Statistical Modeling of Bilge Water Discharge from Ships During Normal Operation

Abstract

:1. Introduction

2. Data Collection

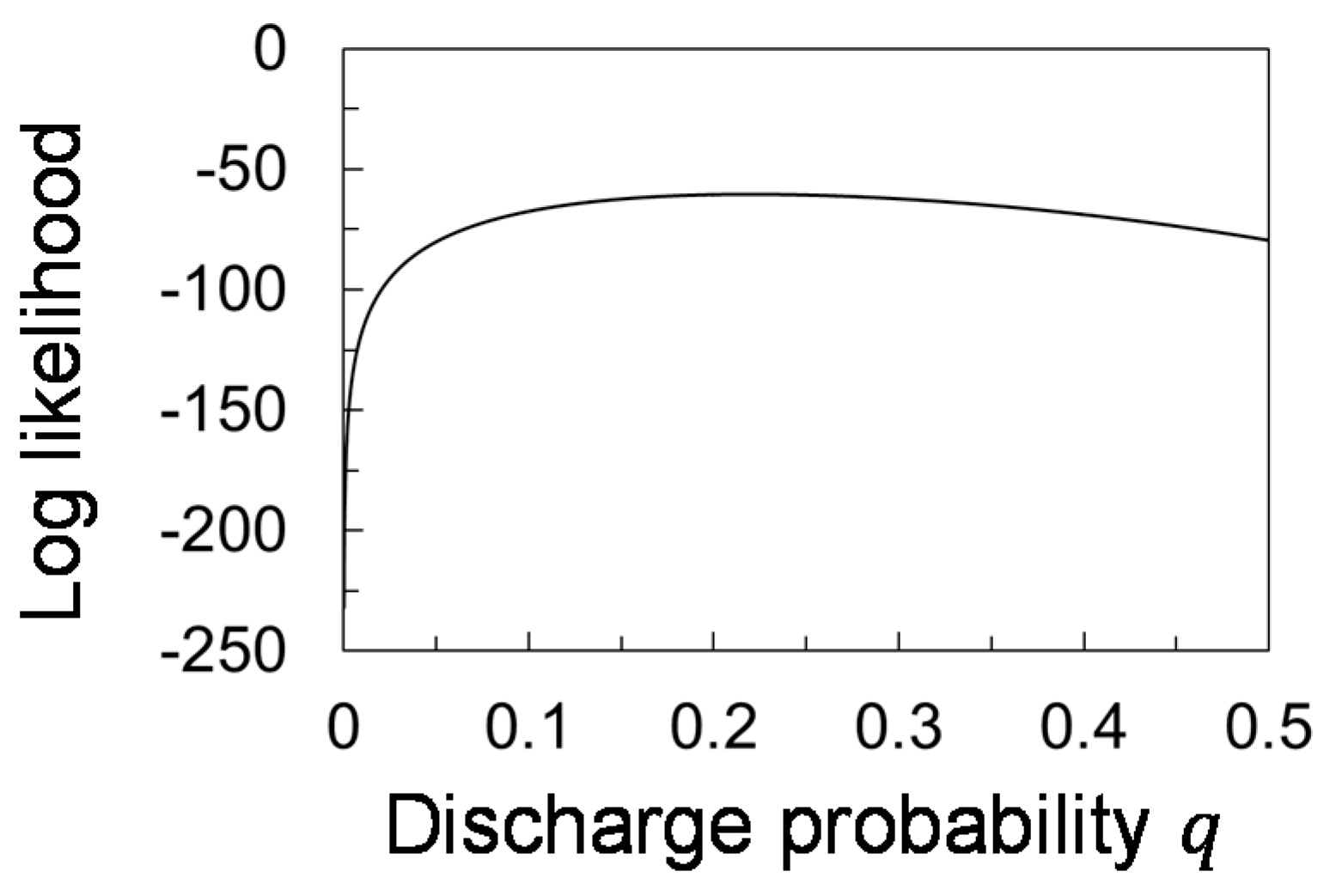

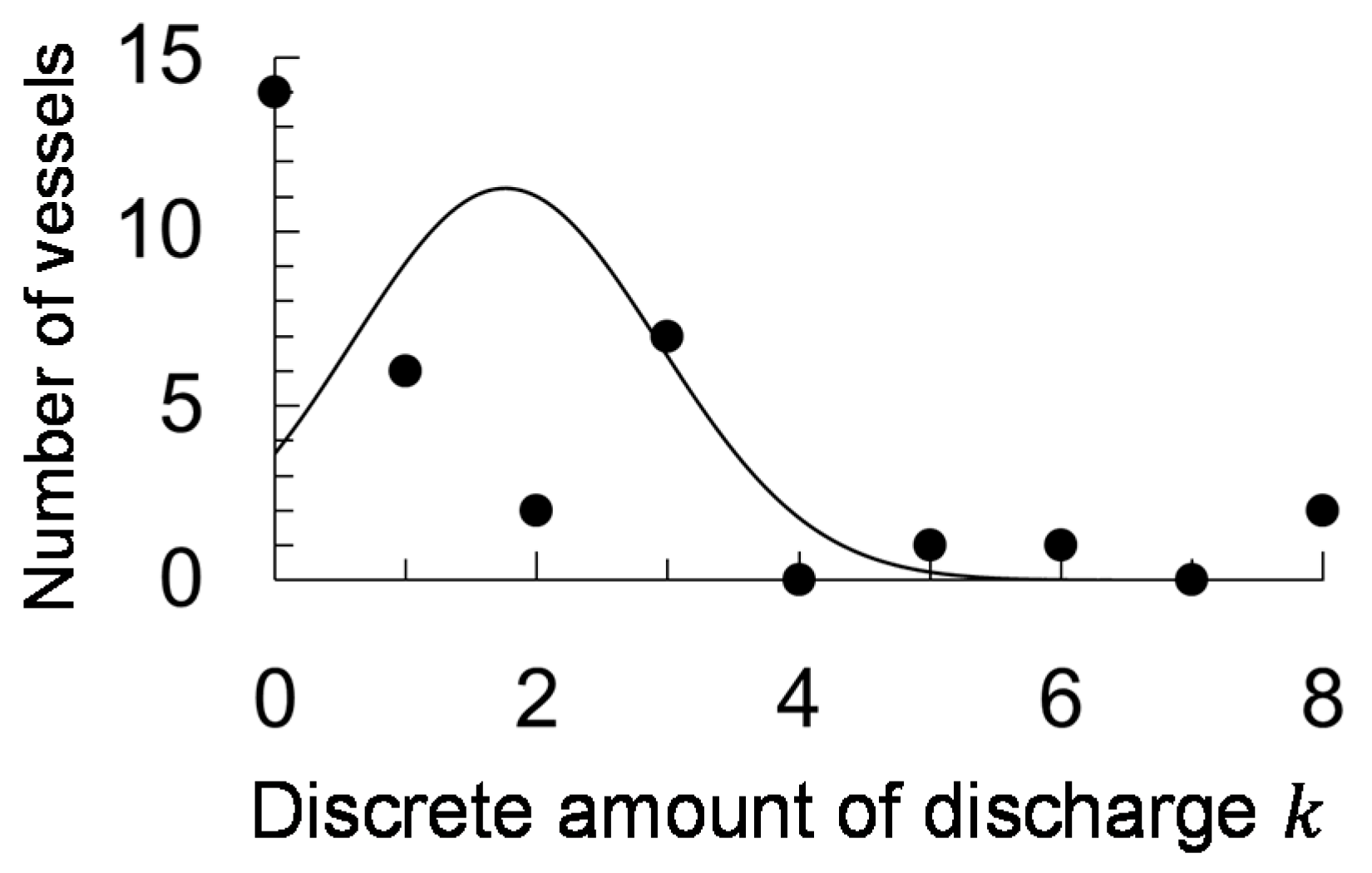

3. Constant Discharge Probability Model

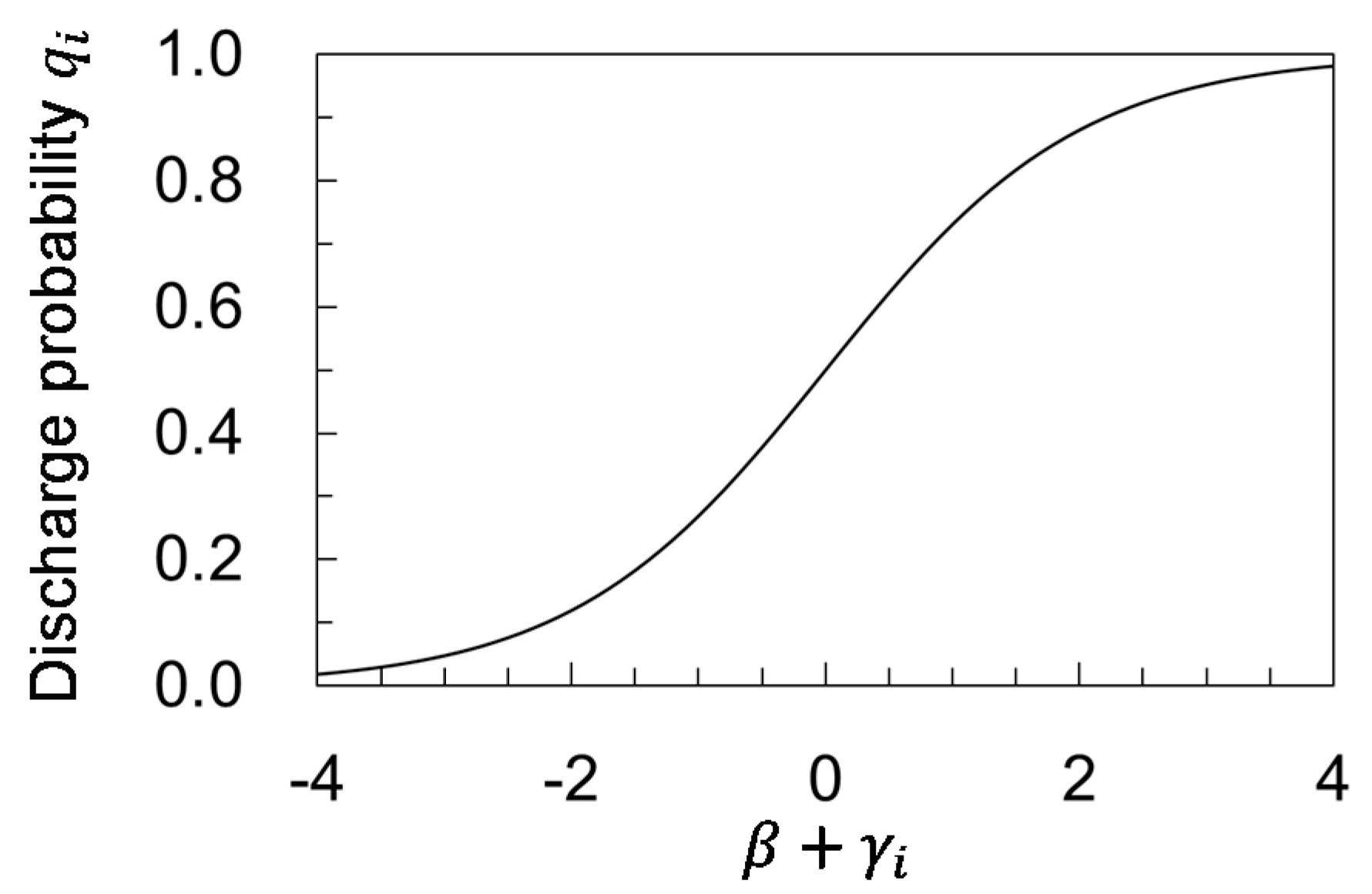

4. Variable Discharge Probability Model

4.1. Formulation

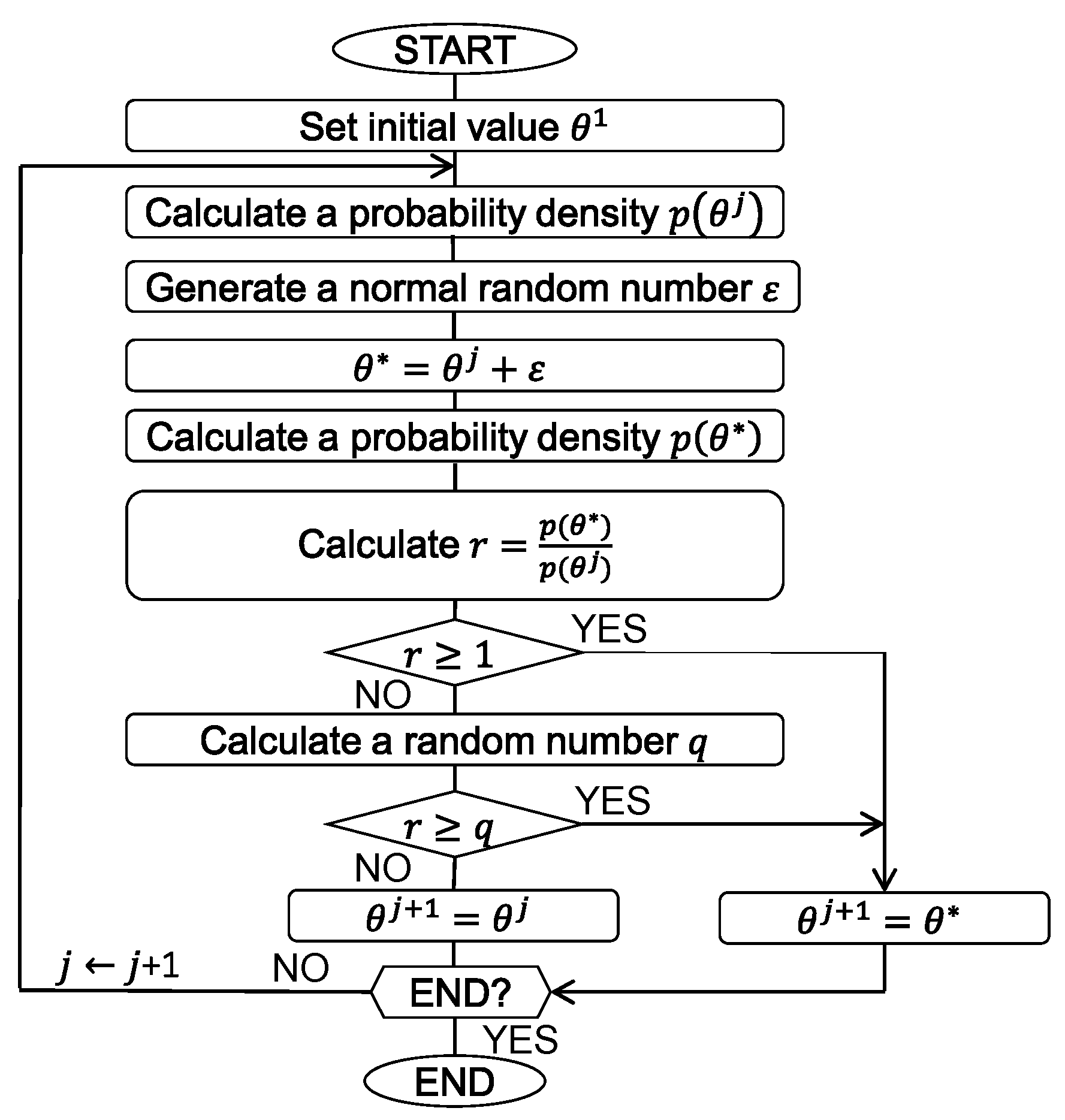

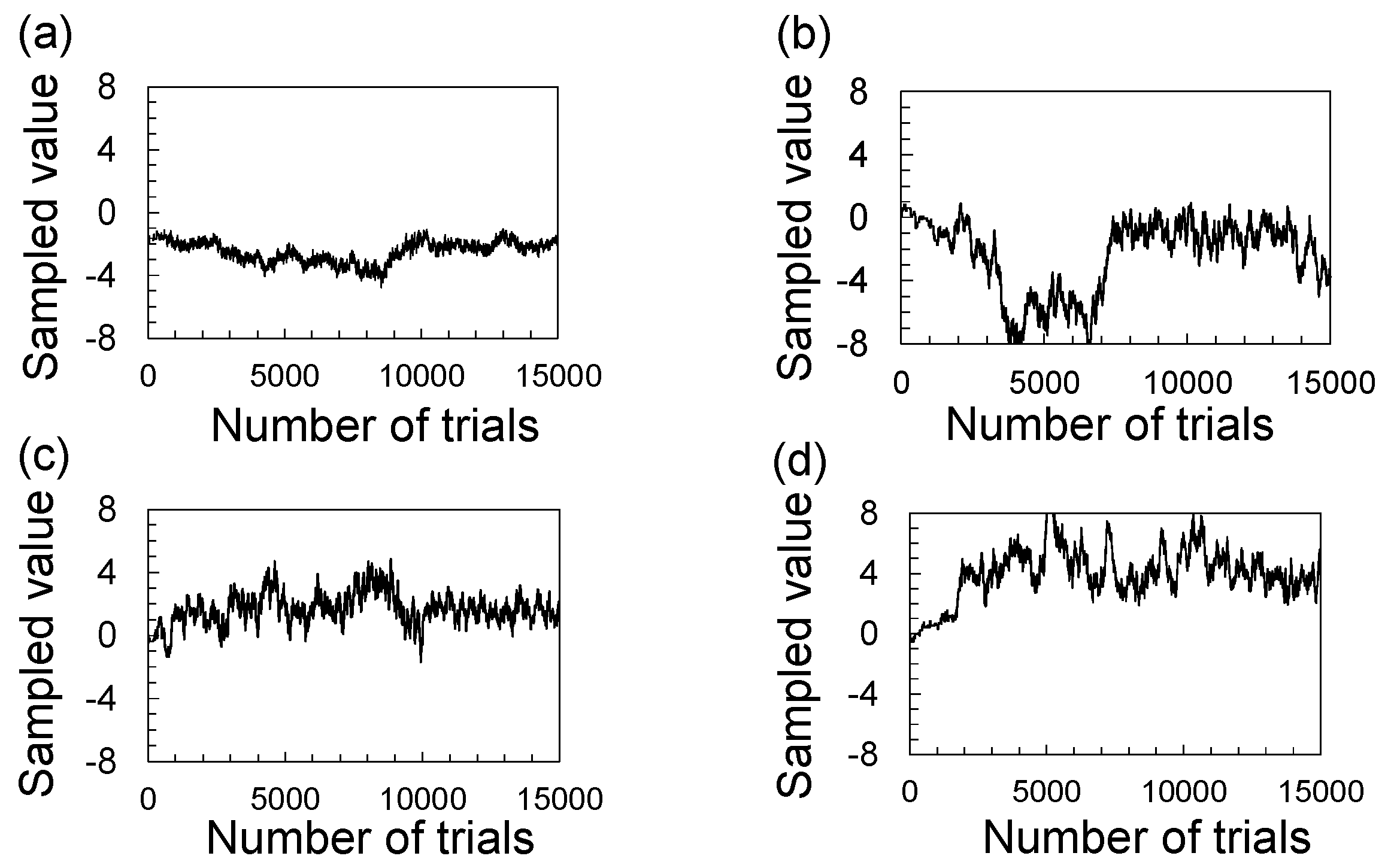

4.2. Numerical Method for Parameter Specification

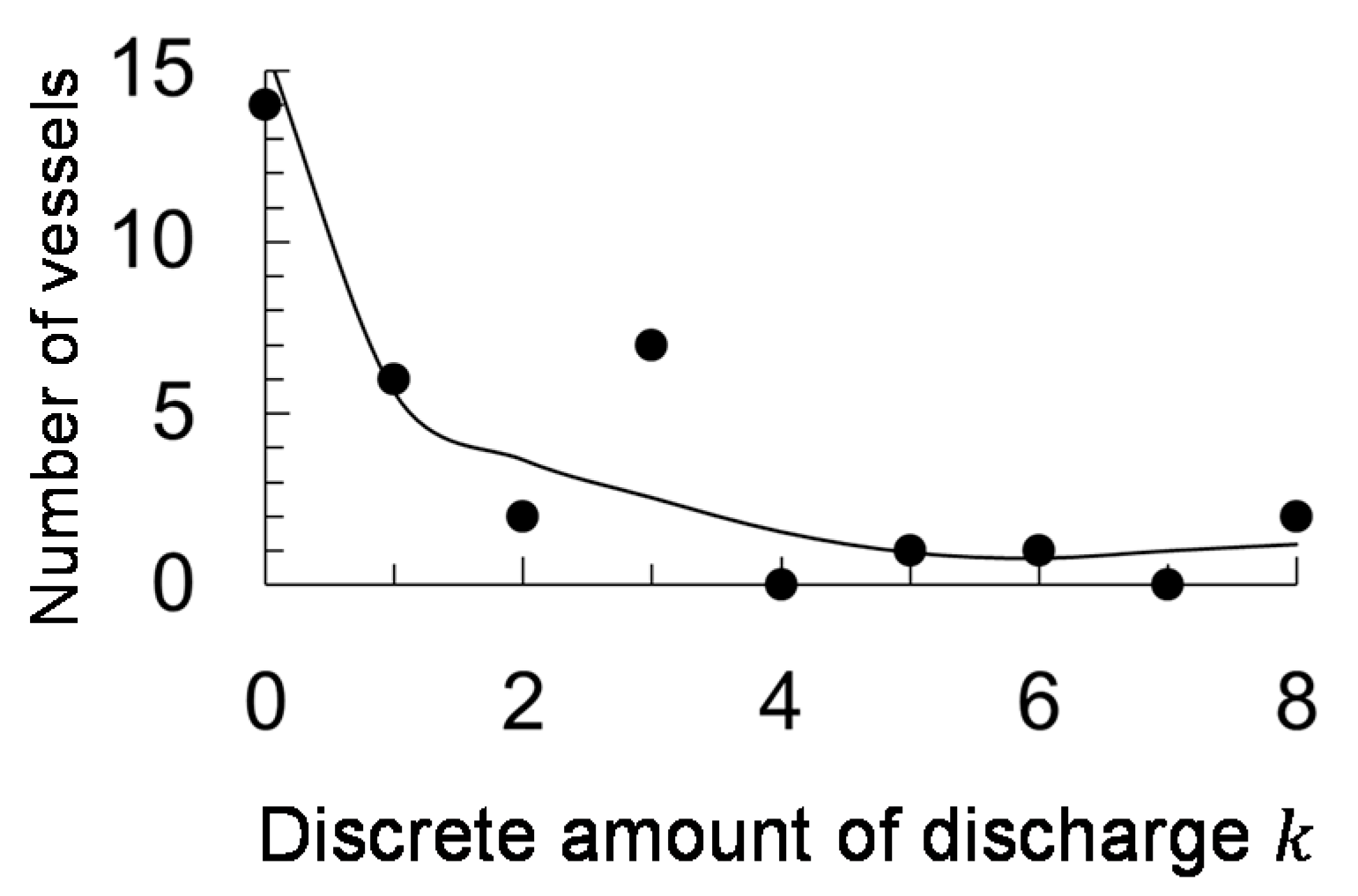

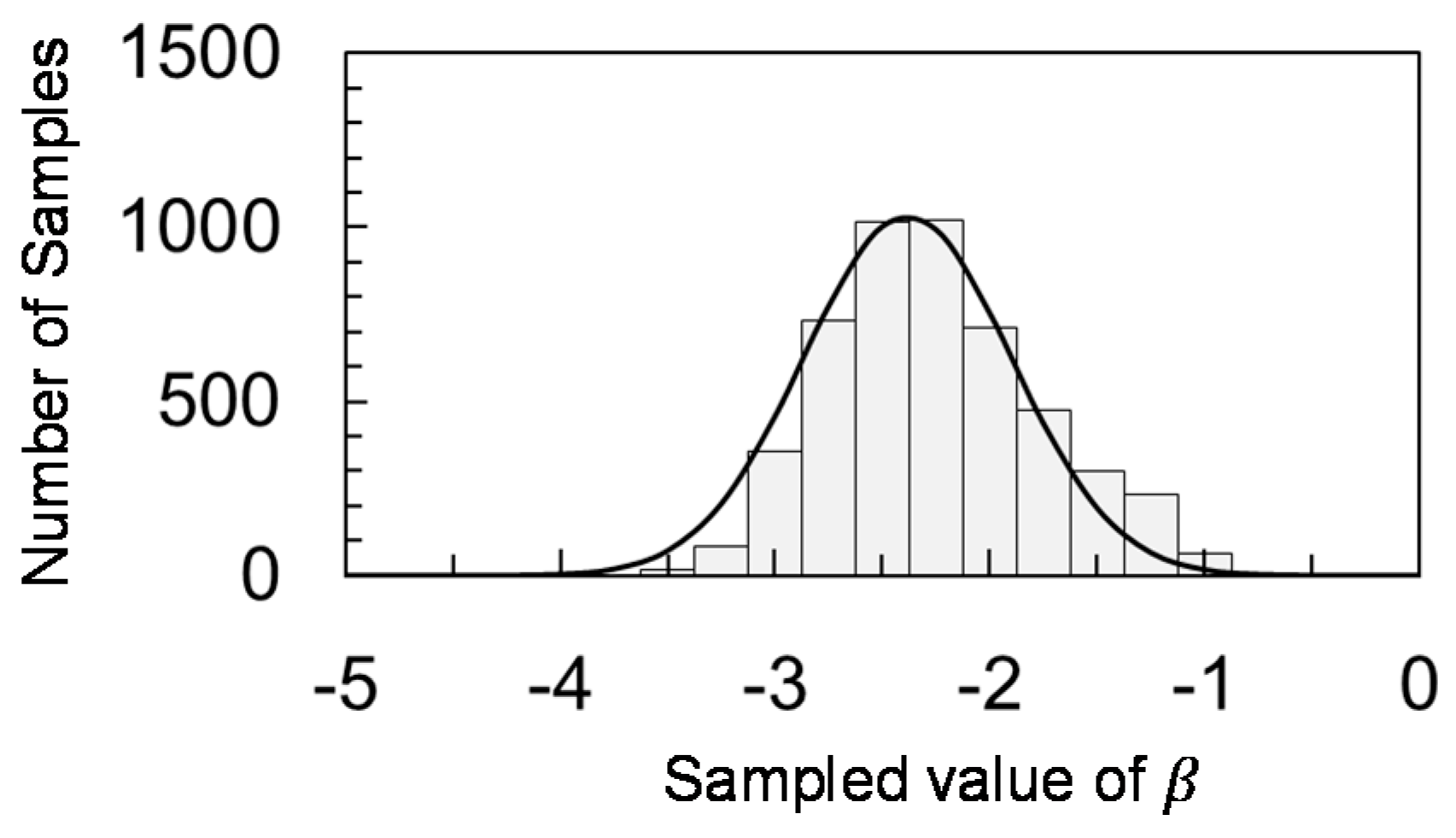

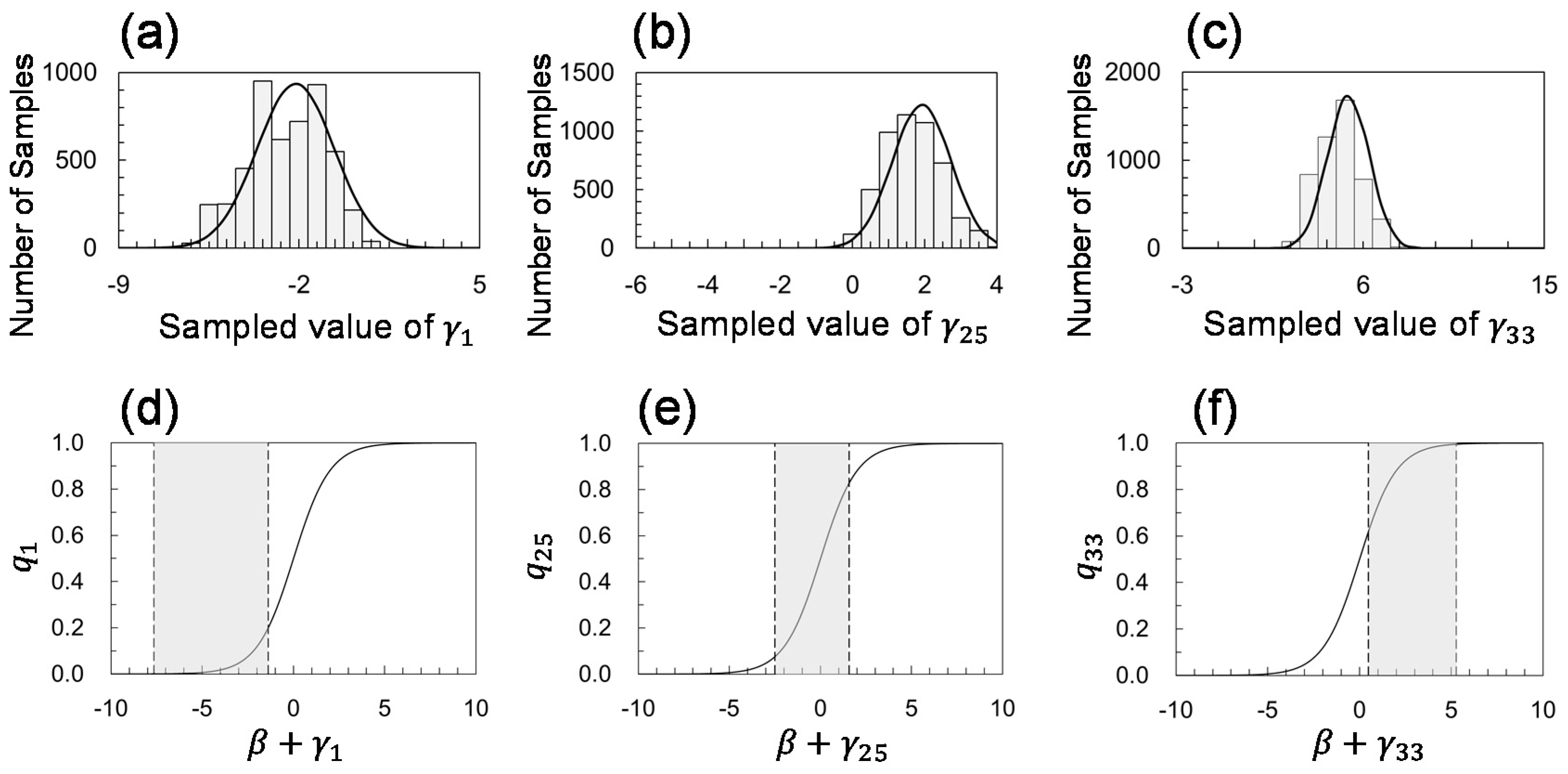

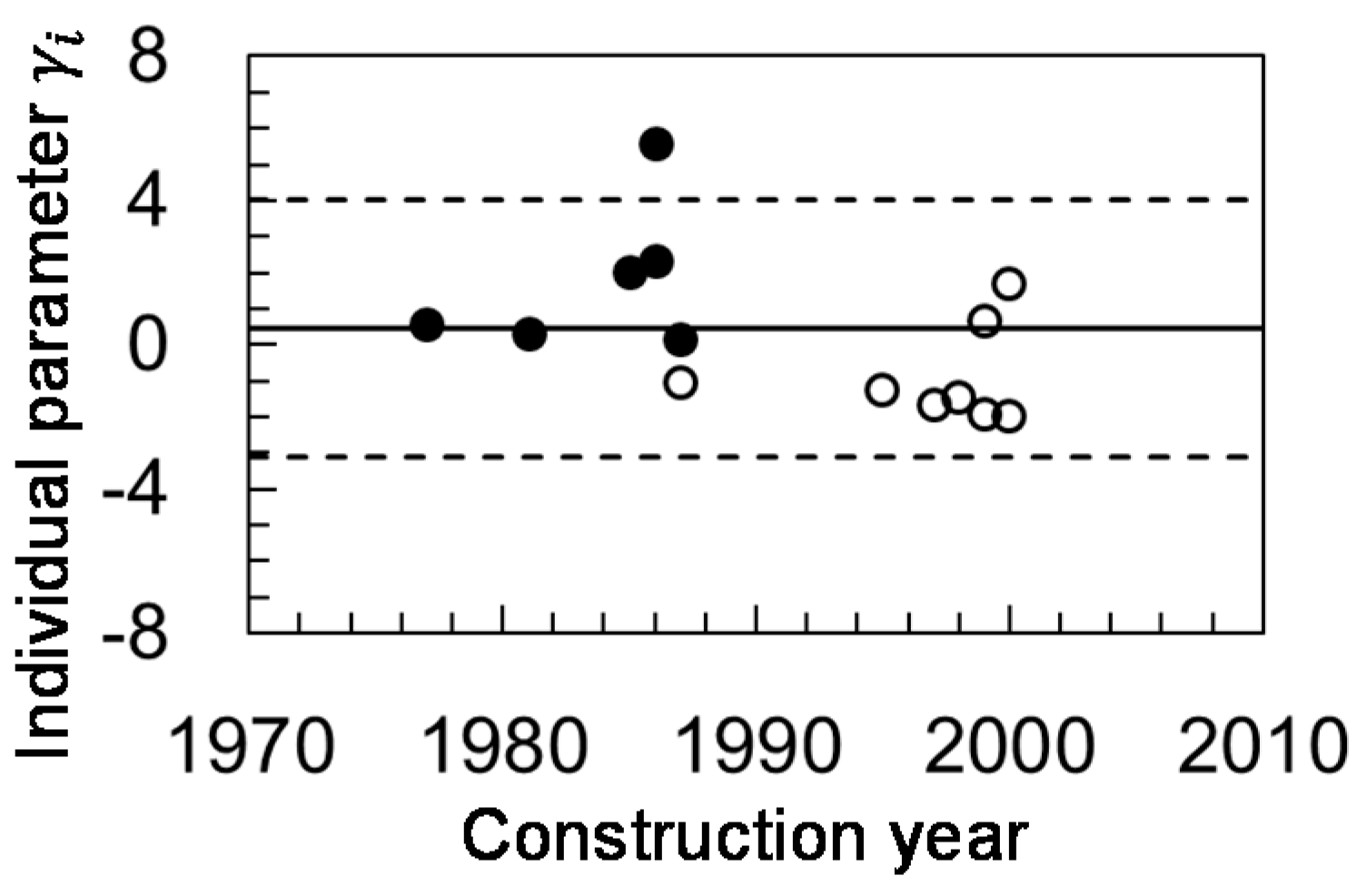

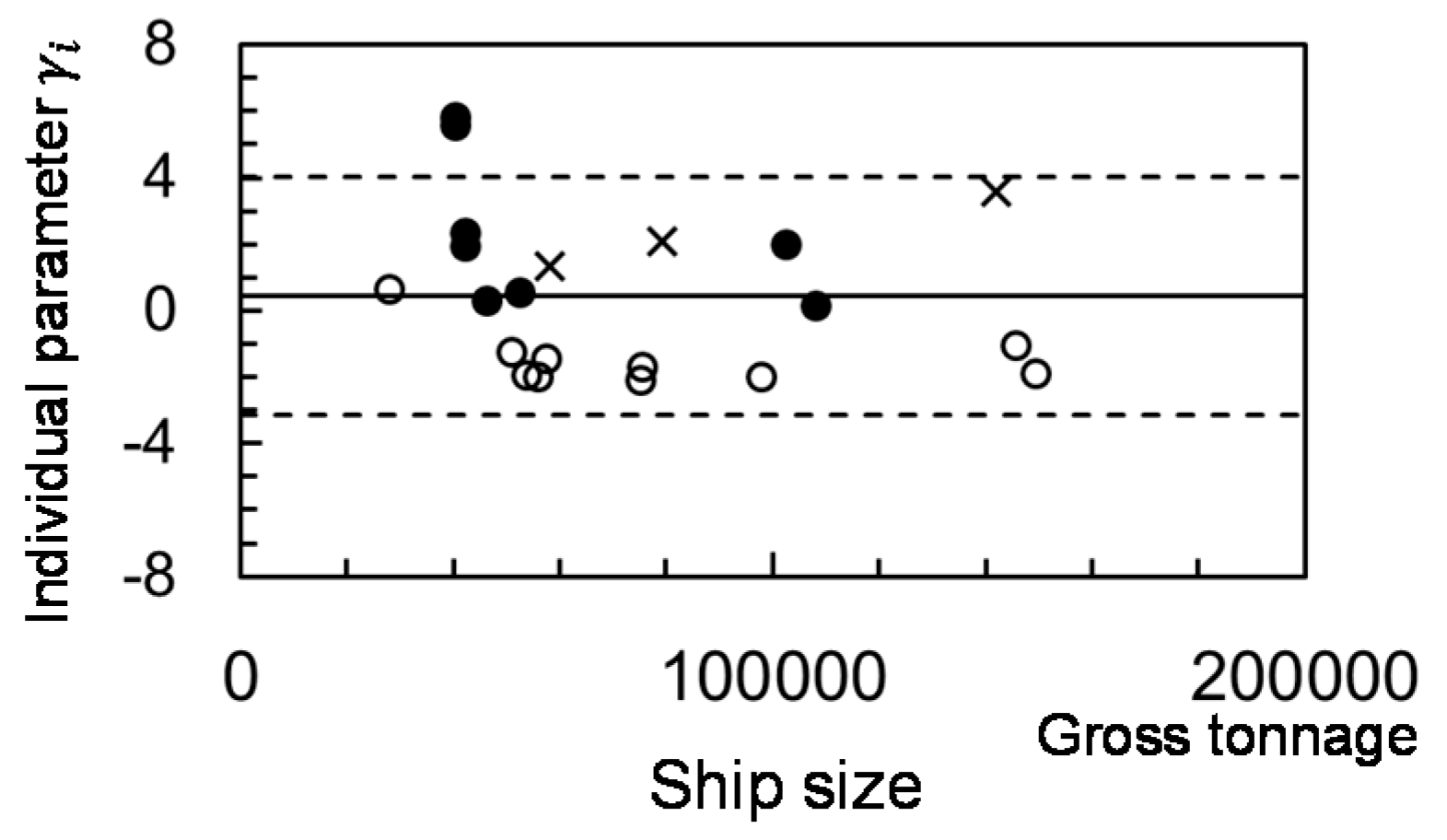

4.3. Results and Discussion of Variable Discharge Probability Model

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Geyer, R.A. Marine Environmental Pollution, 1 Hydrocarbon; Elsevier: Amsterdam, The Netherlands, 1980; p. 591. [Google Scholar]

- Gerhard, W.A.; Lundgreen, K.; Drillet, G.; Baumler, R.; Holbech, H.; Gunsch, C.K. Installation and use of ballast water treatment systems—Implications for compliance and enforcement. Ocean Coast. Manag. 2019, 181, 104907. [Google Scholar] [CrossRef]

- National Research Council. Oil in the Sea III Inputs, Fates, and Effects; National Academy of Sciences: Washington, DC, USA, 2002; p. 265. [Google Scholar]

- United States Environmental Protection Agency. Vessel General Permit; United States Environmental Protection Agency: Washington, DC, USA. Available online: https://www.epa.gov/npdes/vessels-vgp (accessed on 20 February 2020).

- Billheimer, D. Compositional receptor modeling. Environmetrics 2001, 12, 451–467. [Google Scholar] [CrossRef]

- Hayashi, T.I.; Kashiwagi, N. A Bayesian approach to probabilistic ecological risk assessment: Risk comparison of nine toxic substances in Tokyo surface waters. Environ. Sci. Pollut. Res. 2011, 18, 365–375. [Google Scholar] [CrossRef] [PubMed]

- International Maritime Organization. Work Programme of the Committee and Subsidiary Bodies, the Concept of the Integrated Bilge Water Treatment System (IBTS) and the Bilge Volume Generated in IBTS Machinery Space. Marine Environment Protection Committee (MPEC) 51/6, Agenda item 20; International Maritime Organization: London, UK, 2004. [Google Scholar]

- International Maritime Organization. Measures to Promote Integrated Bilge Water Treatment System, Proposal for Promotion of Integrated Bilge Water Treatment Systems (IBTS). Sub-Committee on Ship Design and Equipment (DE) 54/17, Agenda Item 17; International Maritime Organization: London, UK, 2010. [Google Scholar]

- Ueda, K.; Yamanouchi, H.; Hatori, K.; Yamane, K.; Yoshida, K.; Aya, T.; Sakane, Y.; Iijima, N. Treatment measures of engine room bilge. Proc. Natl. Marit. Res. Inst. Annu. Res. Present. 2004, 4, 261–264. [Google Scholar]

- Organization for Economic Co-operation and Development (OECD). Cost Savings Stemming from Non-Compliance with International Environmental Regulations in the Maritime Sector, DSTI/DOT/MTC (2002)8/FINAL; Organization for Economic Co-operation and Development (OECD): Paris, France, 2003. [Google Scholar]

- Dobson, A.J.; Barnett, A.G. An Introduction to Generalized Linear Models, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2008; p. 307. [Google Scholar]

- Gelman, A.; Carlin, J.B.; Stern, H.S.; Dunson, D.B.; Vehtari, A.; Rubin, D.B. Bayesian Data Analysis, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2013; p. 661. [Google Scholar]

- Gilks, W.R.; Richardson, S.; Spiegelhalter, D.J. Markov Chain Monte Carlo in Practice; Chapman & Hall/CRC: London, UK, 1996; p. 486. [Google Scholar]

| No. | IBTS | Size [GT] | Ship Type | Construction Year | Bilge Water Amount | Discrete Value of Bilge Water Amount | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | W/ | 145635 | Tanker | 1987 | 0.0000 | 0 | [7] |

| 2 | W/ | 149407 | Tanker | 1999 | 0.0000 | 0 | [7] |

| 3 | W/ | 50890 | Bulk | 1995 | 0.0010 | 0 | [7] |

| 4 | W/ | 75637 | Container | 1997 | 0.0280 | 0 | [7] |

| 5 | W/ | 75201 | ND | ND | 0.1753 | 0 | [8] |

| 6 | W/ | 57623 | PCC | 1998 | 0.2330 | 0 | [7] |

| 7 | W/ | ND | Bulk | ND | 0.2532 | 0 | [9] |

| 8 | W/ | ND | Container | ND | 0.2532 | 0 | [9] |

| 9 | W/ | ND | PCC | ND | 0.2532 | 0 | [9] |

| 10 | W/ | 55880 | PCC | 2000 | 0.2890 | 0 | [7] |

| 11 | W/ | ND | ND | ND | 0.3945 | 0 | [9] |

| 12 | W/ | 97825 | ND | ND | 0.4148 | 0 | [8] |

| 13 | W/O | ND | Bulk | ND | 0.4274 | 0 | [9] |

| 14 | W/ | 53822 | Container | 2003 | 0.4880 | 0 | [7] |

| 15 | W/ | 27986 | Bulk | 1999 | 0.5010 | 1 | [7] |

| 16 | W/O | 108000 | Bulk | 1987 | 0.6720 | 1 | [7] |

| 17 | W/O | 52214 | PCC | 1977 | 0.6790 | 1 | [7] |

| 18 | W/ | ND | VLCC | ND | 0.7562 | 1 | [9] |

| 19 | W/O | ND | PCC | ND | 0.8219 | 1 | [9] |

| 20 | W/O | 46047 | PCC | 1981 | 0.9770 | 1 | [7] |

| 21 | W/ | 160079 | Tanker | 2000 | 1.0000 | 2 | [7] |

| 22 | ND | 58192 | ND | ND | 1.1000 | 2 | [10] |

| 23 | W/O | ND | ND | ND | 1.5123 | 3 | [9] |

| 24 | W/O | 42145 | ND | ND | 1.6866 | 3 | [8] |

| 25 | ND | 79275 | ND | ND | 1.7000 | 3 | [10] |

| 26 | W/O | 42145 | Container | 1986 | 1.7100 | 3 | [7] |

| 27 | W/O | ND | VLCC | ND | 1.8411 | 3 | [9] |

| 28 | W/O | 145635 | Tanker | 1987 | 1.8530 | 3 | [7] |

| 29 | W/O | 102395 | Bulk | 1985 | 1.8810 | 3 | [7] |

| 30 | W/O | ND | Container | ND | 2.8931 | 5 | [8] |

| 31 | ND | 141881 | ND | ND | 3.0000 | 6 | [10] |

| 32 | W/O | 40354 | ND | ND | 4.0893 | 8 | [8] |

| 33 | W/O | 40354 | Container | 1986 | 4.1460 | 8 | [7] |

| Mean | Variance | |

|---|---|---|

| Observation [7,8,9,10] | 1.774 | 5.143 |

| Constant discharge probability model | 1.774 | 1.381 |

| Variable discharge probability model | 1.627 | 5.886 |

| With IBTS | Without IBTS |

|---|---|

| −1.571 | 1.233 |

| With IBTS | Without IBTS | |

|---|---|---|

| Bulk | −1.615 | −0.060 |

| Container | −1.794 | 2.919 |

| PCC | −1.594 | −0.259 |

| Tanker | −1.029 | 1.200 |

| VLCC | 0.065 | 1.420 |

| Unknown | −2.765 | 1.631 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Motoyoshi, M.; Nishi, Y. Statistical Modeling of Bilge Water Discharge from Ships During Normal Operation. J. Mar. Sci. Eng. 2020, 8, 320. https://doi.org/10.3390/jmse8050320

Motoyoshi M, Nishi Y. Statistical Modeling of Bilge Water Discharge from Ships During Normal Operation. Journal of Marine Science and Engineering. 2020; 8(5):320. https://doi.org/10.3390/jmse8050320

Chicago/Turabian StyleMotoyoshi, Munekazu, and Yoshiki Nishi. 2020. "Statistical Modeling of Bilge Water Discharge from Ships During Normal Operation" Journal of Marine Science and Engineering 8, no. 5: 320. https://doi.org/10.3390/jmse8050320

APA StyleMotoyoshi, M., & Nishi, Y. (2020). Statistical Modeling of Bilge Water Discharge from Ships During Normal Operation. Journal of Marine Science and Engineering, 8(5), 320. https://doi.org/10.3390/jmse8050320