Observer-Based Active Fault-Tolerant Control of an Asymmetric Twin Wind Turbine

Abstract

:1. Introduction

2. Problem Statement

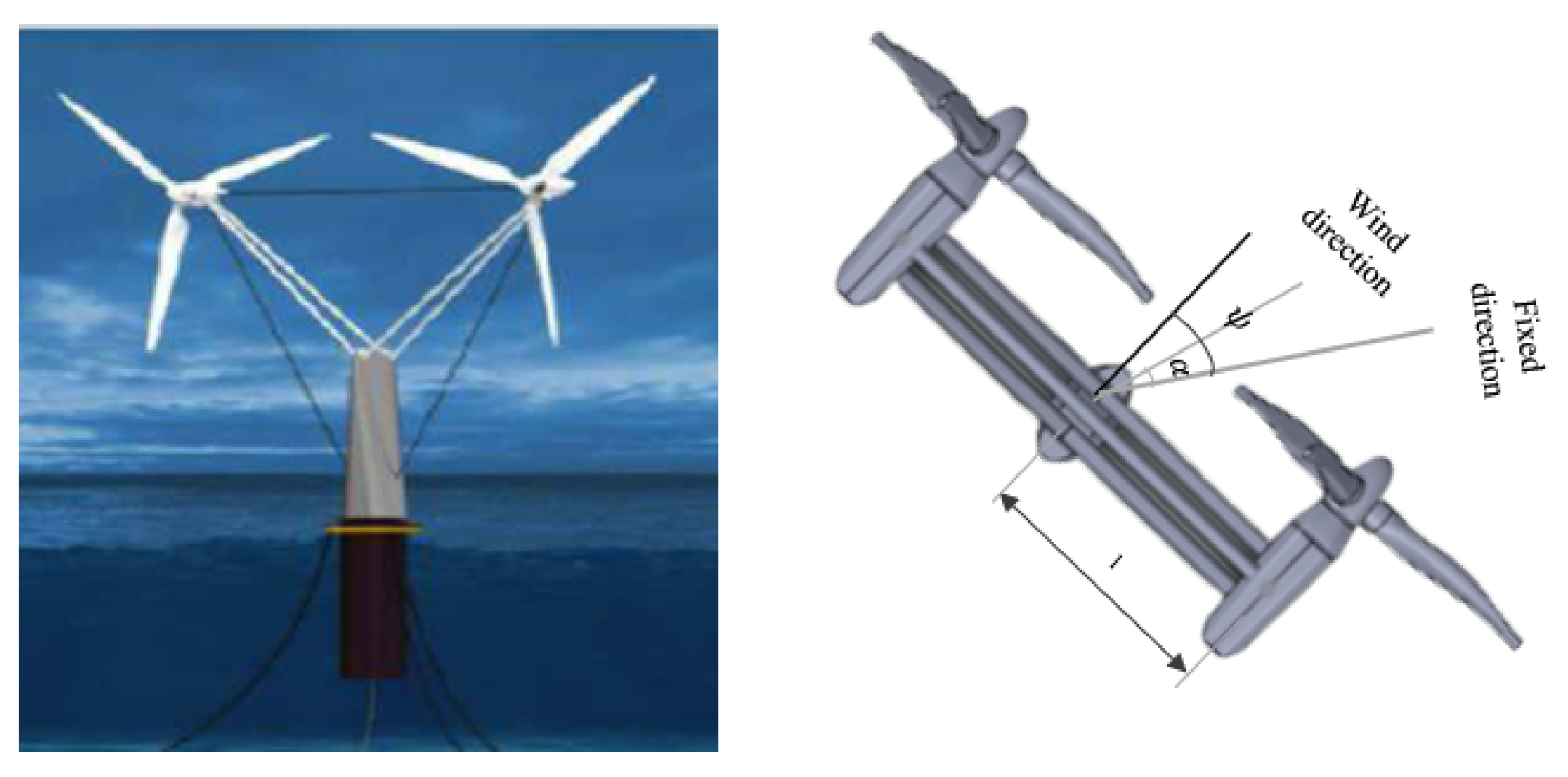

2.1. Healthy Twin Wind Turbine Description

2.2. Faulty Twin Wind Turbine Description

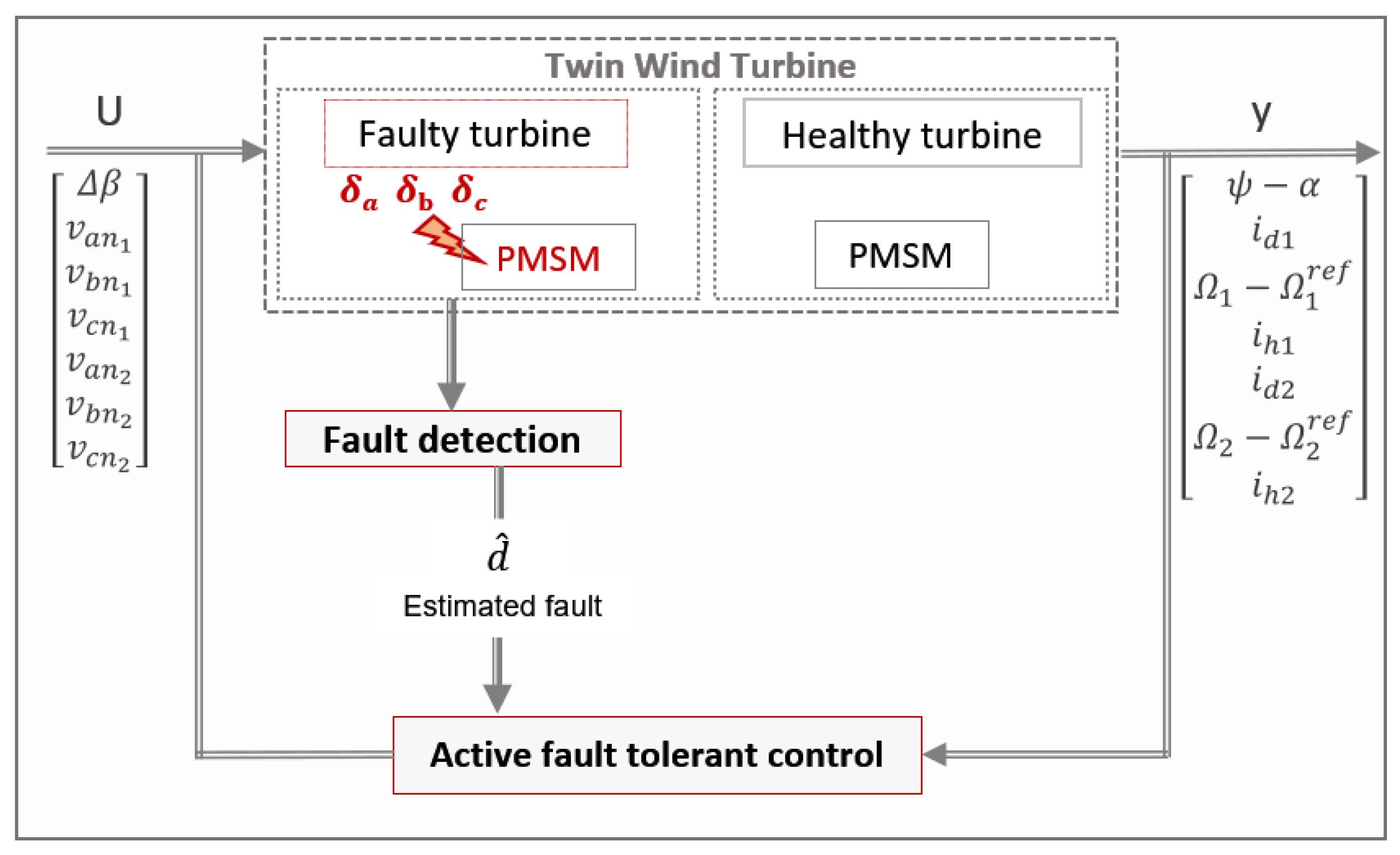

2.3. Control Strategy

3. Active Fault-Tolerant Control and Diagnosis Method

3.1. Active Fault-Tolerant Control

3.2. Fault Estimation

3.3. Observer-Based Active Fault-Tolerant Control

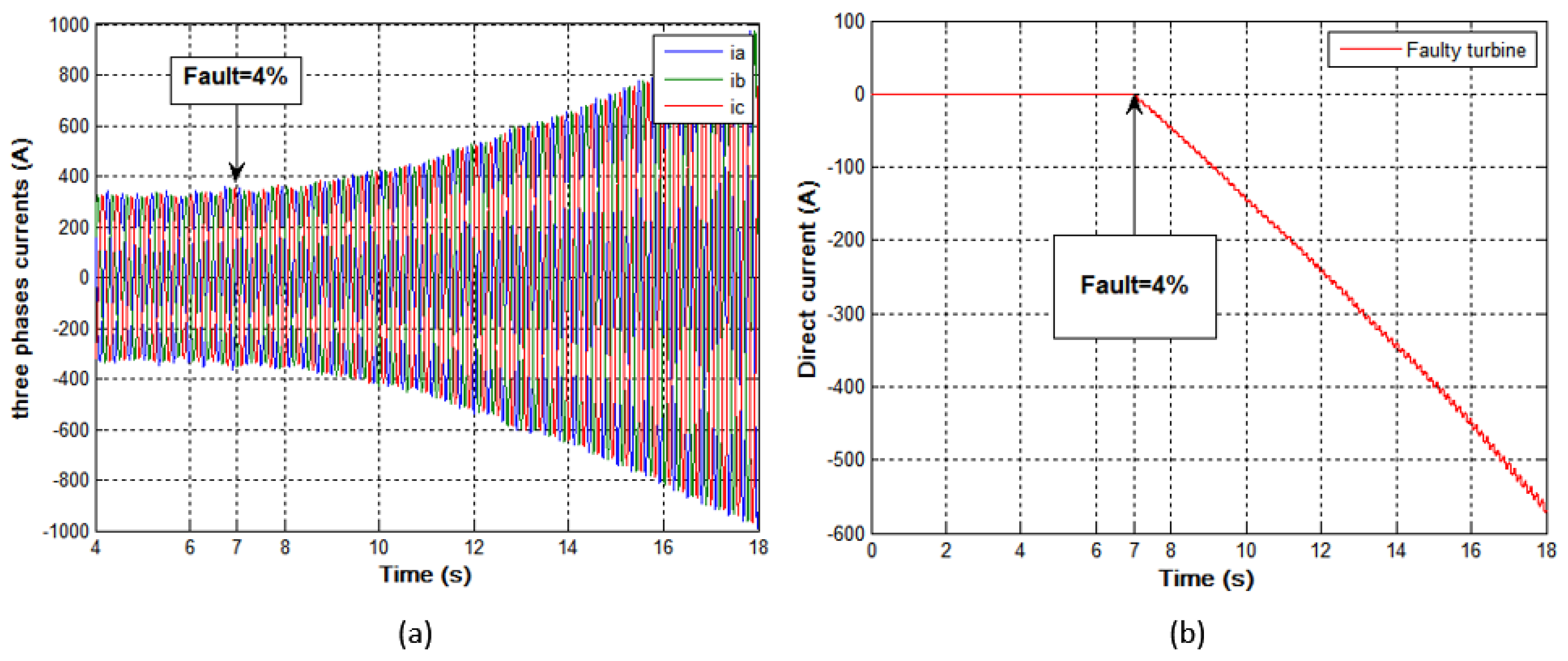

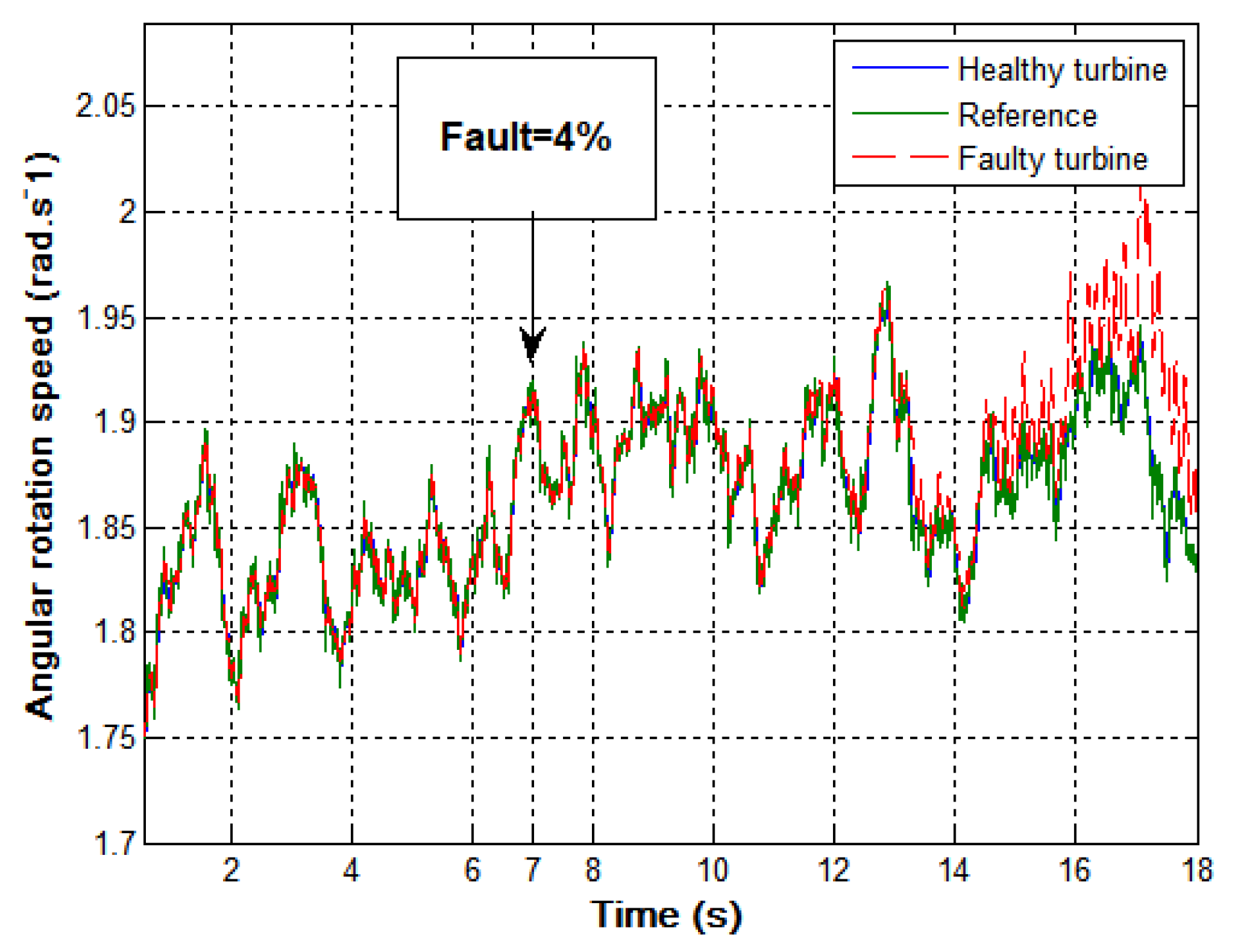

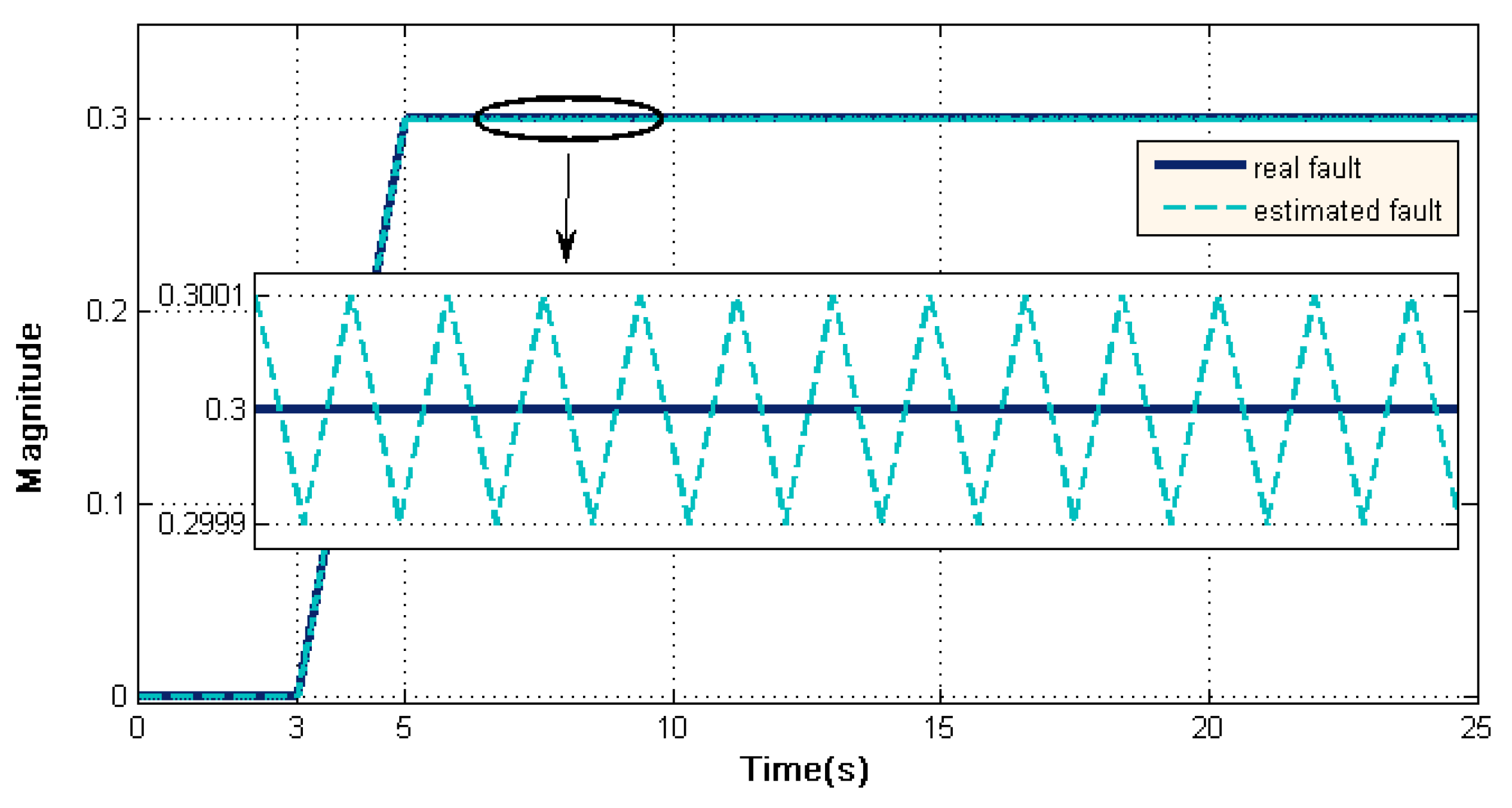

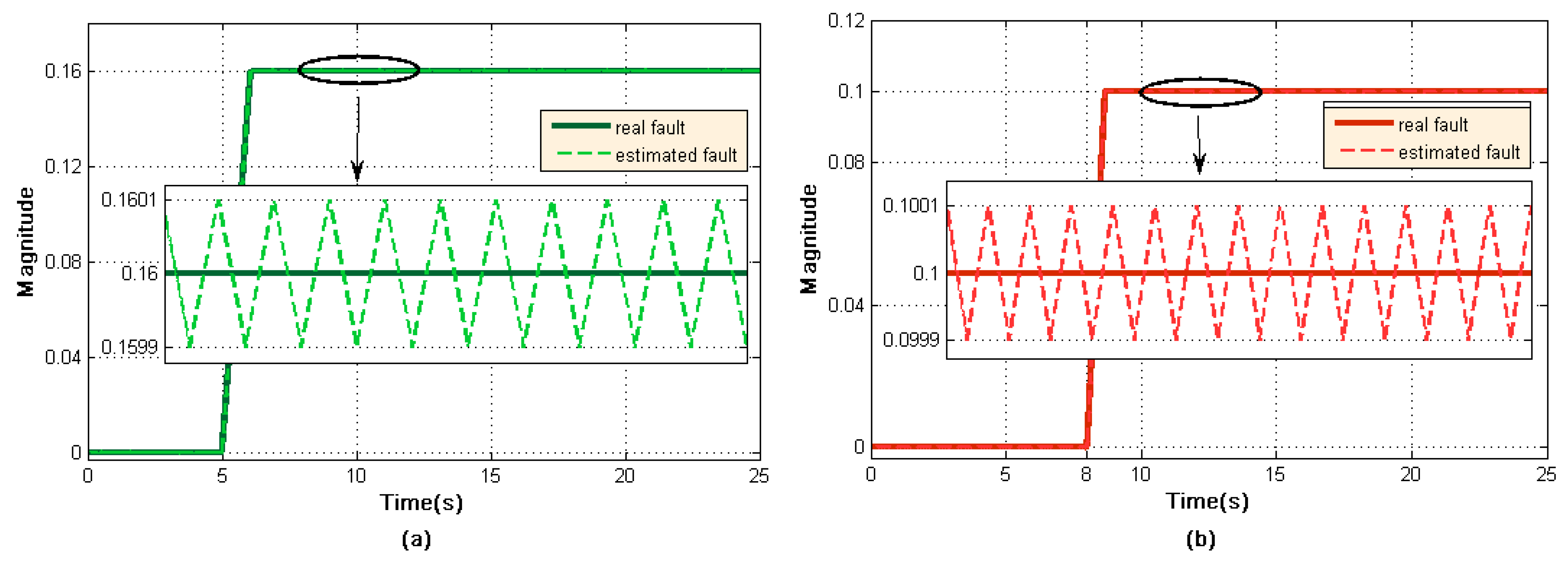

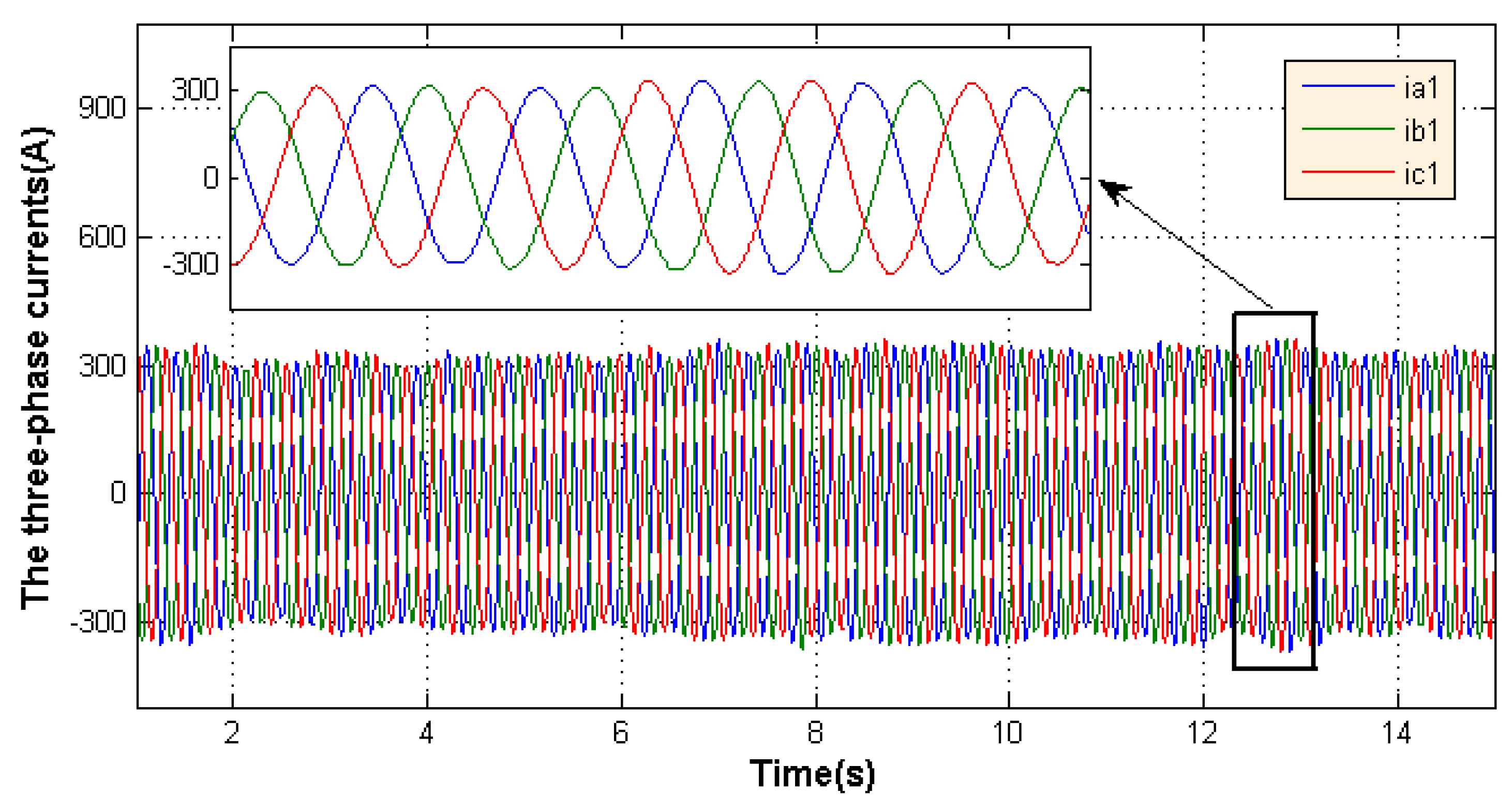

4. Simulation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| TWT | Twin Wind Turbine |

| PMSM | Permanent Magnet Synchronous Machine |

| MCSA | Motor Current Signature Analysis |

| DWT | Discrete Wavelet Transforms |

| CWT | Continuous Wavelet Transforms |

| FDI | Fault Detection and Isolation |

| AFTC | Active Fault-Tolerant Control |

| ISS | Input to-State Stable |

| HOSM | High Order Sliding Mode |

Appendix A

References

- Herskovits, A.; Laffitte, O.; Thome, P.; Tobie, A. V-Shaped, bi-Rotor Wind Generator on a Spar Floating Structure. French Patent WO2014060420 A, 24 April 2014. Volume 1. [Google Scholar]

- Ghane, M.; Nejad, A.R.; Blanke, M.; Gao, Z.; Moan, T. Statistical fault diagnosis of wind turbine drivetrain applied to a 5 MW floating wind turbine. J. Phys. Conf. Ser. 2016, 753, 052017. [Google Scholar] [CrossRef] [Green Version]

- Liu, L. Robust Fault Detection and Diagnosis for Permanent Magnet Synchronous Motors. Ph.D. Thesis, The Florida State University, Tallahassee, FL, USA, 2006. [Google Scholar]

- Otava, L.; Graf, M.; Buchta, L. Interior Permanent Magnet Synchronous Motor Stator Winding Fault Modelling. IFAC-PapersOnLine 2015, 48, 324–329. [Google Scholar] [CrossRef]

- Nandi, S.; Toliyat, H.A.; Li, X. Condition monitoring and fault diagnosis of electrical motors—A review. IEEE Trans. Energy Convers. 2005, 20, 719–729. [Google Scholar] [CrossRef]

- Henao, H.; Capolino, G.A.; Fernandez-Cabanas, M.; Filippetti, F.; Bruzzese, C.; Strangas, E.; Pusca, R.; Estima, J.; Riera-Guasp, M.; Hedayati-Kia, S. Trends in fault diagnosis for electrical machines: A review of diagnostic techniques. IEEE Ind. Electron. Mag. 2014, 8, 31–42. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.; Wilkinson, M. Condition monitoring and fault diagnosis of a wind turbine with a synchronous generator using wavelet transform. In Proceedings of the Conference on Power Electronics, Machines and Drives, York, UK, 2–4 April 2008. [Google Scholar]

- Yang, W.; Tavner, P.; Wilkinson, M. Condition monitoring and fault diagnosis of a wind turbine synchronous generator drive train. IET Renew. Power Gener. 2008, 3, 1–11. [Google Scholar] [CrossRef]

- Bechkaoui, A.; Ameur, A.; Bouras, S.; Hadjadj, A. Open-circuit and inter-turn short-circuit detection in PMSG for wind turbine applications using fuzzy logic. Energy Procedia 2015, 74, 1323–1336. [Google Scholar] [CrossRef] [Green Version]

- Basak, D.; Tiwari, A.; Das, S. Fault diagnosis and condition monitoring of electrical machines—A Review. In Proceedings of the 2006 IEEE International Conference on Industrial Technology, Singapore, 16–18 August 2006; pp. 3061–3066. [Google Scholar]

- Garcia, E.A.; Frank, P.M. Deterministic nonlinear observer-based approaches to fault diagnosis: A survey. Control Eng. Pract. 1997, 5, 663–670. [Google Scholar] [CrossRef]

- Ng, K.Y.; Tan, C.P.; Edwards, C.; Kuang, Y.C. New results in robust actuator fault reconstruction for linear uncertain systems using sliding mode observers. Int. J. Robust Nonlinear Control. IFAC-Affil. J. 2007, 17, 1294–1319. [Google Scholar] [CrossRef]

- Yan, X.G.; Edwards, C. Adaptive sliding-mode-observer-based fault reconstruction for nonlinear systems with parametric uncertainties. IEEE Trans. Ind. Electron. 2008, 55, 4029–4036. [Google Scholar]

- Alwi, H.; Edwards, C.; Tan, C.P. Fault Detection and Fault-Tolerant Control Using Sliding Modes; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Chen, W.; Ding, S.X.; Haghani, A.; Naik, A.; Khan, A.Q.; Yin, S. Observer-based FDI schemes for wind turbine benchmark. IFAC Proc. Vol. 2011, 44, 7073–7078. [Google Scholar] [CrossRef]

- Wei, X.; Verhaegen, M. Fault detection of large scale wind turbine systems: A mixed H∞/H- index observer approach. In Proceedings of the 16th Mediterranean Conference on Control and Automation, Ajaccio, France, 25–27 June 2008; pp. 1675–1680. [Google Scholar]

- Wei, X.; Verhaegen, M. Sensor and actuator fault diagnosis for wind turbine systems by using robust observer and filter. Wind Energy 2011, 14, 491–516. [Google Scholar] [CrossRef]

- Odgaard, P.F.; Stoustrup, J. Unknown input observer based scheme for detecting faults in a wind turbine converter. IFAC Proc. Vol. 2009, 42, 161–166. [Google Scholar] [CrossRef] [Green Version]

- Guenoune, I.; Plestan, F.; Chermitti, A.; Evangelista, C. Modeling and robust control of a twin wind turbines structure. Control Eng. Pract. 2017, 69, 23–35. [Google Scholar] [CrossRef]

- Makni, M.; Haidar, I.; Barbot, J.P.; Plestan, F.; Feki, N.; Abbes, M.S. Analysis and control of Twin Wind Turbine subject to asymmetric fault. In Proceedings of the IEEE Conference on Control Technology and Applications (CCTA), Montreal, QC, Canada, 24–26 August 2020; pp. 1–6. [Google Scholar]

- Pillay, P.; Krishnan, R. Modeling of permanent magnet motor drives. In Motor Control and Power Electronics, Proceedings of the IECON’87, Cambridge, MA, USA, 4–6 November 1987; International Society for Optics and Photonics: Bellingham, WA, USA, 1987; Volume 854, pp. 289–293. [Google Scholar]

- Makni, M.; Haidar, I.; Barbot, J.P.; Plestan, F.; Feki, N.; Abbes, M.S. Active fault tolerant control for twin wind turbine subject to asymmetric fault. arXiv 2021, arXiv:2108.07238. [Google Scholar]

- Tahoumi, E.; Evangelista, C.; Plestan, F.; Ghanes, M.; Barbot, J.; Puleston, P. Energy efficient control derived from homogeneous algorithm—Application to a wind system. Control Eng. Pract. 2020, 103, 104586. [Google Scholar] [CrossRef]

- Khalil, H.K. High-Gain Observers in Nonlinear Feedback Control; SIAM: Philadelphia, PA, USA, 2017. [Google Scholar]

- Yu, L.; Zheng, G.; Barbot, J.P. Dynamical sparse recovery with finite-time convergence. IEEE Trans. Signal Process. 2017, 65, 6146–6157. [Google Scholar] [CrossRef] [Green Version]

- Cruz-Zavala, E.; Moreno, J.A. Homogeneous high order sliding mode design: A Lyapunov approach. Automatica 2017, 80, 232–238. [Google Scholar] [CrossRef]

- Bernuau, E.; Polyakov, A.; Efimov, D.; Perruquetti, W. Verification of ISS, iISS and IOSS properties applying weighted homogeneity. Syst. Control Lett. 2013, 62, 1159–1167. [Google Scholar] [CrossRef] [Green Version]

| Name | Description | Name | Description |

|---|---|---|---|

| wind speed | inductance matrix in healthy case | ||

| blade radius | inductance matrix in faulty case | ||

| air density | electromagnetic force | ||

| pitch blade | reference of the i-th angular speed | ||

| tip speed ratio | severity of the fault | ||

| stator resistance | d | fault vector | |

| is the Lie derivative of h with respect to f | is the Lie bracket of f and g |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makni, M.; Haidar, I.; Barbot, J.-P.; Plestan, F.; Feki, N.; Abbes, M.S. Observer-Based Active Fault-Tolerant Control of an Asymmetric Twin Wind Turbine. Information 2022, 13, 113. https://doi.org/10.3390/info13030113

Makni M, Haidar I, Barbot J-P, Plestan F, Feki N, Abbes MS. Observer-Based Active Fault-Tolerant Control of an Asymmetric Twin Wind Turbine. Information. 2022; 13(3):113. https://doi.org/10.3390/info13030113

Chicago/Turabian StyleMakni, Mariem, Ihab Haidar, Jean-Pierre Barbot, Franck Plestan, Nabih Feki, and Mohamed Slim Abbes. 2022. "Observer-Based Active Fault-Tolerant Control of an Asymmetric Twin Wind Turbine" Information 13, no. 3: 113. https://doi.org/10.3390/info13030113

APA StyleMakni, M., Haidar, I., Barbot, J.-P., Plestan, F., Feki, N., & Abbes, M. S. (2022). Observer-Based Active Fault-Tolerant Control of an Asymmetric Twin Wind Turbine. Information, 13(3), 113. https://doi.org/10.3390/info13030113