Flexible Pile Group Interaction Factors under Arbitrary Lateral Loading in Sand

Abstract

1. Introduction

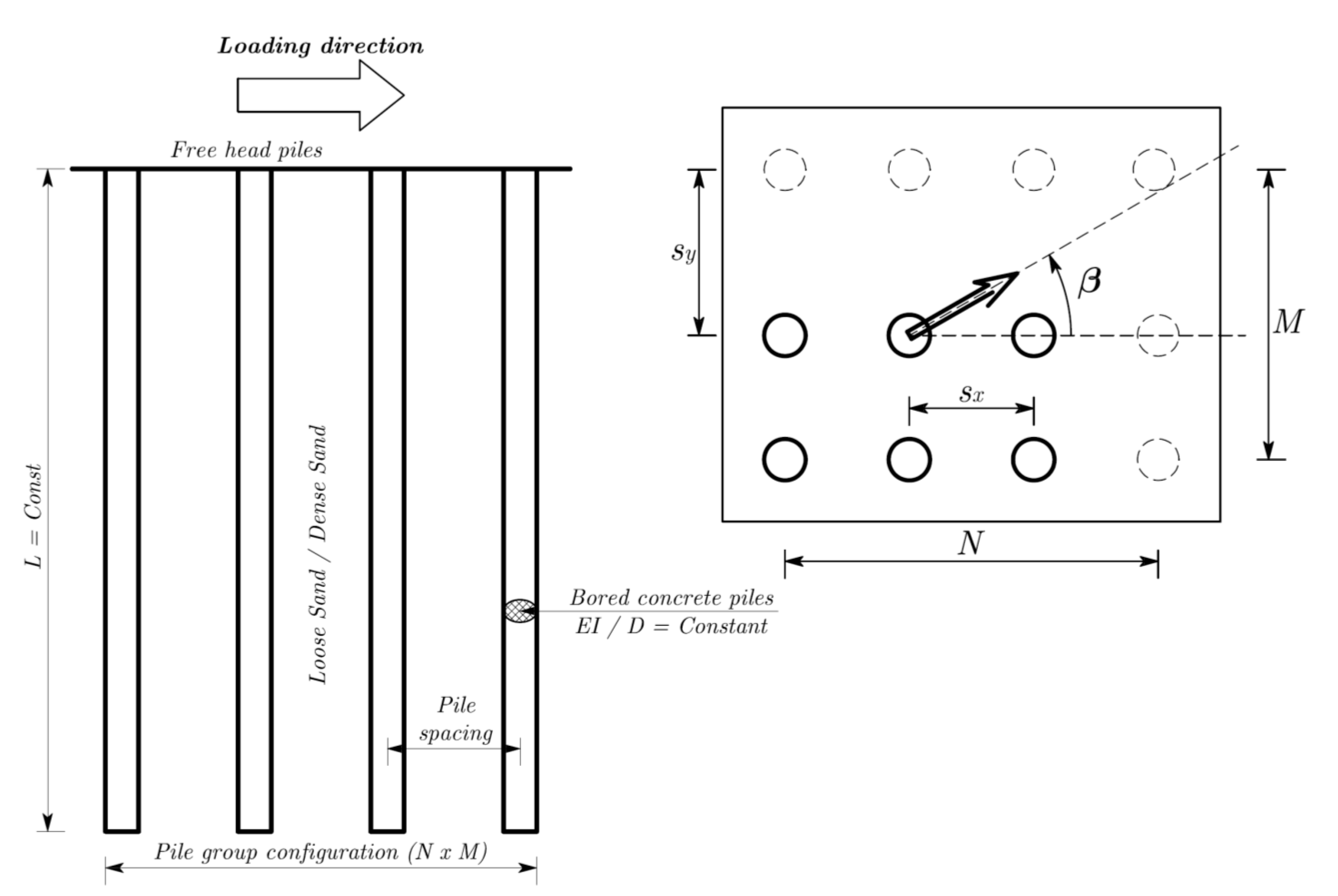

2. Research Methodology and Scope

3. Numerical Model

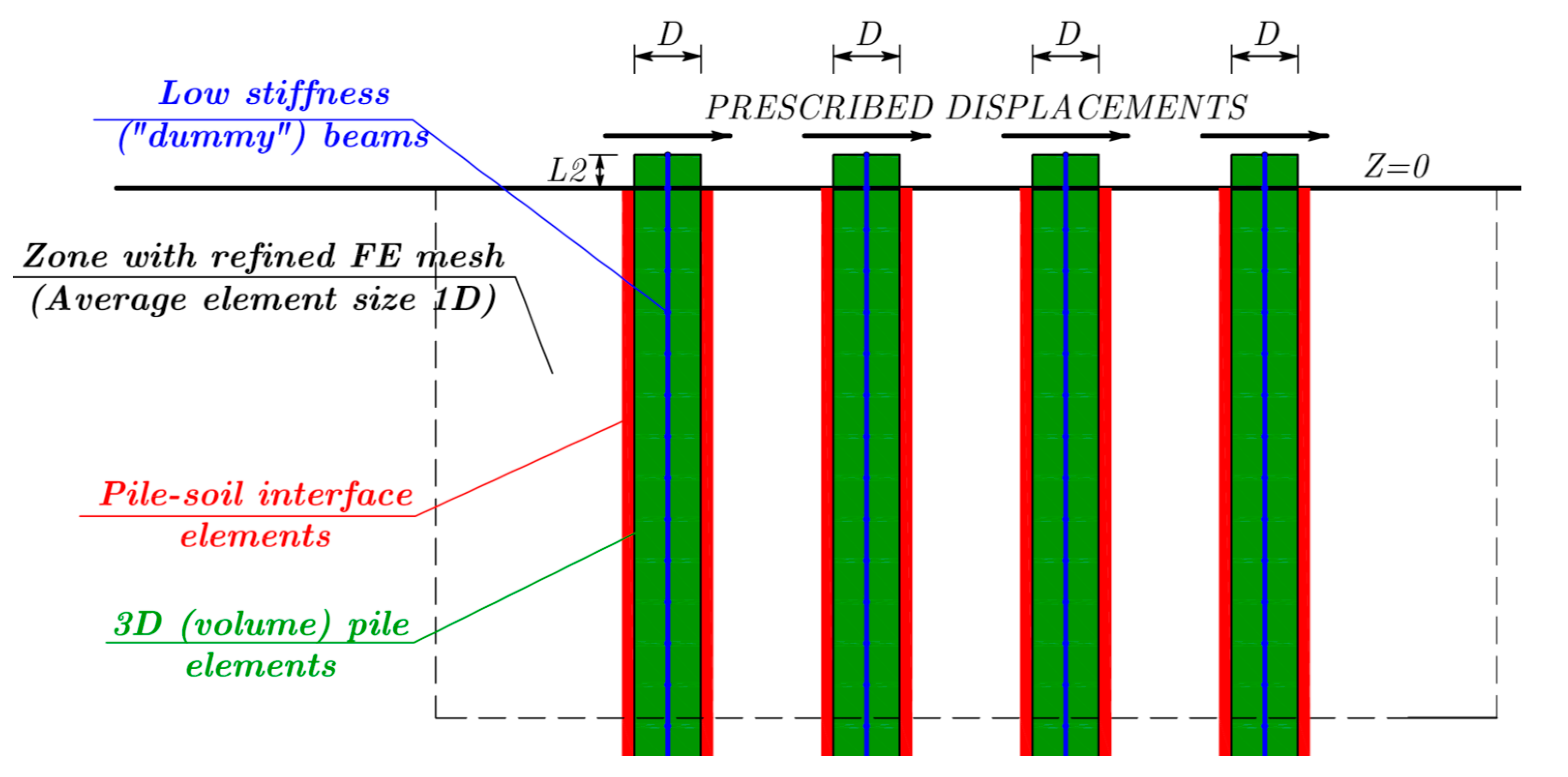

3.1. Model Components

3.1.1. Pile

3.1.2. Pile–Soil Interface

3.1.3. Soil

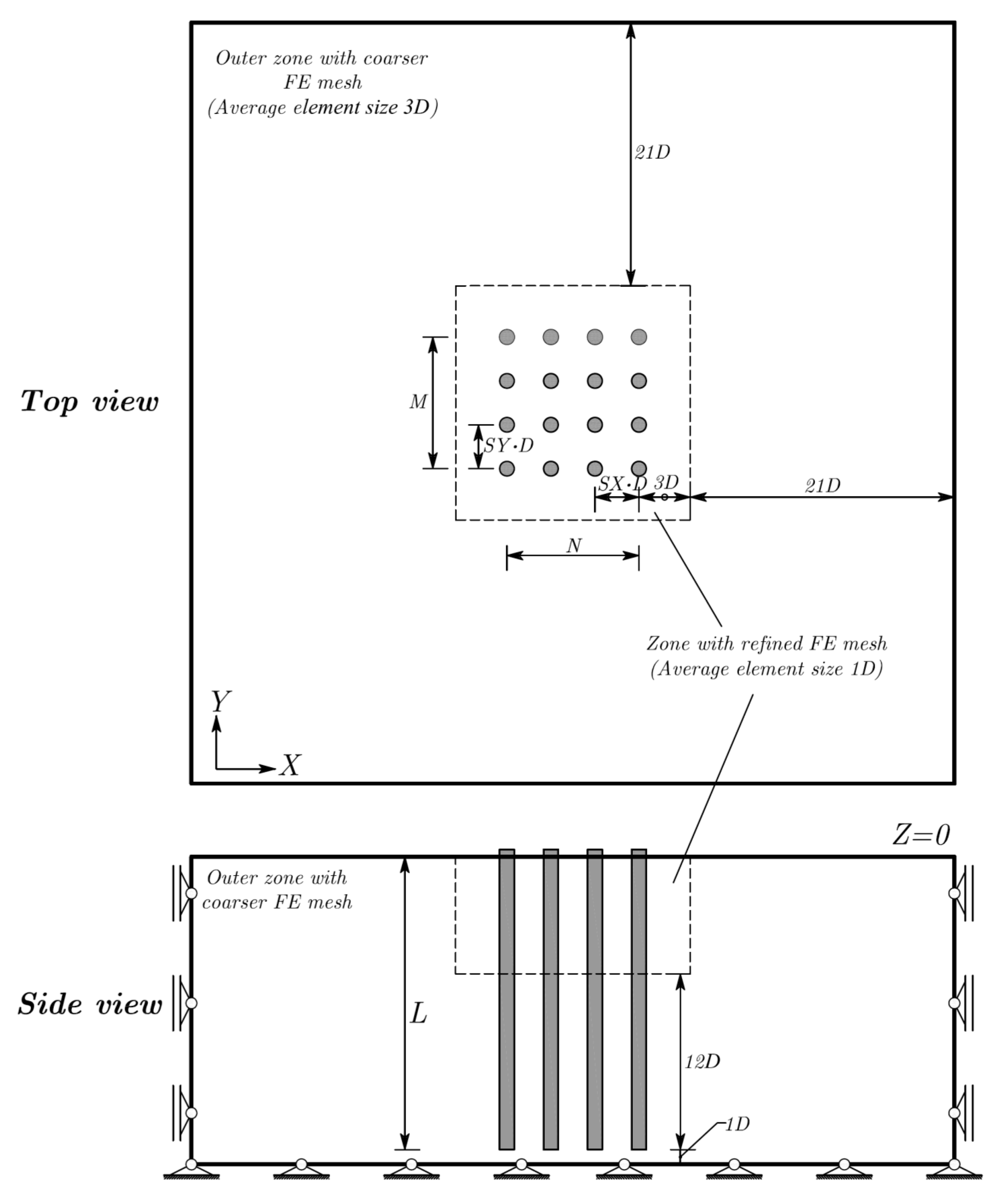

3.2. Model Geometry, Discretization, and Boundary Conditions

3.3. Calculation Stages

- Initial (K0) stage—initial stress field in the soil is established. Horizontal stress state is calculated using the Jaky’s formula [77]: K0 = 1 − sin φ′.

- Construction stage—soil volume is replaced with 3D finite elements that represent the piles (wished-in-place concept). Interface elements are also activated in this stage

- Prescribed displacements (4 increments)—the prescribed displacements up to 0.1D are applied at the pile top, in desired loading direction. The prescribed displacements simulate the displacement control test under static loading conditions.

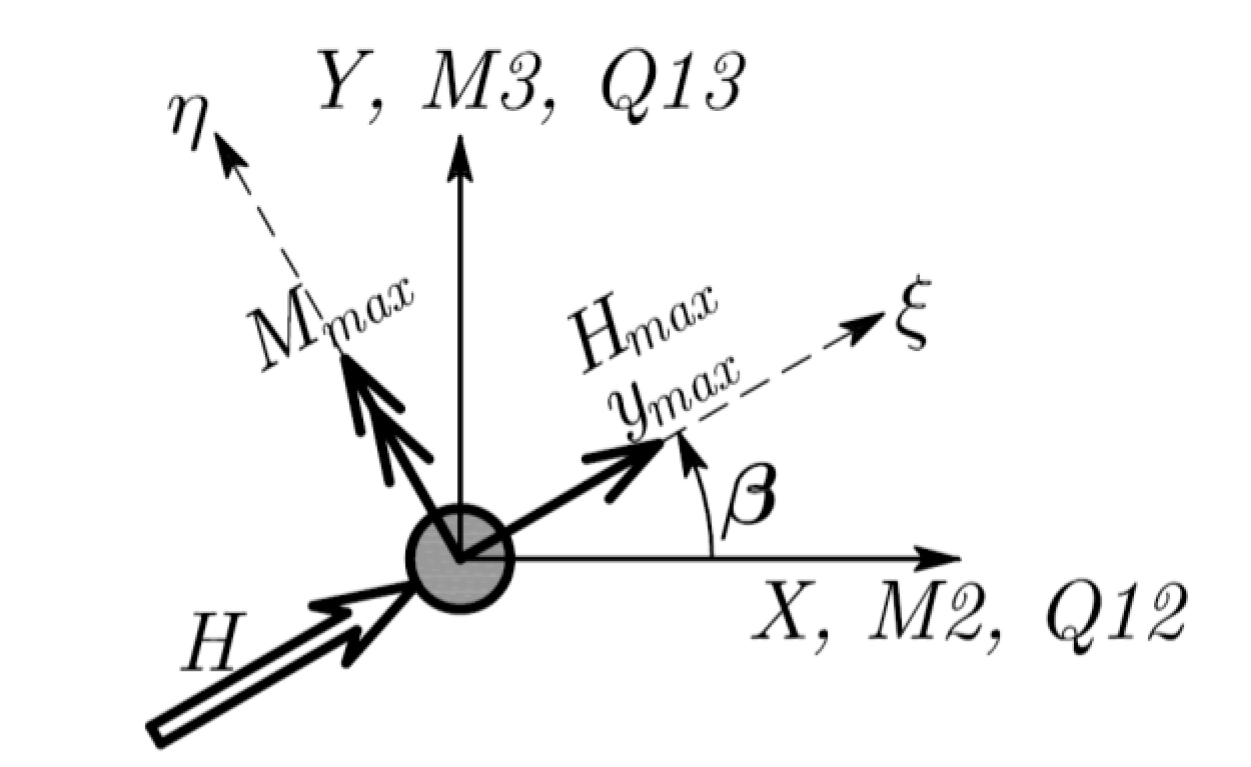

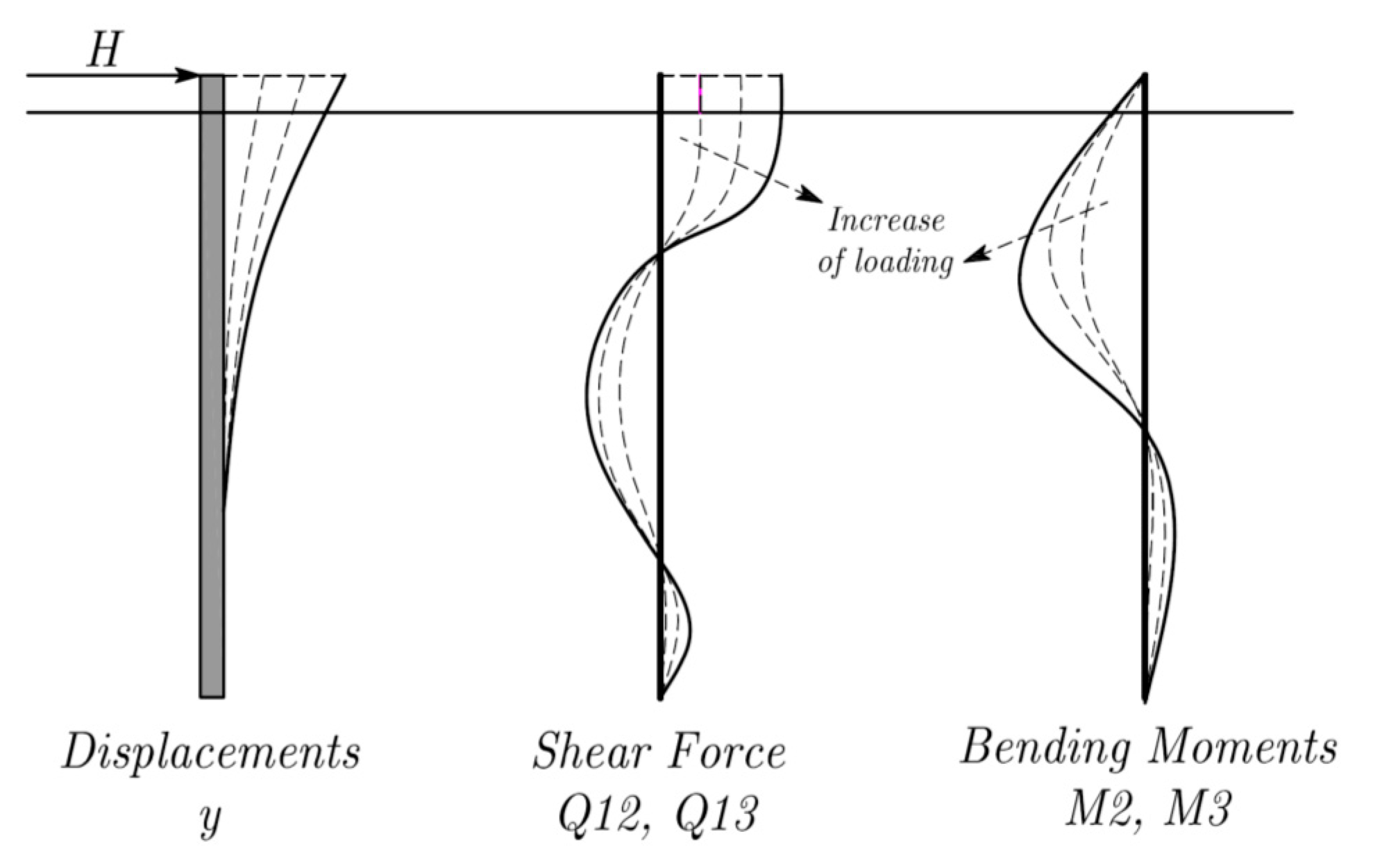

3.4. Post-Processing of the Results

3.5. Automatization of the Calculation Procedures

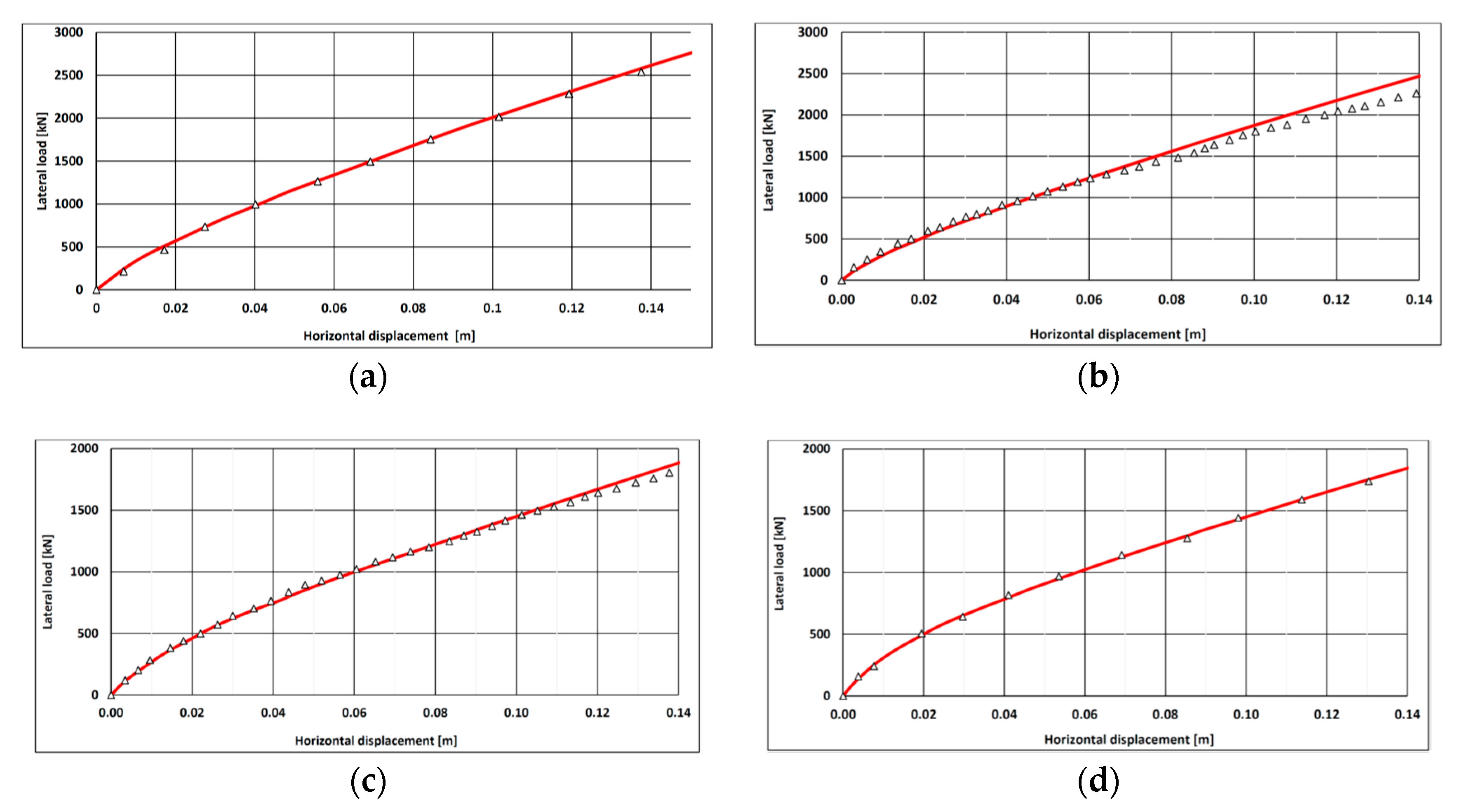

3.6. Model Validation

3.6.1. Experimental Results

3.6.2. Validation Results

4. Parametric Study

5. Results and Discussion

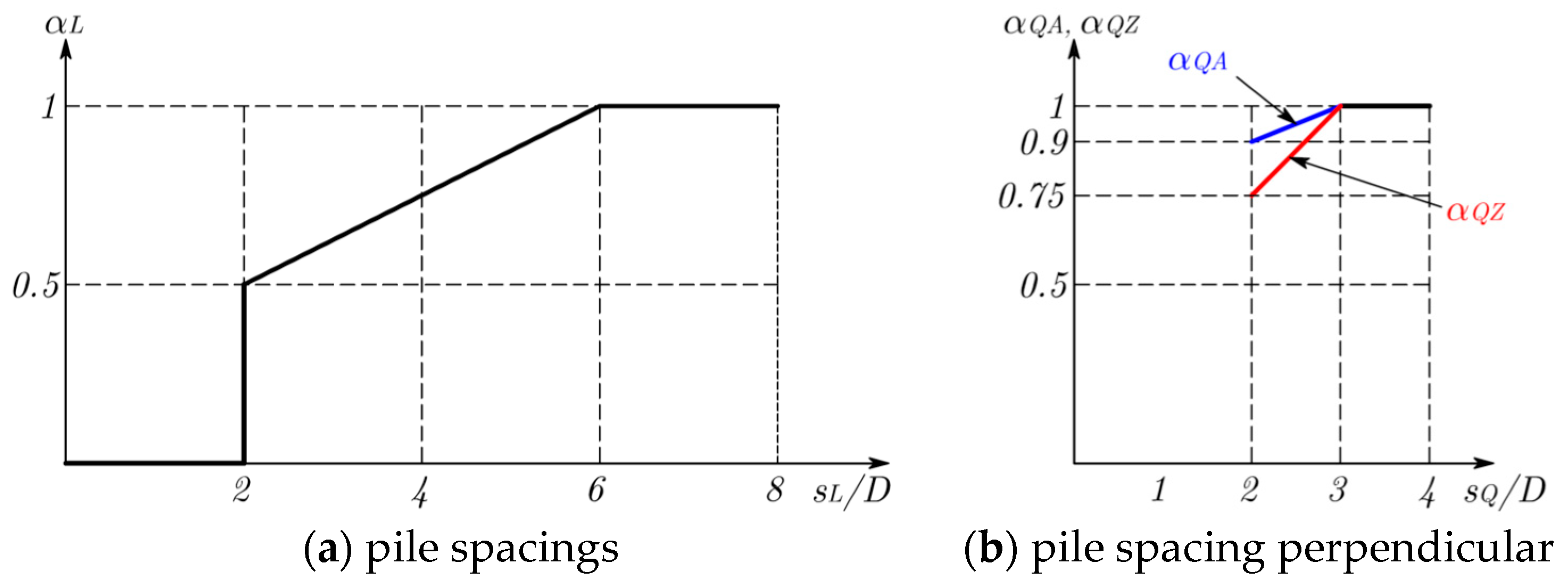

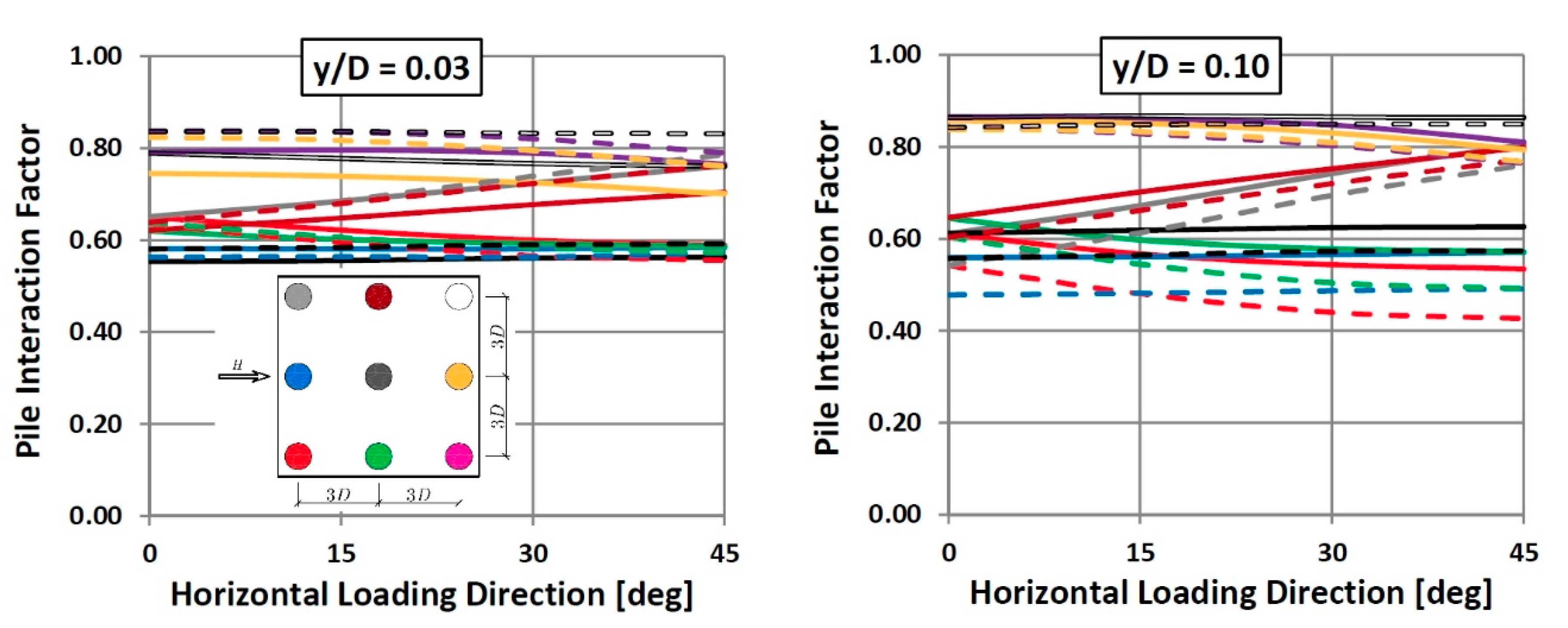

5.1. Pile Interaction Factors

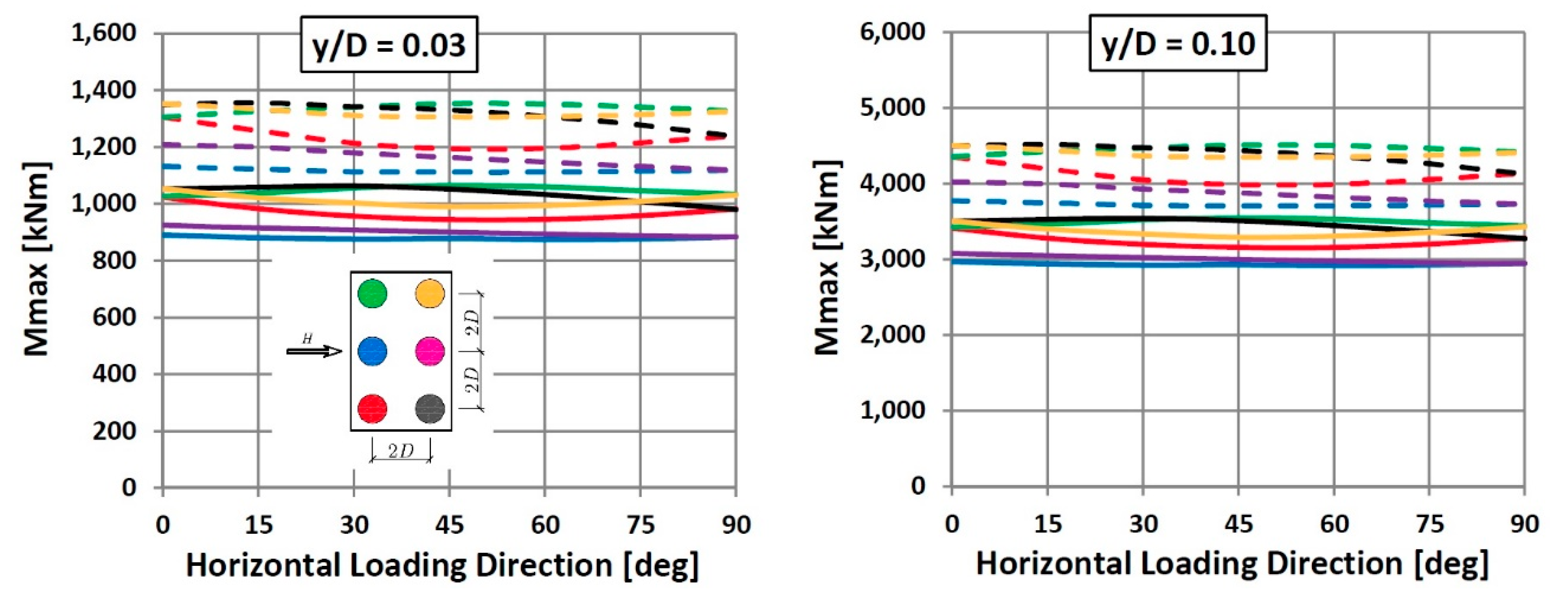

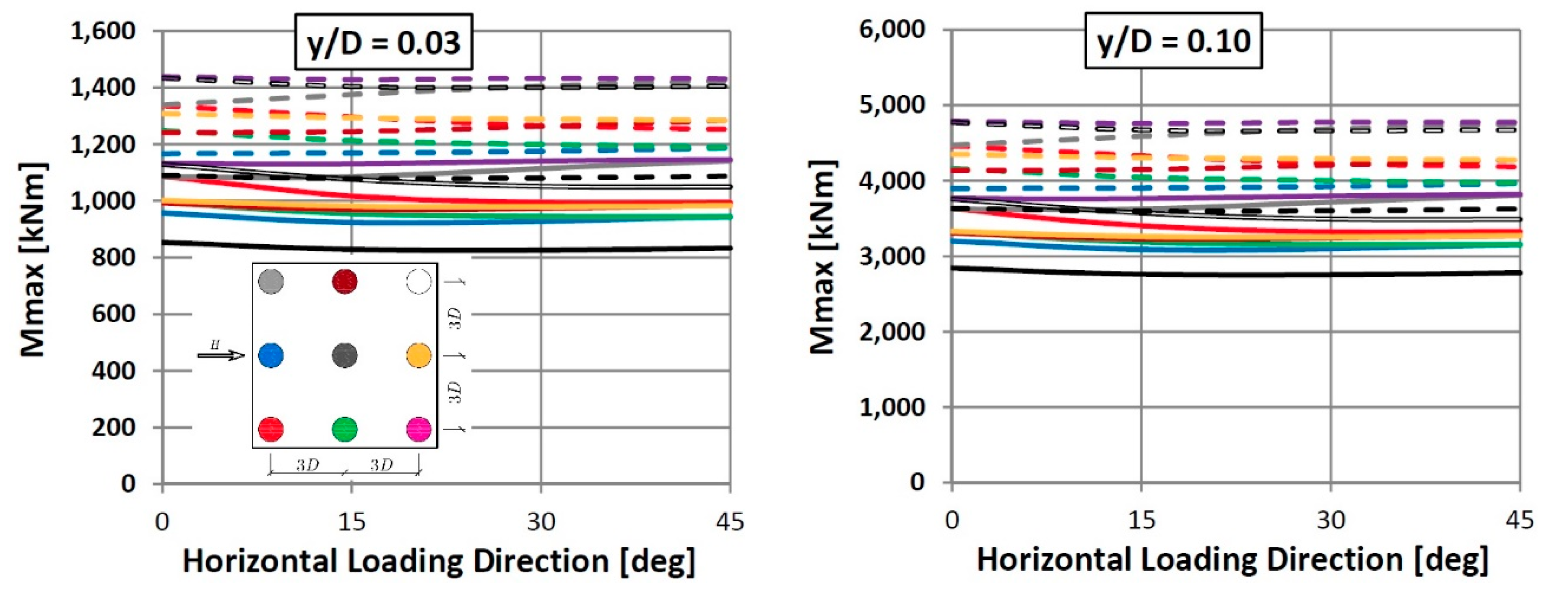

5.2. Maximum Bending Moments

6. Conclusions

- Modeling of the laterally loaded pile group using the full 3D finite element model provides reasonable results for the case of the bored piles.

- As expected, the level of interaction between the piles is higher at higher displacement levels. The influence of the displacement level on the pile group interaction effects should be investigated in more detail, especially at small displacement levels.

- The interaction level is decreased with increased pile spacing. By means of quantification, interaction factors are between 0.6–0.9 for working load levels, and 0.4–0.9 for high loading levels.

- The pile interaction factors are dependent on soil type, but soil conditions are less important factor, compared to pile group configuration, displacement level, and pile position inside the pile group.

- The influence of the loading direction on the maximum bending moments is relatively small, which is expected, given the central symmetry of the circular piles. The soil conditions significantly affect the bending moments. The displacement level does not affect the maximum bending moment distribution between the piles. Bending moment discrepancies are more pronounced with the increased number of piles.

- The force in some individual piles inside the pile group significantly changes with the change of loading direction. These piles can be considered as sensitive, because the change of the loading direction can be unpredictable. The critical positions of these piles inside the pile group have been identified for the considered pile group configurations.

- The concept of multiple numerical simulations, followed with original computer programs, could be easily extended to other numerical models and more used in everyday practice. Bearing in mind that the simulation sets can be run during the night, this approach leads to the optimum use of hardware and software resources.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rao, S.N.; Ramakrishna, V.; Rao, M.B. Influence of Rigidity on Laterally Loaded Pile Groups in Marine Clay. J. Geotech. Geoenviron. 1998, 124, 542–549. [Google Scholar] [CrossRef]

- Comodromos, E.M.; Pitilakis, K.D. Response evaluation for horizontally loaded fixed-head pile groups using 3-D non-linear analysis. Int. J. Numer Anal. Methods Geomech. 2005, 29, 597–625. [Google Scholar] [CrossRef]

- European Committee for Standardization. Eurocode 7: Geotechnical Design—Part. 1: General Rules; European Committee for Standardization: Bruxelles, Belgium, 2004. [Google Scholar]

- Randolph, M. Design methods for pile group and piled rafts. In Proceedings of the 13th International Conference on Soil Mechanics and Geotechnical Engineering, New Delhi, India, 5–10 January 1994; pp. 61–82. [Google Scholar]

- Burland, J.; Broms, B.; De Mello, V.F.B. Behaviour of foundations and structures. In Proceedings of the 9th International Conference on Soil Mechanics and Geotechnical Engineering, Tokyo, Japan, 10–15 July 1977; pp. 495–546. [Google Scholar]

- Mandolini, A.; Viggiani, C. Settlement of piled foundations. Géotechnique 1997, 47, 791–816. [Google Scholar] [CrossRef]

- Poulos, H.G.; Davis, E.H. Pile Foundation Analysis and Design; Wiley: New York, NY, USA, 1980. [Google Scholar]

- Papadopoulou, M.C.; Comodromos, E.M. On the response prediction of horizontally loaded fixed-head pile groups in sands. Comput. Geotech. 2010, 37, 930–941. [Google Scholar] [CrossRef]

- Lesny, K. Design of laterally loaded piles-limits of limit state design. In Proceedings of the Geo-Risk 2017: Reliability-Based Design and Code Developments, Denver, CO, USA, 4–7 June 2017; pp. 267–276. [Google Scholar]

- Winkler, E. Die Lehre von der Elasticität und Festigkeit: Mit Besonderer Rücksicht auf ihre Anwendung in der Technik, für Polytechnische Schulen, Bauakademien, Ingenieure, Maschinenbauer, Architekten, etc.; Dominicius: Prague, Czech Republic, 1867. [Google Scholar]

- Hetenyi, M. Beams on Elastic Foundation: Theory with Applications in the Fields of Civil and Mechanical Engineering; The University of Michigan Press: Ann Arbor, MI, USA, 1946. [Google Scholar]

- Terzaghi, K. Evaluation of coefficients of subgrade reaction. Geotechnique 1955, 5, 297–326. [Google Scholar] [CrossRef]

- Broms, B.B. Lateral resistance of piles in cohesive soils. J. Soil Mech. Found. Div. 1964, 90, 27–64. [Google Scholar]

- Broms, B.B. Lateral resistance of piles in cohesionless soils. J. Soil Mech. Found. Div. 1964, 90, 123–158. [Google Scholar]

- Norris, G. Theoretically based BEF laterally loaded pile analysis. In Proceedings of the 3rd International Conference on Numerical Methods in Offshore Piling, Nantes, France, 21–22 May 1986; pp. 361–386. [Google Scholar]

- Ashour, M.; Pilling, P.; Norris, G. Documentation of the strain wedge model program for analyzing laterally loaded piles and pile groups. In Proceedings of the 32nd Engineering Geology and Geotechnical Engineering Symposium, Boise, ID, USA, 26–28 March 1997; pp. 26–28. [Google Scholar]

- Ashour, M.; Norris, G.; Pilling, P. Lateral loading of a pile in layered soil using the strain wedge model. J. Geotech. Geoenviron. 1998, 124, 303–315. [Google Scholar] [CrossRef]

- Ashour, M.; Pilling, P.; Norris, G. Assessment of pile group response under lateral load. In Proceedings of the 4th International Conference on Recent Advances in Geotechnical Earthquake Engineering and Soil Dynamics, San Diego, CA, USA, 25–28 June 2001. [Google Scholar]

- Ashour, M.; Pilling, P.; Norris, G. Lateral behavior of pile groups in layered soils. J. Geotech. Geoenviron. 2004, 130, 508–592. [Google Scholar] [CrossRef]

- McClelland, B.; Focht, J. Soil modulus for laterally loaded piles. J. Soil Mech Found. Div 1958, 82, 1–22. [Google Scholar]

- Matlock, H. Correlations for design of laterally loaded piles in soft clay. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 22–24 April 1970; pp. 77–94. [Google Scholar]

- Reese, L.C.; Cox, W.R.; Koop, F.D. Analysis of laterally loaded piles in sand. In Offshore Technology in Civil Engineering Hall of Fame Papers from the Early Years; American Society of Civil Engineers: Reston, VA, USA, 1974; pp. 95–105. [Google Scholar]

- Dodds, A.M.; Martin, G.R. Modeling Pile Behavior in Large Pile Groups under Lateral Loading. Technical Report mceer-07-0004; University of Southern California: Los Angeles, CA, USA, 2007. [Google Scholar]

- Robertson, P.K.; Davies, M.P.; Campanella, R.G. Design of laterally loaded driven piles using the flat dilatometer. Geotech. Test. J. 1989, 12, 30–38. [Google Scholar]

- Briaud, J.L.; Smith, T.; Meyer, B. Laterally loaded piles and the pressuremeter: Comparison of existing methods. In Laterally Loaded Deep Foundations: Analysis and Performance; ASTM International: West Conshohocken, PA, USA, 1984. [Google Scholar]

- Brown, D.A.; Morrison, C.; Reese, L.C. Lateral load behavior of pile group in sand. J. Geotech. Eng. ASCE 1988, 114, 1261–1276. [Google Scholar] [CrossRef]

- Brown, D.A.; Shie, C.F. Three dimensional finite element model of laterally loaded piles. Comput. Geotech. 1990, 10, 59–79. [Google Scholar] [CrossRef]

- Brown, D.A.; Shie, C.F. Some numerical experiments with a three dimensional finite element model of a laterally loaded pile. Comput. Geotech. 1991, 12, 14–162. [Google Scholar] [CrossRef]

- Brown, D.A.; Shie, C.F. Numerical experiments into group effects on the response of piles to lateral loading. Comput. Geotech. 1990, 10, 211–230. [Google Scholar] [CrossRef]

- Wakai, A.; Gose, S.; Ugai, K. 3-D elasto-plastic finite element analyses of pile foundations subjected to lateral loading. Soils Found. 1999, 39, 97–111. [Google Scholar] [CrossRef]

- Yang, Z.; Jeremic, B. Numerical study of group effects for pile groups in sands. Int. J. Numer. Anal. Met. 2003, 27, 1255–1276. [Google Scholar] [CrossRef]

- Comodromos, E.; Papadopoulou, M. Response evaluation of horizontally loaded pile groups in clayey soils. Geotechnique 2012, 62, 329–339. [Google Scholar] [CrossRef]

- Papadopoulou, M.C.; Comodromos, E.M. Explicit extension of the p-y method to pile groups in sandy soils. Acta Geotech 2014, 9, 485–497. [Google Scholar] [CrossRef]

- Comodromos, E.M.; Papadopoulou, M.C. Explicit extension of the p-y method to pile groups in cohesive soils. Comput Geotech 2013, 47, 28–41. [Google Scholar] [CrossRef]

- Poulos, H.G. Behavior of laterally loaded piles: I—single piles. J. Soil Mech. Found. Div. 1971, 97, 711–731. [Google Scholar]

- Poulos, H.G. Behavior of laterally loaded piles: II—pile groups. J. Soil Mech. Found. Div. 1971, 97, 733–751. [Google Scholar]

- Banerjee, P.K.; Driscoll, R.M. Three-dimensional analysis of vertical pile groups. In Proceedings of the Second International Conference on Numerical Methods in Geomechanics, Blacksburg, VA, USA, 1 June 1976; pp. 438–450. [Google Scholar]

- Fayyazi, M.S.; Taiebat, M.; Finn, W.L. Group reduction factors for analysis of laterally loaded pile groups. Can. Geotech. J. 2014, 51, 758–769. [Google Scholar] [CrossRef]

- Lemnitzer, A.; Khalili-Tehrani, P.; Ahlberg, E.R.; Rha, C.; Taciroglu, E.; Wallace, J.W.; Stewart, J.P. Nonlinear Efficiency of Bored Pile Group under Lateral Loading. J. Geotech. Geoenviron 2010, 136, 1673–1685. [Google Scholar] [CrossRef]

- Ashour, M.; Ardalan, H. Employment of the p-multiplier in pile-group analysis. J. Bridg. Eng 2011, 16, 612–623. [Google Scholar] [CrossRef]

- Otani, J.; Pham, K.D.; Sano, J. Investigation of failure patterns in sand due to laterally loaded pile using X-ray CT. Soils Found. 2006, 46, 529–535. [Google Scholar] [CrossRef]

- Hajialilue-Bonab, M.; Azarnya-Shahgoli, H.; Sojoudi, Y. Soil deformation pattern around laterally loaded piles. Int. J. Phys. Model. Geo. 2011, 11, 116–125. [Google Scholar] [CrossRef]

- Hajialilue-Bonab, M.; Sojoudi, Y.; Puppala, A.J. Study of strain wedge parameters for laterally loaded piles. Int. J. Geomech. 2013, 13, 143–152. [Google Scholar] [CrossRef]

- Iai, S.; Tobita, T.; Hussien, M.N.; Ozutsumui, N.; Rollins, K. Soil-pile interaction under lateral load. In Soil-Foundation-Structure Interaction; CRC Press: Boca Raton, FL, USA, 2010; pp. 117–124. [Google Scholar]

- Morita, K.; Otani, J.; Mukunoki, T.; Hironaka, J.; Pham, K.D. Evaluation of vertical and lateral bearing capacity mechanisms of pile foundations using X-ray CT. In Proceedings of the International Workshop on Recent Advances of Deep Foundations, Yokosuka, Japan, 1–2 February 2007; pp. 217–223. [Google Scholar]

- German Institute for Standardization. Subsoil—Verification of the Safety of Earthworks and Foundations—Supplementary Rules to DIN EN 1997–1; German Institute for Standardization: Berlin, Germany, 2010. [Google Scholar]

- German Institute for Standardization. DIN 4014: Bored Cast-in-Place Piles: Formation, Design and Bearing Capacity; German Institute for Standardization: Berlin, Germany, 1990. [Google Scholar]

- Deutschen Gesellschaft für Geotechnik, e.V. Deutschen Gesellschaft für Geotechnik e.V.: EA-Pfähle: Empfehlungen des Arbeitskreises “Pfähle”; Wilhelm Ernst & Sohn: Berlin, Germany, 2012. [Google Scholar]

- Klüber, E. Tragverhalten von Pfahlgruppen unter Horizontal Belastung. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 1988. [Google Scholar]

- Kotthaus, M. Zum Tragverhalten von horizontal belasteten Pfahlreihen aus langen Pfählen in Sand. Ph.D. Thesis, Ruhr-Universität Bochum, Bochum, Germany, 1992. [Google Scholar]

- Randolph, M.F. The response of flexible piles to lateral loading. Geotechnique 1981, 31, 247–259. [Google Scholar] [CrossRef]

- Ochoa, M.W.; O’Neill, M. Lateral pile interaction factors in submerged sand. J. Geotech. Eng. ASCE 1989, 115, 359–378. [Google Scholar] [CrossRef]

- Fan, C.C.; Long, J.H. A modulus-multiplier approach for non-linear analysis of laterally loaded pile groups. Int. J. Numer Anal. Met. 2007, 31, 1117–1145. [Google Scholar] [CrossRef]

- Su, D.; Yan, W. A multidirectional p-y model for lateral sand-pile interactions. Soils Found. 2013, 53, 199–214. [Google Scholar] [CrossRef]

- Mayoral, J.M.; Pestana, J.M.; Seed, R.B. Multi-directional cyclic p-y curves for soft clays. Ocean. Eng. 2016, 115, 1–18. [Google Scholar] [CrossRef]

- Georgiadis, K.; Sloan, S.; Lyamin, A. Ultimate lateral pressure of two side-by-side piles in clay. Geotechnique 2013, 63, 733–745. [Google Scholar] [CrossRef]

- Su, D.; Zhou, Y.G. Effect of Loading Direction on the Response of Laterally Loaded Pile Groups in Sand. Int. J. Geomech. 2015, 16, 04015051. [Google Scholar] [CrossRef]

- Brown, D.A.; O’Neill, M.W.; Hoit, M.; McVay, M.; El Nagger, M.H.; Chakraborty, S. Static and Dynamic Lateral Loading of Pile Groups. Technical Report NCHRP 24; Transportation Research Board: Washington, DC, USA, 2001. [Google Scholar]

- Huang, A.B.; Hsueh, C.K.; O’Neill, M.W.; Chern, S.; Chen, C. Effects of construction on laterally loaded pile groups. J. Geotech. Geoenviron. 2001, 127, 385–397. [Google Scholar] [CrossRef]

- McVay, M.; Casper, R.; Shang, T.I. Lateral response of three-row groups in loose to dense sands at 3D and 5D pile spacing. J. Geotech. Eng. 1995, 121, 436–441. [Google Scholar] [CrossRef]

- Rollins, K.M.; Peterson, K.T.; Weaver, T.J. Lateral load behavior of full-scale pile group in clay. J. Geotech. Geoenviron. 1998, 124, 468–478. [Google Scholar] [CrossRef]

- Cox, W.R.; Dixon, D.A.; Murphy, B.S. Lateral-load tests on 25.4-mm (1-in.) diameter piles in very soft clay in side-by-side and in-line groups. In Laterally Loaded Deep Foundations: Analysis and Performance; ASTM International: West Conshohocken, PA, USA, 1984. [Google Scholar]

- Reese, L.C.; Van Impe, W.F. Single Piles and Pile Groups under Lateral Loading; CRC Press: Boca Raton, FL, USA, 2011; Available online: https://books.google.com.hk/books/about/Single_Piles_and_Pile_Groups_Under_Later.html?id=7qg0SwAACAAJ&redir_esc=y (accessed on 14 October 2020).

- Chandrasekaran, S.; Boominathan, A.; Dodagoudar, G. Group interaction effects on laterally loaded piles in clay. J. Geotech. Geoenviron. 2010, 136, 573–582. [Google Scholar] [CrossRef]

- McVay, M.; Zhang, L.; Molnit, T.; Lai, P. Centrifuge testing of large laterally loaded pile groups in sands. J. Geotech. Geoenviron. 1998, 124, 1016–1026. [Google Scholar] [CrossRef]

- Van Impe, W. Foreword: Belgian geotechnics’ experts research on screw piles. In Belgian Screw Pile Technology Design and Recent Developments; A.A. Balkema: Rotterdam, The Netherlands; Momenta: London, UK, 2003. [Google Scholar]

- Basile, F. Analysis and design of pile groups. In Numerical Analysis and Modelling in Geomechanics; CRC Press: Boca Raton, FL, USA, 2003; pp. 278–315. [Google Scholar]

- Mokwa, R.L.; Duncan, J.M. Rotational Restraint of Pile Caps during Lateral Loading. J. Geotech. Geoenviron. 2003, 129, 829–837. [Google Scholar] [CrossRef]

- Reese, L.C.; Van Impe, W.F. Single Piles and Pile Groups under Lateral Loading; CRC Press: Boca Raton, FL, USA, 2000; Available online: https://books.google.com.hk/books/about/Single_Piles_and_Pile_Groups_Under_Later.html?id=jEs5z6-2xG4C&redir_esc=y (accessed on 14 October 2020).

- Brinkgreve, R.B.J.; Kumarswamy, S.; Swolfs, W.M.; Waterman, D.; Chesary, A.; Bonnier, P.G.; Haxaire, A. PLAXIS 3D AE—User Manual; Plaxis BV: Delft, The Netherlands, 2015. [Google Scholar]

- Marjanovic, M.; Vukicevic, M.; König, D.; Schanz, T.; Schäfer, R. Modeling of laterally loaded piles using embedded beam elements. In Proceedings of the International Conference “Contemporary achievements in Civil Engineering 2016”, Subotica, Serbia, 22 April 2016; pp. 349–358. [Google Scholar]

- Bowles, J. Foundation Analysis and Design; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Comodromos, E.M.; Papadopoulou, M.C.; Rentzeperis, I.K. Effect of cracking on the response of pile test under horizontal loading. J. Geotech. Geoenviron. 2009, 135, 1275–1284. [Google Scholar] [CrossRef]

- Tedesco, G. Offshore Tower or Platform Foundations: Numerical Analysis of a Laterally Loaded Single Pile or Pile Group in Soft Clay and Analysis of Actions on a Jacket Structure. Master’s Thesis, University of Bologna, Bologna, Italy, 2013. [Google Scholar]

- Zhang, Y.; Andersen, K.H.; Tedesco, G. Ultimate bearing capacity of laterally loaded piles in clay - Some practical considerations. Marine Struct. 2016, 50, 260–275. [Google Scholar] [CrossRef]

- Schanz, T.; Vermeer, P.A. Formulation and verification of the Hardening Soil Model. In Beyond 2000 in Computation Geotechnics—10 Years of PLAXIS; Balkema: Rotterdam, The Netherlands, 1999; pp. 1–16. [Google Scholar]

- Jaky, J. The coefficient of earth pressure at rest. J. Soc. Hung. Arch. Eng. 1944, 78, 355–358. [Google Scholar]

- Garnier, J.; Gaudin, C.; Springman, S.M.; Culligan, P.J.; Goodings, D.; König, D.; Kutter, B.; Phillips, R.; Randolph, M.F.; Thorel, L. Catalogue of scaling laws and similitude questions in geotechnical centrifuge modelling. Int. J. Phys. Model. Geo. 2007, 7, 1–23. [Google Scholar] [CrossRef]

- Kayalar, A. Bettung von Horizontal Belasteten Pfahlreihen und Bohrpfahlwänden. Bachelar‘s Thesis, Ruhr-Universität Bochum, Bochum, Germany, 2012. [Google Scholar]

| Centrifuge Model | Prototype | Real Structure | |

|---|---|---|---|

| Pile diameter D (m) | 0.030 | 1.5 | 1.5 |

| Pile embedment length L (m) | 0.600 | 30 | 30 |

| Pile length above ground level L2 (m) | 0.085 | 4.25 | 4.25 |

| Pipe wall thickness t (m) | 0.002 | 0.10 | |

| Pipe inner diameter d (m) | 0.026 | 1.30 | |

| Young’s modulus E (MN/m2) | 70 000 | 70,000 | 30,508 |

| Moment of inertia I (m4) | 1.73 × 10−8 | 0.108 | 0.2485 |

| Bending stiffness EI (kNm2) | 1.2130 | 7,581,448 | 7,581,448 |

| Model Parameter | Value |

|---|---|

| Volumetric weight γ (kN/m3) | 16.6 |

| Cohesion c’ (kN/m2) | 0 |

| Angle of internal friction ϕ’ (°) | 35 |

| Dilation angle ψ (°) | 5 |

| Triaxial loading stiffness E50 (kN/m2) | 28,800 |

| Oedometer loading stiffnessEoed (kN/m2) | 28,800 |

| Triaxial unloading stiffness Eur (kN/m2) | 115,200 (=4E50) |

| Poisson’s ratio ν (-) | 0.25 |

| m (-) | 0.47 |

| Rinter (-) | 0.654 |

| Model Parameter | Model Validation | Parametric Study | |

|---|---|---|---|

| Dense Sand | Loose Sand | Dense Sand | |

| Volumetric weight γ (kN/m3) | 16.6 | 16 | 18 |

| Cohesion c’ (kN/m2) | 0 | 0 | 0 |

| Angle of internal friction ϕ’ (°) | 35 | 30 | 42 |

| Dilation angle ψ (°) | 5 | 0 | 12 |

| Triaxial loading stiffness E50 (kN/m2) | 28,800 | 15,000 | 30,000 |

| Oedometer loading stiffnessEoed (kN/m2) | 28,800 | 15,000 | 30,000 |

| Triaxial unloading stiffness Eur (kN/m2) | 115,200 | 60,000 | 120,000 |

| Poisson’s ratio ν (-) | 0.25 | 0.25 | 0.25 |

| m (-) | 0.47 | 0.50 | 0.50 |

| Rinter (-) | 0.654 | 0.65 | 0.65 |

| Pile Group Shape | N × M | Sx (D) | Sy (D) | Loading Direction β (°) |

|---|---|---|---|---|

| Square | 2 × 2 | 2 | 2 | 0/15/30/45 |

| 3 × 3 | 3 | 3 | ||

| Rectangle | 2 × 2 | 2 | 3 | 0/15/30/45/60/75/90 |

| 2 | 4 | |||

| 2 | 5 | |||

| 3 | 4 | |||

| 3 | 5 | |||

| 4 | 5 | |||

| 2 × 3 | 2 | 2 | ||

| 2 | 3 | |||

| 2 | 4 | |||

| 3 | 2 | |||

| 3 | 3 | |||

| 3 | 4 | |||

| 3 | 5 | |||

| 4 | 2 | |||

| 4 | 3 | |||

| 4 | 4 | |||

| 4 | 5 | |||

| 5 | 3 | |||

| 5 | 4 | |||

| 5 | 5 | |||

| 3 × 3 | 2 | 3 | ||

| 2 | 4 | |||

| 2 | 5 | |||

| 3 | 4 | |||

| 3 | 5 | |||

| 4 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marjanović, M.; Vukićević, M.; König, D. Flexible Pile Group Interaction Factors under Arbitrary Lateral Loading in Sand. J. Mar. Sci. Eng. 2020, 8, 800. https://doi.org/10.3390/jmse8100800

Marjanović M, Vukićević M, König D. Flexible Pile Group Interaction Factors under Arbitrary Lateral Loading in Sand. Journal of Marine Science and Engineering. 2020; 8(10):800. https://doi.org/10.3390/jmse8100800

Chicago/Turabian StyleMarjanović, Miloš, Mirjana Vukićević, and Diethard König. 2020. "Flexible Pile Group Interaction Factors under Arbitrary Lateral Loading in Sand" Journal of Marine Science and Engineering 8, no. 10: 800. https://doi.org/10.3390/jmse8100800

APA StyleMarjanović, M., Vukićević, M., & König, D. (2020). Flexible Pile Group Interaction Factors under Arbitrary Lateral Loading in Sand. Journal of Marine Science and Engineering, 8(10), 800. https://doi.org/10.3390/jmse8100800