Abstract

The concrete structure in the coastal area suffers from the combined erosion of sulfate and dry–wet cycles. In this study, in order to modify ordinary concrete, fly ash, slag powder, silica fume and polyester fiber are added separately. The crack resistance of concrete was studied through mechanical performance test and three-point bending fracture test of notched beam under sulfate dry–wet cycles. The load-crack opening displacement (P-CMOD) curve characteristics, fracture toughness and fracture energy of modified concrete after corrosion are calculated and analyzed. Results reveal that the P-CMOD curve of modified concrete after corrosion has gone through four stages of damage: initial bending section, proportional elastic section, stable expansion section and softening section. With the increase of dry–wet cycles, the overall corrosion resistance and toughening coefficient of modified concrete increases first and then decreases. Adding 25% fly ash can significantly enhance the fracture toughness of concrete in the initial stage. The addition of polyester fiber and slag is beneficial to the improvement of the instability toughness and fracture energy of the concrete in the later stage.

1. Introduction

The durability of engineering structures is one of the significant subjects in civil engineering, hydraulic engineering and traffic engineering. Over the years, the development of marine energy has attracted more and more attention from coastal countries, and the construction of concrete structures in the coastal and offshore environment is increasing, which puts higher requirements on the durability and corrosion resistance of coastal concrete. Under the erosion of sea water, sulfate is the most destructive corrosive substance among various corrosive media [1,2,3,4].

The object of sulfate corrosion damage is the concrete itself, mainly physical salt expansion damage, supplemented by chemical reaction with cement hydrate, causing concrete cracking or even peeling, and then providing corrosion channels for other corrosive media such as chloride [5]. Researchers have conducted a lot of research on the macro-mechanical properties of concrete after being eroded by sulfate dry–wet cycles. The main evaluation indicators are strength, dynamic elastic modulus, mass loss and expansion rate, etc. [6,7,8,9,10]. However, the current research does not involve the fracture properties of concrete. Fracture performance is an important index for evaluating concrete performance [11]. For the past few years, there are few literatures on the influence of external environment on the fracture performance of concrete, especially in the sulfate environment.

Based on the defects of concrete materials, exploring and researching new materials and technologies that improve the corrosion resistance of concrete has become a research hotspot. Adding an appropriate amount of admixtures to ordinary concrete components for modification is a more economical way to improve the durability of concrete structures [12]. Fracture mechanics, also called “crack body mechanics”, is a discipline that studies the strength of components working with defects or cracks. Fracture mechanics is an effective theory for studying the crack propagation and structural safety life after macroscopic cracks appear in concrete [13]. The Double-K fracture model well describes the two transients of concrete material cracking and instability [14]. The study is carried out after different admixtures are modified. The fracture performance of concrete after corrosion is evaluated, and the effect of different admixtures on the corrosion resistance of ordinary concrete is evaluated. Mineral admixtures can be used to modify the concrete to improve the crack resistance and durability of hydraulic concrete [15,16]. According to the law of occurrence and development of cracks in modified concrete structures under sulfate deterioration, the degree of deterioration of concrete is correctly evaluated, so that effective measures are taken to prevent the occurrence of diseases and ensure the long-term safe and stable operation of coastal engineering.

Silica fume, slag and fly ash are by-products of industrial production. Long-term accumulation of silica fume, slag and fly ash not only takes up a lot of land, but also pollutes the surrounding environment and groundwater. Silica fume, slag and fly ash have excellent physical and chemical properties, such as reducing the consumption of cement, improving the workability of concrete, improving the impermeability and durability of concrete, etc. In addition, mineral admixtures also improve the ability of concrete to resist sulfate attack. Therefore, the application of silica fume, slag and fly ash to concrete production is regarded as an important way to solve the problem of treatment. Thus, choosing appropriate admixtures and admixture ratios, carrying out the performance degradation test of concrete in sodium sulfate solution in the laboratory and analyzing the influence of different admixtures and admixture ratios on the fracture performance of concrete have important engineering significance.

In order to compare with ordinary concrete, this study selects four kinds of admixtures of fly ash, slag, silica fume and polyester fiber to prepare modified concrete beams. After the sulfate corrosion test in the alternate dry–wet environment, the evolution of the mechanical properties of the concrete was studied. Moreover, the fracture toughness of the modified concrete was measured according to the three-point bending fracture test method. The influence of relative cracking toughness, relative instability toughness and relative fracture energy were investigated in order to provide a design basis for improving the durability of coastal engineering under the action of various deterioration factors.

2. Experimental Program

2.1. Materials

P.O 42.5 Ordinary Portland Cement was adopted in this study. Coarse aggregate is limestone crushed stone with a particle size of 5–20 mm, and its apparent density is 2765 kg/m3. The fine aggregate is ordinary river sand with a fineness modulus of 2.87, and its apparent density is 2583 kg/m3. For first-grade fly ash, the designed content is 15%, 20% and 25% respectively, the designed content of slag is 30% and the designed content of silica fume is 10%. The above-mentioned admixtures are all internally blended. Designed dosage of polyester fiber is 0.9 kg/m3, using the external blending method. The physical performance indicators of various admixtures are shown in Table 1, Table 2, Table 3 and Table 4. The concrete mix is shown in Table 5.

Table 1.

Physical properties of fly ash (%).

Table 2.

Physical properties of slag.

Table 3.

Physical properties of silica fume.

Table 4.

Properties of polyester fiber.

Table 5.

Mix proportion of concrete (kg/m3).

2.2. Exposure Conditions

The dry–wet cycle effect makes the chemical reaction and physical erosion alternately occur in the process of sulfate corrosion of concrete, and they promote each other, which intensifies the corrosion damage of concrete. Due to the limitation of test purpose and test conditions, domestic and foreign scholars have set up a variety of different dry–wet cycle methods, which are mainly divided into two categories, natural drying and oven drying, respectively [10]. Taking into account that the oven drying method may cause instability and decomposition of certain components of concrete and ettringite crystals, natural drying is more consistent with the actual coastal conditions [17]. In this study, the specimen is completely immersed in the sodium sulfate solution for 5 days, and then naturally dried outdoors for 5 days, taking 10 days as a cycle. 5% sodium sulfate solution is used as a corrosion solution in this study, and the solution is changed every two weeks until the end of the test [18,19,20]. The drying–wetting cyclic test condition is shown in Table 6.

Table 6.

Drying–wetting cyclic test condition.

2.3. Experiment Methods

The specimen was put into the curing room and cured under standard conditions for 28 days. After the specimens have experienced 0, 2, 4, 6, 8, 10 and 12 dry–wet cycles, the mechanical and three-point bending fracture tests were carried out, respectively. The test of the same group of specimens should be completed within 24 h.

2.3.1. Mechanical Strength

The test of strength was conducted according to Chinese standard GB50081-2002 [21]. Compressive strength and splitting tensile strength tests were conducted on an Electro-hydraulic servo universal testing machine (Model: WAW-1000B) with a load capacity of 1000 kN, and the loads were applied at a rate of 0.5 and 0.05 MPa/s, respectively. The peak load was recorded during the test by an acquisition system.

The compressive strength, fcc (MPa), was calculated by Equation (1):

where P (N) is the peak load, and A (mm2) is the pressure area of the specimen. The splitting tensile strength, fts (MPa), was calculated using Equation (2):

where P (N) is the peak load, and A (mm2) is the fracture surface area of the specimen.

2.3.2. Fracture Test of Three-Point Bending Beam

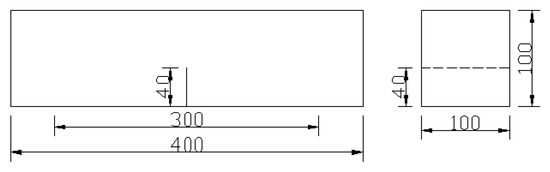

The three-point bending method is the test method recommended by the International Federation of Materials and Structure Laboratories (RILEM). This method has low requirements for the stiffness of the testing machine, simple operation method and relatively stable concrete fracture test curve. Therefore, the three-point bending beam method is used in this experiment [22]. The size of the concrete beam specimen is L × B × h = 400 × 100 × 100 mm, and the span (S) is 300 mm. After the predetermined corrosion age is reached, an initial crack (ao/h = 0.4) with a depth of 40 mm and a width of 3 mm is cut at the bottom of it. The size of the test piece is shown in Figure 1.

Figure 1.

Three-point bending fracture test beam (mm).

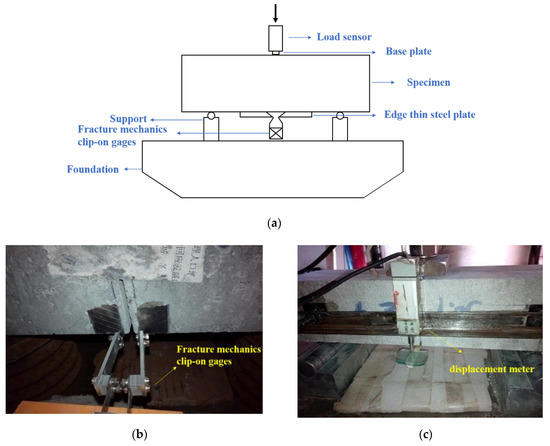

The electro-hydraulic servo universal testing machine was adopted, the maximum test force was 2000 kN and the graded loading method was adopted. The steel plate of length × width × height = 120 × 10 × 5 mm was selected as the force transmission plate; the rolling bearing was used, and its height should meet requirements for clip-on extensometers. Load cell (BJR-1 (Shanghai Automation Instrument Co., Ltd, Shanghai, China)) with a measuring range of 50 kN was used to record the load, displacement sensor (YHD-30 (Liyang instrument factory, Liyang, China)) was used to record the mid-span deflection and clamp extensometer (YYJ-4/10, (General Iron and Steel Research Institute, Beijing, China)) was used to detect the Crack Mouth Opening Displacement (CMOD) value of the crack opening displacement. First, the dimensions of the specimen and the length of the prefabricated crack were measured, then the specimen was placed on the rolling support, a glass sheet was installed at the bottom of one side of the specimen and a 0.5 mm thin blade was installed at the tip of the prefabricated crack on the other side and clamped. Finally, the load sensor and displacement sensor were installed. The loading device was started, the data acquisition system was connected and zero was collected when the force transmission device, load sensor and test piece were about to touch. Uniform and continuous loading occurred at a rate of 10–100 N/s to failure of the specimen. The schematic diagram of three-point bending fracture test loading is shown in Figure 2.

Figure 2.

Fracture experiment process of three-point bending beam. (a) Diagram of three-point bending fracture test, (b) fracture mechanics clip-on gages, (c) displacement meter.

3. Result and Discussion

3.1. Compressive Strength

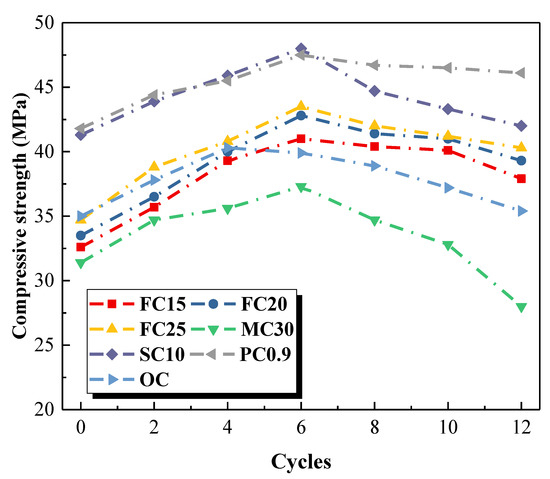

Figure 3 shows the change in compressive strength of modified concrete. Within 12 dry–wet cycles, the development of the compressive strength of concrete subjected to sulfate corrosion can be roughly divided into two stages: the initial strength growth stage and the performance deterioration stage. This is because at the initial stage of corrosion, sulfate ions penetrate into the concrete and react with cement hydration products to form expansive products such as ettringite and gypsum [23]. These expansive substances fill the internal pores of the concrete and cause a certain expansive internal stress in the concrete. However, the tensile strength of concrete has not been reached, and it is not enough to produce expansive cracks. On the contrary, the ettringite crystals fill the interface area between the concrete pores and the aggregate paste to a certain extent, which improves the compactness of the concrete and strengthens the concrete to a certain extent. Therefore, the strength of concrete is significantly improved in the initial stage. As the corrosion time increases, there are no more pores in the concrete to accommodate a large amount of swelling products, and the swelling internal stress gradually exceeds its tensile strength to cause cracks. The cracks continue to form and expand, making the sulfate ions penetrate into the concrete and accelerate the progress of corrosion. These processes promote each other and proceed alternately, resulting in the continuous decline of the strength of the concrete in the later stage, and finally the expansion and cracking.

Figure 3.

Compressive strength variation.

Results show that the compressive strength of concrete shows a trend of first increasing and then decreasing. The compressive strength of ordinary concrete reached the maximum value of 40.3 MPa by the fourth dry–wet cycle, after which the concrete strength continued to decrease. The compressive strength of fly ash concrete, slag concrete, silica fume concrete and polyester fiber concrete reached the maximum by the sixth dry–wet cycle. The compressive strength of SC30 concrete is always lower than that of ordinary concrete, and the strength at the end of corrosion is only 79.1% of ordinary concrete, indicating that the addition of slag failed to increase the ability of concrete to be corroded by sodium sulfate. The reason for this phenomenon is that in addition to the low slag content, which has no obvious effect on the improvement of concrete compactness and C3A dilution, the more important thing is the difference in the composition of the calcium silicate hydrate (C-S-H) gel. Studies have found that Al can be bound to the hydrated C-S-H structure. Assuming that the composition of C-S-H is represented by Al/Ca and Si/Ca, when Si/Ca in C-S-H increases, Al/Ca also increases. When the slag content is low, the ratio of Si/Ca and Al/Ca in the hydrated C-S-H is very small, with the corresponding ratios in ordinary concrete, and the amount of Al absorbed by C-S-H is also less. If the alumina content in the slag is high, a large amount of aluminum will be released into the concrete pore solution, and the formation of ettringite will be added to adversely affect the corrosion resistance of concrete. When the slag content in the concrete is high, the Si/Ca and Al/Ca values in the hydration C-S-H will increase, which will bind a large amount of aluminum in the C-S-H structure, thereby improving the corrosion resistance of the concrete. The incorporation of silica fume significantly improves the corrosion resistance of concrete to sulfate. At the end of the dry–wet cycle, the compressive strength of silica fume concrete is increased by 18.6% compared with ordinary concrete. The addition of silica fume to the concrete saves the amount of cement, reduces the amount of ettringite and gypsum, and silica fume is a fine particle smaller than cement particles, which can be better filled in the gaps between the cement particles, thereby increasing the concrete density. In addition, with the increase of the corrosion time, the pozzolanic effect of silica fume plays a significant role. The active SiO2 in silica fume reacts with Ca(OH)2 to produce low-alkalinity hydrated calcium silicate with higher strength and better stability. It can reduce or eliminate Ca(OH)2, improve the quality of hydrated calcium silicate cementing material, optimize the composition of concrete and fill the cement hydrate between the cementitious material [24], so the incorporation of silica fume effectively improves the ability of concrete to be attacked by sulfate.

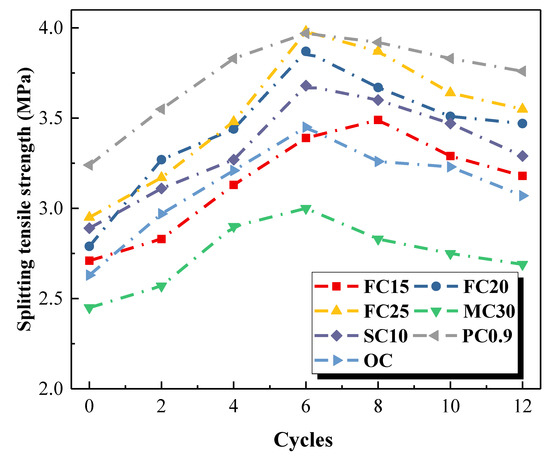

3.2. Splitting Tensile Strength

Figure 4 shows the change in splitting tensile strength of modified concrete. It can be seen from the figure that the splitting tensile strength and compressive strength of concrete are basically the same, and the overall trend is initial increase and later decline. The 30% slag content failed to increase the splitting tensile strength of eroded concrete, but adversely affected it. In the tenth dry–wet cycle, the splitting tensile strength of slag concrete was only 85.1% of that of ordinary concrete. The addition of polyester fiber can significantly improve the splitting tensile strength of eroded concrete by more than 20%. The splitting strength of concrete with 10% silica fume is significantly higher than that of ordinary concrete, but, compared with the effect of silica fume on the compressive strength, the increase of splitting strength is lower. The higher the amount of fly ash, the higher the splitting tensile strength of concrete. In addition, the increase in strength of concrete with fly ash content of 20% and 25% is also higher than the compressive strength, indicating that the addition of fly ash is more conducive to improving the splitting tensile strength of concrete attacked by sulfate. This is because sulfate ions react with cement hydration products to form ettringite and gypsum in the early stage of corrosion. The expansion effect of these two products can improve the compactness of concrete and increase the strength of concrete. However, the 15% and 20% fly ash content are relatively low, and the active effect of fly ash has not been fully reflected in the initial stage, so the improvement of the sulfate corrosion performance of concrete is not obvious [25]. As the erosion time increases, the active silica and alumina contained in the fly ash react with the calcium hydroxide in the concrete to form hydrated calcium silicate and hydrated calcium aluminate. These gels block the concrete pores, refine the pore structure and effectively extend the pore channels, and slow down the speed of SO42− ions in the pores. On the other hand, the fly ash activity effect consumes Ca(OH)2 and reduces the concentration of Ca(OH)2 in the concrete, so the Ca(OH)2 reacting with SO42− ions is also reduced, thus slowing down the crystal expansion stress. In addition to the active effect, the morphological effect and micro-aggregate effect of fly ash can also enhance the compactness of concrete and improve the sulfate resistance of concrete [24].

Figure 4.

Splitting tensile strength variation.

3.3. Fracture Properties

3.3.1. Fracture Properties Evaluation Index

The Double-K fracture criterion includes two parameters: initiation toughness () and instability toughness (). The slot end stress intensity factor K = can be used as the basis for judging the crack propagation of important structures. The slot end stress intensity factor K = can be used as a basis for judging the propagation of cracks in general structures. The calculation of initiation toughness () and instability toughness () are shown in the following:

where m (kg) is the mass of the specimen, g is the acceleration of gravity, S (m) is the specimen span, ac (m) is the effective crack length, t (m) is the thickness of the specimen, H (m) is the height of the specimen and F (kN) is the load. When F is the initiation load (FQ), the calculation result is the initiation toughness (). When F is the maximum load (Fmax), the calculation result is the instability toughness ().

Since the material dispersion of different types of concrete has a greater impact on the test results, in order to eliminate the impact, the relative cracking toughness (RQ), relative instability toughness (Rs) and relative fracture energy (RF) are defined to characterize the fracture toughness variation of modified concrete after corrosion:

where (on), (on) and GF(on) are the cracking toughness, instability toughness and fracture energy of ordinary concrete after the n dry–wet cycles, respectively. (n), (n) and GF(n) are the cracking toughness, instability toughness and fracture energy of modified concrete after the n dry–wet cycles, respectively. RQ(n), RS(n) and RF(n) are the relative cracking toughness, relative instability toughness and relative fracture energy of modified concrete after the n dry–wet cycles, respectively.

3.3.2. P-CMOD Curve of Concrete Exposed to Dry–Wet Cycles

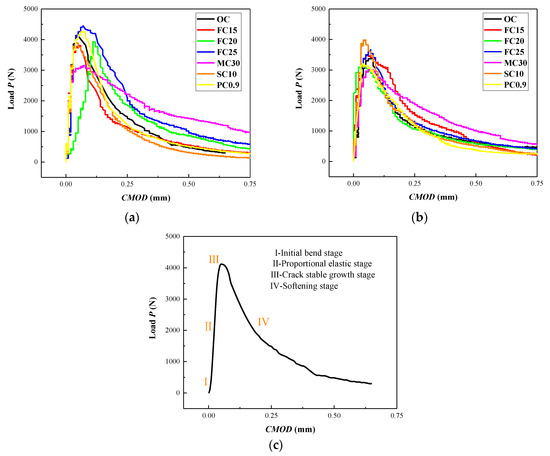

The fracture test results show that the development of cracks in concrete with different admixtures is different under load, but the overall development of cracks is along the local area of the front edge of the prefabricated crack tip. A micro-crack is initially generated, and then the width of the crack continues to increase and extends upwards until the specimen fractures. Figure 5 plots the load-crack opening displacement (P-CMOD) curve of 7 groups of sulfate-corroded concrete after the sixth and twelfth dry–wet cycles.

Figure 5.

The load-crack opening displacement (P-CMOD) curve of eroded concrete in the (a) sixth and (b) twelfth dry–wet cycles. (c) P-CMOD characteristic curve.

The development of the load-crack opening displacement curve of corroded concrete can be roughly divided into four stages:

- (1)

- Initial bend stage: When the load is small, the opening displacement of the crack opening is large, the curve shows a nonlinear development and the curve is concave. On the one hand, the micro-cracks in the concrete were closed before loading and opened after loading; on the other hand, the surface of the concrete was loosened and damaged due to more micro-cracks caused by sulfate corrosion.

- (2)

- Proportional elastic stage: After the first stage, the curve rises in a straight line, the opening displacement of the crack opening increases approximately proportionally with the load value, and the P-CMOD curve develops linearly. At this stage, the internal micro-cracks in the concrete are stable, no new cracks are generated, and the crack tip area is in a stable elastic state.

- (3)

- Crack stable growth stage. As the load gradually increases to a certain value, the straight line turns into a curve, and the load corresponding to the inflection point is the crack initiation load. The crack enters the steady-state propagation stage, and micro-cracks are generated in the tip area of the crack, and the width is slowly increased, but the micro-cracks are not completely connected, and the macroscopic visible cracks have not yet formed on the surface.

- (4)

- Softening stage: After the load reaches the maximum value, that is, the instability load, the opening displacement of the crack opening increases rapidly, the load drops sharply, and the curve enters a softening stage. The cracks in the front edge area of the tip are connected to each other, and the macro-cracks appear and rapidly develop to the upper part of the section. The opening displacement of the crack opening increases continuously, and the cracks of the specimen expand in an unsteady state until the specimen fractures.

Concrete is a brittle material. The crack development traces of concrete with different admixtures are different, but in general, the development of cracks always starts along the local area of the front edge of the prefabricated crack tip, first forming a micro-crack. Then, the crack width keeps increasing and gradually develops upwards until the test block breaks, as shown in Figure 6.

Figure 6.

Fracture propagation process: (a) Initial fracture morphology, (b) fracture morphology in unstable stage.

3.3.3. Fracture Toughness of Modified Concrete

According to the test results of the initiation load, FQ, and the instability load, Fmax, of the concrete, the initiation toughness and instability toughness of the concrete can be calculated by Equations (3) and (4), thereby obtaining the relative fracture toughness RQ(n) and RS(n). Table 7 is the fracture toughness of modified concrete exposed to 6 and 12 dry–wet cycles. As shown in the Table 7, the overall cracking load and instability load increase first and then decrease with the increase of dry–wet cycles, and the ratio of the two is 0.7 to 0.9. At the initial stage of corrosion, part of the sulfate radicals enters the concrete to form expansive products such as gypsum and ettringite, which fills the crevices of the concrete, increases the density, improves the crack resistance and limits cracking performance of concrete, and therefore increases the fracture toughness [26,27]. With the increase of corrosion age, the volume of crystallization products expands and exceeds the bearing capacity of the pores, resulting in a large number of micro-cracks, and these micro-cracks form new channels, which accelerate the corrosion rate of sulfate [28]. Thus, the crack resistance performance and the fracture toughness are reduced.

Table 7.

Fracture toughness of modified concrete exposed to 6 and 12 dry–wet cycles.

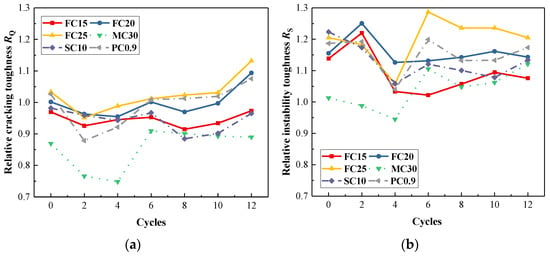

Figure 7a shows the curve of relative cracking toughness of modified concretes corroded by sulfate. The relative cracking toughness of modified concrete decreases with the increase of dry–wet cycles. Generally, after two dry–wet cycles, RQ starts to increase and the rate increases. After 6 dry–wet cycles, the relative cracking toughness of polyester fiber concrete, 20% fly ash concrete and 25% fly ash concrete were increased by 7.5%, 9.3% and 13.2% respectively, compared with ordinary concrete. The whole corrosion period of slag concrete is lower than ordinary concrete under the same conditions. This is due to the fact that the activity of ground slag is relatively high, the heat of hydration is relatively high and the auto-shrinkage increases with the amount of slag (<75%), so that the cracking toughness of slag concrete is lower. Silica fume particles are small and have a large specific surface area. When mixed with concrete, it will cause early plastic shrinkage and drying shrinkage, and the crack resistance is slightly weaker. The above analysis shows that adding 20% or 25% fly ash or polyester fiber can effectively improve the cracking toughness of concrete in the late stage, while adding slag will reduce the cracking toughness of concrete.

Figure 7.

Evolution of relative fracture toughness. (a) Relative cracking toughness, (b) relative instability toughness.

Figure 7b shows the curve of relative instability toughness of modified concretes corroded by sulfate. Due to the addition of mineral admixtures, the growth rate of the early strength of the modified concrete is lower than that of ordinary concrete, and the relative instability toughness of each modified concrete also decreases first and then rises with the increase of dry–wet cycles. Except for slag concrete being lower than ordinary concrete in the initial stage of corrosion, the RS of all modified concrete is higher than ordinary concrete. Slag powder can reduce the C3A content in the concrete mixture, and at the same time, generate calcium silicate hydrate (C-S-H). On the one hand, it reduces the amount of ettringite formed by sulfate, and on the other hand, it reduces the permeability of concrete and prevents sulfate corrosion. Silica fume particles are small, which can improve the interface structure and bonding force, form a dense structure, and also effectively prevent the intrusion of harmful ions, so the incorporation of slag and silica fume will increase the instability toughness of concrete. Tests show that the addition of admixtures can significantly improve the instability toughness of concrete, and 25% fly ash has the best toughening effect. Polyester fiber, silica fume and slag are conducive to the improvement of the later instability toughness of concrete. On the whole, adding fly ash will significantly improve the cracking toughness of concrete and have better crack resistance, and adding polyester fiber and slag will significantly improve the instability toughness of concrete and have better crack-limiting effects. It is recommended to use 20%–25% fly ash and polyester fiber mixed concrete.

3.3.4. Fracture Energy of Modified Concrete

The fracture energy is defined as the surface energy consumed per unit area of crack propagation. The area enclosed by the load-deflection curve of concrete is the fracture energy. The fracture energy of modified concrete and ordinary concrete corroded by sulfate under dry–wet cycles is shown in Table 8.

Table 8.

Fracture energy of concrete expose to dry–wet cycles.

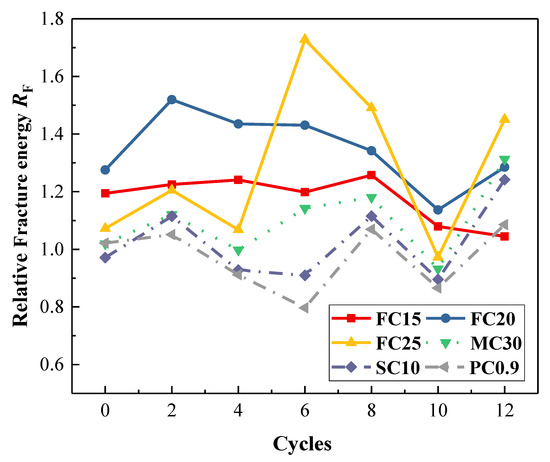

The relative fracture energy change curve of modified concrete is shown in Figure 8. The results show that the relative fracture energy of modified concrete has a basically similar change trend, with the growth of dry–wet cycles first rising and then falling. In the early stage, high content of fly ash, polyester fiber and slag will significantly increase the fracture energy of concrete. This is due to the fact that the expansive products of ettringite and gypsum crystals filled the internal pores of the concrete and made the concrete structure compact, so the fracture energy of the early concrete was improved. With the progress of the erosion reaction, the large internal stress formed by a large number of swelling products in the concrete causes the internal micro-cracks to continue to expand, the pore structure is destroyed gradually, and the later fracture energy is reduced. It is worth noting that the RF value increased at the twelfth cycle. This is because as the erosion time increases, the concrete specimen has changed from brittleness to a certain degree of toughness, and the ultimate mid-span deflection has increased. Therefore, the area enclosed by the P-CNOD curve increased correspondingly, and the fracture energy also increases. The fracture energy of silica fume concrete changes smoothly during the entire corrosion cycle, and its value is lower than that of ordinary concrete. It is due to the steep decline of the load-deflection curve after the load-deflection curve reaches the peak, indicating that the silica fume concrete is brittle and quickly destroyed after entering the unstable fracture. The test results show that high-volume fly ash can increase the fracture energy of concrete the most in the early stage of corrosion. The addition of slag can also increase the fracture energy of concrete, while the addition of silica fume can reduce the fracture energy of concrete.

Figure 8.

Evolution of relative fracture energy.

4. Conclusions

The main conclusions of this study are summarized as follows:

- (1)

- After the concrete is corroded by sulfate, the compressive strength, splitting tensile strength, Double-K fracture toughness and fracture energy generally showed a second-order change pattern that increased first and then decreased with the increase of erosion time. The P-CMOD development curve of modified concrete corroded by sulfate includes 4 stages of damage: initial bending section, proportional elastic section, stable expansion section and softening section

- (2)

- The higher the amount of fly ash, the better the improvement effect on the fracture performance of concrete. The incorporation of slag failed to improve the compressive strength, splitting tensile strength and Double-K fracture toughness of concrete attacked by sulfate, but it significantly increased the fracture energy of concrete. The compressive strength of silica fume concrete was significantly higher than that of fly ash concrete and slag concrete, and the fracture energy value was lower than that of ordinary concrete, indicating that the effect of silica fume on improving the fracture performance of concrete is limited. Polyester fiber improved the fracture performance of concrete in sulfate erosion. The fracture toughness of Double-K in the later stage of erosion was lower than 25% of fly ash concrete, but the fracture energy was the highest.

- (3)

- For coastal engineering that suffers from combined erosion of sulfate and dry–wet cycles, it is recommended to use modified concrete mixed with 20% to 25% fly ash and polyester fiber in projects to improve the corrosion resistance and extend service life of infrastructure. For the proposed hydraulic concrete buildings in a corrosive environment, fracture toughness can be used as one of the important performance indicators in the anti-cracking design of concrete to effectively prevent the occurrence of sudden fracture disasters.

Author Contributions

Conceptualization, J.-j.G.; Data curation, K.W.; Funding acquisition, J.-j.G. and C.-g.Q.; Investigation, J.-j.G.; Methodology, J.-j.G. and K.W.; Project administration, K.W.; Resources, C.-g.Q. and K.W.; Writing—original draft, K.W.; Writing—review and editing, J.-j.G., C.-g.Q. and K.W. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (Nos. U2040224, 51879244 and 51679221) and the Program for Innovative Research Team (in Science and Technology) in University of Henan Province of China (No. 20IRTSTHN009).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used to support the findings of this study are available from the corresponding author upon request.

Acknowledgments

The financial support from Zhengzhou University Postgraduate Independent Innovation Project and Zhengzhou University are also acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nehdi, M.; Suleiman, A.; Soliman, A. Investigation of Concrete Exposed to Dual Sulfate Attack. Cem. Concr. Res. 2014, 64, 42–53. [Google Scholar] [CrossRef]

- Han, T.; Wang, X.; Li, N.; Li, D.; Han, N.; Xing, F. Damage and Degradation Mechanism for Single Intermittent Cracked Mortar Specimens under a Combination of Chemical So-Lutions and Dry-Wet Cycles. Constr. Build. Mater. 2019, 213, 567–581. [Google Scholar] [CrossRef]

- Ragoug, R.; Metalssi, O.O.; Barberon, F.; Torrenti, J.-M.; Roussel, N.; Divet, L.; De Lacaillerie, J.-B.D. Durability of Cement Pastes Exposed to External Sulfate Attack and Leaching: Physical and Chemical Aspects. Cem. Concr. Res. 2019, 116, 134–145. [Google Scholar] [CrossRef]

- He, S.-H.; Zhang, Q.-F.; Ding, Z.; Xia, T.-D.; Gan, X.-L. Experimental and Estimation Studies of Resilient Modulus of Marine Coral Sand under Cyclic Loading. J. Mar. Sci. Eng. 2020, 8, 287. [Google Scholar] [CrossRef]

- Sutrisno, W.; Suprobo, P.; Wahyuni, E.; Iranata, D. Experimental Test of Chloride Penetration in Reinforced Concrete Subjected to Wetting and Drying Cycle. Appl. Mech. Mater. 2016, 851, 846–851. [Google Scholar] [CrossRef]

- Taengua, E.J.G.; Sonebi, M.; Hossain, K.; Lachemi, M.; Khatib, J.M. Effects of the addition of nanosilica on the rheology, hydration and development of the compressive strength of cement mortars. Compos. Part B Eng. 2015, 81, 120–129. [Google Scholar] [CrossRef]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and Durability Properties of Self Consolidating High Performance Concrete Incorporating Natural Zeolite, Silica Fume and Fly Ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- Xie, F.; Li, J.; Zhao, G.; Zhou, P.; Zheng, H. Experimental Study on Performance of Cast-in-Situ Recycled Aggregate Concrete under Different Sulfate Attack Exposures. Constr. Build. Mater. 2020, 253, 119144. [Google Scholar] [CrossRef]

- He, R.; Zheng, S.N.; Vincent, J.L.; Wang, Z.D.; Fang, J.H.; Shao, Y. Damage Mechanism and Interfacial Transition Zone Char-Acteristics of Concrete under Sulfate Erosion and Dry-Wet Cycles. Constr. Build. Mater. 2020, 255. [Google Scholar] [CrossRef]

- Wang, K.; Guo, J.; Wu, H.; Yang, L. Influence of Dry-Wet Ratio on Properties and Microstructure of Concrete under Sulfate Attack. Constr. Build. Mater. 2020, 263, 120635. [Google Scholar] [CrossRef]

- Kohal, R.-J.; Kilian, J.B.; Stampf, S.; Spies, B.C. All-Ceramic Single Crown Restauration of Zirconia Oral Implants and Its In-fluence on Fracture Resistance: An Investigation in the Artificial Mouth. Materials 2015, 8, 1577–1589. [Google Scholar] [CrossRef] [PubMed]

- Chu, T.X.H.; Zheng, J.; Chen, D.; Nguyen, T.T.H.; Elbashiry, E.; Tang, V.T. Utilization of Industrial Waste in Cement in a Marine Environment with a Tropical Climate. J. Mar. Sci. Eng. 2019, 7, 245. [Google Scholar] [CrossRef]

- An, Q.; Ming, W.; Chen, M. Experimental Investigation on Cutting Characteristics in Nanometric Plunge-Cutting of BK7 and Fused Silica Glasses. Materials 2015, 8, 1428–1441. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Barai, S.V. Size-effect Prediction from the Double-K Fracture Model for Notched Concrete Beam. Int. J. Damage Mech. 2010, 19, 473–497. [Google Scholar] [CrossRef]

- Ferraris, C.F.; Obla, K.H.; Hill, R. The Influence of Mineral Admixtures on the Rheology of Cement Paste and Concrete. Cem. Concr. Res. 2001, 31, 245–255. [Google Scholar] [CrossRef]

- Wang, J.; Guo, Z.; Zhang, P.; Yuan, Q.; Guan, Q. Fracture Properties of Rubberized Concrete under Different Temperature and Humidity Conditions Based on Digital Image Cor-Relation Technique. J. Clean. Prod. 2020, 276, 124106. [Google Scholar] [CrossRef]

- Melchers, E.R. Long-Term Durability of Marine Reinforced Concrete Structures. J. Mar. Sci. Eng. 2020, 8, 290. [Google Scholar] [CrossRef]

- GB/T 749-2008. Test Method for Resistance of Cement to Sulfate Attack; Chinese Standard Institution Press: Beijing, China, 2008. [Google Scholar]

- GB/T 50082-2009. Standard for Test Method of Long-Term Performance and Durability of Ordinary Concrete; Chinese Standard Institution Press: Beijing, China, 2009. [Google Scholar]

- ASTM C1012. Standard Test Method for Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- GB/T 50081-2002. Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Building Industry Press: Beijing, China, 2002. [Google Scholar]

- DLT 5332-2005. Norm for Fracture Test of Hydraulic Concrete; Chinese Standard Institution Press: Beijing, China, 2006. [Google Scholar]

- EI-Didamony, H.; Helmy, I.; Mostafa, K. Durability of Sulfate Resisting Slag Blended Cement and Mortars in Sea Water. Indian J. Eng. Mater. Sci. 1996, 3, 35–40. [Google Scholar]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of Fresh and Hardened Fly Ash/Slag Based Geopolymer Concrete: A Review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Yang, L.; Liu, G.; Gao, D.; Zhang, C. Experimental Study on Water Absorption of Unsaturated Concrete: W/C Ratio, Coarse Aggregate and Saturation Degree. Constr. Build. Mater. 2021, 272, 121945. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, T.; Luo, T.; Zhou, M.; Zhang, K.; Ma, W. Study on the Deterioration of Concrete under Dry–Wet Cycle and Sulfate Attack. Materials 2020, 13, 4095. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Huang, B.; Yuan, Y.; Deng, M. Deterioration Process of Concrete Exposed to Internal Sulfate Attack. Materials 2020, 13, 1336. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.; Chen, J.; Lu, C. Fractal Cracking Patterns in Concretes Exposed to Sulfate Attack. Materials 2019, 12, 2338. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).