Abstract

Industry 4.0 has revolutionized manufacturing processes and facilities through the creation of smart and sustainable production facilities. Blockchain technology (BCT) has emerged as an invaluable asset within Industrial Revolution 4.0 (IR4.0), offering increased transparency, security, and traceability across supply chains. This systematic literature review explores the role of BCT in creating smart and sustainable manufacturing facilities, while exploring its implications for supply chain management (SCM). Through a detailed examination of 82 research articles, this review highlights three areas where BCT can have a dramatic effect on smart and sustainable manufacturing: firstly, BCT can promote green production methods by supporting efficient resource use, waste reduction strategies and eco-friendly production methods; and secondly, it allows companies to implement smart and eco-friendly manufacturing practices through BCT solutions. BCT promotes intelligent manufacturing systems by facilitating real-time data sharing, predictive maintenance, and automated decision-making. Furthermore, BCT strengthens SCM by increasing visibility, traceability, and collaboration between partners of SC operations. The review also highlights the potential limitations of BCT, such as scalability challenges and the need for standardized protocols. Future research should focus on addressing these limitations and further exploring the potential of BCT in IR4.0.

1. Introduction

Industry 4.0 (IR4.0) refers to the incorporation of innovative cutting-edge cyber technologies into companies’ business operations, such as “blockchain technology” (BCT), “big data”, “cloud computing”, “Artificial Intelligence (AI)”, “3D printing”, “smart manufacturing”, “autonomous robots”, “Internet of Things (IoTs)”, “RFID Tags”, and so on. These innovative cutting-edge digital technologies are gaining much traction in management practices as digitalization (conversion to digital format), and this is regarded as a positive trend that can lead to a competitive edge, economic expansion, gaining innovative capability, and operational development [1,2,3,4]. While the practical use of such technologies (particularly BCT) in the context of firms’ operational activities, logistics, and supply chain (SC) members is relatively new and unestablished, it is clear that this technology will undoubtedly reshape the relationship between businesses, logistics, and SCs members [5,6,7,8].

Furthermore, by implementing such cutting-edge digital technologies, businesses can gain a competitive edge over their rivals by differentiating themselves, cutting costs or improving efficiency, and supporting innovation [9]. They also assist companies in rethinking their economic paradigm (value propositions), optimally organizing their processes, streamlining the way they are structured [4], transforming their mechanism of value creation [10], and sharing widespread knowledge, data, and information across the entire company [11]. As such, implementing industrial 4.0 applications will result in an improved firm act. Nevertheless, the applications of IR4.0 technologies in the development of smart and sustainable manufacturing facilities have long been a source of contention in the world of management, with critics arguing that such investments might take a long time to pay off [3]. This is can be explained by the substantial costs and high level of knowledge and skills required for their deployment [12]. Alternative viewpoints posit that certain developed technologies may not yield statistically significant improvements in business performance within the realm of short-term investments [11,13].

More specifically, academics from different fields have extensively investigated the multifaceted outcomes of Industry 4.0 (IR4.0). The initial research primarily centered on its expediency and value-related benefits [14,15]. In contrast, newer studies have expanded their focus to encompass strategic and operational consequences, including innovation performance [3,16], supply chain management (SCM) effectiveness [13,17], and financial results [18,19]. However, due to the diverse fields and disciplines involved in studying the IR4.0—business performance relationship, our comprehension of how IR4.0 influences firm performance, the mediating and moderating factors affecting its effectiveness, and the mechanisms and barriers shaping its outcomes remains limited. While recent investigations have explored mediating variables such as competitive advantage [20], SC visibility [7,21,22], and technological functionality [23], contributing to our knowledge, inconsistent findings in earlier research and the complex nature of IR4.0 call for a deeper exploration of the underlying mechanisms and organizational determinants linking IR4.0 to business innovation [24] and the advancement of intelligent and sustainable manufacturing facilities [3]. This research is particularly relevant as it responds to the scholarly call for further investigation. It is also important to note that a momentous portion of prior research in this domain suffers from limitations, as is discussed in the following sections, such as being in early stages of development, relying on descriptive or anecdotal methods, lacking comprehensive coverage of the entire SC, or exhibiting regional and sectoral biases.

In light of the above, this study explores the role of BCT in developing smart and sustainable manufacturing facilities. It also analyzes the implications of BCT for the future of SCM. To achieve these objectives, the following research questions (RQs) have been posed: RQ1: What role does BCT play in the development of smart and sustainable manufacturing facilities? By unlocking the answer to this crucial question, we focus on how BCT enhances resource efficiency, optimizes production processes, and enables real-time data analysis for informed decisions, driving intelligent and smart operations. RQ2: What specific SC performance metrics can be improved using BCT? By unlocking the answer to this crucial question, we can explore key BCT features critical for practical use in SCs and smart manufacturing. We also critically review the literature on the role of BCT in supporting the key objectives of SCs. Consequently, we zero in on areas such as visibility, flexibility, traceability, and streamlined logistics and collaboration within the SC network, aiming to quantify BCT’s impact. RQ3: How can BCT be used to develop new sustainable practices for manufacturers? This question pushes boundaries, exploring how BCT can birth novel approaches to circular economy models, closed-loop production systems, and responsible waste management strategies, propelling sustainable practices into the future.

2. Literature Review

2.1. Industry 4.0

IR4.0, as described by [25], is a framework that hinges on integrating vertical and horizontal value chains, digitizing services and products, and introducing innovative business models. It can be viewed as a “policy-driven product”, as indicated by [26]. Ghobakhloo [27] outlines IR4.0 as a holistic system that creates value by integrating advanced technologies and processes that are guided by twelve “design principles” and influenced by fourteen contemporary technological developments. This concept comprises six aspects and principles, as well as four components, which encompass “vertical networking”, “horizontal integration”, “business solutions”, and “expanding technologies” [25].

Prior works, such as [9,28], have identified more than ten essential elements/factors of success for implementing Industry 4.0. Nonetheless, existing studies have predominantly concentrated on three aspects: “drivers and barriers”, “implementation patterns”, and “maturity assessment”. These drivers and barriers can be categorized into “technology, society, and environment”, with technology-related factors being central. For instance, the acceptance of IR4.0 is influenced by variables such as “information technology maturity”; “technology incentives” [29]; “investments in advanced manufacturing technologies”; “novel technologies” such as “BCT, big data, cloud computing, AI, 3D-printing, smart manufacturing, robotics, augmented reality, IoTs, RFID Tags” [13,30]; and so on. Technological advances that help in the integration of SC information [13,30] and enhance SC “collaboration” and “transparency” [31] are also pivotal drivers. Regarding to the “social factors”, these encompass “sustaining government policies” [29], “legislation, and public advisory systems” [32]. Ecological elements/factors encompass socioeconomic and business sustainability dimensions, with market environments in emerging or developed economies being examples of socioeconomic factors [9]. Various business environmental factors play crucial roles, including top management support [9,28,30,33], worker participation [32], human resource development [34], and change facilitation [28].

In addition, most of the research on how to implement Industry 4.0 focuses on using new information technologies, especially front-end technologies such as block chain technology and Digital Twin solutions encompassing “intelligent manufacturing”, “intelligent SCs”, and “smart manufacturing” serving as the core [9,35,36]. With regard to assessing the maturity of IR4.0 implementation, it is considered as another vital research area, aiding companies in understanding their current implementation level and guiding further improvement.

Manufacturing companies have tackled challenges arising from IR4.0 by innovating business models [37], fostering innovative ecosystems [38], achieving value-based innovation [39], formulating global strategies [1,40], adopting data-driven and sustainable manufacturing practices [41,42,43], and establishing smart factories [23]. Previous works has identified two noteworthy sets of IR4.0-related business practice relationships. First, studies have found a complementary impact on “IR4.0-lean management relationship” [44], enhancing existing practices like Lean Manufacturing principles [45], Lean Six Sigma [46], and “total quality management” [46]. These complementary relationships help to promote the circular economic system and sustainable growth [37,43]. However, some studies have suggested no significant improvements in environmental sustainability from all IR4.0 technologies [46].

Second, earlier works indicated that IR4.0 can benefit various aspects of SC management, including “innovation” [47], “technology transformation” [33], “sustainability dissemination” [31], resilience, ripple effects, and risk mitigation [48], and synergy with Lean Manufacturing principles [49].

Several categorizations of IR4.0 applications have emerged in the literature [50]. The most common classification distinguishes between “physical process-driven technologies” and “digital technologies”. The first is physical technologies, which encompass “hardware components” are primarily used to enhance tangible production processes. Examples include “additive manufacturing, collaborative robots, and transportation systems” [51]. The second is a broad range of “digital technologies”, categorized into three distinct subgroups. (i) “Digital Interface Technologies”: these encompass network-connectable hardware components, such as “BC”, “cyber-physical systems”, “IoT”, and “visualization technologies” [52,53]. (ii) “Network Technologies”: these are predominantly software components like “cloud computing” and “cybersecurity solutions” [54,55]. (iii) “Data Processing Technologies”: these are also information-driven software components, e.g., “artificial intelligence”, “simulation”, and “big data analytics” [56,57].

A common reference [50] is the “ten pillars of IR4.0 technologies”, which include “BCT”, “big data analytics”, “autonomous robots”, “simulation”, “horizontal and vertical systems integration”, “IoT”, “cybersecurity”, “cloud computing”, “additive manufacturing”, and “augmented reality” [13,50]. The interpretations of these pillars may vary, with some focusing on specific components. For instance, Frank et al. [36] emphasize “the connectivity and intelligence capabilities of IoT, cloud computing, and big data analytics”. Rojko [58] underscores the application of “cyber-physical systems” and “IoT”. Moeuf et al. [34] replace “additive manufacturing” with “cyber-physical systems”, change systems integration to “machine-to-machine” (M2M) communication, and revise “autonomous robots” to “collaborative robots”. Certain works, such as the work of Roblek et al. [59] have limited the focus to four major technological components: “cyber-physical systems”, “IoT”, “IoS”, and “smart factories”.

In this review, we identify 18 widely utilized technologies in the literature [50], grouped into five categories. (i) “Infrastructure Technologies”: this category includes “cloud computing” and “big data collection”. (ii) “Tracking and Monitoring Technologies” [13]: this category encompasses “BC”, “digitalized control systems”, “real-time tracking technologies”, “sensors”, “RFID tags”, and “M2M communication”. (iii) “Production Technologies”: this category comprises “3D printing” and “additive manufacturing”. (iv) “Transport Technologies”: this category covers “autonomous robots” and “drones”. (v) “Digital Technologies”: this category focuses on “IoT”, “big data analytics”, “cybersecurity”, “simulation”, “augmented reality”, and “artificial intelligence”. These technologies collectively form the foundation of contemporary research in IR4.0 [50].

In the realm of “BCT”, its potential to facilitate the effective implementation of IR4.0 innovations has been highlighted [60]. The various applications of BCT, particularly in manufacturing and SC domains, are emphasized by [61]. Numerous enablers, drivers, and capabilities of BCT for IR4.0 innovation are discussed in the next sections and subsections.

More importantly, the utilization of BCT in the domain of decision-making shows promise. It forms an essential foundation for the future of manufacturing and SCM. An efficient decision-making process serves as the primary defense against uncertainties for any organization. A particularly promising potential application may involve using BCT to streamline and enhance decision-making. For any organization, ensuring a decision-making process is the most efficient way to deal with all uncertainties. SCM specialists are required by most businesses in order to develop and implement procedures used for making decisions to ensure competitiveness. An individual’s decision-making is improved when a BCT protocol is used, facilitating outcome predictions. Studies such as [60,61,62] have shown how vital effective decision-making is to success through the tracking and monitoring tools of BCT.

Recent studies on IR4.0 innovation mostly adhere to the antecedents–practice–response–performance logic, with a focus on technical aspects [9]. The current focus of antecedents is primarily at the technical level. Similarly, the effects of “social and environmental factors”, which are the focus of our research in the context of a sustainable manufacturing system, have received little attention. The practice of “IR4.0 innovation” primarily focuses on the implementation of relevant sophisticated technological innovations, whereas IR4.0′s “strategic response” discuss the digital and intelligent changes in businesses and their SCs enabled by these sophisticated technological innovations. Given the significant investment required in the early stages of IR4.0 adoption, it is not yet known how IR4.0 can be used to improve organizational financial performance. Figure 1 outlines the existing research on IR4.0 innovation against this backdrop.

Figure 1.

Theoretical framework of IR4.0 innovation.

2.2. BCT

“BCT” is a P2P process that does not require an intermediary. To this end, each of the different parties elaborated in any transaction functions as “nodes”, and this process is verified through “cryptography” (i.e., “hash”). Records of these transactions are maintained in a single, transparent database across all participating organizations. Once a record is transmitted to the “distributed ledger network”, it is nearly impossible to change, as it is in an unalterable record of past activity [63].

The cryptography, or hashing process, converts “tangible assets” (such as raw materials), or “intangible assets” (such as file ownership), into a digitally encoded “token”. This token can be logged, monitored, and transmitted using a “private key” on the BCT [64]. The invention of BCT can be traced back to 2008 to Satoshi Nakamoto, an anonymous author of the “Bitcoin white paper”, which describes a data structure that incorporates data records referred to as “blocks in a chain”.

Following the studies of [21,65], BCT is characterized as follows:

- (i)

- BCT is intended to be “distributed and synchronised via networks”, allowing companies to connect and exchange data, and, therefore, is suitable for multi-actor enterprise networks that consist of SCs or financial partnerships.

- (ii)

- BCTs provide “smart contracts”, which are agreements that parties form beforehand and hold within the network. “A smart contract” is a code protocol designed to promote, validate, or execute the agreed clauses and conditions of the contract on a digital basis. This allows for the execution of legitimate contracts without the need for third-party interference because it is entirely performed digitally. This also affords various parties on the network the mutual trust that everyone will comply with the rules.

- (iii)

- BCT relies on using “P2P networks”, where an agreement on the validity of a transaction is reached among all relevant parties, and these networks serve to keep incorrect or possibly deceitful transactions away from the database.

- (iv)

- Lastly, BCT is considered “data immutable”, which means that the agreed-upon transactions are logged and not altered. It offers a history of assets; thus, it is easy to know where it is, where it has been, and what has occurred in every object in its lifetime.

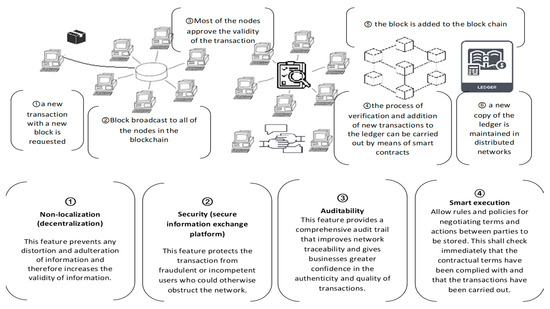

BCT stands apart from conventional information system architectures due to the incorporation of its four fundamental features, as shown in Figure 2:

Figure 2.

An overview of the steps and features of BCT information and transactions.

- (i)

- Non-localization (decentralized database): Centralized databases are more vulnerable to hacking, manipulation, or crashing. By contrast, decentralized databases are more reliable and trusted due to the reliability of the intermediary or other network members [65];

- (ii)

- Security: This is an essential requirement for reliable and long-term information exchange. It is necessary for managing the demands among members of the network [66]. Transaction history is only available to authorized network users, while no one else can remove or change data without the consent of others;

- (iii)

- Auditability: BCT is a more open system, enabling auditors and third parties, such as compliance officers, to easily access the data. Due to its transparency and immutability, BCs force companies to operate within the framework of consumer protection legislation and regulations [65,67].

- (iv)

- Smart execution: Another feature of BCT is the self-execution of digital transactions using decentralized cryptographic mechanisms that astutely bridge protocols and user interfaces to foster regulated and secure communications across computer networks [24].

2.3. Key Classification of BCT

A key advantage of this technology in a work-related setting where no one party retains control is that it addresses issues of transparency and responsibility between individuals and organizations where priorities are not inherently mutually aligned [66]. It allows for updating data relevant to all of the participants in real time, eliminating the need for time-consuming and inaccurate reconciliation procedures that require the confidential information of each party/participant.

BCT reaches the economy using a variety of techniques, which can be categorized as shown in Table 1:

Table 1.

BCT techniques and example applications.

3. Methodology

This study utilized a “systematic literature review” (SLR) approach to collect “data” based on well-known scientific principles, minimizing subjective influences (bias) in research endeavors. The SLR is a “replicable, scientific, and transparent method based on comprehensive literature searches that enhances methodological rigor and reliability throughout the review process” [69,70,71]. The approach followed (SLR) aligns with the research goal of knowledge development by synthesizing prior research, identifying “knowledge gaps”, and “establishing the foundation for new research” [72]. The study process began with developing the “research protocol”, which was then complemented by carrying out and analyzing the query string with “inclusion and exclusion criteria” adapted from [73].

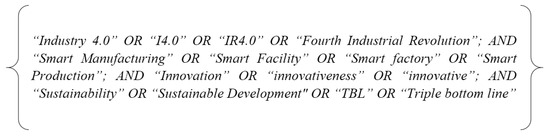

A key step in SLR research is to select “search phrases” that will access a broad spectrum of sources. To this end, we first developed the three research questions by consulting with industry experts and identifying key concerns, which would serve as the basis for our research. Next, we explored potential synonyms and alternative phrases for all relevant topics. Finally, we used Boolean operators (AND, OR) to combine these phrases and generate a search string.

In this study, we structured our search terms according to the established “population” and “intervention” framework [72]. For the population, we focused on the scope of application, which, in our case, is “IR4.0”, while the “intervention” included BCT innovation and sustainable manufacturing. An initial pilot search with a few selected phrases revealed that some yielded irrelevant results. Notably, the acronym “IR4.0” proved far more prevalent than “Fourth Industrial Revolution” in the literature. Building on these preliminary findings and consultations with information retrieval bibliographers, we opted for the broader term “sustainable manufacturing facilities” to encompass a wide range of sustainability concepts, including “triple bottom line” (TBL), “circular economy”, and “sustainable development”. Similarly, we used terms like “smart manufacturing” and “smart factories” to capture the development of smart and sustainable manufacturing facilities. The final search string (as shown in Figure 3) was, thus, developed to address the key questions of this investigation within its defined scope.

Figure 3.

The search string tailored to the research scope.

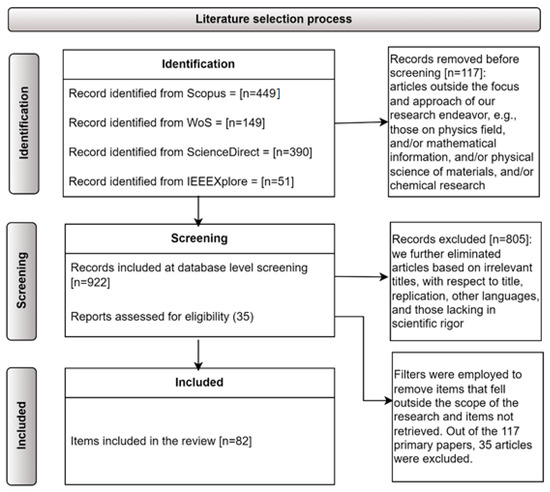

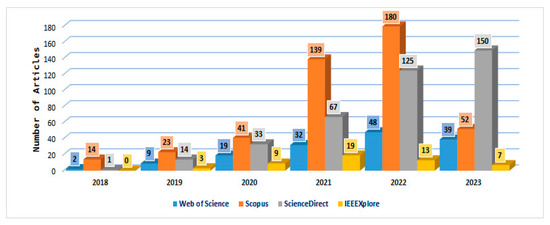

This literature review employed four electronic databases—“IEEEXplore, ScienceDirect, Web of Science, and SCOPUS”—to gather scholarly papers. These databases represent the most extensive and appropriate collections for our research endeavor, as demonstrated by different scholars (e.g., [72,74]). Our keyword searches targeted “article titles and abstracts” to gather as much pertinent literature as possible on IR4.0 innovation, sustainability, and smart manufacturing. We identified a total of (1039) items in the four databases. Each of the outcomes of the search was then entered into a “Microsoft Excel spreadsheet”. In phase 1, the collected documents were classified by the “date of publication” (2018–2023). Following the guidelines of the PRISMA declaration [75]. Figure 4 illustrates “the literature selection approach” used in this study. Moreover, Table 2 and Figure 5 show that the items identified in the four databases were found relevant for further exploration.

Figure 4.

Literature selection process based on PRISMA flowchart on three levels.

Table 2.

The items identified in the four databases prioritized for in-depth analysis.

Figure 5.

Publication distribution in the four chosen databases.

In the first phase, we implemented a preliminary screening filter to eliminate papers outside the focus and approach of our research endeavor, e.g., those on the fields of physics, and/or mathematical information, and/or physical science of materials, and/or chemical research. This phase yielded 922 items from the initial count of (1039). In the second phase, we further eliminated articles based on irrelevant titles, replication, other languages, and those lacking in scientific rigor. This resulted in 117 distinct items. In the final phase, the authors themselves screened these 117 papers against the specific research aims and objectives defined in Table 3, applying the inclusion and exclusion criteria outlined therein.

Table 3.

Inclusion and exclusion criteria.

We carefully selected and rigorously examined all primary studies to eliminate researcher bias. Triangulation among researchers and detailed data extraction protocols ensured consistent evaluation. Following recommendations in [74], we assessed all major articles for quality and study characteristics, considering factors such as research rigor, relevance, study type, methodology, domain, industry type, publisher, sustainability aspects, and innovation type. Our key quality criteria included the following: (1) whether the research articles appropriately outlined the study terms, (2) whether the data recuperation and investigation methods were abundantly apparent, (3) whether results were drawn, and (4) whether the article was useful for theory and practice. The authors read each “original article” independently prior to incorporating its findings into the study. This approach facilitated the discussion and resolution of any discrepancies. To end with, one author took a comprehensive view of the entire systematic literature review (SLR) and each step involved, ensuring a consistent analysis and interpretation of findings, grouping results, and disseminating them effectively. We sought to identify and elucidate the link between the various constructs of our study. These links can bridge the gap between a diversity of knowledge on different types of “IR4.0 innovations”, ultimately advancing various aspects of smart and sustainable manufacturing facilities.

Following the application of a series of filters based on the aforementioned criteria, each article was meticulously assessed by the authors, leading to a unanimous decision regarding its “inclusion or exclusion”. A stringent selection process was employed to identify pertinent articles. Filters were employed to remove items (articles) that fell outside the scope of the research. Of the initial 117 primary papers, 35 articles were excluded due to their insufficient coverage of IR4.0 innovation outcomes in terms of processes, products, and other relevant aspects. The final selection for data extraction and analysis consisted of 82 articles.

4. Analysis and Results

4.1. Descriptive Analysis

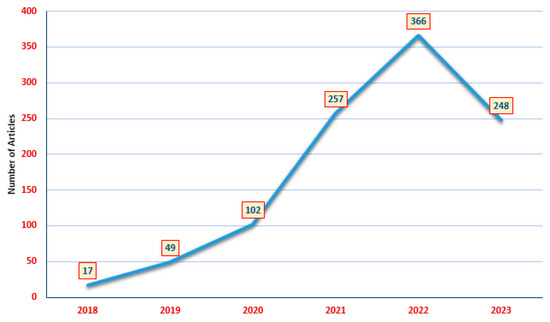

Our final set of data for the current study included 82 research articles published between 2018 and August 2023. We limited our search to studies published after 2018, as this topic has gained significant traction within the academic and professional communities [1]. Nonetheless, our findings suggest that academic discussions and debates about the influence of IR4.0 innovation on the development of smart and sustainable manufacturing facilities likely began earlier, possibly around 2017. Since then, the amount of new research on this subject has skyrocketed, highlighting the growing interest among scholars in the critical and pertinent domain of digitalization, IR4.0 and IR5.0 innovations, and their connections to sustainability. Figure 6 below illustrates this trend of increasing publications over time.

Figure 6.

The spread of research contributions across a timeline.

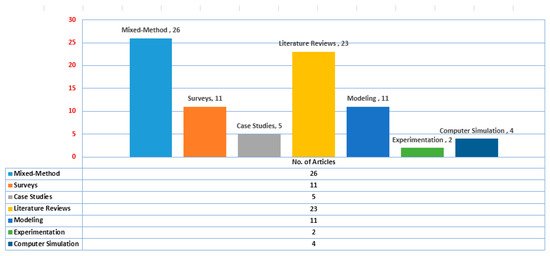

Given the importance of research methods, we observed a variety of techniques used to explore the link between IR4.0 innovation (specifically BCT) and the sustainability of smart manufacturing facilities. As shown in Figure 7, mixed-method studies (combined qualitative and quantitative approaches) are the most prevalent (n = 26), followed by surveys (n = 11), case studies (n = 5), literature reviews/conceptual studies (n = 23), modeling studies (n = 11), and a smaller number of studies employing experimentation (n = 2) and computer simulation (n = 4). These results indicate that the present study’s theme has received academic focus from both qualitative and quantitative standpoints. Theoretical and review articles have explained how IR4.0 technologies, with particular emphasis on BCT, influence various forms of innovations for sustainable development, while case studies have largely endorsed hypothetical concepts with empirical applications. Conversely, experimentation, prototyping, and simulation methods need to be utilized to help assess design problems and recommend effective solutions.

Figure 7.

Overview of research methods used in the reviewed studies.

Our bibliographic analysis revealed that the sample studies were published in 38 different sources. The largest proportion of primary articles (n = 14) appeared in the “International Journal of Production Research”, followed by “Sustainability” (n = 9). The “Journal of Cleaner Production” published (n = 6) primary articles, and the journal of “Production Planning & Control” published (n = 5) articles; similarly, “Technological Forecasting and Social Change” published (n = 5) articles. The remaining 44 articles were published across a variety of journals.

While our results suggest a wide range of journals publishing research on this topic, identifying recurring themes, author groups, or journal-specific features could be valuable for future research. Table 4 provides a complete list of primary study venues, and Table 5 highlights the most prolific authors contributing to this domain.

Table 4.

Primary articles relating to the journal’s publisher.

Table 5.

The ten most influential scholars in the field of study.

According to Table 5, the top ten studies reveal a collective exploration of the transformative potential of IR4.0 and BCT in shaping smart and sustainable manufacturing practices. A prominent theme across all ten studies is the use of advanced technologies to optimize resource utilization, reduce environmental impact, and support circular economy principles.

These studies highlight the significance of IR4.0 technologies such as AI, IoT, and big data analytics in increasing production efficiency, minimizing waste, and creating closed-loop manufacturing processes. Notably, BCT plays a crucial role in enhancing supply chain transparency, traceability, collaboration, and facilitating sustainable manufacturing practices across networks of peers.

These studies convincingly demonstrate the transformative potential of IR4.0 and BCT technologies in shaping sustainable manufacturing’s future. By adopting them, manufacturing facilities can maximize resource usage while simultaneously decreasing environmental impact and contributing to a more circular economy, ultimately paving the way for a sustainable future in manufacturing.

More recently, we focused on six studies [23,24,43,57,96,101] particularly relevant to this literature review’s exploration of IR4.0 innovations and smart manufacturing. These studies shed light on the potential of these technologies to revolutionize manufacturing processes while enhancing sustainability. They emphasize the pivotal role of BCT in optimizing production efficiency, minimizing waste, and enabling closed-loop processes, thereby laying the foundation for smart and sustainable manufacturing practices.

While acknowledging the challenges and limitations inherent in implementing technological advancements, the aforementioned studies recognize their transformative potential for manufacturing. For instance, [23] highlights the need for an objective performance measurement system to effectively assess IR4.0 initiatives. Similarly, ref. [96] emphasizes the importance of security and privacy when utilizing BCT.

Despite these challenges, a general consensus emerges from these studies: IR4.0 and smart manufacturing hold immense promise for the future of the industry. By embracing these advancements, manufacturing facilities can unlock significant improvements in resource utilization, environmental impact reduction, and contributions to a broader circular economy, paving the way for a more sustainable and prosperous future.

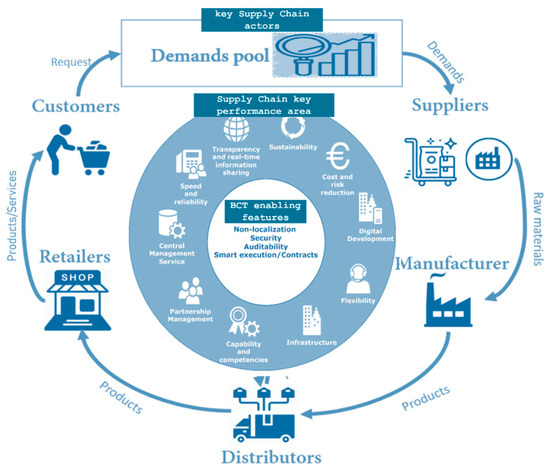

4.2. BC-Based SC

An SC is described as a series of interconnected actors (including suppliers/vendors, distributors, manufacturers/producers, transporters/carriers, retailers/buyers, warehouses, and customers) engaged in the manufacturing and delivery chain of products/and services, from the stage of procurement to the final customer or the point of consumption [1]. In the conventional model, an SC entails various stages and locations. Thus, it is challenging to track events across the entire chain. Furthermore, as a result of the lack of visibility in the SC, “buyers and customers” cannot be entirely confident about the actual value of goods or services [20]. Additionally, several non-traceable elements, including environmental incidents, are also embedded within the SC, potentially fostering issues (e.g., counterfeiting, forced labor, and poor manufacturing conditions). BCT can serve as an effective solution to enhance transparency within SCs, thereby acting as a security guarantor.

4.3. Key Features for Implementing BCT in SCs

BCT can address the challenges of manufacturers and other SC participants and support key SC management purposes such as “cost reduction”, “quality improvement”, “speed”, “reliability”, “risk mitigation”, “sustainability”, and “flexibility” [7,20]. The study of [102] emphasized that efficiency through BC-based SC technology can result in increased market reach, as well as balanced and equitable trade relationships and pricing structures for SC participants. This would then improve transparency and traceability in SC processes and play a role in mitigating and resolving current sustainability challenges that intersect social justice, economic sustainability, and environmental protection. Therefore, among the various operations that are anticipated to undergo significant advancements with the advent of BCT, the SC demands particular attention. The key features of BCT that are critical for application and practical use in SCs and a smart manufacturing system are as follows:

- Traceability, accountability, and visibility: The most common use of BCT for SC purposes is the verification of the source of the goods (mainly the location, time, and producer) and details of the route of the flow of goods from the starting point “its origin” (the back-end SC) to the place of consumption (the front-end SC). “Traceability, accountability, and visibility” issues are critical in providing quality logistics services to customers. To increase the accuracy of tracking the goods from their source to their final destination, BCT is commonly employed in conjunction with RFID tags for items that have different product details and are scanned in a non-contact transfer manner through radio waves imitating different “scanners” [66]. Once the data are gathered and digitized, BCT enables its verification, insertion into a shared distributed ledger, enhancement, and real-time validation. Therefore, BCT serves as a tool for mapping the SC and as a protected platform for exchanging “information”. The benefits of using BCT to record and share information are that all participants in the SC have equal access to real-time updates on product movements and operations [66].

- Boosting demand forecast: The difficulty of forecasting demand is becoming more acute as product life cycles shorten and manufacturing lead times extend. In these scenarios, SCs are increasingly confronting the possibility of either an overabundance of production capacity (stemming from decreased consumer demand) or inadequate product availability [20]. Nevertheless, traditional methods of information sharing, such as the use of an electronic data exchange network to incorporate various coding standards (standards), or the introduction of an “integrated ERP system” to gain “visibility”, are costly and impractical. This is due to BCTs relying on an alternative technology, namely, “peer-to-peer networking”. In this peer-to-peer network, each node serves as a repository for the entire transaction history, encompassing both client and server activities. This distributed approach ensures that all nodes agree on the current state of the ledger, safeguarding data consistency [20]. Consequently, BCTs find an efficient and long-term exchange of information that is central to the management of demand in the supply network [66]. In practice, this means that on the basis of available orders, every entity within the SC develops its demand estimate based on the orders placed by the downstream link (from the distributed ledger). These demands are referred to as derived demands.

- Improved partnership, contract management, and governance of SC partners: The “creation and management” of SCs or network partnerships as per the traditional (“conventional”) method necessitates collaborative efforts, including information dissemination and resource sharing, decision-making coordination, alignment of interests, and a process of trusted exchange [13,79,87,98,100,103,104,105,106,107,108,109,110]. As SCs consist of a series or “network” of interconnected partnerships, the competitive edge of SCs can only be sustained by a positive inter-organizational cooperation among SC participants. Information transparency is a feature of BCT resulting in fast and reliable information shared with the entire community of BCT users. If the BCT features apply to the entire SC of the final product, these BCT features forward information immediately and whenever necessary to all approved actors of the distributed network within the SC, including suppliers of product components [79]. Consequently, this improves SC partnerships and overall performance. In addition, a smart contract execution also improves contract management and the governance of SC partners. A “smart contract” is a self-executing computer program that mimics a traditional contract to oversee digital assets and clearly define the rights and responsibilities of the involved SC members [20]. Upon meeting a set of criteria, the “smart contract” will execute automatically without any human intervention. It can streamline the negotiation process, standardize the terms, automate the execution, and facilitate the real-time monitoring of the contract’s performance. Consequently, specific tasks (e.g., payments) can be carried out through an open disclosure (“transparency”) and effectively [20].

- Improved manufacturing cycle: A substantial volume of information is produced during the manufacturing cycle, ranging from tracking the origins of conflict-free raw materials to implementing process improvement methodologies as in the case of Lean and Six Sigma methodologies. BCT validates manufacturing parameters that are perceived as bulk operations. Smart contracts, equipped with executive powers, can enforce and validate terms and conditions to facilitate the large scale automation of units [111]. By leveraging BC, high-quality data can be centralized, standardized, and shared with all participants in a network to enable better decision-making. BCT can also assist in the additive manufacturing process through constructing a more documentable and design-related process [63].

The essential characteristics (“features”) of BCTs create a great interest in the context of industry and SCs, with the potential to become Industry 5.0 [63]. Considering how BCTs disrupt different segments, it is inevitable that SCs and manufacturers will reap the benefits of it.

4.4. Role of BCT in the Development of Smart and Sustainable Manufacturing Facilities

Earlier sections describe how BCT can be used to create a more secure, traceable, authentic, and collaborative environment while boosting demand forecasts and improving the manufacturing cycle. In this part, we explain the role of “BCT” in the development of smart and sustainable manufacturing facilities, as found in both the literature and practical applications. According to [101], “BCT” has been widely adopted across diverse industries in industrialized and developed economies, leading to innovative applications in smart manufacturing within four key areas: ensuring data security; increasing data sharing, traceability and trust mechanisms; increasing system development; and performance improvement. These areas are summarized in Table 6 below.

Table 6.

Key application areas of BCT in smart manufacturing.

4.5. Potential Use of BCT to Facilitate SCM

A wide range of benefits can be realized by implementing BCTs that are important to the management of the SC, as presented in Figure 8 and Table 7 below. These benefits reflect the role of BCT implementation in achieving the objectives of the SC and offer a summary of how they are linked to the key features of BCT.

Figure 8.

The role of BCT in supporting the key objectives of SCs.

Table 7.

A review of the scholarly literature on the role of BCT in supporting the key objectives of SCs.

The cited literature shows both the excitement surrounding BCT in the industrial and SC sectors and its potential to emerge as a defining technology for Industry 5.0 [63]. The transformative power of BCT, already evident in its disruption of various industries, suggests that SCs will soon be next in line for its transformative impact. A comprehensive study conducted by “Chain-Business Insights” surveyed supply chain practitioners to assess the adoption and utilization of BCT in SCM. The study’s key findings, as outlined in [63], revealed the following. (i) Limited understanding: over 40% of the participants indicated a lack of in-depth understanding of BCT, demonstrating their early stage comprehension of its potential applications. (ii) Focus on traceability: the majority of the participants (80%) envisioned utilizing BCT primarily for product tracking throughout the SC, highlighting its potential to enhance transparency and traceability. (iii) Improved visibility: nearly half of the participants recognized improved SC-visibility as a key benefit of BCT implementation, emphasizing its ability to provide real-time insights into product movement and status. (iv) Growing adoption: nearly half of the participants expressed their companies’ plans to implement BCT in the near future, indicating a growing recognition of its potential transformative impact on SCM. (v) Understanding is key: a lack of understanding remained the most significant barrier to adoption, with 27.5% of the participants citing it as the biggest problem.

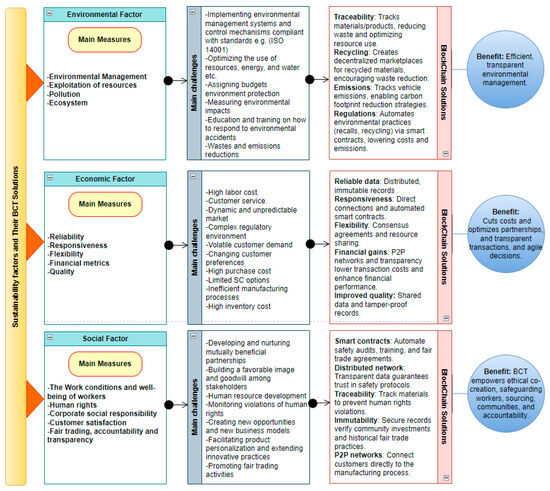

4.6. How BCT Can Be Used to Make Manufacturing More Sustainable

Sustainable manufacturing requires considering and balancing “economic”, “social”, and “environmental” aspects. As mentioned earlier, centralized information management in traditional SCs carries risks of data loss and system failures due to security vulnerabilities, mismanagement, and attacks [76,81]. This can ultimately erode trust among SC participants. More specifically, centralized manufacturing SCs lack the appropriate degree of “dependability and transparency” in SC practices, productions, and operations [81]. As a result, enhancing the visibility, data security, trustworthiness, and traceability of current SC processes is crucial for developing trust relationships and achieving sustainability, as highlighted above in this paper. BCT facilitates sustainable manufacturing practices by enabling a reliable, transparent, traceable, and secure SC [121]. The positive impacts of BCT on the three pillars of “sustainability”, commonly known as the triple bottom line (TBL), namely, “economic, environmental, and social”, are presented in Table 8 and Figure 9.

Table 8.

BCT solutions and their sustainability implications.

Figure 9.

BCT solutions for the challenges of sustainability factors.

5. Discussion

This study identified multiple fields where further investigation is needed to address gaps in the existing body of knowledge. One such area is BCT’s potential to enable both innovative business solutions and the widespread use of smart and sustainable manufacturing systems. Forthcoming research efforts should concentrate on delving into the effects of various IR4.0 technologies on the generation of groundbreaking innovations such as:

- Developing new business models: a dynamic network of interconnected businesses, facilitated by BCT, seamlessly collaborating to create and deliver value to customers in entirely new ways.

- Fostering innovative ecosystems: BCT can empower the creation of collaborative environments where startups, established companies, and research institutions can co-innovate and bring revolutionary ideas to life.

- Achieving value innovation: by leveraging BCT’s transparency and traceability features, businesses can optimize their operations, develop data-driven insights, and create new revenue streams through improved products and services.

With a specific emphasis on developing countries, it would be particularly insightful to explore the viability of IR4.0 innovation in emerging economies and how BCT can leverage smart manufacturing to reduce costs and accelerate the time to market for new technologies:

- Reduce costs: streamlined, automated processes enabled by BCT can lead to significant cost savings in areas like production, logistics, and inventory management.

- Accelerate time to market: improved transparency and shorter production cycles facilitated by BCT can bring new technologies to market faster, giving businesses a competitive edge.

Furthermore, BCT applications to boost long-term profitability vary between industries. Future research should explore the potential advantages of BCT for different sectors, focusing on how it can contribute to: (i) enhanced circular economy strategies: BCT can enable closed-loop production systems by tracking materials and resources throughout their lifecycle, promoting waste reduction and resource conservation; (ii) cost-effectiveness: streamlined supply chains, optimized resource utilization, and reduced waste generation, all facilitated by BCT, can lead to significant cost savings and improved financial performance.

Notable in this literature review is that BCT remains in its early development and exploratory stages, with applications in industrial settings still emerging [1,5,6,7,8,60,101]. As a result, numerous formidable challenges must be overcome before the full range of BCT gains can be actualized. One of the major challenges is the decentralized consensus algorithm, a core component of BCT, which demands a heavy load on computing infrastructure, requires vast data storage, and entails intensive energy utilization. As a result, implementing consensus mechanisms with high-power consumption and low-power IoT devices is impractical. Similarly, the effectiveness of smart manufacturing and digital logistics systems is reliant on a wide variety of IoT devices, which makes integrating these devices with BCT components a difficult task. To overcome these obstacles, future research efforts must focus on developing solutions for system integration and conservation mechanisms.

Lastly, the current generation of BCT systems may struggle to handle the demands of high-throughput applications, limiting their potential use in large-scale smart manufacturing. The exponential growth in the user base and the corresponding expansion of the ledger mandate an equivalent increase in the BCT’s data processing and storage infrastructure. This limitation could hinder the adoption of BCT in high-volume smart manufacturing environments, leading to increased system latency, higher storage costs, and decreased performance. Future research should concentrate on addressing scalability limitations and developing high-performance BC-enabled smart manufacturing systems.

6. Conclusions, Implications, and Limitations

The main focus of this systematic review is to explore the impact of BCT applications in developing smart and sustainable manufacturing facilities. It addresses three research questions:

RQ1: What role does BCT play in developing smart and sustainable facilities?

RQ2: What specific SC performance metrics can be improved using BCT?

RQ3: How can BCT be used to develop new sustainable practices for manufacturers?

To address these questions, 82 research studies are critically examined and analyzed. The discussion explores, in detail, the implications of using BCT for achieving “sustainable manufacturing” and meeting SC objectives. Drawing from referenced articles and Table 6, this review categorizes the benefits of BCT for “sustainable performance”, “smart manufacturing systems”, and “SC management objectives”.

More specifically, with respect to the RQ1, Table 6 summarize the use of BCT in smart and sustainable manufacturing facilities. Its findings reveal how BCT enhances resource efficiency, optimizes production processes, and enables real-time data analysis for informed decisions, driving intelligent and smart operations. To address the second research question RQ2, Section 4.3, Section 4.4 and Section 4.5 discuss the ways in which BCT can enhance essential SC metrics, providing a foundation for explaining how BCT can help organizations achieve their SC goals. Consequently, we zero in on areas such as visibility, flexibility, traceability, and streamlined logistics and collaboration within the SC network, aiming to quantify BCT’s impact. Lastly, regarding RQ3, Section 4.6 discusses how BCT can help manufacturers improve their sustainability performance by utilizing BCT features and characteristics such as smart contracts, peer-to-peer networks, traceability, transparency, security, and distributed and synchronized data sharing.

Considering real-world implications, this study may raise the perception of the benefits of BCT for smart manufacturing, encouraging managers to use digital technologies. This could involve converting paper documents and manual processes to digital formats and transitioning to digital communication and storage. This research also assists manufacturing executives in understanding how BCT can address challenges associated with implementing sustainable strategies, which have long been a source of contention for manufacturers. Additionally, this work serves as a valuable resource for researchers by offering current insights into BCT’s potential contributions to sustainable and smart manufacturing systems.

In terms of theoretical implications, this study reveals that current BCT implementations may lack the necessary scalability to support high-volume usage scenarios. This impedes the adoption of BCT in large-scale manufacturing and makes the transition to digital processes difficult for manufacturers. The growth in BCT participants and the corresponding ledger expansion lead to increased resource demands and decreased performance. Therefore, future research should focus on addressing the scalability issue and developing high-performance BC-enabled smart manufacturing systems.

Although this study successfully addresses the three research questions, it also identifies some limitations that future research can address. Firstly, recognizing the comprehensiveness of WoS, ScienceDirect, Scopus, and IEEE Xplore, future research could consider expanding the scope to include SpringerLink, Wiley Online Library, EBSCO, and ProQuest databases for a more exhaustive search. Additionally, while this review focused on journal articles, incorporating conference papers and book chapters in future reviews could offer a more comprehensive examination of the field. To mitigate potential biases arising from subjectivity in article selection, two authors independently reviewed each piece of literature, with any discrepancies reconciled through collaborative discussions. As discussed above, a significant portion of prior research in this domain exhibits certain limitations: early stage of development, reliance on descriptive/anecdotal methodologies, incomplete coverage of the entire SC, and regional/sectoral biases. Future research should address these limitations and fill these gaps in the literature by: (i) conducting longitudinal studies to track changes and assess long-term impacts within the SC; (ii) employing robust quantitative methodologies for more objective and generalizable findings; (iii) encompassing a wider range of regions and sectors to ensure inclusivity and avoid regional/sectoral biases; (iv) developing novel theoretical frameworks that effectively capture the intricate dynamics of the SC.

Lastly, new research (e.g., [85]) indicates that Web 3.0, fueled by BCT, cryptocurrencies, and NFTs, grants users greater control over their digital assets. This decentralized structure, through mechanisms such as “transparency and energy efficiency”, promotes trust, data privacy, and sustainability. However, hurdles remain in building secure and effective smart contracts, and legal uncertainties persist. To fully unlock Web 3.0′s potential for a future that is secure, empowered, and sustainable, further research is essential. Exploring areas related to building sustainable supply chains with Web 3.0 and integrating AI with responsible governance will be key to unlocking this potential. While some may dismiss it as mere hype, Web 3.0 has the power to reshape the digital landscape, demanding our careful and responsible engagement.

Author Contributions

Conceptualization, M.A. and S.A.; investigation, M.A. and S.A.; resources, M.A. and S.A.; writing—original draft preparation, M.A. and S.A.; writing—review and editing, M.A. and S.A.; visualization, M.A. and S.A.; supervision, M.A.; project administration, M.A.; funding acquisition, M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Deanship of Scientific Research and Innovation at Al-Balqa Applied University in Jordan (Grant Number: DSR-2022#494).

Data Availability Statement

The datasets analyzed during this study are available from the corresponding author upon reasonable request.

Acknowledgments

The research reported in this publication was supported by the Deanship of Scientific Research and Innovation at Al-Balqa Applied University in Jordan (Grant Number: DSR-2022#494).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Khan, I.S.; Ahmad, M.O.; Majava, J. Industry 4.0 innovations and their implications: An evaluation from sustainable development perspective. J. Clean. Prod. 2023, 405, 137006. [Google Scholar] [CrossRef]

- Cirillo, V.; Fanti, L.; Mina, A.; Ricci, A. New digital technologies and firm performance in the Italian economy. Ind. Innov. 2023, 30, 159–188. [Google Scholar] [CrossRef]

- Oduro, S.; De Nisco, A. From Industry 4.0 adoption to innovation ambidexterity to firm performance: A MASEM analysis. Eur. J. Innov. Manag. 2023. [Google Scholar] [CrossRef]

- Mubarik, M.S.; Naghavi, N.; Mubarik, M.; Kusi-Sarpong, S.; Khan, S.A.; Zaman, S.I.; Kazmi, S.H.A. Resilience and cleaner production in industry 4.0: Role of supply chain mapping and visibility. J. Clean. Prod. 2021, 292, 126058. [Google Scholar] [CrossRef]

- Tian, F. A supply chain traceability system for food safety based on HACCP, blockchain & Internet of things. In Proceedings of the 2017 International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; pp. 1–6. [Google Scholar]

- Jeble, S.; Dubey, R.; Childe, S.J.; Papadopoulos, T.; Roubaud, D.; Prakash, A. Impact of big data and predictive analytics capability on supply chain sustainability. Int. J. Logist. Manag. 2018, 29, 513–538. [Google Scholar] [CrossRef]

- Kshetri, N. 1 Blockchain’s roles in meeting key supply chain management objectives. Int. J. Inf. Manag. 2018, 39, 80–89. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Wamba, S.F. Blockchain adoption challenges in supply chain: An empirical investigation of the main drivers in India and the USA. Int. J. Inf. Manag. 2019, 46, 70–82. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, J.Z.; Cao, Y.; Kazancoglu, Y. Intelligent transformation of the manufacturing industry for Industry 4.0: Seizing financial benefits from supply chain relationship capital through enterprise green management. Technol. Forecast. Soc. Change 2021, 172, 120999. [Google Scholar] [CrossRef]

- Bag, S.; Yadav, G.; Dhamija, P.; Kataria, K.K. Key resources for industry 4.0 adoption and its effect on sustainable production and circular economy: An empirical study. J. Clean. Prod. 2021, 281, 125233. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Chae, H.-C.; Koh, C.E.; Park, K.O. Information technology capability and firm performance: Role of industry. Inf. Manag. 2018, 55, 525–546. [Google Scholar] [CrossRef]

- Alazab, M.; Alhyari, S.; Awajan, A.; Abdallah, A.B. Blockchain technology in supply chain management: An empirical study of the factors affecting user adoption/acceptance. Clust. Comput. 2021, 24, 83–101. [Google Scholar] [CrossRef]

- Anand, A.; Fosso Wamba, S.; Sharma, R. The effects of firm IT capabilities on firm performance: The mediating effects of process improvement. In Proceedings of the ACIS 2013 Proceedings, Phuket, Thailand, 31 October–2 November 2013. [Google Scholar]

- Weill, P. The relationship between investment in information technology and firm performance: A study of the valve manufacturing sector. Inf. Syst. Res. 1992, 3, 307–333. [Google Scholar] [CrossRef]

- Díaz-Chao, Á.; Ficapal-Cusí, P.; Torrent-Sellens, J. Environmental assets, industry 4.0 technologies and firm performance in Spain: A dynamic capabilities path to reward sustainability. J. Clean. Prod. 2021, 281, 125264. [Google Scholar] [CrossRef]

- Erkmen, T.; Günsel, A.; Altındağ, E. The role of innovative climate in the relationship between sustainable IT capability and firm performance. Sustainability 2020, 12, 4058. [Google Scholar] [CrossRef]

- Zhu, X.; Yang, Y. Big data analytics for improving financial performance and sustainability. J. Syst. Sci. Inf. 2021, 9, 175–191. [Google Scholar] [CrossRef]

- Del Gaudio, B.L.; Porzio, C.; Sampagnaro, G.; Verdoliva, V. How do mobile, internet and ICT diffusion affect the banking industry? An empirical analysis. Eur. Manag. J. 2021, 39, 327–332. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y. Blockchains in operations and supply chains: A model and reference implementation. Comput. Ind. Eng. 2019, 136, 242–251. [Google Scholar] [CrossRef]

- Cole, R.; Stevenson, M.; Aitken, J. Blockchain technology: Implications for operations and supply chain management. Supply Chain Manag. Int. J. 2019, 24, 469–483. [Google Scholar] [CrossRef]

- Eljazzar, M.M.; Amr, M.A.; Kassem, S.S.; Ezzat, M. Merging supply chain and blockchain technologies. arXiv 2018, arXiv:1804.04149. [Google Scholar]

- Büchi, G.; Cugno, M.; Castagnoli, R. Smart factory performance and Industry 4.0. Technol. Forecast. Soc. Change 2020, 150, 119790. [Google Scholar] [CrossRef]

- Salmerón-Manzano, E.; Manzano-Agugliaro, F. The role of smart contracts in sustainability: Worldwide research trends. Sustainability 2019, 11, 3049. [Google Scholar] [CrossRef]

- Rejikumar, G.; Raja Sreedharan, V.; Arunprasad, P.; Persis, J.; Sreeraj, K.M. Industry 4.0: Key findings and analysis from the literature arena. Benchmarking Int. J. 2019, 26, 2514–2542. [Google Scholar]

- Reischauer, G. Industry 4.0 as policy-driven discourse to institutionalize innovation systems in manufacturing. Technol. Forecast. Soc. Change 2018, 132, 26–33. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Critical factors for the successful implementation of Industry 4.0: A review and future research direction. Prod. Plan. Control 2020, 31, 799–815. [Google Scholar] [CrossRef]

- Lin, D.; Lee, C.K.; Lau, H.; Yang, Y. Strategic response to Industry 4.0: An empirical investigation on the Chinese automotive industry. Ind. Manag. Data Syst. 2018, 118, 589–605. [Google Scholar] [CrossRef]

- Agostini, L.; Filippini, R. Organizational and managerial challenges in the path toward Industry 4.0. Eur. J. Innov. Manag. 2019, 22, 406–421. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an enabler of sustainability diffusion in supply chain: An analysis of influential strength of drivers in an emerging economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Stentoft, J.; Adsbøll Wickstrøm, K.; Philipsen, K.; Haug, A. Drivers and barriers for Industry 4.0 readiness and practice: Empirical evidence from small and medium-sized manufacturers. Prod. Plan. Control 2021, 32, 811–828. [Google Scholar] [CrossRef]

- Wamba, S.F.; Queiroz, M.M. Industry 4.0 and the supply chain digitalisation: A blockchain diffusion perspective. Prod. Plan. Control 2022, 33, 193–210. [Google Scholar] [CrossRef]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, E.; Eburdy, R. Identification of critical success factors, risks and opportunities of Industry 4.0 in SMEs. Int. J. Prod. Res. 2020, 58, 1384–1400. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. -Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Mariani, M.; Borghi, M. Industry 4.0: A bibliometric review of its managerial intellectual structure and potential evolution in the service industries. Technol. Forecast. Soc. Change 2019, 149, 119752. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ayala, N.F.; Frank, A.G. Industry 4.0 innovation ecosystems: An evolutionary perspective on value cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Matthyssens, P. Reconceptualizing value innovation for Industry 4.0 and the Industrial Internet of Things. J. Bus. Ind. Mark. 2019, 34, 1203–1209. [Google Scholar] [CrossRef]

- Stentoft, J.; Rajkumar, C. The relevance of Industry 4.0 and its relationship with moving manufacturing out, back and staying at home. Int. J. Prod. Res. 2020, 58, 2953–2973. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H.D. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When titans meet–Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Change 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Ghadge, A.; Raut, R. A performance measurement system for industry 4.0 enabled smart manufacturing system in SMMEs-A review and empirical investigation. Int. J. Prod. Econ. 2020, 229, 107853. [Google Scholar] [CrossRef]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Impacts of Industry 4.0 technologies on Lean principles. Int. J. Prod. Res. 2020, 58, 1644–1661. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Giglio, R.; Van Dun, D.H. Industry 4.0 adoption as a moderator of the impact of lean production practices on operational performance improvement. Int. J. Oper. Prod. Manag. 2019, 39, 860–886. [Google Scholar] [CrossRef]

- Chiarini, A.; Kumar, M. Lean Six Sigma and Industry 4.0 integration for Operational Excellence: Evidence from Italian manufacturing companies. Prod. Plan. Control 2021, 32, 1084–1101. [Google Scholar] [CrossRef]

- Hahn, G.J. Industry 4.0: A supply chain innovation perspective. Int. J. Prod. Res. 2020, 58, 1425–1441. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Núñez-Merino, M.; Maqueira-Marín, J.M.; Moyano-Fuentes, J.; Martínez-Jurado, P.J. Information and digital technologies of Industry 4.0 and Lean supply chain management: A systematic literature review. Int. J. Prod. Res. 2020, 58, 5034–5061. [Google Scholar] [CrossRef]

- Leang, Y.K.; Rasiah, R. Diffusion of IR4. 0 Technologies in Electronics Manufacturing: The Role of the Embedding Ecosystem. In Digitalization and Development; Routledge: Oxfordshire, UK, 2023; pp. 49–67. [Google Scholar]

- Gibson, I.; Rosen, D.W.; Stucker, B.; Khorasani, M.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021; Volume 17. [Google Scholar]

- Chryssolouris, G.; Mavrikios, D.; Papakostas, N.; Mourtzis, D.; Michalos, G.; Georgoulias, K. Digital manufacturing: History, perspectives, and outlook. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 451–462. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18. [Google Scholar] [CrossRef]

- Armbrust, M.; Fox, A.; Griffith, R.; Joseph, A.; Katz, R.; Konwinski, A.; Lee, G.; Patterson, D.; Rabkin, A.; Stoica, I.; et al. A view of cloud computing. Commun. ACM 2010, 53, 50–58. [Google Scholar] [CrossRef]

- Anderl, R. Industrie 4.0–Technological approaches, use cases, and implementation. at-Automatisierungstechnik 2015, 63, 753–765. [Google Scholar] [CrossRef]

- Chen, M.; Wan, J.; Gonzalez, S.; Liao, X.; Leung, V.C. A survey of recent developments in home M2M networks. IEEE Commun. Surv. Tutor. 2013, 16, 98–114. [Google Scholar] [CrossRef]

- Yao, X.; Zhou, J.; Zhang, J.; Boër, C.R. From intelligent manufacturing to smart manufacturing for industry 4.0 driven by next generation artificial intelligence and further on. In Proceedings of the 2017 5th International Conference on Enterprise Systems (ES), Beijing, China, 22–24 September 2017; pp. 311–318. [Google Scholar]

- Rojko, A. Industry 4.0 concept: Background and overview. Int. J. Interact. Mob. Technol. 2017, 11, 77. [Google Scholar] [CrossRef]

- Roblek, V.; Meško, M.; Krapež, A. A complex view of industry 4.0. Sage Open 2016, 6, 2158244016653987. [Google Scholar] [CrossRef]

- Hayat, A.; Shahare, V.; Sharma, A.K.; Arora, N. Introduction to Industry 4.0. In Blockchain and Its Applications in Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2023; pp. 29–59. [Google Scholar]

- Javaid, M.; Haleem, A.; Singh, R.P.; Khan, S.; Suman, R. Blockchain technology applications for Industry 4.0: A literature-based review. Blockchain Res. Appl. 2021, 2, 100027. [Google Scholar] [CrossRef]

- Sharma, A.K.; Khandait, S. A novel software tool to generate customer needs for effective design of online shopping websites. Int. J. Inf. Technol. Comput. Sci. 2016, 83, 85–92. [Google Scholar] [CrossRef][Green Version]

- Kamble, S.; Gunasekaran, A.; Arha, H. Understanding the Blockchain technology adoption in supply chains-Indian context. Int. J. Prod. Res. 2019, 57, 2009–2033. [Google Scholar] [CrossRef]

- Francisco, K.; Swanson, D. The supply chain has no clothes: Technology adoption of blockchain for supply chain transparency. Logistics 2018, 2, 2. [Google Scholar] [CrossRef]

- Baker, J.; Steiner, J. Blockchain: The Solution for Transparency in Product Supply Chains; Provenance: London, UK, 2015. [Google Scholar]

- Dujak, D.; Sajter, D. Blockchain applications in supply chain. In SMART Supply Network; Springer: Berlin/Heidelberg, Germany, 2019; pp. 21–46. [Google Scholar]

- Chang, Y.; Iakovou, E.; Shi, W. Blockchain in global supply chains and cross border trade: A critical synthesis of the state-of-the-art, challenges and opportunities. Int. J. Prod. Res. 2019, 58, 2082–2099. [Google Scholar] [CrossRef]

- Gupta, M. Blockchain for Dummies (2nd IBM Li); John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Cook, D.J.; Mulrow, C.D.; Haynes, R.B. Systematic reviews: Synthesis of best evidence for clinical decisions. Ann. Intern. Med. 1997, 126, 376–380. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Hart, C. Doing a Literature Review: Releasing the Social Science Research Imagination; Sage: London, UK, 1998. [Google Scholar]

- Kitchenham, B.; Brereton, P. A systematic review of systematic review process research in software engineering. Inf. Softw. Technol. 2013, 55, 2049–2075. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.d.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0-a systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Dybå, T.; Dingsøyr, T. Empirical studies of agile software development: A systematic review. Inf. Softw. Technol. 2008, 50, 833–859. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Roeck, D.; Sternberg, H.; Hofmann, E. Distributed ledger technology in supply chains: A transaction cost perspective. Int. J. Prod. Res. 2020, 58, 2124–2141. [Google Scholar] [CrossRef]

- Manupati, V.K.; Schoenherr, T.; Ramkumar, M.; Wagner, S.M.; Pabba, S.K.; Inder Raj Singh, R. A blockchain-based approach for a multi-echelon sustainable supply chain. Int. J. Prod. Res. 2020, 58, 2222–2241. [Google Scholar] [CrossRef]

- Kim, J.-S.; Shin, N. The impact of blockchain technology application on supply chain partnership and performance. Sustainability 2019, 11, 6181. [Google Scholar] [CrossRef]

- Tijan, E.; Aksentijević, S.; Ivanić, K.; Jardas, M. Blockchain technology implementation in logistics. Sustainability 2019, 11, 1185. [Google Scholar] [CrossRef]

- Khanfar, A.A.; Iranmanesh, M.; Ghobakhloo, M.; Senali, M.G.; Fathi, M. Applications of blockchain technology in sustainable manufacturing and supply chain management: A systematic review. Sustainability 2021, 13, 7870. [Google Scholar] [CrossRef]

- Braccini, A.M.; Margherita, E.G. Exploring organizational sustainability of industry 4.0 under the triple bottom line: The case of a manufacturing company. Sustainability 2018, 11, 36. [Google Scholar] [CrossRef]

- Ko, T.; Lee, J.; Ryu, D. Blockchain technology and manufacturing industry: Real-time transparency and cost savings. Sustainability 2018, 10, 4274. [Google Scholar] [CrossRef]

- Park, A.; Li, H. The effect of blockchain technology on supply chain sustainability performances. Sustainability 2021, 13, 1726. [Google Scholar] [CrossRef]

- Rathor, S.; Zhang, M.; Im, T. Web 3.0 and Sustainability: Challenges and Research Opportunities. Sustainability 2023, 15, 15126. [Google Scholar] [CrossRef]

- Upadhyay, A.; Mukhuty, S.; Kumar, V.; Kazancoglu, Y. Blockchain technology and the circular economy: Implications for sustainability and social responsibility. J. Clean. Prod. 2021, 293, 126130. [Google Scholar] [CrossRef]

- Alhyari, S.; Alazab, M.; Venkatraman, S.; Alazab, M.; Alazab, A. Performance evaluation of e-government services using balanced scorecard. Benchmarking Int. J. 2013, 20, 512–536. [Google Scholar] [CrossRef]

- Subramanian, H. Decentralized blockchain-based electronic marketplaces. Commun. ACM 2017, 61, 78–84. [Google Scholar] [CrossRef]

- Agrawal, T.K.; Kumar, V.; Pal, R.; Wang, L.; Chen, Y. Blockchain-based framework for supply chain traceability: A case example of textile and clothing industry. Comput. Ind. Eng. 2021, 154, 107130. [Google Scholar] [CrossRef]

- Preuveneers, D.; Joosen, W.; Ilie-Zudor, E. Trustworthy data-driven networked production for customer-centric plants. Ind. Manag. Data Syst. 2017, 117, 2305–2324. [Google Scholar] [CrossRef]

- Casado-Vara, R.; Prieto, J.; De la Prieta, F.; Corchado, J.M. How blockchain improves the supply chain: Case study alimentary supply chain. Procedia Comput. Sci. 2018, 134, 393–398. [Google Scholar] [CrossRef]

- Kawaguchi, N. Application of blockchain to supply chain: Flexible blockchain technology. Procedia Comput. Sci. 2019, 164, 143–148. [Google Scholar] [CrossRef]

- Venkatesh, V.; Kang, K.; Wang, B.; Zhong, R.Y.; Zhang, A. System architecture for blockchain based transparency of supply chain social sustainability. Robot. Comput. -Integr. Manuf. 2020, 63, 101896. [Google Scholar] [CrossRef]

- Leng, K.; Bi, Y.; Jing, L.; Fu, H.-C.; Van Nieuwenhuyse, I. Research on agricultural supply chain system with double chain architecture based on blockchain technology. Future Gener. Comput. Syst. 2018, 86, 641–649. [Google Scholar] [CrossRef]

- Siba, K.; Prakash, A. Block-chain: An evolving technology. Glob. J. Enterp. Inf. Syst. 2016, 8, 29–35. [Google Scholar] [CrossRef]

- Christidis, K.; Devetsikiotis, M. Blockchains and smart contracts for the internet of things. IEEE Access 2016, 4, 2292–2303. [Google Scholar] [CrossRef]

- Yu, K.; Tan, L.; Aloqaily, M.; Yang, H.; Jararweh, Y. Blockchain-enhanced data sharing with traceable and direct revocation in IIoT. IEEE Trans. Ind. Inform. 2021, 17, 7669–7678. [Google Scholar] [CrossRef]

- Alazab, M.; Awajan, A.; Mesleh, A.; Abraham, A.; Jatana, V.; Alhyari, S. COVID-19 Prediction and Detection Using Deep Learning. Int. J. Comput. Inf. Syst. Ind. Manag. Appl. 2020, 12, 168–181. [Google Scholar]

- Qiao, R.; Zhu, S.; Wang, Q.; Qin, J. Optimization of dynamic data traceability mechanism in Internet of Things based on consortium blockchain. Int. J. Distrib. Sens. Netw. 2018, 14, 1550147718819072. [Google Scholar] [CrossRef]

- Suifan, T.S.; Diab, H.; Alhyari, S.; Sweis, R.J. Does ethical leadership reduce turnover intention? The mediating effects of psychological empowerment and organizational identification. J. Hum. Behav. Soc. Environ. 2020, 30, 410–428. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, G.; Zhang, Y. A Comprehensive Review of Blockchain Technology-Enabled Smart Manufacturing: A Framework, Challenges and Future Research Directions. Sensors 2022, 23, 155. [Google Scholar] [CrossRef] [PubMed]

- Thiruchelvam, V.; Mughisha, A.S.; Shahpasand, M.; Bamiah, M. Blockchain-based technology in the coffee supply chain trade: Case of burundi coffee. J. Telecommun. Electron. Comput. Eng. 2018, 10, 121–125. [Google Scholar]

- Alhyari, S. Supply Chain Management Paradigms and Their Impact on Competitive Priorities: An Applied Study on Jordanian Airlines Industry. Unpublished Ph.D. Thesis, The World Islamic Sciences and Education University, Amman, Jordan, 2015. [Google Scholar]

- Alhyari, S.; Al-Ali, A.M.; Nuseir, M. Assessing Supply Chain Partnership Performance in Services Organization: Conceptual Model. Afr. Dev. Resour. Res. Inst. J. 2014, 7, 2. [Google Scholar]

- Alhyari, S.; Alazab, M.; Venkatraman, S.; Alazab, M.; Alazab, A. Six Sigma approach to improve quality in e-services: An empirical study in Jordan. Int. J. Electron. Gov. Res. 2012, 8, 57–74. [Google Scholar] [CrossRef]

- Alhyari, S.; Alhyari, M. Toward quality measurement approaches for improving E-government services in Jordan. In It in the Public Sphere: Applications in Administration, Government, Politics, and Planning; IGI Global: Hershey, PA, USA, 2014; pp. 82–98. [Google Scholar]

- Alqudah, S.; Shrouf, H.; Suifan, T.; Alhyari, S. A Moderated Mediation Model of Lean, Agile, Resilient, and Green Paradigms in the Supply Chain. Int. J Sup. Chain. Mgt. Vol. 2020, 9, 158–172. [Google Scholar]

- Suifan, T.; Alazab, M.; Alhyari, S. Trade-off among lean, agile, resilient and green paradigms: An empirical study on pharmaceutical industry in Jordan using a TOPSIS-entropy method. Int. J. Adv. Oper. Manag. 2019, 11, 69–101. [Google Scholar] [CrossRef]

- Suifan, T.; Saa’da, R.; Alazab, M.; Sweis, R.; Abdallah, A.; Alhyari, S. Quality of Information Sharing, Agility, and Sustainability of Humanitarian Aid Supply Chains: An Empirical Investigation. Int. J Sup. Chain. Mgt. Vol. 2020, 9, 1. [Google Scholar]

- Suifan, T.S.; Alhyari, S.; Sweis, R.J. A moderated mediation model of intragroup conflict. Int. J. Confl. Manag. 2019, 31, 91–114. [Google Scholar] [CrossRef]

- Shanley, A. Real-time logistics. Internet of things, advanced analytics, and blockchain solutions such as smart contracts promise to give manufacturers more control over products and supply chains. Biopharm Int. 2017, 9, 47–58. [Google Scholar]

- Appelbaum, D.; Smith, S.S. Blockchain basics and hands-on guidance: Taking the next step toward implementation and adoption. CPA J. 2018, 88, 28–37. [Google Scholar]

- Filipova, N. Blockchain–An opportunity for developing new business models. Bus. Adm. 2018, 28, 75–92. [Google Scholar]

- Biswas, K.; Muthukkumarasamy, V.; Tan, W.L. Blockchain based wine supply chain traceability system. In Proceedings of the Future Technologies Conference (FTC) 2017, Vancouver, BC, Canada, 29–30 November 2017; pp. 56–62. [Google Scholar]

- Angrish, A.; Craver, B.; Hasan, M.; Starly, B. A case study for Blockchain in manufacturing:“FabRec”: A prototype for peer-to-peer network of manufacturing nodes. Procedia Manuf. 2018, 26, 1180–1192. [Google Scholar] [CrossRef]

- Koonce, L. The wild, distributed world: Get ready for radical infrastructure changes, from blockchains to the interplanetary file system to the internet of things. Intellect. Prop. Technol. Law J. 2016, 28, 3. [Google Scholar]