Wind Turbine Blade Life-Time Assessment Model for Preventive Planning of Operation and Maintenance

Abstract

:1. Introduction

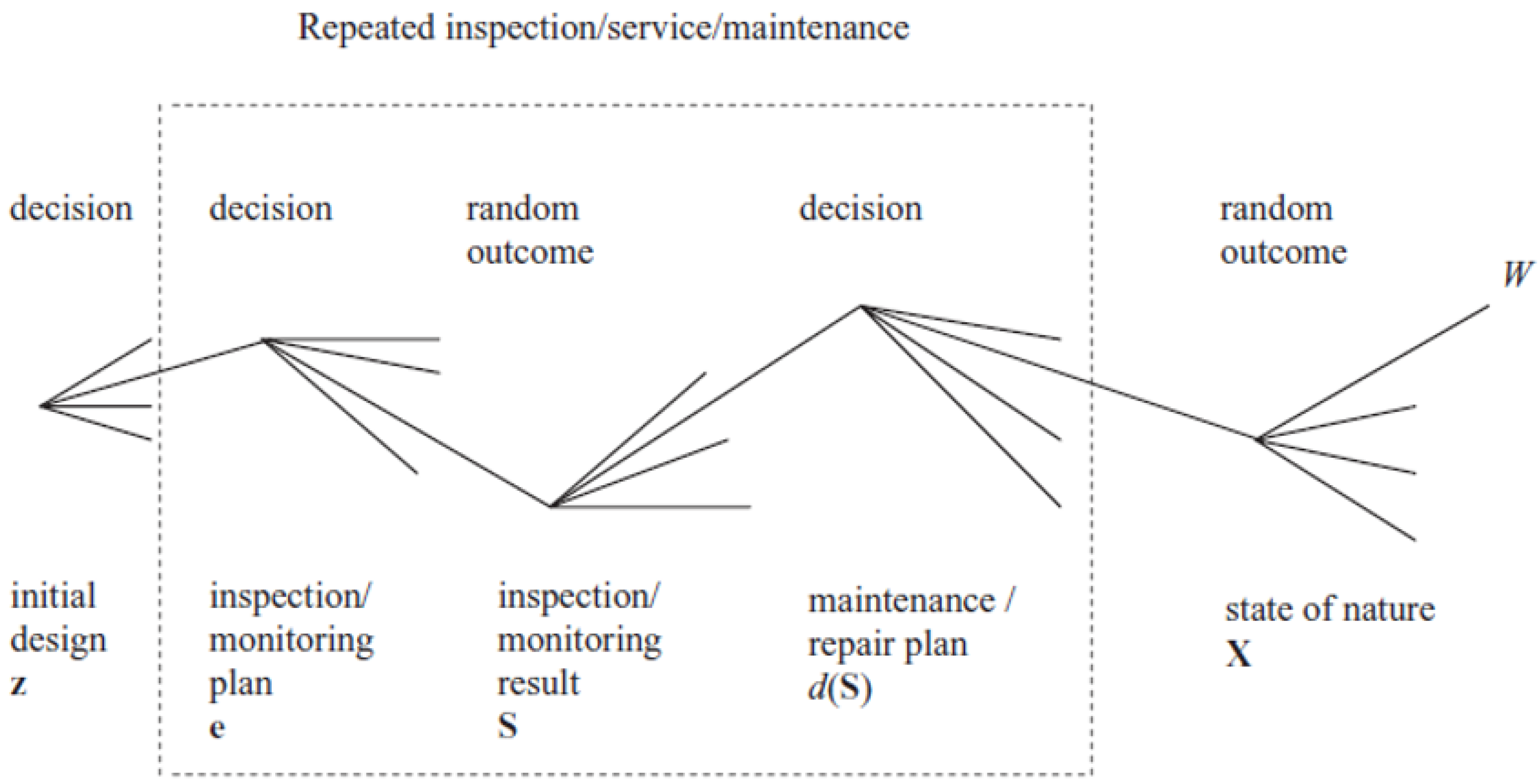

2. Optimal Maintenance and Inspection Planning

3. Model Description

3.1. Weather Conditions

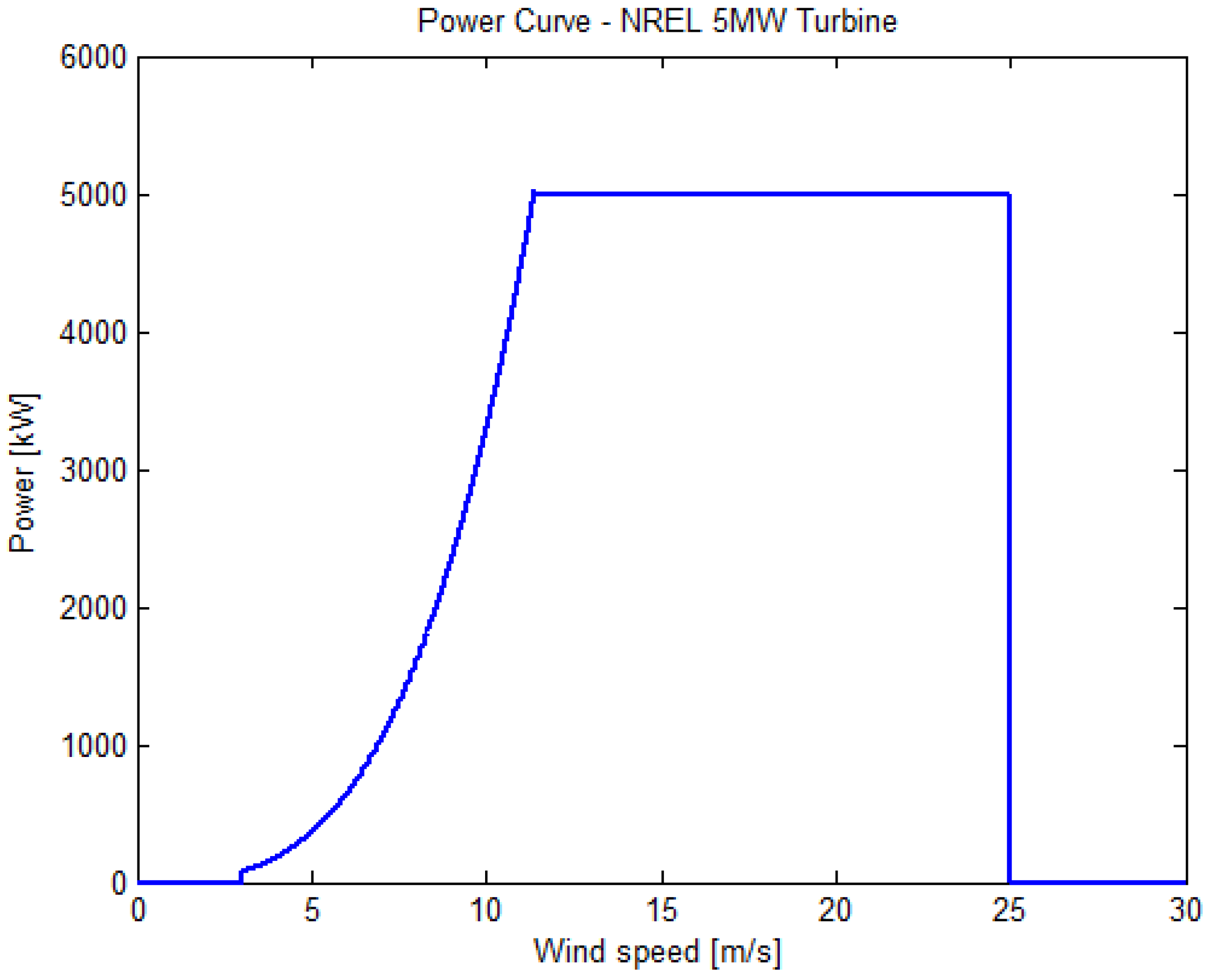

3.2. Power Production

3.3. Transport

| Symbol | Description | Value | Unit |

|---|---|---|---|

| Ulim | Wind limit | 12 | m/s |

| Hs,lim | Wave limit | 1.5 | m |

| Ttr | Transport | 8 | h |

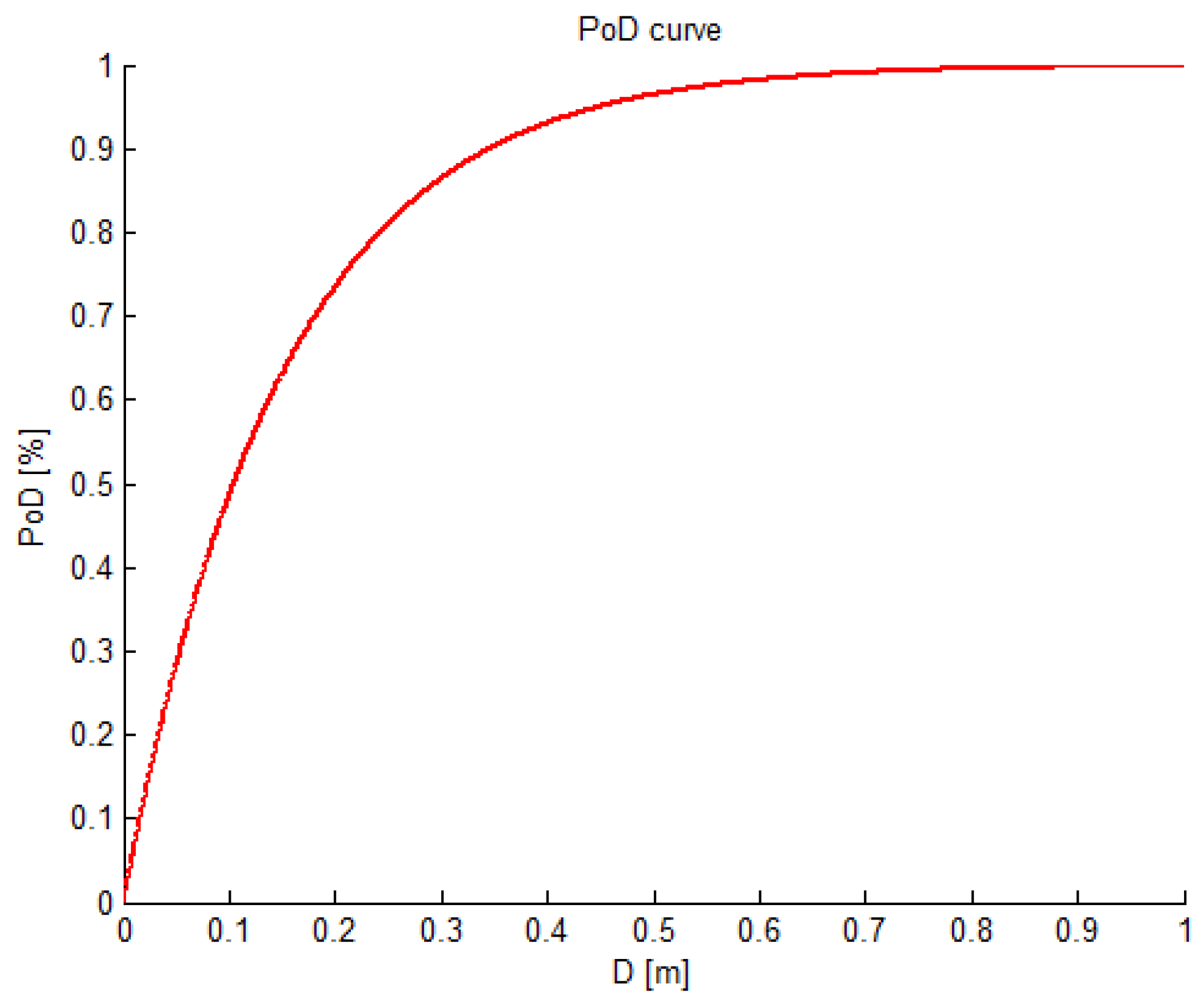

3.4. Inspections

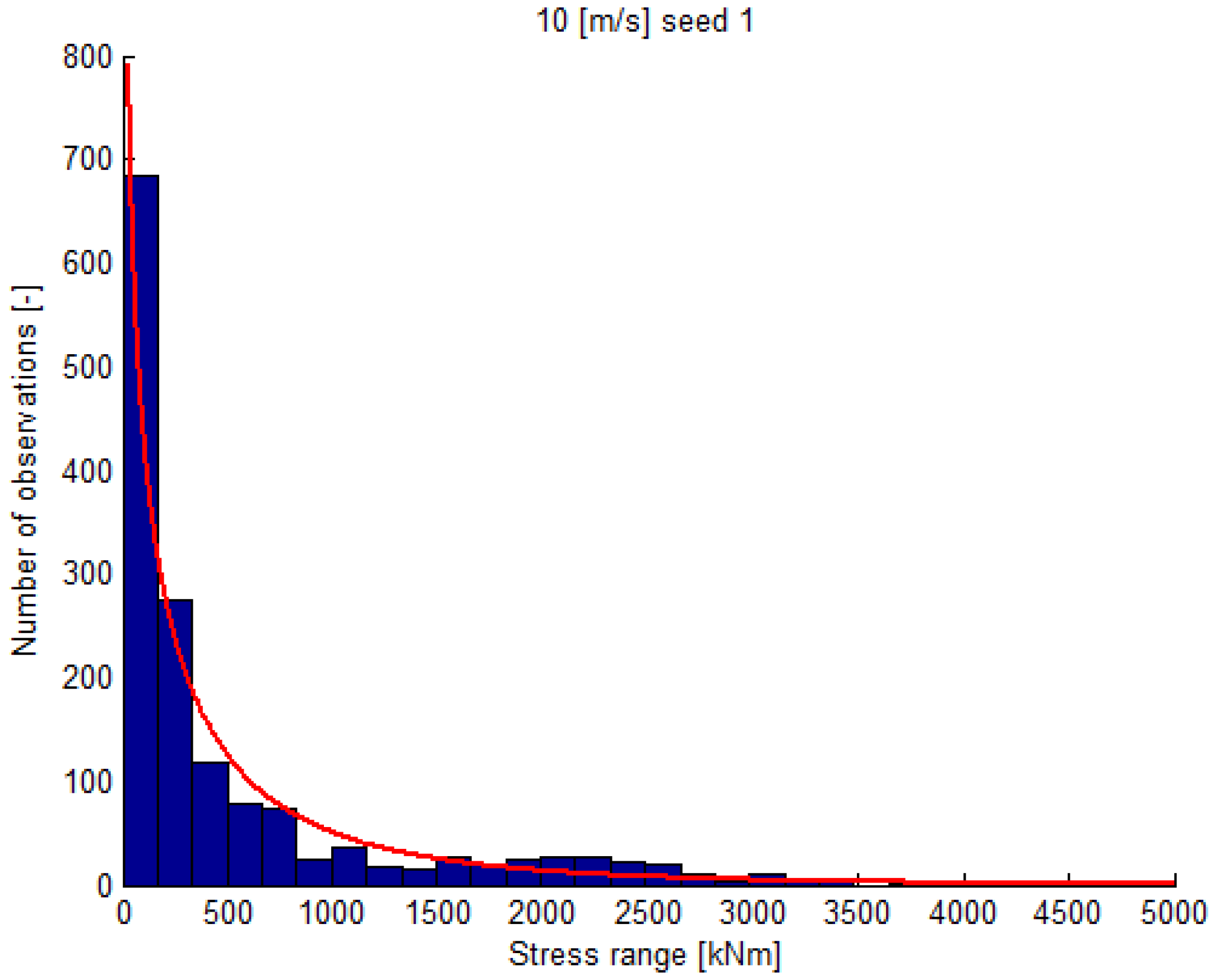

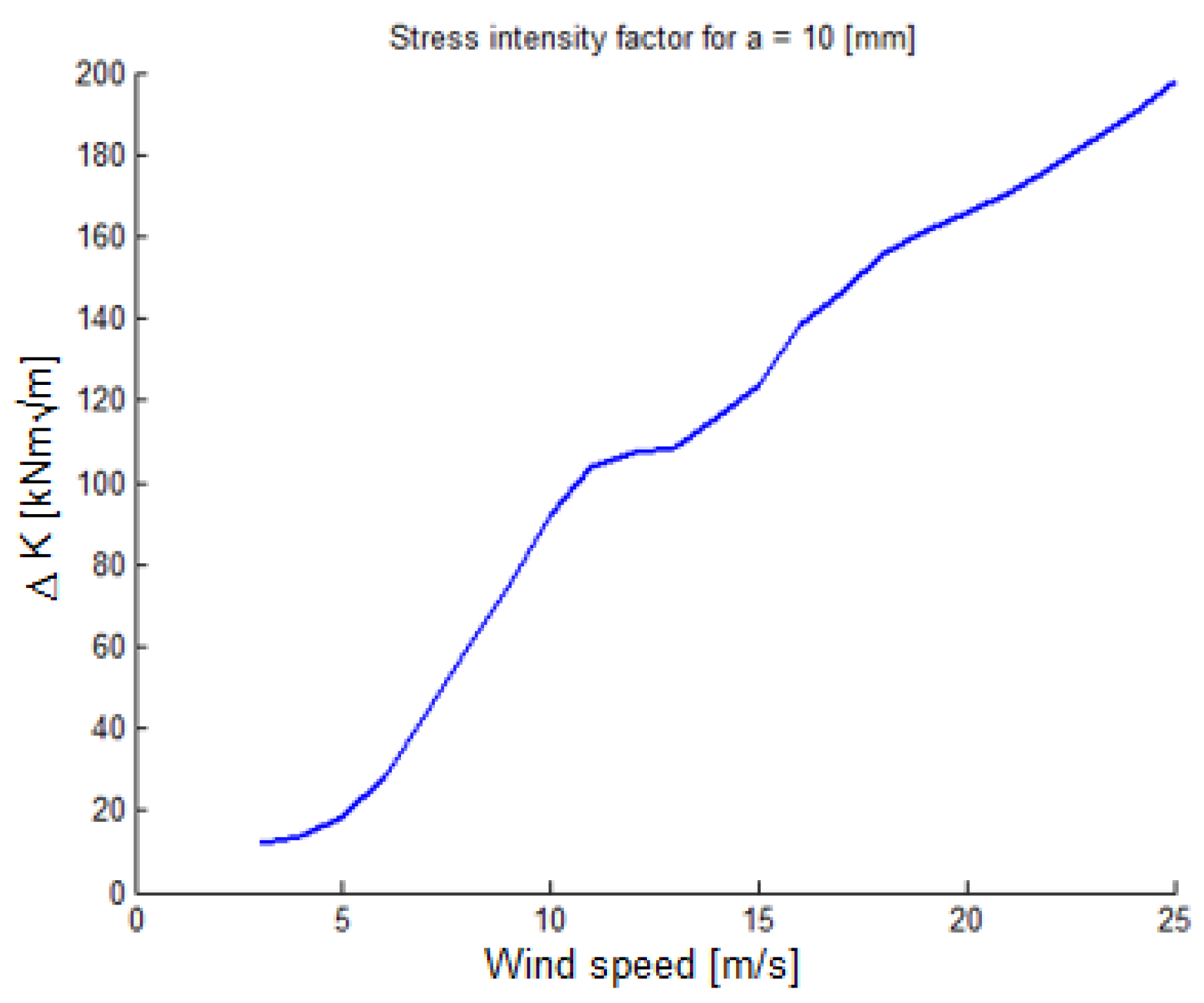

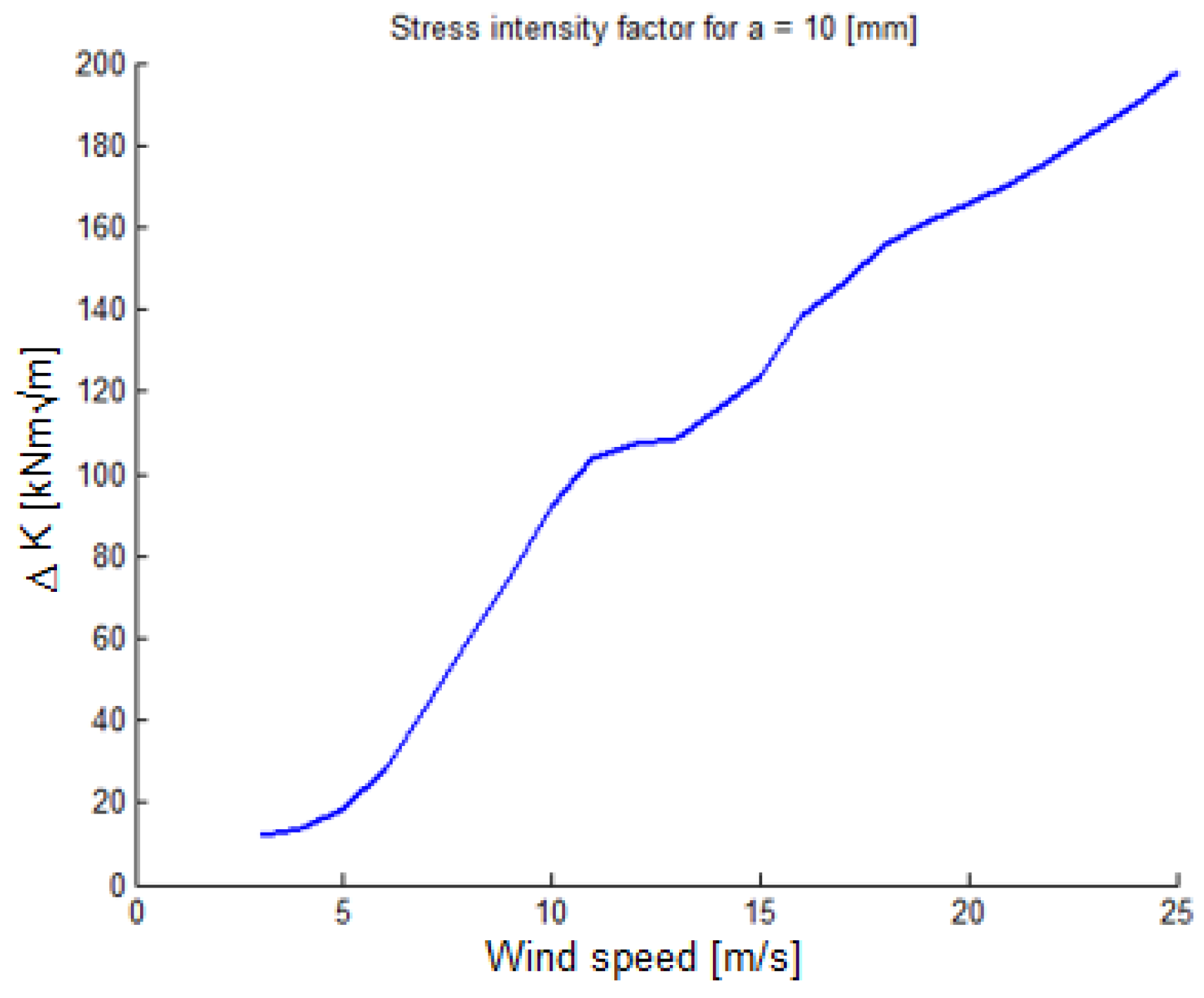

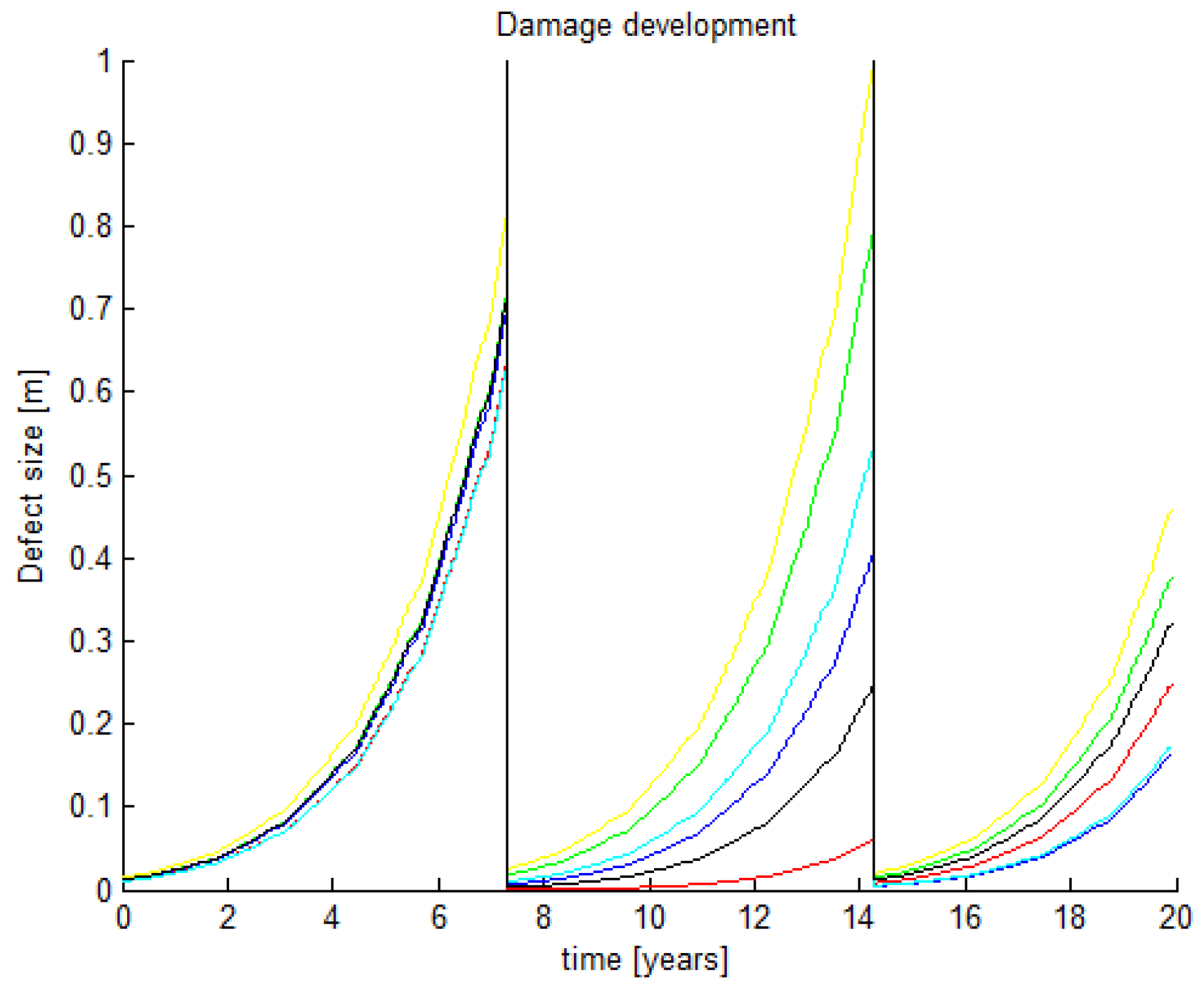

3.5. Damage Model

- crack initiation at the start of the blade’s life

- damage propagation during the blade’s lifetime

- failure is achieved when a crack length reaches afail

- da

- Increase in crack length

- ΔK

- Stress intensity factor

- Δt

- Time period

- A,m,λw

- Material parameters

- R

- Stress ratio

- Δs

- Load range

- a

- Crack length

- f(Δs|u,I)

- Density function of load cycles

3.6. Repair Model

| Preventive | 24 h |

| Corrective | 72 h |

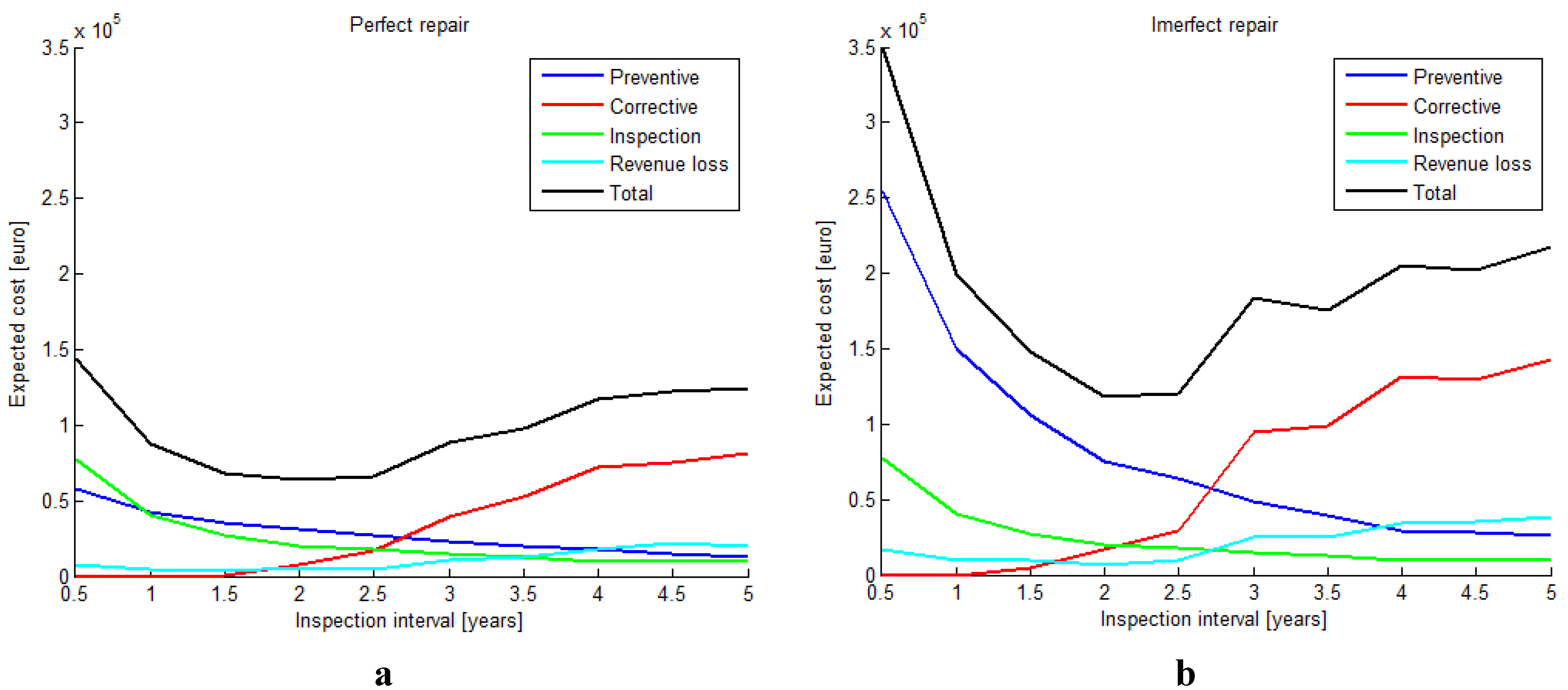

3.7. Cost Model

| Activity | Symbol | Value | Unit |

|---|---|---|---|

| Energy cost | CL | 0.04 | €/kWh |

| Inspection | CIN | 2,500 | € |

| Preventive repair | CREP | 10,000 | € |

| Corrective repair | CF | 100,000 | € |

3.8. Stochastic Model

| Parmeter | Dist | Mean | COV | |

|---|---|---|---|---|

| ain | LN | 10 | 0.15 | mm |

| A | LN | 1.2−9 | 0.05 | |

| m | N | 1.8 | - | - |

| λw | N | 0.8 | 0.05 | - |

4. Results and Discussion

4.1. Inspection Interval

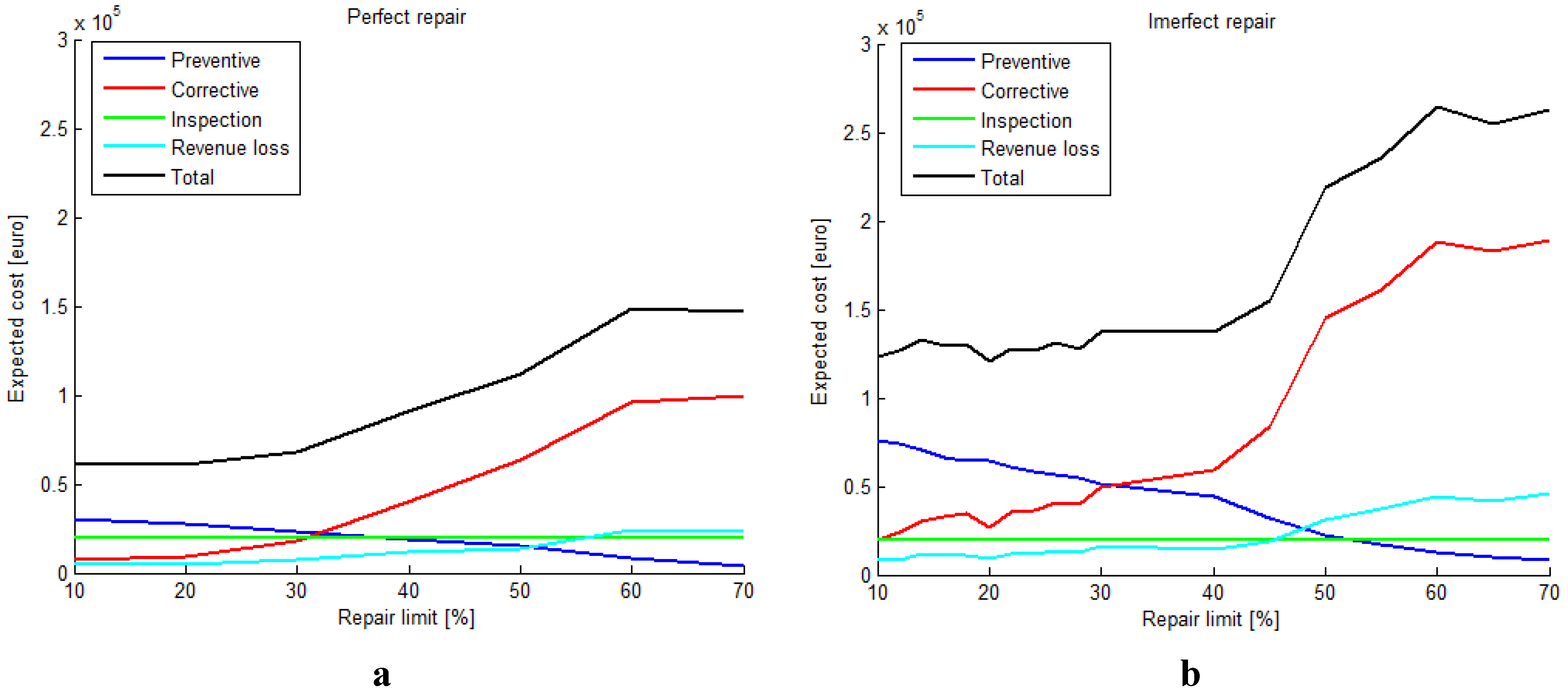

4.2. Repair Limit

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wouter, E.; Obdam, T.; Savenije, F. Current Developments in Wind—2009; Technical Report for Energy Research Centre of The Netherlands: Petten, The Netherlands, 2009. [Google Scholar]

- Chou, J.-S.; Tu, W-T. Failure analysis and risk management of a collapsed large wind turbine tower. Eng. Fail. Anal. 2011, 18, 295–313. [Google Scholar]

- Sørensen, J.D. Framework for risk-based planning of operation and maintenance for offshore wind turbines. Wind Energy 2009, 12, 493–506. [Google Scholar]

- Nielsen, J.J.; Sørensen, J.D. On risk-based operation and maintenance of offshore wind turbine components. Reliab. Eng. Syst. Saf. 2011, 96, 218–229. [Google Scholar]

- Jonkman, J.M.; Buhl, M.L., Jr. FAST User’s Guide; Technical Report for National Renewable Energy Laboratory: Golden, CO, USA, 2005. [Google Scholar]

- Yang, J.; Peng, C.; Xiao, J.; Zeng, J.; Xing, S.; Jin, J.; Deng, H. Structural investigation of composite wind turbine blade considering structural collapse in full-scale static tests. Compos. Struct. 2013, 97, 15–29. [Google Scholar] [CrossRef]

- Stephens, R.I.; Fatemi, A.; Stephens, R.R.; Fuchs, H.O. Metal Fatigue in Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Sørensen, J.D.; Frandsen, S.; Tarp-Johansen, N.J. Effective turbulence models and fatigue reliability in wind farms. Probab. Eng. Mech. 2008, 23, 531–538. [Google Scholar]

- Faulstich, S.; Hahn, P.; Tavner, P. Wind turbine downtime and its importance importance for offshore deployment. Wind Energy 2011, 14, 327–337. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Florian, M.; Sørensen, J.D. Wind Turbine Blade Life-Time Assessment Model for Preventive Planning of Operation and Maintenance. J. Mar. Sci. Eng. 2015, 3, 1027-1040. https://doi.org/10.3390/jmse3031027

Florian M, Sørensen JD. Wind Turbine Blade Life-Time Assessment Model for Preventive Planning of Operation and Maintenance. Journal of Marine Science and Engineering. 2015; 3(3):1027-1040. https://doi.org/10.3390/jmse3031027

Chicago/Turabian StyleFlorian, Mihai, and John Dalsgaard Sørensen. 2015. "Wind Turbine Blade Life-Time Assessment Model for Preventive Planning of Operation and Maintenance" Journal of Marine Science and Engineering 3, no. 3: 1027-1040. https://doi.org/10.3390/jmse3031027

APA StyleFlorian, M., & Sørensen, J. D. (2015). Wind Turbine Blade Life-Time Assessment Model for Preventive Planning of Operation and Maintenance. Journal of Marine Science and Engineering, 3(3), 1027-1040. https://doi.org/10.3390/jmse3031027