Proper Use of Technical Standards in Offshore Petroleum Industry

Abstract

:1. Introduction

- (1)

- The Macondo Deepwater Horizon oil spill occurred in the Gulf of Mexico on 20 April 2010 on the Macondo prospect, around 60 km seaward from the Louisiana coast, where British Petroleum (BP) was the oil company operator while Transocean was the rig contractor. It is to date the largest offshore petroleum accident ever in terms of hydrocarbon release [19,20,21,22,23,24]. It should be noted that the mentioned spill was caused by the Macondo Deepwater Horizon semi-submersible rig, operated by Transocean Ltd., the world’s second largest offshore drilling contractor who is based in Switzerland but also with offices in many other countries. The rig was registered by the American Bureau of Shipping (ABS) and operated under a Marshall Islands flag of convenience and was built by South Korean company Hyundai Heavy Industries. The rig was chartered to British Petroleum, headquartered in London, the United Kingdom, which was the developer of the Macondo prospect with 65% stake, while the United States-based now defunct Anadarko Petroleum Corporation had 25% stake. Last but not least, United States-based MOEX Offshore 2007, a subsidiary of large company, Japanese Mitsui had 10% stake. The cause of the accident was a failure of the cement to form a proper shield of concrete at the base of the Macondo well at the level at which it was supposed to contain oil and gas.

- (2)

- The Montara oil spill occurred on 21 August 2009 in the Montara offshore oil field northwest of the Australian coast in the Timor Sea. Although much smaller in terms of hydrocarbon release compared with the Macondo Deepwater Horizon accident, the Montara oil spill was the first such accident in this part of the world for 25 years [25]. The West Atlas jack-up drilling rig at the Montara prospect was built by Keppel Fels at the Keppel Shipyard in Singapore in 2007 and was one of the largest in the world. The West Atlas rig was owned by the Norwegian–Bermudan Seadrill and operated by PTTEP Australasia (PTTEPAA), a subsidiary of PTT Exploration and Production (PTTEP), an oil and gas exploration company from Thailand. The cause of the accident was a failure of the cement to form a barrier of concrete (failure to install a pressure containment cap on the well).

- (3)

- The Piper Alpha accident occurred on 6 July 1988, offshore in the North Sea about 190 km northeast of Aberdeen, Scotland [26]. It is, to date, the deadliest offshore petroleum accident. The Piper Alpha was a large fixed production platform located at the offshore Piper oilfield, which was operated by Occidental Petroleum (Caledonia) Limited-OXY, a US company. The platform, which had four modules separated by firewalls, was constructed partly by McDermott Engineering in Scotland and partly by the Union Industrielle d’Entreprise in France. The cause of the accident has been unclear to date, but most probably it was due to bad maintenance management—the release of as little as 30 kg of condensate (mainly propane) over thirty seconds through an unsecured blind flange, where a pressure safety relief valve had been removed as part of maintenance on the standby condensate pump [27].

2. Legislation and Technical Standards

2.1. Explicit Exclusions from EU/EEA Product Safety Directives

- (1)

- From the ATEX directive 2014/34/EU: In article 1, section 2(e) “seagoing vessels and mobile offshore units together with equipment on board such vessels or units”;

- (2)

- From the pressure equipment directive 2014/68/EU (essential safety requirements are designed to protect the equipment against hazards caused by pressure): in article 1, section 2(a): “pipelines comprising piping or a system of piping designed for the conveyance of any fluid or substance to or from an installation (onshore or offshore)…”; section 2(i): “well-control equipment used in the petroleum, gas or geothermal exploration and extraction industry and in underground storage which is intended to contain and/or control well pressure; this shall comprise the wellhead (Christmas tree), the blow out preventers (BOP), the piping manifolds and all their equipment upstream”; section 2(j–ii) “…compressors, pumps…”; section 2(n): “ships, rockets, aircraft and mobile off-shore units, as well as equipment specifically intended for installation onboard or the propulsion thereof”;

- (3)

- From the machinery directive 2006/42/EC (the essential health and safety requirements of this directive protect workers and personnel primarily): in article 1, section 2(f): “seagoing vessels and mobile offshore units and machinery installed onboard such vessels and/or units”.

- (1)

- Protection against explosions: The ATEX directive 2014/34/EU protects equipment onshore and on offshore fixed platforms and the ATEX directive 1999/92/EC protects personnel [37]. However, as prescribed by the MODU code, protection against explosions onboard mobile drilling units in the EU/EEA waters goes through the International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres (IECEx). The IECEx was developed mostly for electrical devices [38] and hence explosions caused by mechanical equipment is not extensively covered through this scheme. For the many decades during which mechanical equipment has been used in hazardous areas without causing damage, some accidents have undoubtedly occurred, mostly due to friction and overheating [39]. Following that reasoning, the EU/EEA also included anti-explosive protection for machinery through the ATEX scheme [40]. On the other hand, the main shortcoming under the ATEX scheme is that it allows self-certification in some zones (manufacturer can demonstrate the safety), which is not allowed in the IECEx scheme [41,42,43,44,45,46]. Additionally, the ATEX scheme refers only to equipment and protective systems and does not make any distinction between machinery and electrical equipment [47,48,49,50]. Some other requirements are prescribed in other countries, such as in Russia [51,52].

- (2)

- Protection of pressure equipment: Some equipment under pressure used offshore in the EU/EEA which is not specifically modified by adding, for example, moving compensators [53] (to annul the effect of waves at sea) are under the scope of the pressure equipment directive 2014/68/EU. The pressure equipment directive 2014/68/EU also excludes from its scope almost all equipment under pressure for drilling, exploitation or transport used in petroleum industries, including well-control equipment [54,55,56,57], both offshore on fixed or mobile units, or onshore. Besides, pumps are in the scope of the pressure equipment directive 2014/68/EU only if technical analyses show that the hazard, due to pressure, is the dominant and main factor of risk. Additionally, all assemblies under pressure need to be certified through the notified bodies listed in the EU/EEA NANDO database (the New Approach Notified and Designated Organizations), even when all parts of such assemblies have already been individually attested.

- (3)

- Protection of personnel who works with machinery: Machinery which is used in the EU/EEA onshore or on fixed offshore platforms are under the scope of the machinery directive 2006/42/EC. The transfer of such machinery from mobile units to fixed platforms or onshore without the proper EU/EEA certification, or avoiding payments of custom duties is problematic.

2.2. Certification Using Technical Standards

3. Conclusions

- −

- In the past, harmonized standards developed by CEN or CENELEC assured full conformity, while today to remove barriers for trade in the EU/EEA, any other available technical standards can be used if they can assure compliance to the health and safety requirements of the relevant directives. The umbrella directive 2013/30/EU for oil and gas offshore safety in the EU/EEA allows, and even requires, the use of the best available standards, which are recognized internationally.

- −

- Due to exemption from the scope of the product safety directives, the machinery directive 2006/42/EC, the pressure equipment directive 2014/68/EU, and the ATEX directive 2014/34/EU, drilling ships and, in certain cases, oil and gas equipment used offshore are out of their scope (therefore are not required to fulfil the essential health and safety requirements of these directives and to be certified according to them). However, the use of some of their harmonized standards can be recommended if such practice can increase the overall level of safety. Additionally, it should be double-checked if the observed equipment is really excluded from the scope in every observed particular case (in case of exclusion, the international MODU code applies).

- −

- Well-control equipment is also out of the scope of the pressure equipment directive 2014/68/EU onshore, and it is not required to follow its essential safety requirements (this directive does not refer to essential health requirements). Besides, well-control equipment onshore and offshore on fixed platforms is under the scope of the machinery directive 2006/42/EC and the relevant essential health and safety requirements of this directive should be satisfied.

- −

- Protection against explosions on fixed offshore platforms goes through the European ATEX scheme, while on mobile offshore units through the IECEx scheme.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Notations

- European Union directives:

- −

- Offshore safety directive 2013/30/EU-Directive on safety of offshore oil and gas operations (used as umbrella Directive for offshore oil and gas safety)

- −

- Product safety directives: (1) ATEX directive 2014/34/EU; (2) pressure equipment directive 2014/68/EU; (3) machinery directive 2006/42/EC

- −

- Marine equipment directive 2014/90/EU

- −

- ATEX directive 1999/92/EC for protection of personnel

- Documents, Regulations, and Databases:

- −

- New Legislative Framework package, that reinforces the application and enforcement of internal market legislation in the EU/EEA

- −

- Facing the challenge of the safety of offshore oil and gas activities: 2011/2072(INI), Motion for a European parliament resolution from 26 July 2011

- −

- IECEx: International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres

- −

- International Convention for the Safety of Life at Sea (SOLAS) from 1974 and in force since 25 May 1980

- −

- MODU code: “Code for the construction and equipment of Mobile Offshore Drilling Units of the International Maritime Organization” from 2009

- −

- NANDO: New Approach Notified and Designated Organizations Information System (Conformity Assessment and Acceptance of Industrial Products Notification Bodies)

- −

- Regulation (EU) No 1025/2012, related to European standardization

- −

- “New approach”: Council Resolution of 7 May 1985 on a new approach to technical harmonization and standards

- Standardization and other bodies:

- −

- NORSOK: Norwegian Technical standards

- −

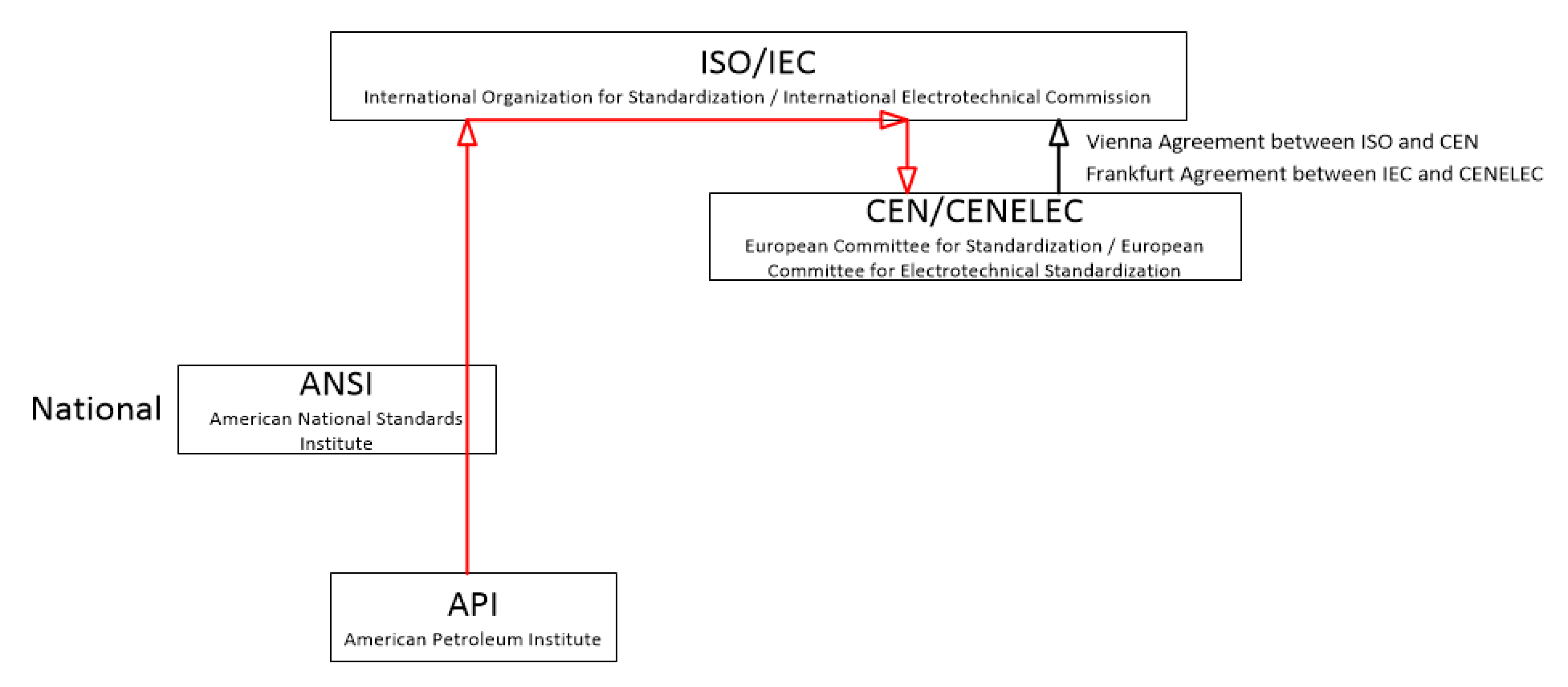

- API: American Petroleum Institute

- −

- ISO: International Organization for Standardization

- −

- TC 67: Technical committee of the ISO “Materials, equipment and offshore structures for petroleum, petrochemical and natural gas industries”

- −

- CEN: Comité Européen de Normalisation

- −

- CENELEC: Comité Européen de Normalisation Électrotechnique

- −

- IEC: International Electrotechnical Commission

- −

- ANSI: American National Standardization Institute

- −

- CABs: Conformity Assessment Bodies

- Agreements:

- −

- Vienna agreement—technical cooperation between ISO and CEN

- −

- Frankfurt agreement—technical cooperation between IEC and CENELEC

- −

- MRAs—Mutual Recognition Agreements promote trade in goods between the EU and third countries and facilitate market access

- Offshore accidents:

- −

- Macondo Deepwater Horizon: the Gulf of Mexico in 2010 (offshore drilling rig, to date the biggest in terms of hydrocarbon release)

- −

- Montara: the Timor Sea in 2009 (offshore drilling rig)

- −

- Piper Alpha: the North Sea in 1988 (fixed production platform, to date the deadliest offshore petroleum accident)

- Companies:

- −

- British Petroleum (BP)

- −

- MOEX Offshore-subsidiary of Mitsui

- −

- Occidental Petroleum (Caledonia) Limited-OXY

- −

- Anadarko Petroleum Corporation—Now defuncted

- −

- PTTEP Australasia (PTTEPAA)—Subsidiary of PTT Exploration and Production (PTTEP)

- −

- Transocean: rig contractor

- −

- Norwegian–Bermudan Seadrill: rig contractor

- −

- Keppel Fels: rig manufacturer

- −

- Hyundai Heavy Industries: rig manufacturer

- −

- McDermott Engineering: platform manufacturer

- −

- Union Industrielle d’Entreprise: platform manufacturer

- Oil fields and Wells:

- −

- Macondo (the Gulf of Mexico)

- −

- Montara (the Timor Sea)

- −

- Piper (the North Sea)

- Rigs and platforms:

- −

- Deepwater Horizon: semi-submersible rig

- −

- West Atlas: jack-up drilling rig

- −

- Piper Alpha: fixed production platform

- Ship registers:

- −

- American Bureau of Shipping (ABS)

- Product marking:

- −

- Conformité Européenne “CE” sign: general conformity with the relevant EU/EEA Directives

- −

- “Wheelmark” sign: conformity with marine equipment Directive 2014/90/EU

- Equipment:

- −

- BOP—Blow out preventers

- −

- “Christmas tree”—Wellhead

References

- Elvidge, C.D.; Ziskin, D.; Baugh, K.E.; Tuttle, B.T.; Ghosh, T.; Pack, D.W.; Erwin, E.H.; Zhizhin, M. A fifteen-year record of global natural gas flaring derived from satellite data. Energies 2009, 2, 595–622. [Google Scholar] [CrossRef]

- Rabe, B.; Kaliban, C.; Englehart, I. Taxing flaring and the politics of state methane release policy. Rev. Policy Res. 2020, 37, 6–38. [Google Scholar] [CrossRef]

- Baalisampang, T.; Abbassi, R.; Khan, F. Overview of marine and offshore safety. Met. Chem. Proc. Saf. 2018, 2, 1–97. [Google Scholar] [CrossRef]

- Fattakhova, E.Z.; Barakhnina, V. Accident rate analysis on the offshore oil and gas production installations and platforms. Int. J. Appl. Fund. Res. 2015, 1. Available online: http://www.science-sd.com/460-24767 (accessed on 14 July 2020).

- Zolotukhin, A.; Gavrilov, V. Russian Arctic petroleum resources. Oil Gas Sci. Technol. 2011, 66, 899–910. [Google Scholar] [CrossRef]

- Aalto, P. Modernisation of the Russian energy sector: Constraints on utilizing Arctic offshore oil resources. Eur. Asia Stud. 2016, 68, 38–63. [Google Scholar] [CrossRef] [Green Version]

- Helle, I.; Mäkinen, J.; Nevalainen, M.; Afenyo, M.; Vanhatalo, J. Impacts of oil spills on Arctic marine ecosystems: A quantitative and probabilistic risk assessment perspective. Environ. Sci. Technol. 2020, 54, 2112–2121. [Google Scholar] [CrossRef] [Green Version]

- Lindholt, L.; Glomsrød, S. The Arctic: No big bonanza for the global petroleum industry. Energy Econ. 2012, 34, 1465–1474. [Google Scholar] [CrossRef]

- Torres, L.; Jiménez-Cabas, J.; González, O.; Molina, L.; López-Estrada, F.-R. Kalman Filters for leak diagnosis in pipelines: Brief history and future research. J. Mar. Sci. Eng. 2020, 8, 173. [Google Scholar] [CrossRef] [Green Version]

- McBain, G. A user’s view of the pressure equipment directive. Meas. Control 2003, 36, 300–304. [Google Scholar] [CrossRef] [Green Version]

- Ciavarella, M.; Carbone, G.; Vinogradov, V. A critical assessment of Kassapoglou’s statistical model for composites fatigue. Facta Univ. Mech. Eng. 2018, 16, 115–126. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, S.; Wang, X.; Fan, Y. Multi-state balanced systems in a shock environment. Reliab. Eng. Syst. Saf. 2020, 193, 106592. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Wang, S.; Sun, L. Reliability and maintenance for performance-balanced systems operating in a shock environment. Reliab. Eng. Syst. Saf. 2020, 195, 106705. [Google Scholar] [CrossRef]

- Zhao, X.; Wu, C.; Wang, X.; Sun, J. Reliability analysis of k-out-of-n: F balanced systems with multiple functional sectors. Appl. Math. Model. 2020, 82, 108–124. [Google Scholar] [CrossRef]

- Luo, F.; Zhang, S.; Yang, D. Anti-explosion performance of composite blast wall with an auxetic re-entrant honeycomb core for offshore platforms. J. Mar. Sci. Eng. 2020, 8, 182. [Google Scholar] [CrossRef] [Green Version]

- Lindøe, P.H.; Baram, M.; Renn, O. Risk Governance of Offshore Oil and Gas Operations; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar] [CrossRef] [Green Version]

- Lindøe, P.H.; Baram, M.S. The role of standards in hard and soft approaches to safety regulation. In Standardization and Risk Governance; Olsen, O.E., Juhl, K.V., Lindøe, P.H., Engen, O.A., Eds.; Routledge: Abingdon, UK, 2020; pp. 235–254. [Google Scholar] [CrossRef]

- Yang, Y. Reforming health, safety, and environmental regulation for offshore operations in China: Risk and resilience approaches? Sustainability 2019, 11, 2608. [Google Scholar] [CrossRef] [Green Version]

- Crone, T.J.; Tolstoy, M. Magnitude of the 2010 Gulf of Mexico oil leak. Science 2010, 330, 634. [Google Scholar] [CrossRef] [Green Version]

- Croisant, S.A.; Lin, Y.L.; Shearer, J.J.; Prochaska, J.; Phillips-Savoy, A.; Gee, J.; Jackson, D.; Panettieri, R.A.; Howarth, M.; Sullivan, J.; et al. The Gulf coast health alliance: Health risks related to the Macondo spill (GC-HARMS) study: Self-reported health effects. Int. J. Environ. Res. Public Health 2017, 14, 1328. [Google Scholar] [CrossRef] [Green Version]

- Zilversmit, L.; Wickliffe, J.; Shankar, A.; Taylor, R.J.; Harville, E.W. Correlations of biomarkers and self-reported seafood consumption among pregnant and non-pregnant women in southeastern Louisiana after the Gulf oil spill: The GROWH study. Int. J. Environ. Res. Public Health 2017, 14, 784. [Google Scholar] [CrossRef]

- Nunziata, F.; Buono, A.; Migliaccio, M. COSMO–SkyMed Synthetic aperture radar data to observe the deep-water horizon oil spill. Sustainability 2018, 10, 3599. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Li, S.; Guo, Z. The Evolution of the coastal economy: The role of working waterfronts in the Alabama Gulf Coast. Sustainability 2015, 7, 4310–4322. [Google Scholar] [CrossRef] [Green Version]

- Moerschbaecher, M.; Day, J.W., Jr. Ultra-deep water Gulf of Mexico oil and gas: Energy return on financial investment and a preliminary assessment of energy return on energy investment. Sustainability 2011, 3, 2009–2026. [Google Scholar] [CrossRef] [Green Version]

- Hayes, J. Operator competence and capacity–Lessons from the Montara blowout. Saf. Sci. 2012, 50, 563–574. [Google Scholar] [CrossRef]

- Paté-Cornell, M.E. Learning from the piper alpha accident: A postmortem analysis of technical and organizational factors. Risk Anal. 1993, 13, 215–232. [Google Scholar] [CrossRef]

- Cullen, L.W. The public inquiry into the Piper Alpha disaster. Drilling Contractor 1993, 49. Available online: https://www.osti.gov/biblio/6208554 (accessed on 27 June 2020).

- Messerlin, P.A. The European Union single market in goods: Between mutual recognition and harmonisation. Aust. J. Int. Aff. 2011, 65, 410–435. [Google Scholar] [CrossRef]

- Pollack, M.A. Theorizing the European Union: International organization, domestic polity, or experiment in new governance? Annu. Rev. Polit. Sci. 2005, 8, 357–398. [Google Scholar] [CrossRef] [Green Version]

- Fiorino, D.J. The New Environmental Regulation; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Manheim, F.T. The Conflict Over Environmental Regulation in the United States: Origins, Outcomes, and Comparisons with the EU and Other Regions; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar] [CrossRef]

- Xu, P.; Du, Z.; Gong, S. Numerical investigation into freak wave effects on deep water pipeline installation. J. Mar. Sci. Eng. 2020, 8, 119. [Google Scholar] [CrossRef] [Green Version]

- Zan, Y.; Guo, R.; Yuan, L.; Wu, Z. Experimental and numerical model investigations of the underwater towing of a subsea module. J. Mar. Sci. Eng. 2019, 7, 384. [Google Scholar] [CrossRef] [Green Version]

- Yu, G.; Zhang, L.; Jia, S.; Geng, Y.; Liu, J. Numerical study on the natural convection of air in a cubic cavity subjected to a yawing motion. J. Mar. Sci. Eng. 2019, 7, 204. [Google Scholar] [CrossRef] [Green Version]

- Yu, G.; Jia, S.; Geng, Y. Numerical investigation into the two-phase convective heat transfer within the hold of an oil tanker subjected to a rolling motion. J. Mar. Sci. Eng. 2019, 7, 94. [Google Scholar] [CrossRef] [Green Version]

- Kaiser, M.J.; Snyder, B. The five offshore drilling rig markets. Mar. Policy 2013, 39, 201–214. [Google Scholar] [CrossRef]

- Marx, I. Combining the best of both worlds. IEEE Ind. Appl. Mag. 2010, 16, 30–34. [Google Scholar] [CrossRef]

- Petitfrere, C.; Proust, C. Analysis of ignition risk on mechanical equipment in ATEX. Proceeding of the 4th IEEE European Conference on Electrical and Instrumentation Applications in the Petroleum and Chemical Industry, Paris, France, 13–15 June 2007; pp. 1–9. [Google Scholar] [CrossRef] [Green Version]

- Leroux, P. New regulations and rules for ATEX directives. IEEE Ind. Appl. Mag. 2006, 13, 43–51. [Google Scholar] [CrossRef]

- Parise, G.; Sutherland, P.E.; Moylan, W.J. Electrical safety for employee workplaces in Europe and in the USA. IEEE Trans. Ind. Appl. 2005, 41, 1091–1098. [Google Scholar] [CrossRef]

- Campbell, J.D.; Chudleigh, J.P. Problems encountered in designing electrical systems for hazardous areas. In IEEE Transactions on Industry and General Applications; IEEE: Piscataway, NJ, USA, 1970; Volume IGA-6, pp. 326–329. [Google Scholar] [CrossRef]

- Rodrigues, A.M.T.G. A Software Application to Define and Rank ATEX Zones. Ph. D. Thesis, Faculdade de Engenharia da Universidade do Porto, Porto, Portugal, 2016. Available online: https://repositorio-aberto.up.pt/bitstream/10216/88507/2/156964.pdf (accessed on 11 June 2020).

- Riikonen, J. ATEX certification for hazardous areas. World Pumps 2010, 2010, 22–24. [Google Scholar] [CrossRef]

- Pommé, R.; Sijrier, H.J. IECEX certification schemes versus ATEX directives. Proceeding of the Petroleum and Chemical Industry Conference Europe—Electrical and Instrumentation Applications (PCIC Europe), Oslo, Norway, 15–17 June 2010; pp. 1–8. Available online: https://ieeexplore.ieee.org/xpl/conhome/5512515/proceeding (accessed on 29 June 2020).

- Nicols, R. ATEX directives for the UK sector. Meas. Control 2003, 36, 147–155. [Google Scholar] [CrossRef]

- Propst, J.E.; Barrios, L.A.; Lobitz, B. Applying the API alternate method for area classification. IEEE Trans. Ind. Appl. 2007, 43, 162–171. [Google Scholar] [CrossRef]

- Khaymedinova, Z. Explosion-Proof Requirements for Electrical Machines in Chemical, Oil and Gas Industry in Russia and CIS Countries. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2009. Available online: https://lutpub.lut.fi/bitstream/handle/10024/46840/nbnfi-fe200908031986.pdf (accessed on 11 June 2020).

- Sinclair, R. ATEX good and bad/A notified body’s perspective. Meas. Control 2003, 36, 140–141. [Google Scholar] [CrossRef]

- Dearden, H.T. Who’s afraid of ATEX? Meas. Control 2006, 39, 17–18. [Google Scholar] [CrossRef]

- Towle, C. ATEX directives/A manufacturer’s viewpoint. Meas. Control 2003, 36, 152–154. [Google Scholar] [CrossRef]

- Hitchen, I.R. Vibration monitoring for rotating machinery. Meas. Control 1980, 13, 97–102. [Google Scholar] [CrossRef]

- Shu-Chao, L. The main differences of general requirements and intrinsic safety between IEC and Russian standards. electric explosion protection. China Nat. Knowl. Infrastruct. J. 2004, 3. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-DQFB200403001.htm (accessed on 11 June 2020).

- Stefanowicz, D. ATEX for installers and maintainers. Meas. Control 2003, 36, 144–158. [Google Scholar] [CrossRef]

- Harvey, S.; Elashvili, I.; Valdes, J.J.; Kamely, D.; Chakrabarty, A.M. Enhanced removal of Exxon Valdez spilled oil from Alaskan gravel by a microbial surfactant. Biotechnology 1990, 8, 228–230. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.I.; Sadiq, R.; Husain, T. Risk-based process safety assessment and control measures design for offshore process facilities. J. Hazard. Mater. 2002, 94, 1–36. [Google Scholar] [CrossRef]

- Mutlu, M.; Tang, Y.; Franchek, M.A.; Turlak, R.; Gutierrez, J.A. Dynamic performance of annular blowout preventer hydraulic seals in deepwater environments. J. Offshore Mech. Arct. Eng. 2018, 140, 061301. [Google Scholar] [CrossRef]

- Crumpton, H. Well Control for Completions and Interventions; Gulf Professional Publishing: Houston, TX, USA, 2018. [Google Scholar] [CrossRef]

- Marangon, A.; Carcassi, M. ATEX Directives: The New Approach. Valutazione e Gestione del Rischio negli Insediamenti Civili ed Industriali, 2006. Available online: http://conference.ing.unipi.it/vgr2006/archivio/Archivio/2006/Articoli/700213.pdf (accessed on 29 June 2020).

- Weightman, R.T.; Warnack, M.F. API and ISO standards can be combined. Oil Gas J. 1992, 90, 50–52. Available online: https://www.ogj.com/home/article/17218930/api-and-iso-standards-can-be-combined (accessed on 10 March 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brkić, D.; Praks, P. Proper Use of Technical Standards in Offshore Petroleum Industry. J. Mar. Sci. Eng. 2020, 8, 555. https://doi.org/10.3390/jmse8080555

Brkić D, Praks P. Proper Use of Technical Standards in Offshore Petroleum Industry. Journal of Marine Science and Engineering. 2020; 8(8):555. https://doi.org/10.3390/jmse8080555

Chicago/Turabian StyleBrkić, Dejan, and Pavel Praks. 2020. "Proper Use of Technical Standards in Offshore Petroleum Industry" Journal of Marine Science and Engineering 8, no. 8: 555. https://doi.org/10.3390/jmse8080555

APA StyleBrkić, D., & Praks, P. (2020). Proper Use of Technical Standards in Offshore Petroleum Industry. Journal of Marine Science and Engineering, 8(8), 555. https://doi.org/10.3390/jmse8080555