Investigation of Growth, Lipid Productivity, and Fatty Acid Profiles in Marine Bloom-Forming Dinoflagellates as Potential Feedstock for Biodiesel

Abstract

1. Introduction

2. Materials and Methods

2.1. Algal Sampling and Cultivation Conditions

2.2. Algal Species Identification

2.3. Determination of Growth Rate in Algal Strains

2.4. Determination of Algal Biomass and Total Lipid Content

2.5. Determination of Fatty Acid Profile in Algal Strains

3. Results and Discussion

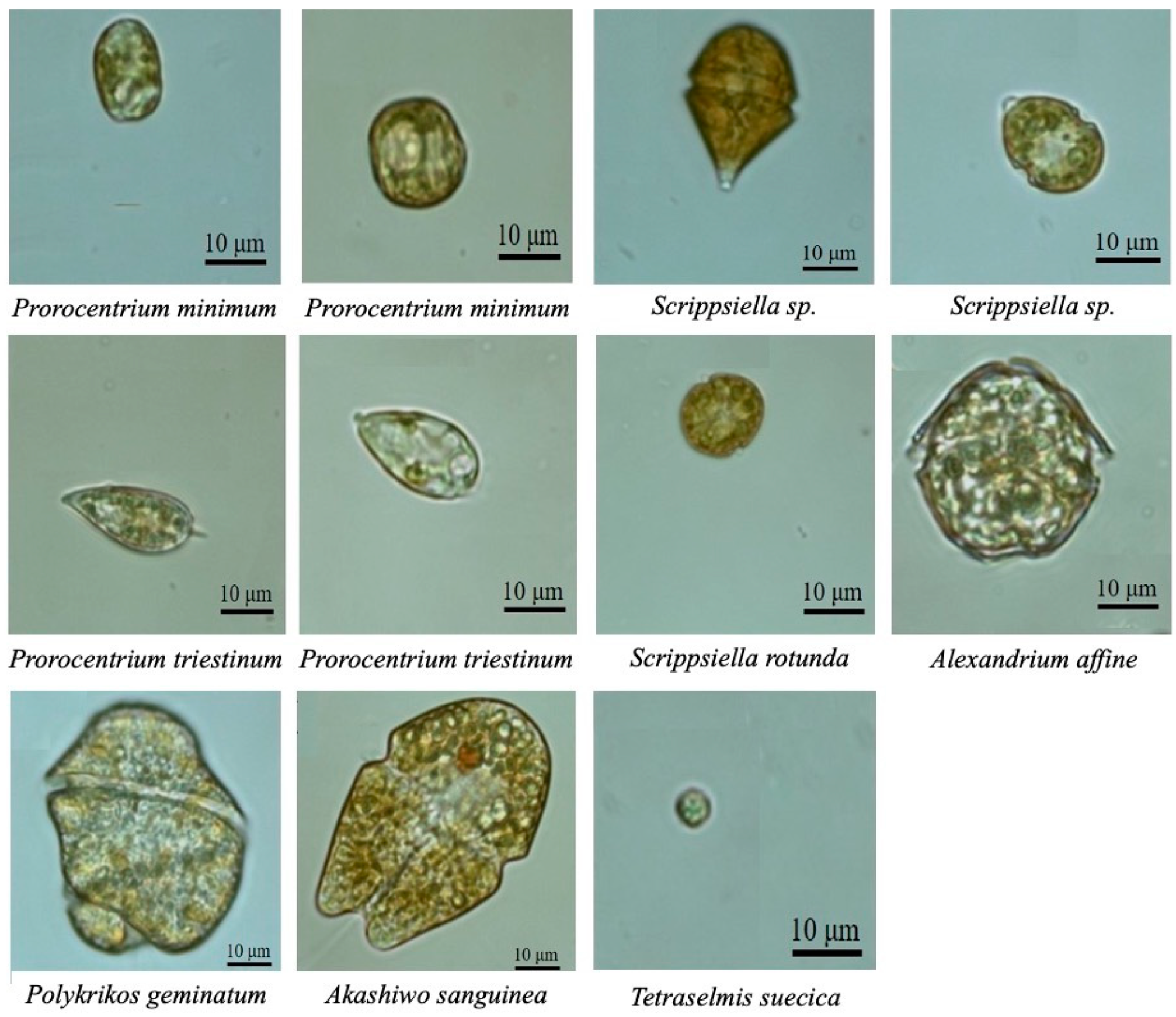

3.1. Identification of Isolated Algal Species

3.2. Growth Rate and Biomass of Selected Algal Strains

3.3. Lipid Content and Productivity of Selected Algal Strains

3.4. Comparison of Growth and Lipid Productivity with Other Freshwater and Marine Species

3.5. Fatty Acid Composition of Selected Algal Strains

3.6. The Potential of Harvesting Natural Algal Bloom Biomass for Biotechnological Purposes

3.7. Other Biotechnological Applications of Fatty Acids Extracted from Microalgae

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Knothe, G. “Designer” biodiesel: Optimizing fatty ester composition to improve fuel properties. Energy Fuels 2008, 22, 1358–1364. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Pulz, O.; Gross, W. Valuable products from biotechnology of microalgae. Appl. Microbiol. Biotechnol. 2004, 65, 635–648. [Google Scholar] [CrossRef]

- Shuba, E.S.; Kifle, D. Microalgae to biofuels: ‘Promising’ alternative and renewable energy, review. Renew. Sustain. Energy Rev. 2018, 81, 743–755. [Google Scholar] [CrossRef]

- Mathiot, C.; Ponge, P.; Gallard, B.; Sassi, J.-F.; Delrue, F.; Le Moigne, N. Microalgae starch-based bioplastics: Screening of ten strains and plasticization of unfractionated microalgae by extrusion. Carbohydr. Polym. 2019, 208, 142–151. [Google Scholar] [CrossRef] [PubMed]

- Greenwell, H.C.; Laurens, L.; Shields, R.; Lovitt, R.; Flynn, K. Placing microalgae on the biofuels priority list: A review of the technological challenges. J. R. Soc. Interface 2010, 7, 703–726. [Google Scholar] [CrossRef] [PubMed]

- De-Bashan, L.E.; Bashan, Y. Immobilized microalgae for removing pollutants: Review of practical aspects. Bioresour. Technol. 2010, 101, 1611–1627. [Google Scholar] [CrossRef]

- Lauritano, C.; Andersen, J.H.; Hansen, E.; Albrigtsen, M.; Escalera, L.; Esposito, F.; Helland, K.; Hanssen, K.Ø.; Romano, G.; Ianora, A. Bioactivity screening of microalgae for antioxidant, anti-inflammatory, anticancer, anti-diabetes, and antibacterial activities. Front. Mar. Sci. 2016, 3, 68. [Google Scholar] [CrossRef]

- Sathasivam, R.; Ki, J.-S. A review of the biological activities of microalgal carotenoids and their potential use in healthcare and cosmetic industries. Mar. Drugs 2018, 16, 26. [Google Scholar] [CrossRef]

- Mata, T.M.; Martins, A.A.; Caetano, N.S. Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 2010, 14, 217–232. [Google Scholar] [CrossRef]

- Huang, G.; Chen, F.; Wei, D.; Zhang, X.; Chen, G. Biodiesel production by microalgal biotechnology. Appl. Energy 2010, 87, 38–46. [Google Scholar] [CrossRef]

- Mascarelli, A.L. Gold rush for algae. Nature 2009, 461, 460. [Google Scholar] [CrossRef]

- Schenk, P.M.; Thomas-Hall, S.R.; Stephens, E.; Marx, U.C.; Mussgnug, J.H.; Posten, C.; Kruse, O.; Hankamer, B. Second generation biofuels: High-efficiency microalgae for biodiesel production. Bioenergy Res. 2008, 1, 20–43. [Google Scholar] [CrossRef]

- Banerjee, A.; Sharma, R.; Chisti, Y.; Banerjee, U. Botryococcus braunii: A renewable source of hydrocarbons and other chemicals. Crit. Rev. Biotechnol. 2002, 22, 245–279. [Google Scholar] [CrossRef]

- Demirbaş, A. Production of biodiesel from algae oils. Energy Sources Part A 2008, 31, 163–168. [Google Scholar] [CrossRef]

- Subashchandrabose, S.R.; Ramakrishnan, B.; Megharaj, M.; Venkateswarlu, K.; Naidu, R. Consortia of cyanobacteria/microalgae and bacteria: Biotechnological potential. Biotechnol. Adv. 2011, 29, 896–907. [Google Scholar] [CrossRef]

- Doan, T.T.Y.; Sivaloganathan, B.; Obbard, J.P. Screening of marine microalgae for biodiesel feedstock. Biomass Bioenergy 2011, 35, 2534–2544. [Google Scholar] [CrossRef]

- Ghasemi, Y.; Rasoul-Amini, S.; Naseri, A.T.; Montazeri-Najafabady, N.; Mobasher, M.A.; Dabbagh, F. Microalgae biofuel potentials. Appl. Biochem Microbiol. 2012, 48, 126–144. [Google Scholar] [CrossRef]

- Fuentes-Grünewald, C.; Garcés, E.; Rossi, S.; Camp, J. Use of the dinoflagellate Karlodinium veneficum as a sustainable source of biodiesel production. J. Ind. Microbiol. Biotechnol. 2009, 36, 1215–1224. [Google Scholar] [CrossRef]

- Delrue, F.; Setier, P.-A.; Sahut, C.; Cournac, L.; Roubaud, A.; Peltier, G.; Froment, A.-K. An economic, sustainability, and energetic model of biodiesel production from microalgae. Bioresour. Technol. 2012, 111, 191–200. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.; Dong, W.; Zhang, X.; Tyagi, R.D.; Drogui, P.; Surampalli, R.Y. The potential of microalgae in biodiesel production. Renew. Sustain. Energy Rev. 2018, 90, 336–346. [Google Scholar] [CrossRef]

- Abomohra, A.E.-F.; Jin, W.; Tu, R.; Han, S.-F.; Eid, M.; Eladel, H. Microalgal biomass production as a sustainable feedstock for biodiesel: Current status and perspectives. Renew. Sustain. Energy Rev. 2016, 64, 596–606. [Google Scholar] [CrossRef]

- Milledge, J.J.; Heaven, S. A review of the harvesting of micro-algae for biofuel production. Rev. Environ. Sci. Biotechnol. 2013, 12, 165–178. [Google Scholar] [CrossRef]

- Brennan, L.; Owende, P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 2010, 14, 557–577. [Google Scholar] [CrossRef]

- Yang, J.; Xu, M.; Zhang, X.; Hu, Q.; Sommerfeld, M.; Chen, Y. Life-cycle analysis on biodiesel production from microalgae: Water footprint and nutrients balance. Bioresour. Technol. 2011, 102, 159–165. [Google Scholar] [CrossRef]

- Agricultural, Fisheries and Conservation Department, HKSAR. Hong Kong Red Tide Information Network. Available online: https://www.afcd.gov.hk/english/fisheries/hkredtide/redtide.html (accessed on 20 May 2020).

- Gobler, C.J. Climate change and harmful algal blooms: Insights and perspective. Harmful Algae 2020, 91, 101731. [Google Scholar] [CrossRef]

- Samarakoon, K.W.; Ko, J.-Y.; Shah, M.M.R.; Lee, J.-H.; Kang, M.-C.; Kwon, O.-N.; Lee, J.-B.; Jeon, Y.-J. In vitro studies of anti-inflammatory and anticancer activities of organic solvent extracts from cultured marine microalgae. Algae 2013, 28, 111–119. [Google Scholar] [CrossRef]

- Assunção, J.; Guedes, A.; Malcata, F.X. Biotechnological and pharmacological applications of biotoxins and other bioactive molecules from dinoflagellates. Mar. Drugs 2017, 15, 393. [Google Scholar] [CrossRef]

- Fuentes-Grünewald, C.; Garcés, E.; Alacid, E.; Rossi, S.; Camp, J. Biomass and lipid production of dinoflagellates and raphidophytes in indoor and outdoor photobioreactors. Mar. Biotechnol. 2013, 15, 37–47. [Google Scholar] [CrossRef]

- Fuentes-Grünewald, C.; Bayliss, C.; Fonlut, F.; Chapuli, E. Long-term dinoflagellate culture performance in a commercial photobioreactor: Amphidinium carterae case. Bioresour. Technol. 2016, 218, 533–540. [Google Scholar] [CrossRef]

- Go, S.; Lee, S.-J.; Jeong, G.-T.; Kim, S.-K. Factors affecting the growth and the oil accumulation of marine microalgae, Tetraselmis suecica. Bioprocess. Biosyst. Eng. 2012, 35, 145–150. [Google Scholar] [CrossRef]

- Griffiths, M.J.; van Hille, R.P.; Harrison, S.T. Lipid productivity, settling potential and fatty acid profile of 11 microalgal species grown under nitrogen replete and limited conditions. J. Appl. Phycol. 2012, 24, 989–1001. [Google Scholar] [CrossRef]

- Moheimani, N.R. Long-term outdoor growth and lipid productivity of Tetraselmis suecica, Dunaliella tertiolecta and Chlorella sp. (Chlorophyta) in bag photobioreactors. J. Appl. Phycol. 2013, 25, 167–176. [Google Scholar] [CrossRef]

- Keller, M.D.; Selvin, R.C.; Claus, W.; Guillard, R.R.L. Media for the Culture of Oceanic Ultraphytoplankton. J. Phycol. 1987, 23, 633–638. [Google Scholar] [CrossRef]

- Lee, F.W.-F.; Ho, K.C.; Lo, S.C.-L. Rapid identification of dinoflagellates using protein profiling with matrix-assisted laser desorption/ionization mass spectrometry. Harmful Algae 2008, 7, 551–559. [Google Scholar] [CrossRef]

- Adachi, M.; Sako, Y.; Ishida, Y. Restriction fragment length polymorphism of ribosomal DNA internal transcribed spacer and 5.8s regions in Japanese Alexandrium species (Dinophyceae). J. Phycol. 1994, 30, 857–863. [Google Scholar] [CrossRef]

- Adachi, M.; Sake, Y.; Ishida, Y. Analysis of Alexandrium (Dinophyceae) species using sequences of the 5.8 S ribosomal DNA and internal transcribed spacer regions 1. J. Phycol. 1996, 32, 424–432. [Google Scholar] [CrossRef]

- Thompson, J.D.; Gibson, T.J.; Plewniak, F.; Jeanmougin, F.; Higgins, D.G. The CLUSTAL_X Windows Interface: Flexible Strategies for Multiple Sequence Alignment Aided by Quality Analysis Tools. Nucleic Acids Res. 1997, 25, 4876–4882. [Google Scholar] [CrossRef]

- Arenas, N.E.; Polanco, J.C.; Coronado, S.M.; Durango, C.J.; Gómez, A. Design of a molecular method for subspecies specific identification of Klebsiella pneumoniae by using the 16S ribosomal subunit gene. Colomb. Médica 2009, 40, 194–201. [Google Scholar]

- Goldman, J.C.; Dennett, M.R. Susceptibility of some marine phytoplankton species to cell breakage during filtration and post-filtration rinsing. J. Exp. Mar. Biol. Ecol. 1985, 86, 47–58. [Google Scholar] [CrossRef]

- Bligh, E.G.; Dyer, W.J. A rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef]

- Lepage, G.; Roy, C.C. Improved recovery of fatty acid through direct transesterification without prior extraction or purification. J. Lipid Res. 1984, 25, 1391–1396. [Google Scholar] [PubMed]

- Griffiths, M.J.; Harrison, S.T. Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J. Appl. Phycol. 2009, 21, 493–507. [Google Scholar] [CrossRef]

- Langer, G.; Nehrke, G.; Probert, I.; Ly, J.; Ziveri, P. Strain-specific responses of Emiliania huxleyi to changing seawater carbonate chemistry. Biogeosciences 2009, 6, 2637–2646. [Google Scholar] [CrossRef]

- Kremp, A.; Godhe, A.; Egardt, J.; Dupont, S.; Suikkanen, S.; Casabianca, S.; Penna, A. Intraspecific variability in the response of bloom-forming marine microalgae to changed climate conditions. Ecol. Evol. 2012, 2, 1195–1207. [Google Scholar] [CrossRef]

- Sassenhagen, I.; Wilken, S.; Godhe, A.; Rengefors, K. Phenotypic plasticity and differentiation in an invasive freshwater microalga. Harmful Algae 2015, 41, 38–45. [Google Scholar] [CrossRef]

- Rodolfi, L.; Chini Zittelli, G.; Bassi, N.; Padovani, G.; Biondi, N.; Bonini, G.; Tredici, M.R. Microalgae for oil: Strain selection, induction of lipid synthesis and outdoor mass cultivation in a low-cost photobioreactor. Biotechnol. Bioeng. 2009, 102, 100–112. [Google Scholar] [CrossRef]

- Weldy, C.S.; Huesemann, M. Lipid production by Dunaliella salina in batch culture: Effects of nitrogen limitation and light intensity. J. Undergrad. Res. 2007, 7, 115–122. [Google Scholar]

- Converti, A.; Casazza, A.A.; Ortiz, E.Y.; Perego, P.; Del Borghi, M. Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem. Eng. Process. Process. Intensif. 2009, 48, 1146–1151. [Google Scholar] [CrossRef]

- Nascimento, I.A.; Marques, S.S.I.; Cabanelas, I.T.D.; Pereira, S.A.; Druzian, J.I.; de Souza, C.O.; Vich, D.V.; de Carvalho, G.C.; Nascimento, M.A. Screening microalgae strains for biodiesel production: Lipid productivity and estimation of fuel quality based on fatty acids profiles as selective criteria. Bioenergy Res. 2013, 6, 1–13. [Google Scholar] [CrossRef]

- Sajjadi, B.; Chen, W.-Y.; Raman, A.A.A.; Ibrahim, S. Microalgae lipid and biomass for biofuel production: A comprehensive review on lipid enhancement strategies and their effects on fatty acid composition. Renew. Sustain. Energy Rev. 2018, 97, 200–232. [Google Scholar] [CrossRef]

- Lin, S. Genomic understanding of dinoflagellates. Res. Microbiol. 2011, 162, 551–569. [Google Scholar] [CrossRef]

- ASTM. D6751 Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels. Available online: http://203.187.160.133:9011/agrifuelsqcs-i.com/c3pr90ntc0td/attachments/1263%20/d6751.46391.pdf (accessed on 20 May 2020).

- Lee, J.-Y.; Yoo, C.; Jun, S.-Y.; Ahn, C.-Y.; Oh, H.-M. Comparison of several methods for effective lipid extraction from microalgae. Bioresour. Technol. 2010, 101, S75–S77. [Google Scholar] [CrossRef] [PubMed]

- Harrington, K.J. Chemical and physical properties of vegetable oil esters and their effect on diesel fuel performance. Biomass 1986, 9, 1–17. [Google Scholar] [CrossRef]

- Knothe, G.; Matheaus, A.C.; Ryan, T.W., III. Cetane numbers of branched and straight-chain fatty esters determined in an ignition quality tester. Fuel 2003, 82, 971–975. [Google Scholar] [CrossRef]

- Automotive Fuels. Fatty Acid Methylesters (FAME) for Diesel Engines. Requirements and Test Methods, British Standard. 2008. Available online: https://www.sis.se/en/produkter/petroleum-and-related-technologies/fuels/liquid-fuels/ssen14214/ (accessed on 20 May 2020).

- Knothe, G. Analyzing biodiesel: Standards and other methods. J. Am. Oil Chem. Soc. 2006, 83, 823–833. [Google Scholar] [CrossRef]

- Grünewald, C.F. Dinoflagellates as feedstock for biodiesel production. In The Science of Algal Fuels. Cellular Origin, Life in Extreme Habitats and Astrobiology; Gordon, R., Seckbach, J., Eds.; Springer: Dordrecht, The Netherlands, 2012; Volume 25, pp. 233–254. [Google Scholar]

- Lee, J.; Cho, D.-H.; Ramanan, R.; Kim, B.-H.; Oh, H.-M.; Kim, H.-S. Microalgae-associated bacteria play a key role in the flocculation of Chlorella vulgaris. Bioresour. Technol. 2013, 131, 195–201. [Google Scholar] [CrossRef]

- Bolch, C.J.; Bejoy, T.A.; Green, D.H. Bacterial associates modify growth dynamics of the dinoflagellate Gymnodinium catenatum. Front. Microbiol. 2017, 8, 670. [Google Scholar] [CrossRef]

- Cho, K.; Heo, J.; Cho, D.-H.; Tran, Q.-G.; Yun, J.-H.; Lee, S.-M.; Lee, Y.J.; Kim, H.-S. Enhancing algal biomass and lipid production by phycospheric bacterial volatiles and possible growth enhancing factor. Algal Res. 2019, 37, 186–194. [Google Scholar] [CrossRef]

- Berthold, D.E.; Shetty, K.G.; Jayachandran, K.; Laughinghouse, H.D., IV; Gantar, M. Enhancing algal biomass and lipid production through bacterial co-culture. Biomass Bioenergy 2019, 122, 280–289. [Google Scholar] [CrossRef]

- Soratana, K.; Barr, W.J.; Landis, A.E. Effects of co-products on the life-cycle impacts of microalgal biodiesel. Bioresour. Technol. 2014, 159, 157–166. [Google Scholar] [CrossRef] [PubMed]

- Damergi, E.; Schwitzguébel, J.-P.; Refardt, D.; Sharma, S.; Holliger, C.; Ludwig, C. Extraction of carotenoids from Chlorella vulgaris using green solvents and syngas production from residual biomass. Algal Res. 2017, 25, 488–495. [Google Scholar] [CrossRef]

- Matos, Â.P.; Feller, R.; Moecke, E.H.S.; de Oliveira, J.V.; Junior, A.F.; Derner, R.B.; Sant’Anna, E.S. Chemical characterization of six microalgae with potential utility for food application. J. Am. Oil Chem. Soc. 2016, 93, 963–972. [Google Scholar] [CrossRef]

- Lee, O.K.; Oh, Y.-K.; Lee, E.Y. Bioethanol production from carbohydrate-enriched residual biomass obtained after lipid extraction of Chlorella sp. KR-1. Bioresour. Technol. 2015, 196, 22–27. [Google Scholar] [CrossRef]

- Norsker, N.-H.; Barbosa, M.J.; Vermuë, M.H.; Wijffels, R.H. Microalgal production—A close look at the economics. Biotechnol. Adv. 2011, 29, 24–27. [Google Scholar] [CrossRef]

- Singh, A.; Nigam, P.S.; Murphy, J.D. Mechanism and challenges in commercialisation of algal biofuels. Bioresour. Technol. 2011, 102, 26–34. [Google Scholar] [CrossRef]

- Abdullah, B.; Muhammad, S.A.F.S.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.M.A. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- Youngs, R.O.; Cook, J.R. Method and Apparatus for Separating Particles from a Liquid. U.S. Patent US8092691B2, 10 January 2012. [Google Scholar]

- Shepherd, S.L. System for Harvesting Algae in Continuous Fermentation. U.S. Patent US8377687B2, 19 February 2013. [Google Scholar]

- Kadir, W.N.A.; Lam, M.K.; Uemura, Y.; Lim, J.W.; Lee, K.T. Harvesting and pre-treatment of microalgae cultivated in wastewater for biodiesel production: A review. Energy Convers. Manag. 2018, 171, 1416–1429. [Google Scholar] [CrossRef]

- Martínez, T.d.C.C.; Rodríguez, R.A.; Voltolina, D.; Morquecho, L. Effectiveness of coagulants-flocculants for removing cells and toxins of Gymnodinium catenatum. Aquaculture 2016, 452, 188–193. [Google Scholar] [CrossRef]

- Li, L.; Pan, G. A universal method for flocculating harmful algal blooms in marine and fresh waters using modified sand. Environ. Sci. Technol. 2013, 47, 4555–4562. [Google Scholar] [CrossRef]

- Wang, S.; Yerkebulan, M.; Abomohra, A.E.-F.; El-Khodary, S.; Wang, Q. Microalgae harvest influences the energy recovery: A case study on chemical flocculation of Scenedesmus obliquus for biodiesel and crude bio-oil production. Bioresour. Technol. 2019, 286, 121371. [Google Scholar] [CrossRef]

- Dassey, A.J.; Theegala, C.S. Harvesting economics and strategies using centrifugation for cost effective separation of microalgae cells for biodiesel applications. Bioresour. Technol. 2013, 128, 241–245. [Google Scholar] [CrossRef]

- Swanson, D.; Block, R.; Mousa, S.A. Omega-3 fatty acids EPA and DHA: Health benefits throughout life. Adv. Nutr. 2012, 3, 1–7. [Google Scholar] [CrossRef]

- Spolaore, P.; Joannis-Cassan, C.; Duran, E.; Isambert, A. Commercial applications of microalgae. J. Biosci. Bioeng. 2006, 101, 87–96. [Google Scholar] [CrossRef]

- Haimeur, A.; Mimouni, V.; Ulmann, L.; Martineau, A.-S.; Messaouri, H.; Pineau-Vincent, F.; Tremblin, G.; Meskini, N. Fish oil and microalga omega-3 as dietary supplements: A comparative study on cardiovascular risk factors in high-fat fed rats. Lipids 2016, 51, 1037–1049. [Google Scholar] [CrossRef]

- Doughman, S.D.; Krupanidhi, S.; Sanjeevi, C.B. Omega-3 fatty acids for nutrition and medicine: Considering microalgae oil as a vegetarian source of EPA and DHA. Current Diabetes Rev. 2007, 3, 198–203. [Google Scholar] [CrossRef]

- Stamey, J.; Shepherd, D.; De Veth, M.; Corl, B. Use of algae or algal oil rich in n-3 fatty acids as a feed supplement for dairy cattle. J. Dairy Sci. 2012, 95, 5269–5275. [Google Scholar] [CrossRef]

- Lum, K.K.; Kim, J.; Lei, X.G. Dual potential of microalgae as a sustainable biofuel feedstock and animal feed. J. Anim. Sci. Biotechnol. 2013, 4, 53. [Google Scholar] [CrossRef]

- Brown, M.; Robert, R. Preparation and assessment of microalgal concentrates as feeds for larval and juvenile Pacific oyster (Crassostrea gigas). Aquaculture 2002, 207, 289–309. [Google Scholar] [CrossRef]

- Chauton, M.S.; Reitan, K.I.; Norsker, N.H.; Tveterås, R.; Kleivdal, H.T. A techno-economic analysis of industrial production of marine microalgae as a source of EPA and DHA-rich raw material for aquafeed: Research challenges and possibilities. Aquaculture 2015, 436, 95–103. [Google Scholar] [CrossRef]

- Charoonnart, P.; Purton, S.; Saksmerprome, V. Applications of microalgal biotechnology for disease control in aquaculture. Biology 2018, 7, 24. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.-Z. Neurotoxins from marine dinoflagellates: A brief review. Mar. Drugs 2008, 6, 349–371. [Google Scholar] [CrossRef] [PubMed]

- Menetrez, M.Y. An overview of algae biofuel production and potential environmental impact. Environ. Sci. Technol. 2012, 46, 7073–7085. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.H.; Jeong, H.J.; Kwon, J.E.; Kang, H.C.; Kim, J.H.; Jang, S.H.; Park, J.Y.; Yoon, E.Y.; Kim, J.S. Mixotrophic ability of the phototrophic dinoflagellates Alexandrium andersonii, A. affine, and A. fraterculus. Harmful Algae 2016, 59, 67–81. [Google Scholar] [CrossRef] [PubMed]

- Hold, G.L.; Smith, E.A.; Rappë, M.S.; Maas, E.W.; Moore, E.R.; Stroempl, C.; Stephen, J.R.; Prosser, J.I.; Birkbeck, T.H.; Gallacher, S. Characterisation of bacterial communities associated with toxic and non-toxic dinoflagellates: Alexandrium spp. and Scrippsiella trochoidea. FEMS Microbiol. Ecol. 2001, 37, 161–173. [Google Scholar] [CrossRef]

- Nguyen-Ngoc, L. An autecological study of the potentially toxic dinoflagellate Alexandrium affine isolated from Vietnamese waters. Harmful Algae 2004, 3, 117–129. [Google Scholar] [CrossRef]

| Species | Strain | Isolation Site | Date of Isolation |

|---|---|---|---|

| Prorocentrium minimum | a | Yim Tin Tsai | 2005 |

| b | Junk Bay | 1998 | |

| Scrippsiella sp. | a b ^ | Ma Wan Sam Mun Tsai | 2011 2012 |

| Prorocentrium triestinum | a | Junk Bay | 1997 |

| b | Sha Tau Kok | 2011 | |

| Scrippsiella rotunda | -- | Junk Bay | 1997 |

| Alexandrium affine | -- | Junk Bay | 1998 |

| Polykrikos geminatum | -- | Ma Wan | 2011 |

| Akashiwo sanguinea | -- | Sha Tau Kok | 2011 |

| Species | Strain | Location of Isolation | Sequence Similarity (%) ^ |

|---|---|---|---|

| Prorocentrum minimum | a | Yim Tin Tsai | 99 |

| Prorocentrum minimum | b | Junk Bay | |

| Scrippsiella sp. | a | Ma Wan | 92 |

| Scrippsiella sp. | b | Sam Mun Tsai | |

| Prorocentrum triestinum | a | Junk Bay | 100 |

| Prorocentrum triestinum | b | Sha Tau Kok |

| Species | Strain | Class | Growth Rate (day−1) | Biomass Concentration (g/L) | Total Lipid Content (% of dry weight (dw)) | Lipid Productivity (mg/L/day) | Reference |

|---|---|---|---|---|---|---|---|

| P. minimum | a | Marine, Dinophyceae | 0.39 | 1.48 ± 0.39 | 18.2 ± 0.4 | 19.2 ± 5.0 | Present study |

| P. minimum | b | 0.38 | 1.25 ± 0.08 | 22.0 ± 0 | 19.6 ± 1.3 | ||

| P. triestinum | a | 0.57 | 1.05 ± 0.19 | 16.2 ± 0 | 18.9 ± 3.4 | ||

| P. triestinum | b | 0.05 | 1.20 ± 0.08 | 25.1 ± 2.5 | 11.1 ± 0.7 | ||

| S. rotunda | - - | 0.25 | 1.27 ± 0.12 | 23.2 ± 0 | 14.2 ± 1.2 | ||

| A. affine | - - | 0.12 | 1.29 ± 0.18 | 19.6 ± 0 | 11.4 ± 1.6 | ||

| P. germinatum | - - | 0.13 | 1.25 ± 0.18 | 20.0 ± 0 | 15.6 ± 2.2 | ||

| A. sanguinea | - - | 0.04 | 1.09 ± 0.16 | 16.3 ± 3.4 | 11.1 ± 1.7 | ||

| Scrippsiella sp. | a | 0.19 | 1.15 ± 0.18 | 22.5 ± 0.1 | 11.5 ± 0.1 | ||

| Scrippsiella sp. | b | 0.28 | 1.42 ± 0.2 | 32.2 ± 0.0 | 47.3 ± 6.7 | ||

| Scrippsiella sp. ^ | - - | - - | 1.35 ± 0.04 | 30.9 ± 2.6 | - - | ||

| T. suecica | - - | Marine, Chlorophyceae | 0.72 | 1.82 ± 0.08 | 26.1 ± 0 | 47.3 ± 2.2 | |

| Thalassionema sp. | - - | Marine, Bacillariophyceae | 0.58-0.85 | 0.05–0.08 | 0.9–17.8 | - - | [17] |

| Dunaliella salina | - - | Marine, Chlorophyceae | - - | - - | 34–44 | 36–46 | [49] |

| Nannochloropsis sp. | - - | Marine, Eustigmatophyceae | 0.42–0.62 | 0.22–0.4 | 39.5–44.8 | - - | [17] |

| - - | 0.76 | 1.74 | 24 | 42 | [33] | ||

| Nannochloropsis oculata | - - | 0.07 | - - | 13.89 | 10.10 | [50] | |

| Isochrysis sp. | - - | Marine, Haptophyceae | 1.32 | 1.74 | 24 | 42 | [33] |

| Chlorella vulgaris | - - | Freshwater, Chlorophyceae | 0.14 | - - | 14.71 | 20.22 | [50] |

| - - | 1.34 | 1.65 | 14 | 27 | [33] | ||

| Scenedesmus obliquus | - - | Freshwater, Chlorophyceae | 0.21 | 0.16 | 16.73 | 26.77 | [51] |

| Scenedesmus sp. | - - | 1.15 | 2.61 | 9 | 29 | [33] |

| Species | P. minimum | P. triestinum | Scrippsiella sp. | A. sanguinea | P. germinatum | A. affine | S. rotunda | T. suecica | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Strain | a | b | a | b | a | b * | Field sample ^ | -- | -- | -- | -- | -- |

| Myristic acid (C14:0) | 2.7 ± 0.8 | N.D. | N.D. | 2.1 ± 0.2 | N.D. | 2.7 ± 0.4 | 3.6 ± 0.0 | 2.2 ± 0.8 | 3.8 ± 1.4 | N.D. | 1.3 ± 0.2 | 6.2 ± 0 |

| Pentadecanoic acid (C15:0) | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. |

| Palmitic acid (C16:0) | 10.4 ± 0.8 | 17.8 ± 2.9 | 11.3 ± 0 | 18.6 ± 3.6 | 11.4 ± 0.4 | 17.1 ± 0.0 | 11.1 ± 0.3 | 15.5 ± 1.4 | 15.2 ± 0.5 | 16.8 ± 0.2 | 13.5 ± 0.9 | 25.2 ± 1.4 |

| Palmitoleic acid (C16:1n7) | N.D. | N.D. | N.D. | 3.5 ± 0.7 | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | 15.9 ± 0 |

| cis-10-Heptadecenoic Acid (C17:1) | N.D. | N.D. | N.D. | N.D. | 1.4 ± 0.4 | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | 5.1 ± 0 |

| Stearic acid (C18:0) | N.D. | N.D. | N.D. | 1.8 ± 2.5 | 1.7 ± 0.8 | 2.1 ± 0.1 | 1.4 ± 0.1 | 3.1 ± 1.4 | 3.0 ± 0.5 | N.D. | 1.73 ± 0.2 | 7.5 ± 0 |

| Oleic acid (C18:1n9) | N.D. | N.D. | N.D. | N.D. | N.D. | 2.2 ± 0.1 | 1.4 ± 0.1 | 4.5 ± 3.2 | 3.3 ± 0.2 | N.D. | N.D. | 13.6 ± 0 |

| Linoleic acid (C18:2n6) | N.D. | N.D. | N.D. | N.D. | N.D. | 1.2 ± 0.3 | 0.2 ± 0.3 | N.D. | N.D. | N.D. | N.D. | 11.8 ± 1.1 |

| γ-Linolenic acid (C18:3n6) | N.D. | N.D. | N.D. | N.D. | N.D. | 9.9 ± 0.4 | 4.0 ± 0.6 | N.D. | N.D. | N.D. | N.D. | 8.5 ± 0 |

| α-Linolenic acid (C18:3n3) | 19.3 ± 4.5 | 15.4 ± 1.5 | 3.6 ± 0.2 | 23.5 ± 1.6 | 18.8 ± 4.7 | N.D. | N.D. | N.D. | 5.1 ± 1.7 | 6.4 ± 0.2 | 18.3 ± 0.8 | 3.8 ± 1.3 |

| cis-11-Eicosapentaenoic Acid (C20:1) | 3.7 ± 0.1 | 2.6 ± 0.1 | 1.2 ± 0.0 | 3.4 ± 0.1 | 4.2 ± 0.8 | 4.6 ± 0.0 | 16.0 ± 0.0 | N.D. | N.D. | 4.8 ± 0.8 | 3.48 ± 0.3 | N.D. |

| Arachidonic acid (C20:4n6)(AA) | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. |

| cis-5,8,11,14,17-Eicosapentaenoic acid (C20:5n3)(EPA) | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. |

| Behenic acid (C22:0) | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. |

| Erucic acid (C22:1n9) | 7.2 ± 2.2 | N.D. | N.D. | N.D. | N.D. | 3.2 ± 0.2 | 9.5 ± 1.8 | 16.8 ± 2.3 | 17.0 ± 6.7 | 16.4 ± 0.1 | N.D. | N.D. |

| Docosahexaenoic acid (C22:6n3)(DHA) | 56.6 ± 8.4 | 64.2 ± 1.4 | 84 ± 8.0 | 47.5 ± 4 | 60.5 ± 4.5 | 57.1 ± 0.4 | 52.7 ± 2.9 | 57.9 ± 7.5 | 52.4 ± 6.6 | 55.6 ± 1.0 | 61.7 ± 1.4 | N.D. |

| Lignoceric acid (C24:0) | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. |

| Species | P. minimum | P. triestinum | Scrippsiella sp. | A. sanguinea | P. germinatum | A. affine | S. rotunda | T. suecica | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Strain | a | b | a | b | a | b * | field sample ^ | |||||

| Saturated (% of total FAME) | 13.1 + 1.7 | 17.9 + 3.0 | 11.3 + 0.0 | 22.5 + 6.2 | 13.2 + 1.3 | 21.8 + 0.5 | 16.1 + 0.4 | 20.7 + 2.0 | 13.2 + 1.3 | 16.8 + 0.2 | 16.9 + 0.6 | 32.8 + 3.6 |

| Monounsaturated (% of total FAME) | 10.9 ± 2.3 | 2.6 ± 0.1 | 2.3 ± 0.0 | 6.9 ± 0.6 | 5.7 ± 1.2 | 9.9 ± 0.1 | 15.1 ± 2.5 | 21.3 ± 5.5 | 5.7 ± 1.2 | 22.8 ± 0.3 | 3.6 ± 0.3 | 40.8 ± 0.0 |

| Polyunsaturated (% of total FAME) | 75.9 ± 3.9 | 79.6 ± 2.9 | 87.5 ± 4.1 | 70.7 ± 5.7 | 79.3 ± 0.2 | 67.0 ± 0.1 | 68.8 ± 2.9 | 58.0 ± 7.5 | 79.0 ± 0.2 | 60.3 ± 0.1 | 79.5 ± 0.3 | 11.3 ± 0.0 |

| FAME content (mg/g of dw) | 22.7 ± 2.2 | 23.9 ± 4.7 | 27.2 ± 0 | 34.4 ± 2.4 | 32.0 ± 2.6 | 55.2 ± 9.3 | 73.0 ± 7.5 | 26.1 ± 0.9 | 21.8 ± 9.4 | 23.7 ± 14.3 | 46.1 ± 12.3 | 53.1 ± 0.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.J.; Wu, K.-C.; Chan, S.C.-Y.; Yau, Y.-H.; Chan, K.-K.; Lee, F.W.-F. Investigation of Growth, Lipid Productivity, and Fatty Acid Profiles in Marine Bloom-Forming Dinoflagellates as Potential Feedstock for Biodiesel. J. Mar. Sci. Eng. 2020, 8, 381. https://doi.org/10.3390/jmse8060381

Xu SJ, Wu K-C, Chan SC-Y, Yau Y-H, Chan K-K, Lee FW-F. Investigation of Growth, Lipid Productivity, and Fatty Acid Profiles in Marine Bloom-Forming Dinoflagellates as Potential Feedstock for Biodiesel. Journal of Marine Science and Engineering. 2020; 8(6):381. https://doi.org/10.3390/jmse8060381

Chicago/Turabian StyleXu, Steven Jingliang, Kam-Chau Wu, Sophie Cheuk-Yan Chan, Yiu-Hung Yau, Kin-Ka Chan, and Fred Wang-Fat Lee. 2020. "Investigation of Growth, Lipid Productivity, and Fatty Acid Profiles in Marine Bloom-Forming Dinoflagellates as Potential Feedstock for Biodiesel" Journal of Marine Science and Engineering 8, no. 6: 381. https://doi.org/10.3390/jmse8060381

APA StyleXu, S. J., Wu, K.-C., Chan, S. C.-Y., Yau, Y.-H., Chan, K.-K., & Lee, F. W.-F. (2020). Investigation of Growth, Lipid Productivity, and Fatty Acid Profiles in Marine Bloom-Forming Dinoflagellates as Potential Feedstock for Biodiesel. Journal of Marine Science and Engineering, 8(6), 381. https://doi.org/10.3390/jmse8060381