Application of Improved Particle Swarm Optimisation Algorithm in Hull form Optimisation

Abstract

:1. Introduction

2. Space Reduction Technique Based on Partial Correlation Analysis

2.1. Partial Correlation Analysis

2.2. Partial Correlation Coefficient and Degree-of-Space Reduction

3. Improved Particle Swarm Optimisation

3.1. Particle Swarm Optimisation

3.2. Improvement of Particle Swarm Optimisation

3.2.1. Data Processing of Particle Swarm Population Initialisation

3.2.2. Data Processing of Particle Iterative Optimisation

3.2.3. Particle Velocity Adjustment Strategy

3.2.4. Particle Cross-Boundary Configuration

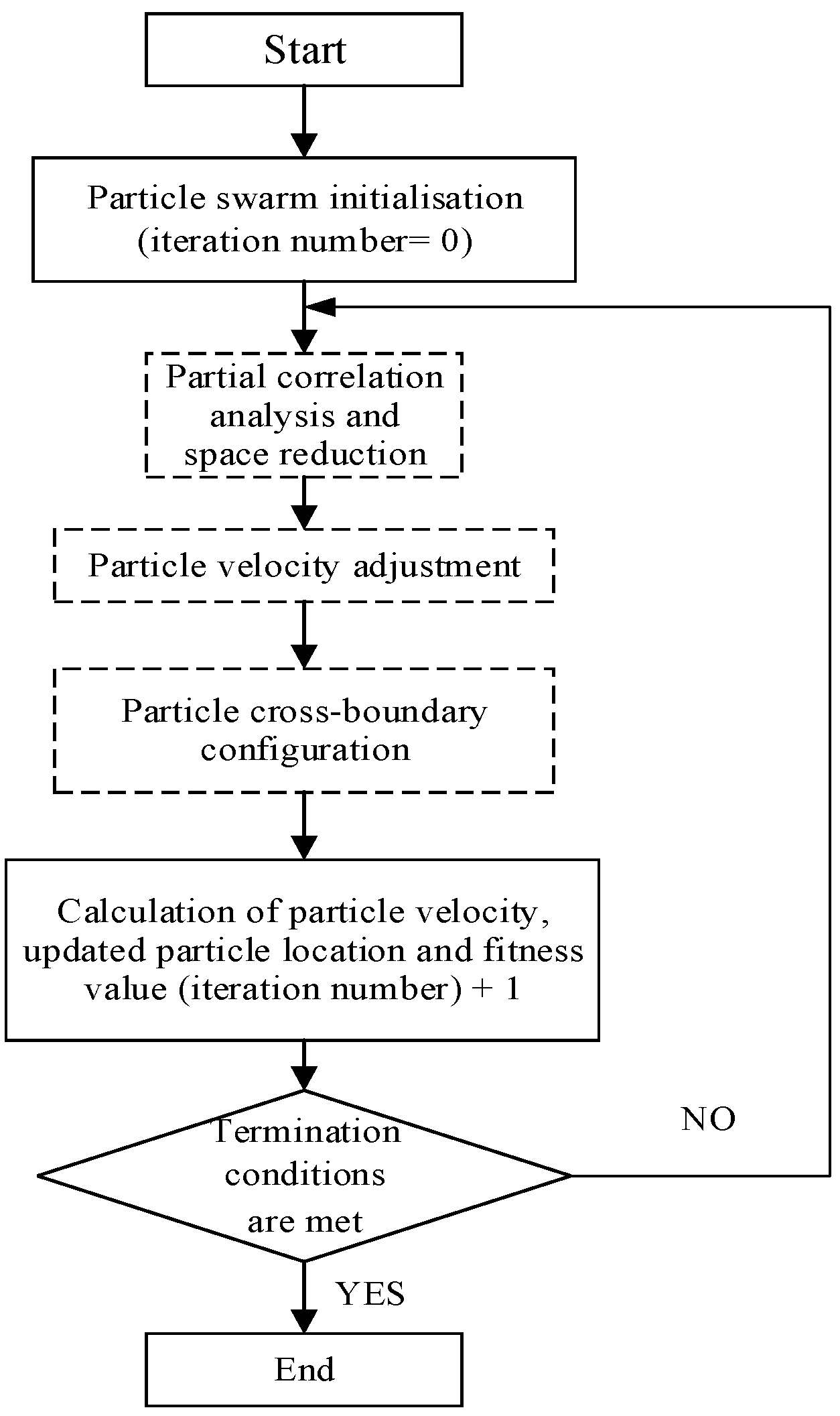

3.3. Optimisation Framework of Improved Particle Swarm Optimisation Algorithm

- (1)

- input the parameters such as the number of particles and the number of iterations at the start of the algorithm;

- (2)

- perform the initialisation process by randomised sampling using the particle swarm algorithm;

- (3)

- perform data mining on the initialisation data and perform space reduction while completing the particle velocity adjustment;

- (4)

- configure the cross-boundary particles in the iterative optimisation process, and perform data mining and space reduction after reaching a certain number of iterations;

- (5)

- determine whether the optimisation is terminated by the maximum number of iterations.

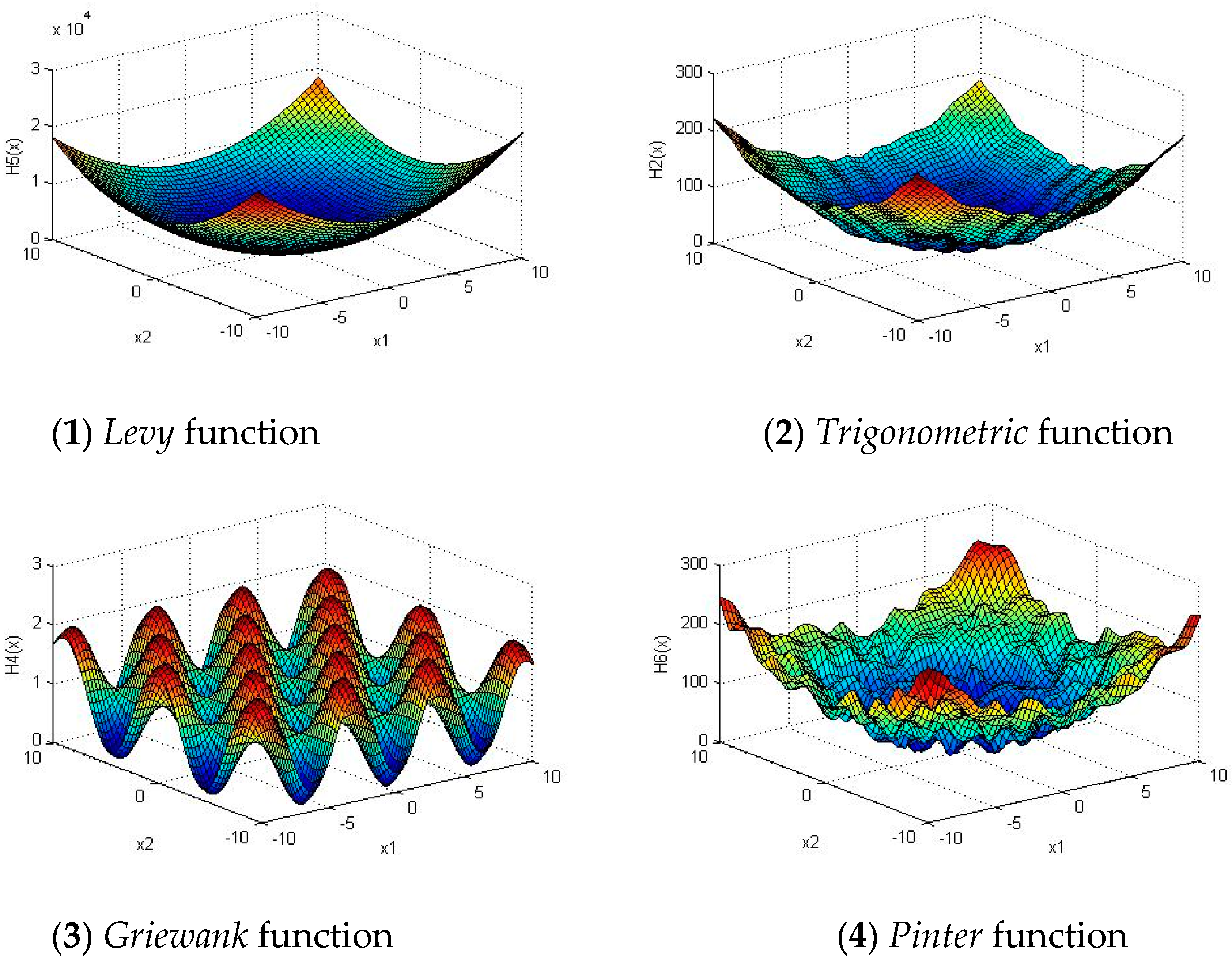

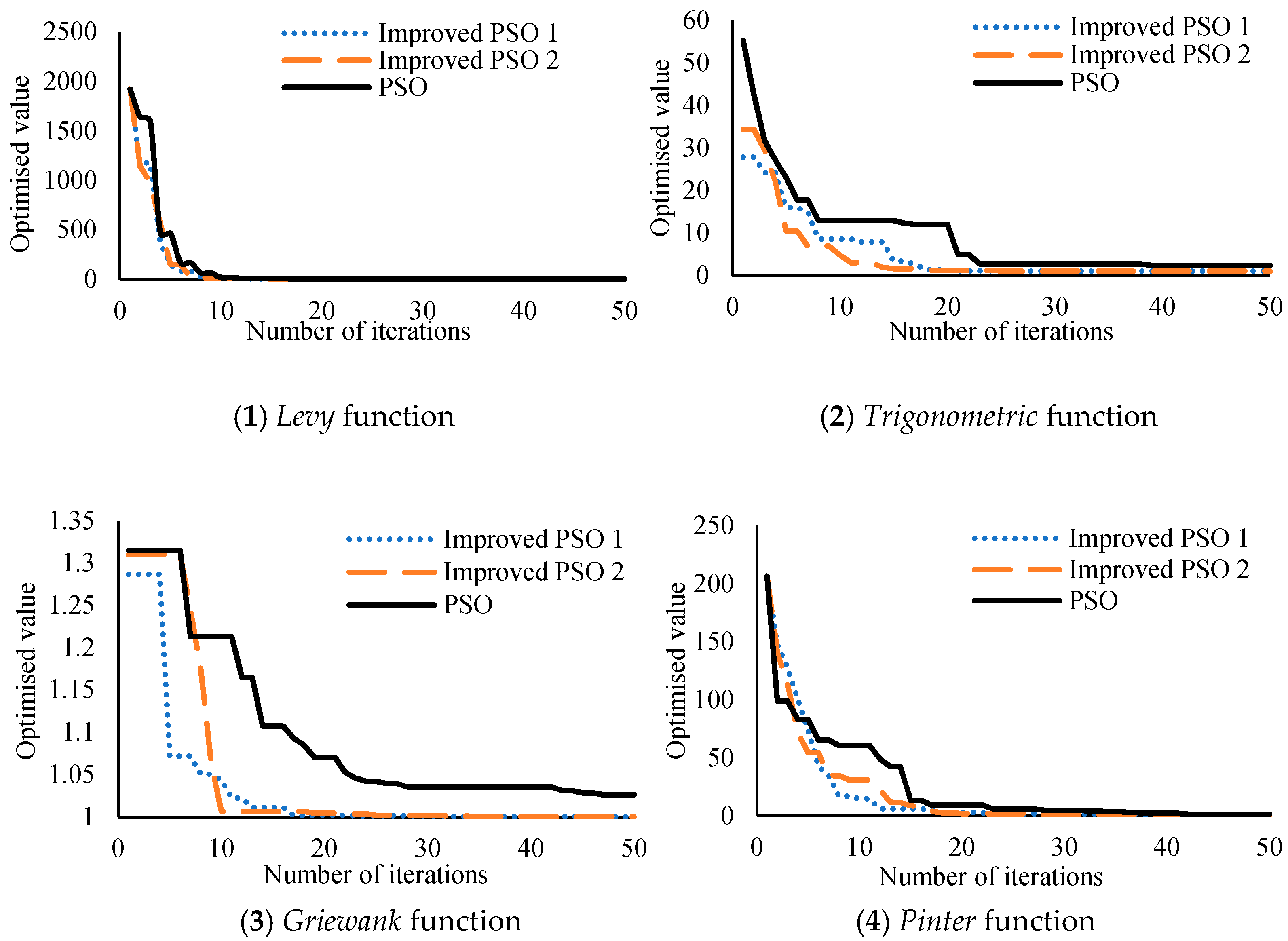

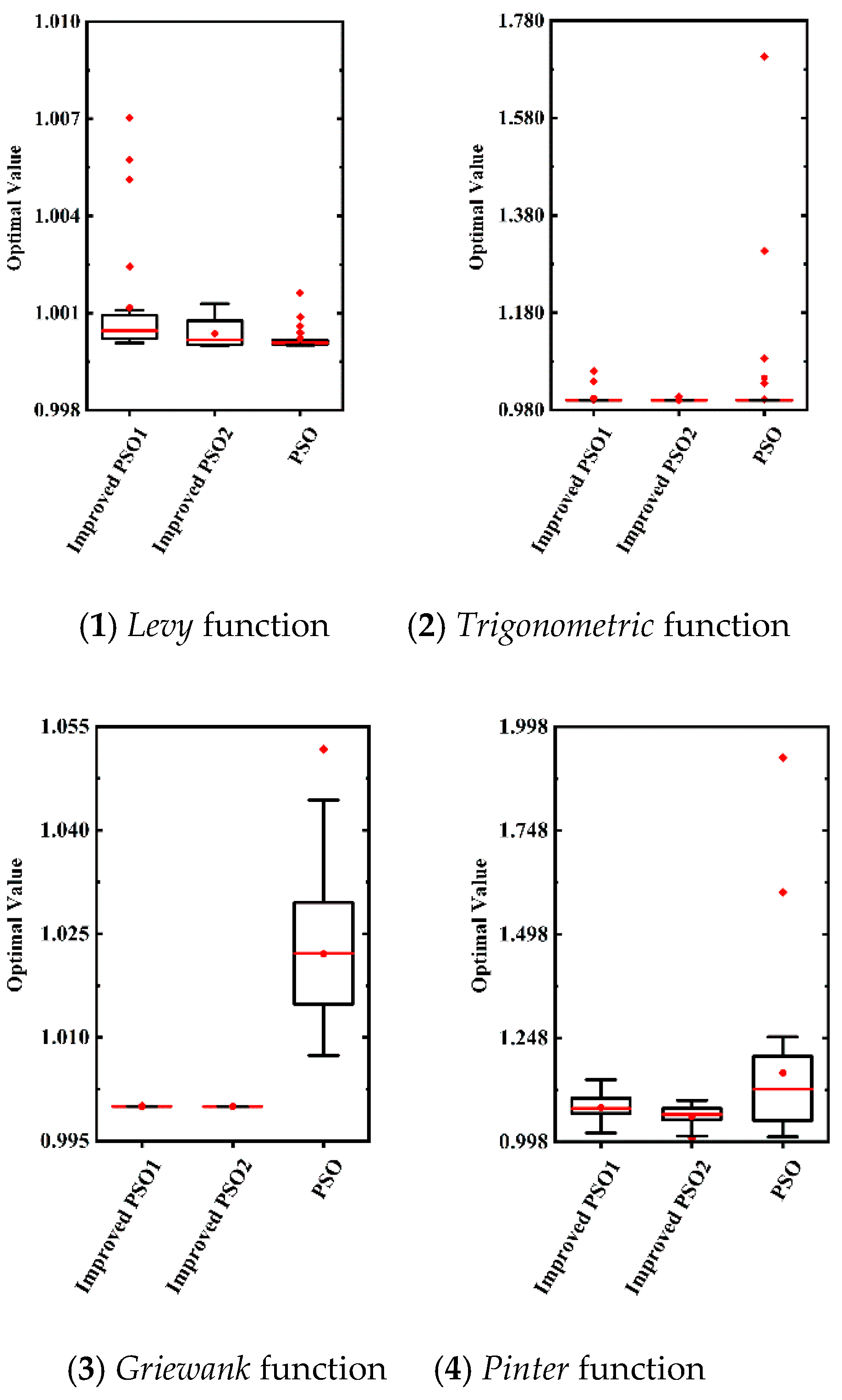

4. Function Examples of the Improved Particle Swarm Optimisation Algorithm

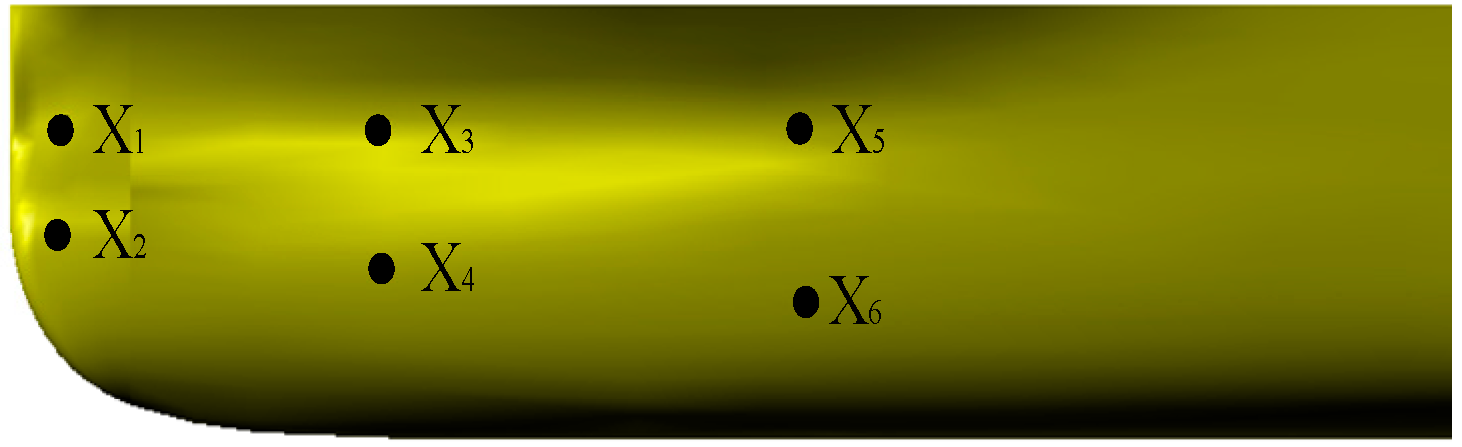

5. Bow Shape Optimisation in Engineering Vessel

5.1. Definition of Optimisation

Optimisation Problem Definition

5.2. Flowchart of Hull Form Optimisation

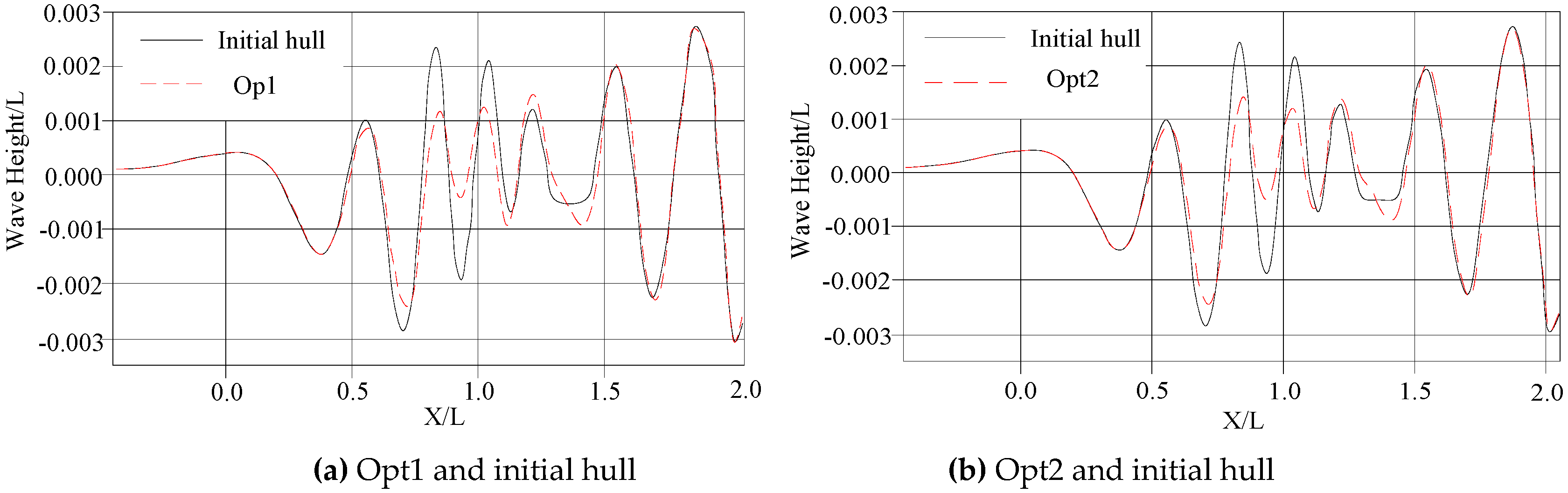

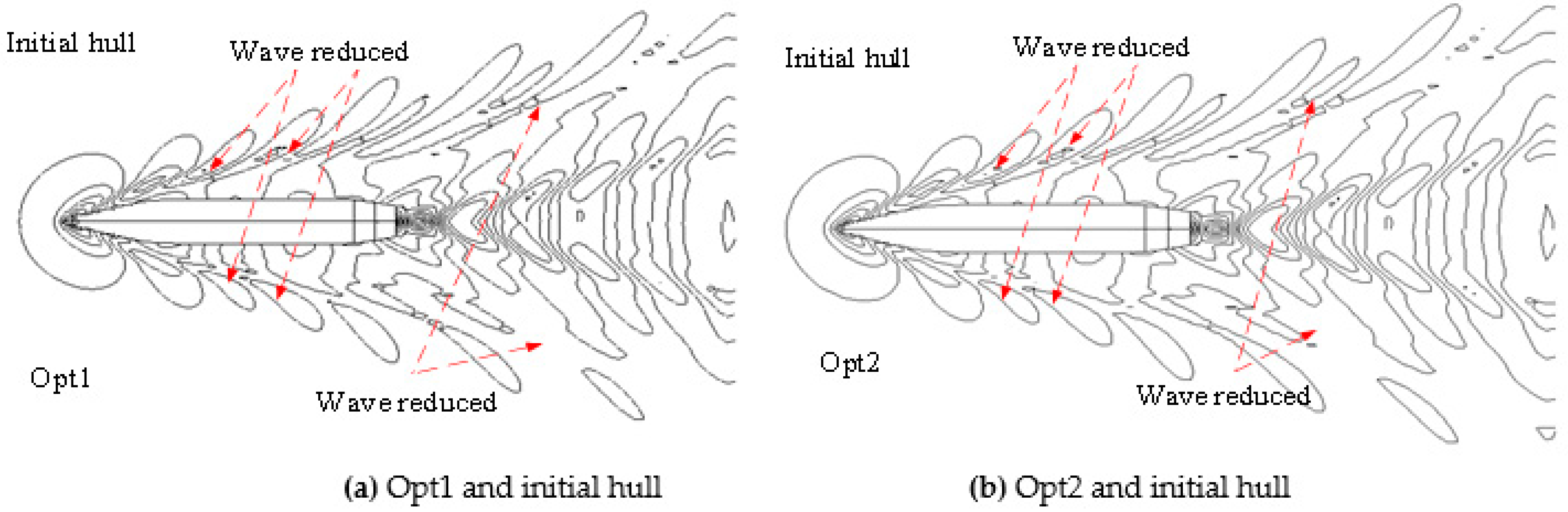

5.3. Hull Form Optimisation Results

6. Conclusions

- (1)

- For the optimisation of a simple space, the improved PSO algorithm did not significantly enhance the optimisation efficiency and performance compared with the PSO algorithm, and both algorithms can obtain fast convergence results. For more complex optimisation problems, PSO more easily falls into the local optimal solution, whereas the improved PSO algorithm can avoid the local optimum owing to datamining of the optimised data in the optimisation process, which can provide guidance on the optimisation of subsequent particles.

- (2)

- The application of the algorithm in engineering practice is verified by hull form optimisation. This algorithm can improve the optimisation efficiency to a certain extent while ensuring high performance, thus reducing the overall time of hull form optimisation. This has certain value in engineering applications.

- (3)

- Our study used partial correlation analysis for datamining. Because the coefficient obtained by a partial correlation analysis cannot directly perform space reduction, a certain relationship must be established. For optimisation with too many iterations, the segmentation reduction method and the linear reduction method may lose the optimal solution. In the particle initialisation stage, the particle information obtained cannot be evenly distributed in the optimisation space. As a result, the optimisation information obtained by the previous datamining is not accurate, leading to reduced optimisation efficiency. Further research is required to address these issues.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Campana, E.F.; Peri, D.; Tahara, Y.; Stern, F. Shape optimisation in ship hydrodynamics using computational fluid dynamics. Comput. Methods Appl. Mech. Eng. 2006, 196, 634–651. [Google Scholar] [CrossRef]

- Peri, D. Design optimisation of ship hulls via CFD technologies. J. Ship Res. 2001, 45, 140–149. [Google Scholar] [CrossRef]

- Harries, S. Systematic optimization—A key for improving ship hydrodynamics. Hansa 2005, 142, 36, 38, 40–42. [Google Scholar]

- Kim, H.; Yang, C.; Jeong, S.; Noblesse, F. Hull form design exploration based on response surface method. In Proceedings of the Twenty-first International Offshore and Polar Engineering Conference, Maui, HI, USA, 19–24 June 2011. [Google Scholar]

- Kim, H.; Yang, C. A new surface modification approach for CFD-based hull form optimisation. J. Hydrodyn. Ser. B 2010, 22, 520–525. [Google Scholar] [CrossRef]

- Kim, H.; Yang, C.; Noblesse, F. Hull form optimisation for reduced resistance and improved seakeeping via practical designed-oriented CFD tools. In Proceedings of the Conference on Grand Challenges in Modeling & Simulation, Ottawa, ON, Canada, 11 July 2010; pp. 375–385. [Google Scholar]

- Feng, B.; Hu, C.; Liu, Z.; Zhan, C.; Chang, H. Ship resistance performance optimisation design based on CAD/CFD. In Proceedings of the International Conference on Advanced Computer Control, Harbin, China, 18–20 January 2011; pp. 251–255. [Google Scholar]

- Feng, B.; Dong, S.; Chang, H. The influence of experimental design method on design space exploration. In Proceedings of the International Conference on Fuzzy Systems and Knowledge Discovery IEEE, Zhangjiajie, China, 15–17 August 2015; pp. 1681–1687. [Google Scholar]

- Shen, T.; Feng, B.; Liu, Z.; Chang, H. Research of hull form modification method based on interpolation of radial basis function. Shipbuild. China 2013, 4, 45–54. [Google Scholar]

- Chang, H.; Cheng, X.; Liu, Z.; Feng, B.; Zhan, C. Sample selection method for ship resistance performance optimisation based on approximated model. J. Ship Res. 2016, 60, 1–13. [Google Scholar] [CrossRef]

- Chang, H.; Feng, B.; Liu, Z.; Zhan, C.; Cheng, X. The application of approximate model for ship resistance performance optimisation. Shipbuild. China 2012, 1, 88–98. [Google Scholar]

- Chang, H.; Feng, B.; Liu, Z.; Zhan, C.; Cheng, X. Research on application of approximate model in hull form optimisation. Shipbuild. China 2012, 53, 88–98. [Google Scholar]

- Harries, S.; Abt, C. Faster turn-around times for the design and Optimization of functional surfaces. Ocean Eng. 2019, 193, 106470.1–106470.18. [Google Scholar] [CrossRef]

- D’Agostino, D.; Serani, A.; Diez, M. Design-space assessment and dimensionality reduction: An off-line method for shape reparameterization in simulation-based Optimization. Ocean Eng. 2020, 197, 106852. [Google Scholar] [CrossRef]

- Serani, A.; Stern, F.; Campana, E.F.; Diez, M. Hull-form stochastic Optimization via computational-cost reduction methods. Eng. Comput. 2021, 2, 1–25. [Google Scholar]

- Khan, S.; Serani, A.; Diez, M.; Kaklis, P. Physics-Informed Feature-to-Feature Learning for Design-Space Dimensionality Reduction in Shape Optimization. In Proceedings of the AIAA Scitech 2021 Forum, Music City Center Nashville, Nashville, TN, USA, 11–15 & 19–21 January 2021. [Google Scholar]

- Tezzele, M.; Salmoiraghi, F.; Mola, A.; Rozza, G. Dimension reduction in heterogeneous parametric spaces with application to naval engineering shape design problems. Adv. Modeling Simul. Eng. Sci. 2018, 5, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Serani, A.; Pellegrini, R.; Wackers, J.; Jeanson, C.E.; Diez, M. Adaptive multi-fidelity sampling for CFD-based Optimization via radial basis function metamodels. Int. J. Comput. Fluid Dyn. 2019, 33, 237–255. [Google Scholar] [CrossRef]

- Chunna, L.; Hai, F.; Chunlin, G. Development of an efficient global Optimization method based on adaptive infilling for structure Optimization. Struct. Multidiplinary Optim. 2020, 7, 3383. [Google Scholar]

- Zhang, S.; Zhang, B.; Tezdogan, T.; Xu, L.; Lai, Y. Computational fluid dynamics-based hull form Optimization using approximation method. Eng. Appl. Comput. Fluid Mech. 2018, 12, 74–88. [Google Scholar] [CrossRef] [Green Version]

- Coppedè, A.; Gaggero, S.; Vernengo, G.; Villa, D. Hydrodynamic shape Optimization by high fidelity CFD solver and Gaussian process based response surface method. Appl. Ocean Res. 2019, 90, 101841. [Google Scholar] [CrossRef]

- Pellegrini, R.; Serani, A.; Liuzzi, G.; Rinaldi, F.; Diez, M. Hybridization of Multi-Objective Deterministic Particle Swarm with Derivative-Free Local Searches. Mathematics 2020, 8, 546. [Google Scholar] [CrossRef] [Green Version]

- Tezdogan, T.; Zhang, S.; Demirel, Y.K.; Liu, W.; Xu, L.; Yuyan, L. An investigation into fishing boat optimisation using a hybrid algorithm. Ocean Eng. 2018, 167, 204–220. [Google Scholar] [CrossRef] [Green Version]

- Serani, A.; Leotardi, C.; Iemma, U.; Campana, E.F.; Fasano, G.; Diez, M. Parameter selection in synchronous and asynchronous deterministic particle swarm optimization for ship hydrodynamics problems. Appl. Soft Comput. 2016, 49, 313–334. [Google Scholar] [CrossRef] [Green Version]

- Leotardi, C.; Serani, A.; Diez, M.; Campana, E.F.; Gusso, R. Dense conjugate initialization for deterministic PSO in applications: ORTHOinit+. Appl. Soft Comput. 2021, 4, 107121. [Google Scholar] [CrossRef]

- Khalili-Damghani, K.; Abtahi, A.R.; Tavana, M. A new multi-objective particle swarm optimisation method for solving reliability redundancy allocation problems. Reliab. Eng. Syst. Saf. 2013, 111, 58–75. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R.C.; Shi, Y. The Particle Swarm. Swarm Intell. 2001, 1, 287–325. [Google Scholar]

- Angeline, P.J. Evolutionary optimization versus particle swarm optimization: Philosophy and performance differences. In Proceedings of the 7th Annual Conference on Evolutionary Programming, San Diego, CA, USA, 25–27 March 1998. [Google Scholar]

- Eberhart, R.C.; Shi, Y. Comparison between Genetic Algorithms and Particle Swarm Optimization; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Cheng, S.; Shi, Y.; Qin, Q. Dynamical exploitation space reduction in particle swarm optimisation for solving large scale problems. In Proceedings of the Evolutionary Computation, IEEE, Brisbane, QLD, Australia, 10–15 June 2012; pp. 1–8. [Google Scholar]

- Noel, M.M. A new gradient-based particle swarm optimisation algorithm for accurate computation of global minimum. Appl. Soft Comput. J. 2012, 12, 353–359. [Google Scholar] [CrossRef]

- Shi, J.; Li, P.; Liu, G.; Liu, P. Parameter Estimation of Chaotic Systems Based on Improved Particle Swarm Optimisation Algorithm. J. Huazhong Univ. Sci. Technol. 2018, 46, 70–76. [Google Scholar]

- Reungsinkonkarn, A.; Apirukvorapinit, P. Search space reduction of particle swarm optimisation for hierarchical similarity measurement model. In Proceedings of the Computer Science and Software Engineering (JCSSE), 2014 11th International Joint Conference, Chon Buri, Thailand, 14–16 May 2014. [Google Scholar]

- Zhang, L.; Sun, J.; Guo, C. A novel multi-objective discrete particle swarm optimisation with elitist perturbation for reconfiguration of ship power system. Pol. Marit. Res. 2017, 24, 1. [Google Scholar]

- Wang, J.; Li, H. Particle swarm optimisation with enhanced global search and local search. J. Intell. Syst. 2017, 26, 3. [Google Scholar]

- Wu, K.; Feng, B.; Chang, H. The design method for hull optimisation based on partial correlation analysis. Ship Eng. 2016, 10, 46–51. [Google Scholar]

- He, X. Modern Statistical Analysis Methods and Applications. Master’s Thesis, Renmin University Press, Beijing, China, 1998. [Google Scholar]

- Jia, J. Statistical Case Studies and Analysis. Master’s Thesis, Renmin University Press, Beijing, China, 2010. [Google Scholar]

- Coello, C.A.C.; Pulido, G.T.; Lechuga M, S. Handling multiple objectives with particle swarm optimisation. IEEE Trans. Evol. Comput. 2004, 8, 256–279. [Google Scholar] [CrossRef]

- Coello, C.A.C.; Lamont, G.B.; Veldhuizen, D.A.V. Evolutionary Algorithms for Solving Multi-Objective Problems; Springer: Berlin/Heidelberg, Germany, 2002; p. 576. [Google Scholar]

- Fang, K.T. Uniform design: An application of number-theoretic methods to experimental designs. Acta Math. Appl. Sin. 1980, 3, 363–372. [Google Scholar]

- Cheng, X.; Shen, T.; Feng, B.; Liu, Z. The determination method and application of support radius in hull surface deformation. Shipbuild. China 2016, 57, 127–137. [Google Scholar]

- Shen, T. The method and application of hull surface deformation based on radial basis function interpolation. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2015. [Google Scholar]

- Zheng, Q. Development and application of an interdisciplinary and comprehensive optimisation platform for ship hydrodynamic performance. In Proceedings of Digital Shipbuilding Conference in 2018; The Chinese Society of Naval Architects and Marine Engineers: Shanghai, China, 2018; p. 6. [Google Scholar]

| Range of x | [−5,5] | [−4,5] | [−3,5] | [−2,5] | [−1,5] | [0,5] |

|---|---|---|---|---|---|---|

| Variable median | x = 0 | x = 0.5 | x = 1 | x = 1.5 | x = 2 | x = 2.5 |

| Optimal value | x = 0 | |||||

| Partial correlation coefficient | −0.021 | 0.260 | 0.524 | 0.736 | 0.872 | 0.894 |

| Rij (Absolute Value) | 0.00–0.05 | 0.05–0.15 | 0.15–0.25 | 0.25–0.35 | 0.35–0.45 | 0.45–0.55 | 0.55–0.65 | 0.65–0.75 | 0.75–0.85 | 0.85–0.95 | 0.95–1.00 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Coerp | 0% | 5% | 10% | 15% | 20% | 25% | 30% | 35% | 40% | 45% | 50% |

| Function Name | Optimisation Method | Convergent Algebra | Optimisation Optimal Value | Theoretical Optimal Value |

|---|---|---|---|---|

| Levy | PSO | 12 | 1.296 | 1 |

| Improved PSO 1 | 11 | 1.250 | ||

| Improved PSO 2 | 11 | 1.001 | ||

| Trigonometric | PSO | 39 | 2.332 | 1 |

| Improved PSO 1 | 21 | 1.000 | ||

| Improved PSO 2 | 20 | 1.000 | ||

| Griewank | PSO | 28 | 1.026 | 1 |

| Improved PSO 1 | 16 | 1.000 | ||

| Improved PSO 2 | 10 | 1.000 | ||

| Pinter | PSO | 35 | 1.423 | 1 |

| Improved PSO 1 | 18 | 1.050 | ||

| Improved PSO 2 | 19 | 1.011 |

| Length between Perpendiculars Lpp (m) | Waterline Width Bwl (m) | Draft T (m) | Block Coefficient Cb | Drainage Volume (m3) | Wet Surface Area Swet (m2) | Floating Centre Longitudinal Position Lcb (m) |

|---|---|---|---|---|---|---|

| 4.995 | 0.770 | 0.255 | 0.674 | 0.646 | 4.764 | 2.518 m |

| Optimisation Variable | Lower Limit | Upper Limit |

|---|---|---|

| Y1 | 0.01000 | 0.01300 |

| Y2 | 0.04000 | 0.06000 |

| Y3 | 0.07200 | 0.09700 |

| Y4 | 0.08500 | 0.12500 |

| Y5 | 0.20000 | 0.24000 |

| Y6 | 0.17000 | 0.22000 |

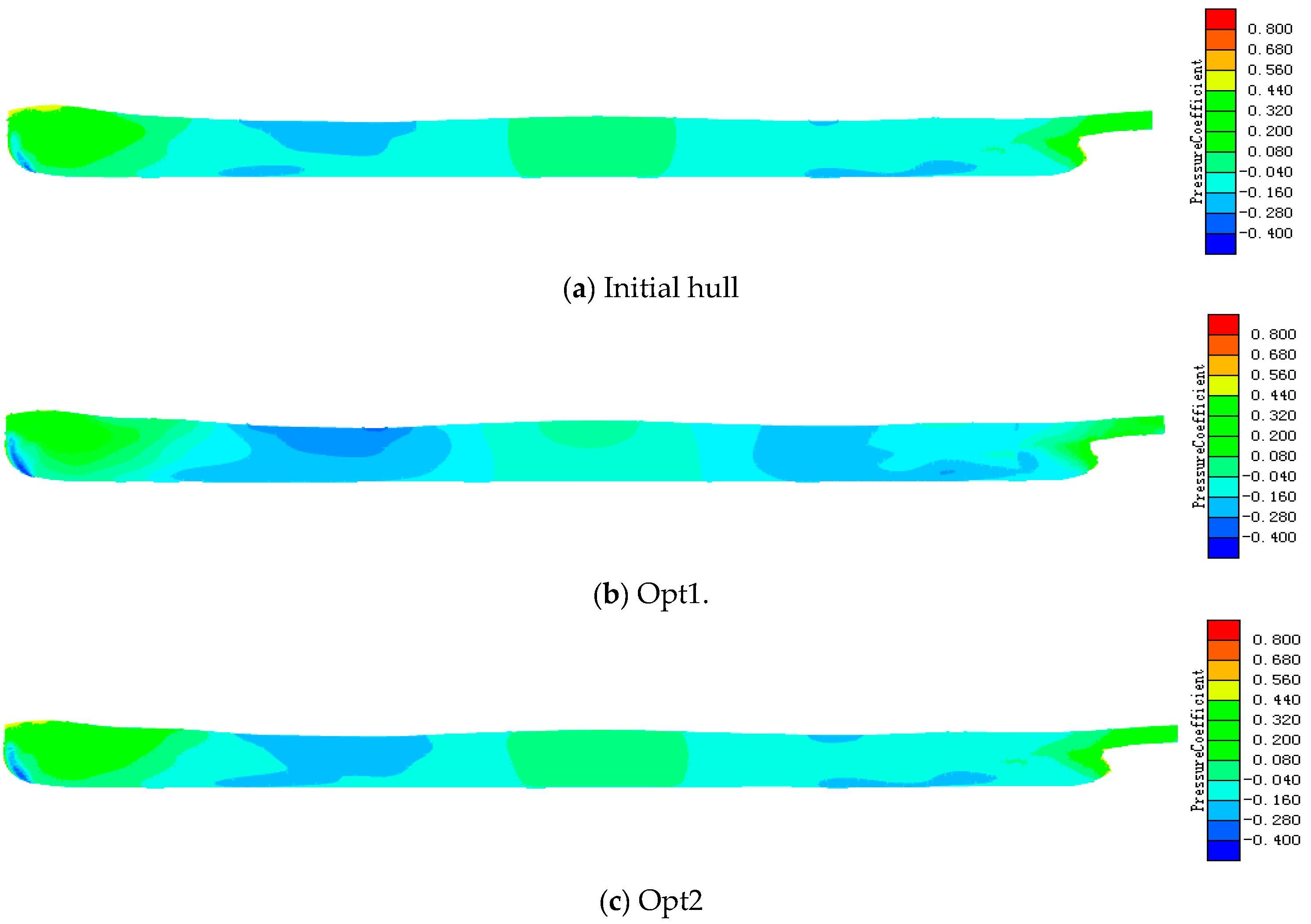

| Parameter | X1 | X2 | X3 | X4 | X5 | X6 | Cw 103 | Change |

|---|---|---|---|---|---|---|---|---|

| Initial hull | 0.0116 | 0.0474 | 0.0859 | 0.1013 | 0.1938 | 0.2183 | 1.337 | 0% |

| Opt1 | 0.0107 | 0.0600 | 0.0720 | 0.0959 | 0.1941 | 0.2127 | 1.200 | −10.24% |

| Opt2 | 0.0112 | 0.0600 | 0.0722 | 0.0939 | 0.1939 | 0.2157 | 1.202 | −10.10% |

| Floating Centre Longitudinal Position (m) | Drainage Volume (m3) | Wet Surface Area (m2) | Total Drag Coefficient Ct 103 | Change | |

|---|---|---|---|---|---|

| Initial hull | 2.518 | 0.646 | 4.764 | 4.909 | 0 |

| Opt1 | 2.520 | 0.646 | 4.774 | 4.758 | −3.07% |

| Opt2 | 2.519 | 0.646 | 4.773 | 4.764 | −2.96% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Q.; Feng, B.-W.; Liu, Z.-Y.; Chang, H.-C. Application of Improved Particle Swarm Optimisation Algorithm in Hull form Optimisation. J. Mar. Sci. Eng. 2021, 9, 955. https://doi.org/10.3390/jmse9090955

Zheng Q, Feng B-W, Liu Z-Y, Chang H-C. Application of Improved Particle Swarm Optimisation Algorithm in Hull form Optimisation. Journal of Marine Science and Engineering. 2021; 9(9):955. https://doi.org/10.3390/jmse9090955

Chicago/Turabian StyleZheng, Qiang, Bai-Wei Feng, Zu-Yuan Liu, and Hai-Chao Chang. 2021. "Application of Improved Particle Swarm Optimisation Algorithm in Hull form Optimisation" Journal of Marine Science and Engineering 9, no. 9: 955. https://doi.org/10.3390/jmse9090955

APA StyleZheng, Q., Feng, B.-W., Liu, Z.-Y., & Chang, H.-C. (2021). Application of Improved Particle Swarm Optimisation Algorithm in Hull form Optimisation. Journal of Marine Science and Engineering, 9(9), 955. https://doi.org/10.3390/jmse9090955