Marine Geomechanical Approach to Well Trajectory Optimization in Fractured Reservoirs: A Case Study from the X Block, Zhujiangkou Basin

Abstract

1. Introduction

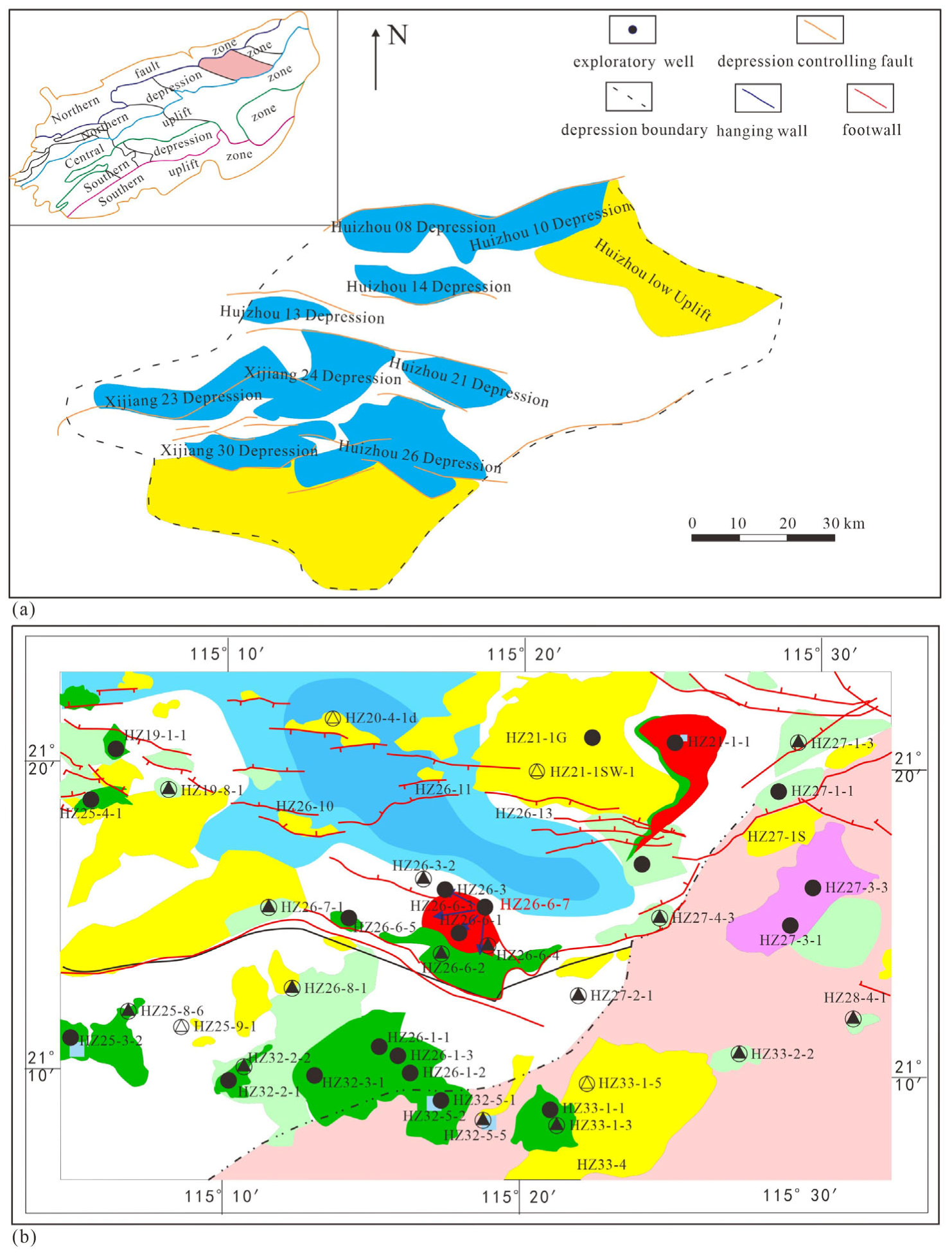

2. Geological Setting

3. Method and Technique

3.1. Marine Rock Mechanics and In Situ Stress Characterization

3.2. Three-Dimensional Geomechanical Modeling and Stress Field Simulation

3.3. Fracture Prediction and Marine Fracture-Prone Zone Identification

3.4. Integration of Marine Multisource Data for Well Trajectory Evaluation

3.5. Dynamic Risk Assessment Along Potential Well Trajectories

3.6. Intelligent Well Trajectory Optimization Workflow in Offshore Reservoirs

4. Results

4.1. Developmental Characteristics of Structural Fractures

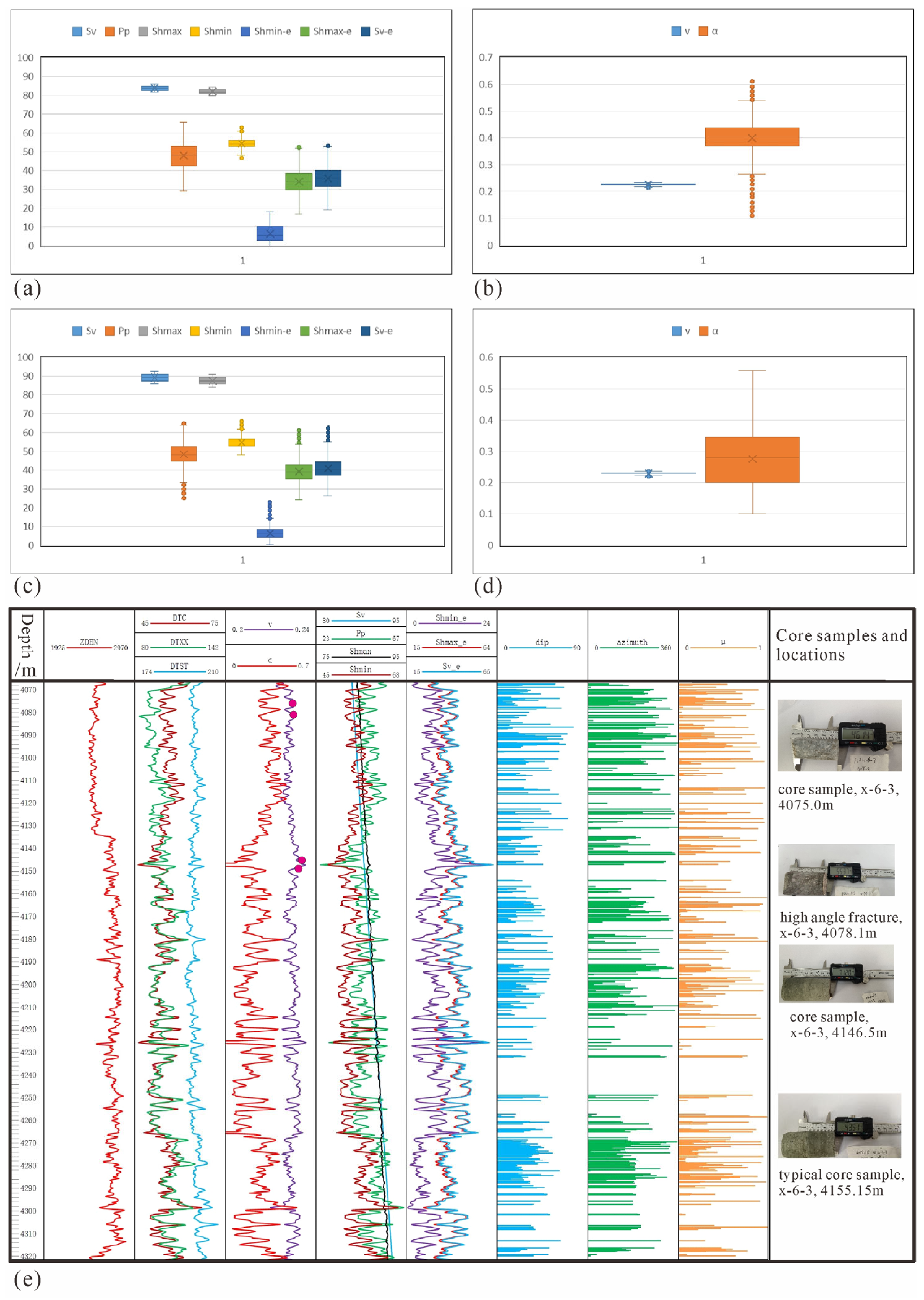

4.2. Geomechanical Characteristics of Typical Well Sections

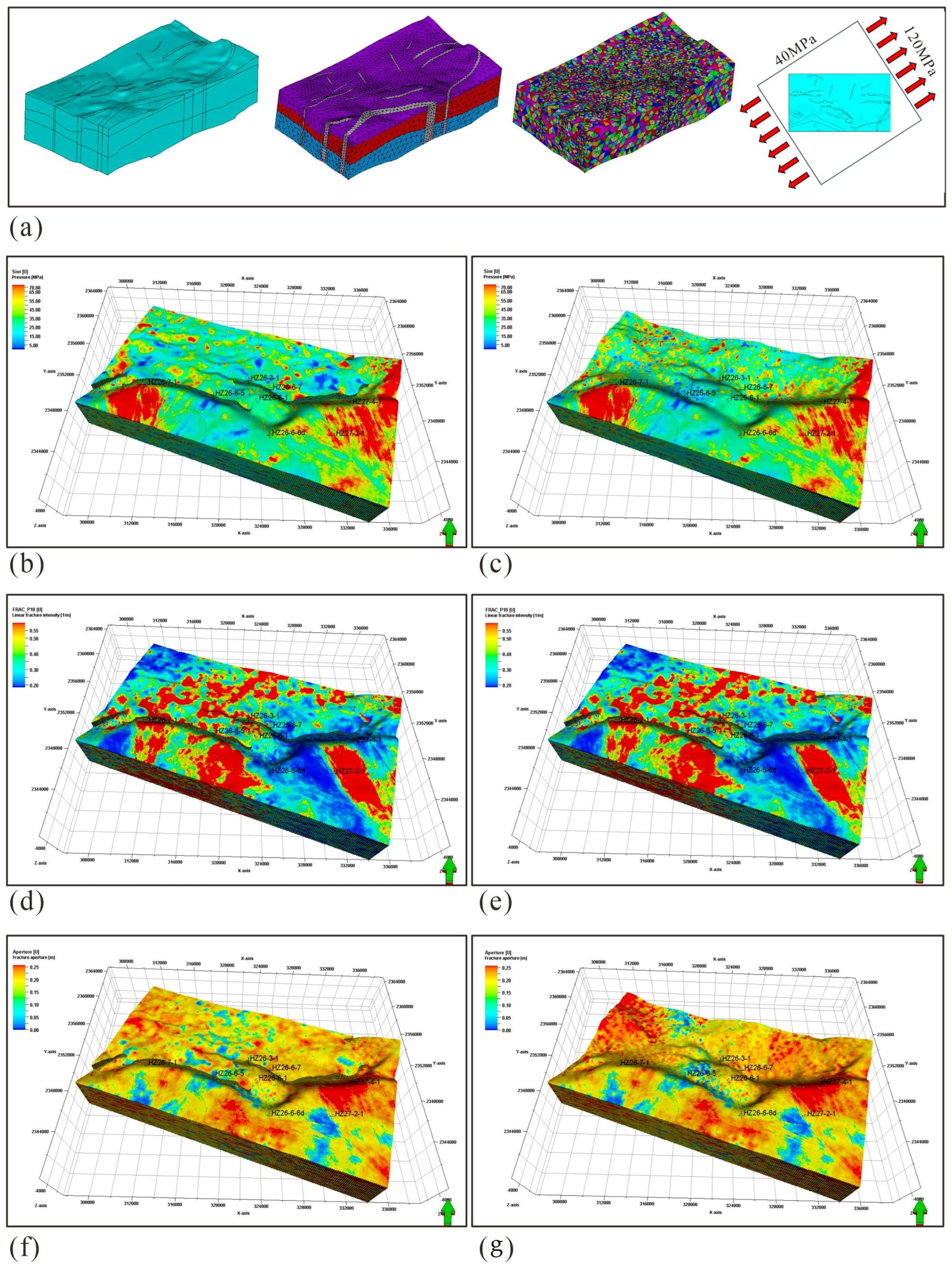

4.3. Geomechanical Modeling and Numerical Simulation

5. Discussion

5.1. Distributional Characteristics of Fracture Activity in Marine Setting

5.2. Key Parameters Influencing Well Trajectory Optimization in Offshore Reservoirs

- (1)

- Parameter integration. Geological and geomechanical factors controlling wellbore stability and fracture intersection were compiled, including fracture characteristics (density, aperture, dip angle, strike, and activity), fault attributes (scale and proximity), and stress field components (effective normal and shear stresses, principal stress magnitudes, and stress intensity). These inputs were mapped within the 3D geomechanical model to delineate candidate drilling domains.

- (2)

- Threshold-based screening. Zones with unfavorable conditions—such as high stress intensity or densely clustered active fractures—were filtered out using calibrated parameter thresholds derived from core observations, borehole failures, and log responses. This step identified geomechanically stable regions suitable for potential wellbore placement.

- (3)

- Quantitative sensitivity analysis. Grey relational analysis was applied to evaluate the relative influence of each parameter on trajectory optimization. Results show that fracture-related attributes exert the strongest control, with grey relational indices for fracture density (0.3142), aperture (0.2885), activity (0.3188), and dip angle (0.3306). Fault scale (0.2308) and distance to fault (0.2547) further emphasize the critical role of fault proximity in offshore well planning. Among stress attributes, effective shear stress (0.1517) and stress intensity (0.1514) were more relevant to drilling risk than absolute stress magnitudes, underscoring the role of localized stress concentrations in marine basins.

- (4)

- Trajectory adjustment. Based on the sensitivity rankings, well paths were iteratively adjusted to avoid geomechanically adverse domains while maximizing contact with moderately developed conductive fractures. This entailed deviating trajectories away from intensely fractured or fault-damage zones, steering towards structurally favorable corridors, and incorporating sidetracking contingencies when fault crossings were unavoidable (Table 2).

- (5)

- Field validation. Compared with the original design, the optimized well path demonstrated a 25% reduction in drilling-related stability issues, a 40% increase in cumulative fracture exposure, and a 30% improvement in initial production rate. These outcomes confirm that the parameter-driven, geomechanics-based workflow effectively transforms subsurface stress–fracture characterization into practical guidance for safer and more productive drilling.

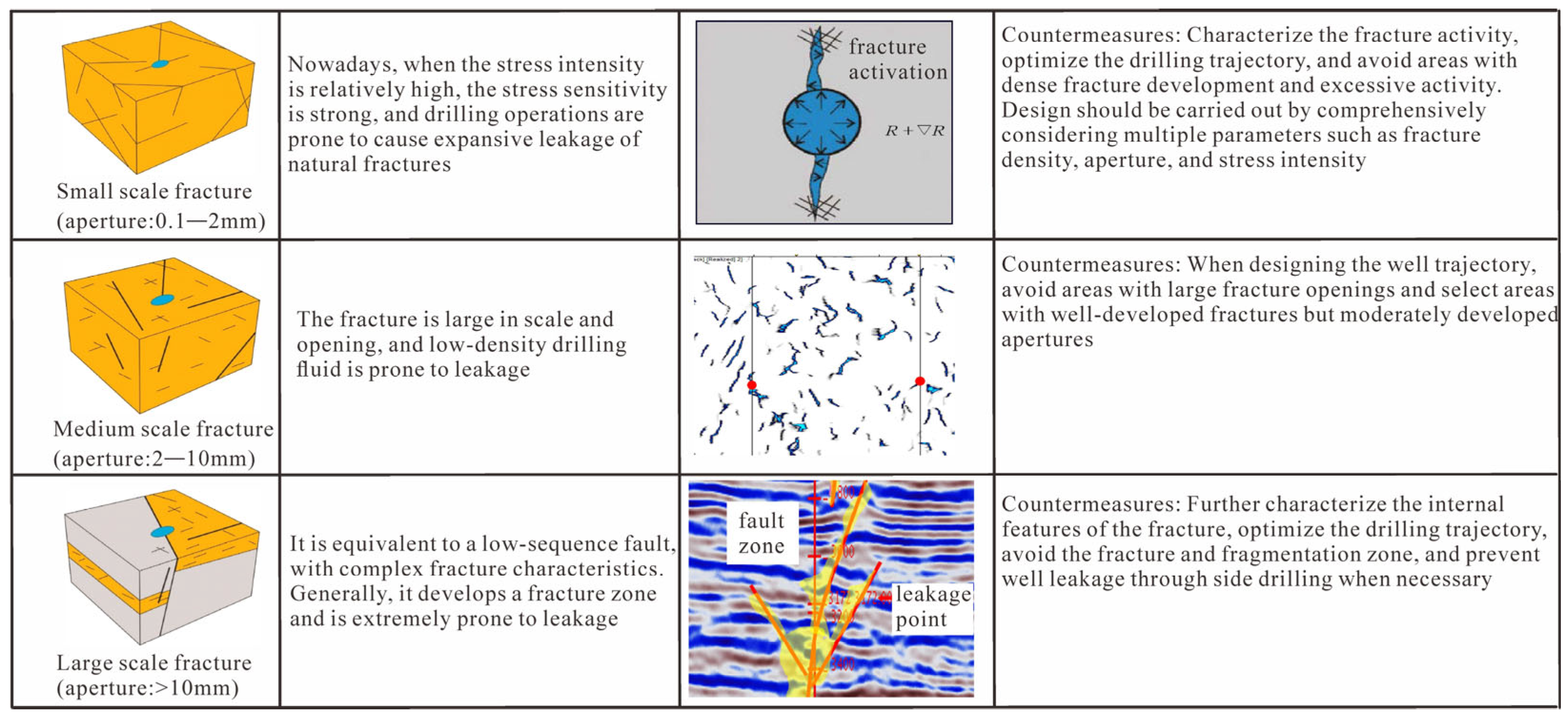

5.3. Marine-Adapted Well Trajectory Optimization Strategies Based on Fracture Scale Classification

- (1)

- Small-scale fractures (aperture 0.1–2 mm): Predominantly occurring in shale-dominated intervals, these stress-sensitive fractures are prone to aperture closure, dilation under pressure imbalance, or fluid invasion under high in situ stress, potentially causing lost circulation and wellbore instability. Trajectories were therefore routed to avoid zones of dense, highly active small fractures. Risk assessment combined fracture density, aperture, and local stress intensity to identify mechanically favorable drilling corridors.

- (2)

- Medium-scale fractures (aperture 2–10 mm): These moderately conductive fractures provide potential flow paths but pose significant mud-loss risk in offshore environments, especially under low-density drilling fluids. Trajectory planning targeted regions with moderately developed, mechanically stable fractures, identified through integration of seismic interpretation, borehole image logs, and geomechanical modeling. This balance minimized formation damage while maintaining reservoir connectivity.

- (3)

- Large-scale fractures (aperture > 10 mm): Typically associated with low-order faults or major fracture corridors, these zones exhibit complex internal damage, high connectivity, and elevated mechanical risk, particularly near structural highs or basin-margin faults. Detailed geomechanical characterization, including stress concentration and fault core architecture, informed trajectory adjustments to circumvent direct intersection of high-risk corridors. When unavoidable, sidetracking strategies were incorporated to reduce wellbore instability.

6. Conclusions

- (1)

- A three-dimensional marine geomechanical model was constructed by integrating multi-source data—such as core observations, borehole imaging, well logs, and marine seismic interpretation—capturing the tectono-sedimentary complexity of the offshore Zhujiangkou Basin. The model enabled quantitative calculation of principal stress orientations, effective normal and shear stresses, and stress intensity, revealing clear vertical and lateral stress zoning patterns critical for safe and effective wellbore design in marine strata.

- (2)

- A discrete fracture network (DFN) integrated with the geomechanical model was used to evaluate the spatial distribution and activity of natural fractures in the offshore reservoir setting. By coupling fracture density, aperture, orientation, and in situ stress conditions, a fracture activity index was developed to classify fractures into inactive, moderately active, and highly active types—providing a practical basis for identifying geomechanically sensitive zones along prospective marine well paths.

- (3)

- Grey relational analysis was employed to quantify the influence of key geological and geomechanical parameters on trajectory optimization. The results show that fracture development parameters—particularly density, aperture, activity, and dip angle—and proximity to faults exert the strongest control. Among stress-related attributes, effective shear stress and overall stress intensity were found to be more relevant to trajectory risk evaluation than absolute stress magnitudes, especially in offshore formations affected by long-term tectonic reactivation and compaction.

- (4)

- Tailored trajectory strategies were proposed based on fracture scale classification. For small-scale stress-sensitive fractures typical of marine mudstone intervals, it is recommended to avoid dense, active zones to minimize instability. For medium-scale conductive fractures, targeting moderately developed regions reduces the risk of lost circulation while maintaining reservoir connectivity. For large-scale fracture corridors or low-order marine faults, trajectory planning should avoid intensely damaged zones, with sidetracking options considered when fault crossing is unavoidable.

- (5)

- The workflow was successfully applied to a geomechanically complex offshore fractured reservoir, demonstrating its capacity to dynamically adjust well paths in response to evolving stress and fracture conditions. This capability enhances both drilling safety and reservoir contact, thereby improving development performance in marine settings characterized by heterogeneity and structural complexity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gross, M.R.; Eyal, Y. Throughgoing fractures in layered carbonate rocks. Geol. Soc. Am. Bull. 2007, 119, 1387–1404. [Google Scholar] [CrossRef]

- Zeng, L.; Wang, Z.; Xiao, S.; Zhang, G. The origin and geological significance of low dip-angle fractures in the thrust zones of the western basins of China. Acta Pet. Sin. 2008, 30, 56. [Google Scholar]

- Zhang, H.; Yin, G.; Wang, H. Effects of natural fractures geomechanical response on gas well productivity in Kuqa Depression, Tarim Basin. Nat. Gas Geosci. 2019, 30, 379–388. [Google Scholar]

- Jiang, T.; Zhang, H.; Xu, K.; Yin, G.; Wang, H.; Wang, Z.; Liu, X.J. Technology and practice for quantitative optimization of borehole trajectory in ultra-deep fractured reservoir: A case study of Bozi A gas reservoir in Kelasu structural belt, Tarim Basin. China Pet. Explor. 2021, 26, 149–161. [Google Scholar]

- Zhao, T.; Zhang, J.; Ding, W.; Zhao, R.; Radwan, A.E.; Wang, X. Characteristics and application of present in situ stress field of a strike-slip fault: A 3D finite-element simulation study. Geol. Mag. 2022, 159, 2361–2378. [Google Scholar]

- Laubach, S.E.; Ward, M.E. Diagenesis in porosity evolution of opening-mode fractures, Middle Triassic to Lower Jurassic la Boca Formation, NE Mexico. Tectonophysics 2006, 419, 75–97. [Google Scholar] [CrossRef]

- Liu, B.; Song, Y.; Zhu, K.; Su, P.; Ye, X.; Zhao, W. Mineralogy and element geochemistry of salinized lacustrine organic-rich shale in the Middle Permian Santanghu Basin: Implications for paleoenvironment, provenance, tectonic setting and shale oil potential. Mar. Pet. Geol. 2020, 120, 104569. [Google Scholar] [CrossRef]

- Gong, L.; Wang, J.; Gao, S.; Fu, X.; Liu, B.; Miao, F.; Meng, Q. Characterization, controlling factors and evolution of fracture effectiveness in shale oil reservoirs. J. Pet. Sci. Eng. 2021, 203, 108655. [Google Scholar] [CrossRef]

- Laubach, S.E.; Diaz-Tushman, K. Laurentian palaeostress trajectories and ephemeral fracture permeability, Cambrian Eriboll Formation sandstones west of the Moine Thrust Zone, NW Scotland. J. Geol. Soc. Lond. 2009, 166, 349–362. [Google Scholar] [CrossRef]

- Gale, J.F.; Laubach, S.E.; Olson, J.E.; Eichhubl, P.; Fall, A. Natural fractures in shale: A review and new observations. AAPG Bull. 2014, 98, 2165–2216. [Google Scholar] [CrossRef]

- Brooke-Barnett, S.; Flottmann, T.; Paul, P.K.; Busetti, S.; Hennings, P.; Reid, R.; Rosenbaum, G. Influence of basement structures on in situ stresses over the Surat Basin, southeast Queensland. J. Geophys. Res. Solid Earth 2015, 120, 4946–4965. [Google Scholar] [CrossRef]

- Gottardi, R.; Mason, S.L. Characterization of the natural fracture system of the eagle ford formation (Val Verde County, Texas). AAPG Bull. 2018, 102, 1963–1984. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Wanniarachchi, W.A.M.; Perera, M.S.A.; Rathnaweera, T.D. Investigation of the effect of foam flow rate on foam-based hydraulic fracturing of shale reservoir rocks with natural fractures: An experimental study. J. Petrol. Sci. Eng. 2018, 169, 518–531. [Google Scholar] [CrossRef]

- Lorenz, J.C.; Hill, R.E. Subsurface fracture spacing: Comparison of inferences from slant/horizontal and vertical cores. SPE Form. Eval. 1994, 9, 66–72. [Google Scholar] [CrossRef]

- Ghosh, S.; Galvis-Portilla, H.A.; Klockow, C.M.; Slatt, R.M. An application of outcrop analogues to understanding the origin and abundance of natural fractures in the Woodford Shale. J. Pet. Sci. Eng. 2018, 164, 623–639. [Google Scholar] [CrossRef]

- Ren, Q.Q.; Li, L.F.; Wang, J.; Jiang, R.T.; Li, M.P.; Feng, J.W. Dynamic Evolution mechanism of the fracturing fracture system—Enlightenments from hydraulic fracturing physical experiments and finite element numerical simulation. Pet. Sci. 2024, 21, 3839–3866. [Google Scholar] [CrossRef]

- Smart, K.J.; Ofoegbu, G.I.; Morris, A.P.; McGinnis, R.N.; Ferrill, D.A. Geomechanical modeling of hydraulic fracturing: Why mechanical stratigraphy, stress state, and pre-existing structure matter. AAPG Bull. 2014, 98, 2237–2261. [Google Scholar] [CrossRef]

- Xu, K.; Yang, H.; Zhang, H.; Ju, W.; Li, C.; Fang, L.; Liang, J. Fracture effectiveness evaluation in ultra-deep reservoirs based on geomechanical method, Kuqa Depression, Tarim Basin, NW China. J. Pet. Sci. Eng. 2022, 215, 110604. [Google Scholar] [CrossRef]

- Zoback, M.D. Unconventional Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Lyu, W.; Zeng, L.; Zhou, S.; Du, X.; Xia, D.; Liu, G.; Weng, J. Natural fractures in tight-oil sandstones: A case study of the Upper Triassic Yanchang Formation in the southwestern Ordos Basin, China. AAPG Bull. 2019, 103, 2343–2367. [Google Scholar] [CrossRef]

- Zeng, L.; Gong, L.; Zhang, Y.; Dong, S.; Lyu, W. A review of the genesis, evolution, and prediction of natural fractures in deep tight sandstones of China. AAPG Bull. 2023, 107, 1687–1721. [Google Scholar] [CrossRef]

- Gasparrini, M.; Sassi, W.; Gale, J.F. Natural sealed fractures in mudrocks: A case study tied to burial history from the Barnett Shale, Fort Worth Basin, Texas, USA. Mar. Pet. Geol. 2014, 55, 122–141. [Google Scholar] [CrossRef]

- Mathews, J.P.; Campbell, Q.P.; Xu, H.; Halleck, P. A review of the application of X-ray computed tomography to the study of coal. Fuel 2017, 209, 10–24. [Google Scholar] [CrossRef]

- Shovkun, I.; Espinoza, D.N. Geomechanical implications of dissolution of mineralized natural fractures in shale formations. J. Pet. Sci. Eng. 2018, 160, 555–564. [Google Scholar] [CrossRef]

- Weinberg, K.; Wieners, C. Dynamic phase-field fracture with a first-order discontinuous galerkin method for elastic waves. Comput. Method. Appl. Mech. Eng. 2022, 389, 114330. [Google Scholar] [CrossRef]

- Huo, Q.; Zeng, H.; Zhang, X.; Fang, Q.; Wang, Z.; Fu, L. Shale oil occurrence and reservoir characteristics of the Qijia-Gulong depression in Songliao Basin. Acta Geol. Sin.-Engl. Ed. 2015, 89 (Suppl. S1), 151–153. [Google Scholar] [CrossRef] [PubMed]

- Eftekhari, B.; Marder, M.; Patzek, T.W. Field data provide estimates of effective permeability, fracture spacing, well drainage area and incremental production in gas shales. J. Nat. Gas Sci. Eng. 2018, 56, 141–151. [Google Scholar] [CrossRef]

- Ren, Q.; Feng, J.; Johnston, S.; Peddle, C.; Du, H. Quantitative characterization of interlayer fractures in carbonate rocks based on finite element numerical simulation. J. Pet. Sci. Eng. 2020, 195, 107942. [Google Scholar] [CrossRef]

- Radwan, A.E. Three-dimensional gas property geological modeling and simulation. In Sustainable Geoscience for Natural Gas Subsurface Systems; Gulf Professional Publishing: Houston, TX, USA, 2022; pp. 29–49. [Google Scholar]

- Ren, Q.Q.; Feng, J.W.; Johnston, S.; Zhao, L.B. The influence of argillaceous content in carbonate rocks on the 3D modeling and characterization of tectonic fracture parameters—Example from the carboniferous and ordovician formations in the hetianhe gas field, Tarim Basin, NW China. J. Petrol. Sci. Eng. 2021, 203, 108668. [Google Scholar] [CrossRef]

| Testing Number | Depth/m | CP (MPa) | Strength (MPa) | E (GPa) | µ | Co- (MPa) | IFA |

|---|---|---|---|---|---|---|---|

| 1-1 | 4075.00 | 25.00 | 150.83 | 20.95 | 0.236 | 30.48 | 29.79 |

| 1-2 | 35.00 | 170.58 | 22.33 | 0.240 | |||

| 2-1 | 4078.10 | 15.00 | 102.37 | 22.68 | 0.354 | 25.57 | 32.74 |

| 2-2 | 25.00 | 123.86 | 16.64 | 0.225 | |||

| 2-3 | 35.00 | 139.47 | 15.92 | 0.187 | |||

| 3-1 | 4146.5 | 35.00 | 75.54 | 14.84 | 0.226 | 23.14 | 16.38 |

| 3-2 | 25.00 | 71.04 | 9.46 | 0.168 | |||

| 3-3 | 15.00 | 59.83 | 7.73 | 0.167 | |||

| 3-1 | 4155.15 | 25.00 | 119.58 | 19.85 | 0.117 | 35.71 | 24.35 |

| 3-2 | 35.00 | 133.61 | 20.20 | 0.286 |

| Evaluation Factors | Weight | Sub-Factor | Correlation Coefficient | Relative Correlation Index |

|---|---|---|---|---|

| Fracture development | 0.42 | Fracture linear density | 0.7482 | 0.3142 |

| Fracture aperture | 0.6869 | 0.2885 | ||

| Fracture dip angle | 0.6186 | 0.2598 | ||

| Fracture tendency | 0.7871 | 0.3306 | ||

| Fracture activity | 0.7590 | 0.3188 | ||

| Fault’s influence | 0.36 | Distance to fault | 0.7075 | 0.2547 |

| Fault scale | 0.6412 | 0.2308 | ||

| Stress field | 0.22 | Normal stress | 0.6440 | 0.1417 |

| Shear stress | 0.6897 | 0.1517 | ||

| Minimum stress | 0.6416 | 0.1411 | ||

| Maximum stress | 0.6264 | 0.1378 | ||

| Stress intensity | 0.6881 | 0.1514 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, L.; Xu, J.; Du, Q.; Zhang, G.; Qi, X.; Tang, Y. Marine Geomechanical Approach to Well Trajectory Optimization in Fractured Reservoirs: A Case Study from the X Block, Zhujiangkou Basin. J. Mar. Sci. Eng. 2025, 13, 1732. https://doi.org/10.3390/jmse13091732

Yin L, Xu J, Du Q, Zhang G, Qi X, Tang Y. Marine Geomechanical Approach to Well Trajectory Optimization in Fractured Reservoirs: A Case Study from the X Block, Zhujiangkou Basin. Journal of Marine Science and Engineering. 2025; 13(9):1732. https://doi.org/10.3390/jmse13091732

Chicago/Turabian StyleYin, Lu, Jiafang Xu, Qingjie Du, Guangdong Zhang, Xiao Qi, and Yi Tang. 2025. "Marine Geomechanical Approach to Well Trajectory Optimization in Fractured Reservoirs: A Case Study from the X Block, Zhujiangkou Basin" Journal of Marine Science and Engineering 13, no. 9: 1732. https://doi.org/10.3390/jmse13091732

APA StyleYin, L., Xu, J., Du, Q., Zhang, G., Qi, X., & Tang, Y. (2025). Marine Geomechanical Approach to Well Trajectory Optimization in Fractured Reservoirs: A Case Study from the X Block, Zhujiangkou Basin. Journal of Marine Science and Engineering, 13(9), 1732. https://doi.org/10.3390/jmse13091732