Collapse Strength of Intact Ship Structures

Abstract

:1. Introduction

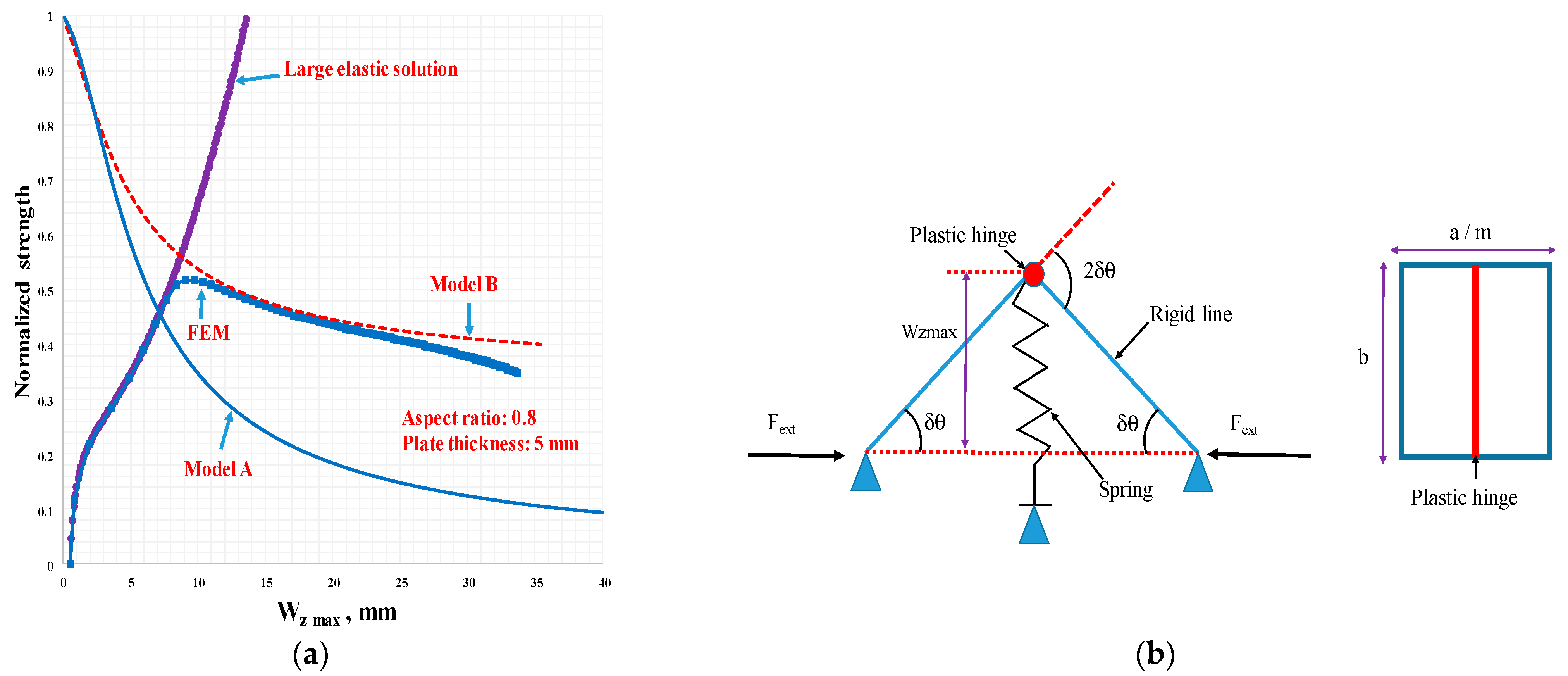

2. Plates

2.1. Plate Collapse Assessment

2.2. Impact of Initial Imperfection

2.3. Impact of Welding Induced Stress

2.4. Load and Boundary Condition Impact

3. Stiffened Panels

3.1. Failure Modes of Stiffened Panels

3.2. Collapse Strength Assessment

3.3. Impact of Governing Factors

3.3.1. Impact of Load and Boundary Conditions

3.3.2. Impact of Material Properties and Welding Induced Effects

4. Box Structures

5. Ship Hull Structures

5.1. Ultimate Strength Assessment

5.2. Buckling and Lateral Pressure Impact on Collapse Strength

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Paik, J.K.; Amlashi, H.; Boon, B.; Branner, K.; Caridis, P.; Das, P.; Fujikubo, M.; Huang, C.H.; Josefson, L.; Kaeding, P.; et al. ISSC Committee III.1 Ultimate Strength. In Proceedings of the 18th International Ship and Offshore Structures Congress, Rostock, Germany, 9–13 September 2012; pp. 285–364. [Google Scholar]

- Guedes Soares, C. Uncertainty Modelling in Plate Buckling. Struct. Saf. 1988, 5, 17–34. [Google Scholar] [CrossRef]

- Paik, J.K.; Thayamballi, A.K. Ultimate Limit State Design of Steel-Plated Structures; Wiley: Chichester, UK, 2003. [Google Scholar]

- Paik, J.K.; Thayamballi, A.K. Ship-Shaped Offshore Installations: Design, Building and Operation; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Frankland, J.M. The Strength of Ship Plating under Edge Compression; U.S. Experimental Model Basin Progress Report 469; U.S. Experimental Model Basin: Washington, DC, USA, 1940. [Google Scholar]

- Faulkner, D. A review of effective plating for use in the analysis of stiffened plating in bending and compression. J. Ship Res. 1975, 19, 1–17. [Google Scholar] [CrossRef]

- Gordo, J.M.; Guedes Soares, C. Approximate load shortening curves for stiffened plates under uniaxial compression. Integr. Offshore Struct. 1993, 5, 189–211. [Google Scholar]

- Guedes Soares, C. Design equation for the compressive strength of unstiffened plate elements with initial imperfections. J. Constr. Steel Res. 1988, 9, 287–310. [Google Scholar] [CrossRef]

- Faulkner, D.; Guedes Soares, C.; Warwick, D.M. Requirements for Structural Design and Assessment; Elsevier: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Guedes Soares, C. Design equation for ship plate elements under uniaxial compression. J. Constr. Steel Res. 1992, 22, 99–114. [Google Scholar] [CrossRef]

- Carlsen, C.A. Simplified collapse analysis of stiffened plates. Nor. Marit. Res. 1977, 5, 135–177. [Google Scholar]

- Dwight, J.B.; Little, G.H. Stiffened steel compression flanges-a simpler approach. Struct. Eng. 1976, 54, 501–509. [Google Scholar]

- Little, G.H. Stiffened steel compression panels—A theoretical failure analysis. Struct. Eng. 1976, 54, 489–500. [Google Scholar]

- Fujikubo, M.; Yao, T. Elastic local buckling strength of stiffened plate considering plate/stiffener interaction and welding residual stress. Mar. Struct. 1999, 12, 543–564. [Google Scholar] [CrossRef]

- Faulkner, D.; Adamchak, J.C.; Synder, G.J.; Vetter, M.F. Synthesis of welded grillages to withstand compression and normal loads. Comput. Struct. 1973, 3, 221–246. [Google Scholar] [CrossRef]

- Cui, W.C.; Mansour, A.E. Generalization of a simplified method for predicting ultimate compressive strength of ship panels. Int. Shipbuild. Prog. 1999, 447, 291–303. [Google Scholar]

- Cui, W.C.; Wang, Y.J.; Pedersen, P.T. Strength of ship plates under combined loading. Mar. Struct. 2002, 15, 75–97. [Google Scholar] [CrossRef]

- Fujita, Y.; Nomoto, T.; Niho, O. Ultimate strength of stiffened plates subjected to compression. J. Soc. Nav. Archit. Jpn. 1977, 141, 190–197. [Google Scholar] [CrossRef]

- Paik, J.K.; Pedersen, P.T. A simplified method for predicting ultimate compressive strength of ship panels. Int. Shipbuild. Prog. 1996, 43, 139–157. [Google Scholar]

- Paik, J.K.; Thayamballi, A.K.; Lee, S.K.; Kang, S.J. A semi-analytical method for the elastic-plastic large deflection analysis of welded steel or aluminum plating under combined in-plane and lateral pressure loads. Thin Wall Struct. 2001, 39, 125–152. [Google Scholar] [CrossRef]

- Tekgoz, M.; Garbatov, Y. Analysis of post-collapse behaviour of rectangular plate employing roof mode plastic solutions. In Developments in Maritime Technology and Engineering; Guedes Soares, C., Santos, T.A., Eds.; Taylor and Frances: London, UK, 2021; Volume 1, pp. 599–608. [Google Scholar]

- Ueda, Y.; Yasukawa, W.; Yao, T.; Ikegami, H.; Ohminami, R. Effect of welding residual stresses and initial deflections on rigidity and strength of square plates subjected to compression. Trans. JWRI 1977, 6, 33–38. [Google Scholar]

- Guedes Soares, C.; Soreide, T.H. Behavior and design of stiffened plates under predominantly compressive loads. Int. Shipbuild. Prog. 1983, 30, 13–27. [Google Scholar] [CrossRef]

- Kmiecik, M. Behaviour of Axially Loaded Simply Supported Long Rectangular Plates Having Initial Deformations; Report No. 84; Ship Research Institute: Trondheim, Norway, 1971. [Google Scholar]

- Crisfield, M.A. Full-range analysis of steel plates and stiffened plating under uniaxial compression. Proc. Inst. Civ. Eng. 1975, 59, 595–624. [Google Scholar] [CrossRef]

- Frieze, P.A.; Dowling, P.J.; Hobbs, R.E. Ultimate load behaviour of plates in compression. In Steel Plated Structures; Dowling, P.J., Harding, J.E., Frieze, P.A., Eds.; Crosby Lockwod Staples: London, UK, 1977; pp. 26–50. [Google Scholar]

- Bradfield, C.D.; Stonor, R.W.P. Simple collapse analysis of plates in compression. J. Struct. Eng. 1984, 110, 2976–2993. [Google Scholar] [CrossRef]

- Harding, J.E.; Hobbs, R.E.; Neal, B.G. The elasto-plastic analysis of imperfect square plates under in-plane loading. Proc. Inst. Civ. Eng. 1977, 63, 137–158. [Google Scholar]

- Matthies, H.; Payer, H.G. Elastic-plastic post-buckling behaviour of ship plating. Comput. Struct. 1981, 13, 745–750. [Google Scholar] [CrossRef]

- Carlsen, C.A.; Czujko, J. The specification of post-welding distortion tolerances for stiffened plates in compression. Struct. Eng. 1978, 56, 133–141. [Google Scholar]

- Dow, R.S.; Smith, C.S. Effects of localized imperfections on compressive strength of long rectangular plates. J. Constr. Steel Res. 1984, 4, 51–76. [Google Scholar] [CrossRef]

- Ueda, Y.; Yao, T. The influence of complex initial deflection modes on the behaviour and ultimate strength of rectangular plates in compression. J. Constr. Steel Res. 1985, 5, 265–302. [Google Scholar] [CrossRef]

- Guedes Soares, C.; Kmiecik, M. Simulation of the ultimate compressive strength of unstiffened rectangular plates. Mar. Struct. 1993, 6, 553–569. [Google Scholar] [CrossRef]

- Guedes Soares, C. A code requirement for the compressive strength of plate elements. Mar. Struct. 1988, 1, 71–80. [Google Scholar] [CrossRef]

- Sadovský, Z.; Teixeira, A.P.; Guedes Soares, C. Degradation of the compression strength of rectangular plates due to initial deflection. Thin Wall Struct. 2005, 43, 65–82. [Google Scholar] [CrossRef]

- Sadovský, Z.; Teixeira, A.P.; Guedes Soares, C. Degradation of the compression strength of square plates due to initial deflection. J. Constr. Steel Res. 2006, 62, 369–377. [Google Scholar] [CrossRef]

- Sadovský, Z.; Guedes Soares, C.; Teixeira, A.P. Random field of initial deflections and strength of thin rectangular plates. Reliab. Eng. Syst. Saf. 2007, 92, 1659–1670. [Google Scholar] [CrossRef]

- Sadovský, Z.; Guedes Soares, C. Artificial neural network model of the strength of thin rectangular plates with weld induced initial imperfections. Reliab. Eng. Syst. Saf. 2011, 96, 713–717. [Google Scholar] [CrossRef]

- Woloszyk, K.; Garbatov, Y. Random field modelling of mechanical behaviour of corroded thin steel plate specimens. Eng. Struct. 2020, 212, 110544. [Google Scholar] [CrossRef]

- Woloszyk, K.; Garbatov, Y. An enhanced method in predicting tensile behaviour of corroded thick steel plate specimens by using random field approach. Ocean Eng. 2020, 213, 107803. [Google Scholar] [CrossRef]

- Cubells, A.; Garbatov, Y.; Guedes Soares, C. Photogrammetry measurements of initial imperfections for the ultimate strength assessment of plates. Int. J. Marit. Eng. 2014, 156, A291–A302. [Google Scholar]

- Chen, B.Q.; Garbatov, Y.; Guedes Soares, C. Displacement measurement of box girder based on photogrammetry. In Proceedings of the 11th International Symposium on Practical Design of Ships and Other Floating Structures, Rio de Janeiro, Brazil, 19–24 September 2010. PRADS2010-20083. [Google Scholar]

- Chen, B.Q.; Garbatov, Y.; Guedes Soares, C. Measurement of weld-induced deformations in three-dimensional structures based on photogrammetry technique. J. Ship Prod. Des. 2011, 27, 51–62. [Google Scholar]

- Kamtekar, A.G. The calculation of welding residual stresses in thin steel plates. Int. J. Mech. Sci. 1978, 20, 207–227. [Google Scholar] [CrossRef]

- Porter Goff, R.F.D. A simplified analysis of the residual longitudinal stresses and strains due to gas-cutting and welding of thin steel plate. Int. J. Mech. Sci. 1979, 21, 287–300. [Google Scholar] [CrossRef]

- Ueda, Y.; Yamakawa, T. Analysis of thermal elastic-plastic stress and strain during welding by finite element method. Join. Weld. Res. Inst. 1971, 2, 90–100. [Google Scholar]

- Little, G.H.; Kamtekar, A.G. The effect of thermal properties and weld efficiency on transient temperatures during welding. Comput. Struct. 1998, 68, 157–165. [Google Scholar] [CrossRef]

- Papazoglou, V.J.; Masubuchi, K. Numerical analysis of thermal stresses during welding including phase transformation effects. J. Press. Vessel. Technol. 1982, 104, 198–203. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Fu, G.; Gu, J.; Lourenco, M.I.; Duan, M.; Estefen, S.F. Parameter determination of double-ellipsoidal heat source model and its application in the multi-pass welding process. Ships Offshore Struct. 2014, 10, 204–217. [Google Scholar] [CrossRef]

- Biswas, P.; Mahpatra, M.; Mandal, N. Numerical and experimental study on prediction of thermal history and residual deformation of double-sided fillet welding. J. Eng. Manuf. 2009, 223, 1–10. [Google Scholar] [CrossRef]

- Biswas, P.; Mandal, N.R.; Sha, O.P. Three-dimensional finite element prediction of transient thermal history and residual deformation due to line heating. J. Eng. Marit. Environ. 2007, 221, 17–30. [Google Scholar] [CrossRef]

- Chang, P.H.; Teng, T.L. Numerical and experimental investigations on the residual stresses of the butt-welded joints. Comput. Mater. Sci. 2004, 29, 511–522. [Google Scholar] [CrossRef]

- Chen, B.Q.; Hashemzadeh, M.; Garbatov, Y.; Guedes Soares, C. Numerical and parametric modelling and analysis of weld-induced residual stresses. Int. J. Mech. Mater. Des. 2014, 11, 439–453. [Google Scholar] [CrossRef]

- Gery, D.; Long, H.; Maropoulos, P. Effects of welding speed, energy input and heat source distribution on temperature variations in butt joint welding. J. Mater. Process. Technol. 2005, 167, 393–401. [Google Scholar] [CrossRef]

- Hashemzadeh, M.; Garbatov, Y.; Guedes Soares, C. Welding-induced residual stresses and distortions of butt-welded corroded and intact plates. Mar. Struct. 2021, 79, 103041. [Google Scholar] [CrossRef]

- Hashemzadeh, M.; Garbatov, Y.; Guedes Soares, C.; O’Connor, A. Friction stir welding induced residual stresses in thick steel plates from experimental and numerical analysis. Ships Offshore Struct. 2021, 1–9. [Google Scholar] [CrossRef]

- Estefen, S.F.; Gurova, T.; Werneck, D.; Leontiev, A. Welding stress relaxation effect in butt-jointed steel plates. Mar. Struct. 2012, 29, 211–225. [Google Scholar] [CrossRef]

- Fu, G.; Gurova, T.; Lourenco, M.I.; Estefen, S.F. Numerical and experimental studies of residual stresses in multipass welding of high strength shipbuilding steel. J. Ship Res. 2015, 59, 133–144. [Google Scholar] [CrossRef]

- Biswas, P.; Mandal, N.R. Effect of welding tacks and sequences on residual stress in stiffened panel fabrication. J. Ocean. Ship Technol. 2011, 2, 99–113. [Google Scholar]

- Adak, M.; Guedes Soares, C. Effects of different restraints on the weld-induced residual deformations and stresses in a steel plate. Int. J. Adv. Manuf. Technol. 2013, 71, 699–710. [Google Scholar] [CrossRef]

- Adak, M.; Mandal, N.R. Numerical and experimental study of mitigation of welding distortion. Appl. Math. Model. 2010, 34, 146–158. [Google Scholar] [CrossRef]

- Choobi, M.S.; Haghpanahi, M.; Sedighi, M. Investigation of the effect of clamping on residual stresses and distortions in butt-welded plates. Mech. Eng. 2010, 17, 387–394. [Google Scholar]

- Hashemzadeh, M.; Garbatov, Y.; Soares, C. Reduction in weld induced distortions of butt-welded plates subjected to preventive measures. In Analysis and Design of Marine Structures V; Guedes Soares, C., Shenoi, A., Eds.; Taylor & Francis Group: London, UK, 2015; pp. 581–588. [Google Scholar]

- Mahapatra, M.M.; Datta, G.L.; Pradhan, B.; Mandal, N.R. Modelling the effects of constraints and single-axis welding process parameters on angular distortions in one-sided fillet welds. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 397–407. [Google Scholar] [CrossRef]

- Ueda, Y.; Yao, T. Fundamental Behavior of Plates and Stiffened Plates with Welding Imperfections. Trans. JWRI 1991, 20, 141–155. [Google Scholar]

- Paik, J.K.; Sohn, J.M. Effects of welding residual stresses on high tensile steel plate ultimate strength: Non-linear finite element method investigations. In Proceedings of the 28th International Conference on Offshore Mechanics and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009. OMAE2009-79297. [Google Scholar]

- Tekgoz, M.; Garbatov, Y.; Guedes Soares, C. Ultimate strength of a plate accounting for shakedown effect and corrosion degradation. In Developments in Maritime Transportation and Exploitation of Sea Resources; CRC Press: Boca Raton, FL, USA, 2014; pp. 395–403. [Google Scholar]

- Tekgoz, M.; Garbatov, Y.; Guedes Soares, C. Ultimate strength assessment of welded stiffened plates. Eng. Struct. 2015, 84, 325–339. [Google Scholar] [CrossRef]

- Gordo, J.M. Effect of Residual Stresses on the Elastoplastic Behaviour of Welded Steel Plates. J. Mar. Sci. Eng. 2020, 8, 702. [Google Scholar] [CrossRef]

- Guedes Soares, C.; Kmiecik, M. Influence of the boundary conditions on the collapse strength of square plates with initial imperfections. In Marine Technology and Transportation; Graczyk, T., Jastrzebski, T., Brebbia, C.A., Burns, R.S., Eds.; Computational Mechanics Publications: Southampton, UK, 1995; pp. 227–235. [Google Scholar]

- Gordo, J.M. Effect of initial imperfections on the strength of restrained plates. J. Offshore Mech. Arct. Eng. 2015, 137, 051401. [Google Scholar] [CrossRef] [Green Version]

- Paik, J.K.; Thayamballi, A.K.; Lee, M.J. Effect of initial deflection shape on the ultimate strength behaviour of welded steel plates under biaxial compressive loads. J. Ship Res. 2004, 48, 45–60. [Google Scholar] [CrossRef]

- Steen, E.; Byklum, E.; Hellesland, J. Elastic post-buckling stiffness of biaxially compressed rectangular plates. Eng. Struct. 2008, 30, 2631–2643. [Google Scholar] [CrossRef]

- Valsgaard, S. Numerical design prediction of the capacity of plates in-plane compression. Comput. Struct. 1980, 12, 729–739. [Google Scholar] [CrossRef]

- Guedes Soares, C.; Gordo, J.M. Compressive strength of rectangular plates under biaxial load and lateral pressure. Thin Wall Struct. 1996, 24, 231–259. [Google Scholar] [CrossRef]

- Guedes Soares, C.; Gordo, J.M. Compressive strength of rectangular plates under transverse load and lateral pressure. J. Constr. Steel Res. 1996, 36, 215–234. [Google Scholar] [CrossRef]

- Becker, H. Instability strength of polyaxially loaded plates and relation to design. In Proceedings of the Steel Plated Structures: An international symposium, London, UK, July 1977; pp. 51–88. [Google Scholar]

- Becker, H.; Colao, A. Compressive Strength of Ship Hull Girders; Ship Structures Committee Report SSC-267; U.S. Coast Guard: Washington, DC, USA, 1977. [Google Scholar]

- Bradfield, C.D.; Stonor, R.W.P.; Moxham, K.E. Tests of long plates under biaxial compression. J. Construct. Steel Res. 1993, 24, 25–56. [Google Scholar] [CrossRef]

- Fujikubo, M.; Yao, T.; Khedmati, M.R.; Harada, M.; Yanagihara, D. Estimation of ultimate strength of continuous stiffened panel under combined transverse thrust and lateral pressure—Part 1: Continuous plate. Mar. Struct. 2005, 18, 383–410. [Google Scholar] [CrossRef]

- Fujita, Y.; Nomoto, T.; Niho, O.; Yoshie, A. Ultimate strength of rectangular plates subjected to combined loading (2nd Report). J. Soc. Nav. Archit. Jpn. 1979, 146, 289–298. [Google Scholar] [CrossRef]

- Smith, C.S.; Anderson, N.; Chapman, J.C.; Davidson, P.C.; Dowling, P.J. Strength of Stiffened Plating under Combined Compression and Lateral Pressure. Trans. RINA 1991, 134, 131–147. [Google Scholar]

- Yao, T.; Fujikubo, M.; Mizulani, K. Collapse behaviour of rectangular plates subjected to combined thrust and lateral pressure. Trans. West-Jpn. Soc. Nav. Archit. 1996, 92, 249–262. [Google Scholar]

- Paik, J.K.; Kim, B.J.; Seo, J.K. Methods for ultimate limit state assessment of ships and ship-shaped offshore structures: Part I—Unstiffened plates. Ocean Eng. 2008, 35, 261–270. [Google Scholar] [CrossRef]

- Paik, J.K.; Kim, B.J.; Seo, J.K. Methods for ultimate limit state assessment of ships and ship-shaped offshore structures: Part II—Stiffened plates. Ocean Eng. 2008, 35, 271–280. [Google Scholar] [CrossRef]

- DNV-PULS. User’s Manual (Version 2.05); Technical Report No. 2004-0406; Det Norske Veritas: Oslo, Norway, 2006. [Google Scholar]

- ALPS/ULSAP. A Computer Program for Ultimate Limit State Assessment for Stiffened Panels; Proteus Engineering: Stevensville, MD, USA, 2006. [Google Scholar]

- ANSYS. User’s Manual; Swanson Analysis Systems Inc.: Houston, TX, USA, 2006. [Google Scholar]

- Hughes, F.O.; Paik, J.K. Ship Structural Analysis and Design; The Society of Naval Architects and Marine Engineers: Alexandria, VA, USA, 1989. [Google Scholar]

- Yao, T.; Nikolov, P.I. Progressive collapse analysis of a ship´s hull under longitudinal bending. Soc. Nav. Archit. Jpn. 1991, 170, 449–461. [Google Scholar] [CrossRef]

- Guedes Soares, C.; Gordo, J.M. Design methods for stiffened plates under predominantly uniaxial compression. Mar. Struct. 1997, 10, 465–497. [Google Scholar] [CrossRef]

- Carlsen, C.A. A parametric study of collapse of stiffened plates in compression. Struct. Eng.—Part B 1980, 58, 33–40. [Google Scholar]

- American Bureau of Shipping. Rules Restatement Report; American Bureau of Shipping: Spring, TX, USA, 1991.

- Paik, J.K.; Kim, B.J. Ultimate strength formulations for stiffened panels under combined axial load, in-plane bending and lateral pressure: A benchmark study. Thin Wall Struct. 2002, 40, 45–83. [Google Scholar] [CrossRef]

- Paik, J.K.; Thayamballi, A.K. An empirical formulation for predicting the ultimate compressive strength of stiffened panels. In Proceedings of the 7th International Offshore and Polar Engineering Conference, Honolulu, HI, USA, 25–30 May 1997; pp. 328–338. [Google Scholar]

- Kim, D.K.; Lim, H.L.; Kim, M.S.; Hwang, O.J.; Park, K.S. An empirical formulation for predicting the ultimate strength of stiffened panels subjected to longitudinal compression. Ocean Eng. 2017, 140, 270–280. [Google Scholar] [CrossRef]

- Kim, D.K.; Lim, H.L.; Yu, S.Y. A technical review on ultimate strength prediction of stiffened panels in axial compression. Ocean Eng. 2018, 170, 392–406. [Google Scholar] [CrossRef]

- Kim, D.K.; Lim, H.L.; Yu, S.Y. Ultimate strength prediction of T-bar stiffened panel under longitudinal compression by data processing: A refined empirical formulation. Ocean Eng. 2019, 192, 106522. [Google Scholar] [CrossRef]

- Kim, D.K.; Young, S.Y.; Lim, H.L.; Cho, N.K. Ultimate compression strength of stiffened panel: An empirical formulation for flat-bar type. J. Mar. Sci. Eng. 2020, 8, 605. [Google Scholar] [CrossRef]

- Ozdemir, M.; Ergin, A.; Yanagihara, D.; Tanaka, S.; Yao, T. A new method to estimate ultimate strength of stiffened panels under longitudinal thrust based on analytical formulas. Mar. Struct. 2018, 59, 510–535. [Google Scholar] [CrossRef]

- Yao, T.; Nikolov, P.I. Progressive collapse analysis of a ship´s hull under longitudinal bending (2nd Report). Soc. Nav. Archit. Jpn. 1992, 172, 437–446. [Google Scholar] [CrossRef]

- IACS. Common Structural Rules for Bulk Carriers with a Length of 90 Meters and Above; DNV: Høvik, Norway, 2006. [Google Scholar]

- IACS. Common Structural Rules for Double Hull Oil Tankers with a Length of 150 Meters and Above; DNV: Høvik, Norway, 2006. [Google Scholar]

- Li, S.; Kim, D.K.; Benson, S. An adaptable algorithm to predict the load-shortening curves of stiffened panels in compression. Ships Offshore Struct. 2021, 16, 122–139. [Google Scholar] [CrossRef]

- Byklum, E.; Amdahl, J. A simplified method for elastic large deflection analysis of plates and stiffened panels due to local buckling. Thin Wall Struct. 2002, 40, 925–953. [Google Scholar] [CrossRef]

- Fujikubo, M.; Harada, M.; Yao, T.; Reza Khedmati, M.; Yanagihara, D. Estimation of ultimate strength of continuous stiffened panel under combined transverse thrust and lateral pressure Part 2: Continuous stiffened panel. Mar. Struct. 2005, 18, 411–427. [Google Scholar] [CrossRef]

- Xu, M.C.; Fujikubo, M.; Guedes Soares, C. Influence of model geometry and boundary conditions on the ultimate strength of stiffened panels under uniaxial compressive loading. J. Offshore Mech. Arct. 2013, 135, 041603. [Google Scholar] [CrossRef]

- Woloszyk, K.; Garbatov, Y.; Kowalski, J.; Samson, L. Numerical and experimental study on effect of boundary conditions during testing of stiffened plates subjected to compressive loads. Eng. Struct. 2021, 235, 112027. [Google Scholar] [CrossRef]

- Tanaka, S.; Yanagihara, D.; Yasuoka, A.; Harada, M.; Okazawa, S.; Fujikubo, M.; Yao, T. Evaluation of ultimate strength of stiffened panels under longitudinal thrust. Mar. Struct. 2014, 36, 21–50. [Google Scholar] [CrossRef]

- Xu, M.C.; Song, Z.J.; Pan, J.; Guedes Soares, C. Ultimate strength assessment of continuous stiffened panels under combined longitudinal compressive load and lateral pressure. Ocean Eng. 2017, 139, 39–53. [Google Scholar] [CrossRef]

- Garbatov, Y.; Tekgoz, M.; Guedes Soares, C. Uncertainty assessment of the ultimate strength of a stiffened panel. In Advances in Marine Structures; Taylor & Francis Group: London, UK, 2011; pp. 659–668. [Google Scholar]

- Gordo, J.M.; Guedes Soares, C. Compressive tests on stiffened panels of intermediate slenderness. Thin Wall Struct. 2011, 49, 782–794. [Google Scholar] [CrossRef]

- Gordo, J.M.; Guedes Soares, C. Compressive tests on short continuous panels. Mar. Struct. 2008, 21, 113–126. [Google Scholar] [CrossRef]

- Xu, M.C.; Guedes Soares, C. Comparison of numerical results with experiments on the ultimate strength of long stiffened panels. In Proceedings of the 30th International Conference on Offshore Mechanics and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; pp. 915–922. [Google Scholar]

- Xu, M.; Guedes Soares, C. Assessment of the ultimate strength of narrow stiffened panel test specimens. Thin Wall Struct. 2012, 55, 11–21. [Google Scholar] [CrossRef]

- Tekgoz, M.; Garbatov, Y.; Guedes Soares, C. Finite element modelling of the ultimate strength of stiffened plates with residual stresses. In Analysis and Design of Marine Structures; CRC Press: Boca Raton, FL, USA, 2013; pp. 309–317. [Google Scholar]

- Tekgoz, M.; Garbatov, Y.; Guedes Soares, C. Ultimate strength assessment of a stiffened plate accounting for welding sequences. In Proceedings of the PRADS2013, Changwon City, Korea, 20–25 October 2013; pp. 1089–1095. [Google Scholar]

- Gannon, L.G.; Pegg, N.G.; Smith, M.J.; Liu, Y. Effect of residual stress shakedown on stiffened plate strength and behaviour. Ships Offshore Struct. 2013, 8, 638–652. [Google Scholar] [CrossRef]

- Li, S.; Kim, D.K.; Benson, S. The influence of residual stress on the ultimate strength of longitudinally compressed stiffened panels. Ocean Eng. 2021, 231, 108839. [Google Scholar] [CrossRef]

- Reckling, K.A. Behaviour of box girders under bending and shear. In Proceedings of the 7th International Ship and Offshore Structures Congress, Paris, France, 1979; pp. 46–49. [Google Scholar]

- Ostapenko, A. Strength of ship hull girders under moment, shear, and torque. In Proceedings of the SSC-SNAME Symposium on Extreme Loads Response, Arlington, VA, USA, 19–20 October 1981; pp. 149–166. [Google Scholar]

- Nishihara, S. Ultimate longitudinal strength of midships cross-section. Nav. Archit. Ocean Eng. 1984, 22, 200–214. [Google Scholar]

- Gordo, J.M.; Guedes Soares, C. Experimental evaluation of the ultimate bending moment of a box girder. Mar. Syst. Ocean. Technol. 2004, 1, 33–46. [Google Scholar] [CrossRef]

- Gordo, J.M.; Guedes Soares, C. Experimental evaluation of the behaviour of a mild steel box girder under bending moment. Ships Offshore Struct. 2008, 3, 347–358. [Google Scholar] [CrossRef]

- Tekgoz, M.; Garbatov, Y.; Guedes Soares, C. Strength analysis of ship-shaped structures subjected to asymmetrical bending moment. In Analysis and Design of Marine Structures; Guedes Soares, C., Shenoi, R.A., Eds.; Taylor & Francis Group: Abingdon, UK, 2015; pp. 415–423. [Google Scholar]

- Yao, T.; Fujikobo, M. Buckling and Ultimate Strength of Ship and Ship-Like Floating Structures; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Dow, R.S. Testing, and analysis of a 1/3-scale welded steel frigate model. In Advances in Marine Structures 2; Spon Press: London, UK, 1991; pp. 749–773. [Google Scholar]

- Kell, C. Investigation of structural characteristics of destroyers “Preston” and “Bruce” part I—Description. Trans. SNAME 1931, 39, 35–64. [Google Scholar]

- Kell, C. Investigation of structural characteristics of destroyers “Preston” and “Bruce” part I—Analysis of data and results. Trans. SNAME 1940, 48, 125–172. [Google Scholar]

- Lang, D.; Warren, W. Structural strength investigation of destroyer Abuera. Trans. Inst. Nav. Arch. 1952, 94, 243–286. [Google Scholar]

- Mansour, A.E.; Yang, J.M.; Thayamballi, A.K. An experimental investigation of ship hull ultimate strength. Trans. SNAME 1990, 98, 411–439. [Google Scholar]

- Sugimura, T.; Nozaki, M.; Suzuki, T. Destructive experiment of ship hull model under longitudinal bending. J. Soc. Nav. Arch. Jpn. 1966, 199, 209–220. (In Japanese) [Google Scholar] [CrossRef]

- Yao, T.; Fujikubo, M.; Yanagihara, D.; Fujii, I.; Matrui, R.; Furui, N.; Kuwamura, Y. Buckling collapse strength of chip carrier under longitudinal bending (1st Report)-collapse test on 1/10-scale hull girder model under pure bending. J. Soc. Nav. Archit. Jpn. 2002, 191, 265–274. [Google Scholar] [CrossRef]

- Sun, H.H.; Guedes Soares, C. An experimental study of ultimate torsional strength of a ship-type hull girder with a large deck opening. Mar. Struct. 2003, 16, 51–67. [Google Scholar] [CrossRef]

- Tanaka, Y.; Ando, T.; Anai, Y.; Yao, T.; Fujikubo, M.; Iijima, K. Longitudinal strength of container ships under combined torsional and bending moments. In Proceedings of the 19th International Offshore and Polar Engineering Conference, Osaka, Japan, 21–26 June 2009; pp. 748–755. [Google Scholar]

- Yao, T. Hull girder strength. Mar. Struct. 2003, 16, 1–13. [Google Scholar] [CrossRef]

- Caldwell, J.B. Ultimate longitudinal strength. Trans. RINA 1965, 107, 411–430. [Google Scholar]

- Ueda, Y.; Rased, S.M.H. An ultimate transverse strength analysis of ship structures. J. Soc. Nav. Archit. Jpn. 1974, 136, 309–324. [Google Scholar] [CrossRef]

- Fujikubo, M.; Kaeding, P. ISUM rectangular plate element with new lateral shape function (2nd report): Stiffened plates under biaxial thrust. J. Soc. Nav. Archit. Jpn. 2000, 188, 479–487. [Google Scholar] [CrossRef]

- Fujikubo, M.; Kaeding, P.; Yao, T. ISUM rectangular plate element with new lateral shape function (1st report): Longitudinal and transverse thrust. J. Soc. Nav. Archit. Jpn. 2000, 187, 209–219. [Google Scholar] [CrossRef]

- Smith, C. Influence of local compressive failure on ultimate longitudinal strength of a ship hull. In Proceedings of the International Symposium on Practical Design in Shipbuilding, Tokyo, Japan, 18–20 October 1977; pp. 73–79. [Google Scholar]

- Sun, H.H.; Wang, X. Procedure for calculating hull girder ultimate strength of ship structures. Mar. Syst. Ocean. Technol. 2005, 1, 127–136. [Google Scholar] [CrossRef]

- Rigo, P.; Toderan, C.; Yao, T. Sensitivity analysis on ultimate hull bending moment. Pract. Des. Ships Other Float. Struct. 2001, 987–995. [Google Scholar]

- Yao, T.; Brunner, E.; Cho, S.R.; Choo, Y.S.; Czujko, J.; Estefen, S.F.; Gordo, J.M.; Hess, P.E.; Naar, H.; Pu, Y.; et al. Committee III.1 Ultimate Strength. In Proceedings of the 16th International Ship and Offshore Structures Congress, Southampton, UK, 20–25 August 2006; pp. 369–458. [Google Scholar]

- Yoshikawa, T.; Bayatfar, A.; Kim, B.J.; Chen, C.P.; Wang, D.; Boulares, J.; Gordo, J.M.; Josefson, L.; Smith, M.; Kaeding, P.; et al. Committee III. 1 Ultimate Strength. In Proceedings of the 19th International Ship and Offshore Structures Congress, Cascais, Portugal, 7–10 September 2015. [Google Scholar]

- Paik, J.K.; Mansour, A.E. A simple formulation for predicting the ultimate strength of ships. J. Mar. Sci. Technol. 1995, 1, 52–62. [Google Scholar] [CrossRef]

- Frieze, P.A.; Lin, Y.T. Ship longitudinal strength modelling for reliability analysis. In Proceedings of the Marine Structural Inspection, Maintenance and Monitoring Symposium, Arlington, VA, USA, 18–19 March 1991; pp. III.C.1–III.C.20. [Google Scholar]

- Mansour, A.; Faulkner, D. On applying the statistical approach to extreme sea loads and ship hull strength. Trans. RINA 1973, 115, 277–314. [Google Scholar]

- Valsgaard, S.; Steen, E. Ultimate hull girder strength margins in present class requirements. In Proceedings of the Marine Structural Inspection, Maintenance and Monitoring Symposium, Arlington, VA, USA, 18–19 March 1991. [Google Scholar]

- Vasta, J. Lessons learned from full-scale structural tests. Trans. SNAME 1958, 66, 165–243. [Google Scholar]

- Viner, A.C. Development of ship strength formulations. In Proceedings of the International Conference on Advances in Marine Structures, Dunfermline, UK, 20–23 May 1986; pp. 152–173. [Google Scholar]

- Gordo, J.M.; Guedes Soares, C. Approximate method to evaluate the hull girder collapse strength. Mar. Struct. 1996, 9, 449–470. [Google Scholar] [CrossRef]

- Yao, T.; Fujikubo, M.; Khedmati, M.R. Progressive collapse analysis of a ship´s hull girder under longitudinal bending considering local pressure loads. J. Soc. Nav. Archit. Jpn. 2000, 188, 507–515. [Google Scholar] [CrossRef]

- Garbatov, Y.; Saad-Eldeen, S.; Guedes Soares, C. Hull girder ultimate strength assessment based on experimental results and the dimensional theory. Eng. Struct. 2015, 100, 742–750. [Google Scholar] [CrossRef]

- Chen, K.Y.; Kutt, L.M.; Piaszczyk, C.M.; Bieniek, M.P. Ultimate strength of ship structures. Trans. SNAME 1983, 91, 149–168. [Google Scholar]

- Amlashi, H.K.K.; Moan, T. Ultimate strength analysis of a bulk carrier hull girder under alternate hold loading condition—A case study Part 1: Non-linear finite element modelling and ultimate hull girder capacity. Mar. Struct. 2008, 21, 327–352. [Google Scholar] [CrossRef]

- Benson, S.; Downes, J.; Dow, R.S. An automated finite element methodology for hull girder progressive collapse analysis. In Proceedings of the 13th International Marine Design Conference, Glasgow, UK, 11–14 June 2012. [Google Scholar]

- Benson, S.; Downes, J.; Dow, R.S. Compartment level progressive collapse analysis of lightweight ship structures. Mar. Struct. 2013, 31, 44–62. [Google Scholar] [CrossRef] [Green Version]

- Benson, S.; Downes, J.; Dow, R.S. Overall buckling of lightweight stiffened panels using an adapted orthotropic plate method. Eng. Struct. 2015, 85, 107–117. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.K.; Park, D.H.; Kim, H.B.; Kim, B.J.; Seo, J.K.; Paik, J.K. Lateral pressure effects on the progressive hull collapse behaviour of a Suezmax-class tanker under vertical bending moments. Ocean Eng. 2013, 63, 112–121. [Google Scholar] [CrossRef]

- Mansour, A.E.; Lin, Y.H.; Paik, J.K. Ultimate strength of ships under combined vertical and horizontal moments. In Proceedings of the Sixth International Symposium on PRADS, Seoul, Korea, 17–22 September 1995; pp. 844–851. [Google Scholar]

- Paik, J.K.; Kim, B.J.; Seo, J.K. Methods for ultimate limit state assessment of ships and ship-shaped offshore structures: Part III—Hull girders. Ocean Eng. 2008, 35, 281–286. [Google Scholar] [CrossRef]

- Paik, J.K.; Thayamballi, A.K.; Che, J.S. Ultimate strength of ship hulls under combined vertical bending, horizontal bending, and shear forces. Trans. SNAME 1996, 104, 31–59. [Google Scholar]

- Tekgoz, M.; Garbatov, Y.; Guedes Soares, C. Strength assessment of an intact and damaged container ship subjected to asymmetrical bending loadings. Mar. Struct. 2018, 58, 172–198. [Google Scholar] [CrossRef]

- Xu, M.; Garbatov, Y.; Guedes Soares, C. Ultimate strength assessment of a tanker hull based on experimentally developed master curves. J. Mar. Sci. Appl. 2013, 12, 127–139. [Google Scholar] [CrossRef]

- Tekgoz, M.; Garbatov, Y.; Guedes Soares, C. Review of ultimate strength assessment of ageing and damaged ship structures. J. Mar. Sci. Appl. 2021, 19, 512–533. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tekgoz, M.; Garbatov, Y. Collapse Strength of Intact Ship Structures. J. Mar. Sci. Eng. 2021, 9, 1079. https://doi.org/10.3390/jmse9101079

Tekgoz M, Garbatov Y. Collapse Strength of Intact Ship Structures. Journal of Marine Science and Engineering. 2021; 9(10):1079. https://doi.org/10.3390/jmse9101079

Chicago/Turabian StyleTekgoz, Mesut, and Yordan Garbatov. 2021. "Collapse Strength of Intact Ship Structures" Journal of Marine Science and Engineering 9, no. 10: 1079. https://doi.org/10.3390/jmse9101079

APA StyleTekgoz, M., & Garbatov, Y. (2021). Collapse Strength of Intact Ship Structures. Journal of Marine Science and Engineering, 9(10), 1079. https://doi.org/10.3390/jmse9101079