Blockchain for Integrated Nuclear Power Plants Management System

Abstract

1. Introduction

2. Review of Plant Management System for Nuclear Power Plants

2.1. The Object and Functions of Plant Management System

- Performance monitoring and analysis

- System optimization

- Safety management

- Maintenance management

- Asset management

- Configuration management

- Fault diagnosis and analysis

- Environmental monitoring and protection

2.2. Maintenance Optimization

2.3. Record Keeping and Reporting

2.4. Current Response System for Accident/Failure of Nuclear Power Plants

2.5. Challenges in Existing Plant Management System

2.6. Instrumentation and Control System of APR 1400

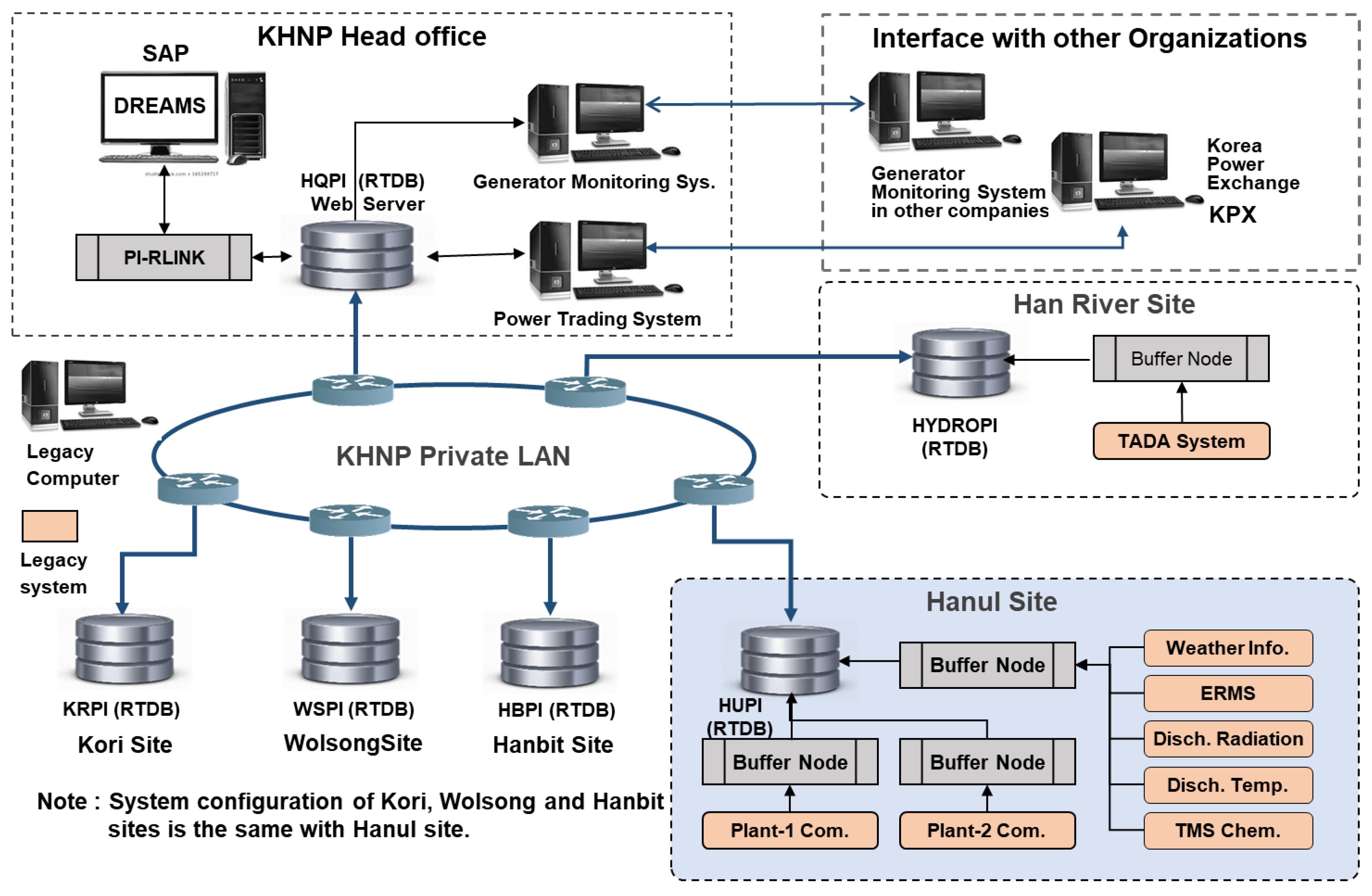

2.7. Integrated Plant Management System for NPPs

3. Implementation of Blockchain for Nuclear Power Plant Management System

3.1. Application of Blockchain Technology in the Plant Management

3.2. Blockchain for Information Management

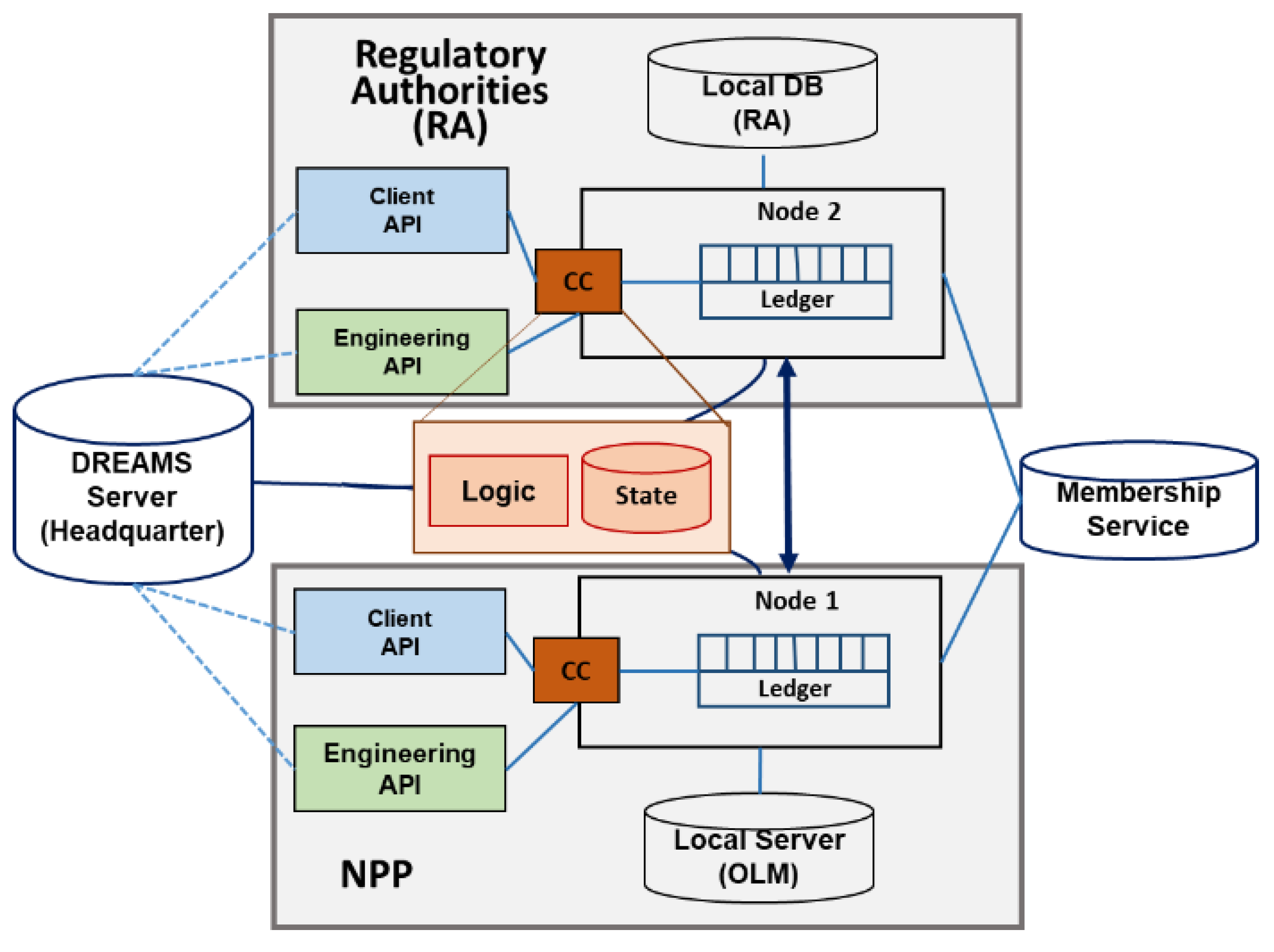

3.3. Blockchain System Architecture

3.3.1. Type of Blockchain

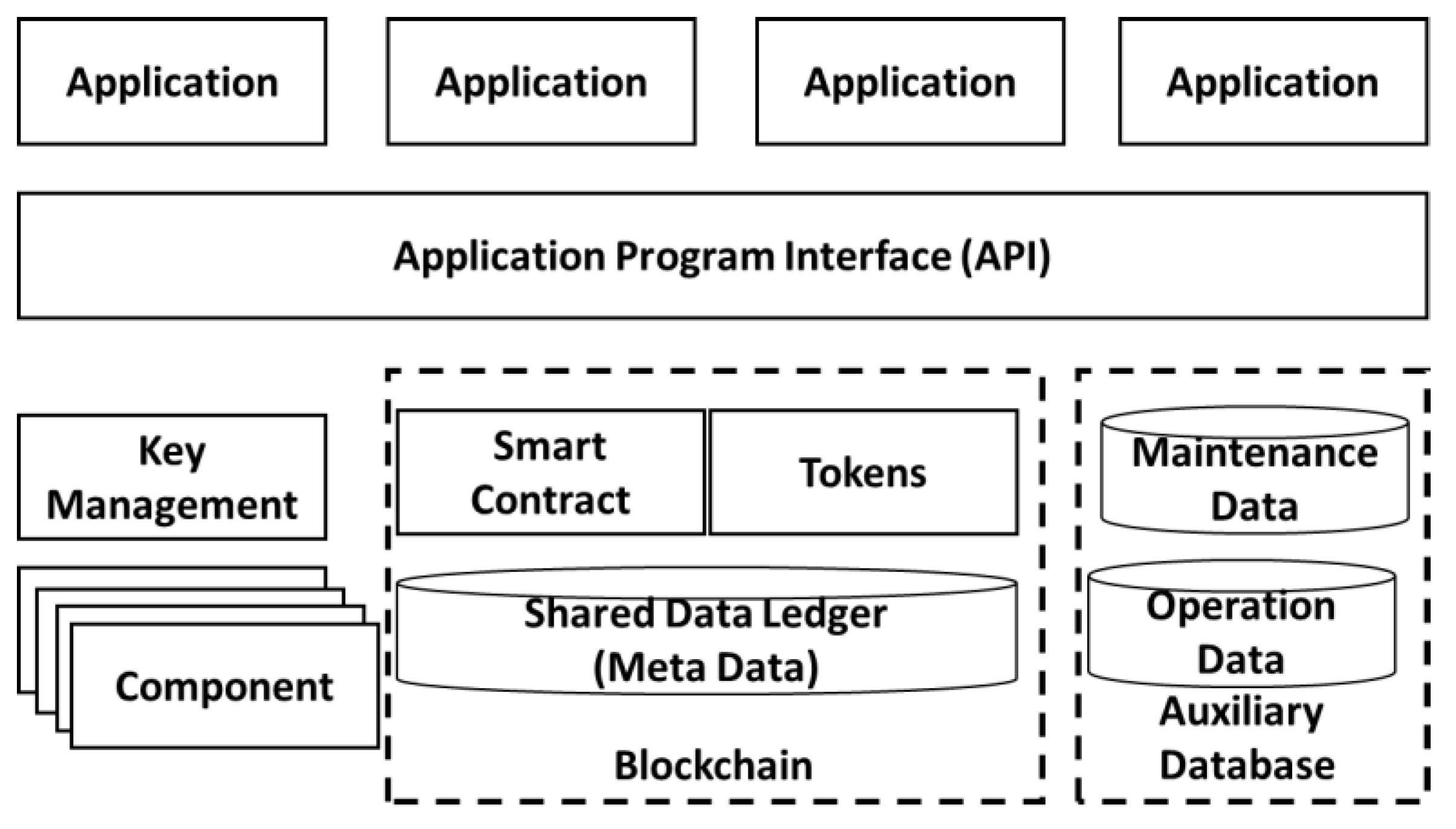

3.3.2. Software Architecture

3.3.3. Framework of the Blockchain for a PMS

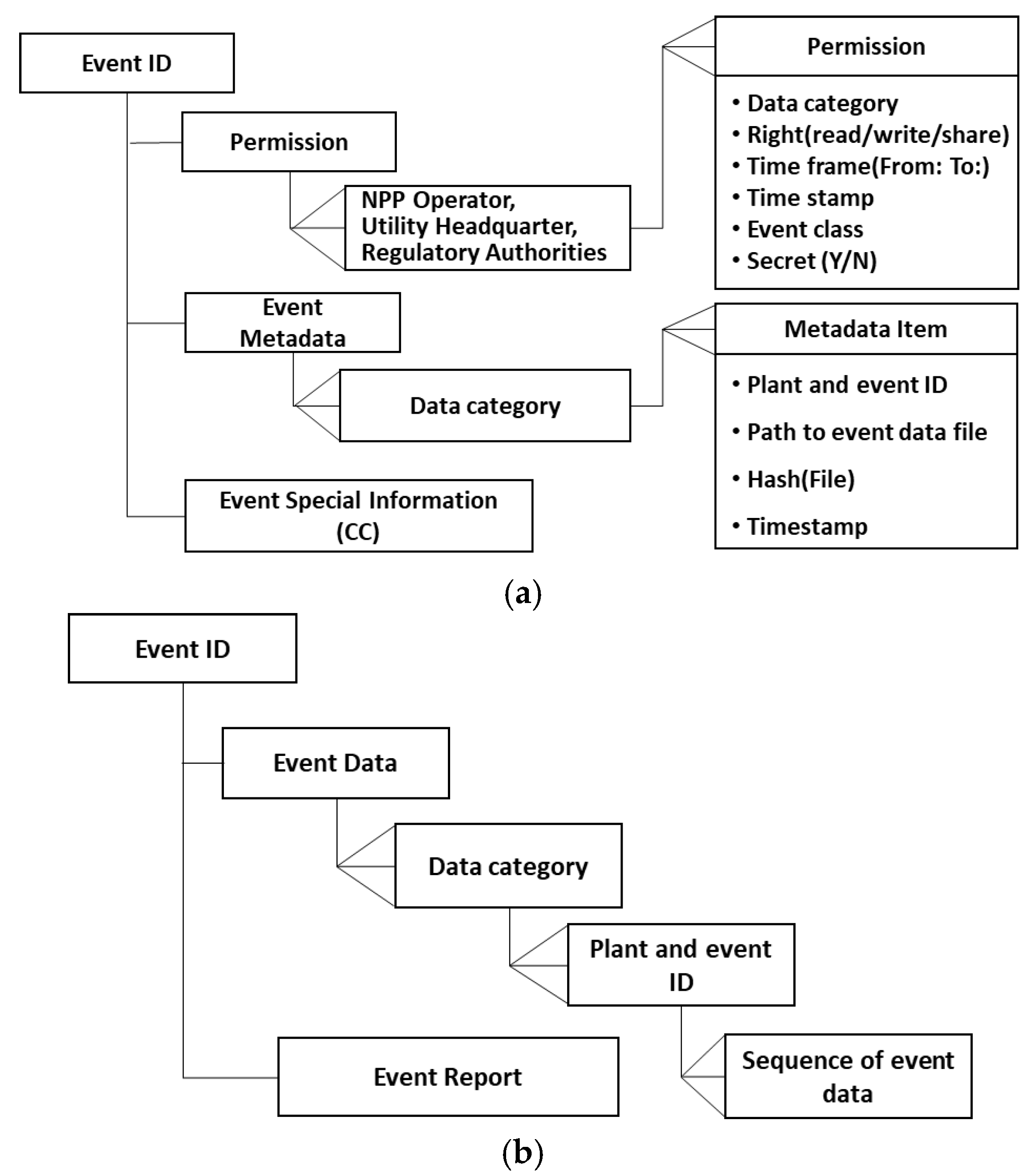

3.4. Data Structure and System Functionality

4. Technologies on Blockchain for Plant Management System

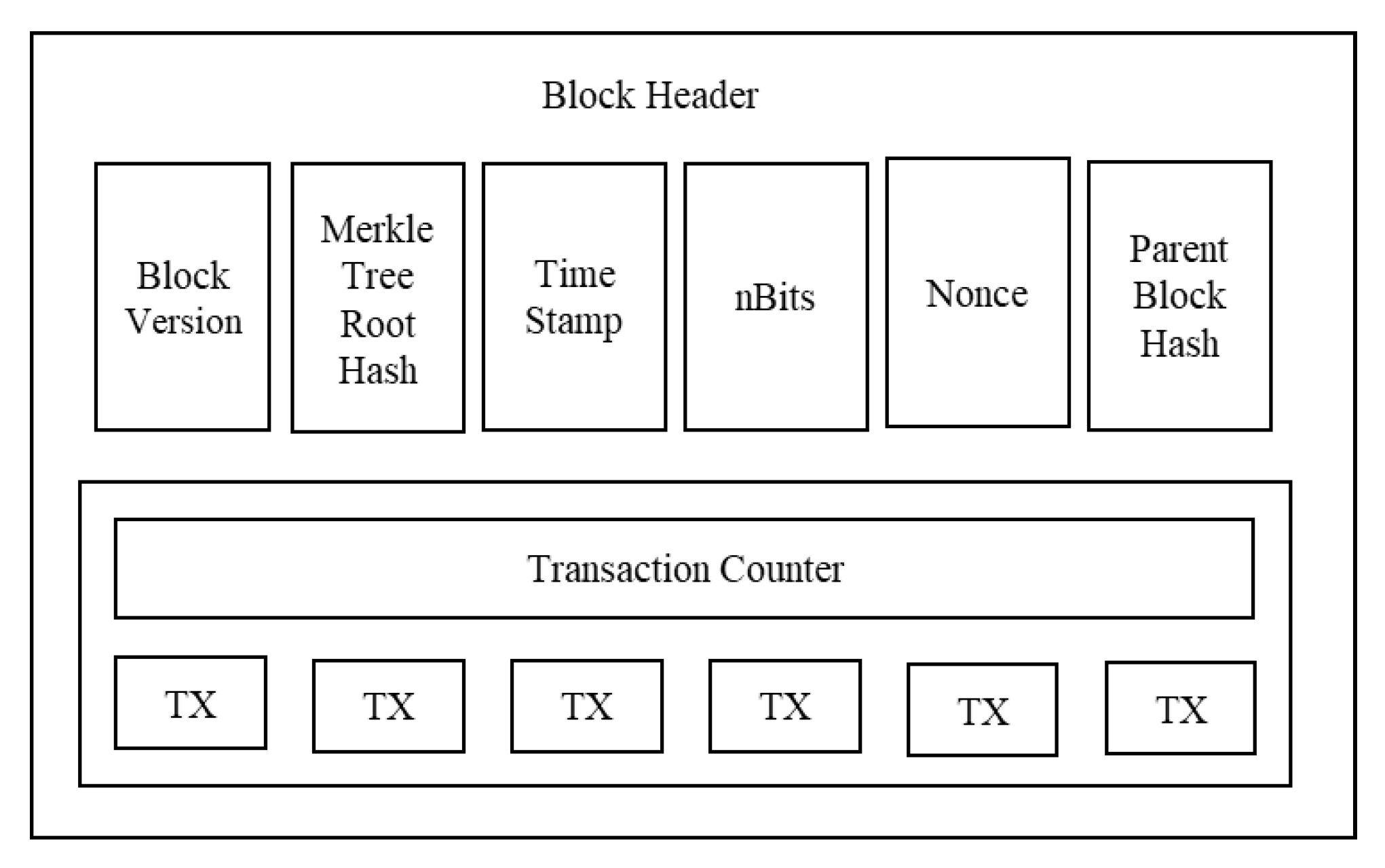

4.1. Block and Chaining Block

4.1.1. Blocks

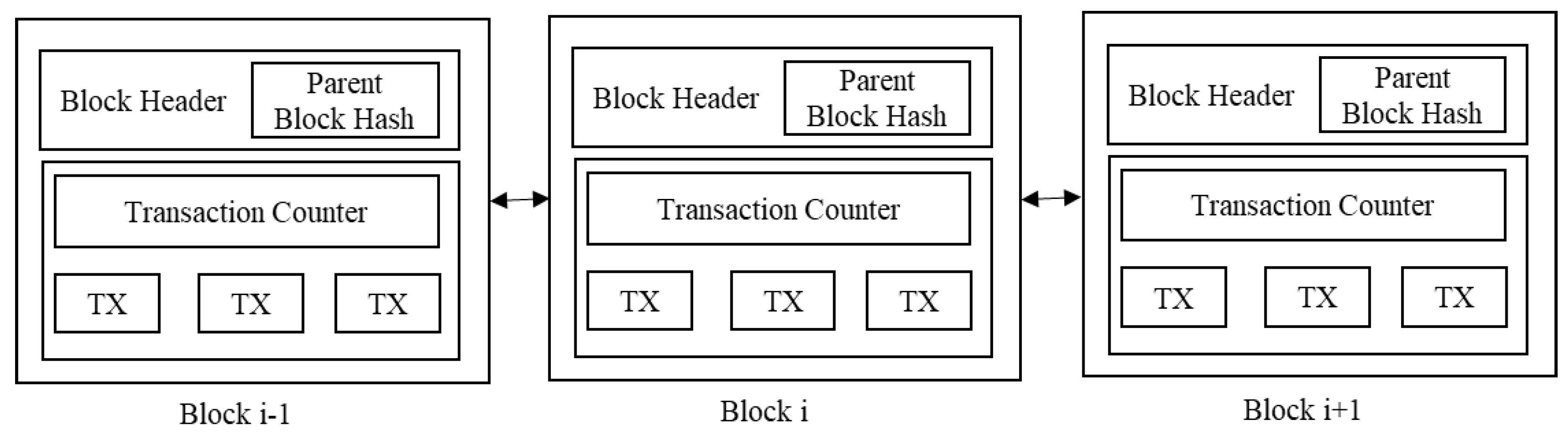

4.1.2. Chaining Blocks

4.2. Hashes

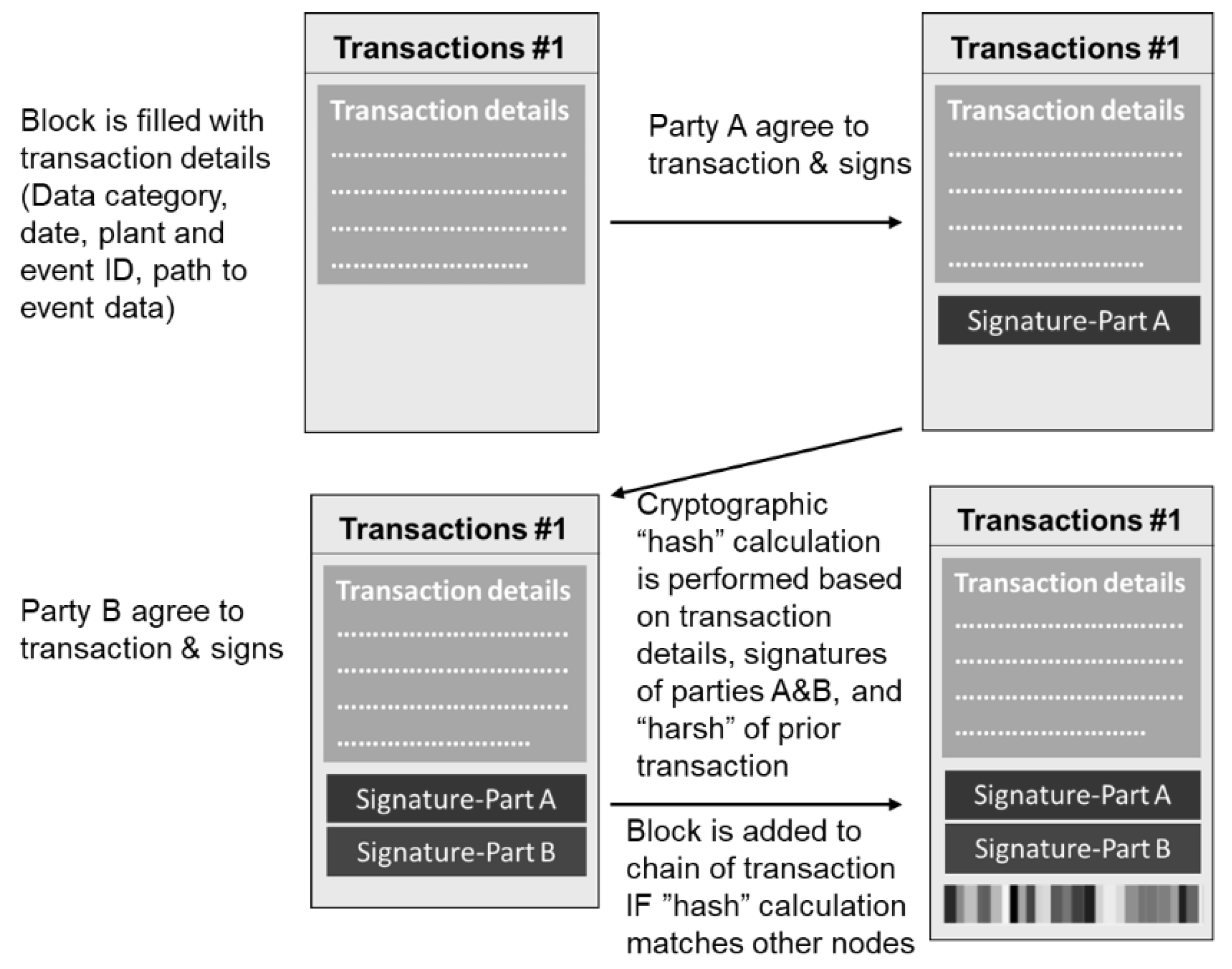

4.3. Transactions

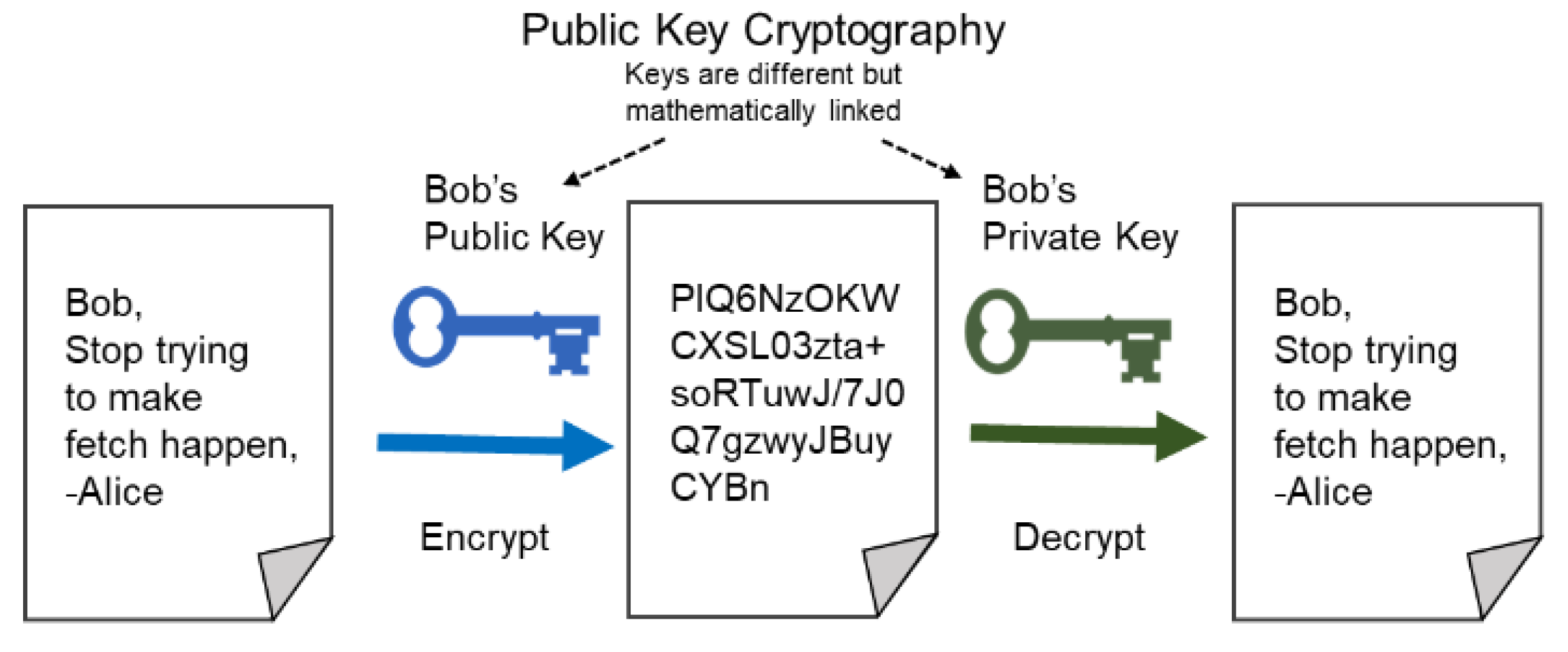

4.4. Cryptography by Asymmetric-Key

- The private key is used for digital signatures.

- The public key is used to derive the address and allows a one-to-many approach for pseudonymity.

- Public keys are used to validate signatures made by private keys.

- Asymmetric key cryptography provides the ability to verify that the user sending the value to another user owns a private key that can sign the value.

5. Conclusions

Funding

Conflicts of Interest

References

- IAEA. Computerization of Operation and Maintenance for Nuclear Power Plants; International Atomic Energy Agency: Vienna, Austria, 1995. [Google Scholar]

- Xu, X.; Lu, Q.; Liu, Y.; Zhu, L.; Yao, H.; Vasilakos, A.V. Designing blockchain-based applications a case study for imported product traceability. Future Gener. Comput. Syst. 2019, 92, 399–406. [Google Scholar] [CrossRef]

- Cai, M.; Li, M.; Cao, W. Blockchain based Data Distribution and Traceability Framework in the Electric Information Management System. Procedia Comput. Sci. 2019, 162, 82–87. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Autom. Constr. 2019, 111, 103063. [Google Scholar] [CrossRef]

- IAEA. Application of the Management System for Facilities and Activites; IAEA: Vienna, Austria, 2006; p. 124. [Google Scholar]

- Doe, G.; Ramsey, C.B. Nuclear Facility Maintenance Management Program Guide for Use with DOE O 433. 1B. Available online: https://www.directives.doe.gov/directives-documents/400-series/0433.EGuide-1-1a/@@images/file (accessed on 22 May 2020).

- IAEA. IAEA Nuclear Energy Series: Maintenance Optimization Programme for Nuclear Power Plants; IAEA: Vienna, Austria, 2018. [Google Scholar]

- CNSC. Reporting Requirements for Nuclear Power Plants; REGDOC-3.1.1; Canadian Nuclear Safety Commission: Ottawa, ON, USA, 2014. [Google Scholar]

- CNSC. Maintenance Programs for Nuclear Power Plants; RD/GD-210; Canadian Nuclear Safety Commission: Ottawa, ON, USA, 2012. [Google Scholar]

- IAEA. The International Nuclear and Radiological Event Scale; IAEA: Vienna, Austria, 2019. [Google Scholar]

- Shin, Y.C.; Chung, H.Y.; Song, T.Y. Advanced MMIS Design Characteristics of APR1400. 2003. Available online: https://www.ipen.br/biblioteca/cd/genes4/2003/papers/1066-final.pdf (accessed on 22 May 2020).

- Korea Hydro. PI Introduction on ERP Project in KHNP. 2003. Available online: https://slideplayer.com/slide/6040008/#.XsnDcrzUr_E (accessed on 22 May 2020).

- Lee, W.B.; Min, S.M.; Park, B.K.; Kim, D.J. System oriented plant maintenance. Key Eng. Mater. 2005, 297, 2693–2699. [Google Scholar] [CrossRef]

- Kumar, N.M. Blockchain: Enabling wide range of services in distributed energy system. Beni-Suef Univ. J. Basic Appl. Sci. 2018, 7, 701–704. [Google Scholar] [CrossRef]

- Maw, A.; Adepu, S.; Mathur, A. ICS-BlockOpS: Blockchain for operational data security in industrial control system. Pervasive Mob. Comput. 2019, 59, 101048. [Google Scholar] [CrossRef]

- Pop, C.; Cioara, T.; Antal, M.; Anghel, I.; Salomie, I.; Bertoncini, M. Blockchain based decentralized management of demand response programs in smart energy grids. Sensors 2018, 18, 162. [Google Scholar] [CrossRef] [PubMed]

- Bürer, M.J.; de Lapparent, M.; Pallotta, V.; Capezzali, M.; Carpita, M. Use cases for Blockchain in the Energy Industry Opportunities of emerging business models and related risks. Comput. Ind. Eng. 2019, 137, 106002. [Google Scholar] [CrossRef]

- Xu, X.; Weber, I.; Staples, M. Architecture for Blockchain Applications; Springer International Publishing: Eveleigh, Australia, 2019. [Google Scholar]

- Bambara, J.J.; Allen, P.R.; Iyer, K.; Madsen, R.; Lederer, S.; Wuehler, M. Blockchain: A Practical Guide to Developing Business, Law, and Technology Solutions; McGraw-Hill: New York, NY, USA, 2018. [Google Scholar]

- Gaur, N.; Desrosiers, L.; Novotny, P.; Ramakrishna, V.; O’Dowd, A.; Baset, S. Hands-On Blockchain with Hyperledger: Building Decentralized Applications with Hyperledger Fabric and Composer; Packt Publishing: Birmingham, UK, 2018. [Google Scholar]

- Dubovitskaya, A.; Xu, Z.; Ryu, S.; Schumacher, M.; Wang, F. Secure and Trustable Electronic Medical Records Sharing using Blockchain. In Proceedings of the AMIA 2017 Annual Symposium, Washington, DC, USA, 4–8 November 2017; pp. 650–659. [Google Scholar]

- Dhillon, V.; Metcalf, D.; Hooper, M. Blockchain Enabled Applications; Apress: Orlando, FL, USA, 2017. [Google Scholar]

- Zhu, Z.; Qi, G.; Zheng, M.; Sun, J.; Chai, Y. Blockchain based consensus checking in decentralized cloud storage. Simul. Model. Pract. Theory 2019, 16, 101987. [Google Scholar] [CrossRef]

- Zheng, Z.; Xie, S.; Dai, H.; Chen, X.; Wang, H. An Overview of Blockchain Technology: Architecture, Consensus, and Future Trends. In Proceedings of the 2017 IEEE 6th International Congress on Big Data, Honolulu, HI, USA, 25–30 June 2017; pp. 557–564. [Google Scholar]

- Yaga, D.; Mell, P.; Roby, N.; Scarfone, K. Blockchain technology overview. arXiv 2019, arXiv:1906.11078. [Google Scholar]

- Di Vaio, A.; Varriale, L. Blockchain technology in supply chain management for sustainable performance: Evidence from the airport industry. Int. J. Inf. Manag. 2019, 52, 102014. [Google Scholar] [CrossRef]

- Bashir, I. Mastering Blockchain; Packt Publishing Ltd.: Birmingham, UK, 2017. [Google Scholar]

- Keerati, R. Preparing for Blockchain—Challenges and Alternatives for Financial Regulators; University of California: Berkeley, CA, USA, 2017. [Google Scholar]

- Sadouskaya, K. Adoption of Blockchain Technology in Supply Chain and Logistics. Bachelor’s Thesis, XAMK, Kouvola, Finland, April 2017; pp. 3–18. [Google Scholar]

| Category | Type | Data |

|---|---|---|

| I | Accident and Failure Event Data | Fault trip Fail to start/stop Accidents and incidents classified in the INES event scale. |

| II | Plant Operation Data (PI Local Server) | Plant operation information - Plant operation variables - Alarms - On/off control status |

| III | Early Warning Data (OLM Local Server) | Variables of major equipment - Main feedwater system - Main generator system - Reactor cooling system - Variation monitoring system - Smart sensors - Plant monitoring program |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, C.-k. Blockchain for Integrated Nuclear Power Plants Management System. Information 2020, 11, 282. https://doi.org/10.3390/info11060282

Chang C-k. Blockchain for Integrated Nuclear Power Plants Management System. Information. 2020; 11(6):282. https://doi.org/10.3390/info11060282

Chicago/Turabian StyleChang, Choong-koo. 2020. "Blockchain for Integrated Nuclear Power Plants Management System" Information 11, no. 6: 282. https://doi.org/10.3390/info11060282

APA StyleChang, C.-k. (2020). Blockchain for Integrated Nuclear Power Plants Management System. Information, 11(6), 282. https://doi.org/10.3390/info11060282