1. Introduction

The marine renewable energy (MRE) sector is emerging as a promising avenue for harnessing affordable and reliable power from ocean resources, such as tidal currents and waves. These energy sources hold particular promise for utility-scale generation [

1,

2], providing electricity to both coastal population centers and remote communities [

3], and for supporting industries like aquaculture and ocean research [

4]. To generate utility-scale electricity, MRE systems must be designed to operate in highly dynamic and corrosive environments, where structural components are continuously subjected to intense mechanical loads and long-term exposure to seawater [

5,

6]. This places significant demands on the materials and manufacturing processes used in critical components such as turbine blades. Furthermore, recent research underscores that hygrothermal aging is a critical challenge for composite marine structures, with water uptake driving plasticization, fiber–matrix debonding, and progressive mechanical degradation. Broader reviews confirm that such hygrothermal processes have contributed to structural failures in aerospace and turbine blades, emphasizing the need for robust durability assessment in marine energy applications [

7].

Tidal turbine blades, akin in design to wind turbine blades, are often fabricated from fiber-reinforced polymer composites because of their advantageous strength-to-weight ratio and inherent resistance to environmental degradation [

8,

9,

10]. However, the performance and durability of these materials can vary considerably depending on the selected fiber type (e.g., glass or carbon [

11]), matrix system (e.g., epoxy, vinyl ester, or thermoplastic [

12,

13,

14]), and manufacturing method (e.g., hand layup, vacuum infusion, prepreg molding [

15,

16]). Understanding how these choices affect both initial structural properties and long-term resistance to seawater degradation is essential for advancing the reliability and service life of MRE components.

Among emerging material options, recyclable thermoplastic resins such as Elium

® have attracted increasing attention because they can be processed using conventional infusion techniques while offering end-of-life recyclability compared to traditional epoxies. As a result, Elium-based composites have become a focal point for recent studies evaluating how novel thermoplastic matrices perform under the combined mechanical and environmental stresses faced by tidal turbine blades. For example, recent experimental studies on glass- and basalt-fiber composites reinforced with Elium

® show that while these systems often retain or even improve mode I fracture toughness through fiber bridging under seawater exposure, they exhibit notable reductions in flexural strength, tensile strength, interlaminar shear strength, and mode II toughness, in some cases exceeding 30–50% loss after immersion [

14,

17]. However, often these reductions in strength have been shown to be less severe than their epoxy counterparts [

17]. These studies highlight both the risks of performance degradation and the potential of recyclable thermoplastics and basalt fibers to provide more sustainable alternatives, provided that long-term aging mechanisms are understood and mitigated through design, processing, and testing protocols tailored to harsh ocean environments [

9,

18].

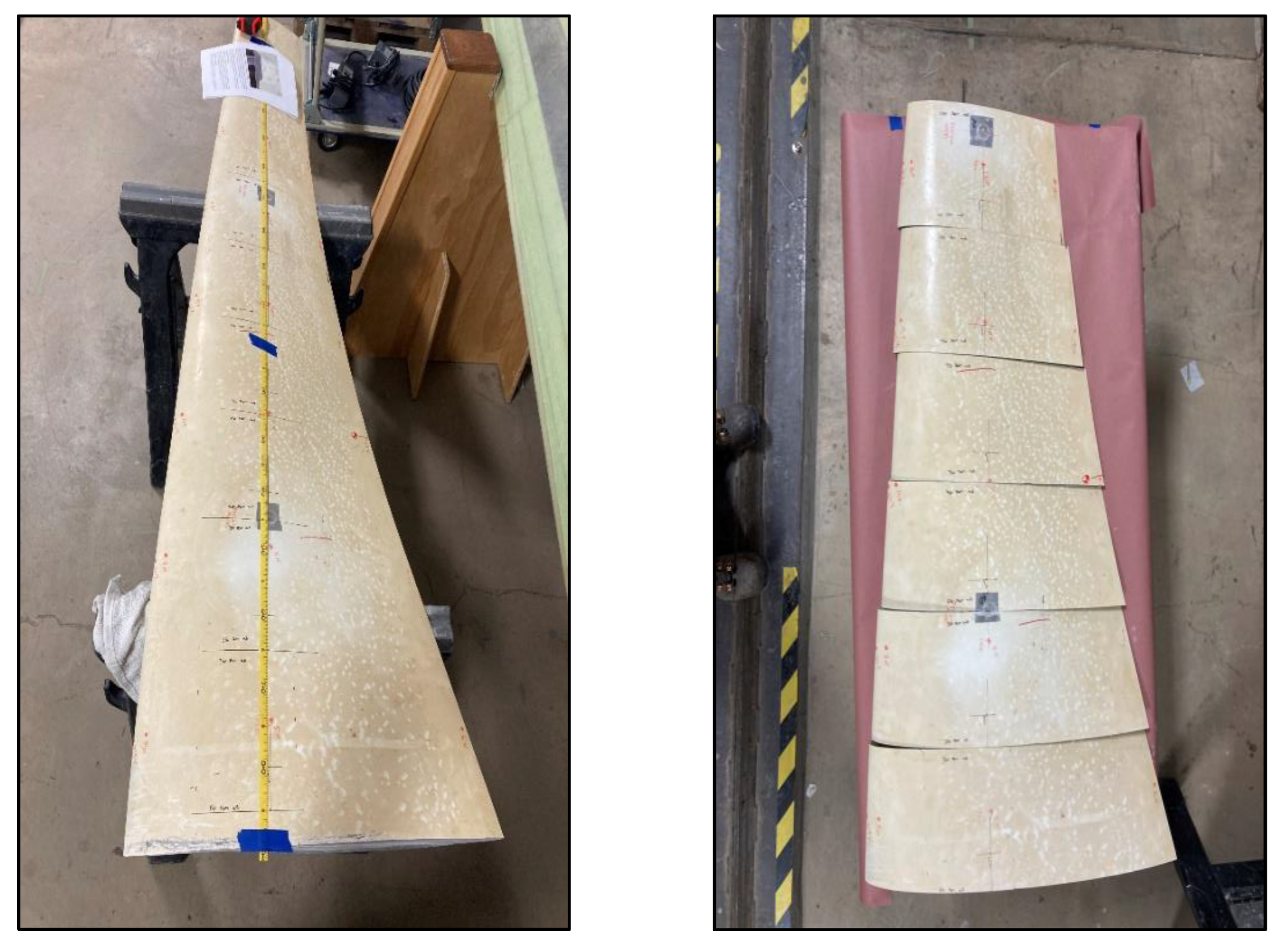

This study focuses on characterizing the hygrothermal and thermomechanical performance of as-manufactured composite blades fabricated using two different material systems: glass fiber-reinforced epoxy and glass/thermoplastic (Elium

®). Hexply M79 epoxy resin was selected as it is a compatible prepreg resin for the fiberglass materials used and is a material used commonly in the marine industry, and the Elium resin is a newer two-part reactive acrylic resin that was selected for its recyclability and potential for improved seawater performance [

19]. Blades made with both Elium resin and epoxy resin were field-tested for 6 months in New York’s East River as part of a collaborative tidal energy deployment between Verdant Power and the National Renewable Energy Laboratory (NREL). Following their retrieval, the blades were subjected to structural testing [

20] and in-depth material characterization [

16] at NREL. Details of the deployment can be found in Murray et al. [

21].

The objective of this work is to evaluate the effects of moisture and temperature exposure on the mechanical and thermal behavior of these composite materials. Through comparative analysis of water absorption, tensile strength, dynamic mechanical performance, and internal laminate quality, this research aims to inform future material selection and manufacturing strategies for tidal turbine blades and other composites operating in harsh marine environments. This study introduces an innovative comparison of epoxy and recyclable thermoplastic tidal turbine blades that were actually deployed in a marine environment, providing rare real-world performance data. By combining hygrothermal aging tests, thermomechanical characterization, and high-resolution XCT imaging, it advances understanding of how composite design and manufacturing influence long-term durability in harsh ocean conditions.

3. Results and Discussion

3.1. Hygrothermal Aging Results

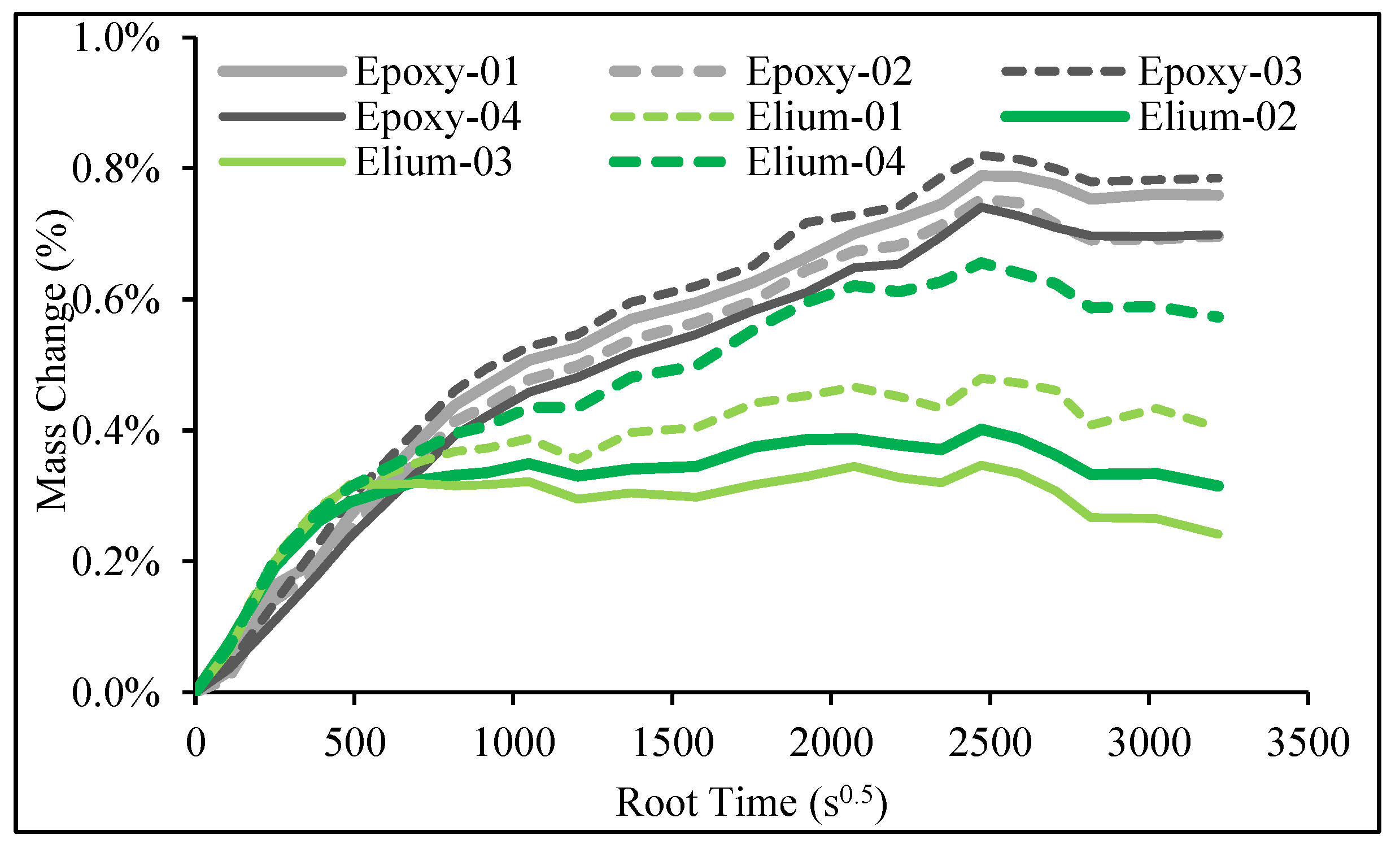

The results of hygrothermal aging are in [

16] and summarized here to provide additional context to the expanded work. The average changes in mass among different batches of specimens exposed to various environmental conditions are compared in

Figure 4. The control specimens experienced a measurable degree of desorption (weight loss) over the 4-month period in dry conditions at 50 °C. This suggests that the specimens had previously absorbed some moisture, though it remains unclear whether this resulted from submersion during the 6-month deployment at the Roosevelt Island Tidal Energy Project site or exposure to water during sectioning and cutting with wet saws.

The epoxy specimens exhibited an average mass increase of 0.76–0.78% over the 2–4-month period, with minimal variation (standard deviations of less than 0.04%) among individual samples. Additionally, the similarity in average mass changes between the 2- and 4-month periods suggests that full water saturation was reached before the end of the initial 2-month conditioning phase. Conversely, the Elium specimens displayed significant differences in mass changes between the 2- and 4-month batches, with an increase of 0.77% after 2 months and 0.54% after 4 months. There was notable variation between individual specimens, with standard deviations greater than 0.25%. The specimens in the 4-month batch showed a lower average mass increase compared to those conditioned for 2 months.

The lower average mass increase for the 4-month Elium batch (evident in

Figure 5), compared to the 2-month batch, may be attributed to the leaching of unreacted monomers or the hydrolysis of ester bonds, both of which promote the extraction of molecules from the composite into the seawater [

30]. The spar cap plies in the Elium blades contained 3% by area weight transverse backing tows, creating resin-rich regions between plies at the microscale, despite the overall higher fiber volume fraction observed at the macroscale. In contrast, the fibers in the epoxy blade’s spar caps were more evenly distributed and did not have these transverse backing tows, likely resulting in more consistent fiber volume fractions at the microscale. Since the specimens were cut along the laminate plane, some may have contained more resin than others, contributing to the observed variations.

Using the data presented in

Figure 5, water diffusion properties were determined by assuming one-dimensional Fickian diffusion [

24]. The maximum mass change was 0.776% ± 0.031% for epoxy and 0.471% ± 0.117% for Elium, and the diffusion coefficient (determined from the initial linear portion of the mass change/root time plot in

Figure 5) was 2.10 ± 0.12 (×10

−13) m

2s

−1 for epoxy and 12.1 ± 4.66 (×10

−13) m

2s

−1 for Elium. The higher water uptake of the epoxy is expected given the structure of the polymers. The epoxy thermoset has stoichiometric tertiary amine bonds and stoichiometric hydroxyl groups which participate in hydrogen bonding and afford higher water uptake. Although the Elium specimens absorbed less water on average than the epoxy specimens, their diffusion coefficients were 5 times higher. This indicates that the Elium specimens reached full saturation in a shorter time. This is consistent with the dense epoxy crosslinked network being more difficult for water to penetrate than the thermoplastic analogue. This is a crucial factor when designing structures that must account for transient water diffusion and its impact on environmental degradation.

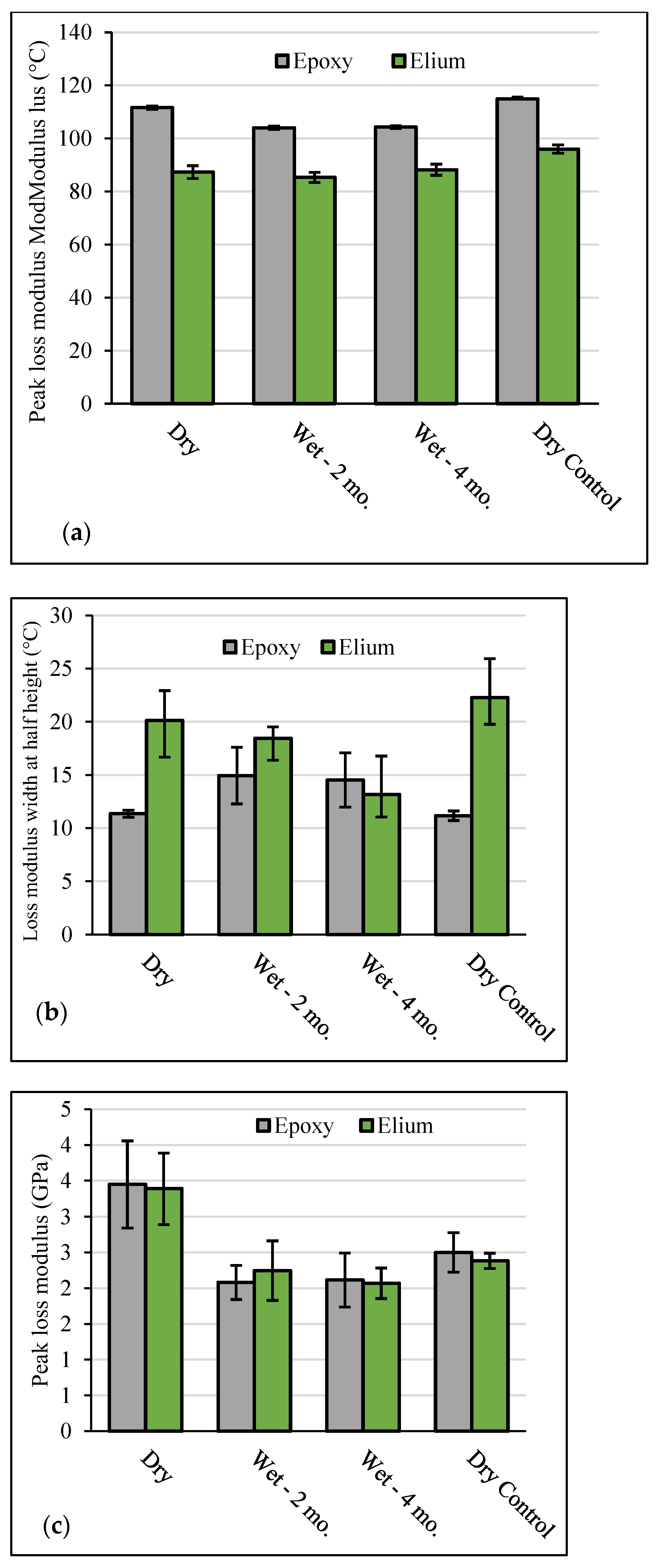

3.2. Dynamic Mechanical Analysis Results

DMA was leveraged to analyze the hygrothermal aging of the polymer matrix within the post-deployed composites through analysis of the loss modulus. The loss modulus garners insight into the viscous response of the composite materials, which is largely a consequence of the molecular motions of the matrix polymer. After a dynamic heating experiment (~25 to 180 °C, 3 °C/min, 20 μm, 1 Hz) in single cantilever, the distribution of the loss modulus with respect to temperature was then quantified and is shown in

Figure 6. Specifically, the distribution was quantified in three metrics: the temperature and the modulus value of the peak (the temperature and magnitude when energy loss is the greatest, respectively), and the temperature range of the loss modulus at half height (the temperature range when molecular motion is significantly observed).

The peak loss modulus temperature (

Figure 6a) is one way to quantify the glass transition temperature (Tg). From these results, the Tg of both resin systems increases from the initial dry control to the 4-month aged dry control which is representative of residual aging or post-curing during this time interval (112 °C vs. 115 °C for the epoxy composites and 87 °C vs. 96 °C for the thermoplastic composites). However, the epoxy system exhibits a reduced Tg compared to the dry control that does not further diminish with continued underwater aging from 2 months to 4 months (112 °C vs. 104 °C vs. 104 °C). The reduced Tg in the epoxy composites can be attributed to water plasticizing the epoxy network and lowering the glass transition temperature, which is further supported by analyzing the loss modulus width at half height (middle). A significant broadening of the loss modulus distribution is observed as the network becomes less ordered from the water penetration (11.3 °C range from the control vs. 15 °C range for the wet tested samples).

Conversely, the thermoplastic samples do not exhibit reduced thermal performance after hygrothermal aging, as the glass transition temperatures are not statistically different from the dry control. In fact, the wet thermoplastic samples show a tighter temperature distribution of the loss modulus, or the viscous response of the material, suggesting that the polymer network is becoming more definite and ordered through continued underwater aging. This attribute is supported by the speculation above that while the thermoplastic composites absorb less water, small molecules and additives leaching out of the composite result in a less plasticized and more uniform polymer matrix. In both cases, the magnitude of the loss modulus peak (

Figure 6b) decreases for the dried control, consistent with post-curing, and for the wet samples, which can be attributed to trapped water absorbing energy dissipation within the glass transition. Overall, hygrothermal aging impacts the thermal performance of both the thermoplastic and thermoset polymer matrix, to a greater extent than just thermal aging. Future MRE composites should be formulated for hydrophobicity to reduce the inclusion of excess, unbound additives.

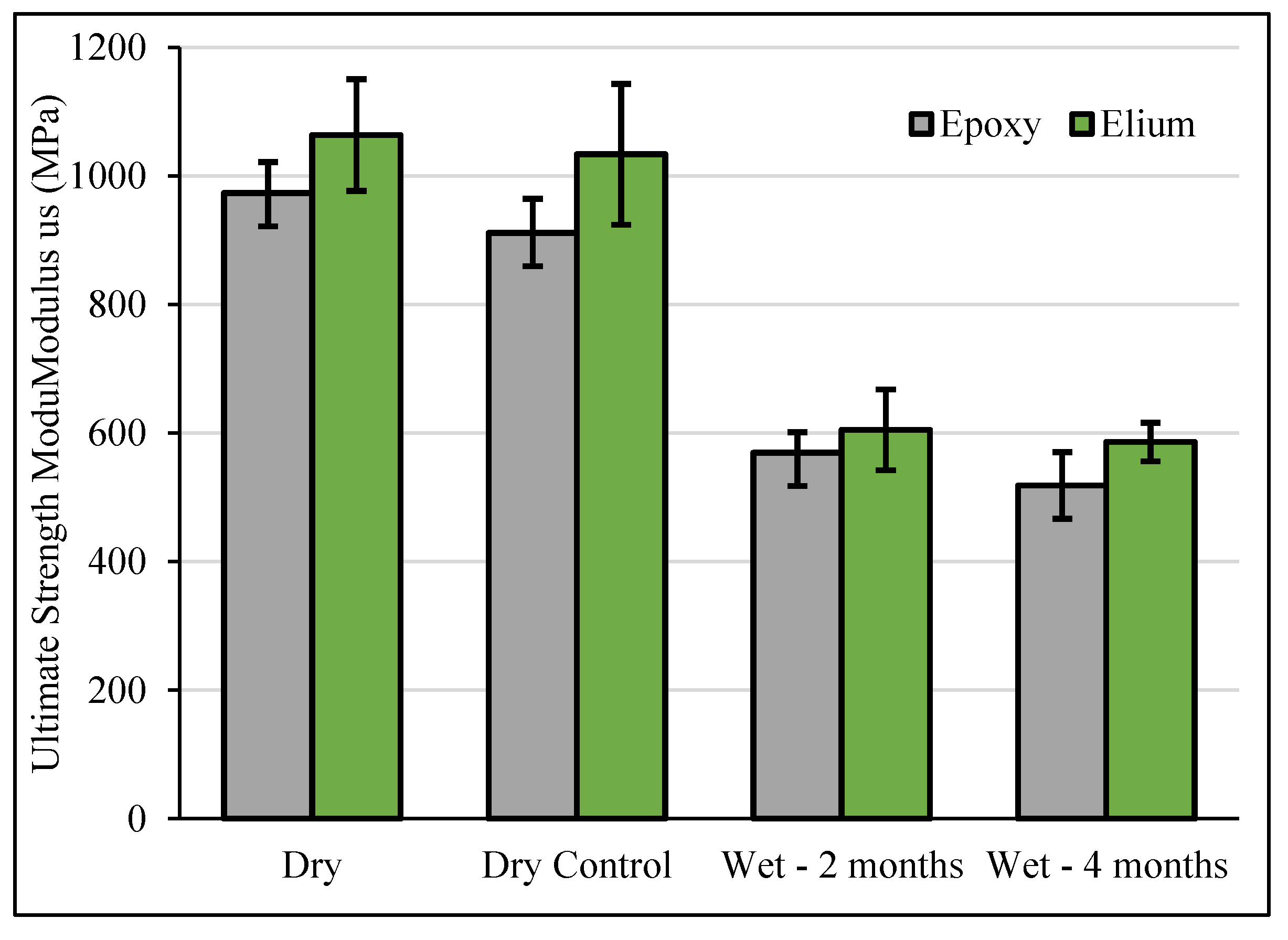

3.3. Tensile Characterization Results

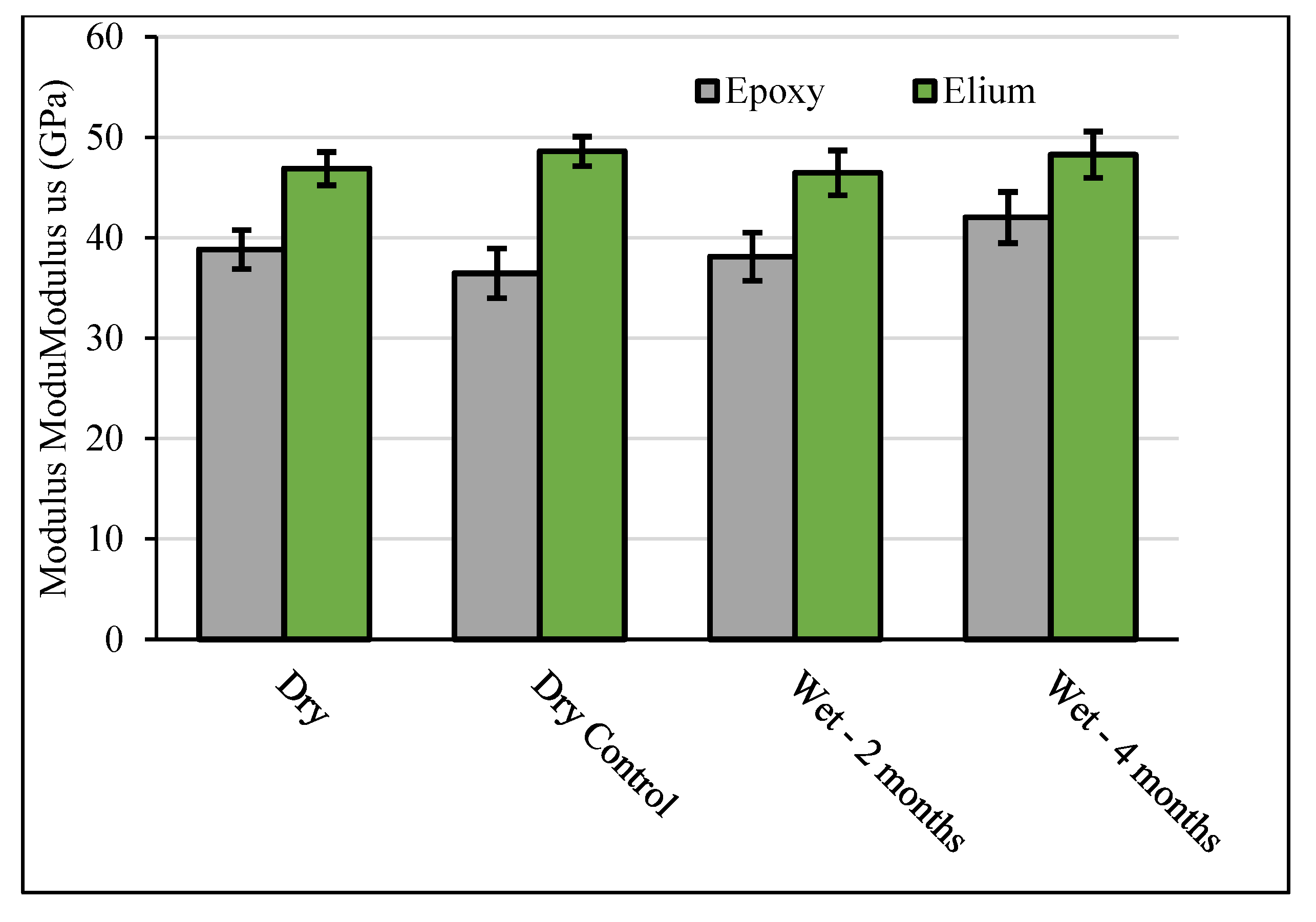

Figure 7 shows the ultimate strength, and

Figure 8 shows the modulus from tensile testing as a function of aging conditions and materials. The Elium specimens had on average 9% higher ultimate strengths and on average 18% higher elastic modulus than the epoxy specimens, likely due to the higher fiber loading. The modulus was not significantly affected by hygrothermal aging. However, the tensile strength decreased by 42% for the 2-month epoxy specimens and 47% for the 4-month epoxy specimens and decreased by 43% for the 2-month Elium specimens and 45% for the 4-month Elium specimens.

This marked reduction in strength, despite stable modulus values, reflects the dominant role of the fiber network in controlling elastic behavior, whereas tensile strength is more sensitive to the matrix–fiber interface. At the macro-scale, all specimens for all hygrothermal aging and control groups of both epoxy and thermoplastic matrices exhibited similar failure modes—explosive and within the gage sections. For the epoxy composites, moisture ingress can lead to plasticization of the polymer matrix, in which absorbed water disrupts secondary bonding and increases molecular mobility. This impairs the matrix’s ability to transfer stress to the reinforcing fibers, resulting in diminished strength. Some degree of plastisization is also possible with the Elium composites, but here the marked reductions in strength could be due to solvation of necessary additives that improve the thermoplastics performance and importantly, the matrix–fiber interface.

In addition to plasticization, hydrolytic degradation (the chemical breakdown of a material caused by reaction with water) may occur, particularly in resins containing reactive functional groups. Epoxy systems cured with amine hardeners can undergo hydrolysis at unreacted amine sites, while acrylic-based thermoplastics like Elium may degrade at ester linkages. Hydrolysis generates hydrophilic groups, leading to resin swelling and further mechanical softening.

3.4. X-Ray Computed Tomography Results

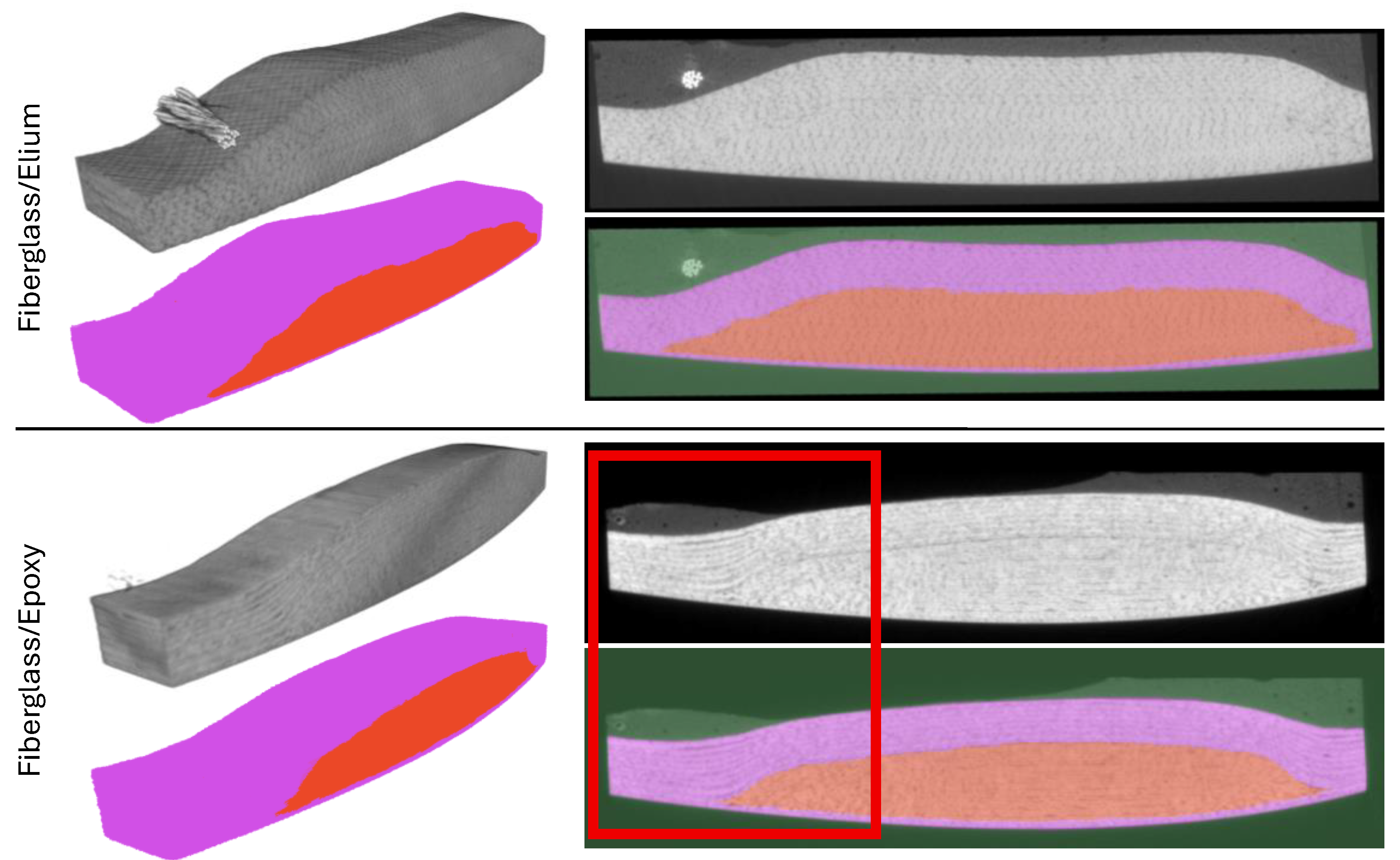

The results from the image segmentation steps outlined in

Section 2.5 are shown in

Figure 9. In these images, renderings of the image data in both 3D (left) and 2D (right) are shown with corresponding segmentation results for the fiberglass/Elium composite (top) and the fiberglass/epoxy (bottom). The segmentation colors for pink, red, and green for 2D correspond to the skin, spar cap, and background, respectively. Visual inspection of the image data showed no evidence of cracks, large defects, or large resin-rich regions for both samples. For the fiberglass/epoxy, evidence of incomplete compaction between layers can be seen from

Figure 9 where ply separation is observed in regions of increased curvature towards the left and right edges as shown.

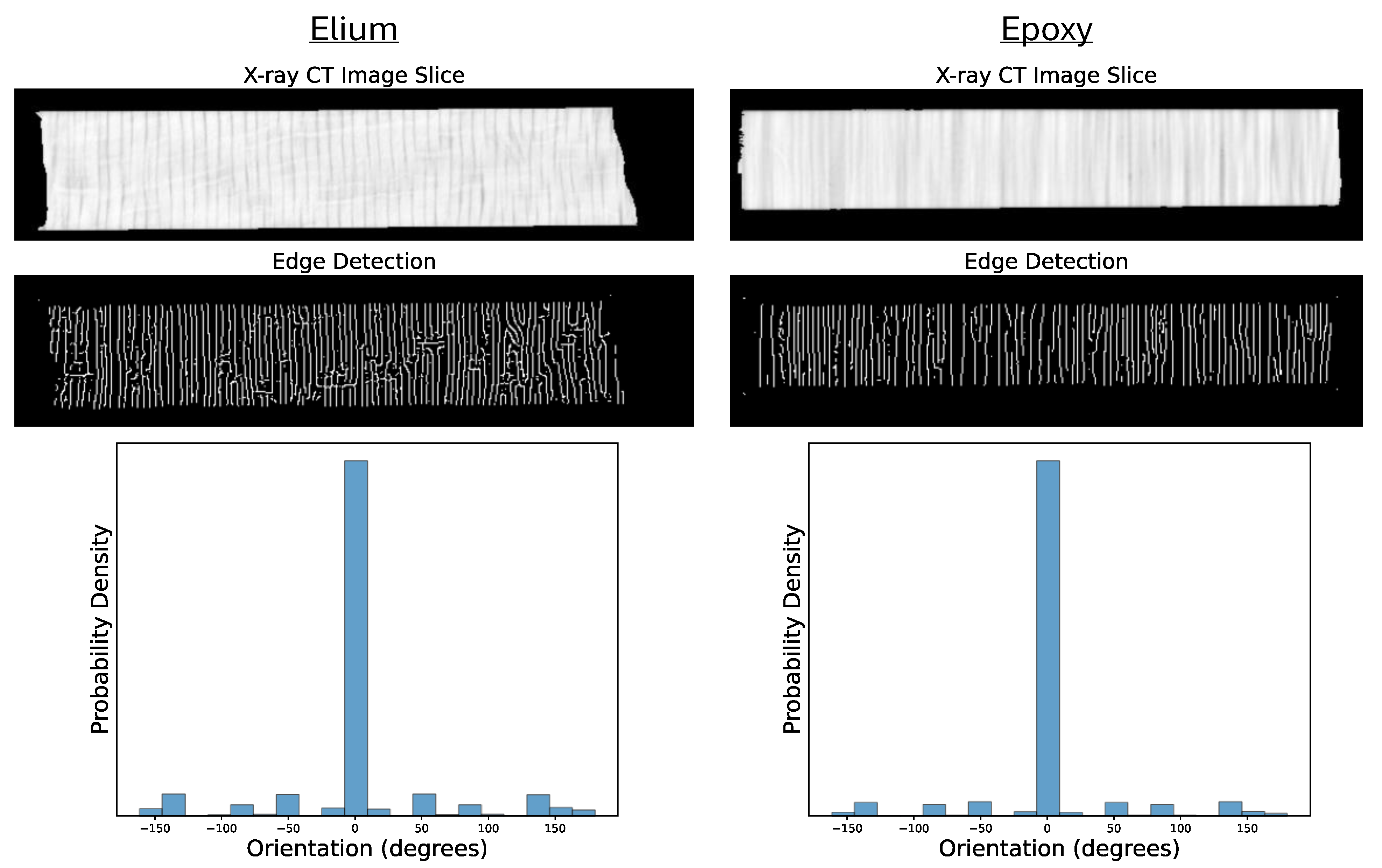

The above results indicate qualitatively that the quality of both composite systems was high after manufacturing. Furthermore,

Figure 10 shows the results from calculating the local orientation. The top row shows a representative image slice where the skin and background were colored black, the middle row shows the results from edge detection, and the bottom row shows the probability density distribution of extracted local orientations. Note that an orientation of “0 degrees” corresponds to a vertical orientation shown in the representative image slices.

From these results, overall misalignment in tow edge orientation was minimal. Slightly higher misalignment can be determined for the fiberglass/Elium composite compared to the fiberglass/epoxy composite. Evidence of misalignment for fiberglass/Elium can be seen in

Figure 10 where the edges of horizontal striations were detected. However, these occurrences do not significantly skew the distribution.

Overall, analysis of the XCT images showed that both composites were manufactured with high quality: no large voids or cracks were present, and the degree of misalignment was low. The above analysis was only performed on one sample from each resin type studied. However, based on the good quality of the samples investigated through image analysis, it is anticipated that similar results would be obtained for other samples examined in this study. Furthermore, the high-quality in sample manufacturing suggests that sample-to-sample variability for mechanical results is likely to be low, which can be observed from

Figure 6,

Figure 7 and

Figure 8. Spread in measurement distributions likely stems from matrix or fiber–matrix dominated effects compared to mechanical behavior of the fibers alone.

Further insights can be taken from the resulting architecture captured via XCT to answer competing mechanism on diffusion effects. It was noted from

Figure 5 that the fiberglass/Elium blades exhibited greater diffusion compared to their epoxy counterpart. Besides the inherent differences in water uptake between thermoset and thermoplastics, the underlying architecture likely plays a role on diffusion rates. The fiberglass/Elium blades consist of individual tows of fiber glass within a given ply. Gaps between tows are larger and longer compared to gaps observed from the fiberglass/epoxy blades (e.g., dark gray regions shown in

Figure 10). These larger gaps provide preferential pathways for water to diffuse into the composite, which leads to higher diffusion coefficients. For the fiberglass/epoxy blades, the increased tortuosity of individual fibers and the surrounding epoxy likely leads to lower diffusion coefficients.

4. Conclusions

This study provides an in-depth evaluation of the hygrothermal response and thermomechanical behavior of as-manufactured glass fiber-reinforced epoxy and thermoplastic (Elium®) tidal turbine blades. Through a combination of accelerated conditioning, mechanical testing, and material characterization, differences in water absorption, diffusion behavior, and strength retention between the two composite systems were identified.

Material characterization through X-ray computed tomography (XCT) showed that both composite turbine blades had little evidence of manufacturing-induced defects and minimal fiber misalignment. While epoxy composites demonstrated more consistent water uptake and superior resistance to early-stage diffusion, the Elium-based thermoplastic laminates showed higher thermal property retention, albeit with significantly faster moisture ingress and greater variability. Furthermore, evidence from XCT showed increased matrix gaps between tows, which likely contributed to the increased moisture ingress compared to the epoxy composites. Importantly, both material systems suffered substantial reductions in tensile strength—exceeding 40%—following prolonged water exposure, emphasizing the vulnerability of fiber–matrix interfaces to moisture-induced degradation, even when elastic moduli appeared unaffected. No statistical changes in moduli were observed for both the epoxy and thermoplastic composites due to hygrothermal aging. This implied that strength degradation was due to degradation of the matrices and fiber/matrix interfaces and not the fibers themselves. Additionally, the DMA results showed that glass transition temperature for was reduced for the epoxy composite specimens and unaffected for the thermoplastic composite specimens, indicating that the hygrothermal aging process had a greater impact on the viscoelastic properties of the epoxy composites.

These findings carry significant implications for the MRE industry. Material systems must not only perform structurally under demanding loads but must also maintain their integrity in harsh, high-moisture environments over extended service lives. This study reinforces the importance of integrating environmental durability into early-stage design decisions, and it highlights the need for advanced resin formulations, robust manufacturing controls, and protective surface treatments. As the MRE sector continues to mature, the insights from this work will help developers make informed choices in material selection, improve predictive models for long-term degradation, and ultimately support the deployment of more resilient, reliable tidal energy systems.