Design Framework of a Traceability System for the Rice Agroindustry Supply Chain in West Java

Abstract

1. Introduction

2. Literature Review

3. Methodology

3.1. Field Survey

3.2. Data Collection

3.3. System Analysis

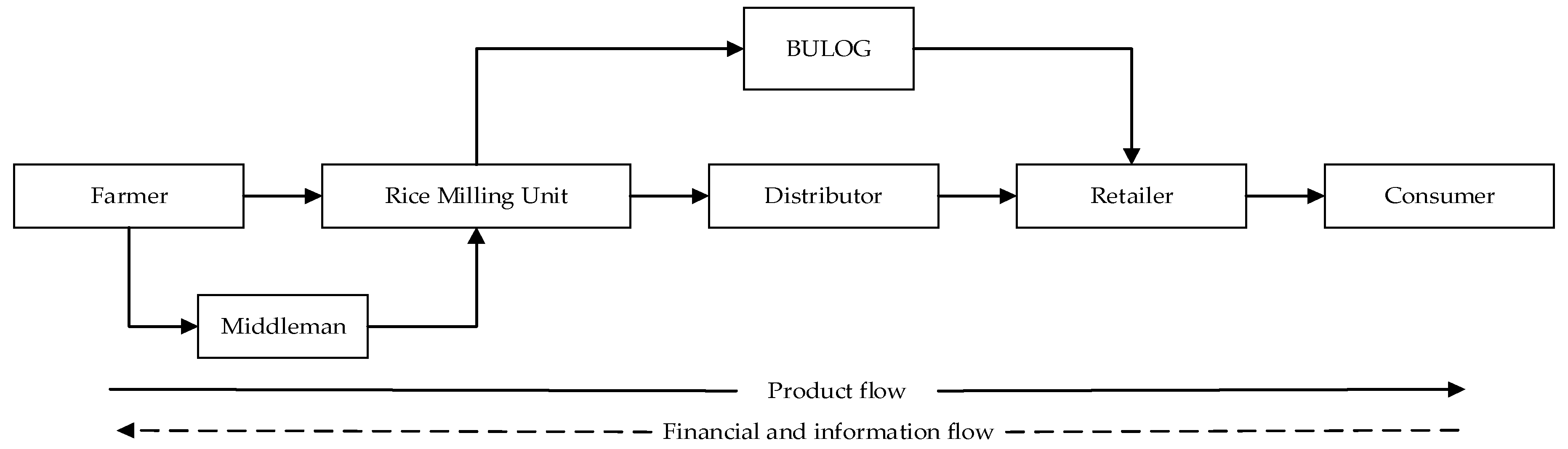

4. Rice Supply Chain

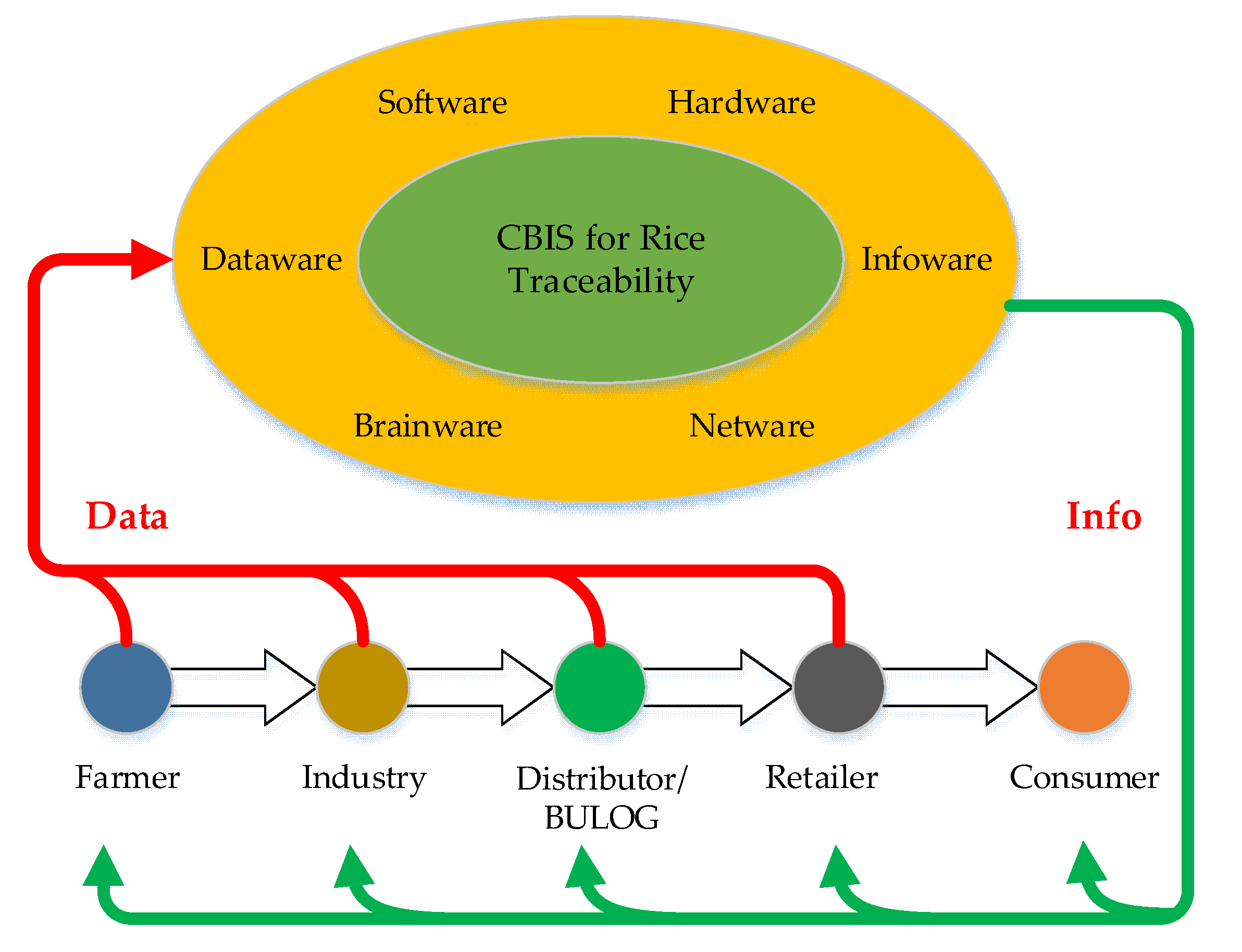

5. Usage Requirement

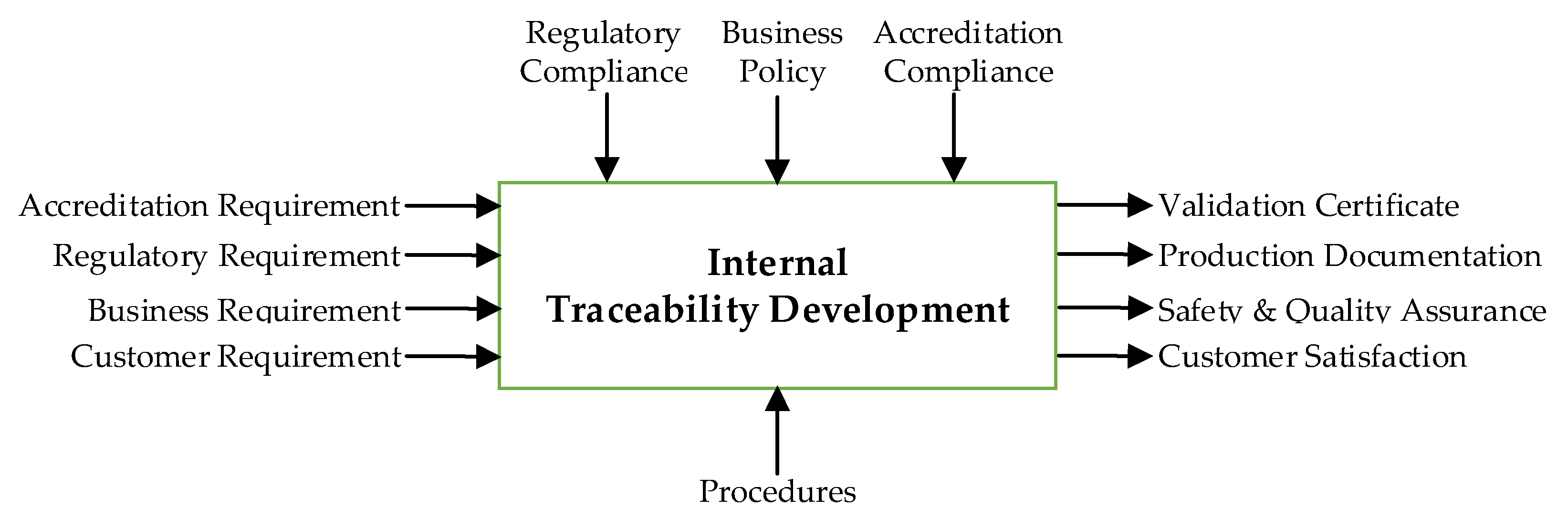

6. Traceability Identification and Planning

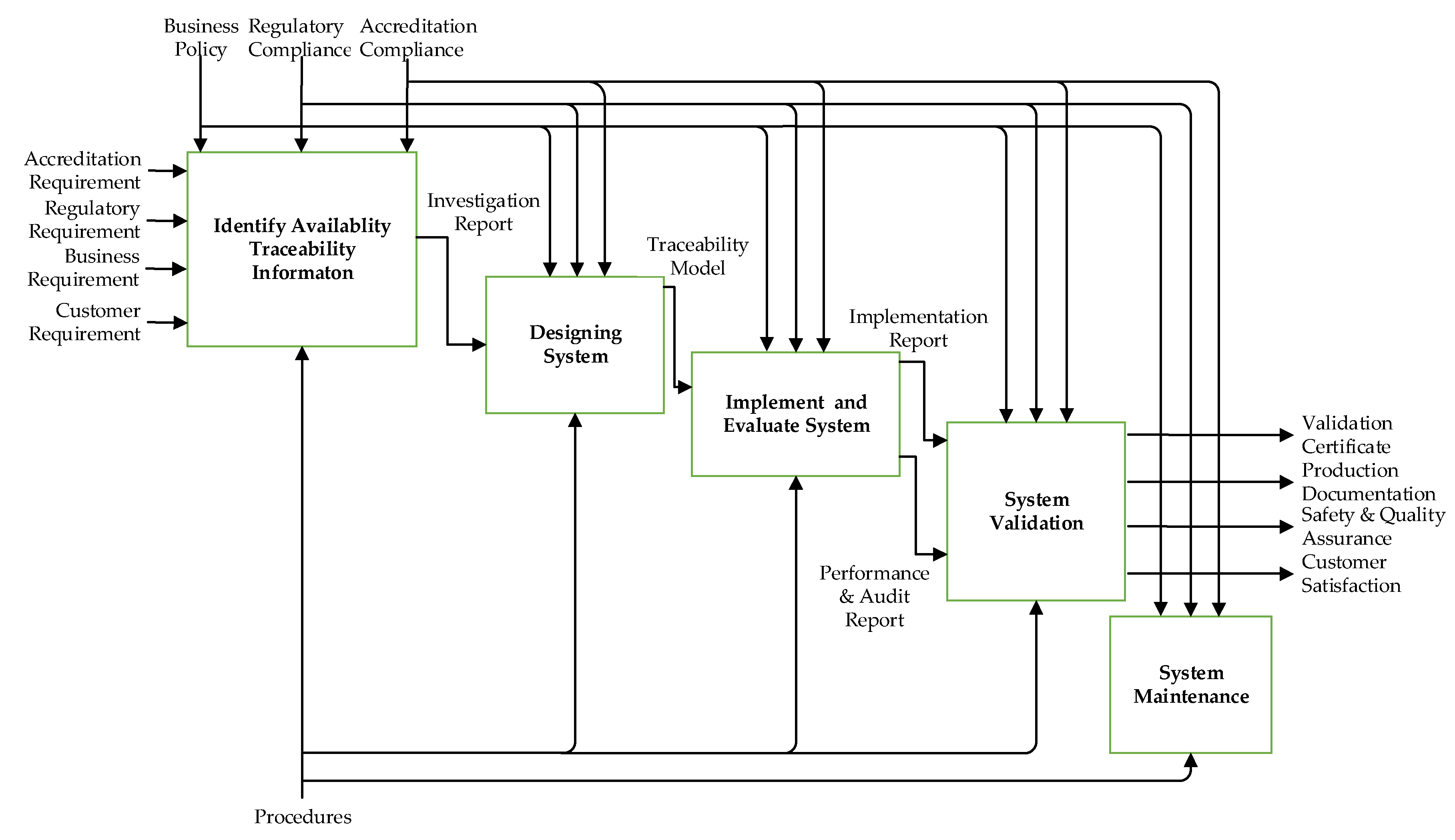

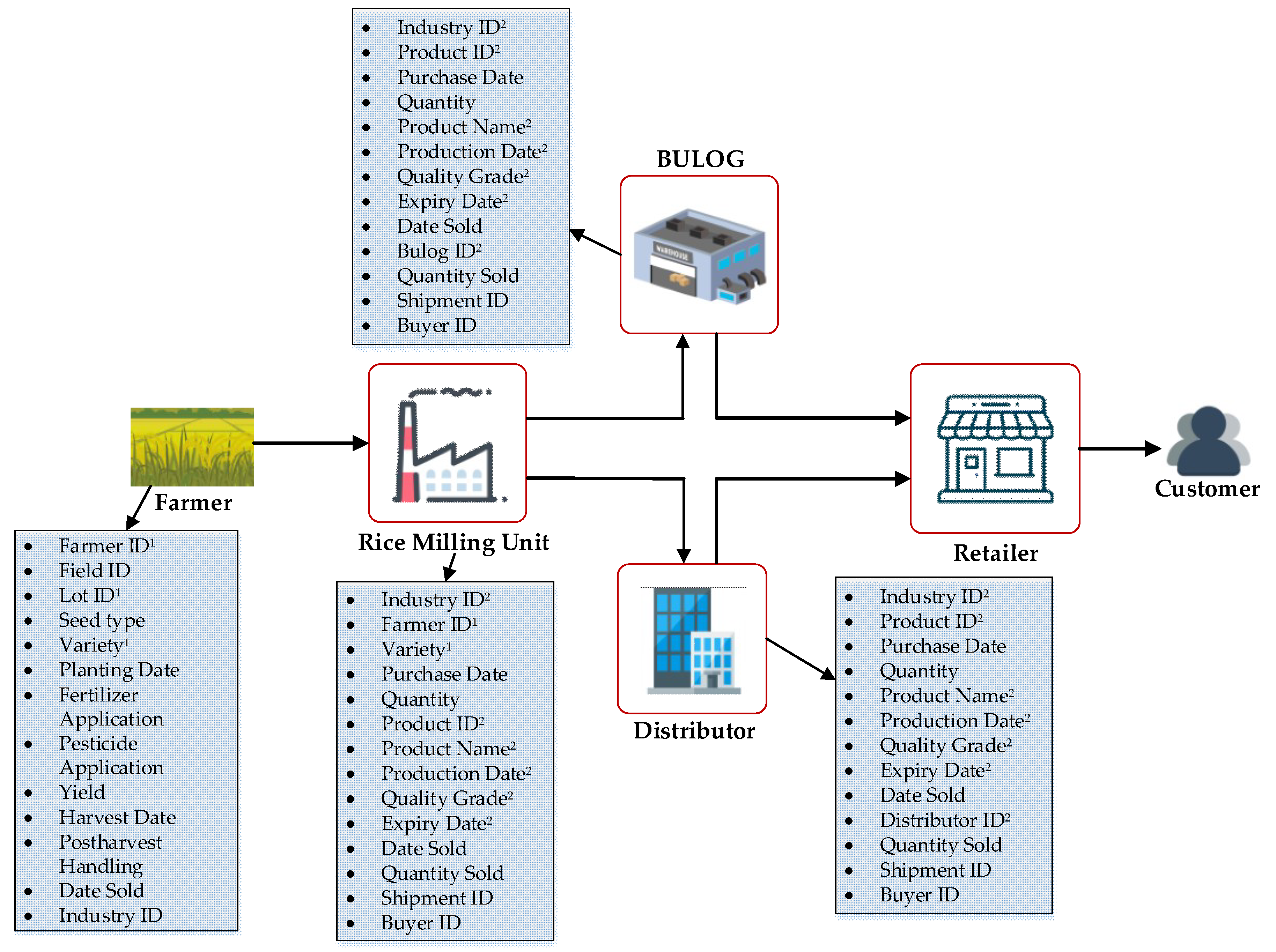

6.1. Identification Availability of Traceability Information

6.2. System Design

6.3. Identification of Availability of Traceability Information

6.4. System Validation

6.5. System Maintenance

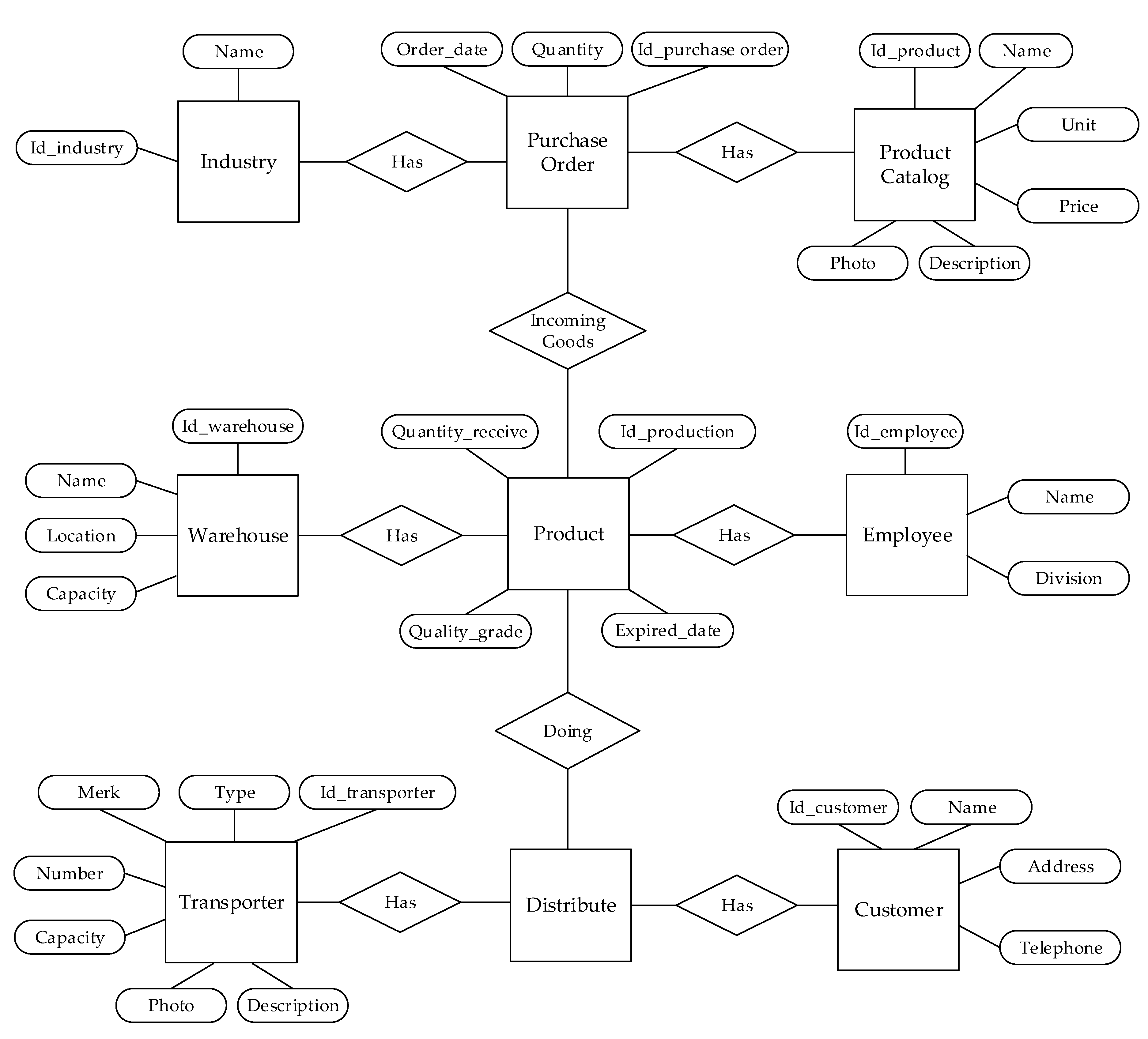

7. Design of Functional Structure of Traceability Systems

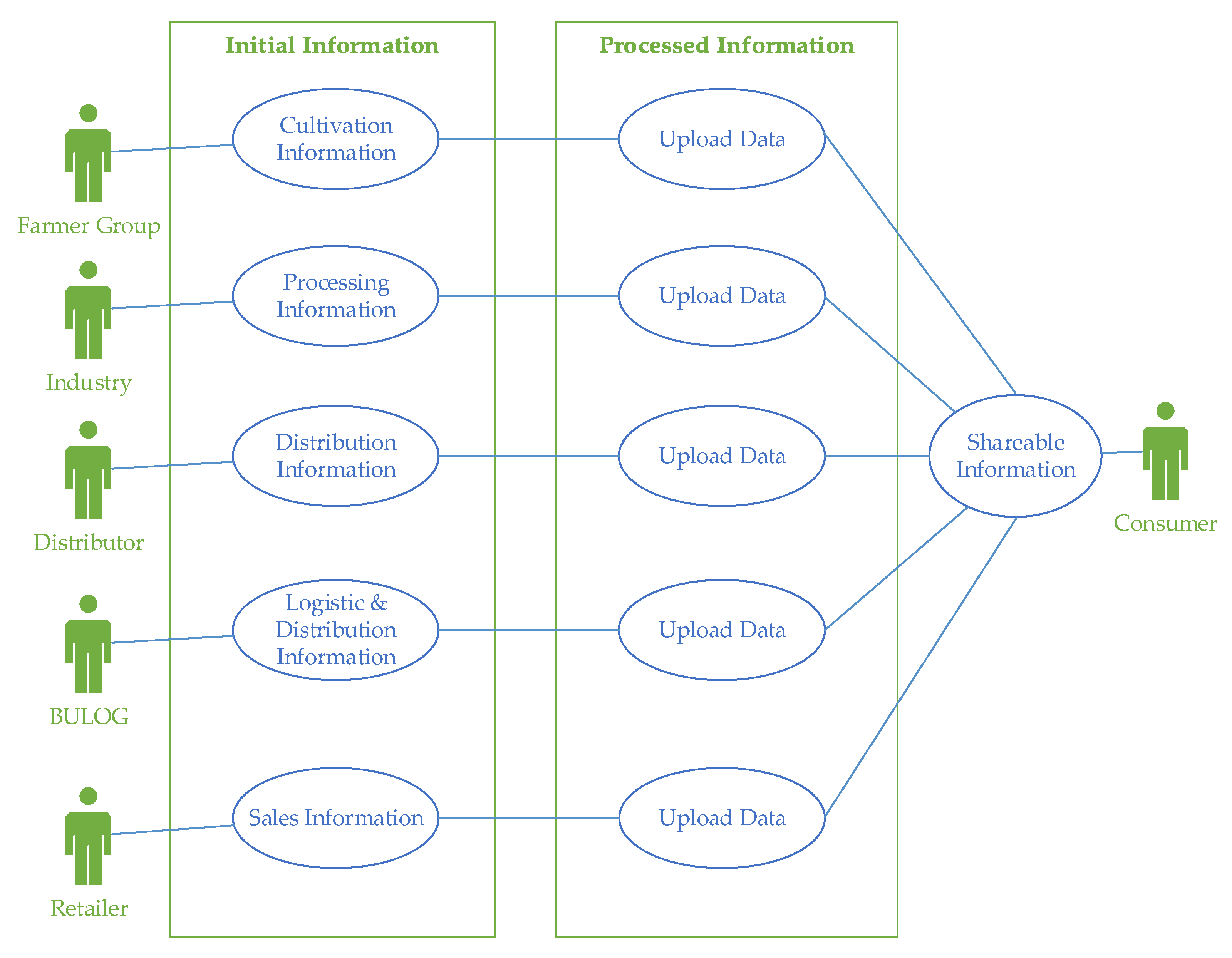

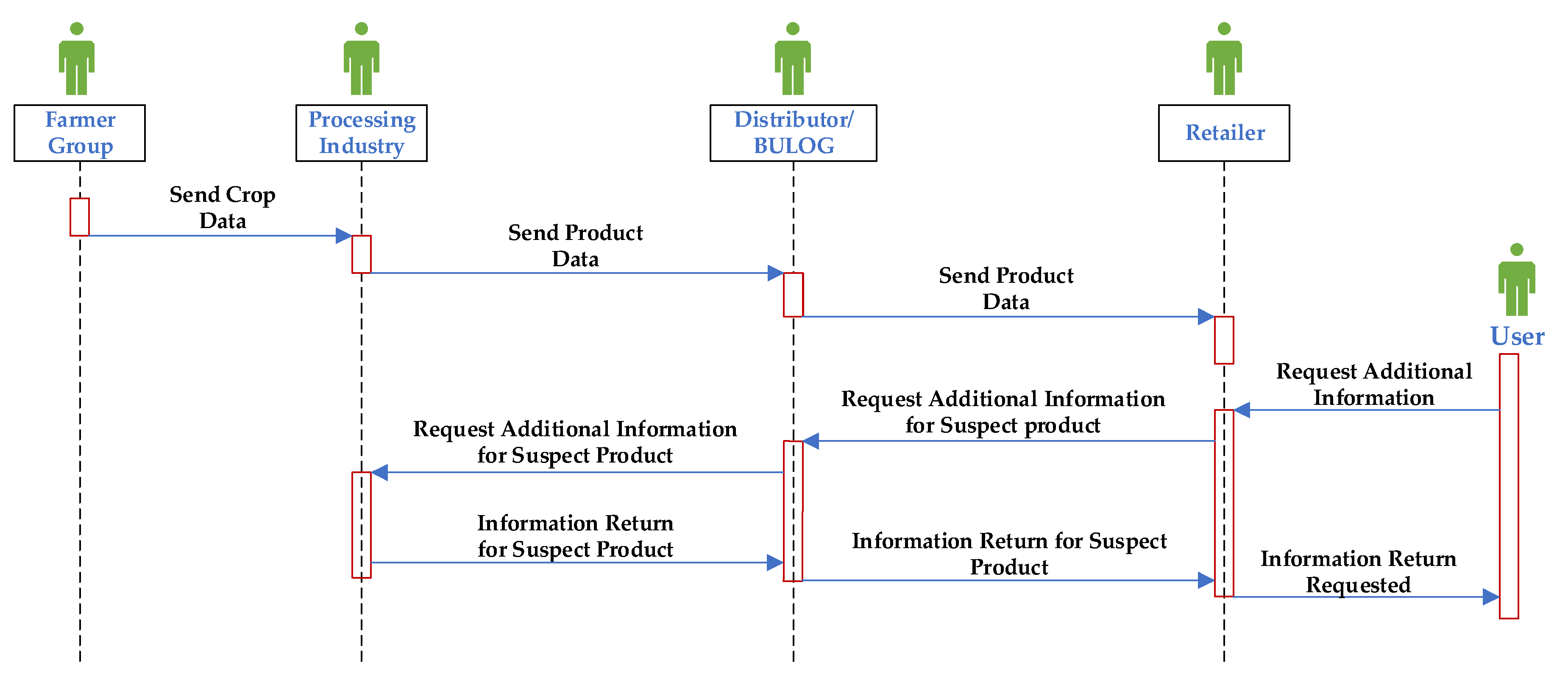

8. Inter-Actor Traceability

9. CBIS to Realize Traceability System

10. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Muthayya, S.; Sugimoto, J.D.; Montgomery, S.; Maberly, G.F. An overview of global rice production, supply, trade, and consumption. Ann. N. Y. Acad. Sci. 2014, 1324, 7–14. [Google Scholar] [CrossRef] [PubMed]

- Pusat Data dan Sistem Informasi Pertanian. Agricultural Commodities Outlook for Food Crops Sub-sector; Agriculture Ministry: Jakarta, Indonesia, 2016. [Google Scholar]

- Indonesia Statistics Center. Distribution of Indonesian Rice Commodity Trade 2016; Indonesia Statistics Center: Jakarta, Indonesia, 2016. [Google Scholar]

- Suismono; Damiadi, S. Prospect of SNI labeled rice. Jurnal Pangan 2010, 19, 30–39. [Google Scholar]

- Ramli, T.A.; Sumiyati, Y. Penyuluhan tentang perlindungan hukum indikasi geografis beras pandanwangi cianjur jawa barat sebagai wujud sumbangsih unisba dalam meningkatkan indeks pembangunan manusia (Counseling about legal protection geographical indications of pandanwangi rice in west java as a manifestation of unique contibution in improving the human development index). Jurnal Hukum Pembangunan 2012, 42, 360–380. [Google Scholar]

- Thakur, M.; Hurburgh, C.R. Framework for implementing traceability system in the bulk grain supply chain. J. Food Eng. 2009, 95, 617–626. [Google Scholar] [CrossRef]

- Vanany, I.; Mardiyanto, R.; Ijtihadie, R.M.; Andri, K.B.; Engelseth, P. Developing electronic mango traceability in Indonesia. Supply Chain Forum Int. J. 2016, 17, 26–38. [Google Scholar] [CrossRef]

- Commission, E. Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002 laying down the general principles and requirements of food law, establishing the European Food Safety Authority and laying down procedures in matters of food safety. Off. J. Eur. Communities 2002, 31, 1–24. [Google Scholar]

- Sudibyo, A. Sistem ketertelusuran pada industri pangan dan produk hasil pertanian (Traceability system in food industry and agricultural product). Warta Industri Hasil Pertanian 2012, 29, 43–62. [Google Scholar]

- Triyanto, D. Development of Traceability System in Broiler Chicken Production Chain; IPB University: Bogor, Indonesia, 2016. [Google Scholar]

- Kumar, V.; Hallqvist, C.; Ekwall, D. Developing a framework for traceability implementation in the textile supply chain. Systems 2017, 5, 33. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, X.; Moga, L.M.; Neculita, M. Modeling and implementation of the vegetable supply chain traceability system. Food Control 2013, 30, 341–353. [Google Scholar] [CrossRef]

- Vanany, I.; Andri, K.B.; Mardiyanto, R.; Puspita, N.F.; Winarsih, W.H. An electronic traceability system for an Indonesian fresh fruit supply chain. IPTEK J. Proc. Ser. 2015, 1, 1. [Google Scholar] [CrossRef][Green Version]

- Rosa, S.L.; Shamsuddin, S.M.; Supriyanto, E.; Sutopo, W. Food Traceability and Security in Supply Chain Using RFID Technology. Proc. Electr. Eng. Comput. Sci. Inform. 2014, 1, 255–258. [Google Scholar]

- Seuring, S.; Sarkis, J.; Müller, M.; Rao, P. Sustainability and Supply Chain Management—An Introduction to the Special Issue; Elsevier: New York, NY, USA, 2008. [Google Scholar]

- Lam, J.K.; Postle, R. Textile and apparel supply chain management in Hong Kong. Int. J. Cloth. Sci. Technol. 2006, 18, 265–277. [Google Scholar] [CrossRef]

- Zhang, X.; Feng, J.; Xu, M.; Hu, J. Modeling traceability information and functionality requirement in export-oriented tilapia chain. J. Sci. Food Agric. 2011, 91, 1316–1325. [Google Scholar] [CrossRef] [PubMed]

- Lotfi, Z.; Mukhtar, M.; Sahran, S.; Zadeh, A.T. Information sharing in supply chain management. Procedia Technol. 2013, 11, 298–304. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management: Strategy, Planning, and Operation; Pearson: Boston, MA, USA, 2013. [Google Scholar]

- Irawan, B. Conversion of Land Rice Field in West Java: Trends and Effect on Rice production; Agriculture Ministry: Jakarta, Indonesia, 2011. [Google Scholar]

- Van Der Vorst, J.G. Performance measurement in agri-food supply-chain networks. Quantifying Agri-food Supply Chain 2006, 15, 15–26. [Google Scholar]

- Folinas, D.; Manikas, I.; Manos, B. Traceability data management for food chains. Br. Food J. 2006, 108, 622–633. [Google Scholar] [CrossRef]

- Satzinger, J.; Jackson, R.; Burd, S. Systems Analysis and Design in a Changing World; Cengage Learning: Boston, MA, USA, 2010. [Google Scholar]

- Klimek, R.; Szwed, P. Formal analysis of use case diagrams. Comput. Sci. 2010, 11, 115–131. [Google Scholar]

- Purwandoko, P.; Seminar, K. Framework for Design of Traceability System on Organic Rice Certification. IOP Conf. Ser. Earth Environ. Sci. 2018, 147, 012044. [Google Scholar] [CrossRef]

- Porto, S.; Arcidiacono, C.; Cascone, G. Developing integrated computer-based information systems for certified plant traceability: Case study of Italian citrus-plant nursery chain. Biosyst. Eng. 2011, 109, 120–129. [Google Scholar] [CrossRef]

- Nanda, M.A.; Seminar, K.B.; Nandika, D.; Maddu, A. Discriminant analysis as a tool for detecting the acoustic signals of termites Coptotermes curvignathus (Isoptera: Rhinotermitidae). Int. J. Technol. 2018, 9, 840–851. [Google Scholar] [CrossRef]

- Nanda, M.A.; Seminar, K.B.; Nandika, D.; Maddu, A. A comparison study of kernel functions in the support vector machine and its application for termite detection. Information 2018, 9, 5. [Google Scholar] [CrossRef]

- Tong, J.C.; Ranganathan, S. Computer-Aided Vaccine Design; Elsevier: New York, NY, USA, 2013. [Google Scholar]

- Ramadhan, F.; Purwandari, N. Sistem Informasi Penjualan Berbasis Web Pada PT. Mustika Jati (Web based sales information system at PT. Mustika Jati). Kalbi Scientia 2018, 5, 43–57. [Google Scholar]

- Huo, B.; Zhao, X.; Zhou, H. The effects of competitive environment on supply chain information sharing and performance: An empirical study in China. Prod. Oper. Manag. 2014, 23, 552–569. [Google Scholar] [CrossRef]

- Li, Y.; Ye, F.; Sheu, C. Social capital, information sharing and performance: Evidence from China. Int. J. Oper. Prod. Manag. 2014, 34, 1440–1462. [Google Scholar] [CrossRef]

- Golan, E.H.; Krissoff, B.; Kuchler, F.; Calvin, L.; Nelson, K.E.; Price, G.K. Traceability in the US Food Supply: Economic Theory and Industry Studies. Available online: https://ageconsearch.umn.edu/record/33939/ (accessed on 22 June 2019).

- Liu, C.; Huo, B.; Liu, S.; Zhao, X. Effect of information sharing and process coordination on logistics outsourcing. Ind. Manag. Data Syst. 2015, 115, 41–63. [Google Scholar] [CrossRef]

- Tai, Y.-M.; Ho, C.-F. Effects of information sharing on customer relationship intention. Ind. Manag. Data Syst. 2010, 110, 1385–1401. [Google Scholar] [CrossRef]

- Regattieri, A.; Gamberi, M.; Manzini, R. Traceability of food products: General framework and experimental evidence. J. Food Eng. 2007, 81, 347–356. [Google Scholar] [CrossRef]

- De, A.; Choudhary, A.; Tiwari, M.K. Multiobjective approach for sustainable ship routing and scheduling with draft restrictions. IEEE Trans. Eng. Manag. 2017, 99, 1–17. [Google Scholar] [CrossRef]

- Alkahtani, M.; Choudhary, A.; De, A.; Harding, J.A. A decision support system based on ontology and data mining to improve design using warranty data. Comput. Ind. Eng. 2019, 128, 1027–1039. [Google Scholar] [CrossRef]

- Awasthi, A. Supplier quality evaluation using a fuzzy multi criteria decision making approach. In Complex System Modelling and Control Through Intelligent Soft Computations; Springer: Berlin, Germany, 2015; pp. 195–219. [Google Scholar]

- Roshan, H.; Afsharinezhad, M. The new approach in market segmentation by using RFM model. J. Appl. Res. Ind. Eng. 2017, 4, 259–267. [Google Scholar]

- Seminar, K.B. Food Chain Transparency for Food Loss and Waste Surveillance. J. Dev. Sustain. Agric. 2016, 11, 17–22. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Purwandoko, P.B.; Seminar, K.B.; Sutrisno; Sugiyanta. Design Framework of a Traceability System for the Rice Agroindustry Supply Chain in West Java. Information 2019, 10, 218. https://doi.org/10.3390/info10060218

Purwandoko PB, Seminar KB, Sutrisno, Sugiyanta. Design Framework of a Traceability System for the Rice Agroindustry Supply Chain in West Java. Information. 2019; 10(6):218. https://doi.org/10.3390/info10060218

Chicago/Turabian StylePurwandoko, Pradeka Brilyan, Kudang Boro Seminar, Sutrisno, and Sugiyanta. 2019. "Design Framework of a Traceability System for the Rice Agroindustry Supply Chain in West Java" Information 10, no. 6: 218. https://doi.org/10.3390/info10060218

APA StylePurwandoko, P. B., Seminar, K. B., Sutrisno, & Sugiyanta. (2019). Design Framework of a Traceability System for the Rice Agroindustry Supply Chain in West Java. Information, 10(6), 218. https://doi.org/10.3390/info10060218