Soiling Losses: A Barrier for India’s Energy Security Dependency from Photovoltaic Power

Abstract

1. Introduction

2. Factors Affecting Accumulation of Soiling on PVs

2.1. Effect of Particle Size

2.2. Effect of Wind

2.3. Effect of Rain and Moisture

2.4. Effect on PV Module Top Surface Material

2.5. Effect of Tilt Angle

3. Soiling Effect on PV Performance

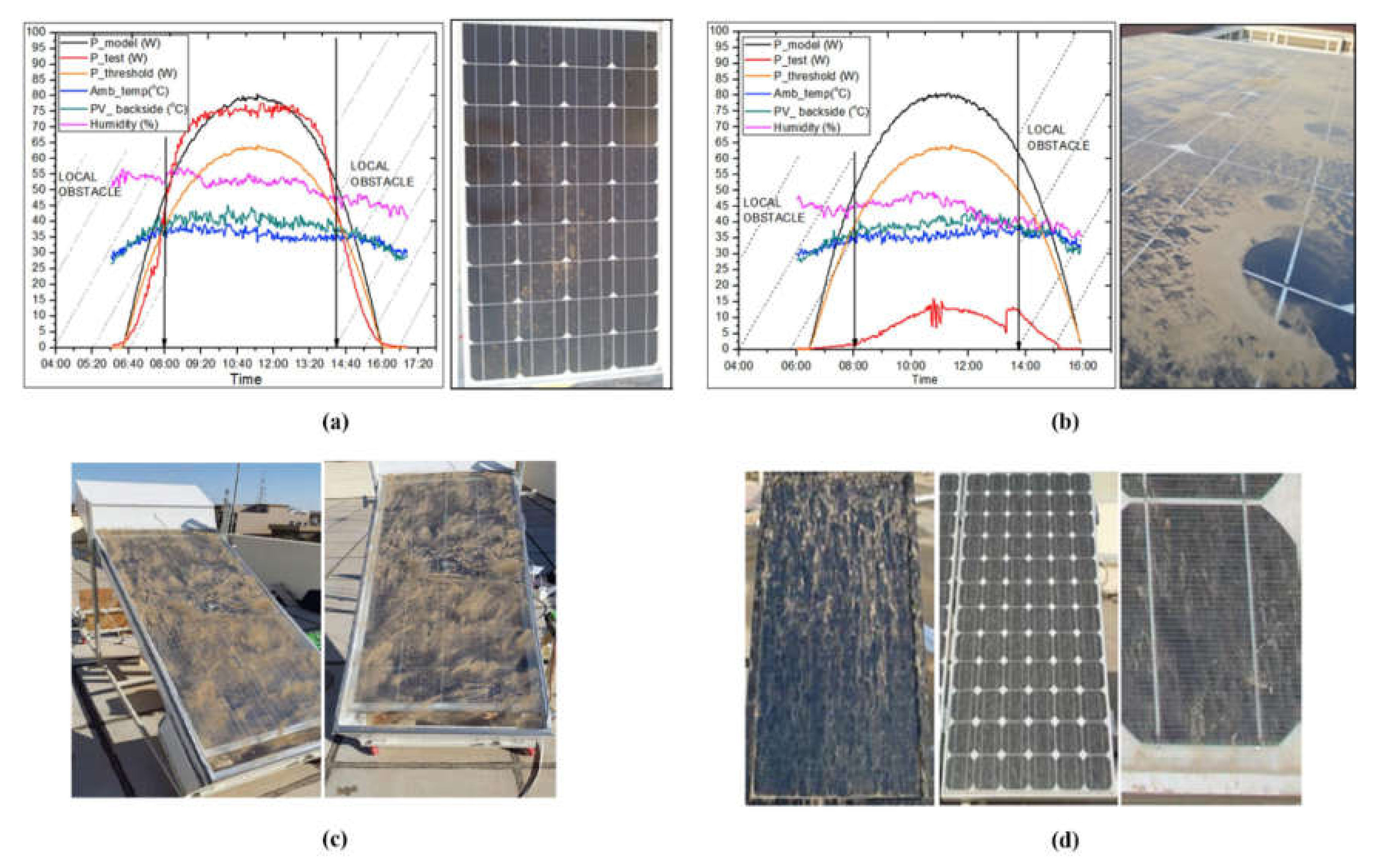

3.1. Effect on PV Power Output

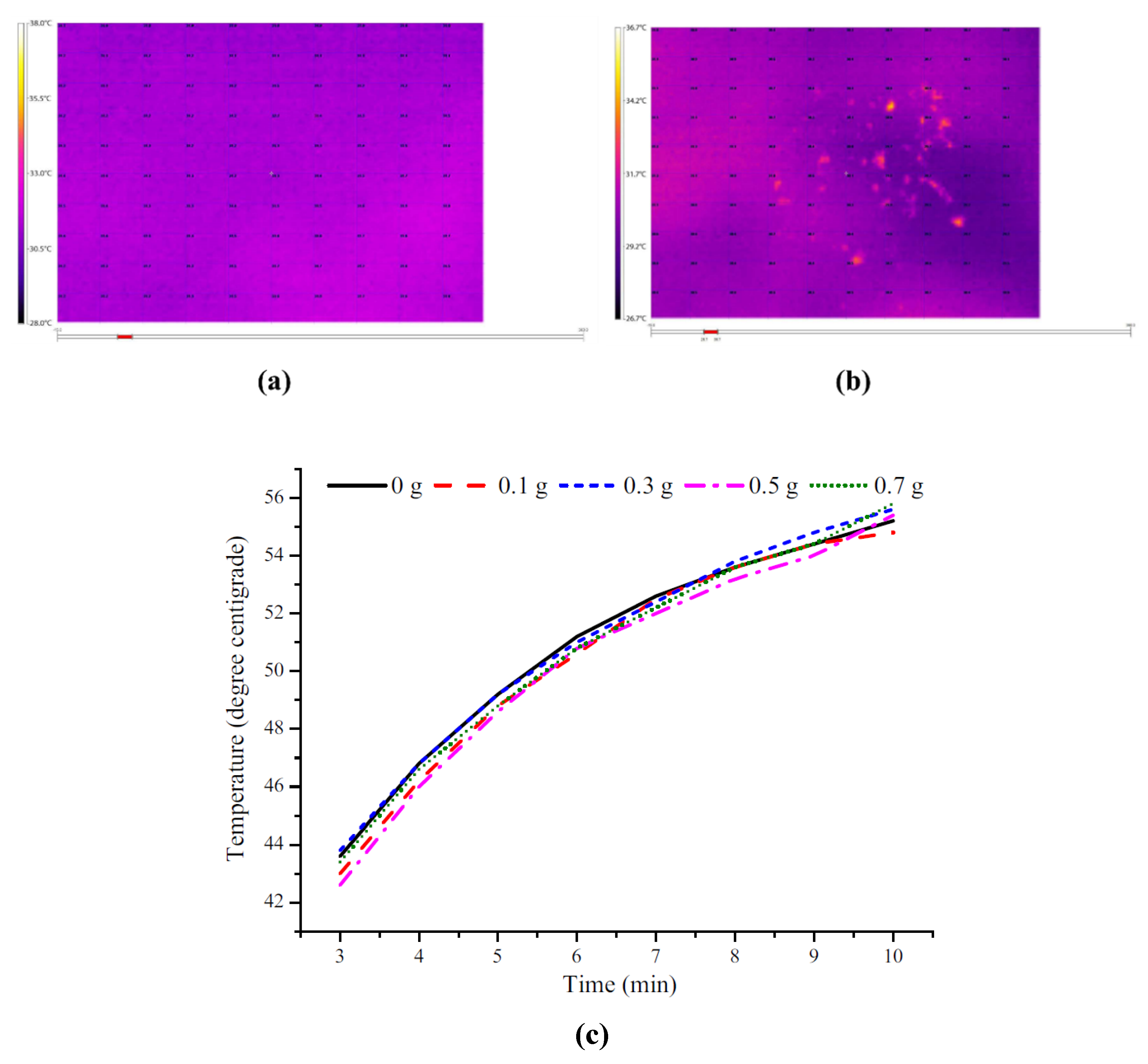

3.2. Effect on PV Temperature

3.3. Soiling Issues on Concentrating PVs (CPVs)

4. Cleaning of Soiled PVs

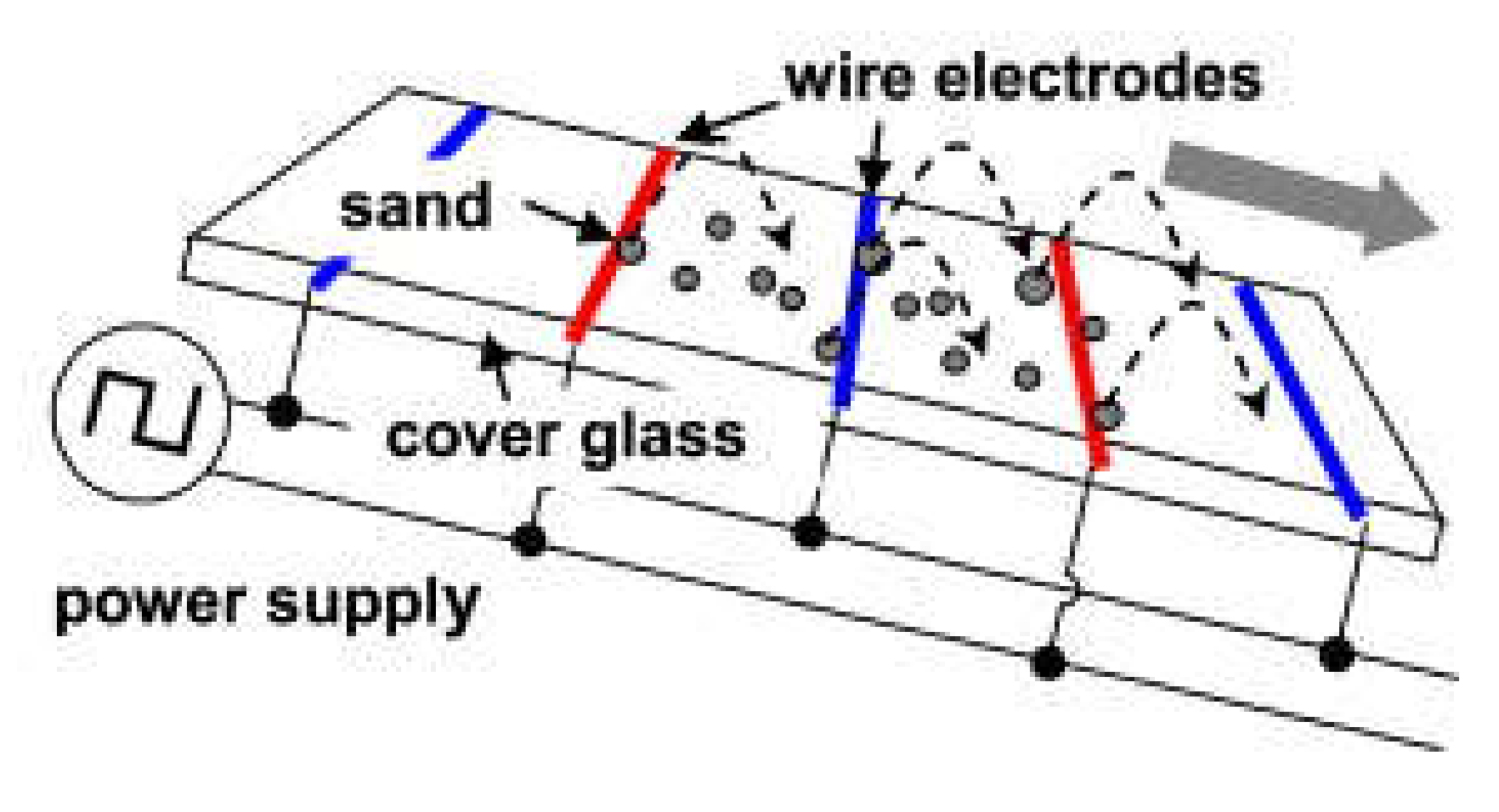

4.1. Electrodynamic Screen (EDS)

4.2. Robotic Cleaning

4.3. Anti-Soiling Coating (Self-Cleaning)

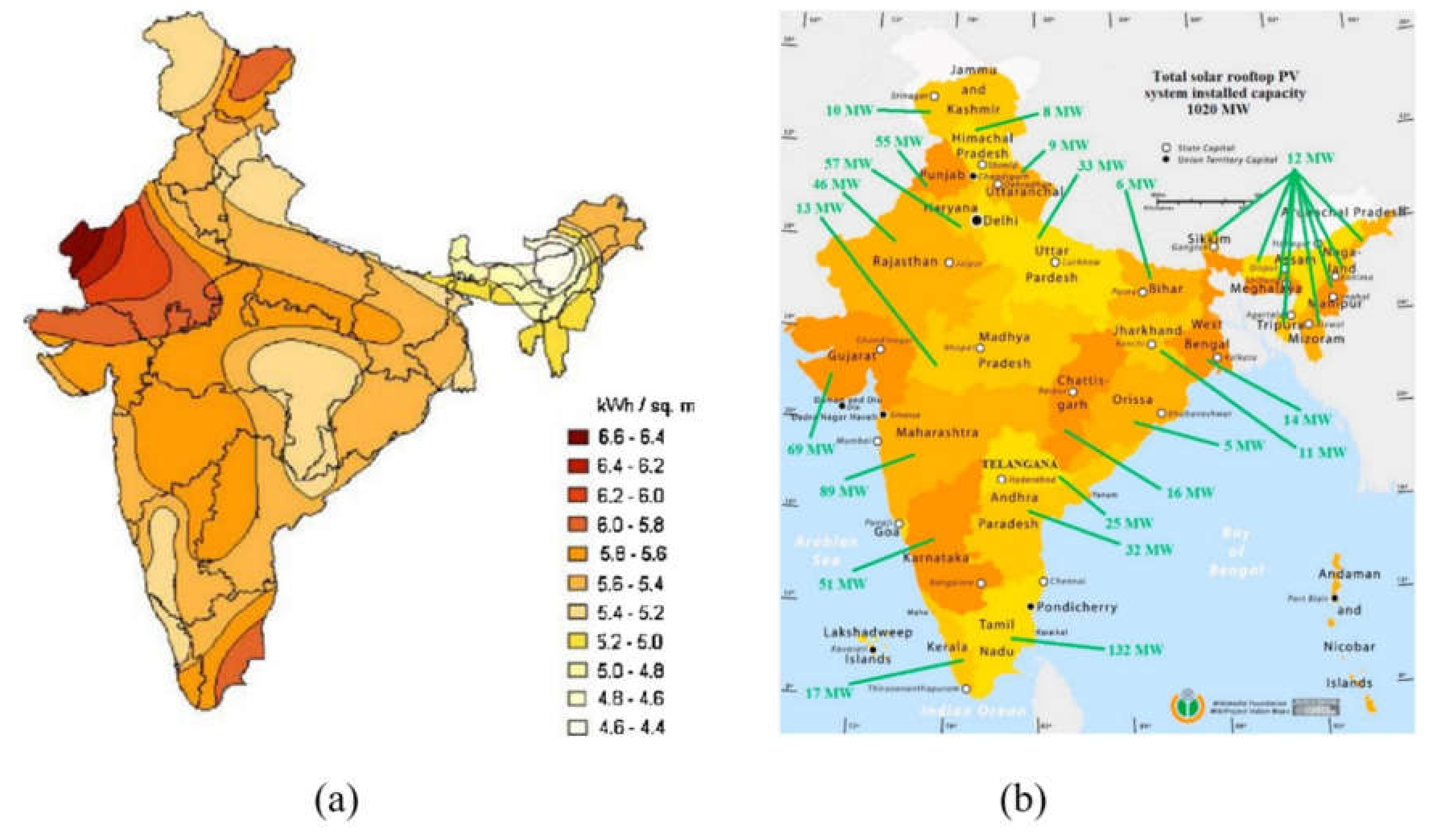

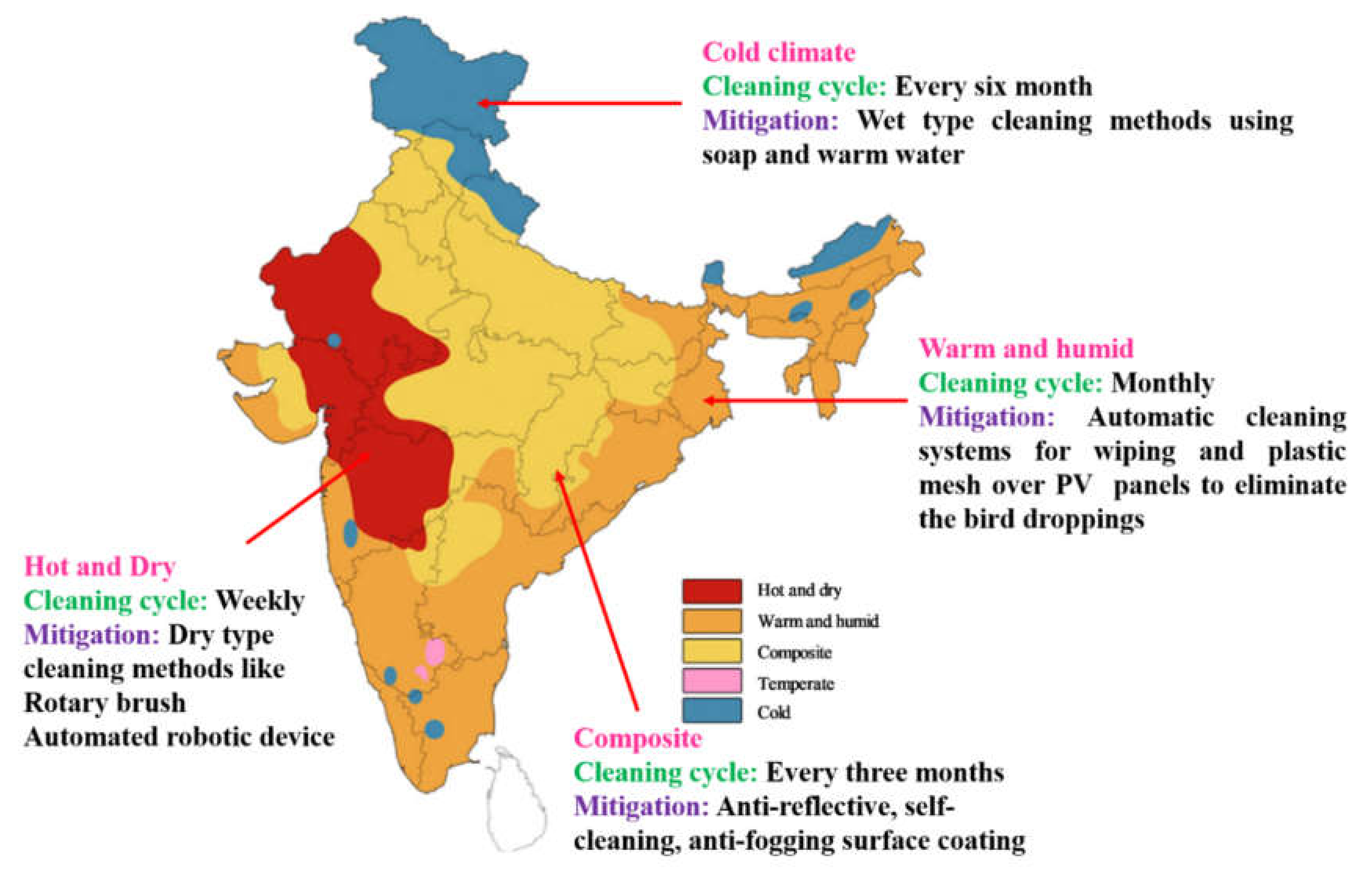

5. Impacts of Dust on India’s PV Generation and Barriers for Energy Security

6. Conclusions

Funding

Conflicts of Interest

References

- Zhiznin, S.Z.; Timohov, V.M.; Dineva, V. Energy security: Theoretical interpretations and quantitative evaluation. Int. J. Energy Econ. Policy 2020, 10, 390–400. [Google Scholar] [CrossRef]

- Miller, B.G. Coal and energy security. Clean Coal Eng. Technol. 2011, 585–612. [Google Scholar] [CrossRef]

- Speight, J.G. Energy security and the environment. Nat. Gas 2019, 361–390. [Google Scholar] [CrossRef]

- Jakstas, T. What Does Energy Security Mean? Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 9780128176887. [Google Scholar]

- Ghosh, A. Possibilities and challenges for the inclusion of the Electric Vehicle (EV) to reduce the carbon footprint in the transport sector: A review. Energies 2020, 13, 2602. [Google Scholar] [CrossRef]

- McKinsey & Company. Global Energy Perspective 2019: Reference Case; Energy Insights: New York, NY, USA, 2019; p. 31. [Google Scholar]

- Mills, A.D.; Levin, T.; Wiser, R.; Seel, J.; Botterud, A. Impacts of variable renewable energy on wholesale markets and generating assets in the United States: A review of expectations and evidence. Renew. Sustain. Energy Rev. 2020, 120, 109670. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Abeykoon, C.; Damo, U.M.; Turan, A. The current and emerging renewable energy technologies for power generation in Nigeria: A review. Therm. Sci. Eng. Prog. 2019, 13, 100390. [Google Scholar] [CrossRef]

- Vakulchuk, R.; Overland, I.; Scholten, D. Renewable energy and geopolitics: A review. Renew. Sustain. Energy Rev. 2020, 122, 109547. [Google Scholar] [CrossRef]

- Xu, R.; Song, Z.; Tang, Q.; Yu, Z. The cost and marketability of renewable energy after power market reform in China: A review. J. Clean. Prod. 2018, 204, 409–424. [Google Scholar]

- Bourcet, C. Empirical determinants of renewable energy deployment: A systematic literature review. Energy Econ. 2020, 85, 104563. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2019; IEA: Paris, France, 2019. [Google Scholar]

- Ghosh, A.; Sundaram, S.; Mallick, T.K. Investigation of thermal and electrical performances of a combined semi- transparent PV-vacuum glazing. Appl. Energy 2018, 228, 1591–1600. [Google Scholar] [CrossRef]

- Ghosh, A.; Selvaraj, P.; Sundaram, S.; Mallick, T.K. The colour rendering index and correlated colour temperature of dye-sensitized solar cell for adaptive glazing application. Sol. Energy 2018, 163, 537–544. [Google Scholar] [CrossRef]

- Alrashidi, H.; Ghosh, A.; Issa, W.; Sellami, N.; Mallick, T.K.; Sundaram, S. Evaluation of solar factor using spectral analysis for CdTe photovoltaic glazing. Mater. Lett. 2019, 237, 332–335. [Google Scholar] [CrossRef]

- Selvaraj, P.; Ghosh, A.; Mallick, T.K.; Sundaram, S. Investigation of semi-transparent dye-sensitized solar cells for fenestration integration. Renew. Energy 2019, 141, 516–525. [Google Scholar] [CrossRef]

- Ghosh, A.; Sarmah, N.; Sundaram, S.; Mallick, T.K. Numerical studies of thermal comfort for semi-transparent building integrated photovoltaic ( BIPV )-vacuum glazing system. Sol. Energy 2019, 190, 608–616. [Google Scholar] [CrossRef]

- Roy, A.; Ghosh, A.; Bhandari, S.; Selvaraj, P.; Sundaram, S.; Mallick, T.K. Color Comfort evaluation of Dye-Sensitized Solar Cell (DSSC) based Building-Integrated Photovoltaic (BIPV) glazing after 2 years of ambient exposure. J. Phys. Chem. C 2019, 123, 23834–23837. [Google Scholar] [CrossRef]

- Ghosh, A.; Bhandari, S.; Sundaram, S.; Mallick, T.K. Carbon counter electrode mesoscopic ambient processed & characterised perovskite for adaptive BIPV fenestration. Renew. Energy 2020, 145, 2151–2158. [Google Scholar]

- Haegel, N.M.; Atwater, H.; Barnes, T.; Breyer, C.; Burrell, A.; Chiang, Y.-M.; De Wolf, S.; Dimmler, B.; Feldman, D.; Glunz, S.; et al. Terawatt-scale photovoltaics: Transform global energy. Science 2019, 364, 836–838. [Google Scholar] [CrossRef]

- Ghosh, A.; Sundaram, S.; Mallick, T.K. Colour properties and glazing factors evaluation of multicrystalline based semi-transparent Photovoltaic-vacuum glazing for BIPV application. Renew. Energy 2019, 131, 730–736. [Google Scholar] [CrossRef]

- Alrashidi, H.; Issa, W.; Sellami, N.; Ghosh, A.; Mallick, T.K.; Sundaram, S. Performance assessment of cadmium telluride-based semi-transparent glazing for power saving in façade buildings. Energy Build. 2020, 215, 109585. [Google Scholar] [CrossRef]

- Karthick, A.; Kalidasa Murugavel, K.; Ghosh, A.; Sudhakar, K.; Ramanan, P. Investigation of a binary eutectic mixture of phase change material for building integrated photovoltaic (BIPV) system. Sol. Energy Mater. Sol. Cells 2020, 207, 110360. [Google Scholar] [CrossRef]

- Karthick, A.; Ramanan, P.; Ghosh, A.; Stalin, B.; Kumar, R.V.; Baranilingesan, I. Performance enhancement of copper indium diselenide photovoltaic module using inorganic phase change material. Asia-Pac. J. Chem. Eng. 2020, e2480. [Google Scholar] [CrossRef]

- Alrashidi, H.; Ghosh, A.; Issa, W.; Sellami, N.; Mallick, T.K.; Sundaram, S. Thermal performance of semitransparent CdTe BIPV window at temperate climate. Sol. Energy 2020, 195, 536–543. [Google Scholar] [CrossRef]

- Smestad, G.P.; Germer, T.A.; Alrashidi, H.; Fernández, E.F.; Dey, S.; Brahma, H.; Sarmah, N.; Ghosh, A.; Sellami, N. Modelling photovoltaic soiling losses through optical characterization. Sci. Rep. 2020, 10, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Ilse, K.K.; Figgis, B.W.; Werner, M.; Naumann, V.; Hagendorf, C.; Pöllmann, H.; Bagdahn, J. Comprehensive analysis of soiling and cementation processes on PV modules in Qatar. Sol. Energy Mater. Sol. Cells 2018, 186, 309–323. [Google Scholar] [CrossRef]

- Xu, R.; Ni, K.; Hu, Y.; Si, J.; Wen, H.; Yu, D. Analysis of the optimum tilt angle for a soiled PV panel. Energy Convers. Manag. 2017, 148, 100–109. [Google Scholar] [CrossRef]

- Conceição, R.; Silva, H.G.; Mirão, J.; Collares-Pereira, M. Organic soiling: The role of pollen in PV module performance degradation. Energies 2018, 11, 294. [Google Scholar] [CrossRef]

- Sarver, T.; Al-Qaraghuli, A.; Kazmerski, L.L. A comprehensive review of the impact of dust on the use of solar energy: History, investigations, results, literature, and mitigation approaches. Renew. Sustain. Energy Rev. 2013, 22, 698–733. [Google Scholar] [CrossRef]

- Micheli, L.; Caballero, J.A.; Fernandez, E.F.; Smestad, G.P.; Nofuentes, G.; Mallick, T.; Almonacid, F. Correlating photovoltaic soiling losses to waveband and single-value. Energy 2019, 180, 376–386. [Google Scholar] [CrossRef]

- Micheli, L.; Deceglie, M.G.; Muller, M. Interpolation techniques. IEEE J. Photovolt. 2018. [Google Scholar] [CrossRef]

- Micheli, L.; Fernandez, E.F.; Smestad, G.P.; Alrashidi, H.; Sarmah, N.; Sellami, N.; Hassan, I.A.I.; Kasry, A.; Nofuentes, G.; Sood, N.; et al. A unified global investigation on the spectral effects of soiling losses of PV glass substrates: Preliminary results. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 2858–2863. [Google Scholar]

- Micheli, L.; Muller, M. An investigation of the key parameters for predicting PV soiling losses. Prog. Photovolt. Res. Appl. 2017, 25, 291–307. [Google Scholar] [CrossRef]

- Bergin, M.H.; Ghoroi, C.; Dixit, D.; Schauer, J.J.; Shindell, D.T. Large reductions in solar energy production due to dust and particulate air pollution. Environ. Sci. Technol. Lett. 2017, 4, 339–344. [Google Scholar] [CrossRef]

- Costa, S.C.S.; Diniz, A.S.A.C.; Kazmerski, L.L. Solar energy dust and soiling R&D progress: Literature review update for 2016. Renew. Sustain. Energy Rev. 2018, 82, 2504–2536. [Google Scholar]

- Figgis, B.; Ennaoui, A.; Ahzi, S.; Rémond, Y. Review of PV soiling particle mechanics in desert environments. Renew. Sustain. Energy Rev. 2017, 76, 872–881. [Google Scholar] [CrossRef]

- Gupta, V.; Sharma, M.; Pachauri, R.K.; Dinesh Babu, K.N. Comprehensive review on effect of dust on solar photovoltaic system and mitigation techniques. Sol. Energy 2019, 191, 596–622. [Google Scholar] [CrossRef]

- Ilse, K.; Micheli, L.; Figgis, B.W.; Lange, K.; Daßler, D.; Hanifi, H.; Wolfertstetter, F.; Naumann, V.; Hagendorf, C.; Gottschalg, R.; et al. Techno-economic assessment of soiling losses and mitigation strategies for solar power generation. Joule 2019, 3, 2303–2321. [Google Scholar] [CrossRef]

- Ghazi, S.; Sayigh, A.; Ip, K. Dust effect on flat surfaces—A review paper. Renew. Sustain. Energy Rev. 2014, 33, 742–751. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Dust and PV performance in Nigeria: A review. Renew. Sustain. Energy Rev. 2020, 121, 109704. [Google Scholar] [CrossRef]

- Pavan, A.M.; Tessarolo, A.; Barbini, N.; Mellit, A.; Lughi, V. The effect of manufacturing mismatch on energy production for large-scale photovoltaic plants. Sol. Energy 2015, 117, 282–289. [Google Scholar] [CrossRef][Green Version]

- Kalogirou, S.A.; Agathokleous, R.; Panayiotou, G. On-site PV characterization and the effect of soiling on their performance. Energy 2013, 51, 439–446. [Google Scholar] [CrossRef]

- Qasem, H.; Betts, T.R.; Mullejans, H.; AlBusairi, H.; Gottschalg, R. Dust-induced shading on photovoltaic modules. Prog. Photovolt. Res. Appl. 2014, 22, 218–226. [Google Scholar] [CrossRef]

- Ghazi, S.; Ip, K.; Sayigh, A. Preliminary study of environmental solid particles on solar flat surfaces in the UK. Energy Procedia 2013, 42, 765–774. [Google Scholar] [CrossRef]

- Chen, J.; Pan, G.; Ouyang, J.; Ma, J.; Fu, L.; Zhang, L. Study on impacts of dust accumulation and rainfall on PV power reduction in East China. Energy 2020, 194, 116915. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T.; Pryor, T. The contribution of dust to performance degradation of PV modules in a temperate climate zone. Sol. Energy 2015, 120, 147–157. [Google Scholar] [CrossRef]

- Hachicha, A.A.; Al-Sawafta, I.; Said, Z. Impact of dust on the performance of solar photovoltaic (PV) systems under United Arab Emirates weather conditions. Renew. Energy 2019, 141, 287–297. [Google Scholar] [CrossRef]

- Elminir, H.K.; Ghitas, A.E.; Hamid, R.H.; El-Hussainy, F.; Beheary, M.M.; Abdel-Moneim, K.M. Effect of dust on the transparent cover of solar collectors. Energy Convers. Manag. 2006, 47, 3192–3203. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E. Degradation of electrical performance of a crystalline photovoltaic module due to dust deposition in northern Poland. Renew. Energy 2015, 78, 418–426. [Google Scholar] [CrossRef]

- Weber, B.; Quiñones, A.; Almanza, R.; Duran, M.D. Performance reduction of PV systems by dust deposition. Energy Procedia 2014, 57, 99–108. [Google Scholar] [CrossRef]

- Lin, J.J.; Noll, K.E.; Holsen, T.M. Dry deposition velocities as a function of particle size in the ambient atmosphere. Aerosol Sci. Technol. 1994, 20, 239–252. [Google Scholar] [CrossRef]

- Appels, R.; Lefevre, B.; Herteleer, B.; Goverde, H.; Beerten, A.; Paesen, R.; De Medts, K.; Driesen, J.; Poortmans, J. Effect of soiling on photovoltaic modules in Norway. Sol. Energy 2013, 96, 283–291. [Google Scholar] [CrossRef]

- Javed, W.; Wubulikasimu, Y.; Figgis, B.; Guo, B. Characterization of dust accumulated on photovoltaic panels in Doha, Qatar. Sol. Energy 2017, 142, 123–135. [Google Scholar] [CrossRef]

- Anderson, M.; Grandy, A.; Hastie, J.; Sweezey, A.; Ranky, R.; Mavroidis, C.; Markkopoulous, Y.P. Robotic device for cleaning photovoltaic panel arrays. Mobile Robotics 2009, 366–367. [Google Scholar]

- Said, S.A.M.; Hassan, G.; Walwil, H.M.; Al-Aqeeli, N. The effect of environmental factors and dust accumulation on photovoltaic modules and dust-accumulation mitigation strategies. Renew. Sustain. Energy Rev. 2018, 82, 743–760. [Google Scholar] [CrossRef]

- Goossens, D.; Van Kerschaever, E. Aeolian dust deposition on photovoltaic solar cells: The effects of wind velocity and airborne dust concentration on cell performance. Sol. Energy 1999, 66, 277–289. [Google Scholar] [CrossRef]

- Goossens, D.; Offer, Z.Y.; Zangvil, A. Wind tunnel experiments and field investigations of eolian dust deposition on photovoltaic solar collectors. Sol. Energy 1993, 50, 75–84. [Google Scholar] [CrossRef]

- Cuddihy, E.F. Theoretical considerations of soil retention. Sol. Energy Mater. 1980, 3, 21–33. [Google Scholar] [CrossRef]

- O’Hara, S.L.; Clarke, M.L.; Elatrash, M.S. Field measurements of desert dust deposition in Libya. Atmos. Environ. 2006, 40, 3881–3897. [Google Scholar] [CrossRef]

- Albert, R.; Albert, I.; Hornbaker, D.; Schiffer, P.; Barabási, A.L. Maximum angle of stability in wet and dry spherical granular media. Phys. Rev. E-Stat. Phys. Plasmas Fluids Relat. Interdiscip. Top. 1997, 56, R6271–R6274. [Google Scholar] [CrossRef]

- Beattie, N.S.; Moir, R.S.; Chacko, C.; Buffoni, G.; Roberts, S.H.; Pearsall, N.M. Understanding the effects of sand and dust accumulation on photovoltaic modules. Renew. Energy 2012, 48, 448–452. [Google Scholar] [CrossRef]

- Mekhilef, S.; Saidur, R.; Kamalisarvestani, M. Effect of dust, humidity and air velocity on efficiency of photovoltaic cells. Renew. Sustain. Energy Rev. 2012, 16, 2920–2925. [Google Scholar] [CrossRef]

- Sayyah, A.; Horenstein, M.N.; Mazumder, M.K. Energy yield loss caused by dust deposition on photovoltaic panels. Sol. Energy 2014, 107, 576–604. [Google Scholar] [CrossRef]

- Park, N.C.; Oh, W.W.; Kim, D.H. Effect of temperature and humidity on the degradation rate of multicrystalline silicon photovoltaic module. Int. J. Photoenergy 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T. Effect of humidity on photovoltaic performance based on experimental study. Int. J. Appl. Eng. Res. 2015, 10, 43572–43577. [Google Scholar]

- Kimber, A.; Mitchell, L.; Nogradi, S.; Wenger, H. The effect of soiling on large grid-connected photovoltaic systems in California and the Southwest Region of the United States. In Proceedings of the Conference Record of the 2006 IEEE 4th World Conference Photovoltaic Energy Conversion, WCPEC-4, Waikoloa, HI, USA, 7–12 May 2006; Volume 2, pp. 2391–2395. [Google Scholar]

- Ascencio-Vásquez, J.; Kaaya, I.; Brecl, K.; Weiss, K.A.; Topič, M. Global climate data processing and mapping of degradation mechanisms and degradation rates of PV modules. Energies 2019, 12, 4749. [Google Scholar] [CrossRef]

- Ascencio-Vásquez, J.; Brecl, K.; Topič, M. Methodology of Köppen-Geiger-Photovoltaic climate classification and implications to worldwide mapping of PV system performance. Sol. Energy 2019, 191, 672–685. [Google Scholar] [CrossRef]

- Bethea, R.M.; Barriger, M.T.; Williams, P.F.; Chin, S. Environmental effects on solar concentrator mirrors. Sol. Energy 1981, 27, 497–511. [Google Scholar] [CrossRef]

- Ramli, M.A.M.; Prasetyono, E.; Wicaksana, R.W.; Windarko, N.A.; Sedraoui, K.; Al-Turki, Y.A. On the investigation of photovoltaic output power reduction due to dust accumulation and weather conditions. Renew. Energy 2016, 99, 836–844. [Google Scholar] [CrossRef]

- Nahar, N.M.; Gupta, J.P. Effect of dust on transmittance of glazing materials for solar collectors under arid zone conditions of India. Sol. Wind Technol. 1990, 7, 237–243. [Google Scholar] [CrossRef]

- Garg, H.P. Effect of dirt on transparent covers in flat-plate solar energy collectors. Solar Energy. 1974, 15, 299–302. [Google Scholar] [CrossRef]

- Bangold, R. The Physics of Blown Snad and Desert Dunes; Springer: Dordrecht, Switzerland, 1941. [Google Scholar]

- Hegazy, A.A. Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew. Energy 2001, 22, 525–540. [Google Scholar] [CrossRef]

- Negash, T. Experimental investigation of the effect of tilt angle on the dust photovoltaic module. Int. J. Energy Power Eng. 2015, 4, 227. [Google Scholar] [CrossRef]

- Cano, J.; John, J.J.; Tatapudi, S.; Tamizhmani, G. Effect of tilt angle on soiling of photovoltaic modules. In Proceedings of the IEEE 40th Photovoltaic Specialists Conference PVSC 2014, Denver, CO, USA, 8–13 June 2014; pp. 3174–3176. [Google Scholar]

- Ullah, A.; Imran, H.; Maqsood, Z.; Butt, N.Z. Investigation of optimal tilt angles and effects of soiling on PV energy production in Pakistan. Renew. Energy 2019, 139, 830–843. [Google Scholar] [CrossRef]

- Ullah, A.; Amin, A.; Haider, T.; Saleem, M.; Butt, N.Z. Investigation of soiling effects, dust chemistry and optimum cleaning schedule for PV modules in Lahore, Pakistan. Renew. Energy 2020, 150, 456–468. [Google Scholar] [CrossRef]

- Luque, E.G.; Antonanzas-Torres, F.; Escobar, R. Effect of soiling in bifacial PV modules and cleaning schedule optimization. Energy Convers. Manag. 2018, 174, 615–625. [Google Scholar] [CrossRef]

- García, M.; Marroyo, L.; Lorenzo, E.; Pérez, M. Soiling and other optical losses in solar-tracking PV plants in navarra. Prog. Photovolt. Res. Appl. 2011, 19, 211–217. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. An analytical indoor experimental study on the effect of soiling on PV, focusing on dust properties and PV surface material. Sol. Energy 2020, 203, 46–68. [Google Scholar] [CrossRef]

- Urrejola, E.; Antonanzas, J.; Ayala, P.; Salgado, M.; Ramírez-Sagner, G.; Cortés, C.; Pino, A.; Escobar, R. Effect of soiling and sunlight exposure on the performance ratio of photovoltaic technologies in Santiago, Chile. Energy Convers. Manag. 2016, 114, 338–347. [Google Scholar] [CrossRef]

- Cordero, R.R.; Damiani, A.; Laroze, D.; MacDonell, S.; Jorquera, J.; Sepúlveda, E.; Feron, S.; Llanillo, P.; Labbe, F.; Carrasco, J.; et al. Effects of soiling on photovoltaic (PV) modules in the Atacama Desert. Sci. Rep. 2018, 8, 1–14. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Fragos, P. Ash deposition impact on the energy performance of photovoltaic generators. J. Clean. Prod. 2011, 19, 311–317. [Google Scholar] [CrossRef]

- Lopez-Garcia, J.; Pozza, A.; Sample, T. Long-term soiling of silicon PV modules in a moderate subtropical climate. Sol. Energy 2016, 130, 174–183. [Google Scholar] [CrossRef]

- Ahmed, O.K.; Mohammed, Z.A. Dust effect on the performance of the hybrid PV/Thermal collector. Therm. Sci. Eng. Prog. 2017, 3, 114–122. [Google Scholar] [CrossRef]

- Jiang, H.; Lu, L.; Sun, K. Experimental investigation of the impact of airborne dust deposition on the performance of solar photovoltaic (PV) modules. Atmos. Environ. 2011, 45, 4299–4304. [Google Scholar] [CrossRef]

- Vivar, M.; Herrero, R.; Antón, I.; Martínez-Moreno, F.; Moretón, R.; Sala, G.; Blakers, A.W.; Smeltink, J. Effect of soiling in CPV systems. Sol. Energy 2010, 84, 1327–1335. [Google Scholar] [CrossRef]

- Qasem, H.; Betts, T.R.; Mullejans, H.; AlBusairi, H.; Gottschalg, R. Dust effect on pv modules. In Proceedings of the PVSAT-7: 7th Photovoltaic Science, Applications and Technology Conference, Edinburgh, Scotland, UK, 6–8 April 2011. [Google Scholar]

- Dorobantu, L.; Popescu, M.O.; Popescu, C.I.; Craciunescu, A. The effect of surface impurities on photovoltaic panels. Renew. Energy Power Qual. J. 2011, 1, 622–626. [Google Scholar] [CrossRef]

- Abderrezek, M.; Fathi, M. Experimental study of the dust effect on photovoltaic panels’ energy yield. Sol. Energy 2017, 142, 308–320. [Google Scholar] [CrossRef]

- Touati, F.; Massoud, A.; Abu-Hamad, J.; Saeed, S. Effects of environmental and climatic conditions on PV efficiency in qatar. Renew. Energy Power Qual. J. 2013, 1, 275. [Google Scholar] [CrossRef]

- Andrea, Y.; Pogrebnaya, T.; Kichonge, B. Effect of industrial dust deposition on photovoltaic module performance: Experimental measurements in the tropical region. Int. J. Photoenergy 2019, 2019. [Google Scholar] [CrossRef]

- Rao, A.; Pillai, R.; Mani, M.; Ramamurthy, P. Influence of dust deposition on photovoltaic panel performance. Energy Procedia 2014, 54, 690–700. [Google Scholar] [CrossRef]

- Mani, M.; Pillai, R. Impact of dust on solar photovoltaic (PV) performance: Research status, challenges and recommendations. Renew. Sustain. Energy Rev. 2010, 14, 3124–3131. [Google Scholar] [CrossRef]

- Bellmann, P.; Wolfertstetter, F.; Conceição, R.; Silva, H.G. Comparative modeling of optical soiling losses for CSP and PV energy systems. Sol. Energy 2020, 197, 229–237. [Google Scholar] [CrossRef]

- He, G.; Zhou, C.; Li, Z. Review of self-cleaning method for solar cell array. Procedia Eng. 2011, 16, 640–645. [Google Scholar] [CrossRef]

- Maghami, M.R.; Hizam, H.; Gomes, C.; Radzi, M.A.; Rezadad, M.I.; Hajighorbani, S. Power loss due to soiling on solar panel: A review. Renew. Sustain. Energy Rev. 2016, 59, 1307–1316. [Google Scholar] [CrossRef]

- Gaier, J.R.; Perezdavis, M.E.; Marabito, M. Aeolian removal of dust types from photovoltaic surfaces on Mars. In Proceedings of the 16th Space Simulation Conference, Albuquerque, NM, USA, 5–8 November 1990; Volume 3096, pp. 379–396. [Google Scholar]

- Al-Housani, M.; Bicer, Y.; Koç, M. Assessment of various dry photovoltaic cleaning techniques and frequencies on the power output of CdTe-type modules in dusty environments. Sustainability 2019, 11, 2850. [Google Scholar] [CrossRef]

- Masuda, S.; Fujibayashi, K.; Ishida, K.; Inaba, H. Confinement and transportation of charged aerosol clouds via electric curtain. Electr. Eng. Jpn. 1972, 92, 43–52. [Google Scholar] [CrossRef]

- Calle, C.I.; Buhler, C.R.; McFall, J.L.; Snyder, S.J. Particle removal by electrostatic and dielectrophoretic forces for dust control during lunar exploration missions. J. Electrost. 2009, 67, 89–92. [Google Scholar] [CrossRef]

- Kawamoto, H.; Uchiyama, M.; Cooper, B.L.; McKay, D.S. Mitigation of lunar dust on solar panels and optical elements utilizing electrostatic traveling-wave. J. Electrost. 2011, 69, 370–379. [Google Scholar] [CrossRef]

- Kawamoto, H.; Shibata, T. Electrostatic cleaning system for removal of sand from solar panels. J. Electrost. 2015, 73, 65–70. [Google Scholar] [CrossRef]

- Guo, B.; Javed, W.; Khoo, Y.S.; Figgis, B. Solar PV soiling mitigation by electrodynamic dust shield in field conditions. Sol. Energy 2019, 188, 271–277. [Google Scholar] [CrossRef]

- Guo, B.; Javed, W. Efficiency of electrodynamic dust shield at dust loading levels relevant to solar energy applications. IEEE J. Photovolt. 2018, 8, 196–202. [Google Scholar] [CrossRef]

- Guo, B.; Javed, W.; Pett, C.; Wu, C.Y.; Scheffe, J.R. Electrodynamic dust shield performance under simulated operating conditions for solar energy applications. Sol. Energy Mater. Sol. Cells 2018, 185, 80–85. [Google Scholar] [CrossRef]

- Guo, B.; Figgis, B.; Javed, W. Measurement of electrodynamic dust shield efficiency in field conditions. J. Electrost. 2019, 97, 26–30. [Google Scholar] [CrossRef]

- Kumar, N.M.; Sudhakar, K.; Samykano, M.; Sukumaran, S. Dust cleaning robots (DCR) for BIPV and BAPV solar power plants-A conceptual framework and research challenges. Procedia Comput. Sci. 2018, 133, 746–754. [Google Scholar] [CrossRef]

- Al Baloushi, A.; Saeed, M.; Marwan, S.; Algghafri, S.; Moumouni, Y. Portable robot for cleaning photovoltaic system: Ensuring consistent and optimal year-round photovoltaic panel performance. In Proceedings of the 2018 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, UAE, 6 February–5 April 2018; pp. 1–4. [Google Scholar]

- Ganesh, V.A.; Raut, H.K.; Nair, A.S.; Ramakrishna, S. A review on self-cleaning coatings. J. Mater. Chem. 2011, 21, 16304–16322. [Google Scholar] [CrossRef]

- Mehmood, U.; Al-sulaiman, F.A.; Yilbas, B.S.; Salhi, B.; Ahmed, S.H.A.; Hossain, M.K. Solar energy materials & solar cells superhydrophobic surfaces with antire flection properties for solar applications: A critical review. Sol. Energy Mater. Sol. Cells 2016, 157, 604–623. [Google Scholar]

- Bhushan, B. Biomimetics: Lessons from Nature—An overview. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 1445–1486. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Li, S.; Li, Y.; Li, H.; Zhang, L.; Zhai, J.; Song, Y.; Liu, B.; Jiang, L.; Zhu, D.; et al. Super-hydrophobic surfaces: From natural to artificial. Adv. Mater. 2002, 14, 1857–1860. [Google Scholar] [CrossRef]

- Bixler, G.D.; Bhushan, B. Bioinspired rice leaf and butterfly wing surface structures combining shark skin and lotus effects. Soft Matter 2012, 8, 11271–11284. [Google Scholar] [CrossRef]

- Bohn, H.F.; Federle, W. Insect aquaplaning: Nepenthes pitcher plants capture prey with the peristome, a fully wettable water-lubricated anisotropic surface. Proc. Natl. Acad. Sci. USA. 2004, 101, 14138–14143. [Google Scholar] [CrossRef]

- Nishimoto, S.; Bhushan, B. RSC Advances Bioinspired self-cleaning surfaces with superhydrophobicity, superoleophobicity, and superhydrophilicity. RSC Adv. 2013, 3, 671–690. [Google Scholar] [CrossRef]

- Jesus, M.A.M.L.d.; Neto, J.T.d.S.; Timò, G.; Paiva, P.R.P.; Dantas, M.S.S.; Ferreira, A.d.M. Superhydrophilic self-cleaning surfaces based on TiO2 and TiO2/SiO2 composite films for photovoltaic module cover glass. Appl. Adhes. Sci. 2015, 3, 169. [Google Scholar] [CrossRef]

- Zhong, H.; Hu, Y.; Wang, Y.; Yang, H. TiO2/silane coupling agent composed of two layers structure: A super-hydrophilic self-cleaning coating applied in PV panels. Appl. Energy 2017, 204, 932–938. [Google Scholar] [CrossRef]

- Fares, E.; Bicer, Y. Comparative performance evaluation of c-Si and GaAs type PV cells with and without anti-soiling coating using energy and exergy analysis. Renew. Energy 2020, 146, 1010–1020. [Google Scholar] [CrossRef]

- Nundy, S.; Ghosh, A.; Mallick, T.K. Hydrophilic and superhydrophilic self-cleaning coatings by morphologically varying ZnO microstructures for photovoltaic and glazing applications. ACS Omega 2020, 5, 1033–1039. [Google Scholar] [CrossRef]

- Pan, A.; Lu, H.; Zhang, L.Z. Experimental investigation of dust deposition reduction on solar cell covering glass by different self-cleaning coatings. Energy 2019, 181, 645–653. [Google Scholar] [CrossRef]

- Oehler, G.C.; Lisco, F.; Bukhari, F.; Uličná, S.; Strauss, B.; Barth, K.L.; Walls, J.M. Testing the durability of anti-soiling coatings for solar cover glass by outdoor exposure in Denmark. Energies 2020, 13, 299. [Google Scholar] [CrossRef]

- Aslam, O.P.M. Badruddin study of the influence of solar variability on a regional (Indian) climate: 1901–2007. Adv. Space Res. 2014, 54, 1698–1703. [Google Scholar] [CrossRef]

- Avashia, V.; Garg, A. Implications of land use transitions and climate change on local flooding in urban areas: An assessment of 42 Indian cities. Land Use Policy 2020, 95, 104571. [Google Scholar] [CrossRef]

- Makade, R.G.; Chakrabarti, S.; Jamil, B.; Sakhale, C.N. Estimation of global solar radiation for the tropical wet climatic region of India: A theory of experimentation approach. Renew. Energy 2020, 146, 2044–2059. [Google Scholar] [CrossRef]

- Ali, M.; Jamil, B. Fakhruddin estimating diffuse solar radiation in India: Performance characterization of generalized single-input empirical models. Urban Clim. 2019, 27, 314–350. [Google Scholar] [CrossRef]

- British Petroleum. BP Energy Outlook—2019: Insights from the Evolving Transition Scenario—India; BP: London, UK, 2019; pp. 1–2. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/energy-outlook/bp-energy-outlook-2019-country-insight-india.pdf (accessed on 28 May 2020).

- Kumar Shukla, U.; Sharma, S. The potential of electricity imports to meet future electricity requirements in India. Electr. J. 2017, 30, 71–84. [Google Scholar] [CrossRef]

- Laha, P.; Chakraborty, B.; Østergaard, P.A. Electricity system scenario development of India with import independence in 2030. Renew. Energy 2019, 151, 627–639. [Google Scholar] [CrossRef]

- IEA. Total Primary Energy Supply 2017; IEA: Paris, France, 2019; Available online: https://www.iea.org/regions/asia-pacific (accessed on 28 May 2020).

- Das, B.; Suresh, A.; Dash, P.S.; Chandra, S.; Díaz, M.C.; Stevens, L.A.; Snape, C.E. Understanding the unusual fluidity characteristics of high ash Indian bituminous coals. Fuel Process. Technol. 2018, 176, 258–266. [Google Scholar] [CrossRef]

- Mahapatro, A.; Mahanta, P. Gasification studies of low-grade Indian coal and biomass in a lab-scale pressurized circulating fluidized bed. Renew. Energy 2019, 150, 1151–1159. [Google Scholar] [CrossRef]

- Bambawale, M.J.; Sovacool, B.K. India’s energy security: A sample of business, government, civil society, and university perspectives. Energy Policy 2011, 39, 1254–1264. [Google Scholar] [CrossRef]

- Sharma, A. India and energy security. Asian Aff. (Lond.) 2007, 38, 158–172. [Google Scholar] [CrossRef]

- Parikh, K.S.; Parikh, J.K.; Ghosh, P.P. Can India grow and live within a 1.5 degree CO2 emissions budget? Energy Policy 2018, 120, 24–37. [Google Scholar] [CrossRef]

- Dhar, S.; Pathak, M.; Shukla, P.R. Transformation of India’s steel and cement industry in a sustainable 1.5 °C world. Energy Policy 2020, 137, 111104. [Google Scholar] [CrossRef]

- Sarangi, G.K.; Mishra, A.; Chang, Y.; Taghizadeh-Hesary, F. Indian electricity sector, energy security and sustainability: An empirical assessment. Energy Policy 2019, 135, 110964. [Google Scholar] [CrossRef]

- Hairat, M.K.; Ghosh, S. 100 GW solar power in India by 2022 – A critical review. Renew. Sustain. Energy Rev. 2017, 73, 1041–1050. [Google Scholar] [CrossRef]

- Gupta, D.; Ghersi, F.; Vishwanathan, S.S.; Garg, A. Achieving sustainable development in India along low carbon pathways: Macroeconomic assessment. World Dev. 2019, 123, 104623. [Google Scholar] [CrossRef]

- Behuria, P. The politics of late late development in renewable energy sectors: Dependency and contradictory tensions in India’s National Solar Mission. World Dev. 2020, 126, 104726. [Google Scholar] [CrossRef]

- Charles Rajesh Kumar, J.; Majid, M.A. Renewable energy for sustainable development in India: Current status, future prospects, challenges, employment, and investment opportunities. Energy Sustain. Soc. 2020, 10, 1–36. [Google Scholar]

- Goel, M. Solar rooftop in India: Policies, challenges and outlook. Green Energy Environ. 2016, 1, 129–137. [Google Scholar] [CrossRef]

- Raina, G.; Sinha, S. Outlook on the Indian scenario of solar energy strategies: Policies and challenges. Energy Strategy Rev. 2019, 24, 331–341. [Google Scholar] [CrossRef]

- Solar Power Europe (SPE). Global Market Outlook for Solar Power: 2019–2023; Solar Power Europe: Brussels, Belgium, 2019; p. 92. Available online: https://www.solarpowereurope.org/global-market-outlook-2019-2023/ (accessed on 28 May 2020).

- Parnell, J. World’s Largest Solar Project will also Be Its Cheapest 2020; Greentechmedia: Boston, MA, USA, 2020; Available online: https://www.greentechmedia.com/articles/read/worlds-largest-solar-project-will-also-be-worlds-cheapest (accessed on 28 May 2020).

- Lam, N.L.; Smith, K.R.; Gauthier, A.; Bates, M.N. Kerosene: A review of household uses and their hazards in low-and middle-income countries. J. Toxicol. Environ. Heal.-Part B Crit. Rev. 2012, 15, 396–432. [Google Scholar] [CrossRef]

- Kumar, A.; Prakash, O.; Dube, A. A review on progress of concentrated solar power in India. Renew. Sustain. Energy Rev. 2017, 79, 304–307. [Google Scholar] [CrossRef]

- Singh, Y.; Pal, N. Obstacles and comparative analysis in the advancement of photovoltaic power stations in India. Sustain. Comput. Inform. Syst. 2020, 25, 100372. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Chauhan, D.S.; Singh, R.P. Decentralized solar rooftop photovoltaic in India: On the path of sustainable energy security. Renew. Energy 2019, 131, 297–307. [Google Scholar] [CrossRef]

- Chattopadhyay, M.; Chattopadhyay, D. Analysis of Indian renewable energy policy using climate data. Electr. J. 2012, 25, 81–93. [Google Scholar] [CrossRef]

- Liu, T.; Marlier, M.E.; DeFries, R.S.; Westervelt, D.M.; Xia, K.R.; Fiore, A.M.; Mickley, L.J.; Cusworth, D.H.; Milly, G. Seasonal impact of regional outdoor biomass burning on air pollution in three Indian cities: Delhi, Bengaluru, and Pune. Atmos. Environ. 2018, 172, 83–92. [Google Scholar] [CrossRef]

- Müller, J.; Mitra, I.; Mieslinger, T.; Meyer, R.; Chhatbar, K.; Gomathinayagam, S.; Giridhar, G. Towards building solar in India—A combined mapping and monitoring approach for creating a new solar atlas. Energy Sustain. Dev. 2017, 40, 31–40. [Google Scholar] [CrossRef]

- Chandrashekhar, V. Air Pollution in India reducing Solar Power Yield by 17–25%; The Times of India: Delhi, India, 2017; Available online: https://timesofindia.indiatimes.com/home/environment/pollution/air-pollution-in-india-reducing-solar-power-yield-by-17-25-study/articleshow/58378057.cms? (accessed on 28 May 2020).

- Gadi, R.; Saxena, M.; Sharma, S.K.; Mandal, T.K. Short-term degradation of air quality during major firework events in Delhi, India. Meteorol. Atmos. Phys. 2019, 131, 753–764. [Google Scholar]

- Rajaram, B.S.; Suryawanshi, P.V.; Bhanarkar, A.D.; Rao, C.V.C. Heavy metals contamination in road dust in Delhi city, India. Environ. Earth Sci. 2014, 72, 3929–3938. [Google Scholar] [CrossRef]

- Badarinath, K.V.S.; Kharol, S.K.; Kaskaoutis, D.G.; Kambezidis, H.D. Case study of a dust storm over Hyderabad area, India: Its impact on solar radiation using satellite data and ground measurements. Sci. Total Environ. 2007, 384, 316–332. [Google Scholar] [CrossRef] [PubMed]

- Mani, F.; Pulipaka, S.; Kumar, R. Characterization of power losses of a soiled PV panel in Shekhawati region of India. Sol. Energy 2016, 131, 96–106. [Google Scholar] [CrossRef]

- Boddupalli, N.; Singh, G.; Chandra, L.; Bandyopadhyay, B. Reprint of: Dealing with dust—Some challenges and solutions for enabling solar energy in desert regions. Sol. Energy 2017, 154, 134–143. [Google Scholar] [CrossRef]

- Yadav, N.K.; Pala, D.; Chandra, L. On the understanding and analyses of dust deposition on Heliostat. Energy Procedia 2014, 57, 3004–3013. [Google Scholar] [CrossRef]

- Vaishak, S.; Bhale, P.V. Effect of dust deposition on performance characteristics of a refrigerant based photovoltaic/thermal system. Sustain. Energy Technol. Assess. 2019, 36, 100548. [Google Scholar] [CrossRef]

- Waldl, H.P.; Das, P.K. Impact of soiling on energy yield of solar PV power plant and developing soiling correction factor for solar pv power forecasting. In Proceedings of the 2nd International Conference on Large-Scale Grid Integration of Renewable Energy in India, New Delhi, India, 4–6 September 2019. [Google Scholar]

- Perry, N. Air Pollution Throws Shade on India’s Solar Success; AFP: Gandhinagar, India, 2017; Available online: https://www.breitbart.com/news/air-pollution-throws-shade-on-indias-solar-success/ (accessed on 28 May 2020).

- Shiva Kumar, B.; Sudhakar, K. Performance evaluation of 10 MW grid connected solar photovoltaic power plant in India. Energy Rep. 2015, 1, 184–192. [Google Scholar] [CrossRef]

- Tejwani, R.; Solanki, C.S. 360° sun tracking with automated cleaning system for solar PV modules. In Proceedings of the 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 2895–2898. [Google Scholar]

| Location | Major Elements | Major Oxides | Origin | |

|---|---|---|---|---|

| Hangzhou (30.25° N, 120.16°), China | Si, Ca, Al, Fe, K, Mg, Na | SiO2, Al2O3, CaO, Fe2O3 | Sand, potash feldspar, straw burning, mechanical wear | [46] |

| Perth (56.39° N, –3.43° E), Australia | Si, Ca, Al, Fe, K | Calcium oxide, quartz, orthoclase (KAlSi3O8) | Acidic and sandy soils from deserts | [47] |

| Doha (25.29° N, 51.51° E), Qatar | Ca, Si, Fe, Mg, Al | Calcite (Ca(CO3)), dolomite (CaMg(CO3)2, quartz (SiO2) | Dolomite, calcite, building, local soil | |

| UAE | SiO2, Fe2O3, CaO | Human activities, wind-blown dust coming from the Arabian Peninsula | [48] | |

| Cairo (30.04° N, 31.24°), E Qatar | Si, Ca, Al, Fe, Mg, K, Na | Quartz (SiO2), calcite (CaCO3) | Cement industry, desert, fossil fuel combustion | [49] |

| Northern Poland | Si, Al, Mg, Fe, K, Ca, P, S | SiO2, Al2O3, MgO | Sand, frictional elements of mechanical components | [50] |

| Location | Details |

|---|---|

| Pavagada (14.1°N, 77.28°E) Solar Park, Karnataka | Used land area 13,000 acres. Currently in operation 2050 MW. |

| Kurnool (15.68°N, 78.28°E) Ultra Mega Solar Park, Andhra Pradesh | Used land area 5932.32 acres. Capacity of 1000 MW. Consist 4000 k PV panel. |

| Kamuthi (9.40° N, 78.36° E) Solar Power Project, Tamil Nadu | Generating capacity of 648 MWp commissioned by Adani Power; consists of 2500 k PV panel. This station is connected to 400 kV substation of the Tamil Nadu Transmission Corp. PV panels are cleaned using self-charge robotic system daily. |

| Bhadla (27.53° N, 71.9° E) Solar Park, Rajasthan | Used land area of 10,000 acres. The park has total capacity of 2255 MW and commissioned power capacity is 115 MW (as of 22nd February 2017). |

| Charanka (23°54′N 71°12′E) Solar park, northern Gujarat | Used land area 5384 acres. The site is the world’s second largest photovoltaic power station and spread across 5384 acres of unused land. Presently operating capacity of 615 MW. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghosh, A. Soiling Losses: A Barrier for India’s Energy Security Dependency from Photovoltaic Power. Challenges 2020, 11, 9. https://doi.org/10.3390/challe11010009

Ghosh A. Soiling Losses: A Barrier for India’s Energy Security Dependency from Photovoltaic Power. Challenges. 2020; 11(1):9. https://doi.org/10.3390/challe11010009

Chicago/Turabian StyleGhosh, Aritra. 2020. "Soiling Losses: A Barrier for India’s Energy Security Dependency from Photovoltaic Power" Challenges 11, no. 1: 9. https://doi.org/10.3390/challe11010009

APA StyleGhosh, A. (2020). Soiling Losses: A Barrier for India’s Energy Security Dependency from Photovoltaic Power. Challenges, 11(1), 9. https://doi.org/10.3390/challe11010009