Identifying Unregulated Emissions from Conventional Diesel Self-Ignition and PPCI Marine Engines at Full Load Conditions

Abstract

1. Introduction

2. Experimental Setup and Method

3. Results and Discussion

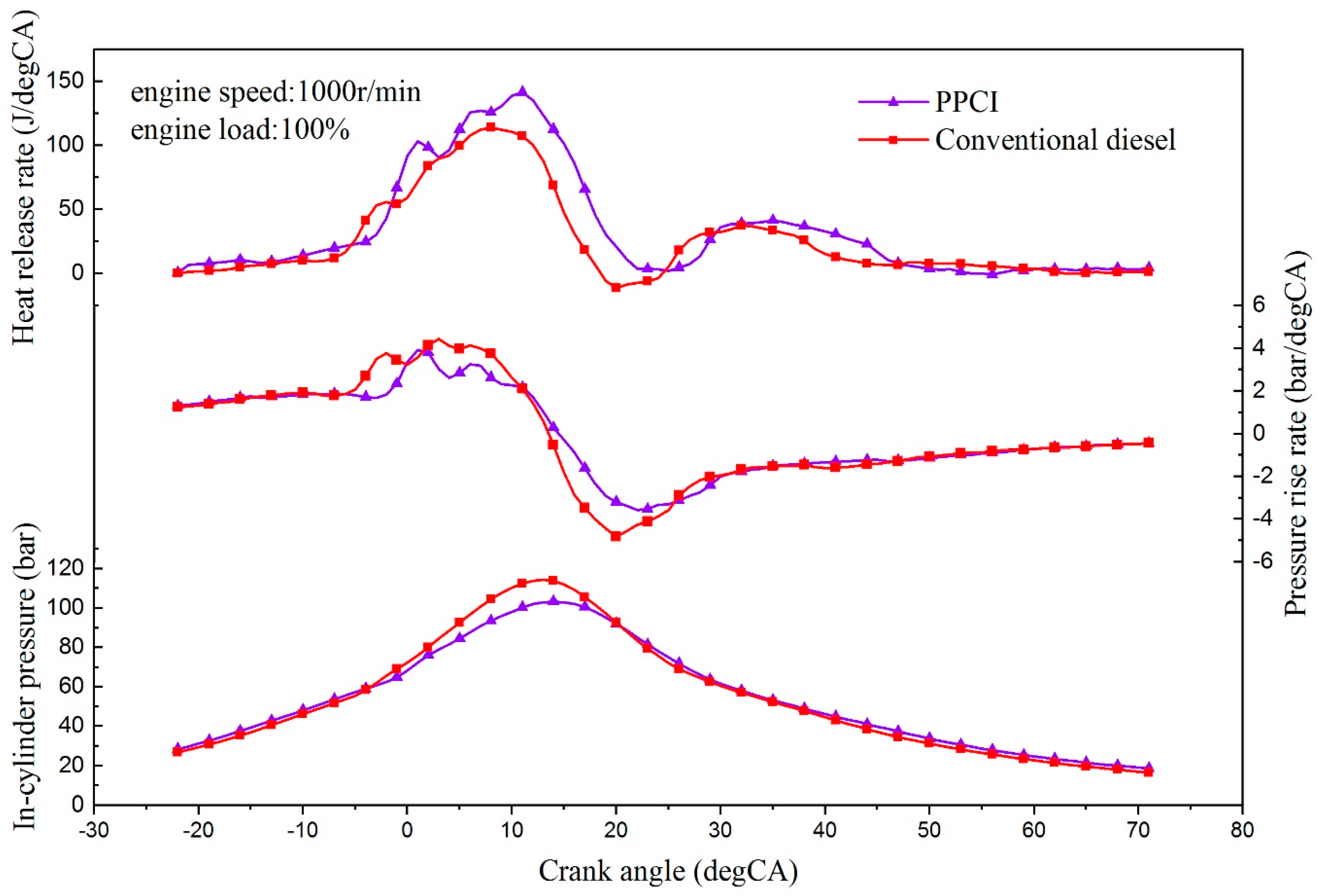

3.1. Engine Combustion Characteristics

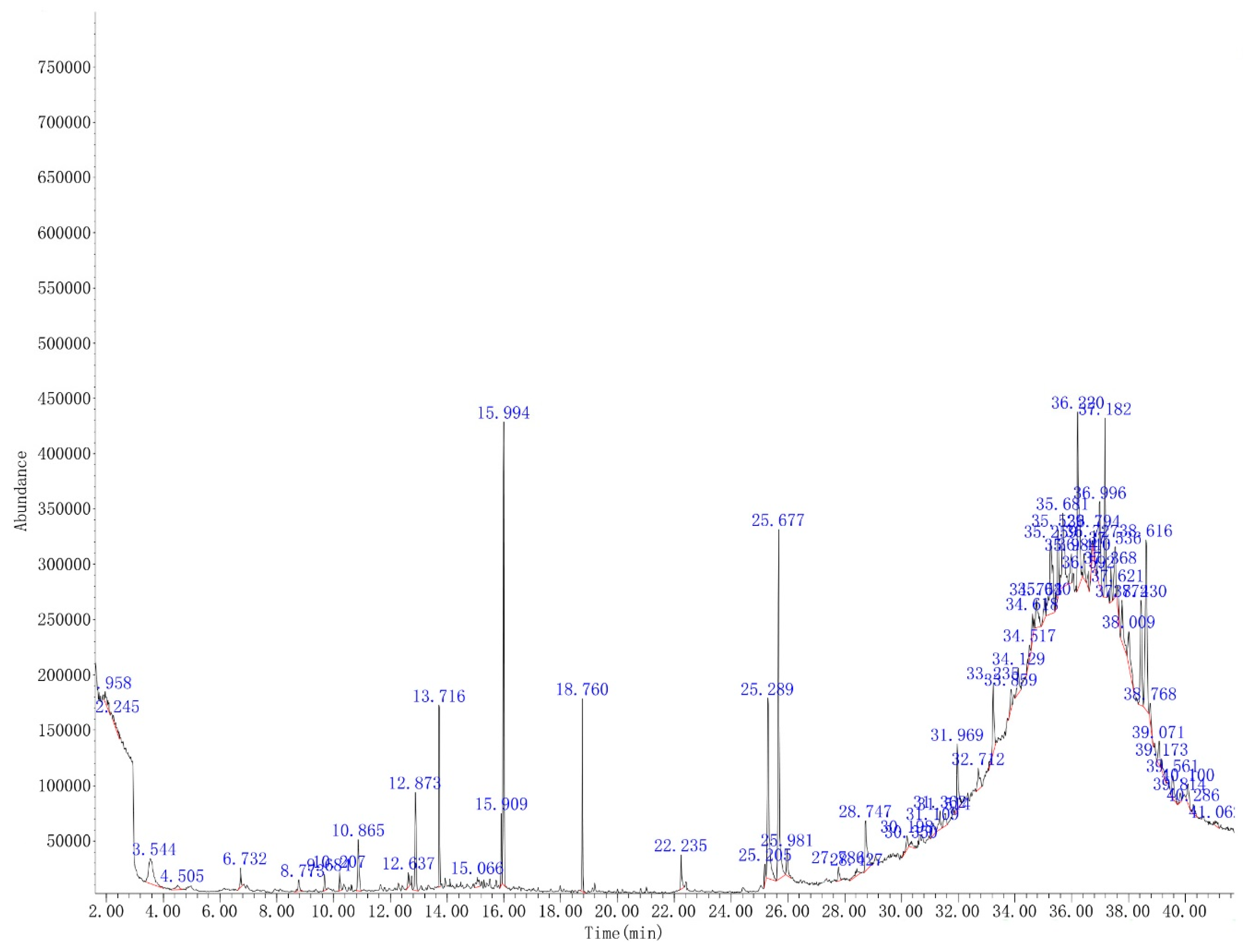

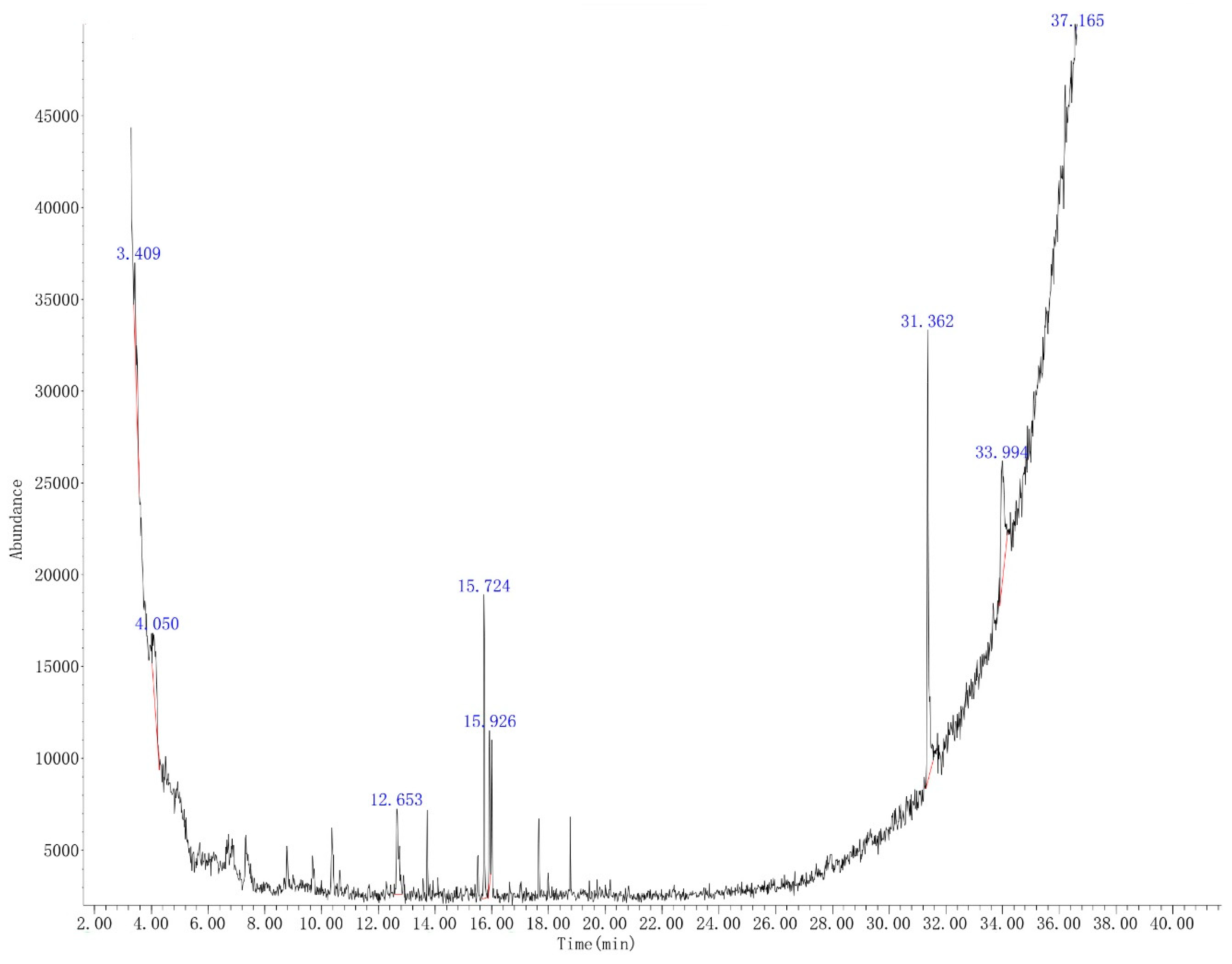

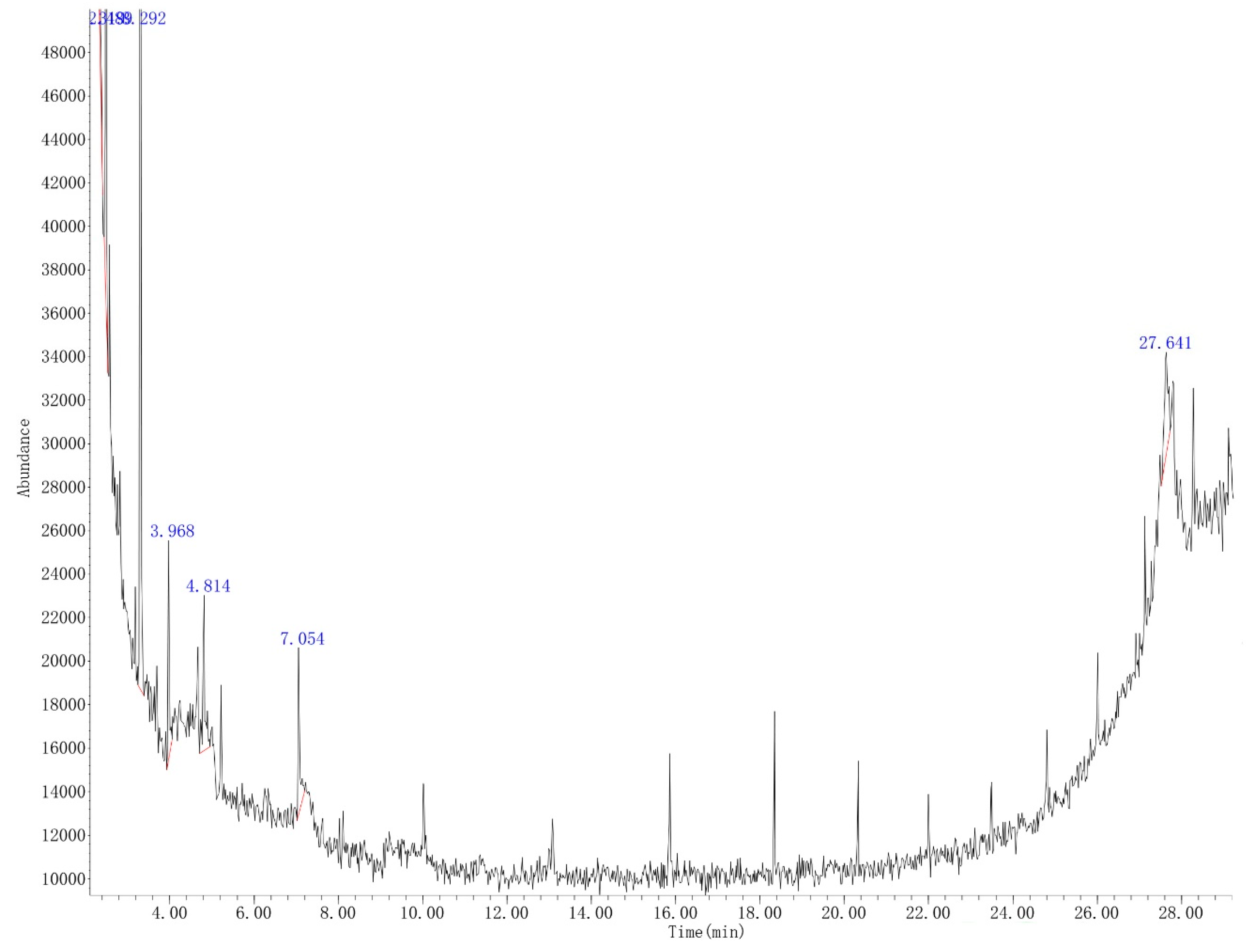

3.2. GC-MS Detection of Unregulated Emissions

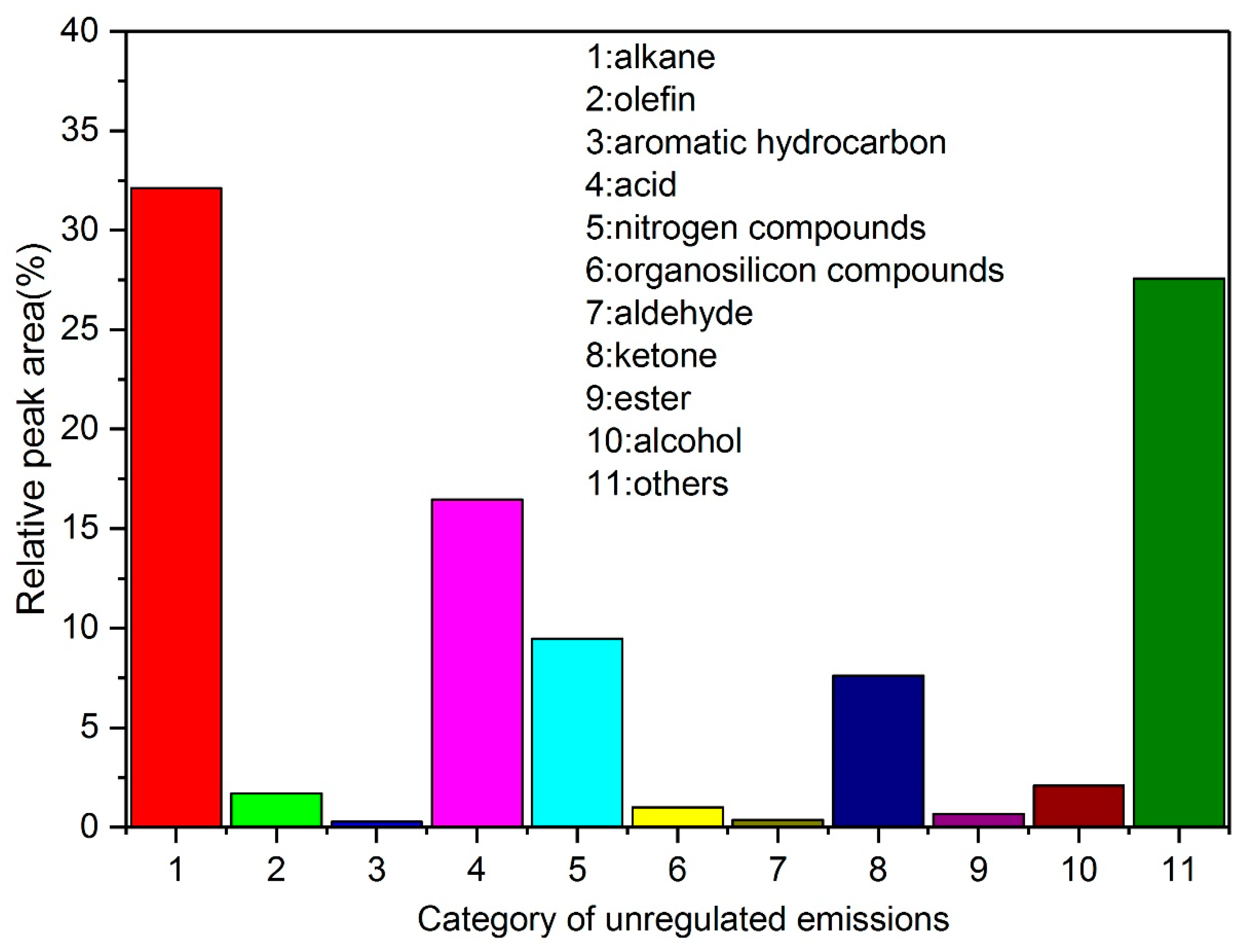

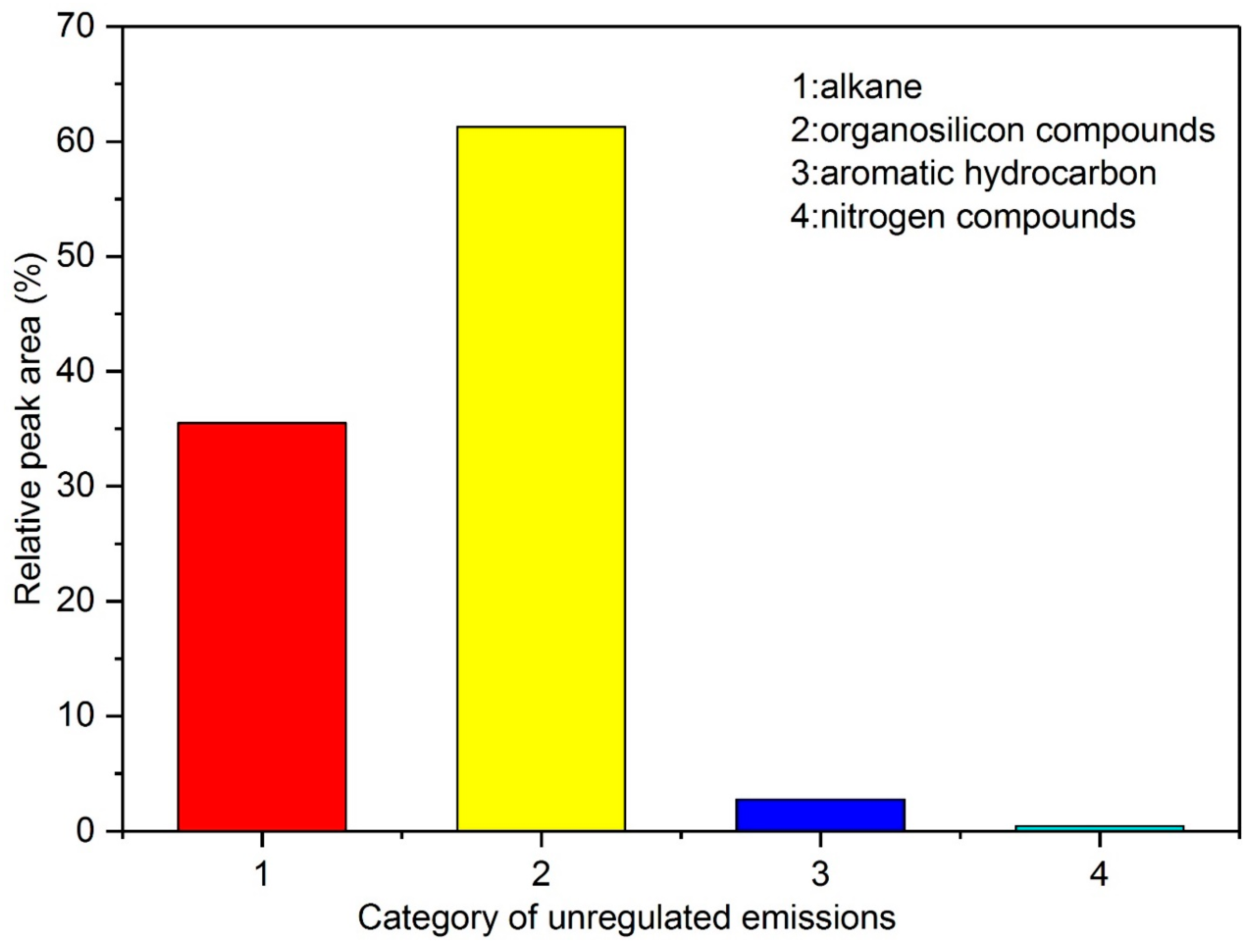

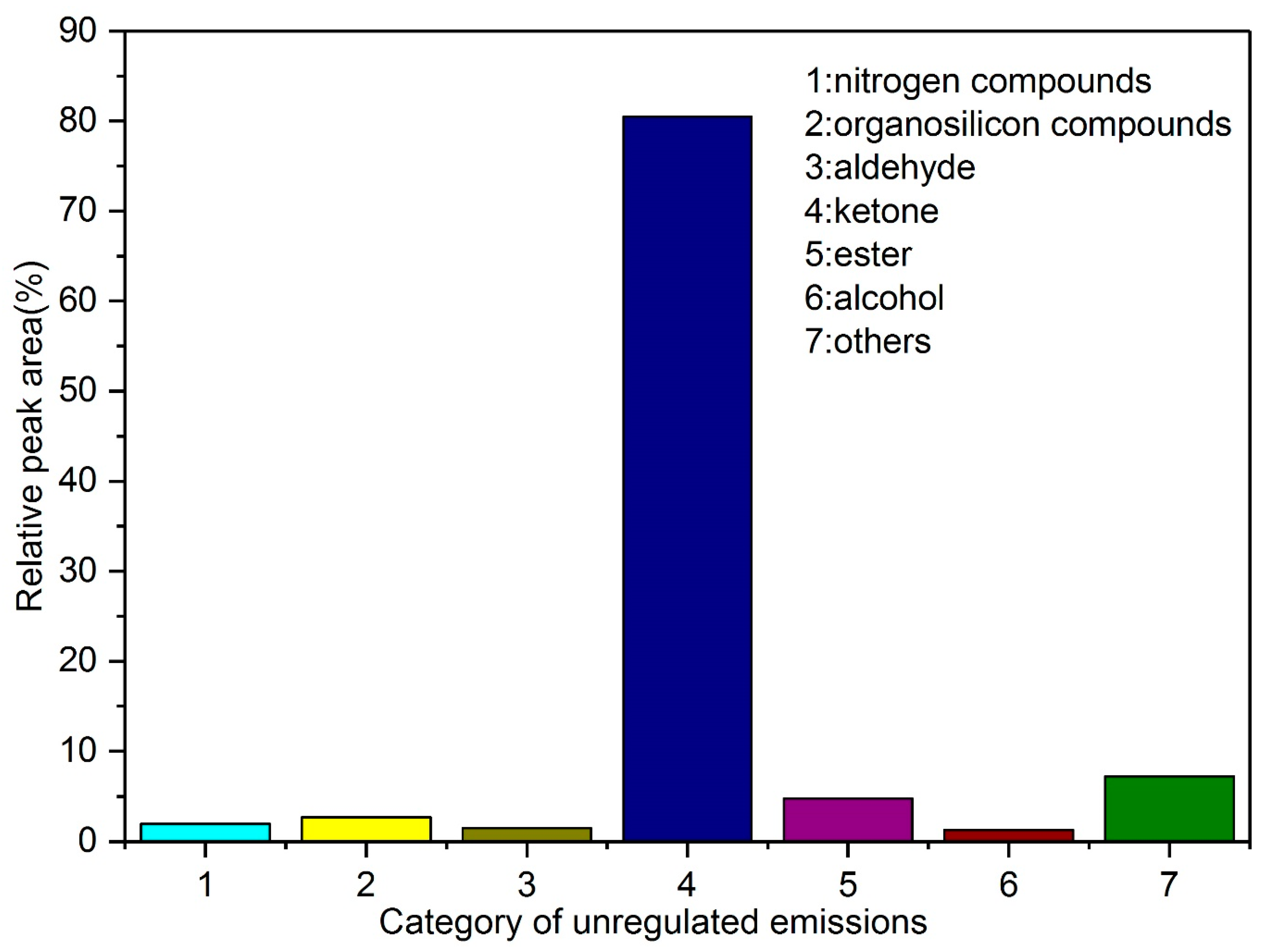

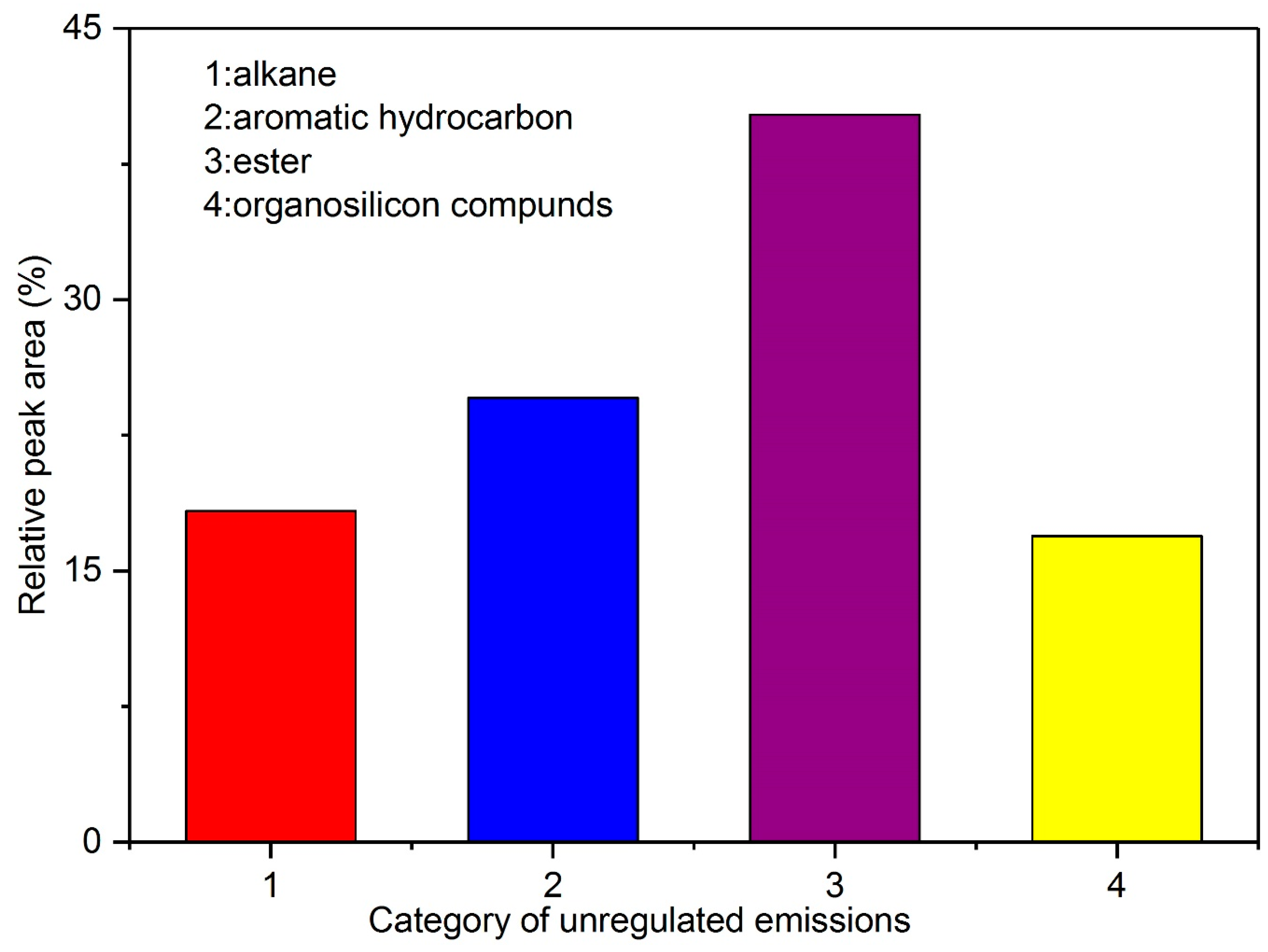

3.3. Semi-Quantitative Analysis on Unregulated Emissions

4. Conclusions

- For the in-pressure curves at 100% load, the maximum in-cylinder pressure of PPCI is almost 11 bar lower than that of conventional diesel combustion, and the crank angle at that moment is also delayed by 2 °CA. Compared to conventional diesel combustion, the maximum pressure rise rate of PPCI is reduced by 3.5%, while the maximum heat release rate of PPCI increases by 23.5%.

- Total ion chromatograms are obtained by chromatograph, and species detected in PPCI unregulated emissions are much less than those in conventional diesel combustion. Further, the peak time of PPCI component is earlier than that of conventional diesel combustion.

- Compared to conventional diesel combustion, the relative concentration of alkane and organic components in PPCI decreases significantly, while ketone and ester increase.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moon, G.; Lee, Y.; Choi, K.; Jeong, D. Emission characteristics of diesel, gas to liquid, and biodiesel-blended fuels in a diesel engine for passenger cars. Fuel 2010, 89, 3840–3846. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Shukla, P.C.; Patel, C.; Gupta, J.G.; Sharma, N.; Prasad, R.K.; Agarwal, R.A. Unregulated emissions and health risk potential from biodiesel (KB5, KB20) and methanol blend (M5) fuelled transportation diesel engines. Renew. Energy 2016, 98, 283–291. [Google Scholar] [CrossRef]

- Gowtham, M.; Mohan, C.; Prakash, R. Effect of n-butanol fumigation on the regulated and unregulated emission characteristics of a diesel engine. Fuel 2019, 242, 84–95. [Google Scholar] [CrossRef]

- Qian, Y.; Chen, F.; Zhang, Y.; Tao, W.; Han, D.; Lu, X. Combustion and regulated/unregulated emissions of a direct injection spark ignition engine fueled with C3-C5 alcohol/gasoline surrogate blends. Energy 2019, 174, 779–791. [Google Scholar] [CrossRef]

- Cheung, C.S.; Zhu, L.; Huang, Z. Regulated and unregulated emissions from a diesel engine fueled with biodiesel and biodiesel blended with methanol. Atmos. Environ. 2009, 43, 4865–4872. [Google Scholar] [CrossRef]

- Man, X.; Cheung, C.S.; Ning, Z.; Wei, L.; Huang, Z. Influence of engine load and speed on regulated and unregulated emissions of a diesel engine fueled with diesel fuel blended with waste cooking oil biodiesel. Fuel 2016, 180, 41–49. [Google Scholar] [CrossRef]

- Tang, S.; Frank, B.P.; Lanni, T.; Rideout, G.; Meyer, N.; Beregszaszy, C. Unregulated Emissions from a Heavy-Duty Diesel Engine with Various Fuels and Emission Control Systems. Environ. Sci. Technol. 2007, 41, 5037–5043. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Shukla, P.C.; Gupta, J.G.; Patel, C.; Prasad, R.K.; Sharma, N. Unregulated emissions from a gasohol (E5, E15, M5, and M15) fuelled spark ignition engine. Appl. Energy 2015, 154, 732–741. [Google Scholar] [CrossRef]

- Zhang, Z.; Cheung, C.S.; Chan, T.L.; Yao, C. Experimental investigation of regulated and unregulated emissions from a diesel engine fueled with Euro V diesel fuel and fumigation methanol. Atmos. Environ. 2010, 44, 1054–1061. [Google Scholar] [CrossRef]

- Tsunemoto, H.; Ishitani, H.; Kaimai, T. Type Effect of Fuel Properties on Unburned HC and Particulate Matter Emissions in a Small Dl Diesel Engine; SAE Technical Paper 2001-01-3387; SAE International in United States: Troy, MI, USA, 1 October 2001. [Google Scholar]

- Li, Z.; Liu, G.; Cui, X.; Sun, X.; Li, S.; Qian, Y.; Jiang, C.; Lu, X. Effects of the variation in diesel fuel components on the particulate matter and unregulated gaseous emissions from a common rail diesel engine. Fuel 2018, 232, 279–289. [Google Scholar] [CrossRef]

- Velji, A.; Yeom, K.; Wagner, U.; Spicher, U.; Rossbach, M.; Suntz, R.; Bockhorn, H. Investigations of the Formation and Oxidation of Soot Inside a Direct Injection Spark Ignition Engine Using Advanced Laser-Techniques; SAE Technical Paper 2010-01-0352; SAE International in United States: Troy, MI, USA, 12 April 2010. [Google Scholar]

- Flowers, D.; Aceves, S.; West brook, C.K.; Smith, J.R.; Dibble, R. Detailed chemical kinetic simulation of natural gas HCCI combustion: Gas composition effects and investigation of control strategies. J. Eng. Gas Turbines Power 2001, 23, 433–439. [Google Scholar] [CrossRef]

- Cheng, C.; Cheung, C.S.; Chan, T.L.; Lee, S.-C.; Yao, C.; Tsang, K. Comparison of emissions of a direct injection diesel engine operating on biodiesel with emulsified and fumigated methanol. Fuel 2008, 87, 1870–1879. [Google Scholar] [CrossRef]

- Pastor, J.V.; Garcia-Oliver, J.M.; Garcia, A.; Mico, C.; Durrett, R. A spectroscopy study of gasoline partially premixed self-ignition spark assisted combustion. Appl. Energy 2013, 104, 568–575. [Google Scholar] [CrossRef]

- Won, H.W.; Peters, N.; Tait, N.; Kalghatgi, G. Sufficiently premixed self-ignition of a gasoline-like fuel using three different nozzles in a diesel engine. J. Automob. Eng. 2012, 226, 698–708. [Google Scholar] [CrossRef]

- Valentino, G.; Corcione, F.E.; Iannuzzi, S.E. Effects of gasoline–diesel and n-butanol–diesel blends on performance and emissions of an automotive direct-injection diesel engine. Int. J. Engine Res. 2012, 13, 199–215. [Google Scholar] [CrossRef]

- An, Y.; Jaasim, M.; Vallinayagam, R.; Vedharaj, S.; Im, H.G.; Johansson, B. Numerical simulation of combustion and soot under partially premixed combustion of low-octane gasoline. Fuel 2018, 211, 420–431. [Google Scholar] [CrossRef]

- Qu, X.; Gong, C.; Liu, J.; Cui, F.; Liu, F. Regulated and unregulated emissions from a DISI methanol engine under homogenous combustion and light load. Fuel 2015, 158, 166–175. [Google Scholar] [CrossRef]

- Wang, H.; Ge, Y.; Tan, J.; Hao, L.; Peng, Z.; Wang, X.; Wu, L.; Li, Y.; Yang, J.; Li, J.; et al. The effects of ash inside a platinum-based catalyst diesel particulate filter on particle emissions, gaseous emissions, and unregulated emissions. Environ. Sci. Pollut. Res. 2018, 25, 33736–33744. [Google Scholar] [CrossRef]

- Xiao, H.; Wang, R.; Zeng, P.; Jiang, A.; Hou, B.; Yang, S. Particulate matter and unregulated emissions of diesel engine fueled with 2-methylfuran diesel blends. Fuel 2017, 208, 168–173. [Google Scholar] [CrossRef]

- Gong, C.; Liu, J.; Peng, L.; Liu, F. Numerical study of effect of injection and ignition timings on combustion and unregulated emissions of DISI methanol engine during cold start. Renew. Energy 2017, 112, 457–465. [Google Scholar] [CrossRef]

- Zhang, Y.; Peräkylä, O.; Yan, C.; Heikkinen, L.; Äijälä, M.; Daellenbach, K.R.; Zha, Q.; Riva, M.; Garmash, O.; Junninen, H.; et al. A novel approach for simple statistical analysis of high-resolution mass spectra. Atmos. Meas. Tech. 2019, 12, 3761–3776. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N.; Pugazhendhi, A. Performance, combustion and emission analysis of microalgae Spirulina in a common rail direct injection diesel engine. Fuel 2019, 255, 115855. [Google Scholar] [CrossRef]

- Nour, M.; Attia, A.M.; Nada, S.A. Improvement of CI engine combustion and performance running on ternary blends of higher alcohol (Pentanol and Octanol)/hydrous ethanol/diesel. Fuel 2019, 251, 10–22. [Google Scholar] [CrossRef]

- Alves, C.A.; Barbosa, C.; Rocha, S.; Calvo, A.I.; Nunes, T.; Cerqueira, M.; Pio, C.; Karanasiou, A.; Querol, X. Elements and polycyclic aromatic hydrocarbons in exhaust particles emitted by light-duty vehicles. Environ. Sci. Pollut. Res. 2015, 22, 11526–11542. [Google Scholar] [CrossRef] [PubMed]

- Gaddam, C.K.; Wal, R.L.V. Physical and chemical characterization of SIDI engine particulates. Combust. Flame 2013, 160, 2517–2528. [Google Scholar] [CrossRef]

- Chen, H.; Wang, M.; Wang, X.; Li, D.; Pan, Z.; Bae, C. Experimental investigation of particulate matter structures under partially premixed combustion in a compression ignition engine. Fuel 2020, 259, 116286. [Google Scholar] [CrossRef]

- Choi, S.; Seong, H. Lube oil-dependent ash chemistry on soot oxidation reactivity in a gasoline direct-injection engine. Combust. Flame 2016, 174, 68–76. [Google Scholar] [CrossRef]

- Lim, J.; Lim, C.; Yu, L.E. Composition and size distribution of metals in diesel exhaust particulates. J. Environ. Monit. 2009, 11, 1614. [Google Scholar] [CrossRef]

- Song, J.; Lee, K.O. Fuel Property Impacts on Diesel Particulate Morphology, Nanostructures, and NOx Emissions; SAE Technical Paper 2007-01-0129; SAE International in United States: Troy, MI, USA, 16 April 2007. [Google Scholar]

- Wisniewski, A., Jr.; Wiggers, V.R.; Simionatto, E.L.; Meier, H.F.; Barros, A.A.C.; Madureira, L.A.S. Biofuels from waste fish oil pyrolysis: Chemical composition. Fuel 2010, 89, 563–568. [Google Scholar] [CrossRef]

- Macor AAvella, F.; Faedo, D. Effects of 30% v/v biodiesel/diesel fuel blend on regulated and unregulated pollutant emissions from diesel engines. Appl. Energy 2011, 88, 4989–5001. [Google Scholar] [CrossRef]

- Cosseron, A.-F.; Bennadji, H.; Leyssens, G.; Coniglio, L.; Daou, T.J.; Tschamber, V. Evaluation and Treatment of Carbonyl Compounds and Fine Particles Emitted by Combustion of Biodiesels in a Generator. Energy Fuels 2012, 26, 6160–6167. [Google Scholar] [CrossRef]

- Liu, Z.G.; Berg, D.R.; Swor, T.A.; Schauer, J.J. Comparative Analysis on the Effects of Diesel Particulate Filter and Selective Catalytic Reduction Systems on a Wide Spectrum of Chemical Species Emissions. Environ. Sci. Technol. 2008, 42, 6080–6085. [Google Scholar] [CrossRef] [PubMed]

- Nelson, P.F.; Tibbett, A.R.; Day, S.J. Effects of vehicle type and fuel quality on real world toxic emissions from diesel vehicles. Atmos. Environ. 2008, 42, 5291–5303. [Google Scholar] [CrossRef]

- Wang, W.G.; Clark, N.N.; Lyons, D.W.; Yang, R.M.; Gautam, M.; Bata, R.M.; Loth, J.L. Emissions Comparisons from Alternative Fuel Buses and Diesel Buses with a Chassis Dynamometer Testing Facility. Environ. Sci. Technol. 1997, 31, 3132–3137. [Google Scholar] [CrossRef]

| Parameters | Details |

|---|---|

| Combustion system | 4-valve PPCI |

| Number of cylinders | 6 |

| Displacement/bore/stroke | 27 L/170 mm/200 mm |

| Compression ratio | 14.5 |

| Rated speed/rated power | 1000 r/min/330 kW |

| Brake specific fuel consumption | 200 g/(kW × h) |

| Injection/injection pressure | Direct injection/up to 35 MPa |

| PFI injection/0.45 MPa | |

| Inlet valve opening/closing | 50 °CA BTDC/40 °CA ABDC |

| Exhaust gases valve opening/closing | 65 °CA BBDC/50 °CA ATDC |

| Properties | Diesel Fuel | Light Hydrocarbon |

|---|---|---|

| Molecular formula | C9–C18 compounds | C5–C6 compounds |

| Liquid density (kg/L) | 0.82–0.87 | 0.65–0.68 |

| Lower heating value (MJ/kg) | 42.4 | 48.2 |

| Cetane number | 50.8 | – |

| Octane number | – | 70 |

| Flash point (°C) | 54 | −38 |

| Kinematic viscosity (@313 K) (mm2/s) | 2.2 | 0.62 |

| Number | Retention Time | Name | Formula | Matching Degree |

|---|---|---|---|---|

| 1 | 3.544 | Tetrachloroethylene | C2Cl4 | 96 |

| 2 | 6.732 | Cyclotetrasiloxane, octamethyl- | C8H24O4Si4 | 90 |

| 3 | 8.773 | Nonanal | C9H18O | 47 |

| 4 | 9.684 | Cyclopentasiloxane, decamethyl- | C10H30O5Si5 | 91 |

| 5 | 10.207 | Benzene, 1,2,4-trichloro- | C6H3Cl3 | 97 |

| 6 | 10.865 | Benzene, 1,2,3-trichloro- | C6H3Cl3 | 97 |

| 7 | 12.637 | Phthalic anhydride | C8H4O3 | 93 |

| 8 | 13.716 | Benzene, 1,2,3,5-tetrachloro- | C6H2Cl4 | 98 |

| 9 | 15.066 | 2-Pentanone, 4-cyclohexylidene-3,3-diethyl- | C15H26O | 43 |

| 10 | 15.909 | Dibenzofuran | C12H8O | 91 |

| 11 | 15.994 | Benzene, pentachloro- | HC6Cl5 | 99 |

| 12 | 18.76 | Benzene, hexachloro- | C6Cl6 | 99 |

| 13 | 22.235 | n-Hexadecanoic acid | C16H32O2 | 95 |

| 14 | 25.205 | 9,12-Octadecadienoic acid (Z,Z)- | C18H32O2 | 99 |

| 15 | 25.289 | 9-Octadecenoic acid,(E)- | C18H34O2 | 99 |

| 16 | 25.677 | Octadecanoic acid | C18H36O2 | 99 |

| 17 | 25.981 | Hexadecanamide | C16H33NO | 87 |

| 18 | 27.786 | 1-Hexadecanethiol | C16H34S | 93 |

| 19 | 28.747 | 9-Octadecenamide, (Z)- | C18H35NO | 98 |

| 20 | 31.109 | 2H-3,9a-Methano-1-benzoxepin, octahydro-2,2,5a,9-tetramethyl-, [3R-(3.alpha.,5a.alpha.,9.alpha.,9a.alpha.)]- | C15H26O | 43 |

| 21 | 31.362 | 2-(Nonyloxycarbonyl)benzoic acid | C17H24O4 | 55 |

| 22 | 31.969 | Heneicosane | C21H44 | 97 |

| 23 | 33.235 | Heptacosane, 1-chloro | C27H55Cl | 99 |

| 24 | 34.129 | Cholest-22-ene, (5.alpha.)- | C27H46 | 53 |

| 25 | 34.517 | 1-Methyl-4-(1-methylethyl)-3-[1-methyl-1-(4-methylpentyl)-5-methylheptyl]cyclohexene | C25H50 | 72 |

| 26 | 34.753 | D-Homoandrostane, (5.alpha., 13.alpha.)- | C20H34 | 93 |

| 27 | 35.259 | 17.alfa.,21.beta.-28,30-Bisnorhopane | C28H48 | 64 |

| 28 | 35.681 | Butanamide, 3-(3-fluorobenzoylhydrazono)-N-(4-fluorobenzyl)- | C18H17F2N3O2 | 60 |

| 29 | 35.984 | Urs-20-en-16-ol, (16.beta., 18.alpha., 19.alpha.)- | C30H50O | 59 |

| 30 | 36.22 | 23,28-Bisnor-17.beta.(H)-hopane | C28H48 | 81 |

| 31 | 36.794 | Antra-9,10-quinone, 1-(3-hydrohy-3-phenyl-1-triazenyl)- | C20H13N3O3 | 68 |

| 32 | 37.536 | 28-Nor-17.alpha.(H)-hopane | C29H50 | 86 |

| 33 | 37.621 | Baccharane | C30H54 | 84 |

| 34 | 38.43 | D:A-Friedooleanane | C30H52 | 50 |

| 35 | 38.616 | 1-Penten-3-one, 1-(2,6,6-trimethyl-1-cyclohexen-1-yl)- | C14H22O | 45 |

| 36 | 39.071 | 9,10-Methanoanthracen-11-ol, 9,10-dihydro-9,10,11-trimethyl- | C18H18O | 46 |

| 37 | 39.561 | 1H-Indole, 1-methyl-2-phenyl- | C15H13N | 43 |

| 38 | 39.814 | Anthracene, 9,10-dihydro-9,9,10-trimethyl- | C17H18 | 55 |

| 39 | 40.286 | 3,3-Diisopropoxy-1,1,1,5,5,5-hexamethyltrisiloxane | C12H32O4Si3 | 50 |

| 40 | 40.1 | 1H-Indole-2-carboxylic acid, 6-(4-ethoxyphenyl)-3-methyl-4-oxo-4,5,6, 7-tetrahydro-, isopropyl ester | C25H50 | 41 |

| 41 | 41.062 | Benzo[h]quinolone, 2,4-dimethyl- | C15H13N | 46 |

| Number | Retention Time | Name | Formula | Matching Degree |

|---|---|---|---|---|

| 1 | 2.298 | n-Hexane | C6H14 | 60 |

| 2 | 3.292 | Toluene | C7H8 | 91 |

| 3 | 3.968 | 1,2-Bis(trimethylsilyl)benzene | C12H22Si2 | 83 |

| 4 | 4.793 | p-Xylene | C8H10 | 95 |

| 5 | 7.054 | Cyclotetrasiloxane, octamethyl- | C8H24O4Si4 | 90 |

| 6 | 15.868 | Cycloheptasiloxane, tetradecamethyl- | C14H42O7Si7 | 91 |

| 7 | 18.341 | Cyclooctasiloxane, hexadecamethyl- | C16H48O8Si8 | 91 |

| 8 | 20.328 | Cyclononasiloxane, octadecamethyl- | C18H54O9Si9 | 94 |

| 9 | 21.998 | Cyclodecasiloxane, eicosamethyl- | C20H60O10Si10 | 49 |

| 10 | 23.16 | Heneicosane | C21H44 | 98 |

| 11 | 24.09 | Docosane | C22H46 | 99 |

| 12 | 24.238 | Nonacosane | C29H60 | 99 |

| 13 | 24.957 | Nonadecane, 9-methyl- | C20H42 | 93 |

| 14 | 25.802 | Tetracosane | C24H50 | 99 |

| 15 | 26.605 | Pentacosane | C25H52 | 99 |

| 16 | 27.387 | Hexacosane | C26H54 | 98 |

| 17 | 27.895 | Acridin-9-yl-[2-(1H-indol-3-yl)-ethyl]-amine | C23H19N3 | 35 |

| 18 | 28.212 | Heptacosane | C27H56 | 99 |

| 19 | 28.296 | Benzoic acid, 2,5-bis(trimethylsiloxy)-, trimethylsilyl ester | C16H30O4Si3 | 55 |

| 20 | 28.529 | Eicosane | C20H42 | 96 |

| 21 | 28.782 | Octadecane, 3-ethyl-5-(2-ethylbutyl)- | C26H54 | 49 |

| Number | Retention Time | Name | Formula | Matching Degree |

|---|---|---|---|---|

| 1 | 3.409 | Fumaronitrile | C4H2N2 | 43 |

| 2 | 4.050 | 2-Cyclohexen-1-ol, 3-methyl- | C7H12O | 38 |

| 3 | 12.653 | Phthalic anhydride | C8H4O3 | 53 |

| 4 | 15.724 | Phenol, 3,5-bis(1,1-dimethylethyl)- | C14H22O | 78 |

| 5 | 15.926 | Dibenzofuran | C12H8O | 78 |

| 6 | 31.362 | Bis(2-ethylhexyl) phthalate | C24H38O4 | 72 |

| 7 | 33.994 | 3,3-Diisopropoxy-1,1,1,5,5,5-hexamethyltrisiloxane | C12H32O4Si3 | 35 |

| 8 | 37.165 | Benzo[h]quinoline, 2,4-dimethyl- | C15H13N | 43 |

| Number | Retention Time | Name | Formula | Matching Degree |

|---|---|---|---|---|

| 1 | 2.319 | Acetic acid, trichloro-, ethyl ester | C4H5Cl3O2 | 10 |

| 2 | 2.489 | Pentane, 2,2,4-trimethyl- | C8H18 | 64 |

| 3 | 3.292 | Toluene | C7H8 | 93 |

| 4 | 3.968 | Cyclotrisiloxane, hexamethyl- | C6H18O3Si3 | 78 |

| 5 | 4.814 | Cyclotrisiloxane, hexamethyl- | C6H18O3Si3 | 47 |

| 6 | 7.054 | Cyclotetrasiloxane, octamethyl- | C8H24O4Si4 | 78 |

| 7 | 27.641 | Tetrasiloxane, decamethyl- | C10H30O3Si4 | 38 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wang, M.; Han, Y.; Chen, H. Identifying Unregulated Emissions from Conventional Diesel Self-Ignition and PPCI Marine Engines at Full Load Conditions. J. Mar. Sci. Eng. 2020, 8, 101. https://doi.org/10.3390/jmse8020101

Wang X, Wang M, Han Y, Chen H. Identifying Unregulated Emissions from Conventional Diesel Self-Ignition and PPCI Marine Engines at Full Load Conditions. Journal of Marine Science and Engineering. 2020; 8(2):101. https://doi.org/10.3390/jmse8020101

Chicago/Turabian StyleWang, Xi, Minfei Wang, Yue Han, and Hanyu Chen. 2020. "Identifying Unregulated Emissions from Conventional Diesel Self-Ignition and PPCI Marine Engines at Full Load Conditions" Journal of Marine Science and Engineering 8, no. 2: 101. https://doi.org/10.3390/jmse8020101

APA StyleWang, X., Wang, M., Han, Y., & Chen, H. (2020). Identifying Unregulated Emissions from Conventional Diesel Self-Ignition and PPCI Marine Engines at Full Load Conditions. Journal of Marine Science and Engineering, 8(2), 101. https://doi.org/10.3390/jmse8020101