Ubiquitous Control of a CNC Machine: Proof of Concept for Industrial IoT Applications

Abstract

:1. Introduction

- Display of the states of the industrial machine via a web-based ubiquitous HMI, making the industrial system in effect a CPS;

- Multi-factor authentication including an administrative password and the IP address of the industrial machine to control access to the web-based ubiquitous HMI of the proposed PoC, to avert potential cyber attacks or threats that are often associated with wireless communication systems such as IIoT systems;

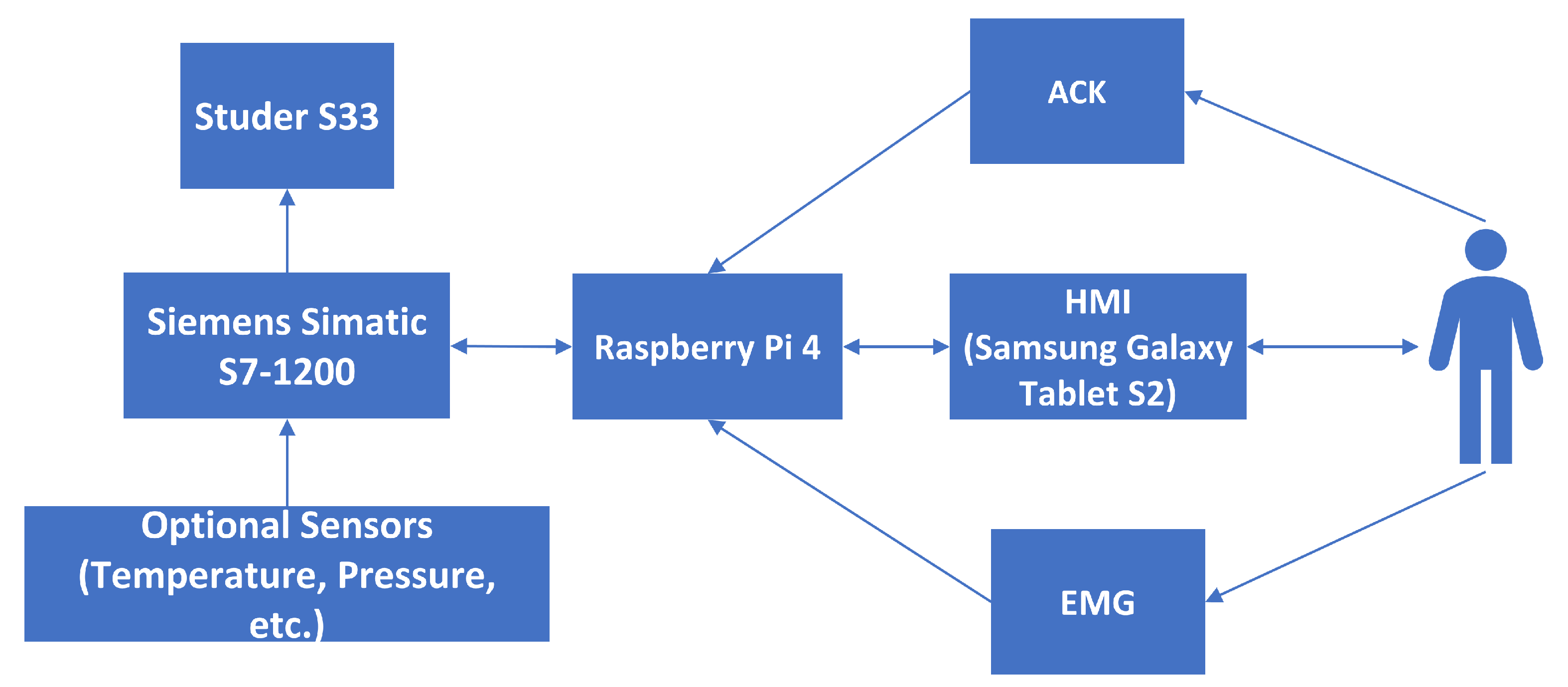

- Touchscreen-based input configurations to manage control actions on the industrial machine over TCP/IP for the remote, quasi-decentralised and ubiquitous control of the industrial machine through the use of multiple agents (a Samsung Galaxy Tablet S2 and a Raspberry Pi 4), acting alongside the traditional PLC-based ICU;

- Conventional override system achieved with emergency and acknowledge actions on the industrial machine via digital signals from push buttons implemented over TCP/IP for the more robust, remote, quasi-decentralised, and ubiquitous control of the industrial machine through the use of multiple agents (a Samsung Galaxy Tablet S2 and a Raspberry Pi 4), acting alongside the traditional PLC-based ICU.

2. Related Work

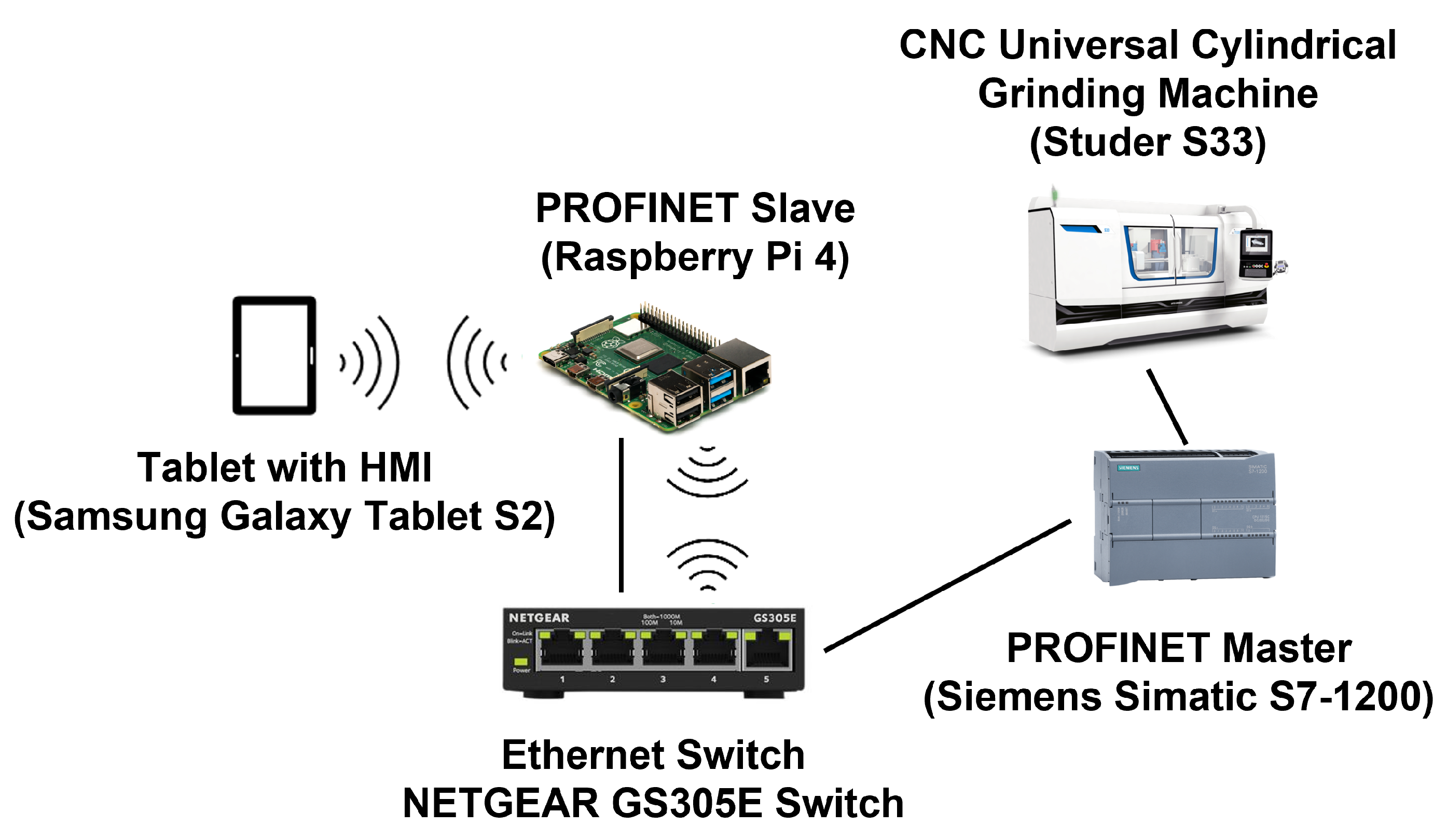

3. Adopted Devices and Systems

3.1. CNC Machine

3.2. PROFINET Master

3.3. Ethernet Switch

3.4. PROFINET Slave

3.5. Tablet with HMI

4. The Proposed PoC

4.1. Configuration

| Begin |

| Open Siemens TIA portal |

| Create a new project to configure Siemens Simatic S7-1200 |

| Select device type = Hardware type |

| Open the “General Settings” |

| In “PROFINET Interface” |

| Set the “IP Address” and “Subnet Mask” to according to the network |

| Under “Advanced Options” |

| Activate “Web Server Access” |

| Under “Protection and Security” |

| Activate the PUT/GET Option |

| In “Pulse Generators (PTO/PWM)” |

| Set “Startup after POWER ON” to “Warm Restart-RUN” |

| In “Web Server” |

| Create a new user and grant full access |

| If (Device == Offline) Then |

| Click “Go online” and “Start search” |

| End |

| If (Device == Found) Then |

| Double click the device |

| End |

| End |

4.2. Operations

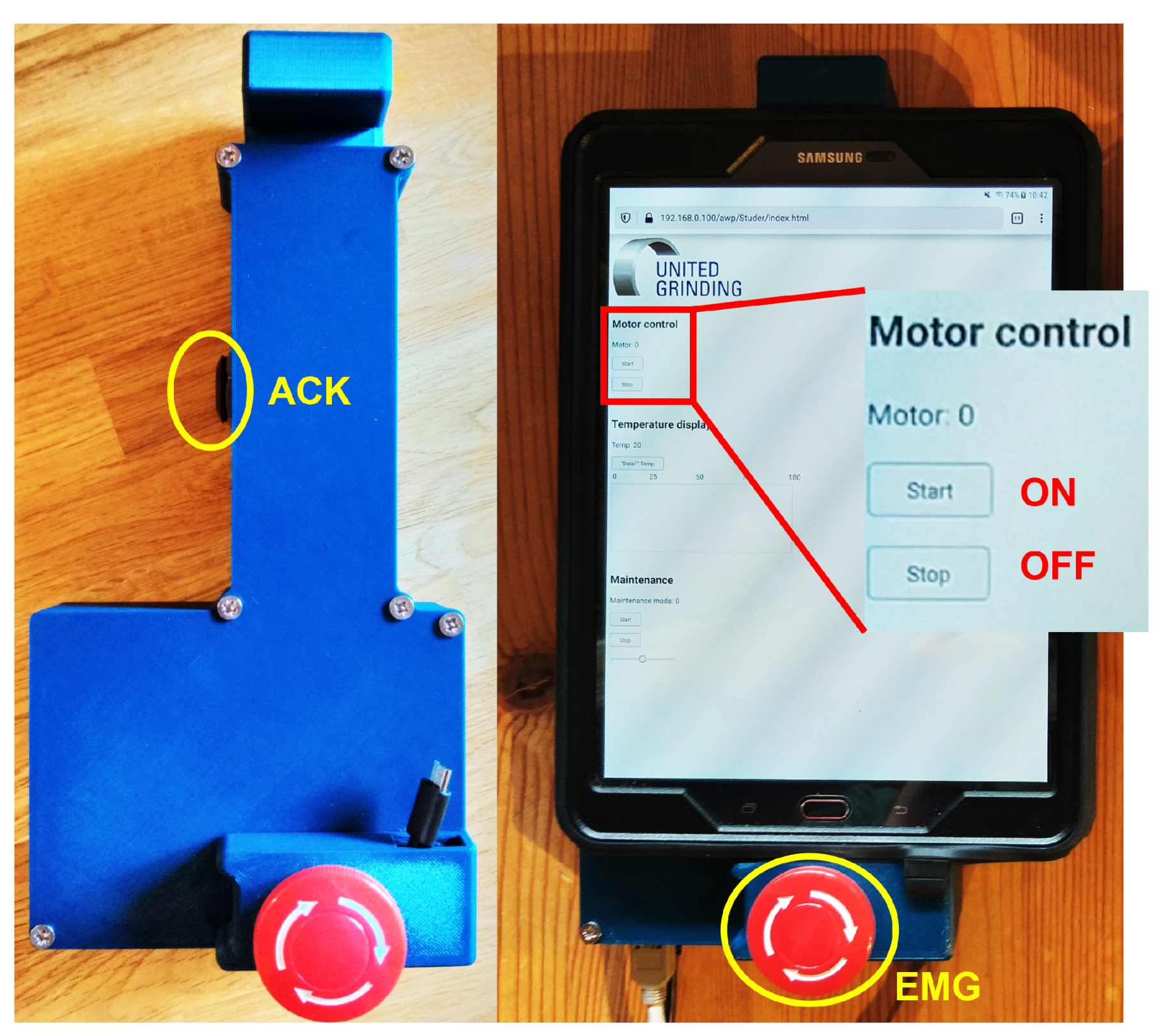

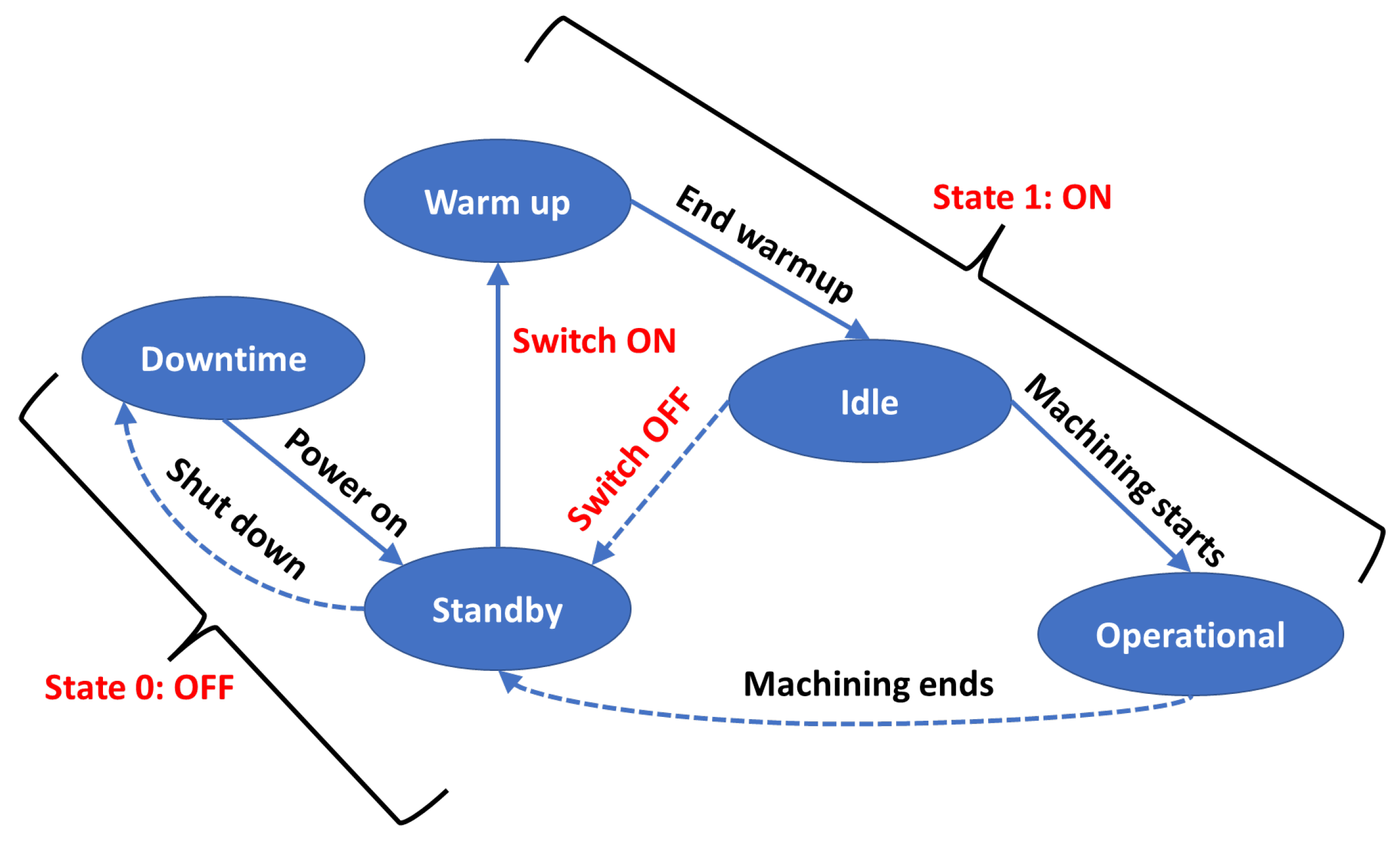

- Step 1: To control the CNC universal cylindrical grinding machine (Studer S33) ubiquitously, the system operator makes use of the touchscreen-operated Tablet (see Figure 3). By using a browser application, installed and configured on the tablet, the system operator enters the IP address of the CNC machine, and the web-based HMI created for the PROFINET master (Siemens Simatic S7-1200) can be accessed using an administrative password (see Figure 3).

- Step 2: Following a successful authentication in Step 1, full administrative access is granted to the web-based HMI. Using the touchscreen of the tablet, the user can perform the following operations on the industrial motor: (1) ON (2) OFF (3) ACK (Acknowledge) (4) EMG (Emergency), as shown in the communication system layout in Figure 4.

- Step 3: Depending on the system operator’s selection in Step 2, while the ACK button is pressed down, the Studer S33 is “started” for ON or “stopped” for OFF. To “shut down/stop” the Studer S33 immediately, the EMG button shown in Figure 4 can used at any time.

- Step 4: Once the Studer S33 is configured in Step 3, it remains in the configured state, and the entire process reiterates back to Step 1.

| Begin |

| Configure the LAN connection of Raspberry Pi 4 |

| Use a fixed IP-address in the file “/etc/dhcp.conf” |

| In the same file (i.e., “/etc/dhcp.conf”) |

| Prioritize WLAN connection over LAN connection |

| Activate the general-purpose I/Os (GPIOs) |

| In the command line |

| Implement “sudo apt-get update |

| To request updates for Raspberry Pi 4 |

| Implement “sudo apt-get install python-rpi.gpio” |

| To insall python-rpi.gpio |

| Implement “sudo adduser $USER gpio” |

| To add user (“USER”) to the group for the GPIOs |

| In the command line |

| Implement “sudo apt install hostapd” |

| To installaccess point software package |

| At the startup (booting) of the Raspberry Pi 4 |

| Implement “sudo systemctl unmask hostapd” |

| And Implement “sudo systemctl enable hostapd” |

| To enable and start access point |

| Implement “sudo apt install dnsmasq“ |

| To install the package for domain name system (DNS) and DHCP |

| DHCP - distribute IP addresses to the connected devices |

| DNS service - translate domain name of devices to IP addresses |

| Implement “sudo DEBIAN_FRONTEND = noninteractive apt … |

| install -y netfilter-persistent iptables-persistent” |

| And Implement “sudo iptables -t nat -A POSTROUTING … |

| -o eth0 -j MASQUERADE“ |

| To add firewall rules for data traffic sharinf between the devices |

| Implement “sudo apt-get install netfilter-persistent -y” |

| To install the service iptables-persistent to save firewall rules |

| Implement “sudo netfilter-persistent save” |

| To save firewall rules |

| Add a static IP-address for “wlan0” in the file “/etc/dhcp.conf” |

| In the command line |

| Implement “sudo nano /etc/sysctl.d/routed-ap.conf” |

| To enable the routing between ethernet and WiFi |

| Add the text “dnsmasq.conf” to the newly created file |

| To enable the routing by setting the configuration for the DHCP service |

| Rename the original file |

| In the command line |

| Implement “sudo mv/etc/dnsmasq.conf /etc/dnsmasq.conf.orig” |

| And Implement “sudo nano/etc/dnsmasq.conf” |

| To have connected devices with IP addresses in the defined DHCP range |

| Implement “sudo rfkill unblock wlan” |

| To unblock WiFi |

| Implement “sudo nano/etc/hostapd/hostapd.conf” |

| To create a new file to configure Wi-Fi |

| Define Wi-Fi service set identifier (SSID), password and others |

| Reboot Device to connect and make access point go live |

| Connect tablet to both Wi-Fi and Raspberry Pi 4 |

| Access the website of the PROFINET master |

| End |

4.3. Analysis and Performance Evaluation

5. Challenges and Opportunities

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mulaydinov, F. Digital Economy Is a Guarantee of Government and Society Development. Ilkogr. Online 2021, 20, 1474–1479. [Google Scholar]

- Foust, J. Spacex’s space-internet woes: Despite technical glitches, the company plans to launch the first of nearly 12,000 satellites in 2019. IEEE Spectr. 2018, 56, 50–51. [Google Scholar] [CrossRef]

- McDowell, J.C. The low earth orbit satellite population and impacts of the SpaceX Starlink constellation. Astrophys. J. Lett. 2020, 892, L36. [Google Scholar] [CrossRef] [Green Version]

- Gralla, P. How the Internet Works; Que Publishing: Upper Saddle River, NJ, USA, 1998. [Google Scholar]

- Weber, R.H.; Weber, R. Internet of Things; Springer: Berlin/Heidelberg, Germany, 2010; Volume 12. [Google Scholar]

- Wood, A.F.; Smith, M.J. Online Communication: Linking Technology, Identity, & Culture; Routledge: London, UK, 2004. [Google Scholar]

- Qasim, I.; Anwar, M.W.; Azam, F.; Tufail, H.; Butt, W.H.; Zafar, M.N. A model-driven mobile HMI framework (MMHF) for industrial control systems. IEEE Access 2020, 8, 10827–10846. [Google Scholar] [CrossRef]

- Misic, V.B.; Misic, J. Machine-to-Machine Communications: Architectures, Technology, Standards, and Applications; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Koulamas, C.; Kalogeras, A. Cyber-physical systems and digital twins in the industrial internet of things [cyber-physical systems]. Computer 2018, 51, 95–98. [Google Scholar] [CrossRef]

- Parnaby, J. Concept of a manufacturing system. Int. J. Prod. Res. 1979, 17, 123–135. [Google Scholar] [CrossRef]

- Shin, K.Y.; Shin, N.H.; Choi, S.W.; Choi, S.H. Systems engineering approach to designing smart condition monitoring systems for smart manufacturing (iccas 2016). In Proceedings of the 2016 16th International Conference on Control, Automation and Systems (ICCAS), Gyeongju, Korea, 16–19 October 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1177–1182. [Google Scholar]

- Alhasnawi, B.N.; Jasim, B.H.; Sedhom, B.E.; Hossain, E.; Guerrero, J.M. A New Decentralized Control Strategy of Microgrids in the Internet of Energy Paradigm. Energies 2021, 14, 2183. [Google Scholar] [CrossRef]

- Jost, J.; Kirks, T.; Mättig, B. Multi-agent systems for decentralized control and adaptive interaction between humans and machines for industrial environments. In Proceedings of the 2017 7th IEEE International Conference on System Engineering and Technology (ICSET), Shah Alam, Malaysia, 2–3 October 2017; pp. 95–100. [Google Scholar] [CrossRef]

- Wang, P.; Govindarasu, M. Multi-Agent Based Attack-Resilient System Integrity Protection for Smart Grid. IEEE Trans. Smart Grid 2020, 11, 3447–3456. [Google Scholar] [CrossRef]

- PROFIBUS & PROFINET International. PROFINET System Description Technology and Application; PROFIBUS and PROFINET International: London, UK, 2012. [Google Scholar]

- Raspberry Pi Foundation. Raspberry Pi 4 Computer MODEL B; Raspberry Pi Foundation: Cambridge, UK, 2019; Available online: https://www.raspberrypi.com/products/raspberry-pi-4-model-b/specifications/ (accessed on 4 October 2021).

- Khorrami, F.; Krishnamurthy, P.; Karri, R. Cybersecurity for Control Systems: A Process-Aware Perspective. IEEE Des. Test 2016, 33, 75–83. [Google Scholar] [CrossRef]

- Dawson, M. Cyber security in industry 4.0: The pitfalls of having hyperconnected systems. J. Strateg. Manag. Stud. 2018, 10, 19–28. [Google Scholar]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Working Group on Centralized Substation Protection and Control; IEEE Power System Relaying Committee. Advancements in Centralized Protection and Control within a Substation. IEEE Trans. Power Deliv. 2016, 31, 1945–1952. [Google Scholar] [CrossRef]

- Luejai, W. Automated Storage and Retrieval System using FIFO Method via PLC-integrated Human Machine Interface. In Proceedings of the 2021 18th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Chiang Mai, Thailand, 9–22 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1002–1005. [Google Scholar]

- Brown, S. Functional safety of electrical machines and drives. In 1997 Eighth International Conference on Electrical Machines and Drives; Conf. Publ. No. 444; IET: London, UK, 1997; pp. 326–330. [Google Scholar]

- Giannoutsos, S.V.; Manias, S.N. A data-driven process controller for energy-efficient variable-speed pump operation in the central cooling water system of marine vessels. IEEE Trans. Ind. Electron. 2014, 62, 587–598. [Google Scholar] [CrossRef]

- Skripcak, T.; Tanuska, P.; Konrad, U.; Schmeisser, N. Toward nonconventional human–machine interfaces for supervisory plant process monitoring. IEEE Trans. Hum.-Mach. Syst. 2013, 43, 437–450. [Google Scholar] [CrossRef]

- Sinuraya, E.W.; Nugraheni, N.; Sukmadi, T.; Warsito, A.; Nugroho, A.; Soetrisno, Y.A.A. Design of Web Based Based Human Machine Interface (HMI) for Electric Tube Furnace. Int. J. Comput. Eng. Inf. Technol. 2018, 10, 201–207. [Google Scholar]

- Jeng, S.L.; Chieng, W.H.; Chen, Y. Web-Based Human-Machine Interfaces of Industrial Controllers in Single-Page Applications. Mob. Inf. Syst. 2021, 2021, 6668843. [Google Scholar] [CrossRef]

- Bakule, L. Decentralized control: An overview. Annu. Rev. Control 2008, 32, 87–98. [Google Scholar] [CrossRef]

- Clark, R. Mobile HMI: Improves plant operations. Control Eng. 2016, 63, 30–33. [Google Scholar]

- ICONICS, MobileHMI, 2017. Available online: https://www.iconics-uk.com/sites/default/files/productbrochure/MobileHMI_1.pdf (accessed on 4 October 2021).

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2018, 101, 1–12. [Google Scholar] [CrossRef]

- Khan, W.Z.; Rehman, M.H.; Zangoti, H.M.; Afzal, M.K.; Armi, N.; Salah, K. Industrial internet of things: Recent advances, enabling technologies and open challenges. Comput. Electr. Eng. 2020, 81, 106522. [Google Scholar] [CrossRef]

- Beresford, D. Exploiting siemens SIMATIC S7 PLCS. Black Hat USA 2011, 16, 723–733. [Google Scholar]

- Siemens. SIMATIC Controller-Take Control of the Future. 2021. Available online: https://new.siemens.com/global/en/products/automation/systems/industrial/plc.html (accessed on 4 October 2021).

- Siemens. Remote Access to SIMATIC HMI Comfort Panels. 2020. Available online: https://cache.industry.siemens.com/dl/files/153/109476153/att_1016758/v3/109476153_Remote_Panels_HTML_V16_DOC_en.pdf (accessed on 4 October 2021).

- Morris, T.H.; Gao, W. Industrial control system cyber attacks. In Proceedings of the 1st International Symposium for ICS & SCADA Cyber Security Research 2013 (ICS-CSR 2013) 1, Leicester, UK, 16–17 September 2013; pp. 22–29. [Google Scholar]

- Candell, R.; Stouffer, K.; Anand, D. A cybersecurity testbed for industrial control systems. In Proceedings of the 2014 Process Control and Safety Symposium, Houston, TX, USA, 6–9 October 2014; pp. 1–16. [Google Scholar]

- Hogan, M.; Piccarreta, B. ; Interagency International Cybersecurity Standardization Working Group. Interagency Report on Status of International Cybersecurity Standardization for the Internet of Things (IoT); Technical Report; National Institute of Standards and Technology: Gaithersburg, MA, USA, 2018. [Google Scholar]

- Sangodoyin, A.O.; Akinsolu, M.O.; Pillai, P.; Grout, V. Detection and Classification of DDoS Flooding Attacks on Software-Defined Networks: A Case Study for the Application of Machine Learning. IEEE Access 2021, 9, 122495–122508. [Google Scholar] [CrossRef]

- Zhang, F.; Kodituwakku, H.A.D.E.; Hines, J.W.; Coble, J. Multilayer Data-Driven Cyber-Attack Detection System for Industrial Control Systems Based on Network, System, and Process Data. IEEE Trans. Ind. Inform. 2019, 15, 4362–4369. [Google Scholar] [CrossRef]

- Gupta, U. Application of Multi factor authentication in Internet of Things domain. arXiv 2015, arXiv:1506.03753. [Google Scholar] [CrossRef]

- Feng, X.; Babatunde, O.; Liu, E. Cyber security investigation for Raspberry Pi devices. Int. Ref. J. Eng. Sci. 2017. Available online: https://uobrep.openrepository.com/handle/10547/622090 (accessed on 4 October 2021).

- Electronics, S. Samsung Galaxy S2 Tablet: User Manual. 2016. Available online: https://www.samsung.com/uk/support/model/SM-T810NZKEBTU/#downloads (accessed on 4 October 2021).

- Richardson, M.; Wallace, S. Getting Started with Raspberry PI; O’Reilly Media, Inc.: Newton, MA, USA, 2012. [Google Scholar]

- Netgear Inc. Datsheet 300 Series-Plus Gigabit Ethernet Switches. 2021. Available online: https://www.netgear.com/images/datasheet/switches/GS305E_GS308E_DS.pdf (accessed on 4 October 2021).

- Berger, H. Automating with SIMATIC S7-1200: Configuring, Programming and Testing with STEP 7 Basic; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Siemens. SIMATIC S7-1200 Easy Book: Device Manual; Siemens: Munich, Germany, 2015. [Google Scholar]

- Fritz Studer AG. S33. 2019. Available online: https://cdn.studer.com/fileadmin/content_live_2019/www.studer.com/01_pdf/01_brochures/englisch/s33-brochure_studer_en.pdf (accessed on 4 October 2021).

- FANUC CORPORATION. Fanuc Series Oi-Model F. 2014. Available online: https://www.fanuc.co.jp/en/product/cnc/fs_0i-fplus.html (accessed on 4 October 2021).

- Raspberry Pi Foundation. Datasheet: Raspberry Pi 4 MODEL B; Raspberry Pi Foundation: Cambridge, UK, 2019. [Google Scholar]

- Spring, J.; Nelson, D.; Lu, X.Y. CACC Truck Instrumentation and Software Development; Technical Report; Institute of Transportation Studies at UC Berkeley: Berkeley, CA, USA, 2018. [Google Scholar]

- Wang, L.; Mahulea, C.; Júlvez, J.; Silva, M. Minimum-time control for structurally persistent continuous Petri Nets. In Proceedings of the 49th IEEE Conference on Decision and Control (CDC), Atlanta, GA, USA, 15–17 December 2010; pp. 2771–2776. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, P. RFID-Driven Energy-Efficient Control Approach of CNC Machine Tools Using Deep Belief Networks. IEEE Trans. Autom. Sci. Eng. 2020, 17, 129–141. [Google Scholar] [CrossRef]

- Liu, Y.; Xiahou, K.; Wang, L.; Wu, Q.H. Switching Control of GSC of DFIGWTs for Disturbance Rejection Based on Bang–Bang Control. IEEE Trans. Power Deliv. 2018, 33, 3256–3259. [Google Scholar] [CrossRef]

- O’Brien, R. Bang-bang control for type-2 systems. In Proceedings of the 2006 Proceeding of the Thirty-Eighth Southeastern Symposium on System Theory, Cookeville, TN, USA, 5–7 March 2006; pp. 163–166. [Google Scholar] [CrossRef]

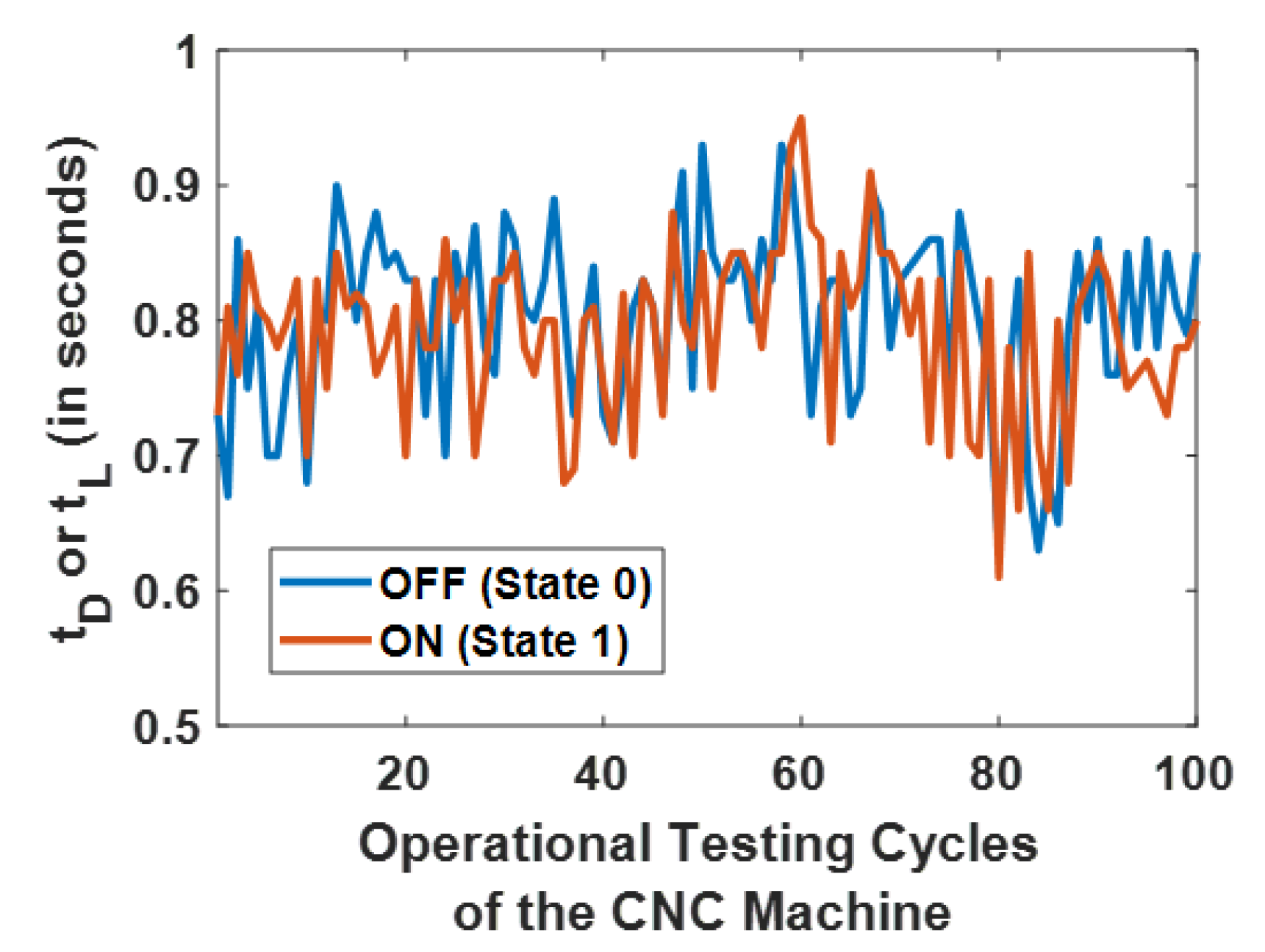

| Operational Mode or Activation State | Best ( or ) | Worst ( or ) | Mean ( or ) | Standard Deviation |

|---|---|---|---|---|

| OFF State (0) | 0.6300 | 0.9300 | 0.8040 | 0.0656 |

| ON State (1) | 0.6100 | 0.9500 | 0.7919 | 0.0613 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aebersold, S.A.; Akinsolu, M.O.; Monir, S.; Jones, M.L. Ubiquitous Control of a CNC Machine: Proof of Concept for Industrial IoT Applications. Information 2021, 12, 529. https://doi.org/10.3390/info12120529

Aebersold SA, Akinsolu MO, Monir S, Jones ML. Ubiquitous Control of a CNC Machine: Proof of Concept for Industrial IoT Applications. Information. 2021; 12(12):529. https://doi.org/10.3390/info12120529

Chicago/Turabian StyleAebersold, Stefan A., Mobayode O. Akinsolu, Shafiul Monir, and Martyn L. Jones. 2021. "Ubiquitous Control of a CNC Machine: Proof of Concept for Industrial IoT Applications" Information 12, no. 12: 529. https://doi.org/10.3390/info12120529