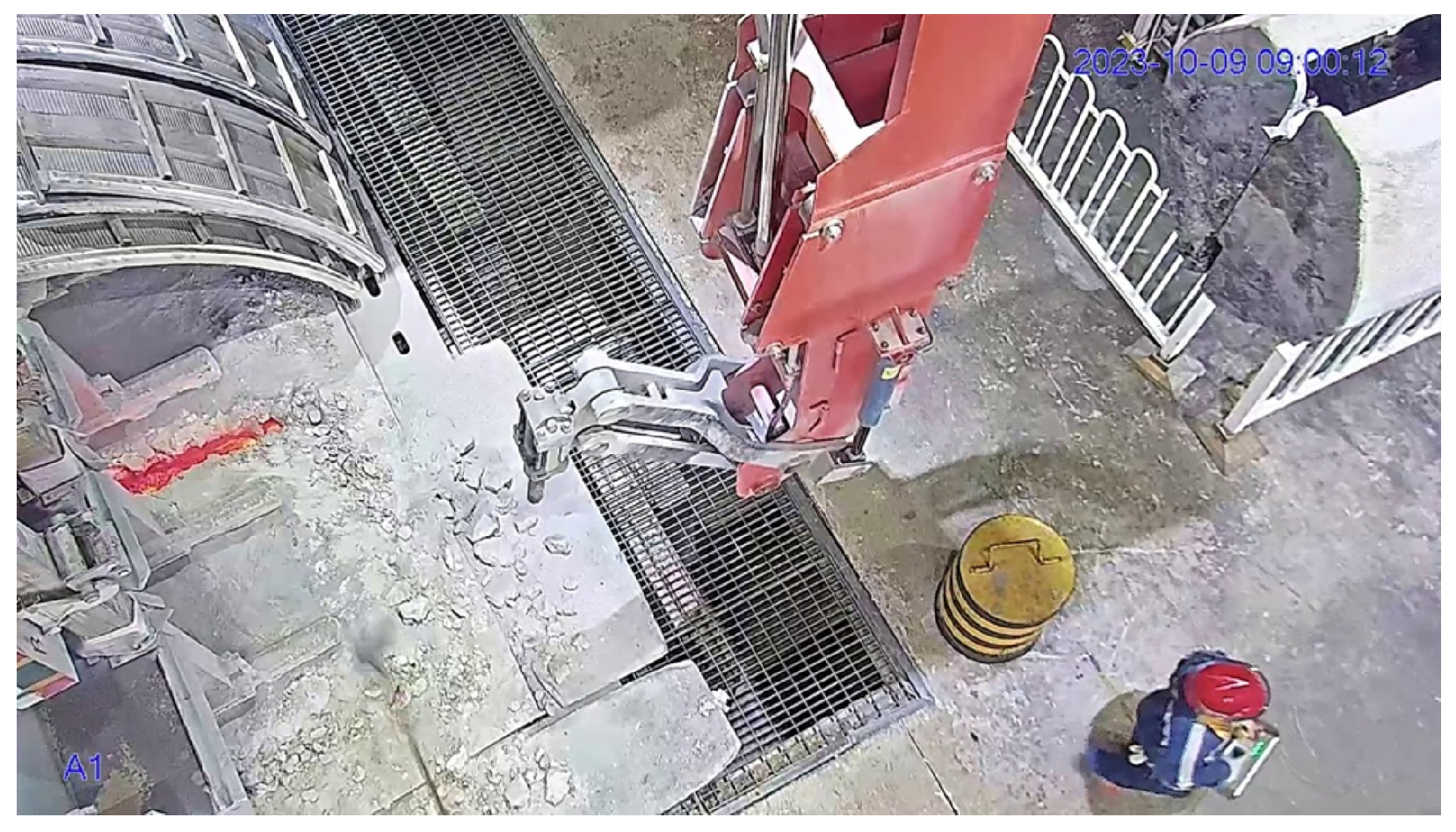

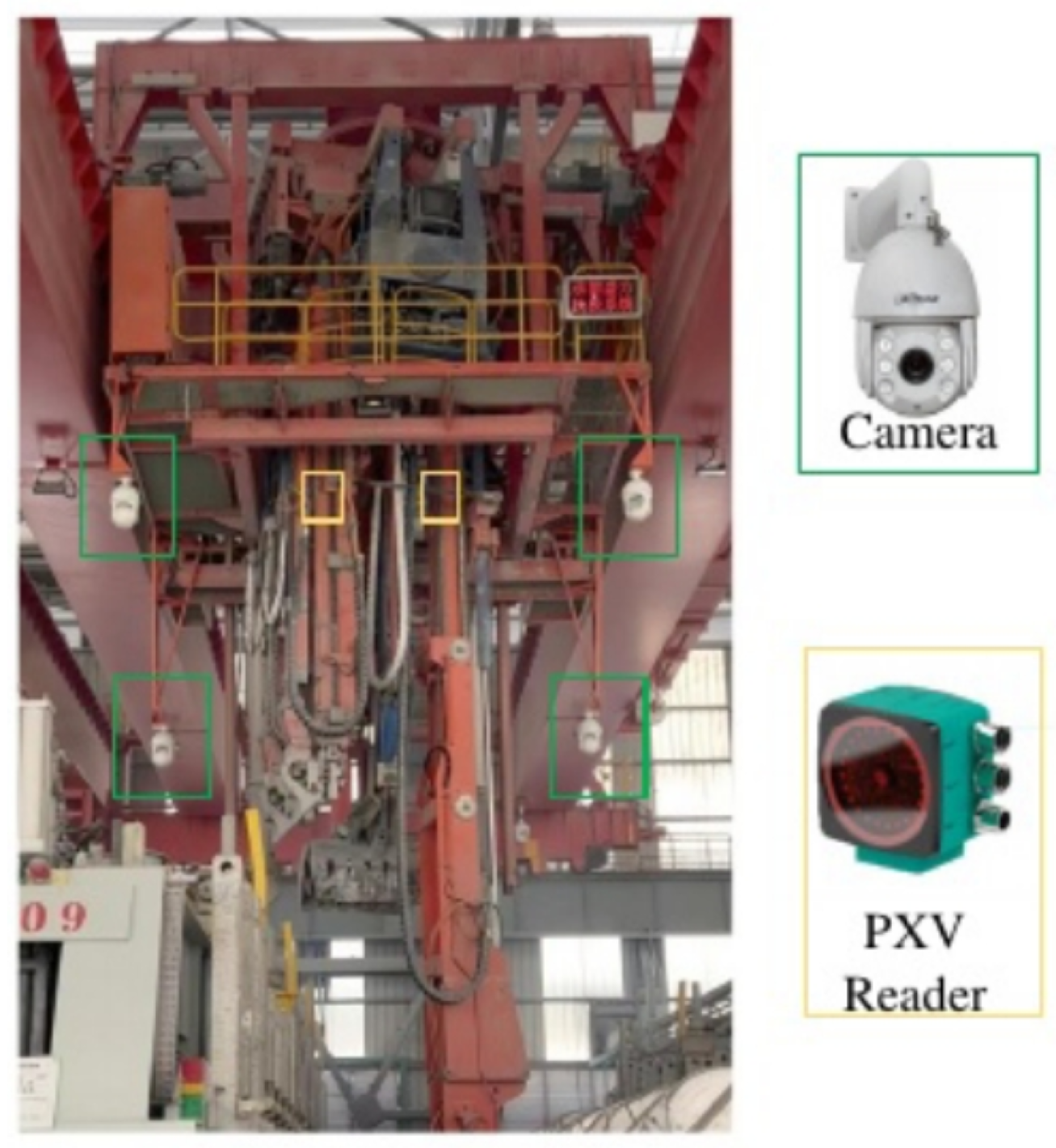

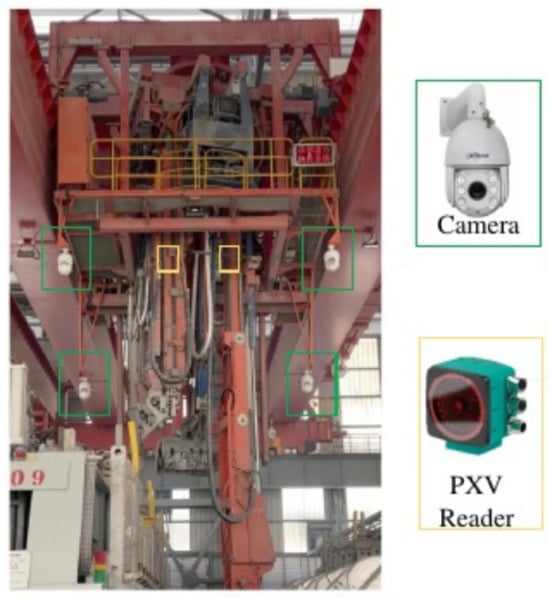

At present, the aluminum electrolysis workshop shown in Figure 3 has used four spherical cameras and non-visual sensors to form an intelligent vision system, which initially realizes the automatic tracking and automatic zoom functions during the operation of the mechanism of the lowering tube, anode replacement, aluminum discharge, and slag retrieval from the digging bucket. The traditional two-dimensional vision technology is the main method of pose estimation, and the pose derivation of the object is completed through the extraction and matching of specific feature points. However, the complexity of the shelling mechanism and the variability of the industrial environment make the 2D vision technology face significant limitations. First, the 2D image feature extraction capability is limited, especially in the case of tilting hydraulic cylinders moving at large angles or in the presence of severe occlusion, where the 2D image is difficult to provide enough geometric details to support high-precision pose estimation. Secondly, traditional 2D vision algorithms have high computational complexity when dealing with complex industrial scenes, resulting in poor real-time performance and failing to meet the demands of efficient production. Finally, strong electromagnetic interference, lighting variations, vibration, and dust in the workshop significantly reduce the success rate of feature matching, further weakening the applicability of 2D vision technology. Together, these issues limit the applicability of 2D image-based pose estimation methods in real industrial scenarios, especially in complex environments such as aluminum electrolysis workshops.

Figure 3.

Site structure diagram.

However, using a 3D camera allows for the collection of a point-cloud representing the tool’s surface, offering a more detailed view of its geometry. Point-cloud-based alignment techniques can directly capture the spatial and structural characteristics of the target object, making them an effective method for pose estimation in complex industrial settings. However, several challenges remain when using point-clouds for end-tool pose estimation in an aluminum electrolysis workshop. Noise is a major issue in this environment. Dust and vibrations often introduce significant noise into the point-cloud data, reducing the accuracy of geometric feature extraction and matching. Complex industrial environments also demand more from feature matching methods, and traditional feature descriptors may not perform well under noisy conditions, affecting the robustness and accuracy of alignment. Furthermore, the large range of geometric deformations presents another challenge. The extensive motion of tilting hydraulic cylinders and dynamic shape changes complicate point-cloud alignment. Traditional alignment algorithms, which assume rigid body transformations, struggle to handle such non-rigid deformations, leading to increased alignment errors. These challenges collectively limit the effectiveness of point-cloud alignment methods in real-world industrial applications, particularly in complex environments like the aluminum electrolysis workshop.

With these improvements, our method addresses the issue of missing data due to occlusion and incomplete point-clouds, resolves the ambiguity in symmetry feature matching to ensure alignment accuracy, and tackles the challenges posed by significant tilting and geometric deformation.

3. Methods

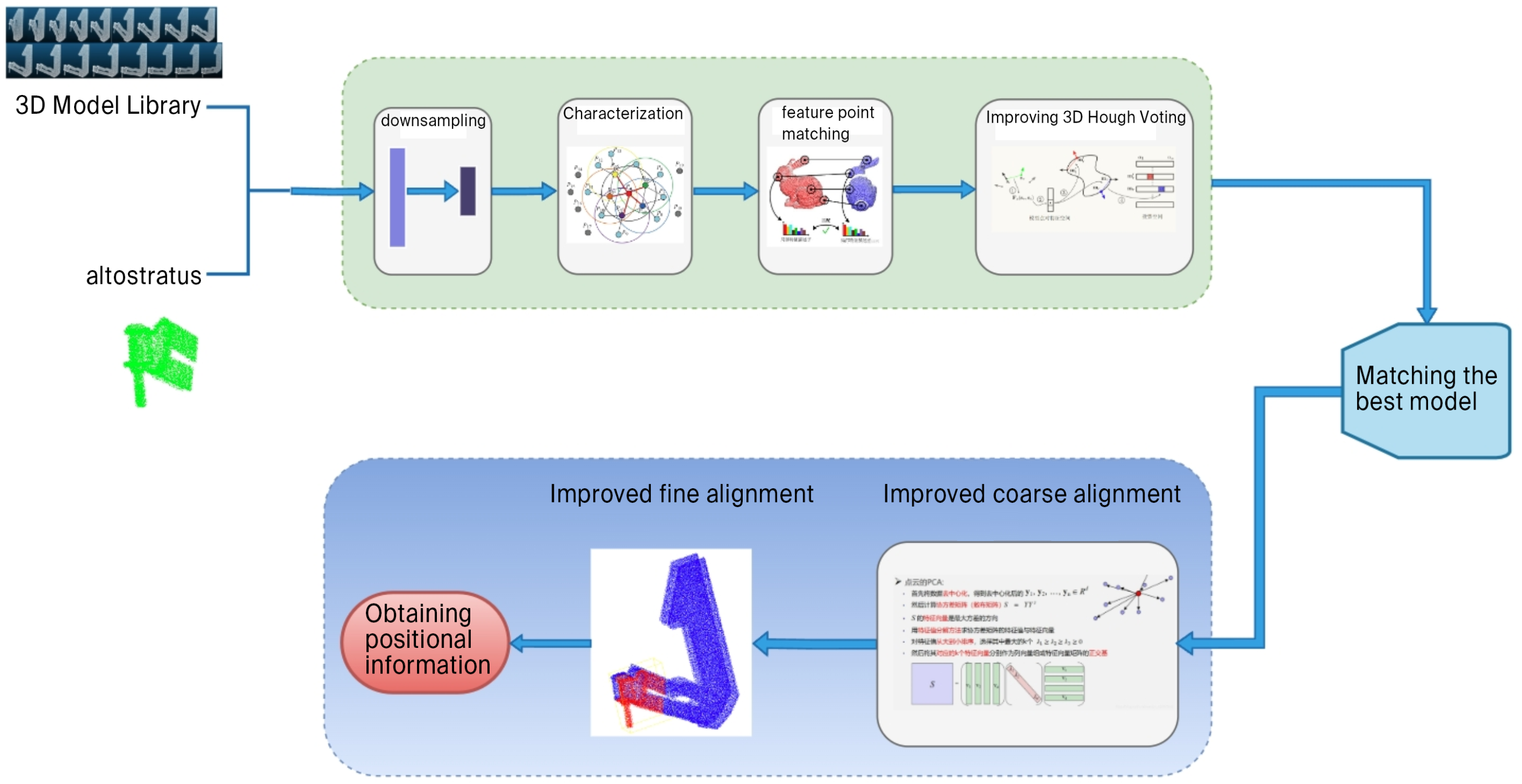

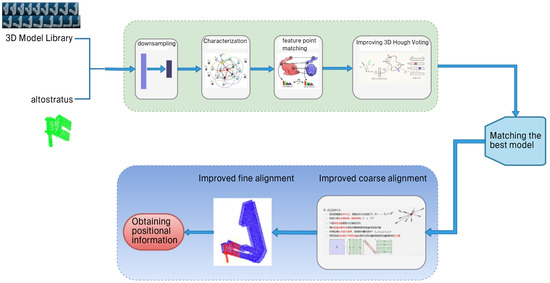

To address the challenges of end-tool pose estimation in the complex environment of an aluminum electrolysis workshop, we propose an enhanced point-cloud alignment method based on FPFH-PCA feature fusion, with its flowchart shown in Figure 4. This method utilizes a multi-level optimization strategy designed to handle high noise levels and complex geometric variations, improving both the robustness and accuracy of the alignment process. Firstly, the robustness and accuracy of the initial matching are significantly enhanced by using weighted 3D Hough voting with adaptive threshold template matching, which is well-suited to feature point extraction and matching in noisy environments. Secondly, a RANSAC-IA coarse alignment method based on FPFH-PCA feature fusion is developed, which improves the accuracy of the initial pose estimation by integrating multi-dimensional feature information, enabling better handling of complex geometric changes in industrial settings. Finally, the optimization strategy that combines point-to-surface distance metrics and symmetric objective functions, along with surface normal information, further refines alignment accuracy and convergence speed. This also enhances the algorithm’s stability, computational efficiency, and geometric consistency. The ICP fine alignment step then provides accurate pose information, completing the entire alignment process.

Figure 4.

Overall framework.

3.1. Weighted 3D Hough Voting with Adaptive Threshold Template Matching Based on FPFH Features

In the pose estimation of the shell-beating mechanism in aluminum electrolysis workshop, improving the robustness and accuracy of the traditional 3D Hough voting algorithm under the interference of high noise and geometric similarity has become an urgent problem to be solved. Since industrial point-cloud data are often locally missing due to sensor noise and viewing angle occlusion, resulting in unreliable feature extraction, while the geometric similarity of shell-beating mechanism components can easily trigger mismatching, further reducing the accuracy of pose estimation. Therefore, to address these problems, we adopt an improved 3D Hough voting method that combines FPFH feature descriptors and introduces a weighting mechanism with adaptive threshold optimization. By enhancing the reliability of feature matching and suppressing noise interference, it aims to improve the stability and accuracy of pose estimation in complex industrial environments. The method provides a more reliable initial pose estimation for the subsequent coarse and fine alignment processes and lays a solid foundation for the overall alignment process.

3.1.1. Weighted 3D Hough Vote

The Hough voting mechanism performs matching screening of feature–point pairs by counting the possible transformation matrices. Traditional methods assign equal weight to all point pairs, which can lead to interference from noise points in the voting results. To address this issue, we propose a weighted voting strategy based on FPFH features.

FPFH (Fast Point Feature Histograms) is a local geometric feature derived from the relationships between normal vectors, and it efficiently captures local structural information in point-clouds. The process involves computing the normal vector based on the geometric distribution of points in the neighborhood of point . For point pairs , the geometric relationships are calculated to characterize them. The specific equations are expressed as follows:

where is the connection vector. The geometric eigenvalues are discretized and counted as histograms, which are used to represent the local characteristics of the points.

First, we extract the FPFH feature descriptors from the reference and target point-clouds, and then calculate the similarity of the FPFH feature between the point i in the reference point-cloud and the point j in the template point-cloud, and determine the weights of the pair of points accordingly. The feature similarity calculation formula is expressed as follows:

where and denote the FPFH feature vectors of point i in the reference point-cloud and point j in the template point-cloud, respectively, and represents the Euclidean distance. The smaller the feature difference, the higher the similarity.

The voting weight is calculated based on the similarity; the calculation formula is expressed as follows:

here, is a parameter that controls the similarity sensitivity, and its selection should be determined based on the feature differences of the actual point-cloud data. Specifically, we calculate the statistical distribution of the squared norm of feature differences in the dataset, and set as a multiple of the standard deviation (e.g., ) to balance sensitivity and robustness. The larger the weight , the higher the feature similarity between the point pairs, and the greater their voting contribution to the transformation parameter space.

In traditional Hough voting, point pairs are mapped to the parameter space according to the transformation parameters with equal voting weights. Weighted 3D Hough voting introduces weights in the cumulative voting process, and its procedure is as follows:

- Point-to-transform parameter estimation: For a point in the reference point-cloud and a point in the template point-cloud, a transform parameter is obtained by calculating the transformation relationship between the two points. The formula is expressed as follows:where denotes the rotation matrix and denotes the translation vector.

- Weighted vote accumulation: The transformation of each point pair is mapped to the corresponding pose in the 3D Hough space. The vote values are accumulated and multiplied by the weight . The formula is expressed as follows:where is the cumulative value in the Hough space, is the indicator function (which equals 1 when T and match, and 0 otherwise), and is the weight of the point pair.

Through the weighting mechanism, high-quality matched point pairs contribute more to the voting in the parameter space, while the contribution of low-quality point pairs is weakened, thus effectively suppressing the influence of noise and mismatched points.

3.1.2. Adaptive Threshold Optimization

In the weighted Hough voting process, the distribution of voting values is significantly influenced by factors such as point-cloud quality and noise levels. The traditional fixed-threshold method often leads to unstable voting results because it cannot adapt to changes in data distribution. To address this issue, we introduce an adaptive thresholding method based on statistical properties. The core idea is to filter valid votes by analyzing the distribution characteristics of the voting values and dynamically determining the optimal threshold. This method automatically adjusts the threshold parameters based on the actual characteristics of the point-cloud data, significantly improving the algorithm’s robustness in varying scenarios.

First, the voting values in Hough space are statistically analyzed to calculate the mean and standard deviation, which are represented by the following formulas:

where N is the total number of parameter poses in the Hough space, and is the voting value at the transformed parameter T. Then, the adaptive thresholds are set dynamically based on the mean and standard deviation . The formula for is expressed as follows: The formula for is expressed as follows:

where is the adjustment coefficient that controls the sensitivity of the threshold. For datasets with low noise levels (signal-to-noise ratio > 20 dB), is set in the range [1.0, 1.5] to maintain detection sensitivity; for moderately noisy data (signal-to-noise ratio 10–20 dB), is adjusted to [1.5, 2.5] to balance robustness and sensitivity; and for highly noisy environments (signal-to-noise ratio < 10 dB), is set to [2.5, 3.0] to enhance noise resistance This adaptive selection strategy ensures the threshold can be tailored to different industrial scenarios of aluminum electrolysis workshops.

Then, based on the adaptive threshold, invalid votes below the threshold are eliminated, and only high-quality results are retained. The voting formula is expressed as follows:

where is the set of valid transformation parameters. Adaptive threshold optimization can dynamically adapt to the features of different datasets, exclude low-quality voting, and improve the stability and accuracy of transform parameter estimation.

After combining weighted 3D Hough voting with adaptive thresholding, the problems of noise point interference and repetitive structure mismatching are effectively solved by introducing FPFH feature weights and statistical adaptive thresholding, which significantly improves the stability and engineering practicability of the pose estimation of shell hitting mechanism. This provides more reliable initial transformation parameters for the subsequent coarse and accurate alignment.

3.2. RANSAC-IA Coarse Alignment Method Based on FPFH-PCA Feature Fusion

In the point-cloud alignment task, the primary goal of coarse alignment is to provide a reasonable initial pose estimate for subsequent fine alignment. For the point-cloud data of the shell-hitting mechanism in the aluminum electrolysis workshop, the data often suffers from issues such as large positional errors or partial missing data due to equipment noise, occlusion, and the complex industrial environment. To address these problems, we adopt a RANSAC-IA coarse alignment method based on FPFH-PCA feature fusion. This method utilizes FPFH to describe the local geometric features of the point-cloud, improving its ability to capture complex shapes. PCA is then used to extract the global principal directions of the point-cloud, enhancing the description of its overall geometric distribution [34]. The method estimates the initial positional transformation of the point-cloud by carefully selecting interior points using RANSAC-IA, achieving efficient coarse alignment.

PCA extracts the principal directions of the global geometry by computing the point-cloud and covariance matrix.The process is to pair the point-cloud , and its covariance matrix is expressed as follows:

where is the center of mass. The eigenvalues and eigenvectors of the covariance matrix are found by singular value decomposition (SVD)

The eigenvector corresponding to the largest eigenvalue represents the principal direction of the point-cloud. PCA features are effective in characterizing the global geometry of the point-cloud, especially for industrial parts with distinct principal axis directions.

Single features are not sufficient to support coarse alignment in this environment, we adopt a FPFH-PCA feature fusion method that takes into account both local geometric information and global morphological information by constructing high-dimensional composite descriptors. Firstly, the FPFH and PCA feature vectors are directly spliced and the formula is expressed as follows:

where, is a local feature of dimension n, and is a global feature of dimension m. The dimension of the spliced feature is . Second, to balance the effect of different features on the distance metric, the spliced feature vectors are normalized. The formula is expressed as follows.

Finally, the feature matching score is calculated using the Euclidean distance, which is represented by the following formula:

where shows the distance function for feature matching. The advantage of this feature fusion method is that FPFH captures the local geometric details and enhances the sensitivity to complex shapes, while PCA extracts the global principal direction of the point-cloud and improves the ability to describe the overall morphology; the combination of the two makes the point-cloud descriptors complementary at both the local and global levels, and improves the robustness and reliability of the matchings.

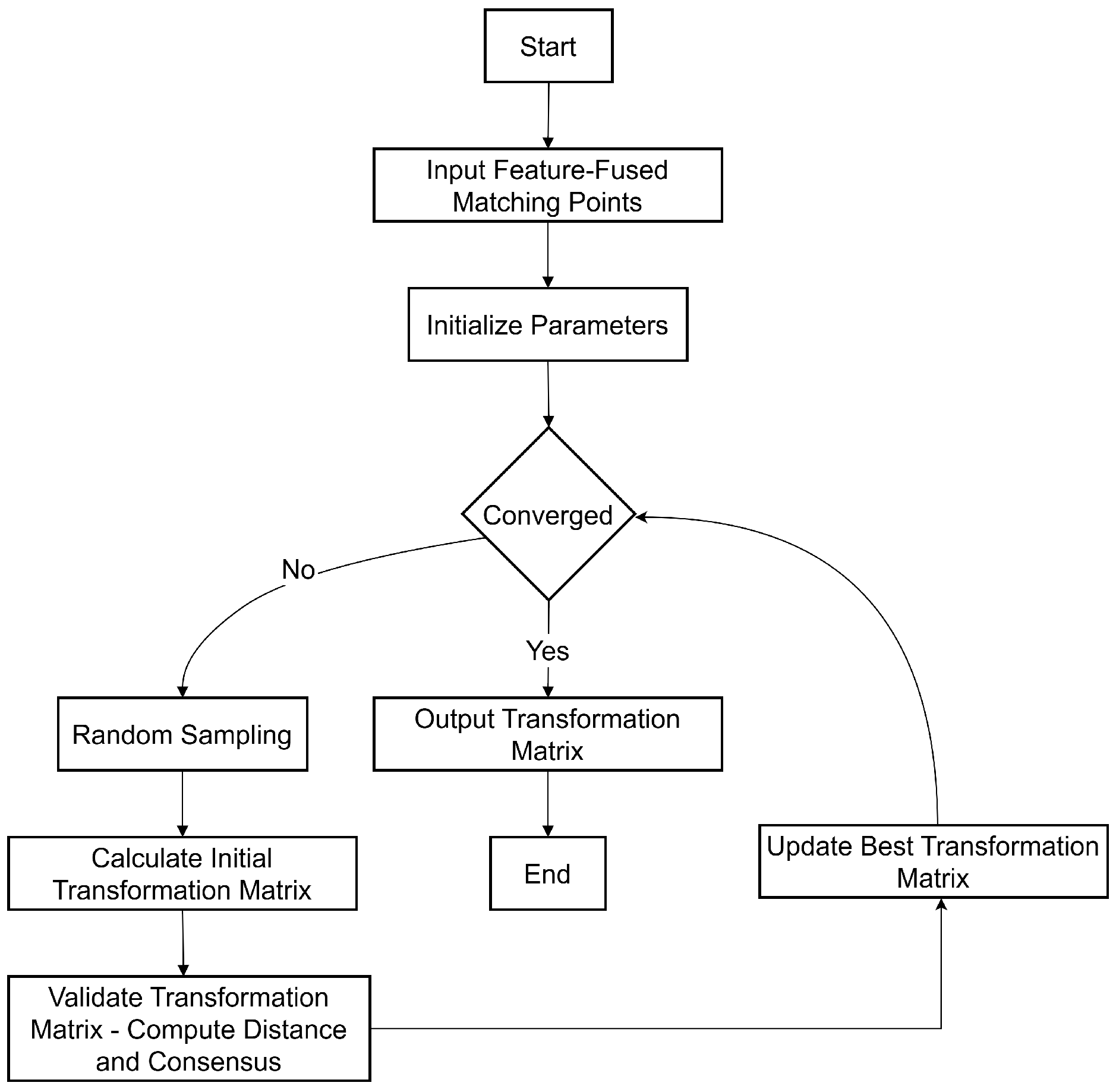

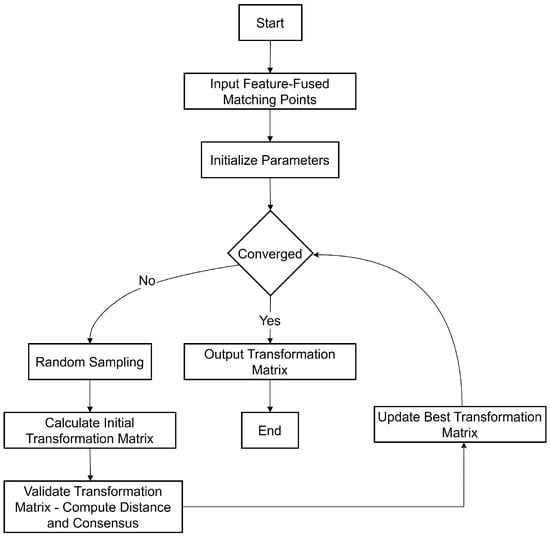

The results of feature matching need to be further optimized for the initial bit pose estimation by the alignment algorithm. In this paper, we use a randomized sampling consistency-based iterative alignment algorithm to efficiently deal with the outliers and noise in the matching outliers and noise in the matching. The flowchart of the algorithm is shown in Figure 5, which mainly consists of the following steps: firstly, input the matched pairs of points after feature fusion and initialize the parameters. Then the transformation matrix is calculated by random sampling, and its validity is verified (involving the calculation of distance and consensus). If the convergence condition is not reached, the best transform matrix is updated, and the above process is repeated; once convergence is achieved, the final transform matrix is output to complete the alignment.

Figure 5.

Flowchart of the feature fusion algorithm.

Its advantage is that RANSAC-IA is able to effectively find reliable initial bit positions in the presence of noise and mismatched points. Utilizing random sampling, it not only reduces the computational overhead, but also ensures the accuracy of the alignment results through consistency verification. With the RANSAC-IA coarse alignment, the point-cloud is initially aligned to the target position, which not only reflects the matching advantage of FPFH-PCA feature fusion, but also lays a solid foundation for the subsequent fine alignment.

3.3. Fine Registration of Point-Clouds with Improved ICP Algorithm

To address the challenges of high noise interference and complex geometric structure changes in point-cloud alignment within the complex environment of an aluminum electrolysis workshop, we propose an improved point-cloud alignment method based on FPFH-PCA feature fusion. This method adopts a multi-stage optimization strategy, significantly enhancing the accuracy and robustness of the alignment through three key stages: feature matching, coarse alignment, and fine alignment.

After completing the RANSAC-IA coarse alignment based on FPFH-PCA feature fusion, the initial pose can be quickly obtained, and the coarse alignment of the two point-clouds can be realized. However, due to the complex industrial environment, the coarse alignment results still contain significant errors, which are insufficient for high-precision pose estimation in practical applications.

To address this issue, we further introduce an improved ICP point-cloud alignment algorithm to refine and optimize the coarse alignment results. This algorithm integrates a point-to-surface distance metric and surface normal information, adopting a symmetric objective function to improve both the convergence speed and stability. As a result, the algorithm effectively enhances the accuracy of the final alignment, ensuring the precision of pose estimation for the shell-hitting mechanism, and satisfying the practical requirements of the industrial environment.

The ICP algorithm is optimized iteratively by using the least squares method to solve the rotation matrix R and translation vector T, to realize the point-cloud alignment. The traditional point-to-point ICP method relies on the minimization of the Euclidean distance of the nearest neighbor points, which is prone to mismatching in the presence of noise, occlusion or missing data, affecting the accuracy and convergence. Meanwhile, it only considers the distance between points, ignoring the local geometric structure of the point-cloud surface, which makes it difficult to cope with the accurate alignment of complex surfaces. To improve the performance, this paper introduces the point-to-surface distance metric and integrates the surface normal information to make the alignment process more consistent with the actual geometric relationship. In addition, a symmetric objective function is adopted to optimize the bidirectional error from the reference point-cloud to the target point-cloud and the inverse direction at the same time, which effectively improves the robustness of the algorithm and the alignment accuracy.

The point-to-surface ICP algorithm is optimized by minimizing the perpendicular distance from the source point to the surface of the target point-cloud, and its core ideas are as follows:

- In each iteration, the reference point-cloud is transformed to the coordinate system of the target point-cloud according to the current transformation matrix .

- Use KD-Tree to search for the nearest neighbor of each point in the reference point-cloud, and calculate the perpendicular distance from the source point to the surface of the target point-cloud.

- Introduce the normal vector information of the point-cloud surface into the error function, so that the optimization process is no longer limited to the Euclidean distance of a single point pair, but combines the geometric features of the surface to solve for a more compatible matching relationship.

For this reason, we introduce a point-cloud normal vector constraint term in the objective function to construct a geometrically meaningful composite error model. Let be a point in the target point-cloud and be a point in the reference point-cloud, and the corresponding normal vectors and , respectively, then the improved objective function is expressed as follows:

where N denotes the number of points in the target point-cloud; M denotes the number of points in the reference point-cloud; is the objective function to measure the degree of matching between the two point-clouds, and the smaller its value, the better the alignment effect; R and T denote the rotation matrix and the translation vector to transform the reference point-cloud to the target point-cloud coordinate system; and are the normal vectors corresponding to the target point and reference point respectively. and are the normal vectors corresponding to the target point and the reference point , which are used to describe the orientation information of the local surface where the point is located.

The traditional point-to-surface ICP method calculates the alignment error by considering only the unidirectional distance from the reference point-cloud to the target point-cloud, ignoring the alignment effect from the target point-cloud to the reference point-cloud. For this reason, a symmetric objective function is designed to incorporate the bidirectional errors of the two groups of point-clouds into the optimization objective, and the specific equations are expressed as follows.

where denotes the error from the reference point-cloud to the target point-cloud, and denotes the error from the target point-cloud to the reference point-cloud.

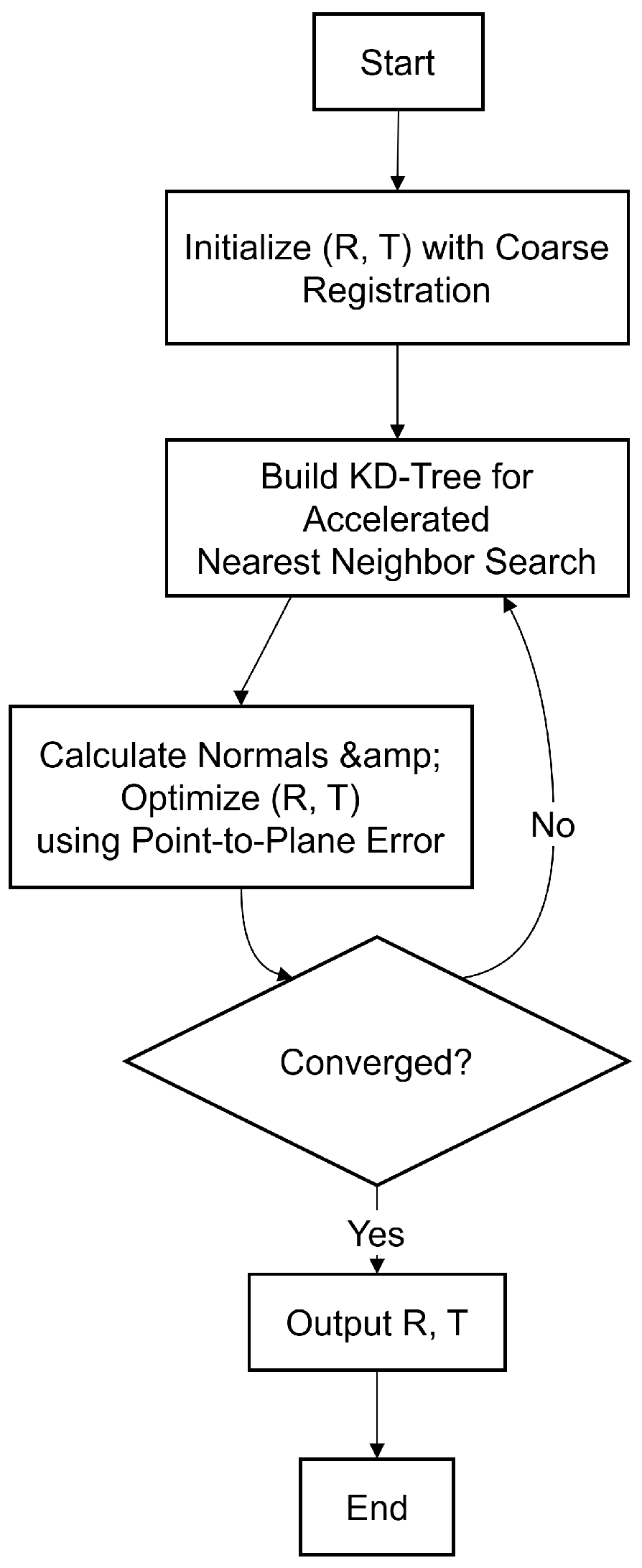

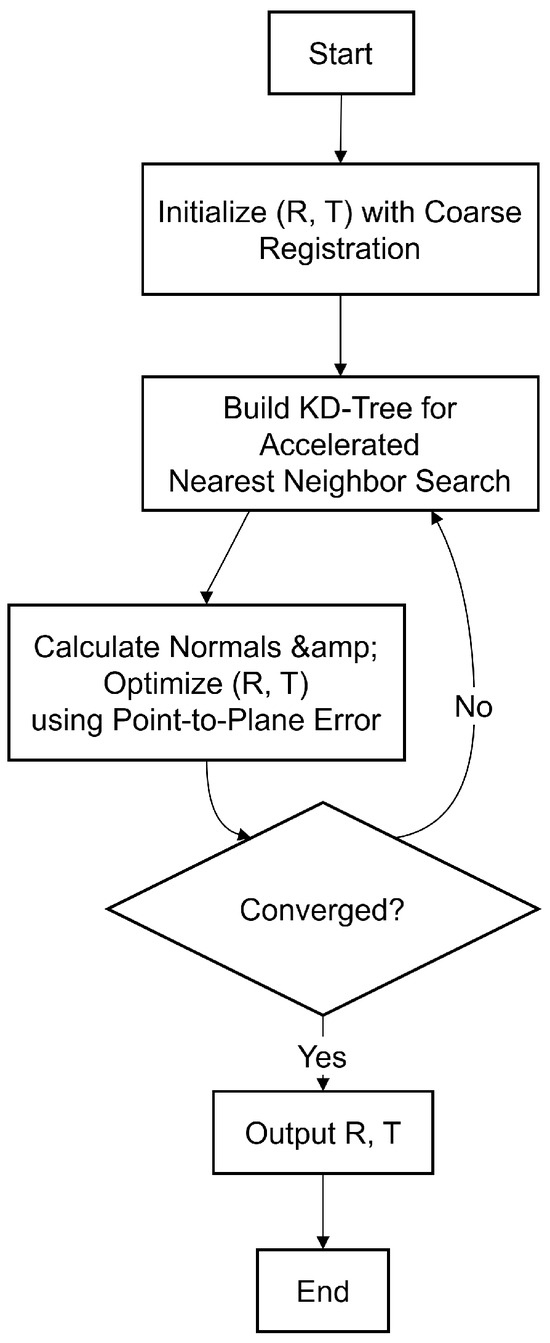

The flowchart of the improved ICP algorithm is shown in Figure 6, which describes the iterative optimization process of a point-cloud alignment algorithm. First, the rotation matrix R and translation vector T are initialized by coarse alignment, and then a KD-Tree is constructed to accelerate the nearest neighbor search. Next, normal vectors are computed, and R and T are optimized using point-to-face error. Determine if they converge, and if not, return to continue optimization; if they have converged, output the final R and T, completing the alignment process. By introducing the point-to-surface error function, the method enables the algorithm to accurately capture the geometric features of the point-cloud surface; at the same time, combined with the symmetric objective function design, it significantly reduces the impact of noise and missing data on the alignment effect, thus realizing fast convergence on the basis of coarse alignment and effectively reducing the number of iterations and computational overhead.

Figure 6.

Flowchart of the improved ICP algorithm.

4. Experimentation and Analysis

In this chapter, the 3D model of the shelling mechanism in an aluminum electrolysis workshop serves as the data source, and the experimental objective is to detect the pose of the shelling head component. The applicability of the method proposed in this paper is verified through point-cloud data captured from various angles in complex industrial scenarios. The experiments are analyzed in terms of both alignment effectiveness and efficiency, with the performance of the improved algorithm comprehensively evaluated by combining the experimental results of coarse alignment and fine alignment.

4.1. Dataset and Experimental Setup

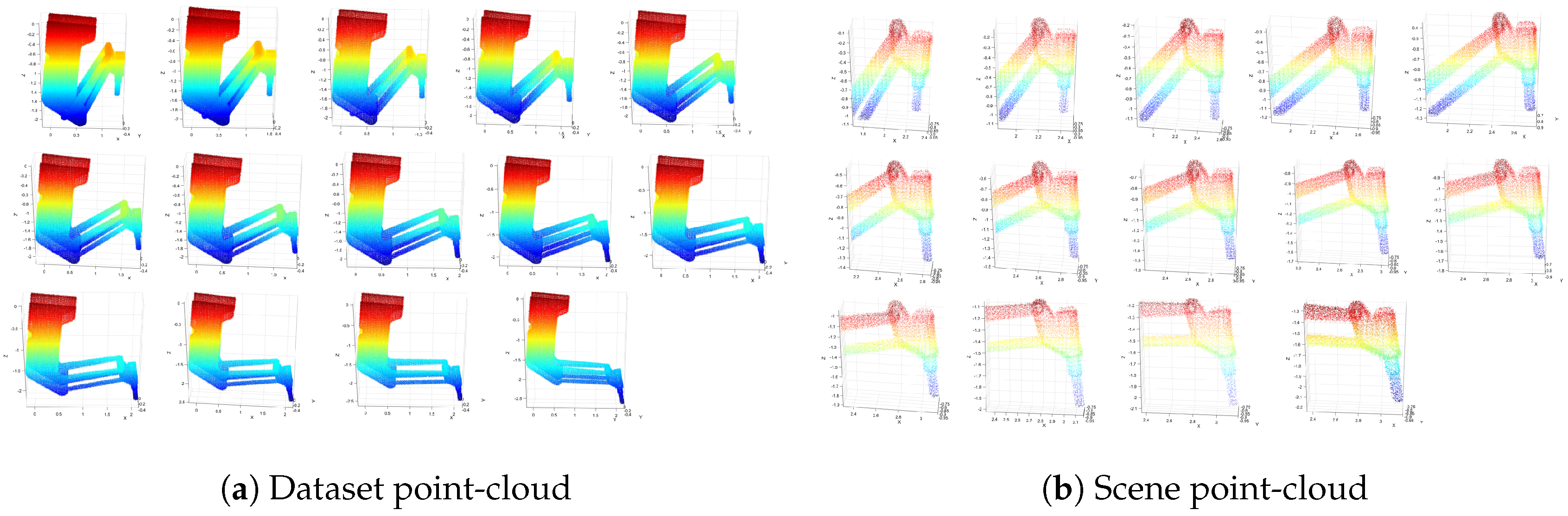

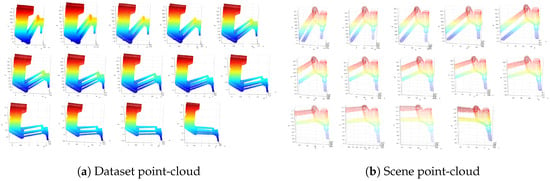

The experimental data are derived from a complete point-cloud model of the shelling mechanism, with the point-cloud of the shelling head section designated as the target for pose detection. Specifically, the model covers a range of hydraulic cylinder tilt angles from to , with point-cloud data generated at intervals. The target point-cloud data are captured using high-precision 3D sensors to ensure high resolution and accuracy, simulating field measurement conditions. To replicate the complexity of real-world industrial environments, Gaussian noise is randomly added and downsampling filtering is applied to each set of target point-cloud data. The reference point-cloud, multi-angle The reference point-cloud, multi-angle target point-clouds, and their corresponding downsampled versions are illustrated in Figure 7. All point clouds are rendered with the jet pseudocolor map to highlight depth variations. In this visualization, color mapping is used to represent the height (Z-axis coordinate) of the point cloud data. Red indicates high-value regions (closer points), while blue represents low-value regions (farther points). This continuous color gradient from red to blue facilitates an intuitive understanding of the distribution and hierarchical differences of the data within three-dimensional space, aiding readers in quickly perceiving the shape characteristics and attribute distribution trends of the point clouds.

Figure 7.

Reference and target point-cloud.

The experimental setup and data characteristics are summarized as follows: For the experimental environment, advanced computer hardware was employed, including high-performance processors, large-capacity memory, and professional-grade graphics processing units, to ensure the efficiency and stability of data processing and algorithm execution. In this chapter, a three-dimensional model of the shelling mechanism in the aluminum electrolysis workshop is utilized as the data source, with the shelling head section serving as the target for pose estimation. The proposed method is validated in complex industrial scenarios by simulating point-cloud data from multiple angles. This analysis is conducted to deepen the understanding of the structural patterns and regularities within the data, thereby laying a solid foundation for the subsequent design of pose estimation and matching algorithms. Furthermore, a comparative analysis of the shelling head point-clouds at different angles is performed. The study investigates the variation patterns and distinctive features across angles, offering valuable references for angle estimation and pose adjustment.

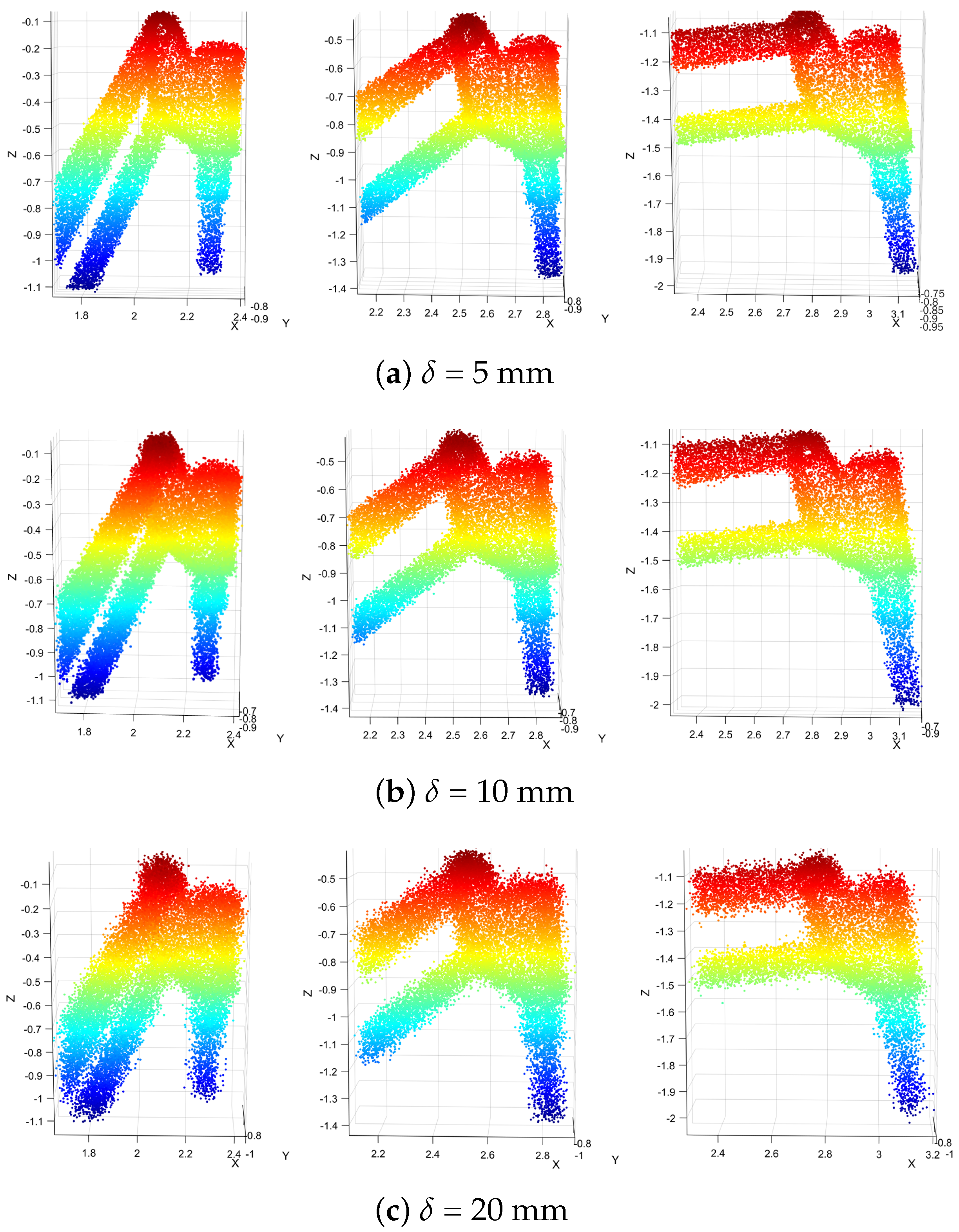

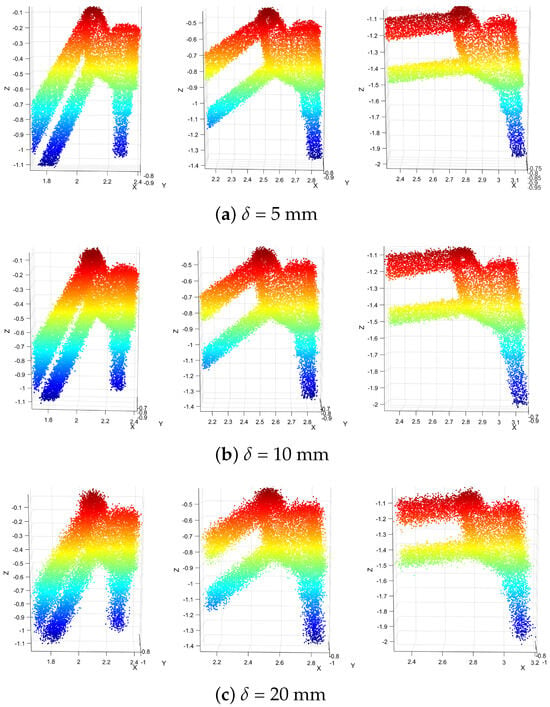

4.2. Results and Analysis of Template Matching Test

To verify the recognition accuracy and robustness of the shelling head in complex industrial environments, we conducted an experiment using weighted 3D Hough voting based on FPFH features with adaptive threshold template matching. In the preparation stage of the experiment, necessary preprocessing steps were performed on the collected reference point-cloud data, including the addition of Gaussian noise and voxel downsampling filtering. These preprocessing steps simulate common data characteristics in real industrial environments. Considering the measurement uncertainty of industrial 3D vision sensors in real working conditions, we established a zero-mean Gaussian noise model () and simulated noise scenarios with different intensities by adjusting the standard deviation ( mm). Specifically, when the mean value is 0, the standard deviation is set to 5 mm, 10 mm, and 20 mm, corresponding to hitting angles of , , and , as shown in Figure 8. The selected values are based on the measurement error range of industrial-grade 3D vision sensors (typically within 5–20 mm under different working distances), thereby ensuring the simulation is consistent with practical conditions.

Figure 8.

Reference point-clouds with Gaussian noise ( = 5, 10, 20 mm) and impact angles of , , and . Columns from left to right correspond to , , and ; rows (a), (b), and (c) correspond to , , and , simulating the measurement uncertainty of industrial 3D vision sensors.

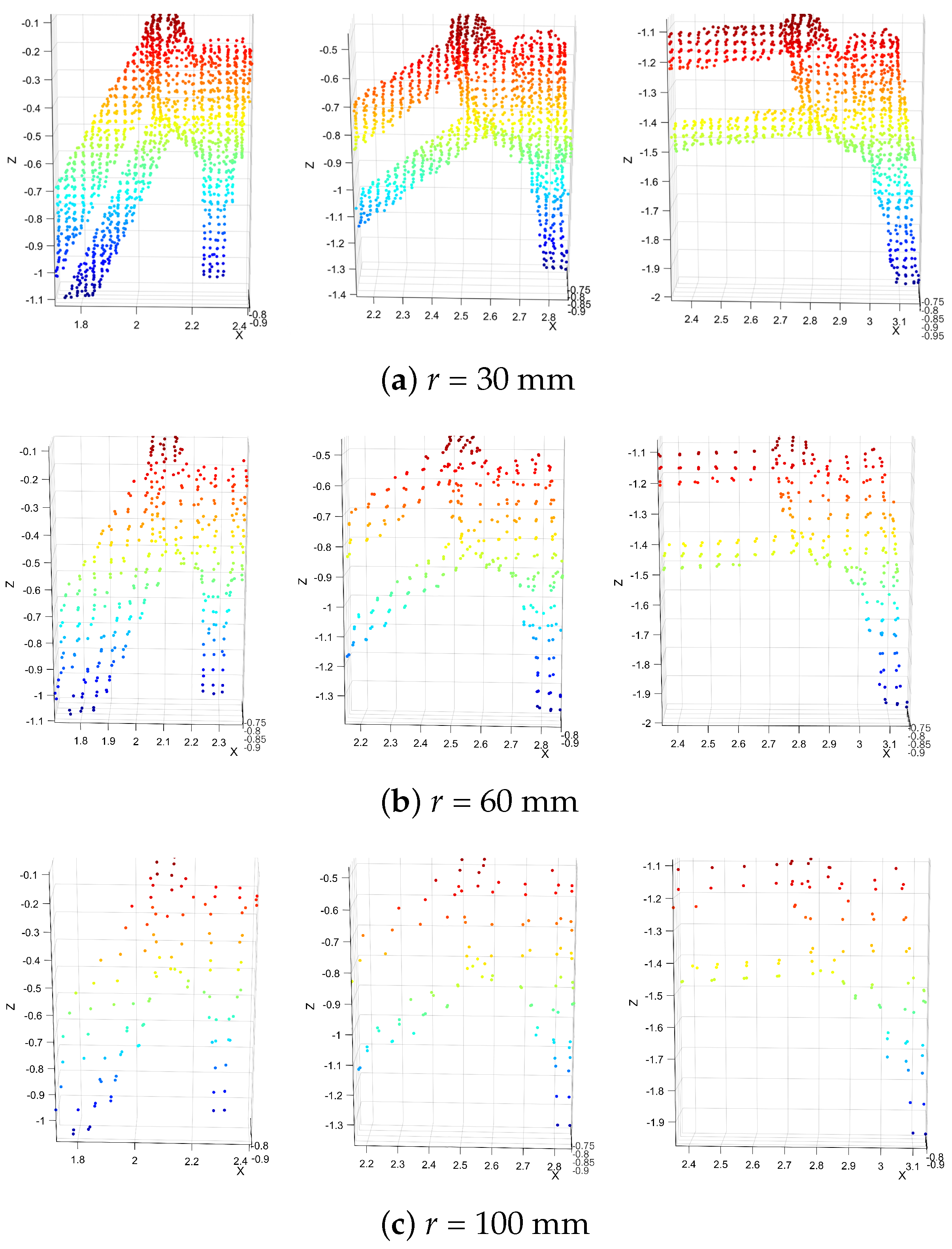

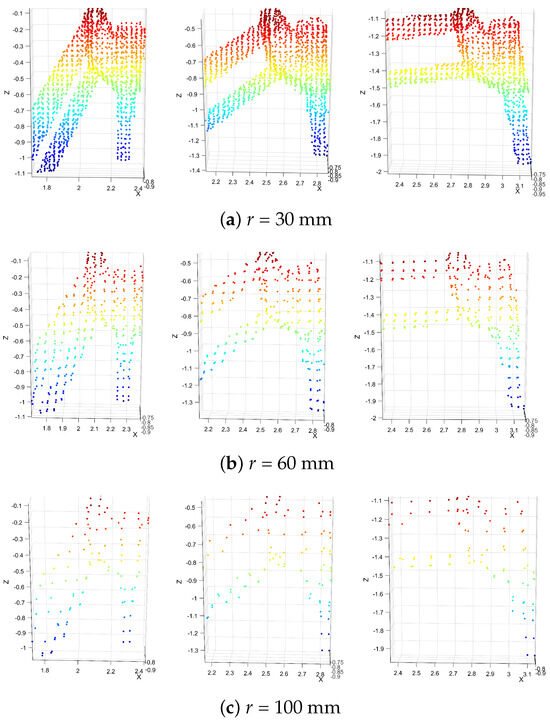

To balance computational efficiency with the need for feature preservation, we adopt a voxel grid downsampling method for point-cloud simplification, which divides the point-cloud space into a cubic voxel grid with side length r. In this study, the voxel sizes r are set to 30 mm, 60 mm, and 10 mm, corresponding to hulling angles of , , and , as shown in Figure 9. These values are not arbitrarily chosen: 30 mm preserves fine structural details at the cost of higher computation, 60 mm achieves a balance between efficiency and accuracy, while 100 mm significantly reduces point density for rapid processing but may sacrifice detail. The selection of these voxel sizes thus enables a sensitivity analysis of the algorithm’s performance across different levels of resolution.

Figure 9.

Downsampled reference point-clouds with different voxel sizes. Results are presented for voxel radii of r = 30 mm, 60 mm, and 100 mm under impact angles of , , and , illustrating the effect of downsampling on point-cloud density and precision. Columns from left to right correspond to , , and ; rows (a), (b), and (c) correspond to r = 30 mm, 60 mm, and 100 mm.

To balance the computational efficiency with the need for feature preservation, we adopt a voxel grid downsampling method for point-cloud simplification, which divides the point-cloud space into a cubic voxel grid with r sides. Among them, the voxel size r of the voxel downsampling filter is set to 30 mm, 60 mm, and 100 mm, and the corresponding hulling angles are , , and , as shown in Figure 9 respectively.

Based on the data analysis presented in Table 1 and Table 2, the proposed method demonstrated clear advantages over the traditional Hough voting template matching algorithm. The experimental results indicated that the improved approach achieved the matching task more efficiently while maintaining high accuracy. Furthermore, by comparing performance under various noise levels and downsampling conditions, it was evident that as the scene complexity increased, the superiority of our method became even more pronounced.

Table 1.

Hough voting method using different downsampling radiuses.

Table 2.

Hough voting with different Gaussian noise levels.

4.3. Test Results and Analysis of Improved Alignment Algorithms

4.3.1. Test Results and Analysis of Coarse Alignment Algorithm

In the first stage of point-cloud alignment, RANSAC-IA with FPFH-PCA feature fusion is employed for coarse alignment to provide a more accurate initial transformation matrix. To evaluate the accuracy of coarse alignment, multiple error metrics are adopted. First, the root mean square error (RMSE) is used to measure the alignment quality, which is defined as follows:

where N is the number of pairs of successfully matched points after alignment, and represents the Euclidean distance between the i-th pair of points. A lower RMSE value indicates better alignment performance, since it means that the average error between the aligned point-cloud and the target point-cloud is smaller.

In addition to RMSE, the angular error (AE) is introduced to evaluate the orientation consistency between the estimated transformation and the ground truth. Specifically, AE is defined as the angular deviation between two rotation matrices, expressed as

where and denote the ground truth and estimated rotation matrices, respectively, and is the trace operator. Both and are elements of the special orthogonal group , i.e., the set of valid 3D rotation matrices (), which ensures pure rotation without scaling or reflection.

To ensure fair evaluation, the ground-truth transformation is obtained from precise manual calibration of the datasets, while the estimated transformation is computed using the proposed algorithm. In all experiments, AE is calculated based only on the rotational part of the transformation, independent of the translation, thereby providing a clear measure of orientation accuracy.

By combining both RMSE and AE, the evaluation becomes more comprehensive, as RMSE reflects geometric matching accuracy, while AE captures orientation deviations. This dual-metric assessment is particularly important for large-scale datasets acquired from real industrial scenarios, where both positional and directional consistency are critical for reliable registration.

Downsampling effectively reduces computational complexity but may negatively impact feature matching accuracy. In the experiments, various levels of downsampling (r = 0, 30 mm, 60 mm, 100 mm) were applied to the original point-cloud. Both the root mean square error (RMSE) and the angular error (AE) were recorded before and after alignment to comprehensively evaluate registration accuracy, as shown in Table 3. To further assess the robustness of the coarse alignment algorithm against noise, Gaussian noise with different standard deviations ( = 5 mm, 10 mm, 20 mm) was added to the reference point-cloud. The corresponding RMSE and AE values before and after alignment are presented in Table 4.

Table 3.

Registration errors (RE), angular errors (AE), and processing time with different downsampling rates.

Table 4.

Registration errors (RE), angular errors (AE), and processing time with different noise levels.

After the RANSAC-IA coarse alignment with FPFH-PCA feature fusion, the results of the coarse alignment experiment showed that the accuracy of the initial pose estimation was significantly improved. This improvement in accuracy laid a solid foundation for subsequent point-to-face ICP fine alignment, making the entire alignment process both fast and accurate. It was worth noting that, by testing the method on different types of point-cloud data, we found that the method was particularly suitable for objects with complex geometries and exhibited excellent stability and accuracy even in the presence of large initial displacement errors. This further demonstrated the potential of the proposed method in practical applications.

4.3.2. Test Results and Analysis of Fine Alignment Algorithm

After completing the coarse alignment, we further apply the improved point-to-surface ICP algorithm for fine alignment, aiming to refine the registration results and enhance overall accuracy. To comprehensively evaluate the robustness of the proposed method, we conducted experiments under varying downsampling rates and noise levels, and compared the performance with SACIA_ICP [35], SACIA_NDT [36], and SACIA_LMICP [37]. To quantify the effectiveness of fine alignment, we recorded the root mean square error (RMSE), angular error (AE), and alignment time before and after fine registration, providing a joint assessment of accuracy and computational efficiency. To establish a benchmark for comparison, the RMSE, AE, and computation time of different methods under the baseline condition are reported in Table 5. Considering the large volume of point-cloud data in industrial applications, voxel grid downsampling with mm was applied to reduce computational complexity. The corresponding RMSE, AE, and runtime results of different fine alignment algorithms are summarized in Table 6. In real-world scenarios, point-cloud data are inevitably affected by noise, which may significantly degrade registration performance. To evaluate the noise robustness of the improved algorithm, Gaussian noise with different standard deviations mm was added to the reference point cloud. The RMSE, AE, and computation time of different methods under noisy conditions are reported in Table 7.

Table 5.

Performance comparison of different algorithms under baseline.

Table 6.

Performance comparison of different algorithms under varying downsampling rates.

Table 7.

Performance comparison of different algorithms under varying noise levels.

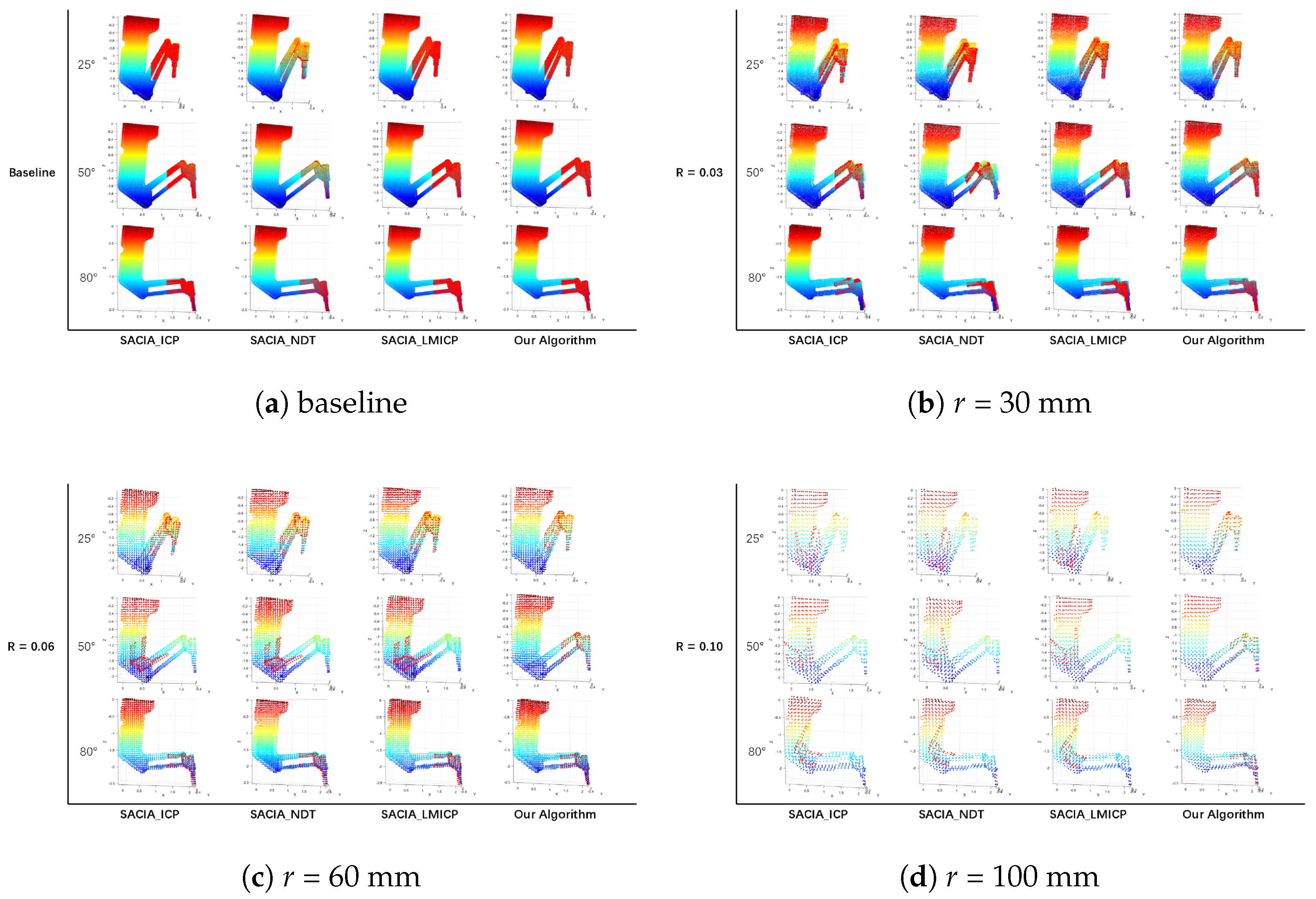

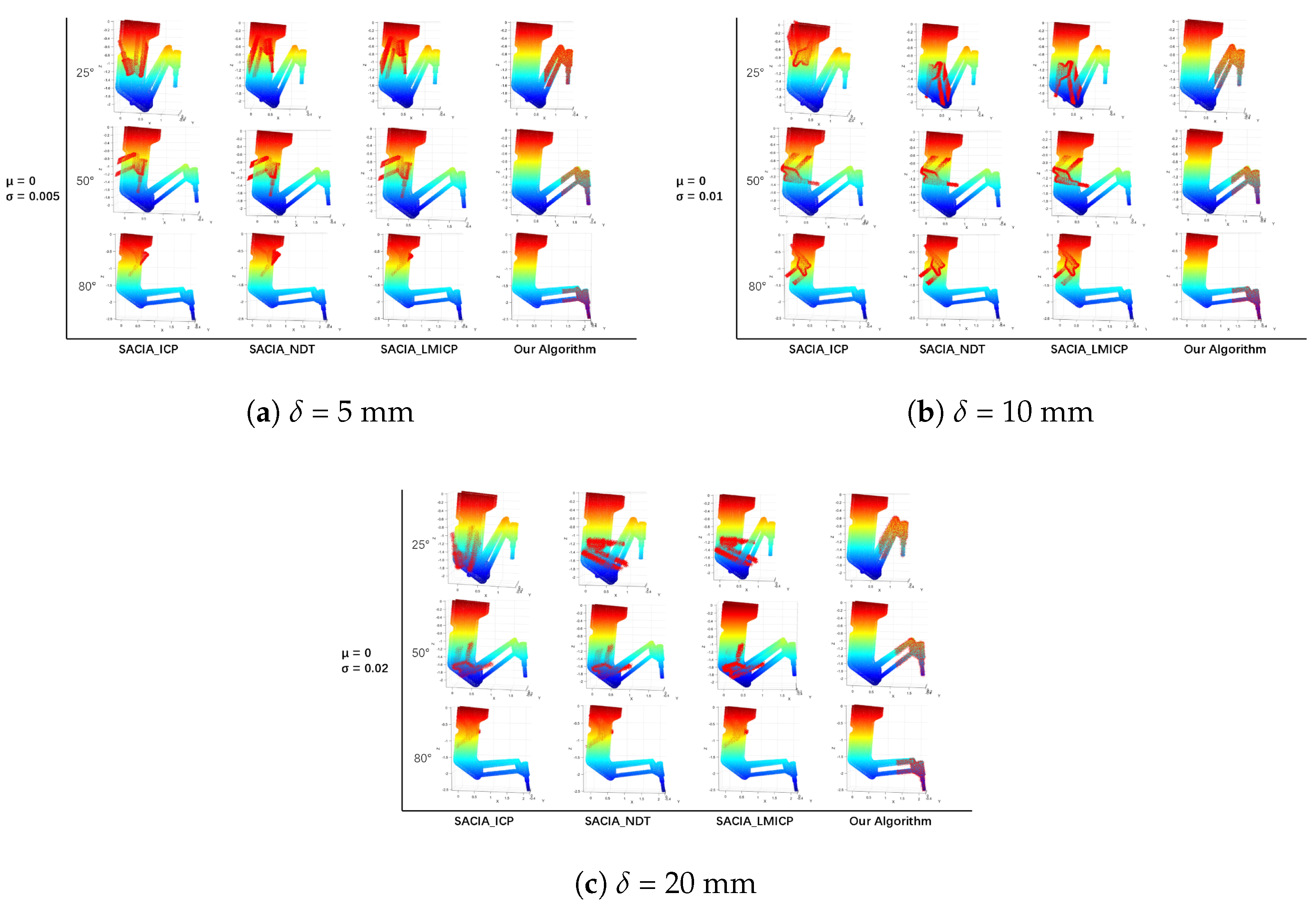

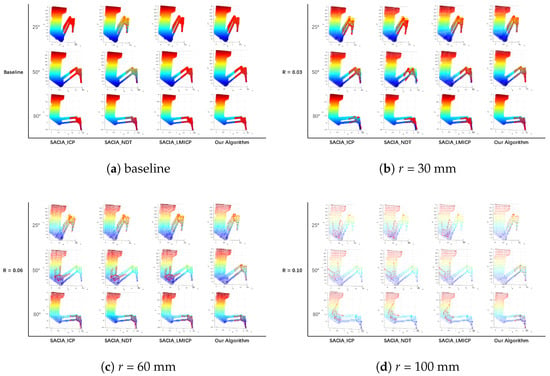

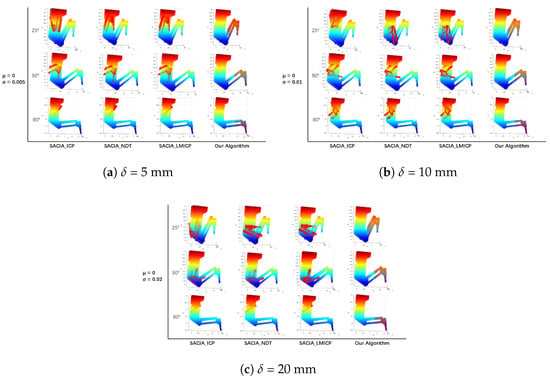

To intuitively demonstrate the performance of different fine alignment algorithms, we visualize the point-clouds before and after alignment and present the alignment results of SACIA_ICP, SACIA_NDT, SACIA_LMICP, and the proposed method. As shown in Figure 10, the alignment outcomes under different downsampling rates mm are compared across the four methods. Similarly, Figure 11 illustrates the alignment performance of each algorithm under various noise levels mm.

Figure 10.

Visual comparison of the proposed algorithm and baseline methods under different downsampling rates. The figure compares the baseline method and the proposed approach with voxel radii of r = 30 mm, 60 mm, and 100 mm, highlighting the improved registration performance of the proposed algorithm in sparse point-cloud conditions.

Figure 11.

Visual comparison of the proposed algorithm under different noise levels. The figure presents the registration results with noise levels of = 5 mm, 10 mm, and 20 mm, demonstrating the robustness of the proposed method in noisy environments.

In this section, we demonstrate the superiority of the proposed algorithm through quantitative analysis and qualitative visualization. The experimental results showed that under different downsampling rates, the proposed method achieved lower RMSE and angular error (AE), while maintaining higher computational efficiency, effectively reducing computational cost without sacrificing accuracy; under various noise levels, the method exhibited greater robustness and was able to maintain high alignment accuracy even in high-noise environments. Furthermore, the visualization results intuitively demonstrated the advantages of the proposed method, which consistently achieved convergence and provided accurate alignment results in point-cloud data with complex geometrical structures.

5. Conclusions

To achieve high-precision pose estimation of the shelling head in the aluminum electrolysis workshop under complex industrial conditions, we propose a multistage optimization pose estimation algorithm based on point-cloud processing. The experimental results show that the proposed method is robust and reliable in real industrial scenarios. The summary of this article is as follows.

- We propose a novel FPFH feature matching algorithm that integrates weighted 3D Hough voting with adaptive thresholds, significantly enhancing the robustness of the algorithm in extreme industrial environments such as high temperatures, dust, and occlusions.

- We combined FPFH descriptors with PCA geometric constraints to construct a hybrid RANSAC-IA coarse registration framework, improving the applicability of the registration algorithm in complex unstructured industrial scenarios and providing a more reliable initial pose for high-precision pose estimation.

- We designed an improved ICP algorithm based on point-to-plane distance and normal vector weighting, which effectively improved the accuracy and stability of attitude estimation.

- Experimental verification conducted at a real aluminum electrolysis industry site shows that the proposed method performs better than traditional registration techniques in terms of alignment accuracy and robustness, effectively improving pose estimation performance in complex environments and meeting the application requirements of this industrial scenario.

Although the multi-stage optimization pose estimation algorithm proposed in this paper is designed for the shell-breaking mechanism in aluminum electrolysis workshops, each of its modules has good versatility and broad application potential, especially in other industrial environments and the field of computer graphics. For example, the RANSAC-IA coarse alignment framework based on geometric constraints from FPFH and PCA can be extended to key equipment component identification and initial alignment tasks in industrial augmented reality (AR) systems. Furthermore, the proposed improved ICP algorithm is also applicable to scenarios that require high-precision model superposition and real-time tracking, such as attitude synchronization and error analysis in digital twin systems. Therefore, the point-cloud registration strategy proposed in this paper not only demonstrates good robustness and accuracy in electrolytic aluminum workshops, but also provides a technical path that can be referenced for broader industrial registration tasks and even model alignment and AR tracking in computer graphics. However, the current work still lacks systematic sensitivity analysis of key parameters such as voxel size and noise levels, and its validation is limited to a specific industrial environment. In future research, we will further explore parameter optimization strategies and extend experiments to more diverse industrial scenarios to enhance the generalization ability of the proposed method. Beyond aluminum electrolysis, the proposed method also shows potential applicability in other domains such as robotics and augmented reality, where reliable and accurate pose estimation is equally critical.

Author Contributions

Data curation: Z.J. conceived of the presented idea, developed the theory, carried out the experiments, and implemented the computer code with algorithmic support. Y.L. (Yonghong Long), W.F., X.L., and Y.L. (Yi Long) were involved in planning and supervised the work. The first draft of the manuscript was written by Z.J., and all authors commented on previous versions of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This paper is funded by the Hunan Provincial Natural Science Foundation 2024JJ7144, 2023JJ50196.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Datasets during the current study are available from the corresponding author on reasonable request. The aluminum electrolysis production process data are available from the aluminum electrolysis Industry in China but restrictions apply to the availability of these data, which were used under license for the current study, and so are not publicly available.

Conflicts of Interest

The authors have no competing interests to declare that are relevant to the content of this article.

References

- Li, X.; Lin, J.; Liu, C.; Liu, A.; Shi, Z.; Wang, Z.; Jiang, S.; Wang, G.; Liu, F. Research on Aluminum Electrolysis from 1970 to 2023: A Bibliometric Analysis. JOM 2024, 76, 3265–3274. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, W.; Zheng, L.; Chen, Q.; Liu, Y.; Lan, S.; Zhu, M. Enhancing production of hydrogen and simultaneous degradation of ciprofloxacin over Sn doped SrTiO3 piezocatalyst. Sep. Purif. Technol. 2025, 353, 128307. [Google Scholar] [CrossRef]

- Pandey, D.; Hansen, H.H.; Dhakal, R.; Aryal, N.; Rai, S.P.; Sapkota, R.; Nielsen, M.O.; Novoa-Garrido, M.; Khanal, P. Interspecies and seasonal variations in macroalgae from the Nordic region: Chemical composition and impacts on rumen fermentation and microbiome assembly. J. Clean. Prod. 2022, 363, 132456. [Google Scholar] [CrossRef]

- Segura, F.; Vivas, F.J.; Andújar, J.M.; Martínez, M. Hydrogen-powered refrigeration system for environmentally friendly transport and delivery in the food supply chain. Appl. Energy 2023, 338, 120945. [Google Scholar] [CrossRef]

- Solheim, A. On the Feasibility of Using Low-Melting Bath to Accommodate Inert Anodes in Aluminium Electrolysis Cells. In Light Metals 2021; Perander, L., Ed.; Springer: Cham, Switzerland, 2021; pp. 511–518. [Google Scholar]

- Cheng, L.; Yang, W.; Ren, Y.; Zhang, L. Effect of Selenium on the Interaction Between Refractory and Steel. Metall. Mater. Trans. B 2019, 50, 1115–1123. [Google Scholar] [CrossRef]

- Besl, P.J.; McKay, N.D. A method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Zhang, Z. A flexible new technique for camera calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef]

- Kim, I.J.; Yun, I. Real-time plasma monitoring technique using incident-angle-dependent optical emission spectroscopy for computer-integrated manufacturing. Robot. Comput.-Integr. Manuf. 2018, 52, 17–23. [Google Scholar] [CrossRef]

- Li, J.; Qiang, K.; Yang, C.; Chen, X.; Li, J.; Zhang, H. Construction and Application of Digital Twin in Aluminum Electrolysis. In Light Metals 2024; Wagstaff, S., Ed.; Springer: Cham, Switzerland, 2024; pp. 453–463. [Google Scholar]

- Rusu, R.B.; Cousins, S. 3D is here: Point Cloud Library (PCL). In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 1–4. [Google Scholar] [CrossRef]

- Zhou, Q.Y.; Park, J.; Koltun, V. Fast Global Registration. In Proceedings of the Computer Vision—ECCV 2016, Amsterdam, The Netherlands, 11–14 October 2016; Leibe, B., Matas, J., Sebe, N., Welling, M., Eds.; Springer: Cham, Switzerland, 2016; pp. 766–782. [Google Scholar]

- Fu, X.; Zhang, Y.; Zhang, W.; Li, Q.; Kong, T. Research on the size of ring forgings based on image detection and point cloud data matching method. Int. J. Adv. Manuf. Technol. 2022, 119, 1725–1735. [Google Scholar] [CrossRef]

- Chen, Y.; Medioni, G. Object modelling by registration of multiple range images. Image Vis. Comput. 1992, 10, 145–155, Range Image Understanding. [Google Scholar] [CrossRef]

- Lynen, S.; Achtelik, M.W.; Weiss, S.; Chli, M.; Siegwart, R. A robust and modular multi-sensor fusion approach applied to MAV navigation. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 3923–3929. [Google Scholar] [CrossRef]

- Rusu, R.B.; Blodow, N.; Beetz, M. Fast Point Feature Histograms (FPFH) for 3D registration. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 3212–3217. [Google Scholar] [CrossRef]

- Zhou, Q.-Y.; Park, J.; Koltun, V. Open3D: A Modern Library for 3D Data Processing. arXiv 2018, arXiv:1801.09847. [Google Scholar] [CrossRef]

- Derpanis, K.G. Overview of the RANSAC Algorithm. Image 2005, 4, 2–3. [Google Scholar]

- Fu, Z.; Zhang, E.; Sun, R.; Zang, J.; Zhang, W. Research on 3D point cloud alignment algorithm based on SHOT features. PLoS ONE 2024, 19, e0296704. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wang, H.; Hu, Q.; Liu, H.; Liu, L.; Bennamoun, M. Deep Learning for 3D Point Clouds: A Survey. IEEE Trans. Pattern Anal. Mach. Intell. 2021, 43, 4338–4364. [Google Scholar] [CrossRef]

- Teng, J.-H.; Liu, B.-H. Three-Stage Dead-Time Adjustment Scheme for Conversion Efficiency Enhancement of Phase-Shift Full-Bridge Converters at Light Loads. IEEE Trans. Ind. Electron. 2021, 68, 1210–1219. [Google Scholar] [CrossRef]

- Ma, H.; Wang, G.; Bai, H.; Xia, Z.; Wang, W.; Du, Z. Robotic grasping method with 6D pose estimation and point cloud fusion. Int. J. Adv. Manuf. Technol. 2024, 134, 5603–5613. [Google Scholar] [CrossRef]

- Ding, X.; Qiao, J.; Liu, N.; Yang, Z.; Zhang, R. Robotic grinding based on point cloud data: Developments, applications, challenges, and key technologies. Int. J. Adv. Manuf. Technol. 2024, 131, 3351–3371. [Google Scholar] [CrossRef]

- Ning, D.; Huang, S. L-PCM: Localization and Point Cloud Registration-Based Method for Pose Calibration of Mobile Robots. Information 2024, 15, 269. [Google Scholar] [CrossRef]

- Osipov, A.; Ostanin, M.; Klimchik, A. Comparison of Point Cloud Registration Algorithms for Mixed-Reality Cross-Device Global Localization. Information 2023, 14, 149. [Google Scholar] [CrossRef]

- Zhao, X.; Yan, F.; Zhao, G.; Wang, C. TGNF-Net: Two-Stage Geometric Neighborhood Fusion Network for Category-Level 6D Pose Estimation. Information 2025, 16, 113. [Google Scholar] [CrossRef]

- Du, K.; Xu, H.; Li, H.; Qu, H.; Fu, C.W.; Liu, S. HybridReg: Robust 3D Point Cloud Registration with Hybrid Motions. In Proceedings of the AAAI Conference on Artificial Intelligence, Philadelphia, PA, USA, 27 February–2 March 2025; Volume 39, pp. 2789–2797. [Google Scholar] [CrossRef]

- Pertigkiozoglou, S.; Chatzipantazis, E.; Daniilidis, K. BiEquiFormer: Bi-Equivariant Representations for Global Point Cloud Registration. arXiv 2024, arXiv:2407.08729. [Google Scholar]

- Wang, Z.; Huang, S.; Butt, J.A.; Cai, Y.; Varga, M.; Wieser, A. Cross-modal feature fusion for robust point cloud registration with ambiguous geometry. ISPRS J. Photogramm. Remote Sens. 2025, 227, 31–47. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, Y.; He, Q.; Fang, Z.; Xu, G.; Fu, J. Grasping pose estimation for SCARA robot based on deep learning of point cloud. Int. J. Adv. Manuf. Technol. 2020, 108, 1217–1231. [Google Scholar] [CrossRef]

- Wang, Y.; Solomon, J.M. Deep Closest Point: Learning Representations for Point Cloud Registration. In Proceedings of the 2019 IEEE/CVF International Conference on Computer Vision (ICCV), Seoul, Republic of Korea, 27 October–2 November 2019; pp. 3522–3531. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z.; Wang, X.; Gao, P.; Li, M. A 3D pickup estimation method for industrial parallel robots based on point cloud simplification and registration. Int. J. Adv. Manuf. Technol. 2024, 133, 5175–5195. [Google Scholar] [CrossRef]

- Yang, X.; Wang, H.; Dong, Z.; Liu, Y.; Li, Y.; Yang, B. A Novel Method for Registration of MLS and Stereo Reconstructed Point Clouds. IEEE Trans. Geosci. Remote Sens. 2024, 62, 5703613. [Google Scholar] [CrossRef]

- Alexiou, E.; Zhou, X.; Viola, I.; Cesar, P. PointPCA: Point cloud objective quality assessment using PCA-based descriptors. EURASIP J. Image Video Process. 2024, 2024, 20. [Google Scholar] [CrossRef]

- Liu, B.; Liu, L.; Tian, F. An Improved SAC-IA Algorithm Based on Voxel Nearest Neighbor Search. Crit. Rev. Biomed. Eng. 2022, 50, 35–46. [Google Scholar] [CrossRef]

- Jing, L.; Wu, B.; Li, X. Point Cloud Registration Method Based on SAC-IA and NDT Fusion. J. Geod. Geodyn. 2021, 41, 378–381. [Google Scholar]

- Wang, H.; Yin, Y.; Jing, Q. Comparative Analysis of 3D LiDAR Scan-Matching Methods for State Estimation of Autonomous Surface Vessel. J. Mar. Sci. Eng. 2023, 11, 840. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).