Experimental Study on the Impact of Water Content on the Strength Parameters of Coral Gravelly Sand

Abstract

Highlights

- Triaxial shear tests and NMR tests on coral gravelly sand with different water content were performed.

- Effects of water content on strength parameters of coral gravelly sand were assessed quantitatively.

- Underlying mechanisms of water content on strength parameters of coral gravelly sand were demonstrated.

- The relationship among the relative breakage index, plastic work and water content was established.

1. Introduction

2. Materials and Methods

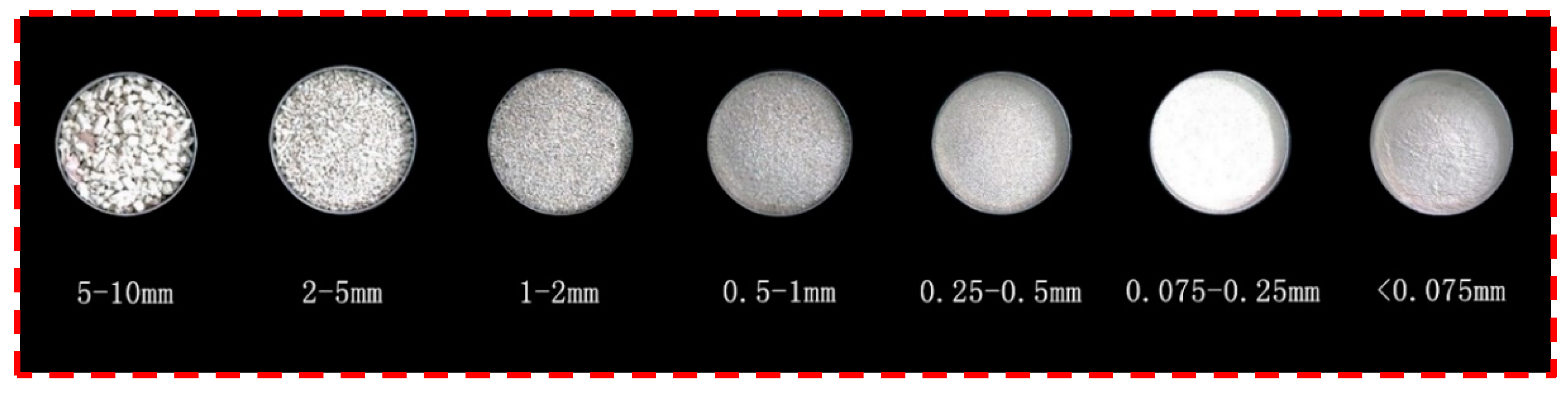

2.1. Experiment Material

2.2. Experiment Scheme

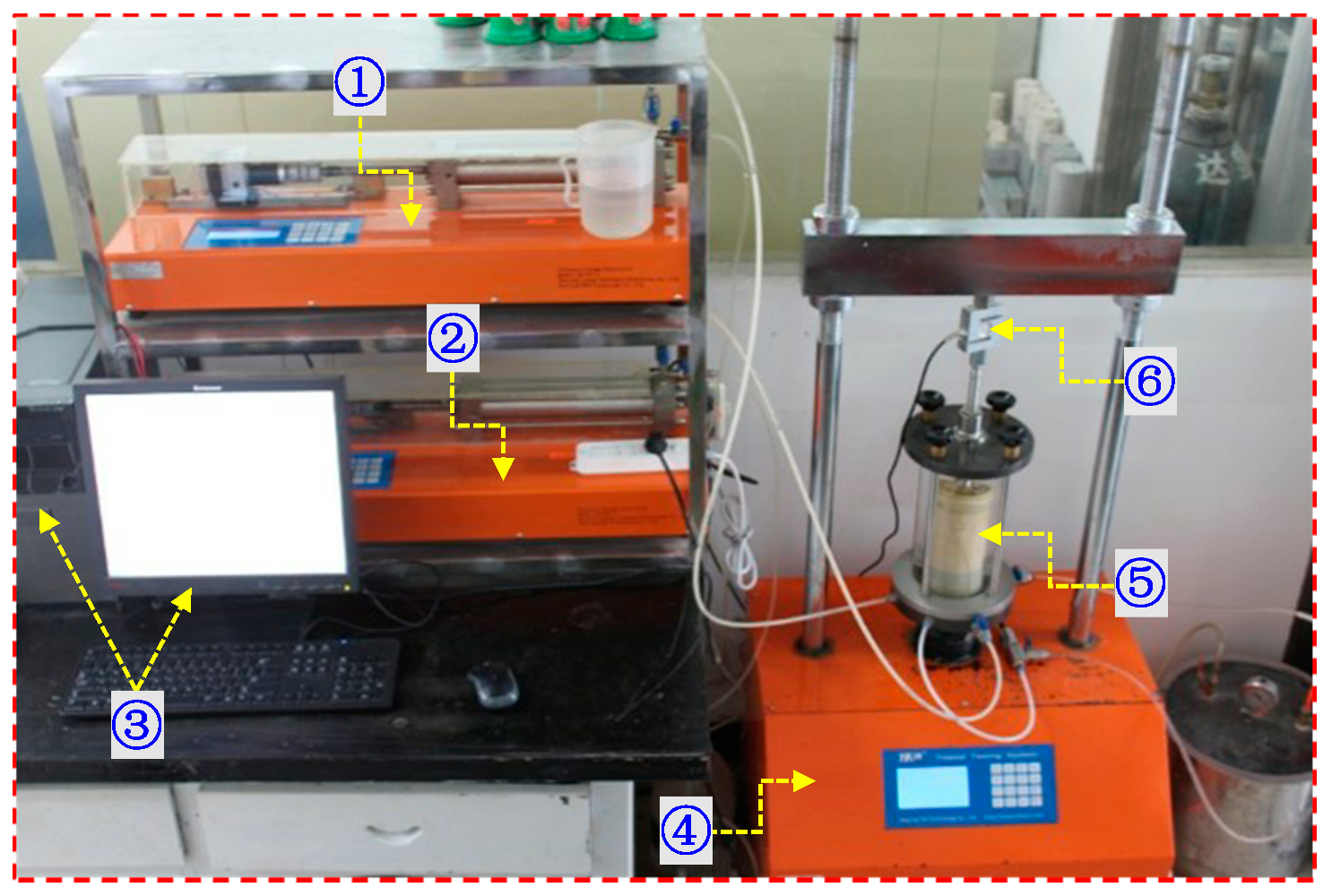

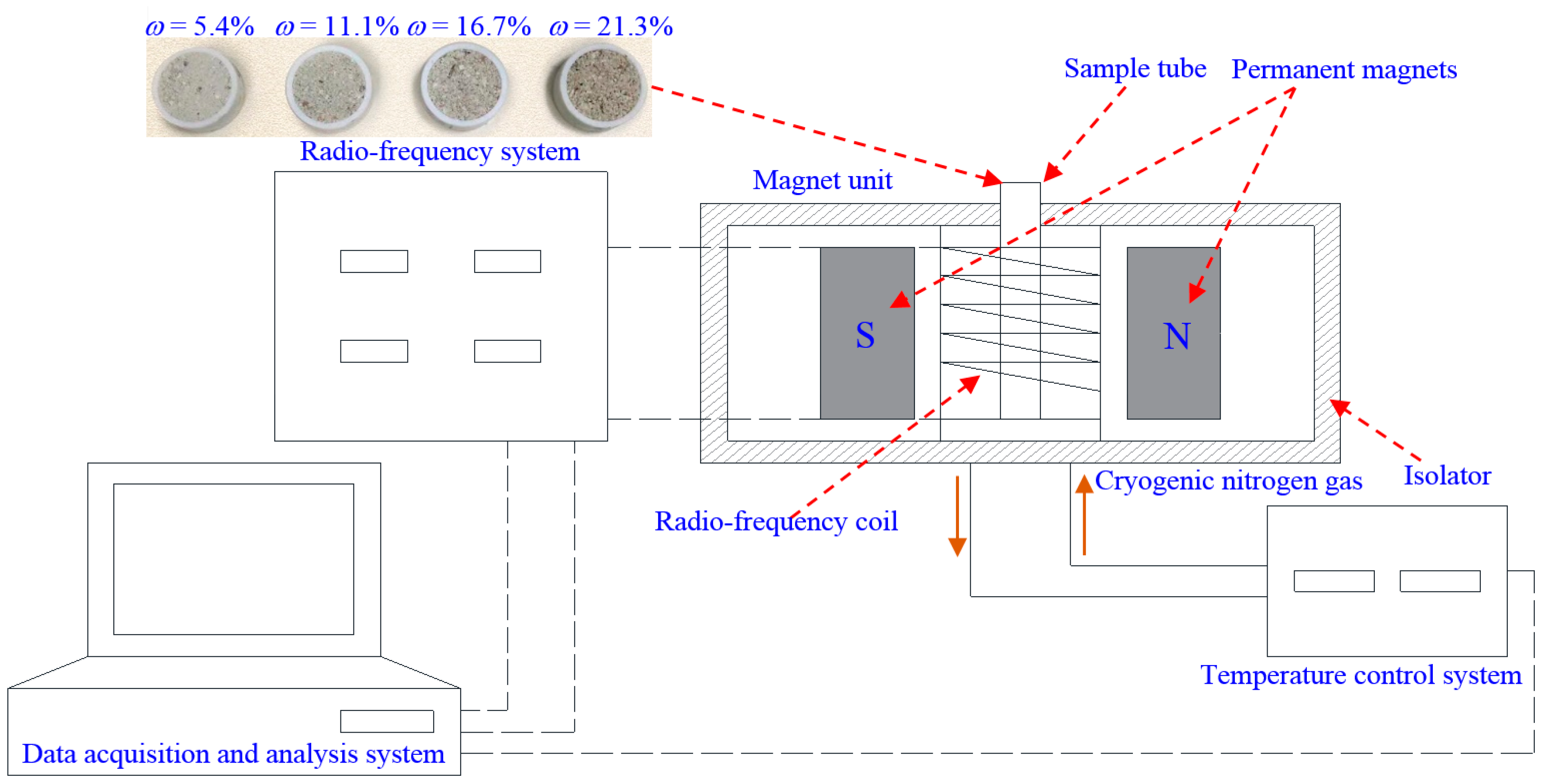

2.3. Experiment Apparatus and Operations

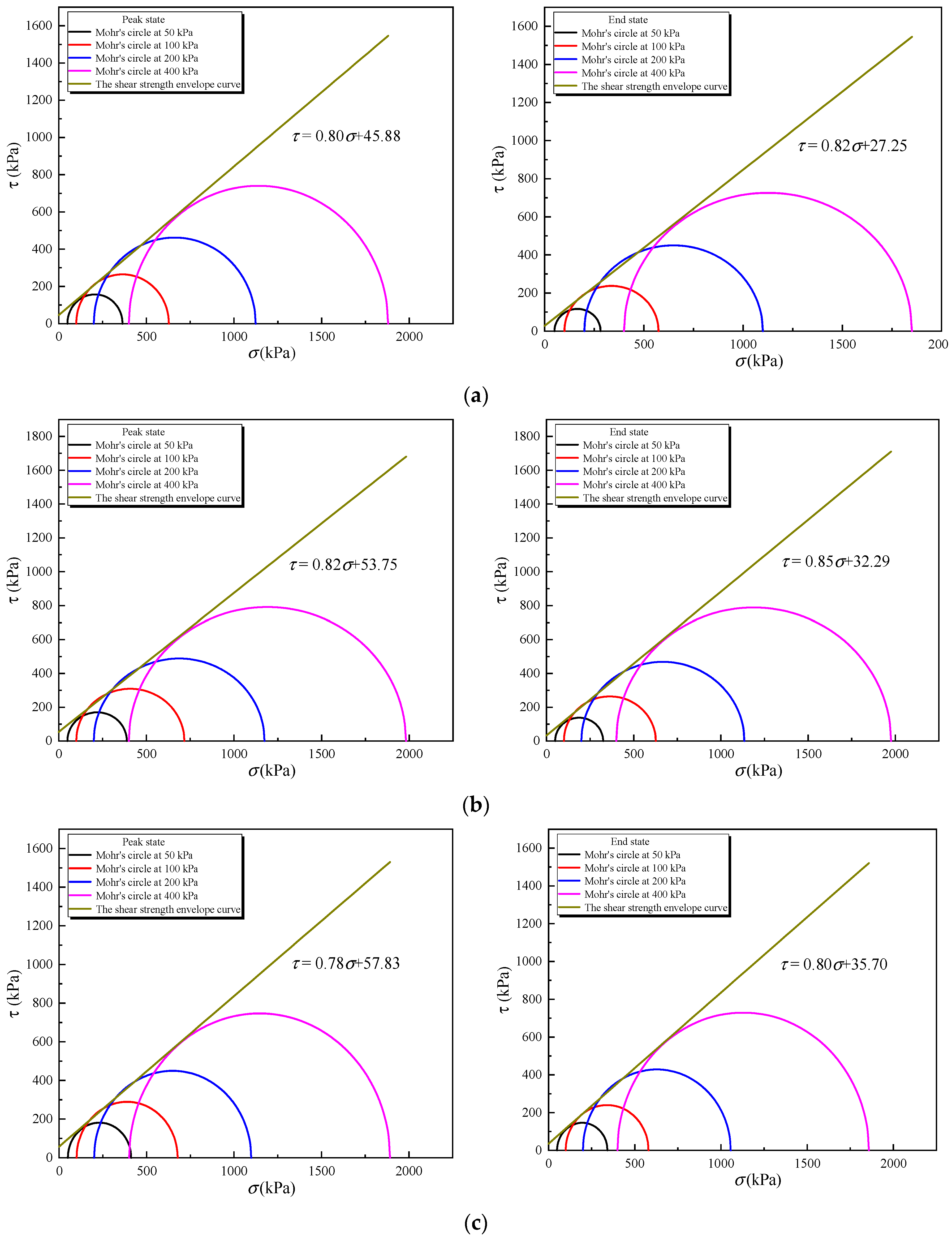

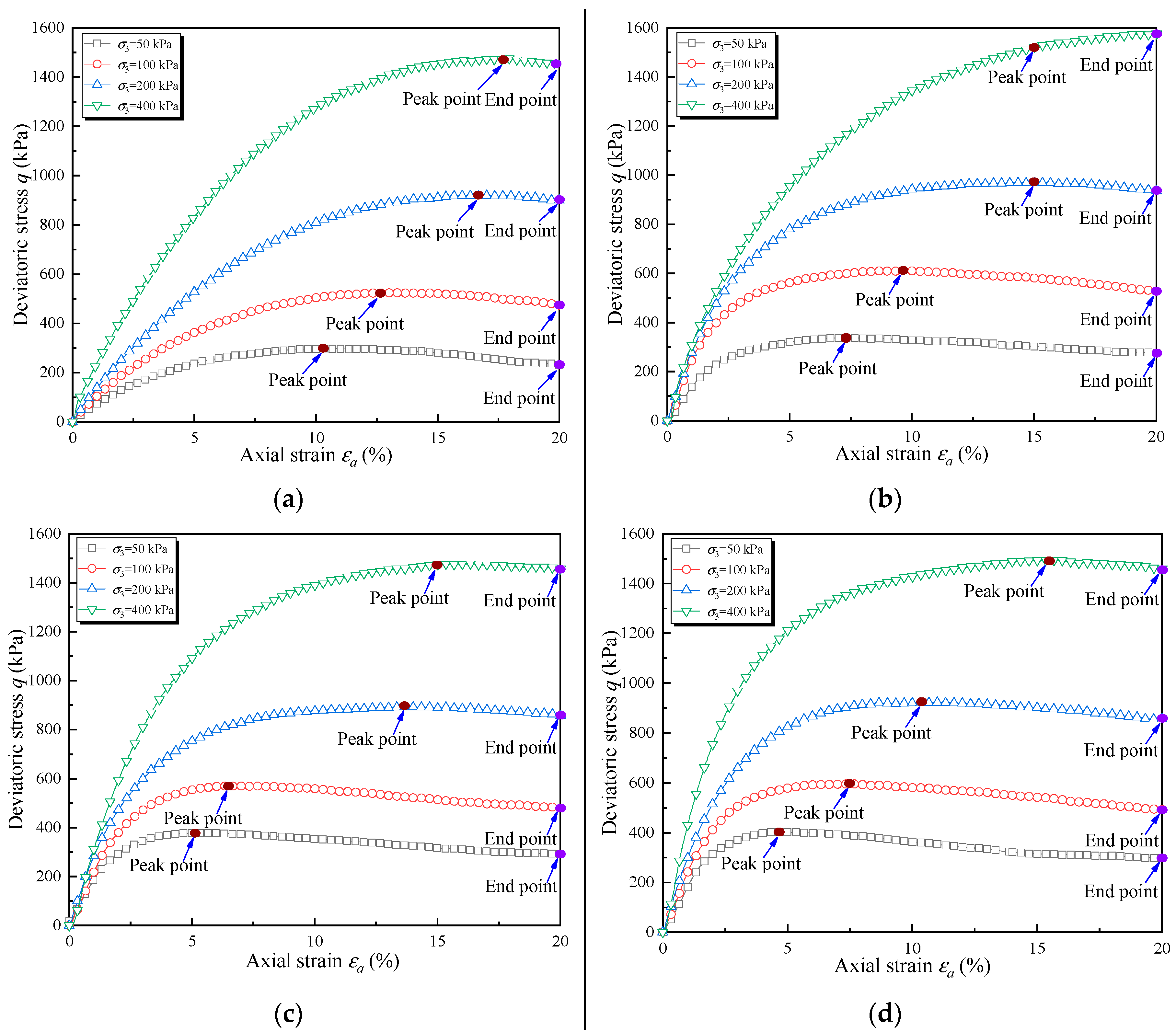

3. Analysis of Strength Parameters

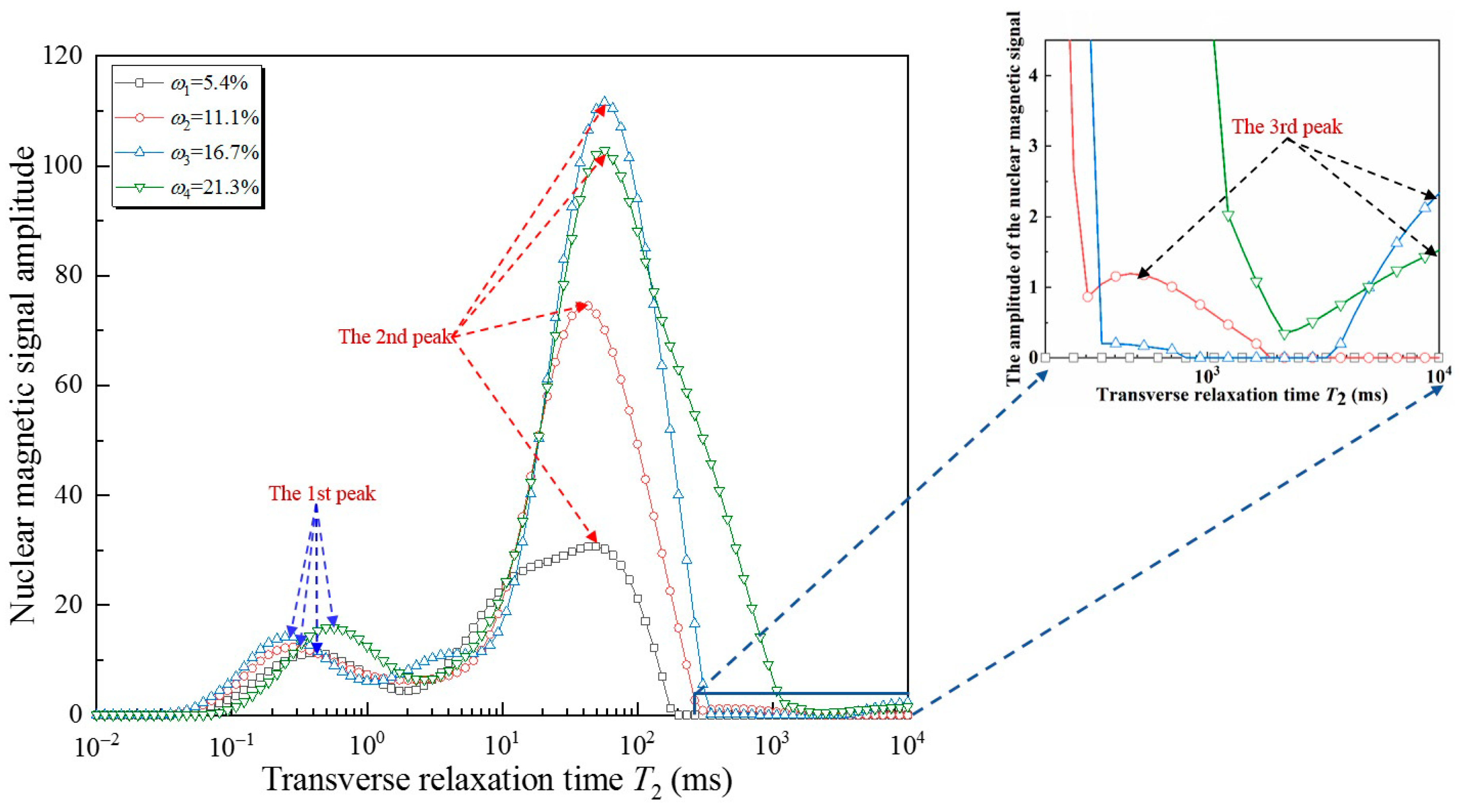

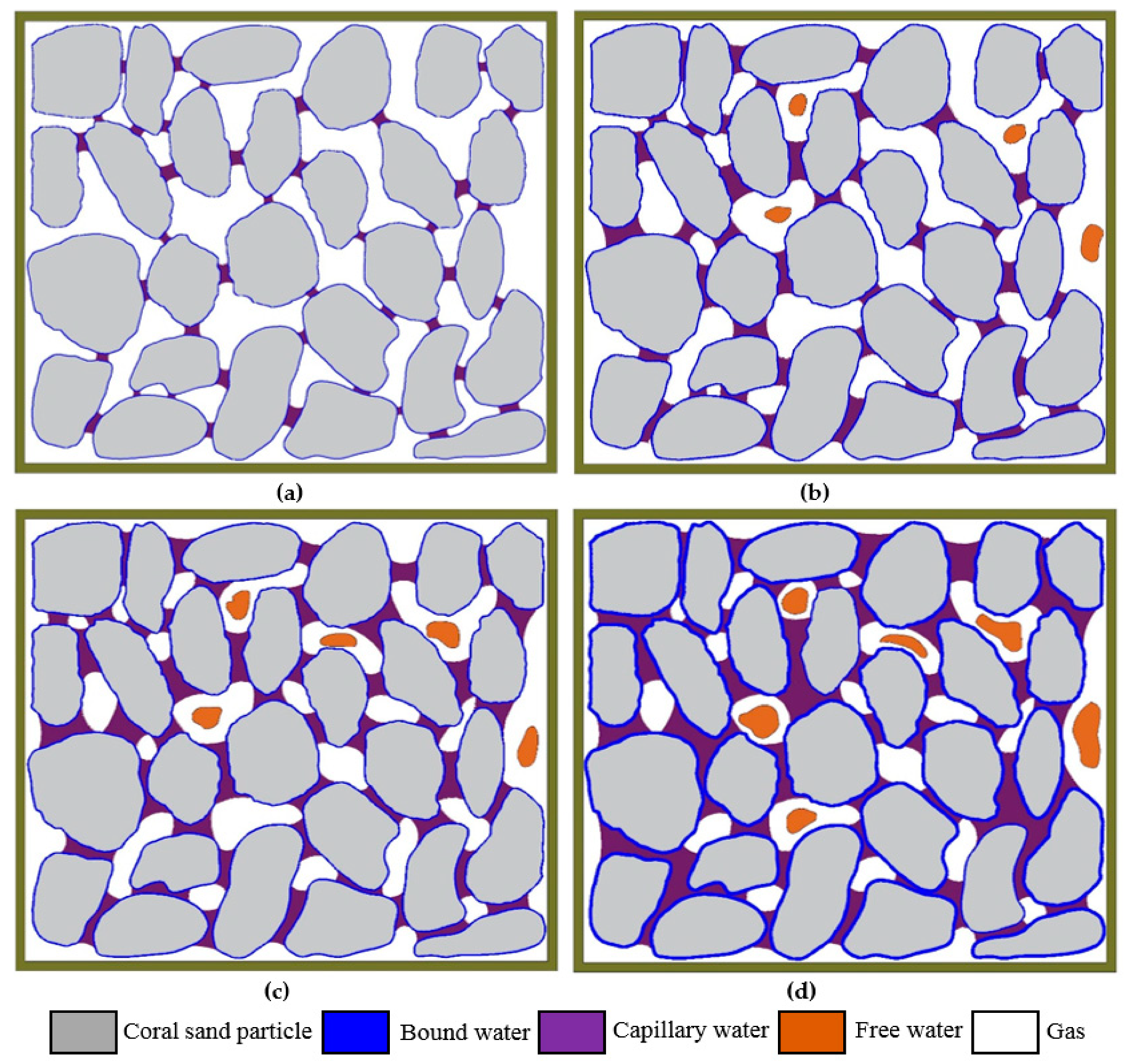

4. Microstructure Analysis

5. Analysis of Particle Breakage

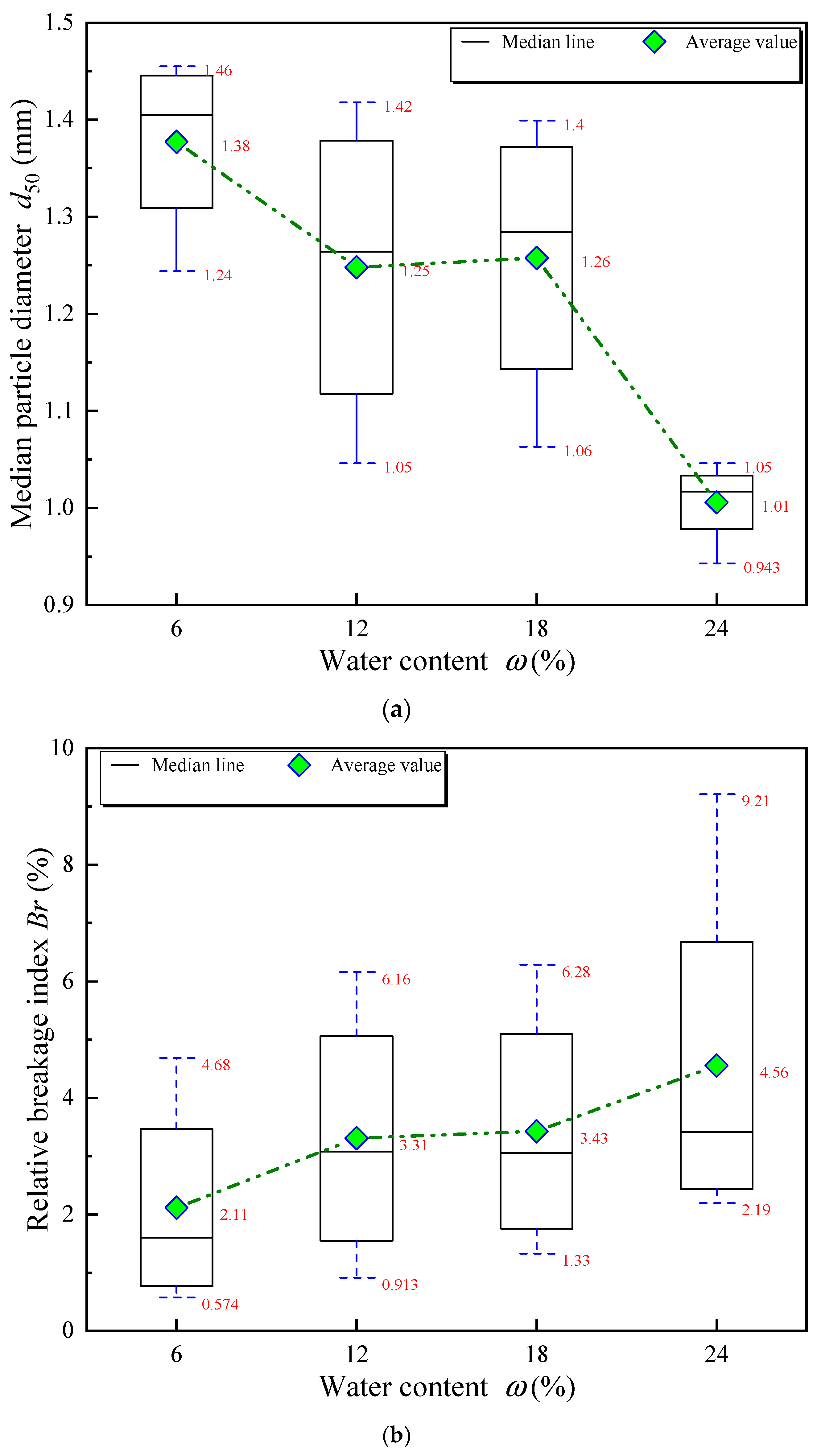

5.1. Relation between Particle Breakage and Water Content

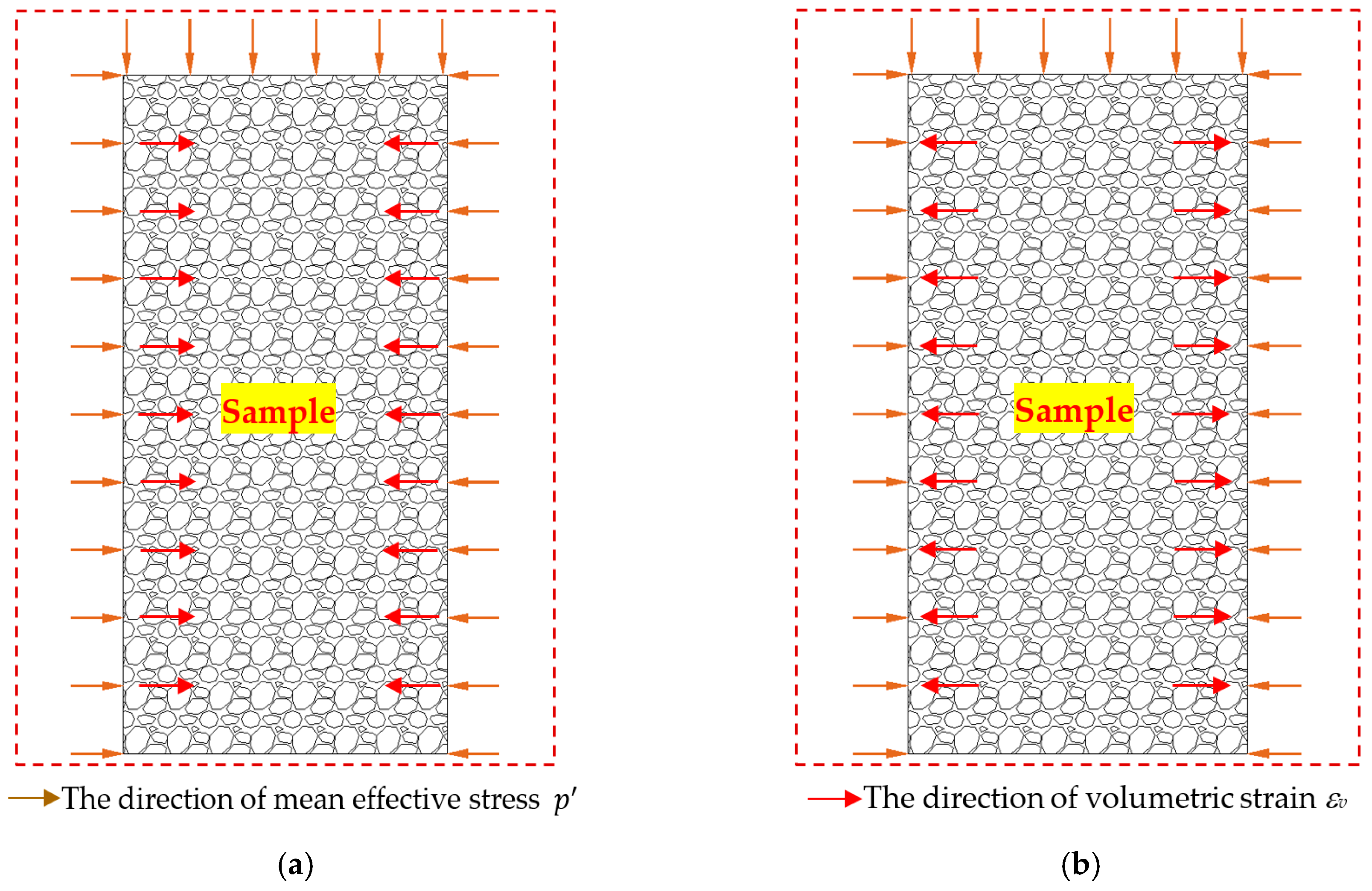

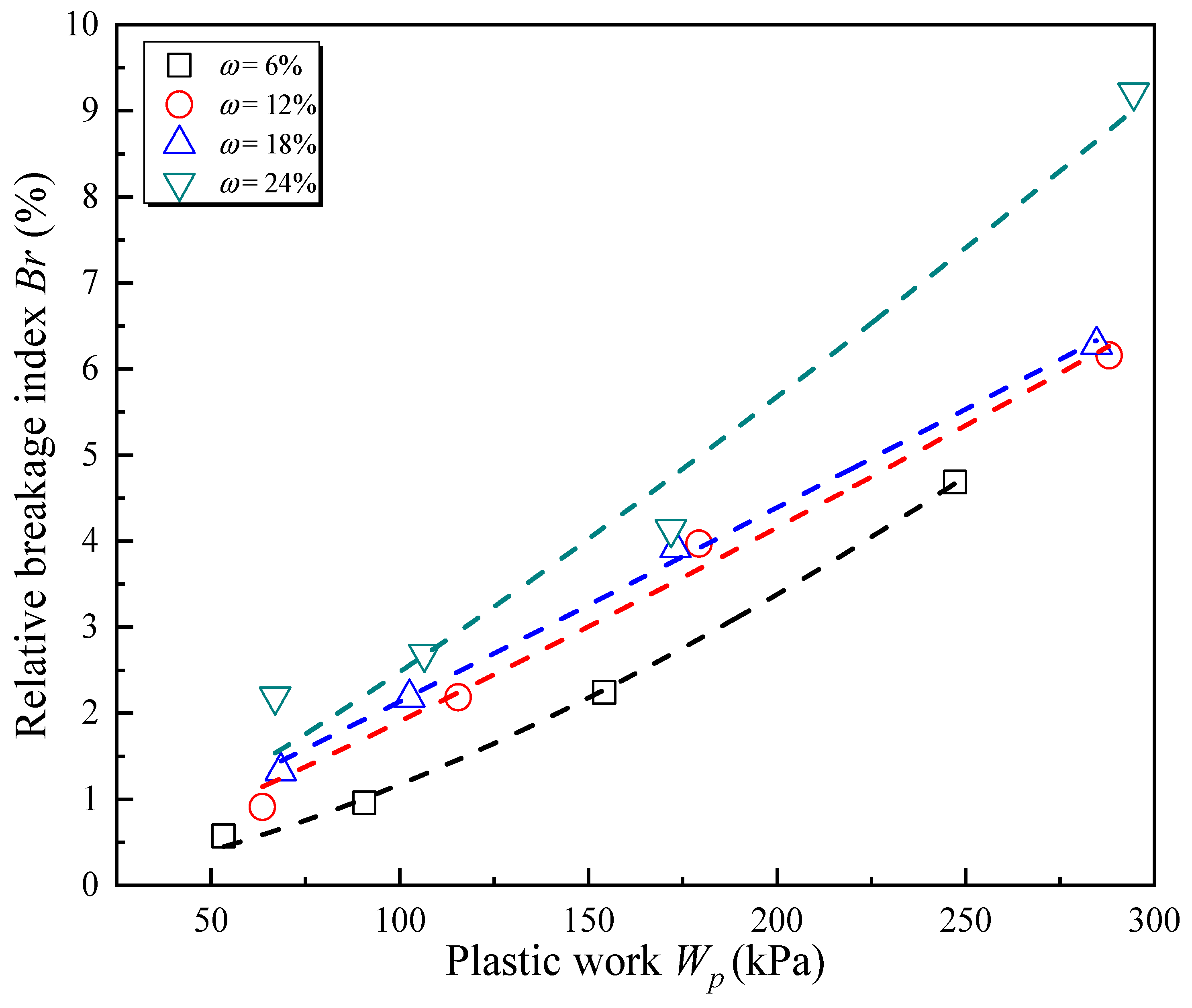

5.2. Relationship between Particle Breakage and Plastic Work

6. Conclusions

- (1)

- Coral gravelly sand with a relative density of 70% and different water contents undergo contraction during the triaxial shear process under confining pressures of 200 and 400 kPa, and the deviatoric stress at 15% of the axial strain is taken as its peak stress, which is the main reason for the peak friction angle being smaller than the friction angle in the end state.

- (2)

- The water content (ω) has less impact on the internal friction angle of coral gravelly sand. As the ω increases, the internal friction angle increases slightly (<1°) and then decreases with the increasing ω, and (the overall change is within 3°). The apparent cohesion is more sensitive to changes in the ω, which increases almost linearly with increasing ω. Therefore, when designing and constructing projects involving coral gravelly sand, the impact of rainfall and seawater tides on the project should be considered.

- (3)

- When the water content (ω) of the sample is small, the pore water mostly exists in the form of bound water and capillary water, and the free water content is relatively small. As the ω of the sample increases, the capillary water content is the highest and grows the fastest among the three pore water types, followed by bound water and free water.

- (4)

- The increase in free water content is the internal cause of the internal friction angle of coral gravelly sand with the water content (ω) greater than 11.1% continuously decreasing with increasing ω. The capillary water content is the main factor impacting the apparent cohesion of coral gravelly sand, and there is a positive correlation between the two.

- (5)

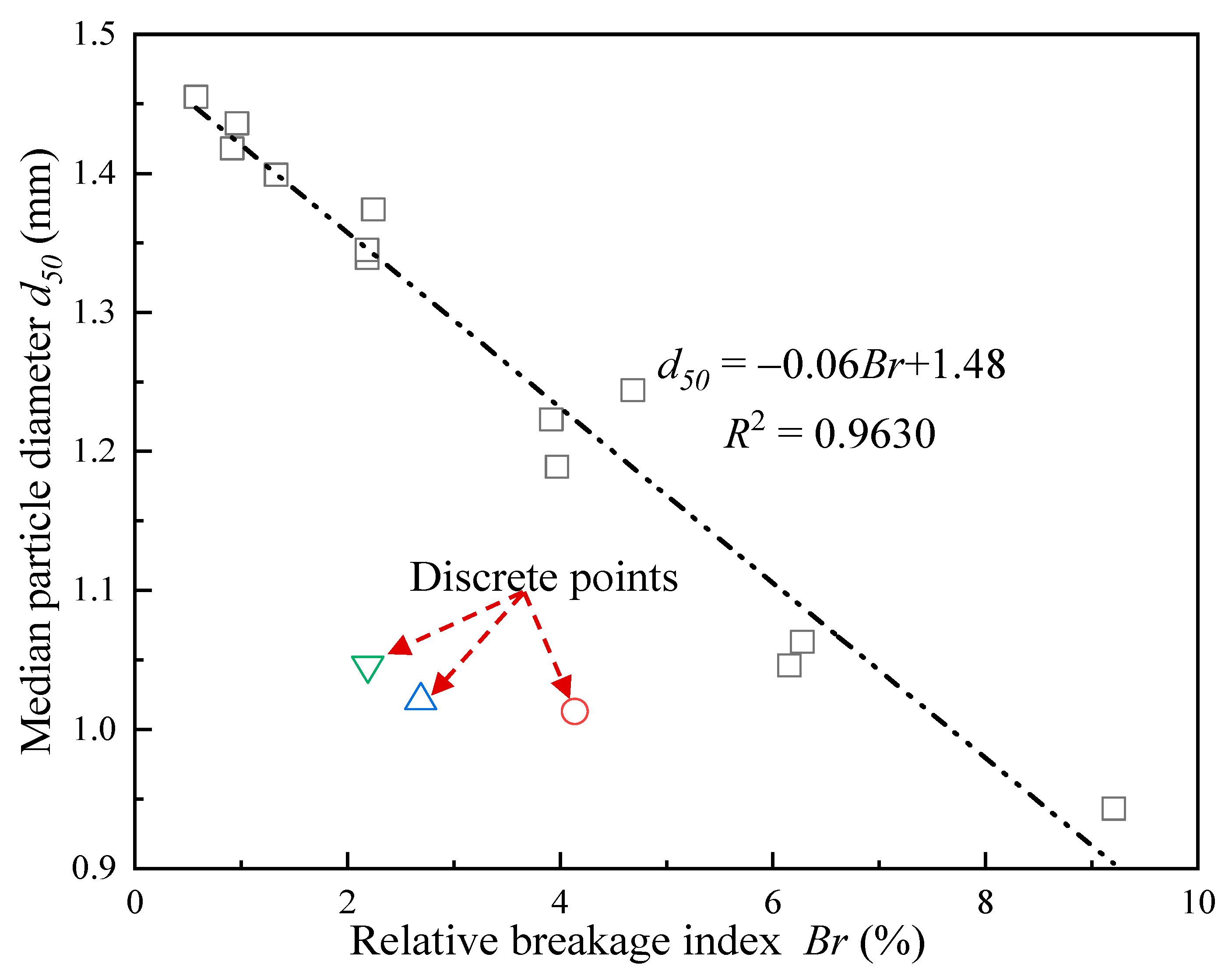

- As the water content (ω) increases, the median particle diameter (d50) gradually decreases, and the relative breakage index (Br) increases with increasing ω. The median particle diameter (d50) is negatively correlated with the relative breakage index (Br) and the linear relationship between the two is obvious except for individual discrete points.

- (6)

- There is a power function relationship between the relative breakage index of the coral gravelly sand and the plastic work. Through statistical analysis of the test data, a calculation model was established to allow for reasonable predictions of the relative breakage index of the coral sand based on the water content (ω) and stress process.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.; Zhu, C.Q.; Wang, X.Z.; Qin, Y. Study of dilatancy behaviors of calcareous soils in a triaxial test. Mar. Georesour. Geotechnol. 2019, 37, 1057–1070. [Google Scholar] [CrossRef]

- Wang, X.Z.; Wang, X.; Hu, M.J.; Zhu, C.Q.; Meng, Q.S.; Wang, R. Study on permeability characteristics of interlayer of calcareous silt in artificial island. Rock Soil Mech. 2017, 38, 3127–3135. [Google Scholar]

- Terzaghi, K. Theoretical Soil Mechanics; John Wiley & Sons, Inc.: New York, NY, USA, 1943. [Google Scholar]

- Li, J.G. Experimental Research on Dynamic Behavior of Saturated Calcareous Sand Under Wave Loading. Ph.D. Thesis, Institute of Rock & Soil Mechanics, Chinese Academy of Sciences, Beijing, China, 2005. [Google Scholar]

- Yu, H.Z. Experimental Research on Dynamic Behavior of Saturated Calcareous Sand Under Complex Stress Conditions. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2006. [Google Scholar]

- Xu, X.Y.; Wang, R.; Hu, M.J.; Meng, Q.S. Experimental study of dynamic characteristics of saturated calcareous soil explosion compaction. Rock Soil Mech. 2012, 33, 402–406. [Google Scholar]

- Lambe, T.W. The engineering behavior of compacted clay. J. Soil Mech. Found. Div. 1958, 184, 46–55. [Google Scholar]

- Mitchell, J.K. Fundamentals of Soil Behavior; John Wiley & Sons, Inc.: New York, NY, USA, 1976. [Google Scholar]

- Miao, L.C.; Zhong, X.C.; Yin, Z.Z. The relationship between strength and water content of expansive soil. Rock Soil Mech. 1999, 20, 71–75. [Google Scholar]

- Lin, H.; Yin, Z.Z. Variation of unsaturated soil strength with water contents. Chin. J. Rock Mech. Eng. 2005, 26, 1499–1503. [Google Scholar]

- Shen, C.N.; Fang, X.W.; Wang, H.W.; Sun, G.S.; Guo, J.F. Research on effects of suction, water content and dry density on shear strength of remolded unsaturated soils. Rock Soil Mech. 2009, 30, 1347–1351. [Google Scholar]

- Bian, J.M.; Wang, B.T. Research on influence of water contents on the shear strength behavior of unsaturated soil. Chin. J. Undergr. Space Eng. 2011, 7, 17–21. [Google Scholar]

- Braja, M.D. Principles of Geotechnical Engineering; Brooks Cole/Thompson Learning: Pacific Grove, CA, USA, 2002. [Google Scholar]

- Xiong, C.R.; Liu, B.C.; Zhang, J.S.; Liu, D.W. Study on relation of shear strength parameters with saturation of remolded unsaturated cohesive soil. Rock Soil Mech. 2003, 24, 195–198. [Google Scholar]

- Cokca, E.; Erol, O.; Armangil, F. Effects of compaction moisture content on the shear strength of an unsaturated clay. Geotech. Geol. Eng. 2004, 22, 285–297. [Google Scholar] [CrossRef]

- Lin, H.Z.; Li, G.X.; Yu, Y.Z.; Lv, H. Influence of matric suction on shear strength behavior of unsaturated soils. Rock Soil Mech. 2007, 28, 1931–1936. [Google Scholar]

- Huang, K.; Wan, J.W.; Chen, G.; Zeng, Y. Testing study of relationship between water content and shear strength of unsaturated soils. Rock Soil Mech. 2012, 33, 2600–2604. [Google Scholar]

- Chen, G.F.; Shi, B.F.; Huang, Z.H.; Zhang, J.J.; Shi, M. Study on the influence of moisture content to shear strength tests for unsaturated soils. J. Eng. Geol. 2012, 20, 127–131. [Google Scholar]

- Wang, H.D.; Gao, C.D.; Liu, F.C. Experimental study of the influence of water content on the mechanical characteristics of unsaturated sandy soil. J. Hunan Univ. Nat. Sci. 2015, 42, 90–96. [Google Scholar]

- Wang, X.; Cui, J.; Wu, Y.; Zhu, C.Q.; Wang, X.Z. Mechanical properties of calcareous silts in a hydraulic fill island-reef. Mar. Georesour. Geotechnol. 2020. [Google Scholar] [CrossRef]

- Alba, J.L.; Audibert, J.M. Pile design in calcareous and carbonaceous granular materials: An historic overview. In Proceedings of the Second International Conference on Engineering for Calcareous Sediments, Balkema, Rotterdam, 21–24 February 1999; Volume 1, pp. 29–44. [Google Scholar]

- Demars, K.R.; Nacci, V.A.; Kelly, W.E.; Wang, M.C. Carbonate content: An index property for ocean sediments. In Proceedings of the 8th Annual Offshore Technology Conference, Houston, TX, USA, 3–6 May 1976; pp. 97–106. [Google Scholar]

- Li, G.; Zhang, J.L.; Yang, Q.; Jiang, M.J. Centrifugal test and numerical assessment for settlement of a large-scale artificial island constructed on deep marine clays. Eur. J. Environ. Civ. Eng. 2017, 21, 172–192. [Google Scholar] [CrossRef]

- Yang, Q.; Ren, Y.B.; Niu, J.L.; Cheng, K.; Hu, Y.X.; Wang, Y. Characteristics of soft marine clay under cyclic loading: A review. Bull. Eng. Geol. Environ. 2018, 77, 1017–1046. [Google Scholar] [CrossRef]

- Shaqour, F.M. Cone penetration resistance of calcareous sand. Bull. Eng. Geol. Environ. 2007, 66, 59–70. [Google Scholar] [CrossRef]

- Hassanlourad, M.; Salehzadeh, H.; Shahnazari, H. Dilation and particle breakage effects on the shear strength of calcareous sands based on energy aspects. Int. J. Civ. Eng. 2008, 6, 108–119. [Google Scholar]

- Hassanlourad, M.; Salehzadeh, H.; Shahnazari, H. Drained shear strength of carbonate sands based on energy approach. Int. J. Geotech. Eng. 2014, 8, 1–9. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.L.; Chen, Q.S.; Ma, Q.F.; Xiang, Y.Z.; Zheng, Y.R. Particle breakage and deformation of carbonate sands with wide range of densities during compression loading process. Acta Geotech. 2017, 12, 1177–1184. [Google Scholar] [CrossRef]

- Shen, Y.; Zhu, Y.H.; Liu, H.L.; Li, A.; Ge, H.Y. Macro-meso effects of gradation and particle morphology on the compressibility characteristics of calcareous sand. Bull. Eng. Geol. Environ. 2018, 77, 1047–1055. [Google Scholar] [CrossRef]

- Wu, Q.; Ding, X.M.; Zhang, Y.L.; Chen, Z.X. Comparative study on seismic response of pile group foundation in coral sand and Fujian sand. J. Mar. Sci. Eng. 2020, 8, 189. [Google Scholar] [CrossRef]

- He, S.H.; Zhang, Q.F.; Ding, Z.; Xia, T.D.; Gan, X.L. Experimental and estimation studies of resilient modulus of marine coral sand under cyclic loading. J. Mar. Sci. Eng. 2020, 8, 287. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, L.X.; Wu, Y.; Yang, Q. New simple correlation formula for the drag coefficient of calcareous sand particles of highly irregular shape. Powder Technol. 2018, 326, 379–392. [Google Scholar] [CrossRef]

- Wang, G.; Ye, Q.G.; Zha, J.J. Experimental study on mechanical behavior and particle crushing of coral sand-gravel fill. Chin. J. Geotech. Eng. 2017, 40, 802–810. [Google Scholar]

- Wang, X.Z.; Wang, X.; Chen, J.W.; Wang, R.; Hu, M.J.; Meng, Q.S. Experimental study on permeability characteristics of calcareous soil. Bull. Eng. Geol. Environ. 2017, 77, 1753–1762. [Google Scholar] [CrossRef]

- Shang, G.W.; Sun, L.Q.; Li, S.; Liu, X.L.; Chen, W.W. Experimental study of the shear strength of carbonate gravel. Bull. Eng. Geol. Environ. 2020, 79, 2381–2394. [Google Scholar] [CrossRef]

- Chinese Ministry of Water Resources. Standard for Soil Test Method (GB/T 50123-2019); China Planning Press: Beijing, China, 2019.

- Wang, X.; Wang, X.Z.; Zhu, C.Q.; Meng, Q.S. Shear tests of interfaces between calcareous sand and steel. Mar. Georesour. Geotechnol. 2019, 37, 1095–1104. [Google Scholar] [CrossRef]

- Zhang, J.M.; Wang, R.; Shi, X.F.; Li, J.G.; Chen, H.Y. Compression and crushing behavior of calcareous sand under confined compression. Rock Soil Mech. 2005, 24, 3327–3331. [Google Scholar]

- Tian, H.H.; Wei, C.F. A NMR-based testing and analysis of adsorbed water content. Sci. Sin. Technol. 2014, 44, 295–305. [Google Scholar]

- Hardin, B.O. Crushing of soil particles. J. Geotech. Eng. 1985, 110, 1177–1192. [Google Scholar] [CrossRef]

- Miura, N.; O-hara, S. Particle crushing of a decomposed granite soil under shear stresses. Soils Found. 1979, 19, 1–14. [Google Scholar] [CrossRef]

- Lade, P.V.; Yamamuro, J.A.; Bopp, P.A. Significance of particle crushing in granular materials. J. Geotech. Eng. 1996, 122, 309–316. [Google Scholar] [CrossRef]

- Wu, Y.; Hyodo, M.; Aramaki, N. Undrained cyclic shear characteristics and crushing behaviour of silica sand. Geomech. Eng. 2018, 14, 1–8. [Google Scholar]

- Wu, Y.; Li, N.; Hyodo, M.; Gu, M.X.; Cui, J.; Spencer, B.F. Modeling the mechanical response of gas hydrate reservoirs in triaxial stress space. Int. J. Hydrogen Energy 2019, 44, 26698–26710. [Google Scholar] [CrossRef]

- Wu, Y.; Yamamoto, H.; Cui, J.; Cheng, H. Influence of load mode on particle crushing characteristics of silica sand at high stresses. Int. J. Geomech. 2020, 20, 04019194. [Google Scholar] [CrossRef]

- Winter, M.J.; Hyodo, M.; Wu, Y.; Yoshimoto, N.; Hasan, M.B.; Matsui, K. Influences of particle characteristic and compaction degree on the shear response of clinker ash. Eng. Geol. 2017, 230, 32–45. [Google Scholar] [CrossRef]

- Wu, Y.; Hyodo, M.; Cui, J. On the critical state characteristics of methane hydrate-bearing sediments. Mar. Petrol. Geol. 2020, 116, 104342. [Google Scholar] [CrossRef]

- Hyodo, M.; Wu, Y.; Aramaki, N.; Nakata, Y. Undrained monotonic and cyclic shear response and particle crushing of silica sand at low and high pressures. Can. Geotech. J. 2017, 54, 207–218. [Google Scholar] [CrossRef]

- Hyodo, M.; Wu, Y.; Nakashima, K.; Kajiyama, S.; Nakata, Y. Influence of fines content on the mechanical behavior of methane hydrate-bearing sediments. J. Geophys. Res. Solid Earth 2017, 122, 7511–7524. [Google Scholar] [CrossRef]

- Kajiyama, S.; Wu, Y.; Hyodo, M.; Nakata, Y.; Nakashima, K.; Yoshimoto, N. Experimental investigation on the mechanical properties of methane hydrate-bearing sand formed with rounded particles. J. Nat. Gas Sci. Eng. 2017, 45, 96–107. [Google Scholar] [CrossRef]

- Wang, X.Z.; Jiao, Y.Y.; Wang, R.; Hu, M.J.; Meng, Q.S.; Tan, F.Y. Engineering characteristics of the calcareous sand in Nansha Islands, South China Sea. Eng. Geol. 2011, 120, 40–47. [Google Scholar] [CrossRef]

- Lee, I.K.; Coop, M.R. The intrinsic behaviour of a decomposed granite soil. Géotechnique 1995, 45, 117–130. [Google Scholar] [CrossRef]

- Chen, W.B.; Liu, K.; Yin, Z.Y.; Yin, J.H. Crushing and flooding effects on one-dimensional time-dependent behaviors of a granular soil. Int. J. Geomech. 2020, 20, 04019156. [Google Scholar] [CrossRef]

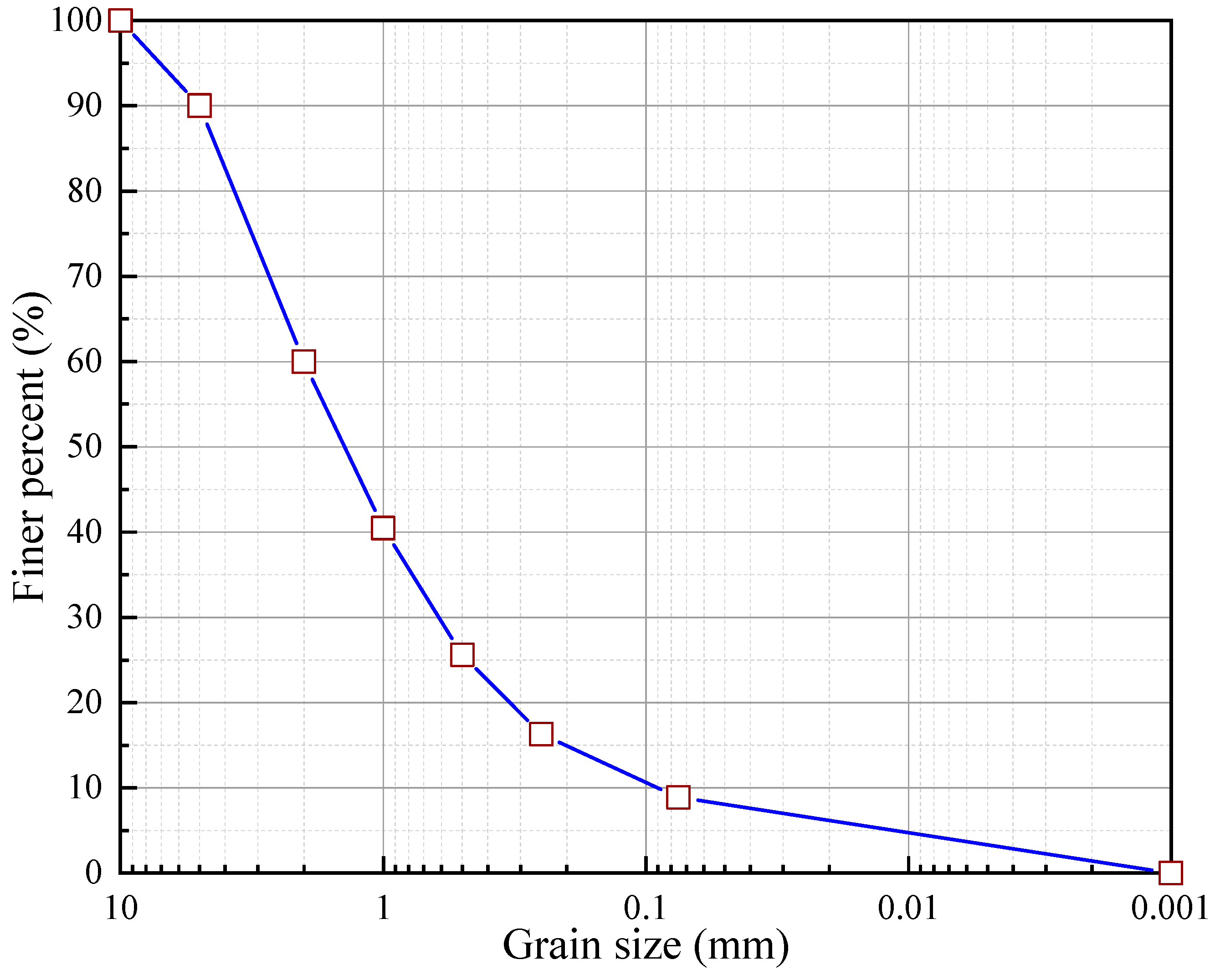

| Sample | d10 (mm) | d50 (mm) | d60 (mm) | Cu | Cc | Specific Gravity Gs | Minimum Dry Density ρdmin (g/cm3) | Maximum Dry Density ρdmax (g/cm3) | Maximum Void Ratio emax | Minimum Void Ratio emin |

|---|---|---|---|---|---|---|---|---|---|---|

| Coral gravelly sand | 0.09 | 1.49 | 2.00 | 20 | 2.08 | 2.73 | 1.19 | 1.52 | 1.29 | 0.80 |

| d10 | Diameter corresponding to 10% finer in the gradation curve | |||||||||

| d50 | Diameter corresponding to 50% finer in the gradation curve | |||||||||

| d60 | Diameter corresponding to 60% finer in the gradation curve | |||||||||

| Cu | Non-uniformity coefficient | |||||||||

| Cc | Curvature coefficient | |||||||||

| Sample | Relative Density Dr (%) | Water Content ω (%) | Sample Size | Test Type | Confining Pressure σ3 (kPa) | Shearing Rate ν (mm/min) | Terminating Strain | |

|---|---|---|---|---|---|---|---|---|

| Diameter D (mm) | Height H (mm) | |||||||

| Coral gravelly sand | 70 | 6, 12, 18, 24 | 61.8 | 120 | CD | 50, 100, 200, 400 | 0.6 | εa = 20% |

| Sample | Relative Density Dr (%) | Water Content ω (%) | Sample Size | |

|---|---|---|---|---|

| Diameter D (mm) | Height H (mm) | |||

| Coral gravelly sand | 70 | 6, 12, 18, 24 | 45 | 20 |

| Sample | Relative Density Dr (%) | Water Content ω (%) | Saturation Sr (%) | Peak State | End State | ||

|---|---|---|---|---|---|---|---|

| c (kPa) | φ (°) | c (kPa) | φ (°) | ||||

| Coral gravelly sand | 70 | 6 | 17.24 | 45.88 | 38.58 | 27.25 | 39.33 |

| 12 | 34.48 | 53.75 | 39.38 | 32.29 | 40.35 | ||

| 18 | 51.73 | 57.83 | 37.88 | 35.70 | 38.63 | ||

| 24 | 68.97 | 70.39 | 37.31 | 38.11 | 38.50 | ||

| Sample | Water Content ω (%) | Confining Pressure σ3 (kPa) | Plastic Work (kPa) | ||

|---|---|---|---|---|---|

| Coral gravelly sand | 6 | 50 | 58.04 | −4.73 | 53.30 |

| 100 | 96.07 | −5.40 | 90.67 | ||

| 200 | 153.01 | 1.17 | 154.18 | ||

| 400 | 235.98 | 11.17 | 247.16 | ||

| 12 | 50 | 66.19 | −2.57 | 63.62 | |

| 100 | 118.61 | −3.14 | 115.47 | ||

| 200 | 181.48 | −2.16 | 179.31 | ||

| 400 | 262.74 | 25.30 | 288.04 | ||

| 18 | 50 | 77.05 | −8.57 | 68.48 | |

| 100 | 111.07 | −8.51 | 102.55 | ||

| 200 | 172.32 | 0.80 | 173.12 | ||

| 400 | 261.91 | 22.81 | 284.72 | ||

| 24 | 50 | 76.80 | −9.82 | 66.97 | |

| 100 | 116.33 | −9.83 | 106.51 | ||

| 200 | 173.91 | −2.02 | 171.89 | ||

| 400 | 278.16 | 16.38 | 294.54 |

| Sample | Water Content ω (%) | Expressions | α | β | R2 |

|---|---|---|---|---|---|

| Coral gravelly sand | 6 | 1.3898 | 0.9883 | ||

| 12 | 1.2783 | 0.9901 | |||

| 18 | 1.0910 | 0.9970 | |||

| 24 | 0.9705 | 0.9428 |

| Sample | Water Content ω (%) | Confining Pressure σ3 (kPa) | Calculated Value | Measured Value | Deviation (Calculated Value/Measured Value) |

|---|---|---|---|---|---|

| Coral gravelly sand | 6 | 50 | 0.50% | 0. 57% | 0.88 |

| 100 | 1.06% | 0. 96% | 1.10 | ||

| 200 | 2.23% | 2.24% | 0.99 | ||

| 400 | 4.31% | 4.68% | 0.92 | ||

| 12 | 50 | 0.85% | 0.91% | 0.94 | |

| 100 | 1.81% | 2.18% | 0.83 | ||

| 200 | 3.14% | 3.97% | 0.79 | ||

| 400 | 5.68% | 6.16% | 0.92 | ||

| 18 | 50 | 1.23% | 1.33% | 0.93 | |

| 100 | 1.92% | 2.18% | 0.88 | ||

| 200 | 3.44% | 3.92% | 0.88 | ||

| 400 | 5.98% | 6.28% | 0.95 | ||

| 24 | 50 | 1.58% | 2.19% | 0.72 | |

| 100 | 2.47% | 2.69% | 0.92 | ||

| 200 | 3.92% | 4.14% | 0.95 | ||

| 400 | 6.59% | 9.21% | 0.72 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Wang, X.; Shen, J.-H.; Cui, J.; Zhu, C.-Q.; Wang, X.-Z. Experimental Study on the Impact of Water Content on the Strength Parameters of Coral Gravelly Sand. J. Mar. Sci. Eng. 2020, 8, 634. https://doi.org/10.3390/jmse8090634

Wu Y, Wang X, Shen J-H, Cui J, Zhu C-Q, Wang X-Z. Experimental Study on the Impact of Water Content on the Strength Parameters of Coral Gravelly Sand. Journal of Marine Science and Engineering. 2020; 8(9):634. https://doi.org/10.3390/jmse8090634

Chicago/Turabian StyleWu, Yang, Xing Wang, Jian-Hua Shen, Jie Cui, Chang-Qi Zhu, and Xin-Zhi Wang. 2020. "Experimental Study on the Impact of Water Content on the Strength Parameters of Coral Gravelly Sand" Journal of Marine Science and Engineering 8, no. 9: 634. https://doi.org/10.3390/jmse8090634

APA StyleWu, Y., Wang, X., Shen, J.-H., Cui, J., Zhu, C.-Q., & Wang, X.-Z. (2020). Experimental Study on the Impact of Water Content on the Strength Parameters of Coral Gravelly Sand. Journal of Marine Science and Engineering, 8(9), 634. https://doi.org/10.3390/jmse8090634