1. Introduction

Shipping, by transferring commodities and passengers, accounts for the carriage of 80% of global trade by volume and 70% by value [

1], and thus plays a crucial role in global trade and nations’ economic growth. Although it is the most fuel-efficient means of transportation, it has negative externalities that impact the environment [

2], such as marine litter, oil spillage, sewage, underwater noise pollution, and transportation of invasive species. One of the most important and challenging issues is air pollution, which consists of both greenhouse gas (GHG) emissions that cause global warming [

3] and air pollutants, which have a direct effect on human health [

4,

5].

The life cycle of a ship consists of the design, construction, operation, and scrapping phases. The IMO, which regulates international shipping, seeks to control and reduce air emissions from shipping by adopting and enforcing stringent environmental regulations in the design and operational phases of ships. However, in addition to air emissions from ship operation, emissions are also generated from the production, maintenance, and scrapping of ships, which have received less attention in terms of controlling and reducing air emissions. If there is a real interest and willingness to reduce emissions from the shipping industry, a holistic and broader vision must be taken into account and mitigation measures must be implemented throughout the life cycle of the ship.

A shipyard is an industrial production facility where certain inputs are used to design, develop, build, repair, or dismantle a ship. Shipbuilding involves many industrial processes, such as cutting, surface treatment, bending, welding, blasting, painting and coating, and fiberglass production [

6]. A significant quantity of pollutants and waste is emitted during these processes, which can have a negative impact on both the environment and human health. Shipbuilding is an energy-intensive industry, producing significant amounts of carbon dioxide (4% of ships’ life cycle emissions, i.e., more than the ports’ contribution, which is about 2% [

7] of ships’ life cycle carbon dioxide emissions), and air pollutants such as carbon monoxide (29% of ships’ life cycle emissions [

8]), SOx, and NOx, which leave a footprint on the environment [

9]. This provides an important first indication of the scale of greenhouse gas and air pollutant emissions from shipyards as part of the ship life cycle. However, emissions are likely to be sensitive to the types of ships on which work is carried out and to the working practices used. Moreover, as the shipping industry moves to carbon-free fuels, such as electricity, sail, and solar power, the share of shipyard activities in the life cycle of a ship is expected to be larger than the operational phase in the coming decades. As an example, a previous study showed that if a car ferry is powered by batteries using electricity from the Norwegian grid, the shipbuilding phase has a greater life-cycle climate impact than the operational phase [

10]. This justifies more extensive research in this area. Despite the Hong Kong Convention on the safe recycling of ships [

11], no comprehensive and effective energy efficiency provisions exist, either for the recycling phase or for the shipbuilding phases. However, consideration of appropriate measures in shipyards can help to minimize GHG emissions and the risks of air pollutants on people and the environment. In addition, it can promote resource savings and improve economic and social benefits.

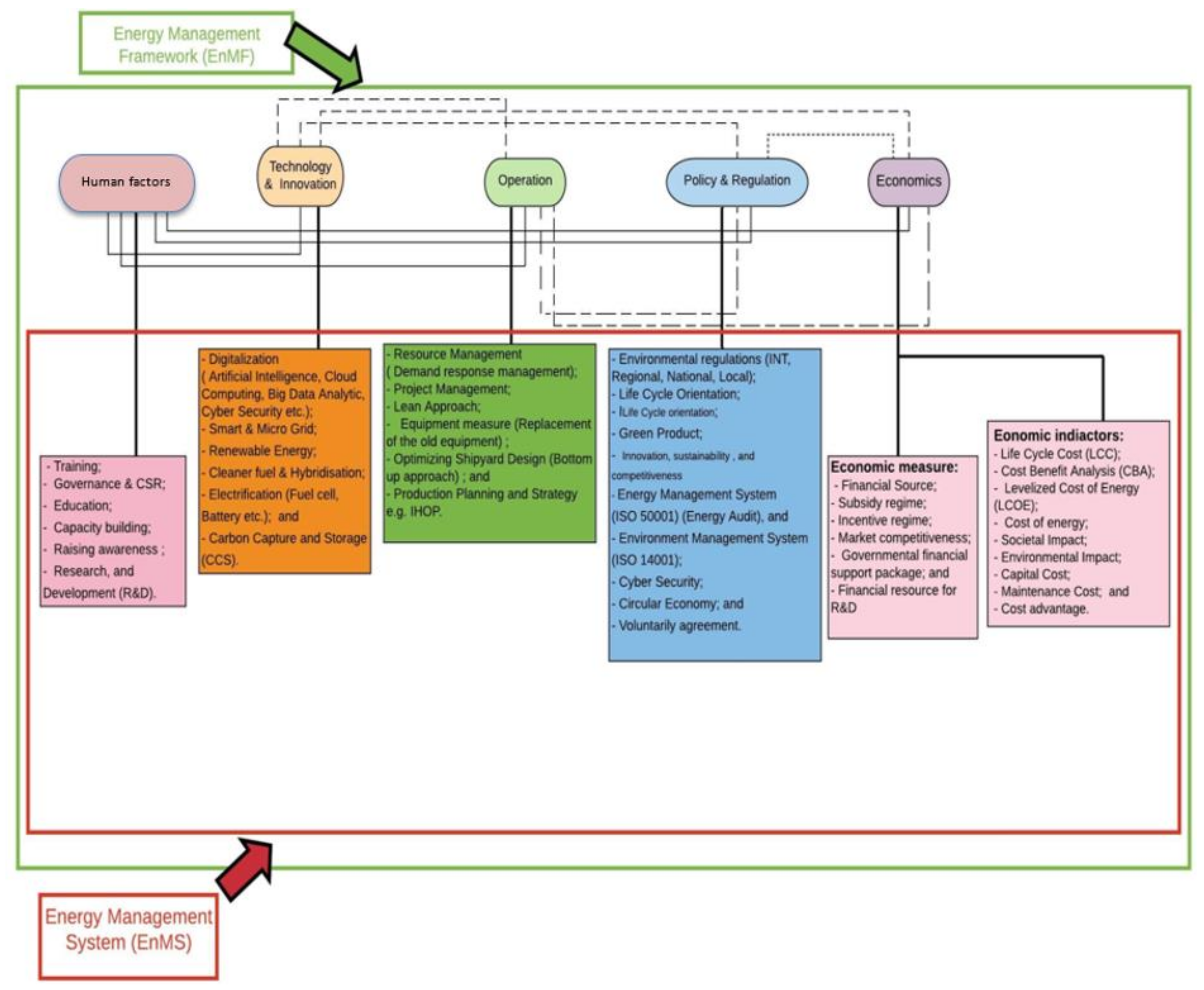

With this in mind, this study focused the management of energy in the short, medium, and long term, in addition to the reduction in air emissions resulting from energy use in shipyards. To address these issues, the study aimed to provide a holistic, systematic, and transdisciplinary energy management framework (EnMF) to the shipyards’ senior decision makers (DMs) as a focused group

1. The purpose was to help them make rational decisions and optimize their decisions in an uncertain environment to improve energy efficiency and reduce air emissions within their portfolio, which is not related to the operational phase of the ships, such as the ships’ main engine. The proposed framework enhances the decision support system (DSS) within the context of the shipbuilding industry. In this study, we used the techniques of Fuzzy Order of Preference by Similarity to Ideal Solution (FTOPSIS) and Fuzzy Analytic Hierarchy Process (FAHP), which are applied extensively in different clusters [

12] and are popular for creating frameworks in the energy sector [

13]. The use of these methods helps managers to compare different options with regards to different criteria and rank them according to their preferences.

The framework serves as a micro-level niche for the shipbuilding industry and, due to its flexible and generic characteristics, it can be adapted and applied to other shipyards and other industries. To demonstrate the validity of the framework, a case study was conducted in a private Turkish shipyard. Adopting the framework proposed in this paper will promote the concept of green shipping in the context of the ship life cycle and support sustainable shipping for a sustainable planet. In addition, it has the potential to contribute to countries’ NDCs under the Paris Agreement and the EU Green Deal by supporting zero-carbon footprint products and decarbonization in the maritime transport sector. The work should be of interest to shipyard owners and managers, offshore managers, international, regional, and local policy makers, and governments. In this context,

Section 2 provides an overview of the EnMF and its elements, in addition to the specific characteristics of the shipyards included in the case study. The methodology and approach are described in

Section 3, and

Section 4 presents the results and recommendations for the application of the EnMF in the shipyard. Finally, conclusions are drawn in

Section 5.

3. Research Methodology

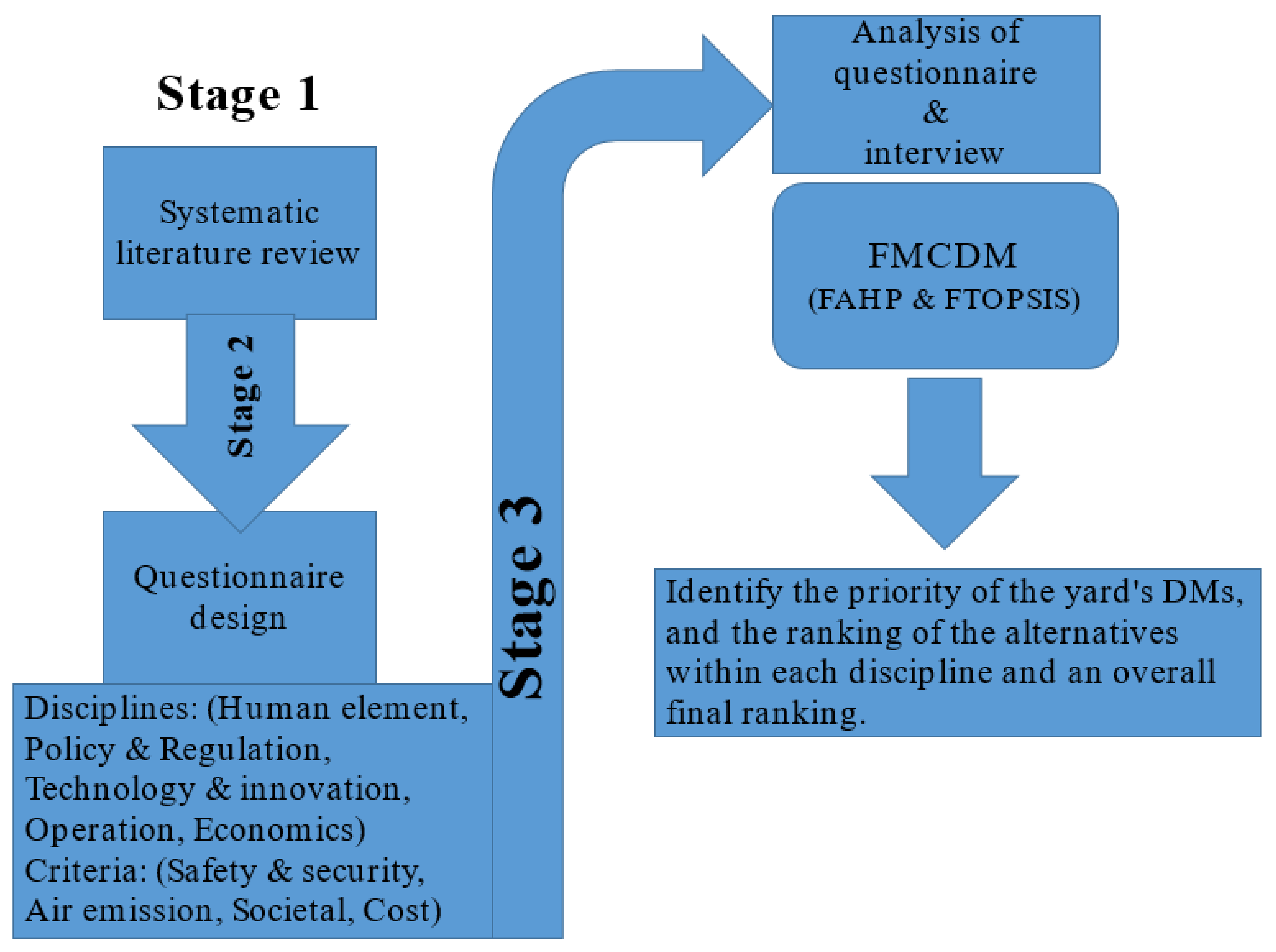

As shown in

Figure 3, the research consisted of a three-step process:

First, a systematic literature review was conducted to identify EnMF alternatives and designs in all five main disciplines, i.e., human factors, technology and innovation, policy and regulation, operations, and economics.

In the second stage, a semi-structured questionnaire was designed to identify the priorities of the shipyards. Based on the identified alternatives, the questionnaire was designed and the interview was conducted with the shipyard’s highest manager.

The third step was the analysis of the interview and the questionnaire to identify the priority of the yard’s DMs, the ranking of the options within each discipline, and an overall final ranking.

During the interview and the study, the authors discovered that the topic is not concrete and that there are ambiguities and an uncertain environment in the shipyard. In an uncertain environment, characterized by a lack of information and inconsistency, DMs generally fail to make appropriate decisions and define their preferences. MCDM can help DMs to understand problems and choose the best option in an ambiguous environment among different alternatives by considering and evaluating different attributes. The FAHP method is one of the techniques used to deal with ambiguous information, which can affect DMs’ preferences for different variables [

72,

73]. FTOPSIS is another MCDM method that is used for ranking of alternatives. By identifying the problems and applying their priorities for each attribute, DMs can evaluate the alternatives, identify preferences, and finally rank and choose the best alternatives among the others. MCDM methods are very popular for solving energy supply problems because these problems involve multiple and often conflicting criteria [

13]. As an example, 41% of the studies of renewable energy investment decision making used one, or a combination, of AHP (analytical hierarchy process), multiple criteria, TOPSIS, and fuzzy methods [

74].

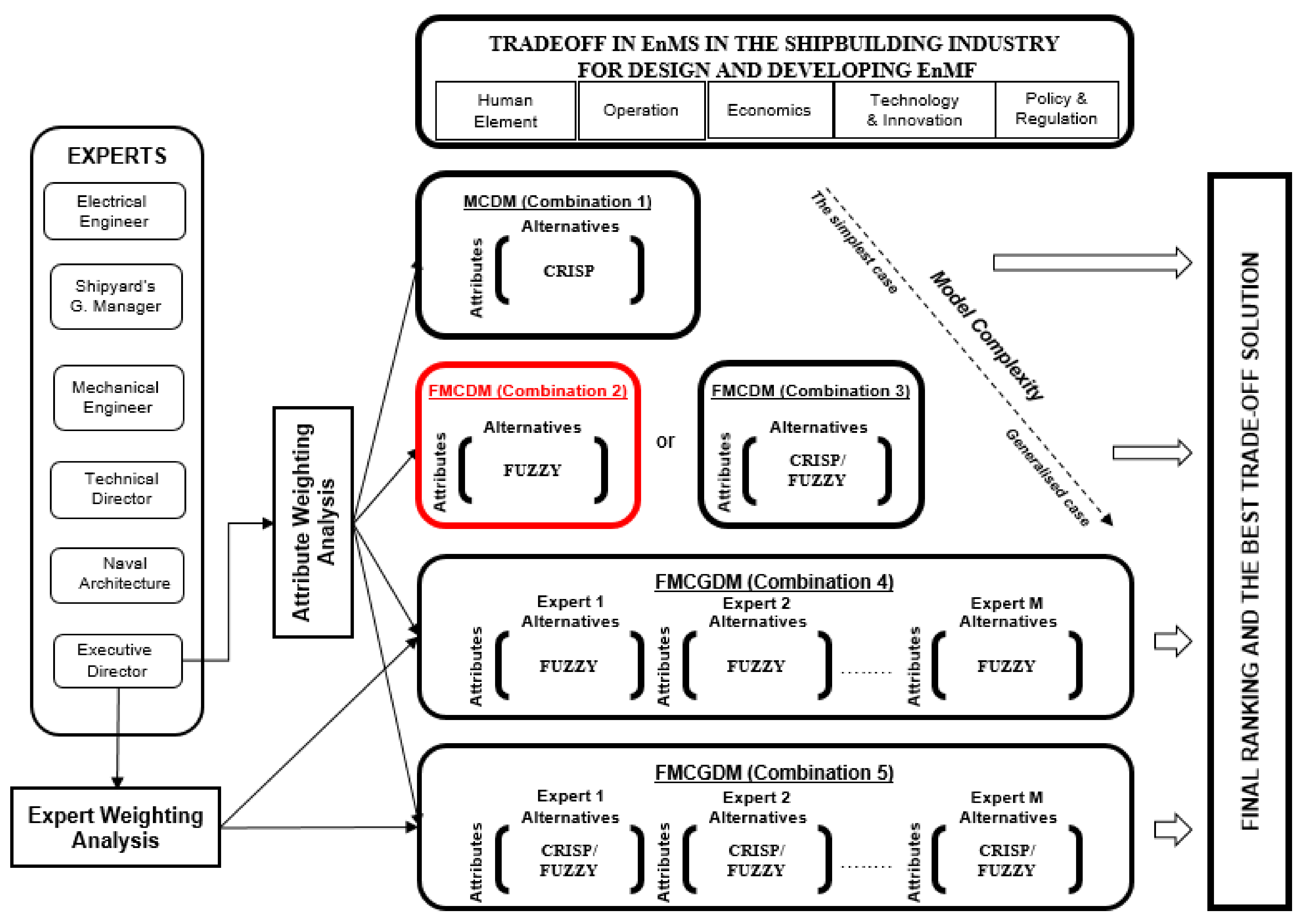

Taking the above into consideration, given the nature of the study, transdisciplinary and MCDM methods were chosen to analyze the questionnaire. In the first step (of the third stage), the FAHP method was used to determine the weights of the main disciplines (human factors, technology and innovation, policy and regulation, operations, and economics) and the weights of the criteria (cost, safety and security, air emissions, and social issues) based on the DM’s priorities. In the second step (of the third stage), the interviewee was asked about his preferences regarding the choice of the proposed alternatives within each discipline (in a linguistic format). Fuzzy Multiple Criteria Decision Making (FMCDM) [

75,

76], which employs FTOPSIS, was used to rank the alternatives within each discipline. Finally, the top three options from each main discipline were selected and, by applying the assigned weight for the main disciplines, the top options were ranked based on the yard’s priorities in the case study.

3.1. Systematic Literature Review

In this study, a systematic literature review was conducted on energy management in shipyards. Due to the limited literature review on energy management in shipyards, the authors aimed to transfer and tailor knowledge and experience from other industrial sectors into shipyards. Based on the literature review, the most important and related options, whose potential to improve energy efficiency and reduce air emissions has been proven, were identified for each discipline.

The literature was identified by searching for keywords in the following databases: Scopus, Science Direct, Google Scholar, Research Gate, and EBSCO. The following specific keywords and combinations thereof were used: “GHG emissions”, “air pollution”, “air emissions”, “energy management”, “energy intensive industry”, “energy efficiency”, “shipping”, “shipbuilding”, “ship repair”, “green shipyard”, “port”, “green production”, “life cycle assessment”, “MCDM”, “interdisciplinary”, “transdisciplinary”, “sustainable shipping”, “alternative energy”, “renewable energy”, “environmental protection”, “decision making”, “socio-technology”, “human factors”, “economics” and “policy and legislation”.

In this research, a total of 663 articles were obtained without duplicates. After the initial screening of titles, conclusions, abstracts, and keywords, 522 articles were excluded because they did not address, or help to improve, energy management in shipbuilding. In the second round, 141 papers were fully analyzed. In addition, 16 papers were included by backward snowball analysis. Thirty-three papers were excluded because they did not contribute explicitly to the development of energy management in the shipbuilding industry. A total of 124 documents were obtained and 89 of these (period 2004–2021) were used for the article.

3.2. Design and Conduct the Semi-Structured Questionnaire/Interview

Based on the literature review and the identified alternatives, the questionnaire’s sections were designed and developed. The questionnaire consisted of eight sections and was designed in a semi-structured format. The questions consisted of a combination of qualitative and quantitative measures, allowing respondents to provide both in-depth responses, in addition to numerical evaluations of the various aspects of their awareness and the use of the alternatives. Because the questionnaire was designed in a semi-structured format, it provided the interviewee with the opportunities to explain more about his concerns and actions regarding the topic [

77,

78].

To validate the framework, an interview was conducted with one of the top managers and key decision makers for the Turkish yard. The interviewee was asked to reflect on his ideas, experiences, and activities, and more generally on how the yard perceives and acts in terms of energy management. Although there were only three key DMs in the shipyard, the interview was conducted with the manager who had the highest weight in the final decision-making process, because the other managers were busy and unwilling to participate in the interview. The authors note that this may affect the accuracy of the results and that if the priorities of all DMs were taken into account, the results may have been more accurate.

3.3. A Transdisciplinary Approach to Analysis of the Questionnaire/Interviews

The EnMF is a multi-sectoral framework consisting of the contribution of different agents based on fuzzy logic. The framework helps the DMs to make better and well-justified decisions when confronted with a complicated situation [

79]. To structure a process and generate a strategic plan with the participation of all of those involved, and to optimize the decisions made for a complex problem, a transdisciplinary approach aligned with optimizing decision methods must be considered and developed [

14].

The third part of the study was the analysis of the questionnaire and interview. This included transdisciplinary and MCDM approaches to identify the priorities for the DM

3 in each discipline and to identify the interlinked alternatives. In sections one and two of the questionnaire, using the FAHP method, the weights of the main disciplines and the criteria were assigned based on the DM priorities. From sections three to seven, the preferences of the DM in choosing the proposed alternatives in each discipline concerning the introduced criteria were questioned in the linguistic format. The data were analyzed and, by applying the FTOPSIS within the FMCDM [

75] (combination 2, please see

Figure 4), the alternatives in each main discipline were ranked. The reason for using combination 2 was that only one DM’s preferences were covered in this study. By increasing the number of DMs, combination 4 can be applied. Moreover, the framework has flexible properties and depending on the type of data (crisp or linguistic) and the number of DMs, any combinations (1–5) in

Figure 4 can be applied in the framework. In the final stage (section eight), by choosing the top three best alternatives from each main discipline and applying the assigned weight for the main disciplines and the FTOPSIS method, the top alternatives were based on the interviewee’s determined priorities.

3.3.1. Fuzzy Analytical Hierarchy Process (FAHP)

As described in

Section 3.3, the FAHP method was used to determine the weighting of attributes for the main disciplines and criteria. AHP is a tool that can be used to analyze different types of issues in different disciplines, such as social, political, economic, and technological problems [

75], in addition for both qualitative and quantitative analysis, and can transfer information (derived from experience) to decision making [

80]. Some literature argues that the traditional AHP method still cannot accurately reflect the human mind-set [

81] and express the DM’s opinion in a comparison of alternatives [

82], and that it uses an unbalanced scale for judgments and cannot overcome uncertainty and the imprecise pairwise comparisons process [

83]. To address all these limitations, the FAHP method was developed. The FAHP method gives the DM more confidence to provide interval assessments instead of fixed value assessments [

84].

Triangular fuzzy numbers (TFN) are represented by three numbers A = (

,

,

); where

a,

b, and

c are the lowest potential value, higher potential value, and the highest potential value of fuzzy number ñ respectively. A as a triangular fuzzy number, where

≤

≤

, has the following function [

85]:

The arithmetic operations between two fuzzy numbers are as follows.

Multiplication of a fuzzy number ⊗:

Division of a fuzzy number ∅:

Subtraction of a fuzzy number ⊖:

Reciprocal of a fuzzy number:

In this study, the geometric mean technique [

86] was used for the analysis of the data to calculate the fuzzy weights.

where

th row, and Ꞷ

i = fuzzy weight of the

th event.

After determining the fuzzy weights for disciplines and criteria, the geometric mean method [

87] was used to obtain the defuzzified (DF) mean of the weights:

3.3.2. Fuzzy TOPSIS

Energy management at the shipyard is undertaken in a highly complex socio-economic environment. In order to make rational decisions about energy, it is important that all factors are considered. However, in a complex context, preference options may not be accurate and rational. Therefore, it is important that DMs are supported by the DSS. This support can be provided by designing and implementing conceptual frameworks for group decision making to help DMs make and optimize rational decisions [

88].

In this study, the importance of the main disciplines and criteria was calculated using the FAHP method (see

Section 3.3.1), and the FTOPSIS method was used to determine the distance between two triangular fuzzy numbers. The FTOPSIS approach is a suitable method for solving group decision-making problems [

79]. To rank all alternatives, the method simultaneously determines the distances to both the fuzzy positive ideal solution (FPIS) and the fuzzy negative ideal solution (FNIS) [

89].

Assuming that each discipline has K options, the weight of each criterion and the rating of the options with respect to each criterion can be calculated as follows:

where

ij K and Ꞷ

j K are the rating and the importance weight of the Kth decision maker (the Ꞷ

j K, the weight for the main disciplines and criteria, were achieved from

Section 3.3.1 utilizing the FAHP method). Thus, a fuzzy multi-criteria group decision-making problem can be shown as follows:

| Alternatives | Criteria (Attributes) |

| C1 | C2 | .... | .... | Cm |

| A1 |

Ծ11 | Ծ12 | .... | .... | Ծ1m |

| A2 |

Ծ12 | Ծ12 | .... | .... | Ծ2m |

| .... | . | . | . | . | . |

| .... | . | . | . | . | . |

| An |

Ծn1 | .... | .... | .... | Ծnm |

| Ꞷ |

Ꞷ1 | Ꞷ2 | .... | .... | Ꞷn |

where

ij, ∀

i;j and Ꞷ

j, j = 1,2, …, n are linguistic variables, which can be described by triangular fuzzy numbers,

ij = (

ij, ij, ij), and Ꞷ

j = (Ꞷ

j1, Ꞷ

j2, Ꞷ

j3). The linear scale transformation was used to convert the different criteria into a comparable scale. The normalized fuzzy decision matrix Ŕ was therefore obtained by the following:

where

are the sets of benefit criteria and cost criteria, respectively, and

By taking into account the different importance of each criterion, the authors constructed the weighted normalized fuzzy decision matrix in the following manner:

where

ṽij = ŕ

ij (.)

Ꞷj.The fuzzy positive ideal solution (FPIS, ) and fuzzy negative ideal solution (FNIS, ) are: = (1, 2, …, n), and = (1, 2, …, n), where, j = (1,1,1) and j = (0,0,0), j = 1, 2, …, n.

The distance of alternatives from FPIS and FNIS are calculated as follows:

The closeness coefficient of each alternative to determine the ranking order of alternatives is calculated by:

In summary, we can determine the best option by taking into account its near coefficient number. The option that was closer to FPIS and further from FNIS was the option that had a C

close to 1.

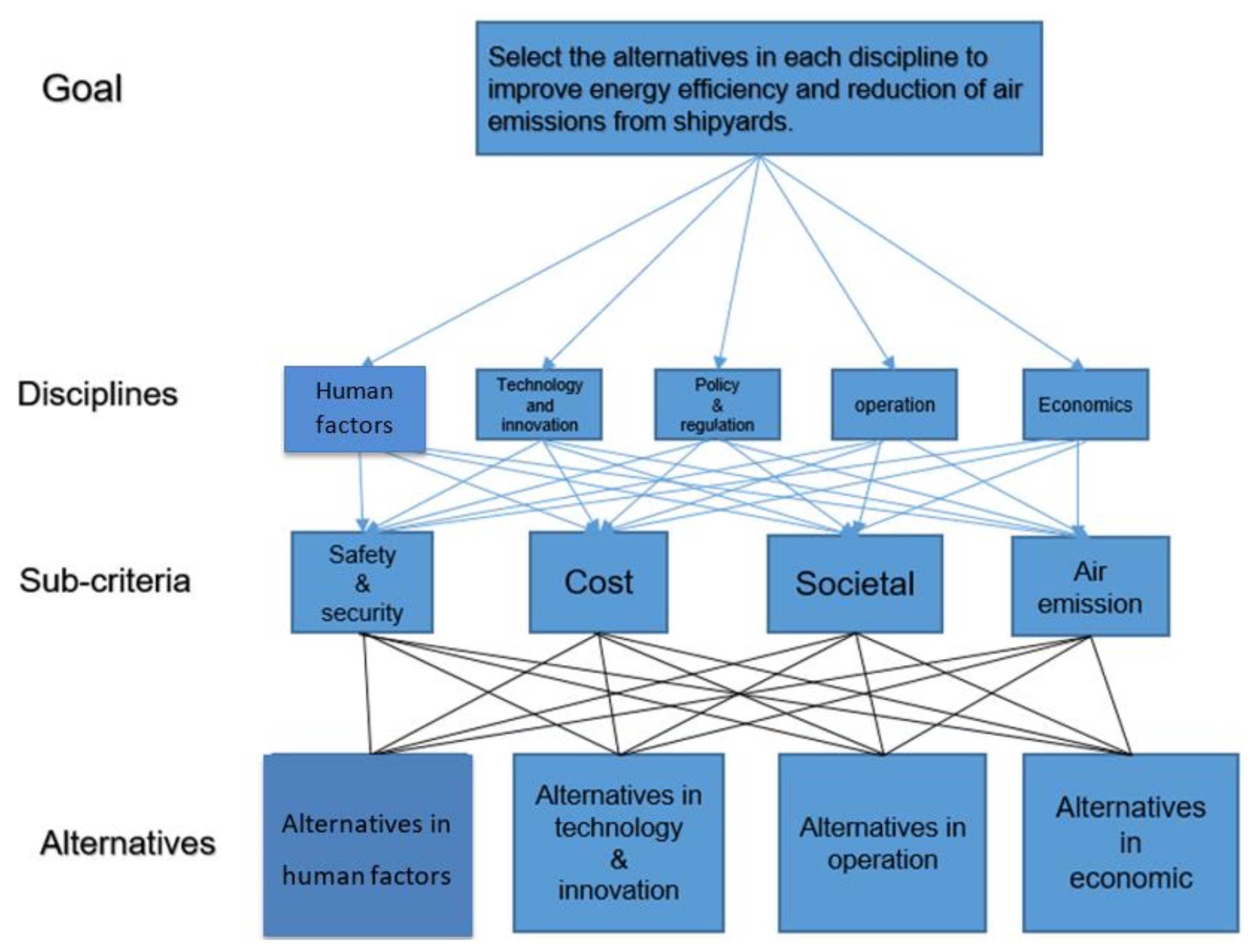

Figure 5 shows the hierarchical decision-making framework for selecting options to improve energy efficiency and reduce the footprint of air emissions at shipyards.

5. Conclusions

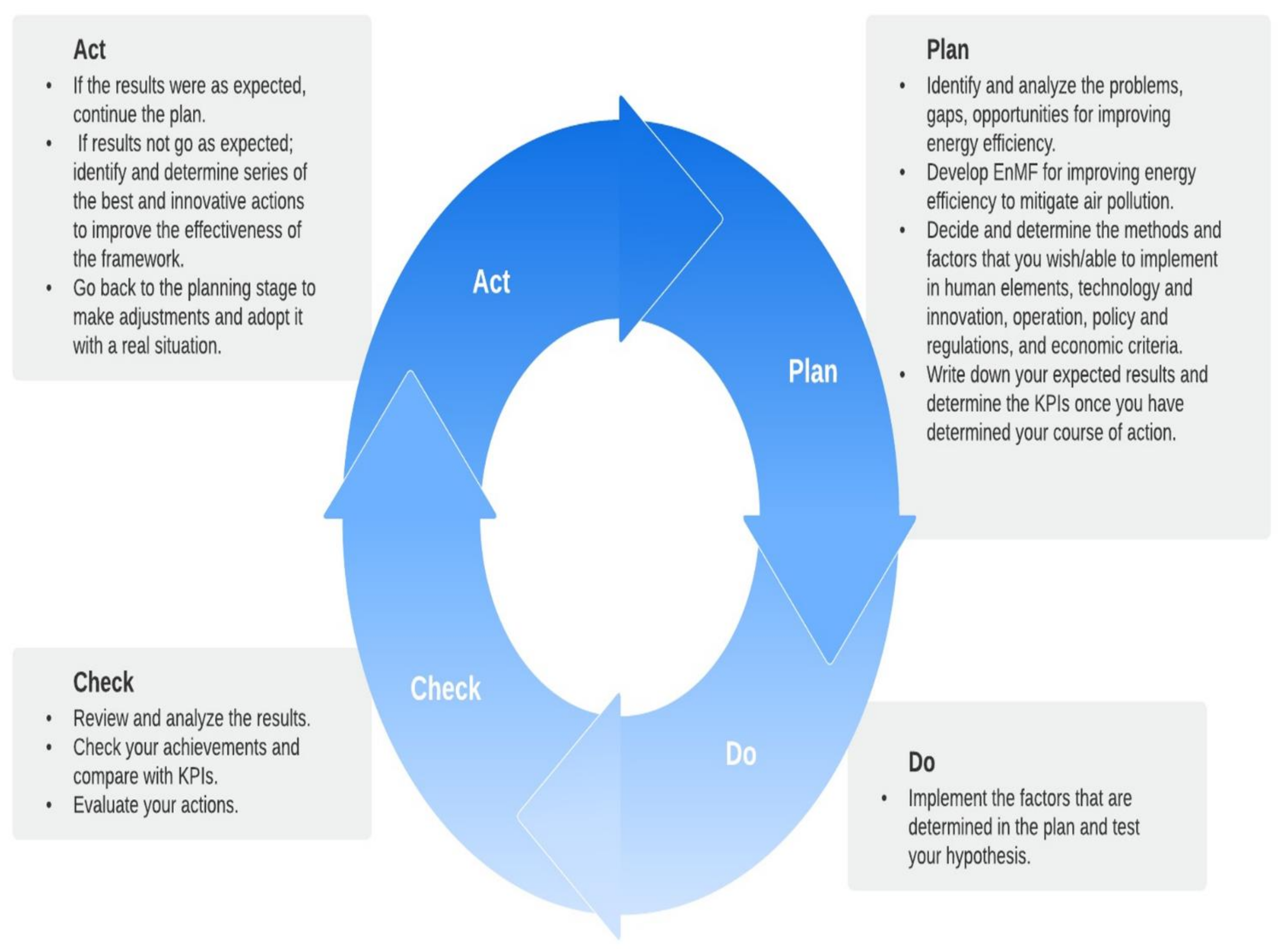

A holistic, systematic, and transdisciplinary approach is necessary to achieve zero emissions over the life cycle of the maritime industry. This study used a mixture of two different FMCDM techniques, i.e., FAHP and FTOPSIS, to identify the priorities of shipyard managers (DMs) in improving the energy efficiency in shipyards and reducing air emissions in the shipbuilding portfolio. This study proposed a transdisciplinary EnMF that enables shipyard managers to make rational decisions and optimize their decisions to improve energy efficiency in their context. The results of the framework can strengthen the DSS in the shipbuilding industry. By taking into account the ranking of alternatives, shipyard DMs can design, develop, and implement energy policies in the short, medium, and long term. However, DMs must use the PDCA cycle and the dynamic aspects of the framework, monitor progress in implementation, and act to promote and update the benchmark measures based on the portfolio, circumstances, and new technologies. This article is addressed to researchers, policy makers, and DMs concerned and/or involved in the shipbuilding industry. This paper can raise awareness among DMs in maritime clusters and promote a holistic, systematic, transdisciplinary, and life-cycle approach to reduce the air emissions of the shipping industry.

The framework was applied to a large private Turkish shipyard, which was used as a case study. To assess the yard’s priorities, 39 alternatives, whose potential to improve energy efficiency and reduce air emissions has been proven, were identified within five disciplines: human factors, operations, policy and regulation, technology and innovation, and economics. The alternatives were ranked according to the priorities and preferences of the yard’s top management.

Table 10 shows the results of the implementation of the framework for the case of the shipyard.

The authors would like to draw attention to the specific limitations that can be addressed in future studies:

The sample of shipyards may be selected from several countries with different economic and geographical areas. The results may obviously differ in each case study.

The types of alternatives in each discipline may vary from those proposed in the current study.

Choosing different alternatives, disciplines, and criteria may change the ranking of alternatives.

Although there were only three main DMs in the case study, the interview was conducted with only one decision maker with the highest weight. This may affect the accuracy of the results. If all DMs’ priorities are taken into account, the results will be more accurate.

Before investing in energy-efficiency projects, a feasibility study must be carried out, taking into account various economic analyses.