1. Introduction

The lifting method and float-over method are the two most commonly used for installing topsides of offshore platforms in the recent decades. The selection of installation technique relies on water depth, topside weight, environmental conditions, and numerous additional factors. The float-over technique is favored when the topside weight surpasses the lifting capabilities of the accessible heavy lift crane [

1]. A float-over installation barge facilitates the transport of the topside into position. Subsequently, the topside is transferred onto the jacket using the Leg Mating Unit (LMU), Deck Support Unit (DSU), and fender systems.

The conventional float-over installation is operated by towing tugs and auxiliary lines. By the cooperation of towing tugs, mooring cables and mating lines, the barge is steered into the slot for mating and load transfer [

2]. Most research emphasizes this approach, particularly the nonlinear dynamics of vessel motions and the intricate interactions among the barge, topside structure, and impact-absorbing system.

Xu et al. [

3,

4] investigated the complex multi-body hydrodynamics of two or three moored barges by experimental and numerical tools, revealing that the hydrodynamic interactions are much more complicated than a single barge. Dessi et al. [

5] used rigid and elastic models to analyze the connection between the barges and the topside. The design considerations of LMU are well discussed in Yuan et al. [

6] and Choi et al. [

7]. A fully coupled time-domain model was established by Chen et al. [

8], which captured the nonlinear dynamics of barge motions, impact-absorbing system and mooring systems. The simulation results agreed well with the commercial computational software. Bai et al. [

9] presented the experimental analysis of an innovative installation method with the rapid transfer technique, and found that the trim angles synchronize with the topside before the second jack-down operation. For the twin-barge float-over system, Bai et al. [

10] conducted experimental researches on two identical barges elastically hinged with the topside in heading, beaming and quartering waves. Results illustrated that the shielding effect had a great influence on the amplitude and phase-difference of the barge motions. More state-of-the-art progress of numerical modeling, model test and in-site measurement of float-over systems is summarized in Fang et al. [

11] and Qin et al. [

12].

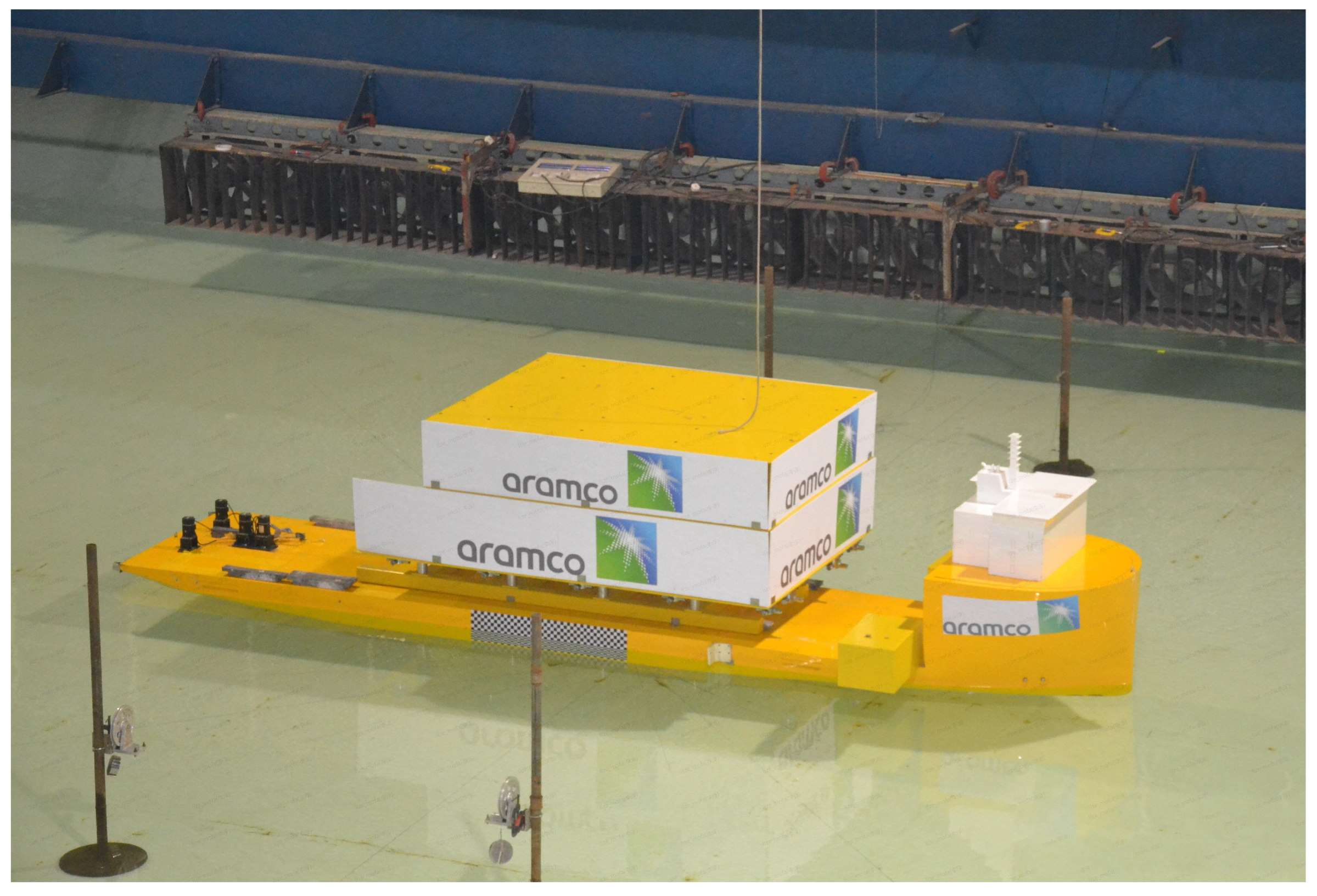

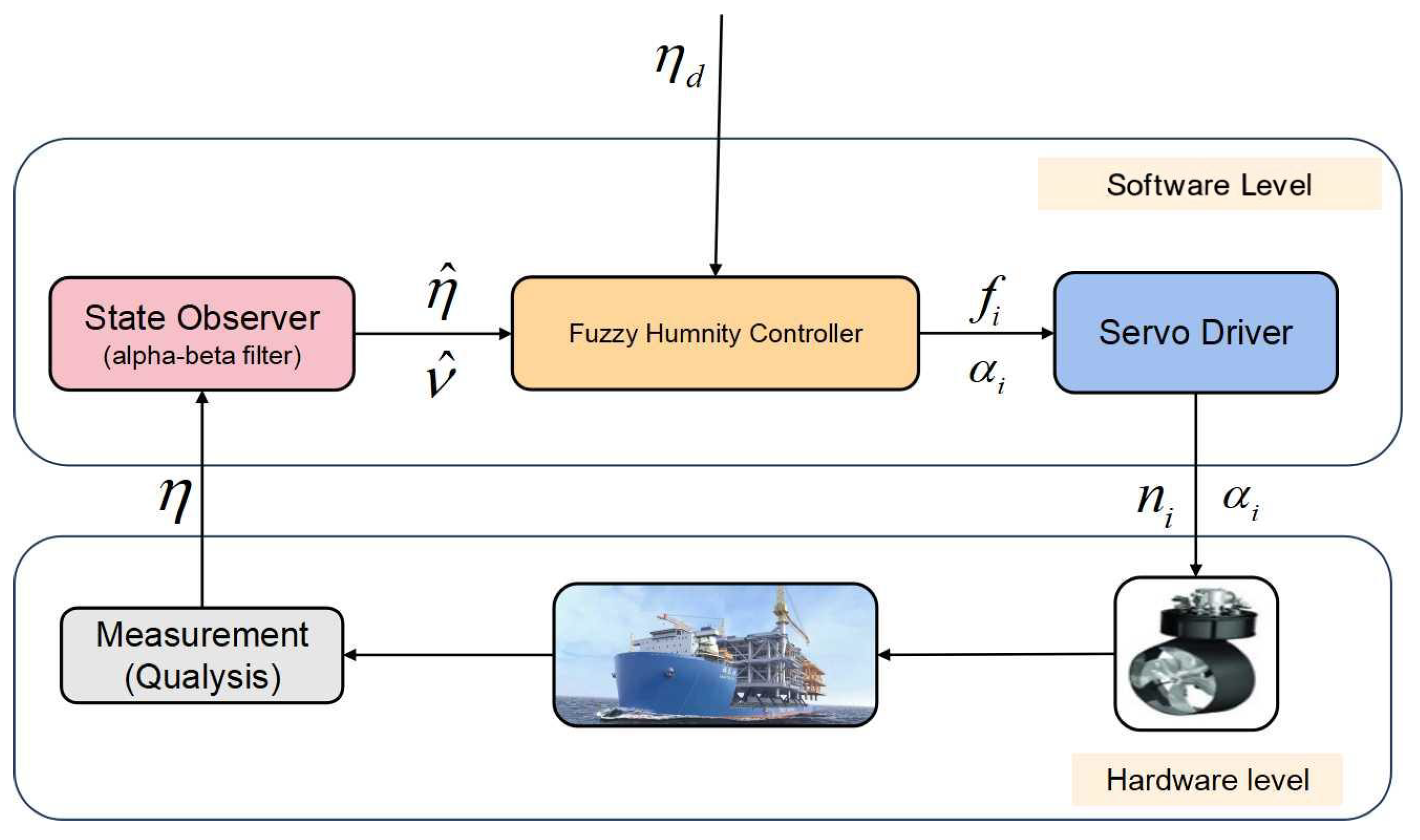

The dynamic positioning (DP) float-over installation is another float-over approach by using a semi-submersible vessel (see

Figure 1). Several DP float-over installation projects have been performed in the last decades, such as Majan Increment Project and Huizhou 25-8 Project. However, the related theoretical studies are limited, particularly concerning the design of the DP controller. Bakar [

13] presented the float-over methodology for the topsides using portable DP2 vessel and the technical challenges for offshore operation. A Deck Transportation Vessel (DTV) was upgraded with DP2 capability by adding two portable azimuth thrusters. Yi et al. [

14] simulated the DP float-over installation with considerations of the sway and surge fenders. He et al. [

15] established a time-domain simulation program to analyze the motion of DP vessel as well as the fender forces. The simulation results agree well with the model test. Wang et al. [

16] investigated the dynamic responses of a twin-barge float-over system integrating flexible connections and DP system. Both numerical simulations and model tests were conducted to analyze the character of the coupled system.

For the DP float-over installation, an advanced control strategy must be designed to ensure the vessel is entering the slot and keeping the impact with fenders within an acceptable limit. The position-keeping problem in float-over installation has been extensively studied by researchers. In addition to traditional proportional–integral–derivative control (PID), model reference adaptive systems, self-tuning regulators, gain scheduling, machine learning methods, real-time parameter estimation, and many other control techniques are adopted to control the vessel motion [

17]. However, most of the control methods require accurate model parameters, which is hard to obtain in practical applications. To deal with the model uncertainty and unknown disturbances, fuzzy logic control is adopted. Yamamoto and Morooka [

18] designed a fuzzy controller for the DP system of a semi-submersible platform, but only sway motion was considered in their simulation. Tzung-Hang Lee and Lin [

19] presented a fuzzy logic controller which takes the vessel heading, yaw rate, position errors and velocity as inputs, and generated the rudder angles, propeller thrust and later bow thrust through fuzzy inference. However, these methods may not perform well in a real complex environment. The control action is just calculated according to the position and velocity feedback, and its relationship with the external excitation is unclear. In this paper, we consider the external loads acting on the vessel, which can be categorized into two parts: dynamic part and static part. The dynamic part is time-varying but has a zero average value. The static part varies very slowly with time and has the same direction as the wind, wave, and current.

Based on the above consideration, this study presents a novel human-inspired fuzzy controller for float-over installations in marine operations. The control system integrates vessel dynamics through position, heading, and velocity measurements to generate control forces. These forces split into dynamic and static components based on human-like logical reasoning. The dynamic component functions as a proportional–derivative (PD) controller, while the static part implements an enhanced integral control with temporal accumulation. The accumulation nature of the static force fundamentally solves the phenomenon of integral saturation and is more flexible than traditional integral control. We validate the controller’s performance through model tests on a DP barge under multi-directional environmental loads. The paper structure flows from experimental setup through numerical modeling and controller design to results and conclusions. This research advances marine control systems by mimicking human decision-making patterns in vessel positioning tasks.

2. Experimental Set-Up

The model-scale experimental investigation is performed at Ocean Engineering Basin, Shanghai Jiao Tong University. The scaling ratio is selected as 1:40 according to the physical capability of the basin, and the Froude scaling law is adopted in the experiment. The model tests examine all the float-over installation phases, with focus on standby and docking operations. The basin measures 50.0 m in length, 30.0 m in width, with 6 m maximum depth capacity. The facility features a variable-depth bottom system (0–6 m range) and can simulate multiple environmental conditions. Motion tracking utilizes an advanced non-contact optical system to record 6-Degree of Freedom (DOF) vessel responses under combined wind–wave–current environmental loads. The 3-DoF sensors monitor fender forces throughout the tests.

2.1. Super X-Class Model

The experimental model of the semi-submersible super X-class vessel replicates key features of the prototype, including major dimensions, hull geometry, mass distribution, and inertial characteristics. The model also maintains accurate displacement values and draft measurements. The model meets ±3% of the specified prototype values for mass and moment inertia. The hull dimensions, center of gravity, and displacement are within ±1%. Major parameters of the barge are listed in

Table 1, and the photo of the vessel model is shown in

Figure 2.

The experimental super X-Class vessel model comprises a wooden core structure with glass-fiber-reinforced plastic (GFRP) coating for waterproofing. The hull design incorporates dedicated compartments for ballast placement, enabling precise adjustment of vessel mass properties, including weight distribution, gravitational center, and rotational inertia parameters. The internal architecture accommodates propulsion components, specifically servo motors and drive systems for thruster operation. Enhanced structural reinforcement is implemented in the deck assembly to mitigate deformation risks from topside loading conditions. Notable features include lateral square panels affixed to the topside structure, specifically designed to simulate wind exposure area characteristics.

The model-scale jacket structure, fabricated from steel, adheres to precise project specifications. This model replicates actual water depth conditions without truncation, maintaining authentic height proportions. The jacket base is securely anchored to the tank floor to eliminate oscillations during docking and undocking operations. The topside consists of an integrated deck that is to be installed on top of the jacket. The topside component exhibits high visual fidelity while maintaining critical physical parameters—mass distribution, structural rigidity, gravitational center, and wind exposure area.

2.2. LMU, DSU and Fender Model

The LMUs are positioned on the main legs of the jacket and barge support structure. Each jacket leg features a stabbing cone at its apex. The LMU system incorporates receiver cones, which are mounted beneath vertical elastomeric shock absorbers. This configuration prevents direct steel-to-steel contact during the mating phase, thus protecting the structural integrity of both topside and jacket components.

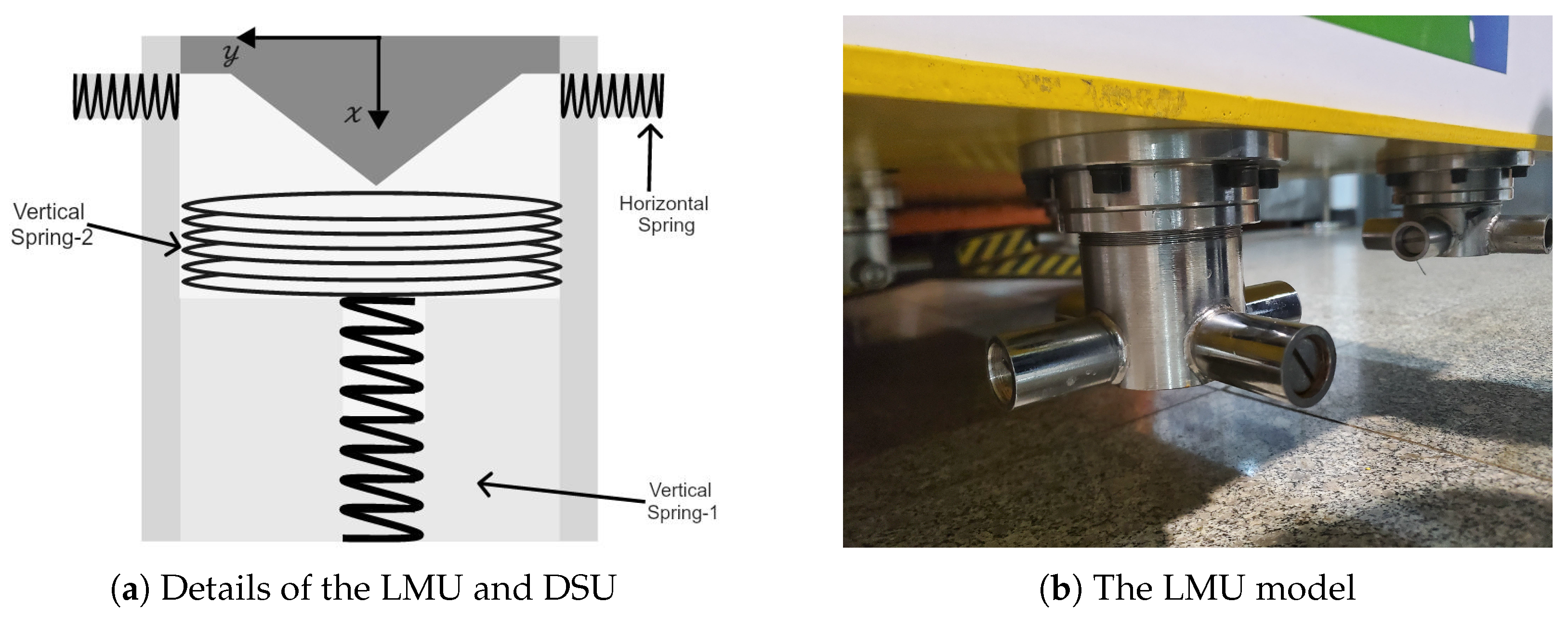

To model the horizontal and vertical stiffness, the LMU is designed as shown in

Figure 3 with a local coordinate system. The DSU is installed on the deck to stabilize the topside. It functions as a shock absorber, reducing impact loads between the topside and the vessel. It restricts both vertical and horizontal movements of the topside during float-over installation. The DSU mounted on the vessel has similar components to the LMU, while the horizontal elastomer of DSUs fixed on the vessel is replaced with the friction material in the receptor cone.

Sway fenders are positioned on each jacket leg to limit the sway motions of the vessel and reduce impact loads on the jacket legs during the mating operation. They are numbered from A1–A4 on one side and B1–B4 on the other side. A nominal gap of 2.5 mm in model scale between the vessel side shell and sway fenders is maintained. Surge fenders are installed on the jacket legs in order to attain perfect pre-mating position prior. By putting a series of known weights on the fender model, the corresponding pressure is measured through a resistive sensor. The stiffness of the mechanical springs matches the required performance characteristics of the sway (reaction force = 500 MT, deflection = 300 mm) and surge fenders (reaction force = 150 MT, deflection = 400 mm). The experimental configuration of LMU, DSU, and fenders is depicted in

Figure 4.

2.3. Thruster Model

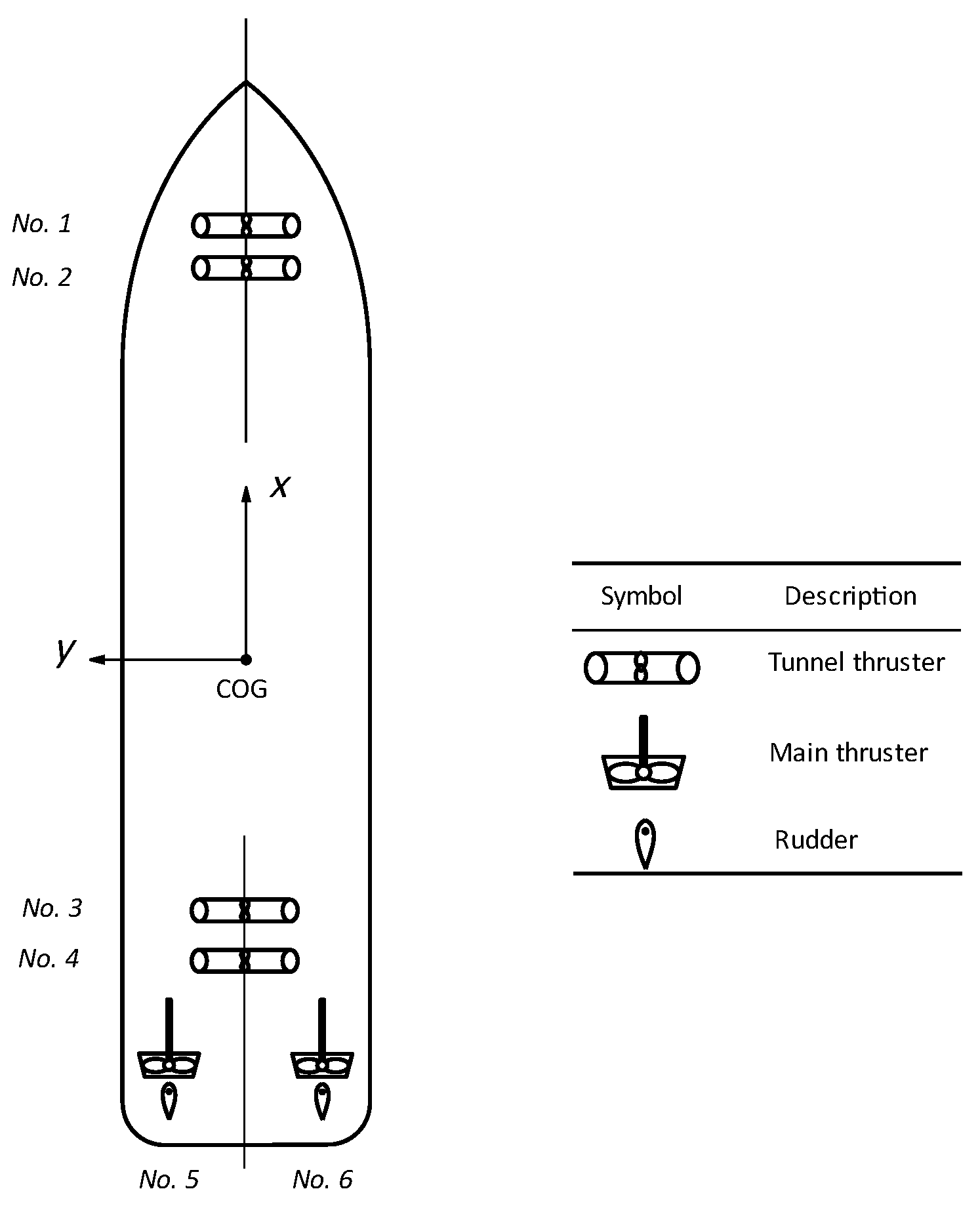

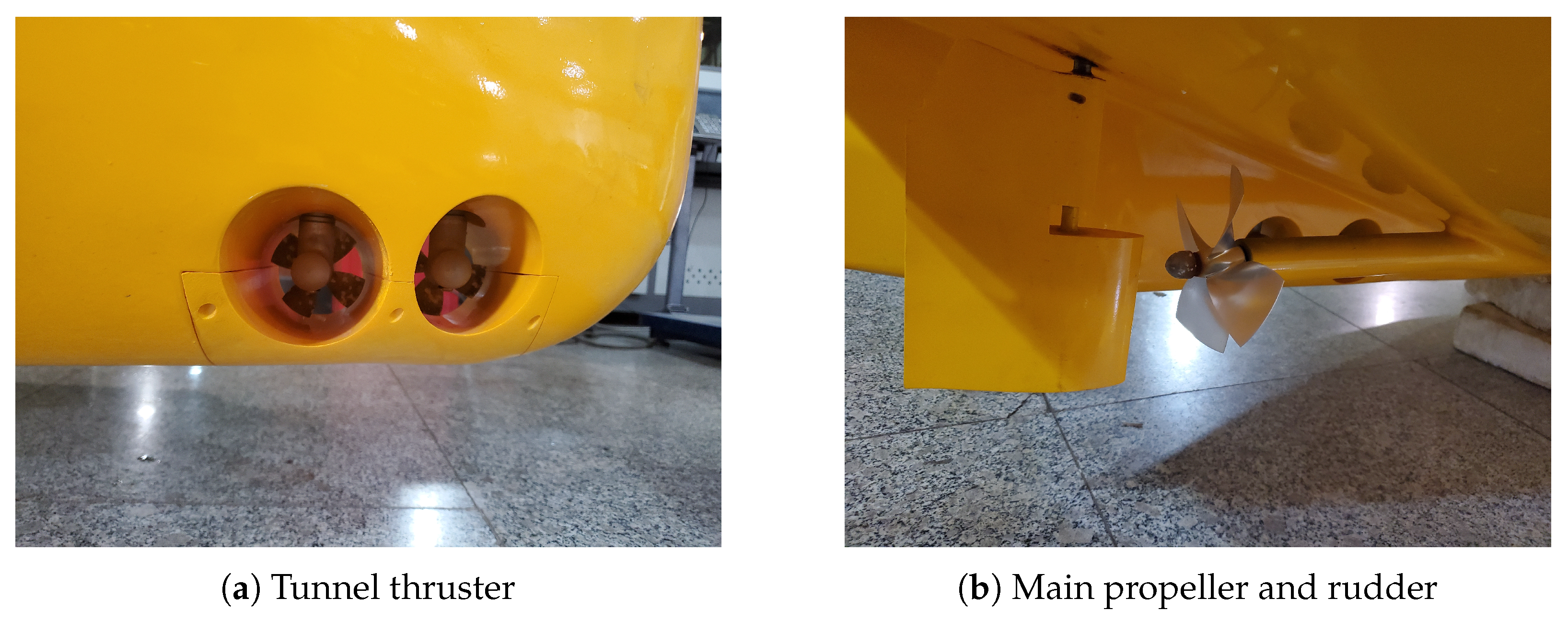

The super X-class vessel model is equipped with four tunnel thrusters (76 mm in diameter) and two main propellers (120 mm in diameter) with rudders. The Ka-470 series propellers are applied in experiments. The thrust configuration is illustrated in

Figure 5 and the physical thruster models can be seen in

Figure 6. The location and maximum thrust are detailed in

Table 2. These thrusters are controlled by the proposed improved fuzzy controller with the real-time motion data provided by a motion-tracking system. The Alpha–Beta filter is used to reconstruct the low-frequency motions from the measured data, as it only needs to adjust a few parameters and does not need the accurate system parameter. The controller then gives the control thrust based on position and velocity errors based on the thrust allocation algorithm [

20]. An onboard controller receives the feedback thrust commands from an onshore system and distributes this over the thrusters. Each servo motor drives each propeller individually [

21]. This model-scale DP system emulates the operational characteristics of an authentic DP mechanism, thereby producing verisimilar positioning behavior and control responses.

4. Results and Discussion

In order to validate the efficacy of the proposed improved fuzzy controller, a series of model tests are conducted using this controller for the standby and docking of super X-class vessel. The sampling frequency of the measured data is set to 50 Hz, while the control frequency is 2 Hz to avoid wear and tear of the thrusters. The results are analyzed by taking the statistics from the time histories and presented in prototype scale.

Stern heading (0 deg), stern quartering (45 deg) and beam (90 deg) seas are simulated in the physical model-scale experiments. The wind, wave, and current are applied in the same direction. A JONSWAP spectrum is used to generate the irregular waves. The environmental conditions used in the model test are based on the measured data at the practical installation site and presented in

Table 10. Before the standby and docking test, single wind and single current tests are conducted to calibrate the speed and measure the environmental loads acting on the vessel for the parameter adjustment of the proposed fuzzy controller. All data in the model test are measured through resistive sensors installed on the barge.

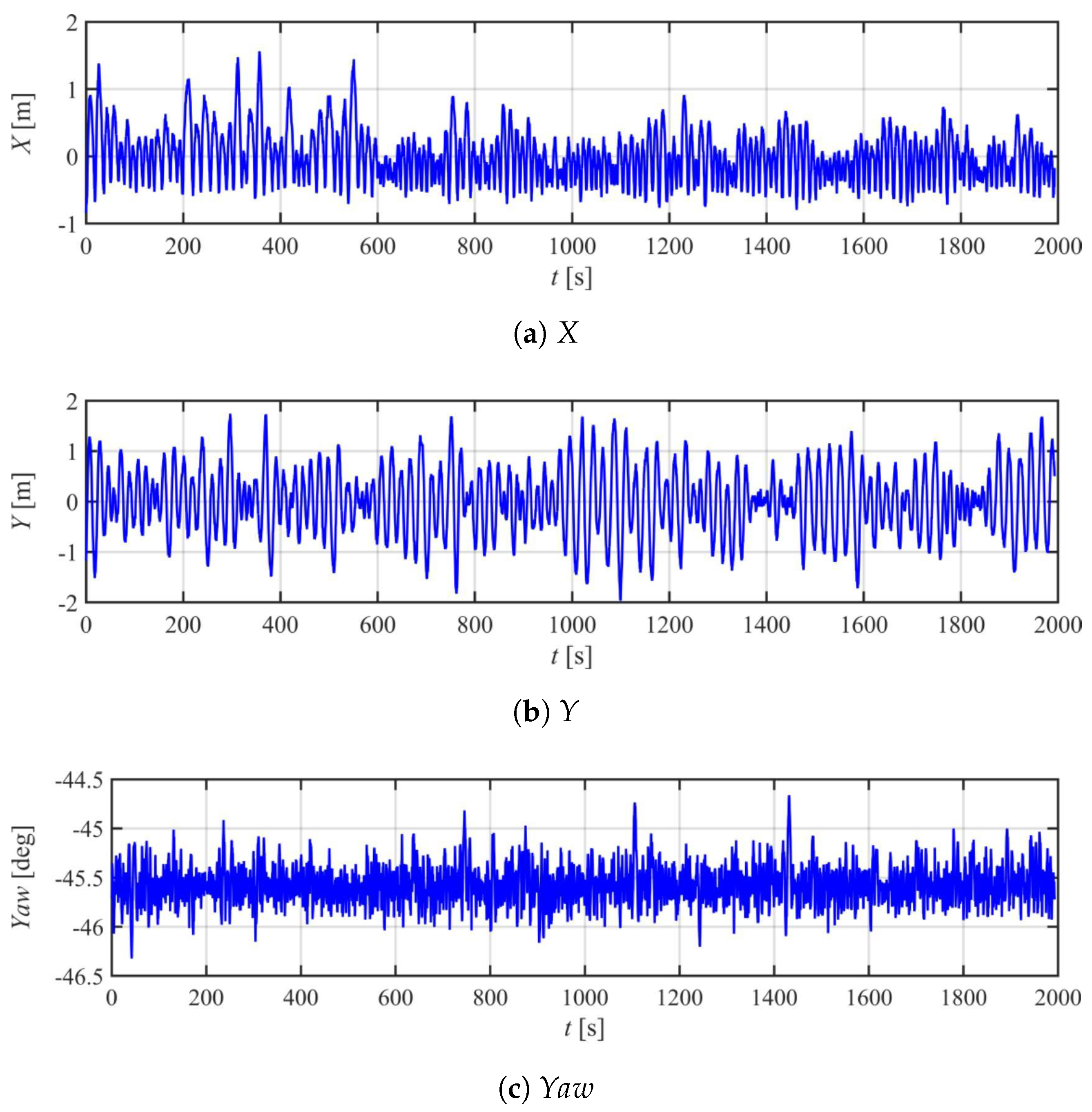

4.1. Standby Tests

Standby in the float-over installation means the station-keeping situation for the waiting operation window. In physical experiments, the vessel model equipped with the DP control system is dynamically positioned at a specified point under the influence of wind, wave, and current. The positioning accuracy, particularly regarding the headings, is of importance in assessing whether the vessel can successfully dock into the slot without any risk of collision. The snapshots of the standby tests are given in

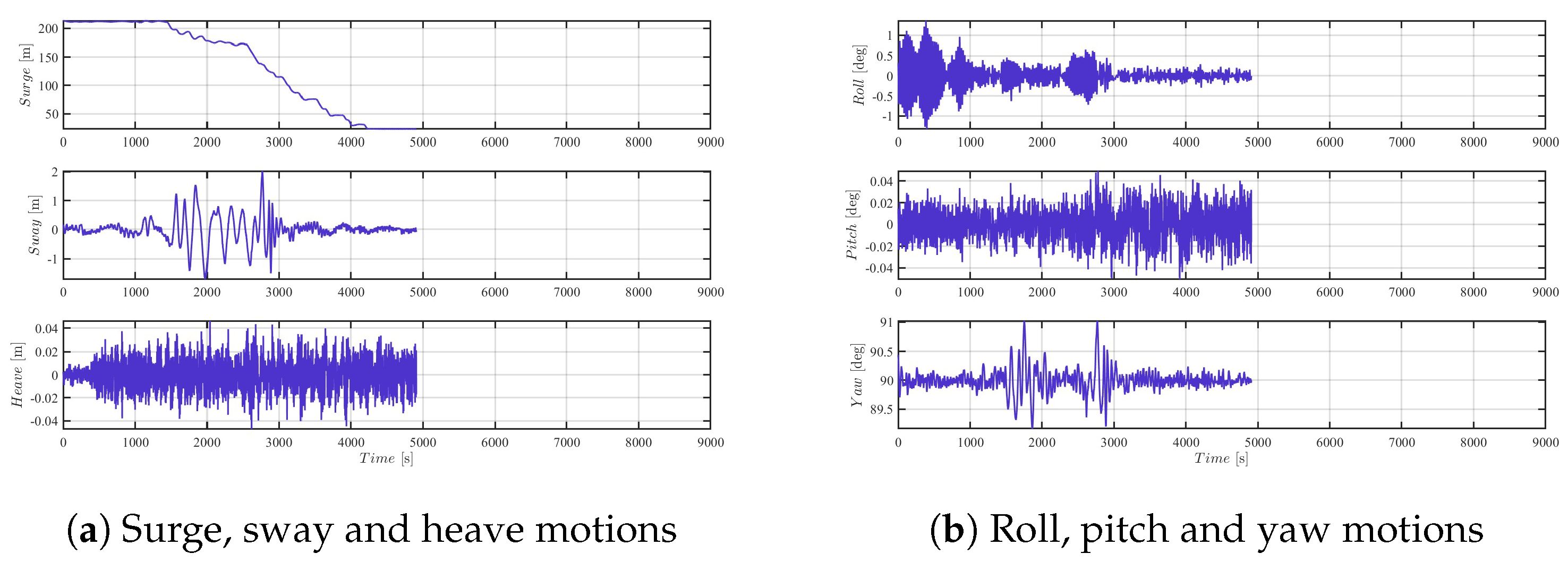

Figure 10, and corresponding motions in one case are presented in

Figure 11,

Figure 12 and

Figure 13. The motion statistics are summarized in

Table 11.

It can be seen that the vessel is well stabilized around the equilibrium position. For the positioning accuracy in the X direction, it is basically within the range of [−2 m, 2 m] for the case of 0 deg. This reduces to [−1 m, 1 m] for the cases of 45 deg and 90 deg. Because the environmental loads always come from X direction, only the two main propellers can help to keep the vessel position. The radius of the propeller is relatively large (120 mm) and must be continuously switched between forward and reverse rotation around the equilibrium, so it is very hard to achieve a better positioning accuracy. For the case of 45 deg and 90 deg, the four tunnel thrusters will work to achieve a more stable control in X direction.

It is indicated that there is a small constant error of about 0.5 deg around the expected heading direction. The variation range of the yaw angle is basically kept in [−0.5 deg, 0.5 deg] for all the three cases. In fact, considering the scale ratio of 1:40, 2 m in the graph corresponds to 5 cm in model-scale. This positioning accuracy is very high for a nearly 6 m vessel model exposed to environmental loads.

The standby stage provides a very important circumstance for the improved fuzzy fuzzy controller to adjust the parameters, such as the absolute value in

Table 5 and

Table 7, as well as the dynamic controller gain

and static controller gain

. According to the positioning situation of the vessel, we carefully tune all the control parameters to achieve a reasonable combination, which will be used in the following docking stage.

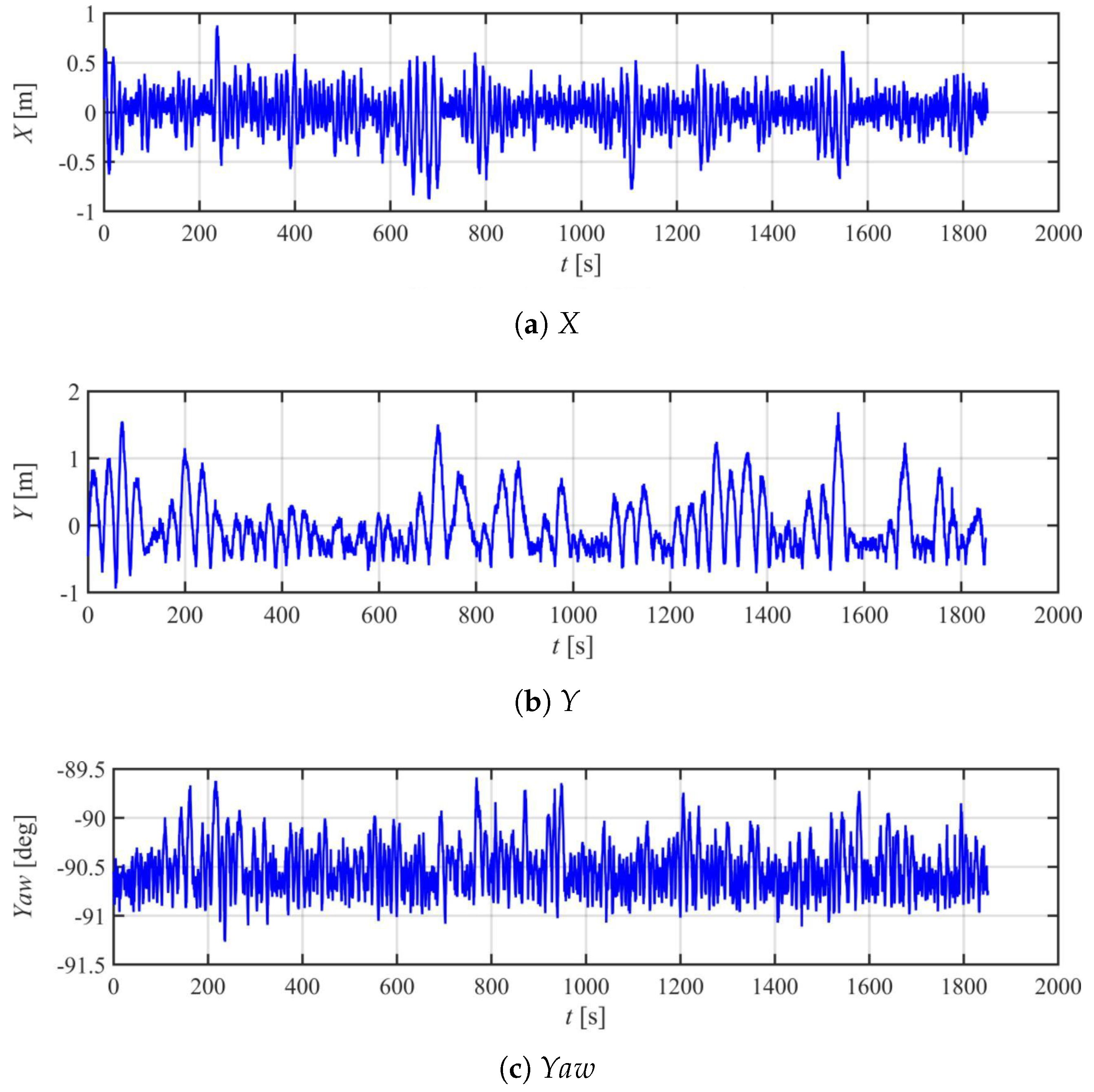

4.2. Docking Test

DP docking experiments are also conducted to evaluate and validate the performance characteristics of the proposed fuzzy control system in maintaining vessel position and heading during docking operations. The vessel is controlled by changing the setpoints manually in order to move forward step by step according to the current positioning accuracy. Special attention needs to be paid when the vessel first enters the slot. The lateral displacement must be maintained within prescribed tolerances prior to transitioning to subsequent reference points, as excessive deviation could result in transverse large collisions between the vessel and the sway fender system.

Figure 14 shows a snapshot of the DP docking test in wave.

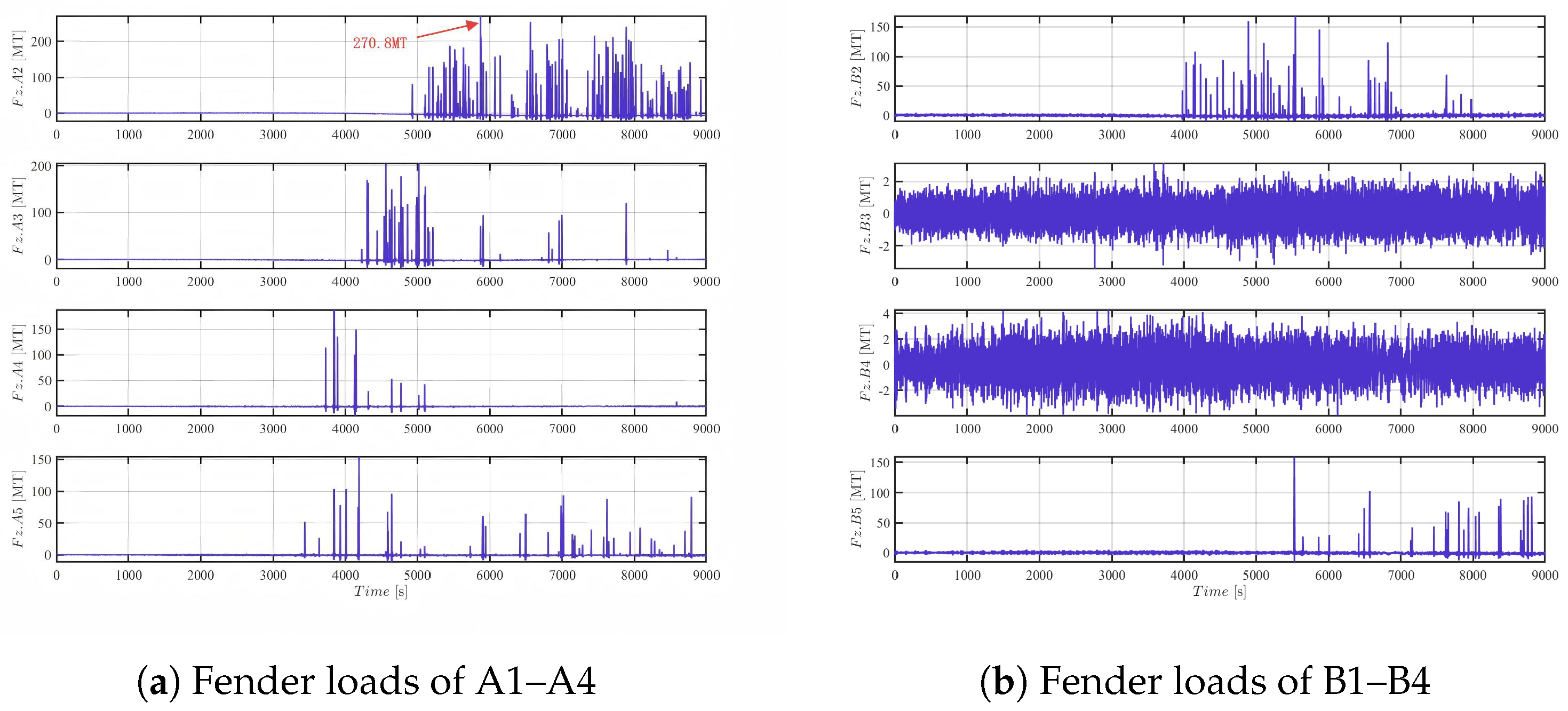

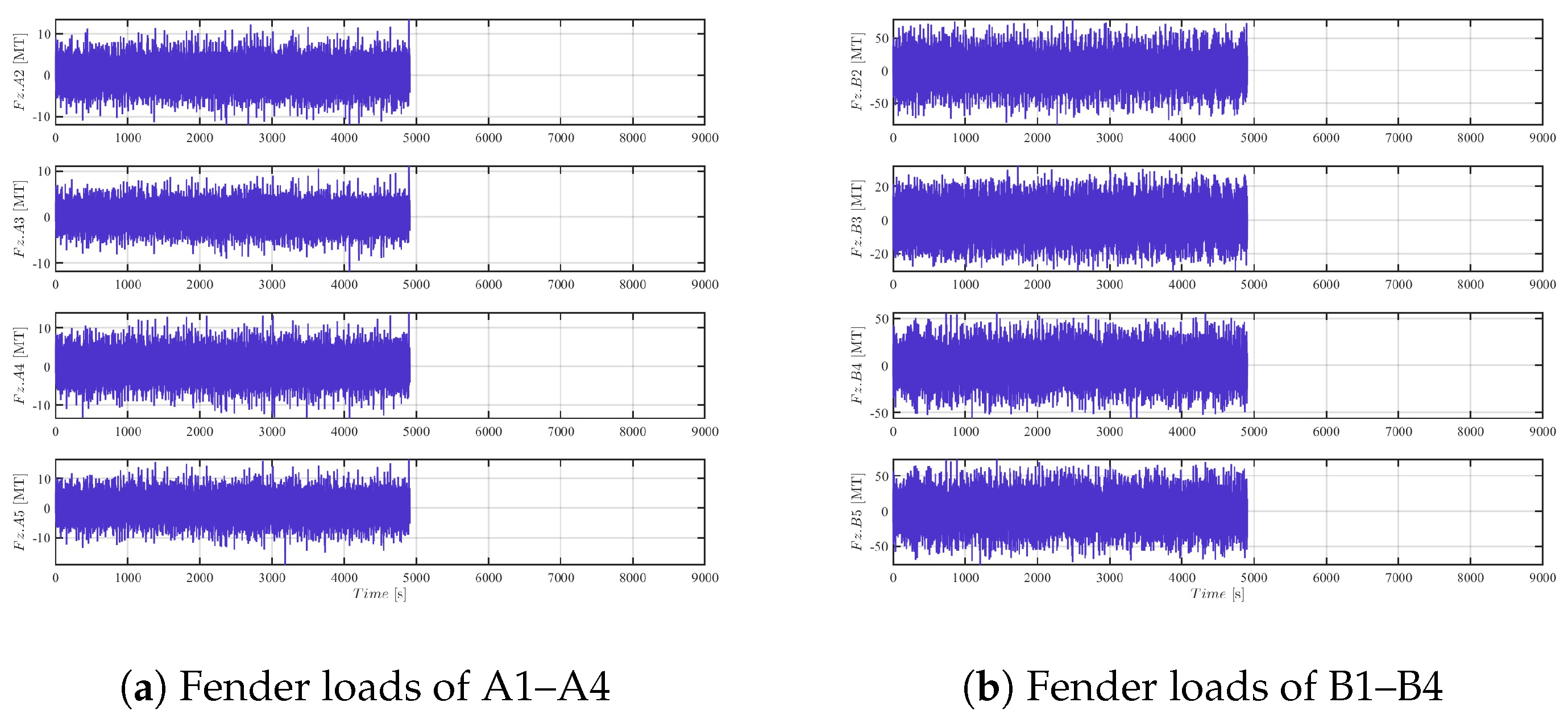

Figure 15 presents the motions of the barge in the 0 deg docking test, and the corresponding sway fender forces are shown in

Figure 16. For sway fenders, the reaction loads in the local Z axis are dominant, so the X-axis component is thus not presented here.

It can be seen that the DP vessel model enters the slot at about 3000 s. Both the motions and fender forces demonstrate strong oscillation characteristics once the vessel enters. Restricted by the sway fenders, the barge is no longer completely controlled by the DP system. Continuous collision with the sway fender changes the barge acceleration immediately and causes the high-frequency oscillations as shown in the figures.

The amplitude of fender force varies greatly ranging from a few tons to hundreds of tons. The maximum reaction load is 270.8 tons, which is much larger than the results of 45 deg and 90 deg as shown later. Considering that the environmental loads come from the surge direction, the sway loads acting on the ship shall be small theoretically. This phenomenon is unexpected, as the environmental loads are primarily aligned with the surge direction, and the sway loads should theoretically be minimal. However, the observed high sway fender forces may be attributed to complex hydrodynamic interactions such as wave diffraction around the jacket structure, thruster hysteresis during rapid directional changes, and coupling effects between sway and roll motions. These effects are known to introduce lateral loads not accounted for in simplified models and have been discussed in prior studies [

15,

17]. Further investigation is warranted to quantify these dynamics and improve predictive accuracy.

First, the environmental condition for the 0 deg heading is much harsher than for the other two wave headings. The environmental loads in the sway direction are also introduced by the jacket and might be larger than expected.

Second, four tunnel thrusters are used to control the heading and sway motion of the barge. As no static force is required in 0 deg, and the sway and yaw angle vary in the vicinity of zero, the tunnel thrusters must continuously change from forward to reverse rotation rapidly to provide the required force. However, due to the inherent hysteresis of the thrusters, forward and reverse rotation will cause insufficient thrust in a short time, then a large sway or yaw angle will be induced and increase the collision with fenders. This shortcoming is determined by the thruster configuration of the barge and incorporating additional azimuth thrusters may address this issue.

Third, the coupling effect between sway and roll motions. As the tunnel thrusters are installed below the center of gravity of the barge, an additional roll moment is induced when controlling the sway and yaw motions. The gap between the vessel side shell and sway fenders is only 2.5 mm in the model test; this roll motion will absolutely cause the collision of the vessel shell with fenders. However, this coupling effect exists for all the DP vessels, especially those with a small water-plane area. Adding the roll motion into the feedback control loop may help to reduce this coupling effect.

The experimental results with respect to 45 deg and 90 deg are presented in

Figure 17,

Figure 18,

Figure 19 and

Figure 20. Except several extreme values, most of the sway fender forces are relatively small. The maximum reaction loads are 213.67 tons and 51.22 tons, respectively. Considering all the experimental results, 90 deg is the best angle to conduct a docking operation with the best positioning accuracy and minimal reaction force, which may be attributed by the relatively small environmental conditions. This is also determined by the thruster configuration of the barge. In the 90 deg docking test, the controller must provide a static force to resist the mean environmental loads, and so all the four tunnel thrusters are always rotating in forward direction. The difference of the rotation speed can provide the rest sway force and yaw moment so that the generated thruster force is very stable. In general, the docking tests are very successful, and performance of the proposed improved fuzzy controller is satisfactory.

5. Conclusions

In this paper, an improved fuzzy control law based on the fuzzy system is developed for the standby and docking stage of the float-over installation. The controller utilizes the measured vessel position, heading, and velocity to produce the control force, which is subsequently divided into dynamic and static components. Both components are calculated based on a series of logical if–then statements informed by human intuition and experience. The dynamic component functions as proportional–derivative control, while the static component provides integral action. The design methodology of the controller is thoroughly detailed. Additionally, a model test is conducted to validate the efficacy of the proposed improved fuzzy control strategy applied to a dynamically positioned barge. The experimental setup accounts for wind, wave, and current at angles of 0 deg, 45 deg, and 90 deg to replicate realistic operational conditions.

The experimental findings indicate that the proposed improved fuzzy control law effectively maintains position and directs the vessel into the jacket slot. The positioning accuracy in X direction is basically within the range of [−2 m, 2 m] for the case of 0 deg, and it reduces to [−1 m, 1 m] for the case of 45 deg and 90 deg. Given that only the four tunnel thrusters are capable of generating transverse forces, particular attention must be paid to docking at 0 degrees. The tunnel thrusters must rapidly alternate between forward and reverse rotations to generate the necessary force, leading to significant reaction forces on the sway fender. Future research will concentrate on incorporating the additional roll moment induced by the thrusters into the controller design. This adjustment aims to mitigate the sway-yaw-roll coupling effect and reduce the risk of collisions with fenders. Additionally, the current control action is essentially discrete, and thus more work should be performed to transform it to continuous by using membership functions. A realistic numerical simulation platform also needs to be established to consider more different cases and may help facilitate future field testing.