1. Introduction

Artificial Intelligence (AI) is broadly defined as the field of computing devoted to creating systems that perform tasks associated with human intelligence, such as reasoning, learning, perception, and decision-making. In essence, AI refers to the simulation of cognitive functions by machines and encompasses a wide range of technologies, from knowledge-based and algorithmic techniques to data-driven approaches like machine learning [

1,

2]. Machine Learning (ML), in particular, is a subfield of AI focused on algorithms that enable computers to learn from data and improve through experience without being explicitly programmed [

3]. Rather than relying on hard-coded rules, ML techniques allow an AI system to automatically discern patterns and adapt its performance as it accumulates more data or “experience”. This adaptive learning capability positions ML as a critical component within the broader AI landscape, providing the statistical and data-driven methods that underpin many modern AI systems.

The linkage between AI and ML can be understood in terms of their roles. AI provides the overall goal of intelligent behavior, while ML offers a powerful means to achieve that intelligence by extracting knowledge from data. In fact, ML has emerged as the “method of choice” for implementing AI solutions in many domains. Numerous contemporary AI achievements—in computer vision, speech recognition, natural language processing, and beyond—are driven by advances in ML algorithms [

4]. By leveraging large datasets and computational learning techniques, ML enables AI systems to automatically refine their models and improve performance, which is often far more efficient than manual programming for complex tasks. At the same time, AI as a field also includes methodologies not based on learning (such as expert systems or traditional optimization algorithms), but ML has become central due to its success in tackling problems of high complexity and variability. These distinctions are important in the context of engineering design, in particular ship design. AI-driven approaches (especially ML models) are increasingly used to augment traditional ship design processes, allowing designers to explore vast design spaces and identify optimal solutions by learning from historical data and simulations. The rapid development of AI techniques has begun to transform ship design, as data-trained ML models can predict performance and inform design decisions much more quickly and adaptively than conventional methods. Overall, ML is conceptually a subset of AI; it provides the learning and pattern-recognition engines within AI, and together they offer a synergistic framework: AI defines the ambition to emulate intelligent problem-solving, and ML supplies the mechanism to realize this intelligence through experience-driven adaptation.

The maritime industry, which is the foundation of the global economy, is currently facing two challenges. The first challenge is adapting to technological advancements, and the second is to address the increasing demand for newly built ships. With the increasing average age of the worldwide fleet, many ships are nearing the end of their operational lifespans. This presents challenges in terms of efficiency, compliance with regulations, and ecological performance. This aging fleet requires an increased focus on fleet renewal, as noted in a recent United Nations report [

5], to ensure that ships are able to meet not only sustainability and environmental demands but also modern operational demands. Building new and more efficient ships not only aligns with international environmental goals but also supports a more resilient and adaptable global fleet.

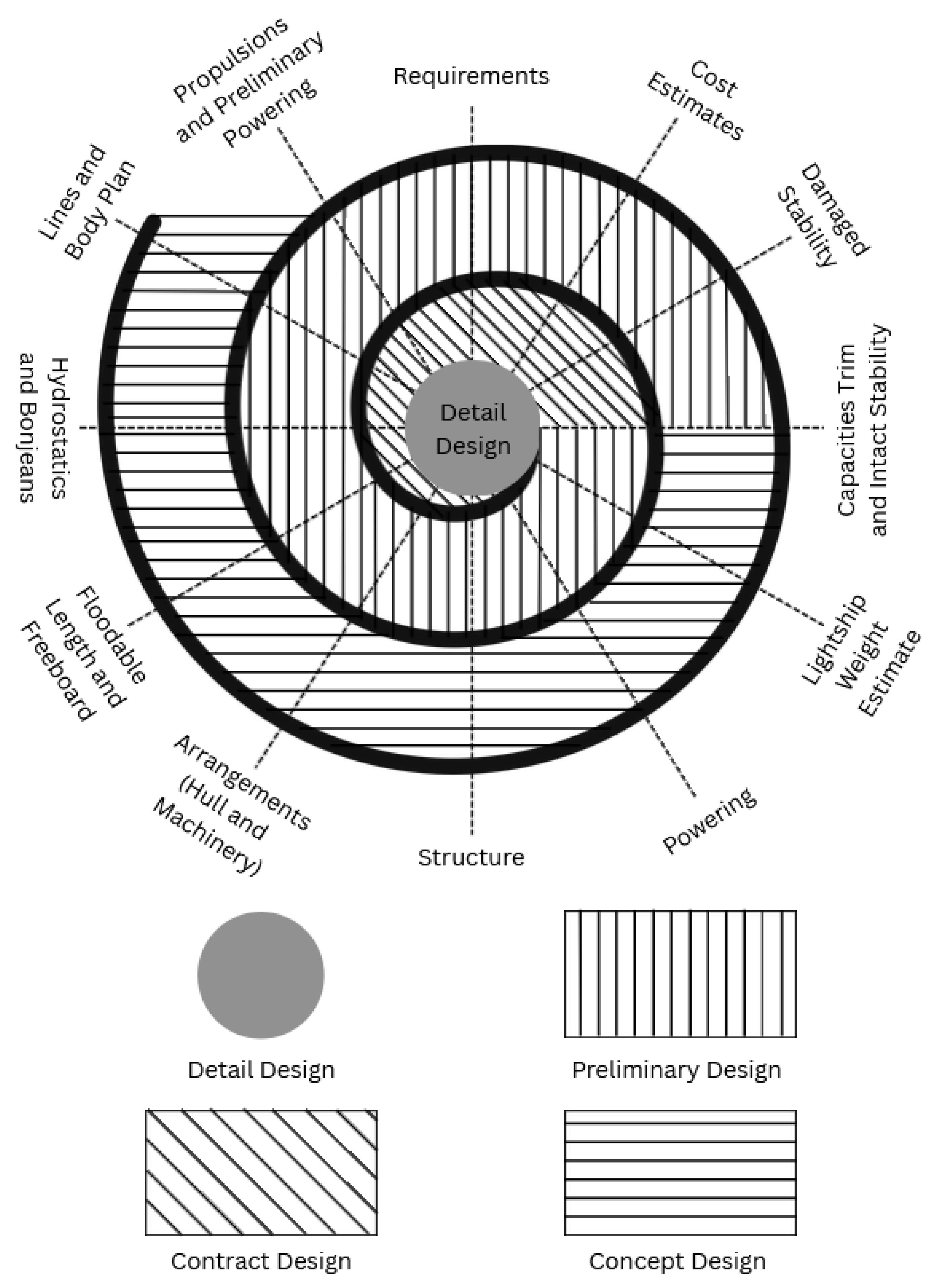

The ship design process is evolving in response to these pressures, taking advantage of digital advances, such as ML, which can enhance traditional methodologies. The most fundamental methodology in the ship design process is the design spiral. The design spiral, which was first introduced by J.H. Evans in 1959 [

6], is an iterative framework used by naval architects to address the complex and varied requirements of a ship. The design spiral summarizes the step-by-step approach to developing a vessel, where each design phase refines critical aspects such as mission requirements, stability, powering, and structural integrity at every design phase. This framework is essential for managing the complex balance between competing design elements, such as cost, safety, and performance, which must meet regulatory standards while fulfilling the operational needs of the owner. ML-driven optimization tools could potentially allow engineers to evaluate thousands of design configurations in a fraction of the time required by traditional methods, as they can leverage vast amounts of historical design data to create predictive models, enabling quick estimates of essential parameters such as weight, resistance, and structural requirements. This automation will reduce the time and resources required to refine and optimize initial designs, allowing naval architects to explore a broader range of options and identify configurations that optimize multiple objectives [

7], see

Figure 1.

As the maritime industry adopts lifecycle-focused practices, ML models become critical for addressing maintenance, environmental impact, and operational efficiency. By leveraging lifecycle data and predictive analytics, ML can support evaluations of how design choices affect performance and regulatory compliance, particularly within optimization-focused contexts. However, expert human knowledge remains vital in later design spiral phases—preliminary, contract, and detail design—where experienced naval architects interpret data, manage real-world complexities, and customize designs to meet owner and regulatory requirements.

Targeted reviews of existing literature reveal a noticeable gap concerning optimization-focused applications in ship design, detailed examinations of these methods, and explicit guidance on future research directions. Previous reviews, such as Shaeffer et al. [

8] and Papanikolaou et al. [

7], often provide generalized overviews without delving deeply into specific techniques, their comparative effectiveness, or limitations in practical applications. Moreover, these reviews frequently lack clear, actionable recommendations to guide subsequent studies or industry adoption effectively. Therefore, a detailed and critical analysis of current methodologies, identifying gaps and clearly articulating future research opportunities, is essential. This deeper level of analysis is crucial not only for bridging theoretical developments with practical implementation but also for guiding researchers and practitioners toward innovative, efficient, and industry-relevant ship structural design solutions.

It is important to acknowledge that AI applications in ship design extend beyond optimization. Other families of methodologies, such as multi-attribute decision-making, using methods like TOPSIS, Monte Carlo and quasi-Monte Carlo-based uncertainty exploration [

9,

10], and regression-based approaches, including multiple linear regression for early-stage design predictions [

11] have also been employed to support trade-off analyses, uncertainty handling, and preliminary decision support. While these methods are valuable, they are not analyzed in depth here. Instead, the purpose of this paper is to provide a focused review of AI-based optimization techniques, particularly those applied to hydrodynamic and structural problems.

By clarifying this scope, the review aims to synthesize state-of-the-art developments in surrogate modeling, optimization algorithms, and hybrid physics–ML approaches as they relate to hydrodynamics and structures. The contribution of this work is two-fold: firstly, to present a critical evaluation of current optimization-based applications in these domains, and secondly, to highlight practical considerations, including data availability, interpretability, and computational resources, that guide the adoption of AI in ship design. Other aspects of ship design, such as maneuvering, stability, and vibration, as well as alternative AI methodologies, are acknowledged but remain beyond the horizon of this review.

The remainder of this study is organized as follows: The research approach followed for this review is discussed in

Section 2. The overview of the different AI/ML models being used in ship design as well as the different optimization algorithms being used by the identified studies is provided in

Section 3. The different AI/ML models are then split into two different categories: Hydrodynamic AI Models,

Section 3.1, and Structural Design AI Models,

Section 3.2. The main findings from the review, along with the identified gaps, trends, limitations, and discussions, are presented in

Section 4. Finally,

Section 5 summarizes the main findings and provides recommendations for future research directions.

2. Research Approach

The research approach of this review takes inspiration from a combination of methodologies by 3 authors [

12,

13,

14]. The 12 steps recommended are to provide a purpose statement, document the databases or search engines used in the search strategy, specify the limits applied, list the inclusion and exclusion criteria, list the search terms used, document the search process, assess retrieved articles for relevance, document a summary table of included articles, provide a statement specifying the number of retrieved articles, conduct a quality appraisal of retrieved literature, critically review the literature, and then check the reference list for accuracy.

The scope of this review was established to provide an overview and critically evaluate the progress on the integration of AI/ML in ship design, leading to the following research questions:

- -

What ML models are being used in the ship design optimization process?

- -

What ship design processes are ML models trying to replace?

- -

How do ML-based methodologies improve efficiency, accuracy, and decision-making in conceptual ship design?

- -

What are the challenges and limitations hindering the adoption of ML in shipbuilding?

Six databases were mainly focused on for this review: Scopus, Google Scholar, MDPI, Web of Science, ResearchGate, and Engineering Village. These six databases represent most peer-reviewed articles in the engineering field. Only studies published in English were included in this review.

Two categories of papers were selected: primary and secondary. The primary sources are papers that have been derived from the search terms, whereas the secondary sources are papers that have been cited in the primary source. The search set of keywords used were “Artificial Intelligence in Ship Design” or “Machine Learning in Ship Design”, “Ship Design Optimization”, “Structural Optimization”, and “Structural Design”. The search terms were derived from the research questions.

Two categories of papers were selected: primary and secondary. The primary sources are papers that have been derived from the search terms, whereas the secondary sources are papers that have been cited in the primary source. The search set of keywords used were “Artificial Intelligence in Ship Design”, “Machine Learning in Ship Design”, “Ship Design Optimization”, “Structural Optimization”, and “Structural Design”. The search terms were derived from the research questions.

The iterative process of selecting papers using this method helps identify authors in the field. A total of 38 papers were reviewed for this analysis. The authorship analysis of the references reveals a predominance of works authored solely by academic institutions (32 of 38), with only six studies produced through academic-industry collaboration and none authored solely by industry, see

Table 1.

This concentration introduces an academic authorship bias, whereby the research landscape is disproportionately shaped by academic priorities, incentives, and evaluation metrics. In such contexts, the resulting body of literature may overemphasize theoretical innovation, model benchmarking, and controlled-environment testing, while under-representing the operational constraints, regulatory complexities, and commercial imperatives faced in real-world ship design projects. The limited industrial authorship also implies fewer opportunities for large-scale validation using proprietary datasets or in-service performance feedback, which can impede the transition from proof-of-concept to full-scale deployment. Consequently, while the reviewed literature provides valuable methodological advances, the skew towards academic authorship suggests that closer integration with industry-led research is essential to ensure applicability, scalability, and adoption within the maritime sector.

3. AI Models in Ship Design

This section provides a focused overview of ML-driven optimization approaches for hydrodynamics and structures employed to refine ship design.

Figure 2 shows the annual distribution of the reviewed literature, showcasing the increasing interest in the topic. This can be explained due to the buzz around AI, the AI race between the biggest companies in the world, and most notably ChatGPT.

3.1. Hydrodynamic AI Models

Ship hydrodynamics encompasses the analysis and prediction of a vessel’s resistance, propulsion, maneuverability, and seakeeping performance within a marine environment. Traditionally, this field has relied heavily on empirical formulae, potential flow theory, and computationally intensive methods such as Computational Fluid Dynamics (CFD) to estimate hydrodynamic forces and optimize hull forms. While these methods have provided robust foundations for ship design, they are often constrained by high computational costs, long turnaround times, and limited capacity to explore the vast design space in early-stage development [

15]. In recent years, AI and ML have emerged as transformative tools in ship hydrodynamics, offering data-driven approaches to surrogate modeling, performance prediction, and optimization. These techniques enable rapid evaluation of numerous design alternatives, thereby facilitating holistic trade-off analysis between speed, efficiency, seakeeping, and fuel consumption. Industry case studies report that ML-based surrogate models can accelerate resistance prediction tasks by orders of magnitude while maintaining high fidelity compared to CFD benchmarks. Furthermore, AI-driven hydrodynamic optimization methods empower naval architects to explore innovative hull geometries and operational profiles that would be impractical to assess using conventional techniques. This section presents a review of contemporary optimization-focused applications of AI and ML in the field of ship hydrodynamics, with a focus on resistance prediction, hull-form optimization, and operational performance enhancement.

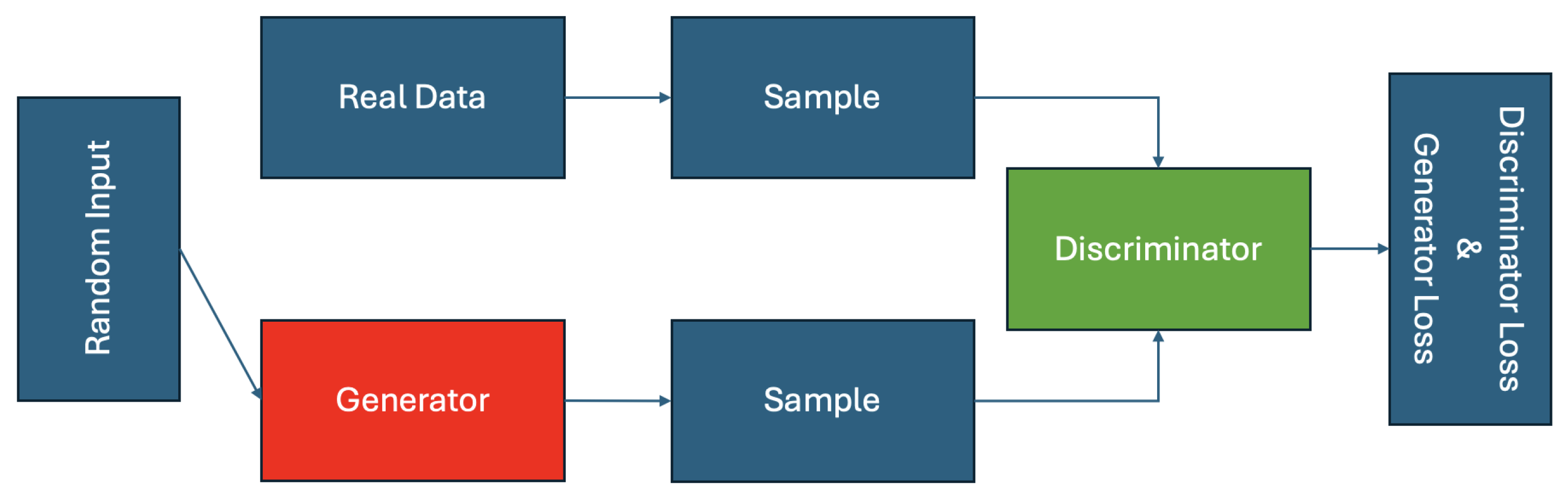

Generative Adversarial Networks (GANs) have emerged as powerful tools for generating novel hull forms by learning the distribution of existing design data. In a GAN framework, a generator network produces new hull geometries, while a discriminator network evaluates their realism, both trained in tandem. ShipHullGAN by Khan et al. [

16] is a notable example of applying GANs to ship design. ShipHullGAN was trained on a dataset of over 52,000 validated ship hull designs spanning various ship types and uses a deep convolutional GAN to generate hull shapes that are versatile and feasible across different ship types. To handle the diverse hull forms, the authors developed a unified shape representation (shape-signature tensor) and even incorporated physics-related features, via geometric moments, to ensure the generated designs respect practical constraints. The result is a generator capable of producing a wide range of hull forms, including both traditional and novel shapes, that remain geometrically valid for engineering use, as claimed by the authors. Recent work has also integrated performance objectives into GAN-based generation. Trinh et al. [

17] proposed a GAN-driven 3D hull design optimization method that replaces CFD reliance by using a hydrodynamic performance-predicting ML model during training. They employed a relativistic average discriminator for more informative feedback and added custom loss terms for the generator: one to constrain design variability within reasonable bounds and another to push the generator towards hulls with improved performance according to the predictor. Employing a relativistic average discriminator and tailored loss functions, their method achieved a 5.25% improvement in hull form factor without adversely affecting other performance metrics. These studies highlight GANs’ role in rapidly exploring hull form variations. These studies demonstrate GANs’ effectiveness in rapidly generating and optimizing hull designs. Major ongoing challenges when using GANs include acquiring sufficiently diverse training data and ensuring physical practicality, which researchers continue addressing through advanced training techniques and hybrid loss functions, see

Figure 3.

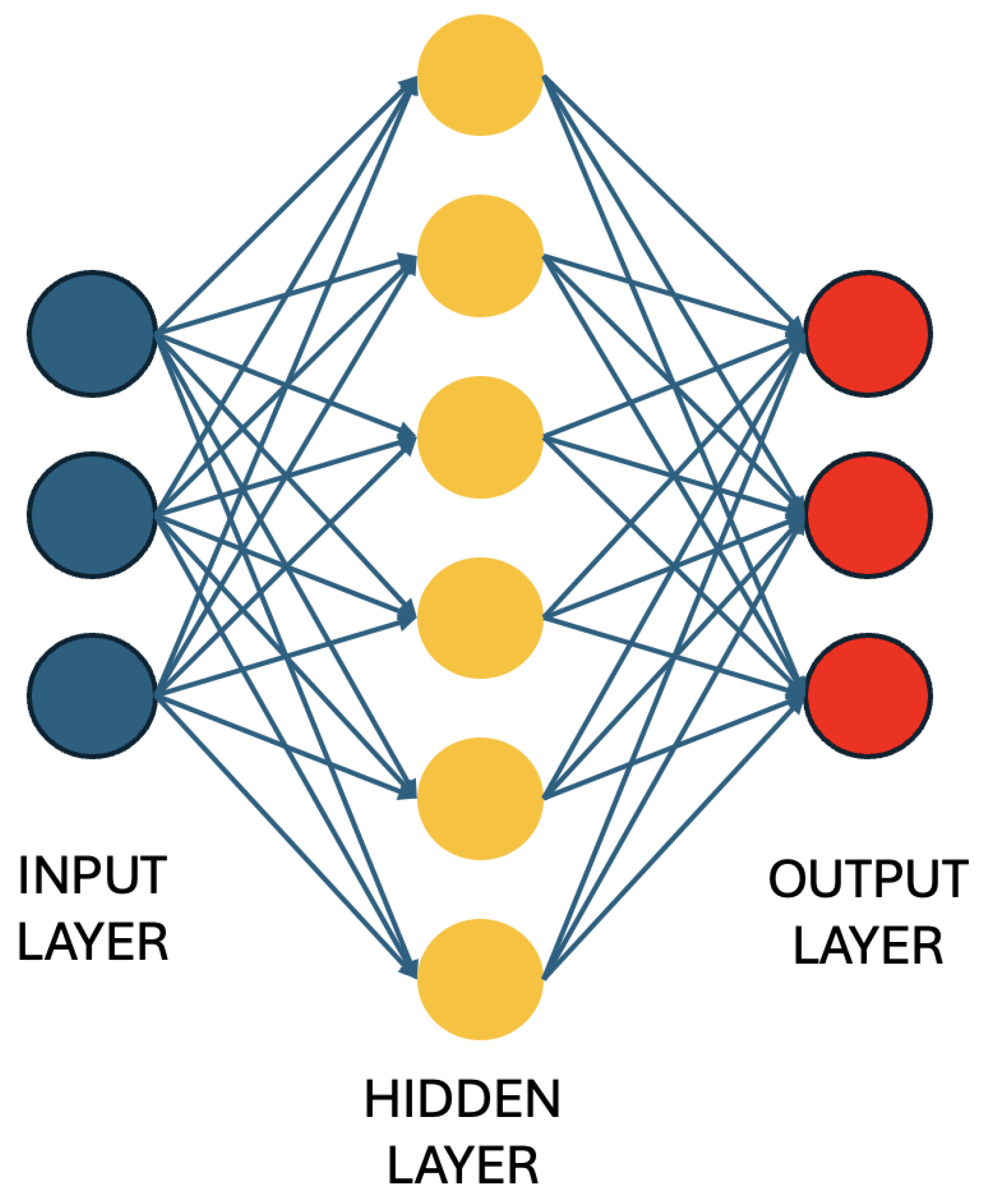

Deep neural networks (DNNs) now underpin both direct and generative approaches to hull-form creation. Variational auto-encoders (VAEs) are especially effective because they compress shapes into a latent space that can be sampled for new variants. Wang et al. [

18] encoded 3D hulls with Laplacian surface parameters, enriching the dataset through Perlin-noise mapping and free-form deformation, and trained a convolutional VAE coupled to a “hydro-predictor” that simultaneously reconstructed geometry and estimated drag. Exploring the latent space produced hulls whose CFD-validated drag coefficients were up to 35% lower than the parent form, proving that a VAE can intelligently navigate the design space. This demonstrates how DNN-based generative models can drive hull shape optimization: the network provides a way to navigate the design space intelligently, proposing shapes that balance novelty and performance. Even when not explicitly generating new shapes, deep neural networks assist hull geometry design by learning complex shape-performance relationships. Yu & Wang [

19] reduced an existing hull database with Principal Component Analysis (PCA) and then trained a DNN to map the resulting PCA scores to resistance. This surrogate evaluated thousands of candidates rapidly, enabling large-scale optimization without repeated simulations. Other classes of deep networks, such as deep belief networks (DBN) and other auto-encoder variants, have been used to capture salient hull features for real-time assessment. For instance, Ao et al. [

20] created a multi-input DNN that takes beam, draft, bow angle, and other parameters as inputs to predict total resistance instantaneously, maintaining accuracy across diverse geometries and mitigating sensitivity issues. In a follow-up study, Ao et al. [

21] integrated such a DNN into the initial hull design loop, calling it an “AI-aided design” approach. The DNN, once trained on a database of hulls and computed resistances, could predict total resistance with less than 4% error on average, narrowing the viable design space long before high-fidelity CFD or prototyping is required. These deep learning applications illustrate how DNNs and VAEs learn the complex non-linear relationships between hull geometry and performance, thus empowering automated or semi-automated generation of hull forms that are likely to meet design objectives, see

Figure 4.

Evolutionary algorithms (EAs) have a long history in hull form generation and optimization, often mimicking natural selection to evolve hull shapes for improved hydrodynamic performance. Among these, Genetic Algorithms (GAs) and Particle Swarm Optimization (PSO) are particularly prominent for navigating high-dimensional design spaces. Dejhalla et al. [

22] demonstrated one of the earliest GA applications in naval architecture by encoding Series-60 hull forms and coupling the GA with Dawson’s potential-flow solver. The evolved hulls exhibited notable reductions in wave resistance, establishing the viability of EAs for hull design. This laid the groundwork for treating hull geometry generation as an optimization problem suitable for evolutionary methods. Subsequently, Chen and Ye [

23] introduced a hybrid “genetic neural network” framework, wherein a GA optimized the weights and thresholds of a neural network trained to predict Series-60 resistance. This enabled rapid resistance estimation, effectively replacing computationally intensive simulations during iterative design. Wan et al. [

24] adopted a similar hybrid approach for a submersible-surface ship, using GA-tuned backpropagation networks to generate high-fidelity resistance predictions with K-fold validation, showcasing the synergy between evolutionary search and data-driven surrogates. Beyond hybrids, purely evolutionary approaches have also been pursued. Ang et al. [

25] proposed an “Industry 4.0” digitalization to fully automate the evolutionary hull-design pipeline. Meanwhile, Zhang et al. [

26] combined arbitrary-shape deformation with an enhanced PSO variant to optimize a bulbous bow, yielding a design with significantly reduced calm-water resistance. These studies affirm the global search capabilities of EAs, particularly for non-linear, multi-modal objective spaces inherent to hull shaping problems. Another example of blending evolution with user interaction is the GenYacht system by Khan et al. [

27] introduced GenYacht, an interactive system in which designers iteratively select preferred yacht hull variants from a diverse population. The design space is subsequently “shrunk” around these selections, refining the population in successive iterations. GenYacht outperformed traditional interactive GAs in both convergence efficiency and user satisfaction, highlighting the utility of human-in-the-loop optimization for incorporating subjective criteria such as esthetics. Although EAs demand many high-fidelity evaluations, hybrid schemes that pair them with fast machine-learning surrogates retain their exploratory power while slashing cost. Consequently, EAs continue to serve as the optimization engine behind modern, ML-assisted hull-form design and parametrization frameworks, see

Figure 5.

Reinforcement Learning (RL) offers a different archetype for hull generation. Rather than exploring the design space through predefined variations, an RL agent learns how to modify a hull form via trial-and-error in a simulated environment. The agent observes the current hull state, applies incremental shape changes (actions), and receives rewards based on performance improvements—typically resistance reduction. Oh et al. [

28] implemented an RL-based hull form optimizer using local shape modifications at the bow and stern. The reward function penalized infeasible designs and rewarded resistance reduction. Two deep RL algorithms, Proximal Policy Optimization (PPO) and Deep Deterministic Policy Gradient (DDPG), were tested. Compared to Genetic Algorithms (GA) and PSO, the RL agent achieved equivalent resistance reductions in just one-fifth of the optimization time. This five-fold speed-up reflects RL’s ability to leverage learned experience, requiring far fewer evaluations during future searches. Another compelling application of RL is in multi-objective design scenarios. Yeo et al. [

29] linked the reward to acoustic target-strength reduction for a submarine, enforced geometric-feasibility and stability constraints, and let the deep RL agent reshape curvature and dimensions that influence sound reflections. By learning to reshape curvature and hull dimensions that affect sonar reflections, the agent achieved a 6.5 decibel reduction in target strength and improved maneuverability over the baseline design. Yeo demonstrated RL’s ability to handle complex objectives and constraints by learning the cause-effect relations through repeated experimentation in the simulation environment. These studies highlight RL’s strength in uncovering non-intuitive, sequential shape modifications under complex constraints. Though training is initially expensive, a trained policy generalizes to related design problems, enabling rapid adaptation, which provides a clear advantage over traditional optimization methods that complete the search in a single, isolated process, see

Figure 6.

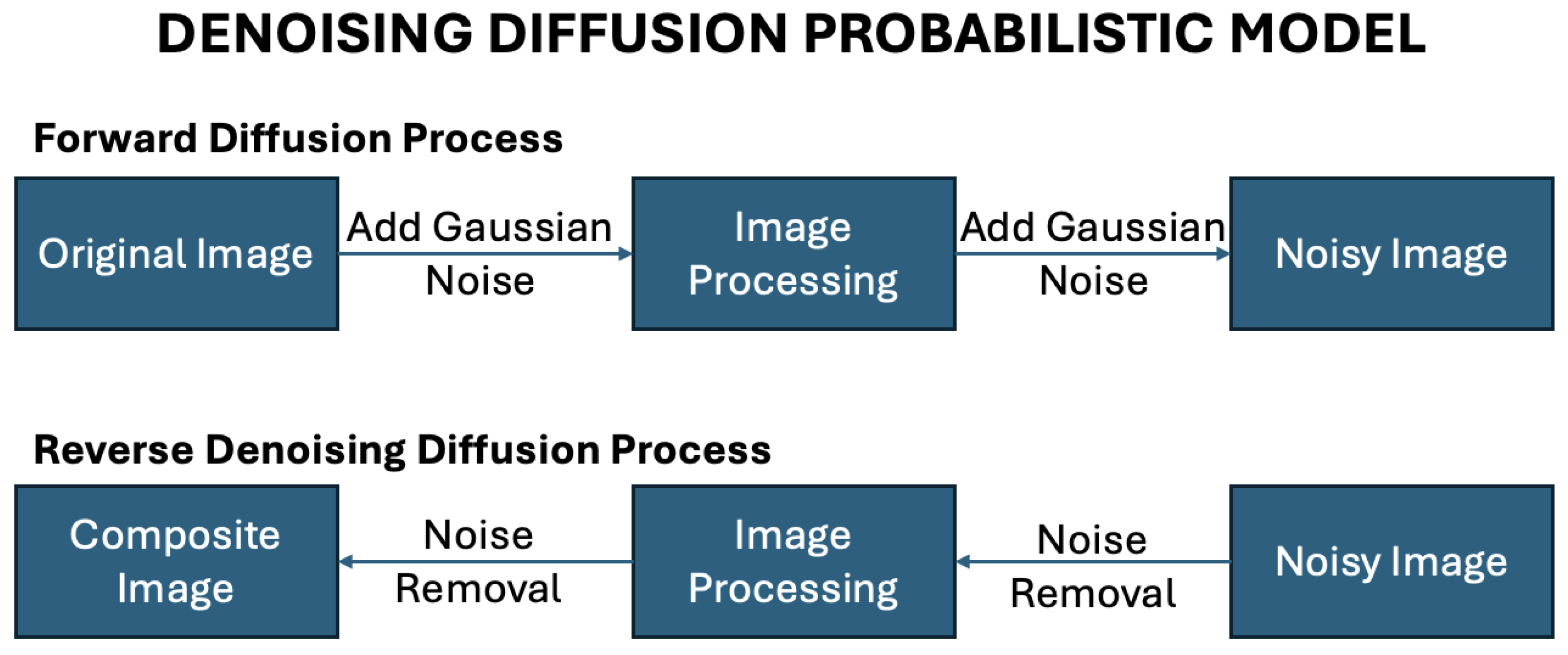

Diffusion Probabilistic Models are a cutting-edge generative approach that has recently been applied to ship hull design. Bagazinski & Ahmed [

30] introduced ShipGen, a denoising diffusion model for parametric hull generation that can handle multiple objectives and constraints. Their model generates hull form parameters, such as principal dimensions, coefficients etc., by iteratively refining random noise into a realistic design, guided by learned probability distributions. By incorporating classifier guidance, the diffusion model was able to produce feasible hull designs that covered the design space much more thoroughly than random sampling, achieving a

coverage of the original data distribution, compared to only ∼0.67% by random sampling. More importantly, ShipGen was able to target performance improvements. On average, generated hulls had 91% lower drag coefficients and significantly higher displacement volume relative to the dataset mean, showing that the model is able to create high-performing designs rather than just replicas of existing ones. However, many have expressed concerns about the feasibility of such a significant reduction in resistance. Continuing their work, Bagazinski & Ahmed [

31] proposed C-SHIPGEN, a conditional diffusion model that allows designers to specify certain constraints (like desired length, beam, and draft) as inputs. C-SHIPGEN, which uses the dataset from SHIP-D [

32], integrates a physics-based guide by using gradients from a resistance prediction model to bias the diffusion process towards low-resistance solutions. In tests, the conditional diffusion model generated hulls that not only met the imposed design constraints but also achieved around 25–30% lower resistance than those designed by a conventional optimization algorithm, all without requiring a separate optimization loop for each new design. Although the results may seem too good to be true and the optimized hull is too long to be a real ship, diffusion models represent a powerful “generate-and-optimize” archetype where the generation of hulls and the optimization for performance happen simultaneously within the model’s iterative de-noising process, see

Figure 7.

Gaussian Mixture Models (GMMs) are a simpler generative strategy; statistical models like GMMs have been used to describe and sample the hull form design space. Thakur et al. [

33] employed a GMM as the core of a generative AI framework for ship design. Using the large Ship-D dataset (30,000 hulls) as a basis, they fitted a GMM to the distribution of hull parameters, enabling them to quickly generate new hull form candidates by sampling from the mixture components. While a GMM is not as expressive as a deep generative model, it offers a mathematically tractable way to capture multimodal distributions in the data. Thakur et al. [

33] also reported that this approach is able to efficiently produce innovative hull designs that explore the extremes and gaps in the dataset, which can then be evaluated for performance. GMMs can be a good choice when data is plentiful, but when one wants a more transparent generative method than a neural network—they allow easy control over output diversity and can be combined with optimization by re-weighting mixture components toward desired objectives.

Parameterized Design Spaces and Shape Interpolation: Some researchers focus on defining a parametric model of the hull form (using spline control points, principal components, or other basis functions, etc.) and then using ML to intelligently navigate this space. The earlier-mentioned PCA approach by Yu & Wang [

19] is one example, where the “generation” of hulls is performed by varying PCA scores within learned bounds. Similarly, methods like auto-encoders can provide a parametrization of hull geometry in a lower-dimensional latent space; designers or algorithms can then interpolate and extrapolate in that space to obtain new shapes. Another example is the SHIP-D dataset; this data was created by using parametric transformations on a set of 12 original ship hulls to achieve a total of 30,000 ship hulls. This dataset provided functional information (such as parametrization, mesh, point cloud, and image representation) as well as 32 hydrodynamic drag measures under different operating conditions along with the ship hulls. These are not generative models in themselves, but rather representation learning approaches that make the task of generating feasible hull forms easier by working in a reduced space where each variable change produces smooth and realistic geometry changes.

Interactive and Knowledge-Based Systems: While not purely ML in the algorithmic sense, systems that incorporate human feedback or domain knowledge into the generation process deserve note. As seen with GenYacht [

27], this interactive evolution is able to guide hull generation. Another angle is using knowledge graphs or rule-based AI to ensure generated hulls meet high-level design knowledge. Maimun et al. [

34] discuss a conceptual AI framework for ship design that would extract and encode expert knowledge and design rules, potentially to guide ML models. For instance, a knowledge-based system might restrict a generative model so that any hull it produces automatically satisfies basic stability criteria or classification society rules, thereby narrowing the generation to meaningful designs. While such approaches are in early stages, they point towards hybrid ML systems that combine data-driven generation with explicit naval architectural knowledge to yield practical hull designs.

3.2. Structural Design AI Models

Ship structural design is a complex, multi-constraint process of determining the number, placement, and scantlings of structural elements such that safety and performance criteria are met. Traditionally, naval architects rely on rule-based methods to produce workable designs that satisfy strength standards, but these are often suboptimal in weight and cost [

35]. Finding a true optimum manually is restrictive given the high-dimensional design space and multitude of constraints. In recent years, AI and ML techniques have increasingly emerged as powerful tools to assist in ship structural design optimization, enabling designers to explore designs beyond conventional baselines. AI-based structural design optimization techniques facilitate multi-criteria design, balancing weight reduction, cost-efficiency, and regulatory compliance. Various industry trials have demonstrated that multi-objective algorithms incorporating AI can reduce overall mass by

and material costs by

. By iteratively refining design parameters, these algorithms are able to effectively negotiate trade-offs among constraints like buckling resistance, fatigue life, and fabrication requirements. Hence, the holistic perspective provided by AI ensures that structural integrity and resource efficiency are both prioritized. This section provides a deep literature survey of applications of ML/AI in the design and optimization of ship hull structures.

Genetic and Evolutionary Algorithms have emerged as foundational artificial intelligence methods for optimizing ship hull structures due to their capability to handle numerous discrete design variables and multiple, often conflicting, objectives simultaneously. Abedin et al. [

35] demonstrated a two-stage optimization approach for a cargo ship’s midship structure using a fractional factorial Design of Experiments (DOE) followed by the NSGA-II genetic algorithm, resulting in approximately a

reduction in structural weight and production costs. This optimization was achieved by intelligently adjusting plate thicknesses, web frame positions, and stiffener arrangements within class society requirements. Similarly, Louvros et al. [

36] employed multi-objective optimization in early-stage design, successfully relocating internal structural elements (bulkheads, decks) to balance multiple design objectives simultaneously. Pereira and Garbatov [

10] extended this approach by integrating risk-based safety assessments into GA optimization frameworks, quantitatively balancing hull weight, structural failure probability, and costs to achieve economically efficient and safe designs. These evolutionary approaches excel at navigating the complex, combinatorial design space typical of ship structures, where traditional gradient-based methods face difficulties due to discrete and discontinuous variables. The efficacy of evolutionary optimization is also evident in studies highlighting significant weight savings. Elhewy et al. [

37] achieved an extraordinary

steel weight and cost reduction through heuristic optimization of an offshore supply vessel structure. Motta et al. [

38] similarly reported an

weight and

cost reduction in a mega-yacht structure using evolutionary methods. However, the practical implications of extreme optimization must be considered. Caprace and Rigo [

39] found purely weight-minimal solutions could increase manufacturing complexity and costs, highlighting the necessity of incorporating manufacturability constraints into the optimization process. Such constraints ensure practicality and compliance with industry standards. Early foundational studies like Sekulski [

40] demonstrated that GAs could adeptly manage numerous scantling variables within industry rules, setting the stage for contemporary research integrating GAs with hybrid approaches. Recent advances further refine these methods, exemplified by Putra et al. [

41] employing hybrid GA techniques to optimize stiffened plates, achieving significant weight reductions while meeting stress and deformation limits. Collectively, these works underline evolutionary algorithms as robust, versatile tools in naval architecture, facilitating significant structural efficiency improvements through optimized configurations, reduced weight, cost savings, and enhanced compliance with safety and manufacturing standards.

Surrogate Models utilizing ML, such as neural networks, GPR, and SVM, have become pivotal in accelerating ship structural optimization by providing rapid approximations of computationally expensive evaluations. Fabris et al. [

42] showcased a surrogate-assisted optimization pipeline combining reduced-order modeling (Proper Orthogonal Decomposition) with GPR to approximate finite element analysis (FEA) outcomes. Their methodology allowed efficient exploration of thousands of design variants, resorting to full FEA only for the most promising configurations. A key innovation was their iterative, data-driven reparametrization of structural elements based on stress patterns, resulting in significantly lighter yet robust designs compared to traditional parametrizations. Similarly, Saptawijaya et al. [

43] investigated neural network-based surrogates, demonstrating their effectiveness in multi-objective ship design optimization. Their findings revealed that although ANNs delivered high predictive accuracy and considerable improvements (e.g.,

weight reduction and

lower power demand), a less precise Kriging model produced a broader and superior Pareto front, suggesting that local accuracy might not always correlate with optimization effectiveness.

Hybrid Methods, such as the integration of surrogates with evolutionary algorithms, further exemplify their potential. Sun et al. [

44] utilized a hybrid SVM-GA method for optimizing the structure of a Very Large Crude Carrier, significantly reducing computational costs and enabling extensive design iterations with notable performance enhancements. Similarly, recent advancements by Qiu et al. [

45] illustrated the effectiveness of ensemble surrogates combining response surfaces, Kriging, radial-basis functions, and neural networks, achieving prediction errors around

relative to high-fidelity simulations. Other studies, such as those by Prebeg et al. [

46] and Chen et al. [

47], effectively employed surrogate models in optimizing structural safety and dynamic responses, confirming substantial efficiency gains by replacing direct simulations with ML-driven approximations. Beyond structural optimization, ANNs have been trained to predict specific structural behaviors, such as the buckling loads of stiffened panels, with accuracies comparable to FEA [

48]. This approach allows rapid real-time assessments during optimization and structural health monitoring. Collectively, these studies underscore surrogate modeling as a cornerstone of modern ship structural optimization, capable of facilitating rapid multi-objective optimization, enhancing computational efficiency, and paving the way toward integration with more autonomous AI-driven design strategies such as reinforcement learning.

Reinforcement Learning (RL) techniques are increasingly utilized in ship structural optimization, iteratively enhancing design strategies beyond conventional methods. Cui et al. [

49] integrated Q-learning with evolutionary algorithms, enabling the RL system to treat design modifications as experiences, iteratively learning effective rules for structural adjustments. Their approach incorporated a hierarchical memory system, short-term for immediate validation and long-term for retention of successful design strategies. This hybrid method achieved an

weight reduction and improved fatigue performance compared to standard genetic algorithms, demonstrating faster convergence due to dynamic exploitation of past design experiences. Similarly, generative design techniques (GDTs) offer innovative, extensive exploration of structural alternatives beyond incremental optimization adjustments. Andrić [

50] demonstrated a multi-level optimization framework combining topological decisions, structural sizing, and internal layout arrangements within a unified Pareto optimization. This methodology yielded diverse structural configurations, significantly improving weight and performance relative to traditional optimization strategies. While generative techniques are still nascent in naval architecture, their ability to autonomously propose novel structural arrangements, such as innovative stiffener layouts and unconventional bulkhead configurations, highlights their potential to revolutionize structural design by leveraging advanced computational models and deep generative methods. As computational capabilities and datasets grow, the integration of reinforcement learning and generative design is poised to significantly enhance the effectiveness and innovation of ship structural optimization.

Graph Neural Networks (GNNs) and

Physics Informed Neural Networks (PINNs) are newer AI models emerging in naval architecture research. GNNs and PINNs are NNs that incorporate domain-specific knowledge into the learning process. GNNs are designed to operate on graph-structured data, making them well-suited for problems where the relationships between entities are as important as the entities themselves. In ship design, GNNs have been explored for modeling complex structural systems. A study by Cai and Jelovica [

51] represented a ship’s stiffened panel structure as a graph of plates and stiffeners. They demonstrated that GNNs can predict stress distributions in 3D stiffened panels under load, effectively serving as a surrogate model for finite element analysis. By embedding the structural topology into the model, the GNN was able to achieve fast, accurate stress predictions, pointing to immense potential for GNN-based reduced-order models in structural design and optimization tasks. This approach allows AI to exploit the connectivity information (which a plain DNN or ensemble might ignore) and thereby handle variations in structural geometry more naturally. The limitation, however, is that GNNs are relatively complex to construct and require expertise in both graph data formulation and neural network training. They also demand careful validation, since any extrapolation beyond the trained graph patterns could lead to unphysical results. PINNs represent another frontier by embedding their networks with physical laws (governing equations, conservation principles, or domain-specific empirical models) into the training objective. Instead of purely fitting data, a PINN is penalized when its outputs violate known physics, effectively blending data-driven learning with first-principles constraints. In marine applications, PINNs have shown promise in scenarios like predicting the dynamic motion of unmanned surface vessels by incorporating the vessel’s dynamic equations into the model. Xu et al. report that a PINN was able to predict surge, sway, and yaw motions with better generalization than a traditional neural network when only limited training data were available, thanks to the embedded physics ensuring physically plausible behavior. The strength of PINNs lies in this ability to retain physical consistency and reduce data requirements, making them attractive for ship design problems where data is scarce or expensive to obtain (such as extreme scenario simulations or novel hull forms). On the downside, formulating a PINN requires good knowledge of the governing physics and sometimes significant computational effort (since each training iteration may involve solving or differentiating the physics equations). Moreover, ensuring that the network architecture can represent the solution space of the physical equations is non-trivial. Despite these challenges, physics-informed models are a crucial development to bridge the gap between pure black-box models and the rich heritage of naval architecture theory.

4. Discussion

This review has critically examined the integration of ML optimization methods in hydrodynamic and structural ship design. The findings of this review underscore that there is no single “best” AI algorithm for ship design. Rather, the suitability of a model is highly context-dependent, echoing the “No Free Lunch” theorem, which states that no inference algorithm can consistently outperform all others across every possible scenario. Each type of AI technique, from genetic algorithms to advanced deep learning architectures, has demonstrated its own strengths in certain ship design applications and limitations in others. For that reason, the optimal choice of algorithm depends on the specific use case, desired outcomes, available data, and available computational power, as well as the need for model interpretability and ease of implementation in the design workflow.

An authorship analysis of the

Section 3 references reveals an additional dimension of bias within the current research landscape. Of the 38 works reviewed in this section, 32 were authored solely by academic institutions, six represented academic-industry collaborations, and none were authored exclusively by industrial organizations. This academic authorship bias implies that the field’s methodological trajectory is largely shaped by academic priorities, such as theoretical innovation, algorithmic benchmarking, and controlled-environment validation. As a result, certain industry-relevant factors, including manufacturability constraints, operational integration, regulatory compliance, and lifecycle cost considerations, may be under-represented. Furthermore, limited direct industry authorship constrains the incorporation of proprietary datasets, full-scale trials, and post-deployment feedback, which are vital for translating research outputs into commercially viable and operationally robust solutions. Bridging this divide will require fostering stronger academic-industry partnerships to ensure that advances in AI ship design methodologies are both theoretically sound and practically deployable, see

Table 2.

This review reveals that a wide spectrum of AI models are being employed across various ship design tasks. Comparisons with other studies in the field confirm that no single approach dominates universally, and simpler models can sometimes perform on par with more complex ones under the right conditions. For example, Yang et al. [

52] tested multiple learning algorithms (from ANNs and SVMs to gradient boosting decision trees) for ship fuel consumption prediction and found that ensemble tree methods, such as random forest, GBDT, and XGBoost, achieved the highest accuracy in that context. Similarly, a benchmark study on ship speed–power modeling reported that an XGBoost model attained the best predictive performance, with an

of 0.995, marginally outperforming a deep neural network and an SVM model [

53]. These cases illustrate that, depending on the nature of the data and problem, classical or ensemble methods can rival deep learning in accuracy, reinforcing the notion that algorithm selection must be case-specific [

54]. Indeed, some research even notes that SVMs may generalize better than ANN-based models in certain situations, exhibiting lower prediction error on test data despite ANNs fitting training data more closely [

55]. Such findings from the literature align with this review’s conclusion that model performance is contingent on problem characteristics and that careful benchmarking of multiple approaches is prudent before settling on a solution.

Each type of AI model offers distinct strengths and comes with particular limitations when applied in different scenarios. DNNs, including multilayer perceptrons, convolutional neural nets, and more specialized architectures, excel at capturing complex non-linear relationships and high-dimensional feature interactions. In hull form and hydrodynamics studies, DNN-based surrogate models have shown the ability to predict resistance and optimize hull shapes with impressive accuracy, effectively supplementing or replacing some traditional CFD evaluations [

56,

57]. The advantage of deep nets is most noticeable when a large amount of data is available, allowing the network to learn subtle patterns. However, these models are typically data-hungry and computationally intensive to train [

58]. They also tend to act as “black boxes” with low interpretability. This lack of transparency can be a drawback in engineering design, where understanding why a prediction was made is often important for gaining domain insights and trust. In contrast, SVMs and related kernel-based methods can perform robustly with smaller datasets or limited features due to their solid theoretical underpinnings and regularization that helps prevent overfitting [

55]. SVMs have been successfully applied, for instance, in predicting ship resistance or seakeeping criteria in cases where data is moderate and noise needs to be handled. They often achieve good generalization, as noted by studies observing SVMs yielding lower test errors than ANNs under certain conditions. Nonetheless, SVMs may struggle to match the flexibility of deep nets on highly complex tasks or very large data, and like DNNs, they do not provide intrinsic interpretability of results. Decision tree-based models, including single decision trees, random forests, and gradient boosting machines, offer a middle ground. These models handle heterogeneous tabular input data well and can capture non-linear effects and feature interactions through ensemble learning, while having the added benefit of some interpretability. Naval architects can extract feature importance rankings or partial dependence plots from them, which is valuable for understanding design drivers [

59]. In ship design contexts, tree ensembles have delivered state-of-the-art accuracy and have matched or exceeded neural network performance in ship powering models [

53]. The main limitations of tree models are their tendency to overfit when not properly tuned (especially single decision trees) and the fact that large ensembles, while more accurate, become less transparent than a small tree. However, they generally require less training data than deep networks to achieve good performance and have faster training times on modest-sized datasets, making them practical for early-stage design studies where data might be limited.

An important observation from this review is the overlap in applicability among different AI methods for key ship design tasks like hull resistance prediction, structural optimization, and surrogate modeling of performance metrics. Multiple approaches can often be applied to the same problem, each with their own trade-offs. For instance, hull resistance or powering predictions have been tackled using simple regression and statistical models, classical ML (SVMs, regression trees), and deep learning surrogates [

60,

61]. All of these can yield useful results, but their effectiveness depends on data quantity and quality. Traditional statistical models or SVMs may suffice when extrapolating within well-understood design spaces or when only a small experimental dataset (towing tank results, high-fidelity data, etc.) is available. In contrast, deep neural nets or boosted trees become advantageous when leveraging large-scale data (such as high-fidelity CFD results across many hull variants) to capture complex interactions among hull parameters. Likewise, in structural design and optimization, early studies relied heavily on genetic algorithms and other evolutionary techniques to explore design alternatives. These methods handle discrete design variables and multiple objectives well, and many works report substantial weight or cost reductions using GA-based optimizations of ship structures. However, surrogate models built with machine learning are increasingly integrated into the optimization loop [

61]. For example, a neural network or GNN may quickly predict structural responses (strength, vibration, etc.) for each candidate design, thereby accelerating the search for an optimal solution. This creates a synergy where learning models assist optimization algorithms, blurring the line between predictive modeling and design optimization. The areas of overlap among methods also mean that researchers often must choose between a purely data-driven and a hybrid approach for a given task. Surrogate modeling in hydrodynamics is a good example where one can train a black-box ANN to emulate a CFD solver’s output or use a PINN that embeds fluid dynamics equations to achieve the same goal. Both approaches aim to replace expensive simulations with rapid predictions, but they differ in data needs and reliability. The comparative analysis suggests that no one method strictly dominates; instead, engineers must evaluate the trade-offs. Sometimes, a simpler model augmented with domain knowledge can outperform a more complex one blindly trained on data, especially when data are limited. For instance, hybrid gray-box models have been shown to match the accuracy of purely data-driven models while requiring far fewer training samples by encoding prior naval architecture knowledge into the model structure [

58]. Such findings reinforce the idea that combining complementary approaches—such as coupling physics-based and ML models—can yield superior outcomes compared to using any single method in isolation.

Finally, the practical implications of these findings for researchers and practicing naval architects are notable. One recurring theme is the tension between model complexity and accuracy versus interpretability and ease of implementation. High-capacity models like deep neural networks or large ensembles can deliver exceptional predictive accuracy, but their opaque nature and heavy data/computation demands can be impediments in practice [

58]. In a design office or classification society setting, the ability to explain a prediction—why a certain hull form is predicted to have lower resistance, or why a structural design is deemed optimal—is often as important as the prediction itself, for reasons of safety, regulatory compliance, and engineering insight. Thus, in cases where interpretability and trust are paramount, engineers might favor decision trees or simpler rule-based AI or use techniques like SHAP values on tree ensembles to extract human-understandable insights, even if this comes at a slight cost in raw accuracy [

59].

Data availability is another practical constraint. Many advanced AI models cannot reach their potential without large, high-quality datasets, yet the maritime industry traditionally suffers from scarce and siloed data [

62,

63]. This means that, in practice, an engineer might opt for a robust model that works well with limited data (such as an SVM or a carefully regularized regression model) rather than a data-hungry deep network. Computational resources also factor into method selection. Training a deep learning model or running a complex GNN can require substantial computing power (GPUs or HPC clusters), which not every organization can readily afford for routine design work. On the other hand, models like surrogate models and ML predictors do not require high-end computation power once deployed; they only demand significant resources during the training phase [

61]. However, it is also worth noting that computational capacity continues to grow and becomes more accessible as developments in high-performance computing and cloud platforms gradually lower this barrier.

As these resources become more commonplace in the maritime industry, the balance may tip more towards using sophisticated models even in early-stage design, since what was computationally prohibitive a decade ago may be feasible now. Regardless, a cost–benefit analysis is essential: the marginal gain in predictive accuracy from an advanced model must justify its complexity and resource requirements. For example, if a simple parametric formula or regression gives an answer within 5% of a brute-force deep learning prediction for a particular hydrodynamic coefficient, the simpler approach might be preferred for expediency. On the other hand, for critical optimizations—such as minimizing fuel consumption or structural weight under tight constraints—even small accuracy gains can translate to large real-world savings, warranting the use of more powerful AI.

The key practical message is that AI models should be chosen and tailored with the specific design context in mind, weighing accuracy, interpretability, data needs, and computational cost. There is a growing recognition that AI is not a magic black box to be applied blindly but a set of tools that, when used judiciously, can augment human expertise. To sum it up, the discussion highlights that the landscape of AI-based optimization methods for hydrodynamic and structural problems is rich with options, each method has a niche where it shines, and the onus is on the engineer or researcher to pick the right tool for the task, possibly even combining tools, to achieve the best outcome.

5. Conclusions

The current state of AI applications in ship design is characterized by a diverse array of modeling techniques, each contributing in different ways to the design process. There is no universally superior AI model in this domain; rather, deep neural networks, support vector machines, decision tree ensembles, graph neural networks, and physics-informed neural networks all have roles to play, with their effectiveness tightly linked to context of use. Key insights from this review include the recognition that model selection should be context-aware and purpose-driven. Cutting-edge deep learning methods (including generative models and reinforcement learning) offer unprecedented capabilities in handling high-dimensional design data and uncovering novel design solutions, whereas established machine learning models still excel in reliability and simplicity when data are limited or transparency is needed. For example, where high accuracy in predicting a complex performance metric (like hull resistance or fuel efficiency) is the priority and sufficient data exist, advanced models such as deep networks or boosted trees have proven successful. Conversely, in scenarios like preliminary design with sparse data, simpler or physics-guided models may yield more trustworthy results. A recurring theme is that successful AI integration requires matching the tool to the task. An SVM or a regression model might be the best choice for quick, interpretable predictions of resistance from a small model test dataset, while a GNN or deep surrogate model could be more appropriate for evaluating many structural design variants in an optimization loop. This nuanced understanding of each model’s strengths and weaknesses and the problem requirements is crucial for making informed methodological choices.

An additional and important finding of this review is the authorship bias embedded in the existing literature. Of the 38 studies reviewed in

Section 3, 32 were authored solely by academic institutions, six were academic–industry collaborations, and none were authored exclusively by industry. This imbalance reflects a research environment predominantly shaped by academic priorities and evaluation metrics. While such work drives theoretical advances and methodological innovation, it also risks under-representing industry-driven challenges such as manufacturability, operational integration, and regulatory compliance. Moreover, limited industry authorship restricts opportunities for large-scale validation with proprietary datasets or in-service performance feedback—key steps in advancing AI applications from proof-of-concept to operational deployment.

The current state of AI-based optimization applications in hydrodynamic and structural ship design is characterized by a diverse array of modeling techniques, each contributing in different ways to the design process. There is no universally superior AI model in this domain. Rather, deep neural networks, support vector machines, decision tree ensembles, graph neural networks, and physics-informed neural networks all have roles to play, with their effectiveness tightly linked to context of use. The evidence from this review confirms that model selection should be context-aware and purpose-driven. Cutting-edge deep learning methods offer unprecedented capabilities in handling high-dimensional design data and uncovering novel design solutions, whereas established machine learning models often excel when data availability is limited or interpretability is a priority.

Another major conclusion is the affirmation of a multi-faceted approach to AI-based optimization in hydrodynamic and structural design problems. Rather than seeking a one-size-fits-all algorithm, researchers and engineers are increasingly combining techniques and domain knowledge to overcome current limitations. There is a clear trajectory towards hybrid modeling strategies that leverage the best of both worlds: data-driven learning and physics-based understanding. One promising direction is the development of gray box or hybrid models that incorporate naval architectural principles or physics-based components alongside machine learning. Such approaches have demonstrated the ability to achieve accuracy comparable to pure black-box models while using less data by encoding prior knowledge (for instance, known hydrodynamic theory or structural mechanics equations) into the model structure. This not only addresses data scarcity issues but also yields models that behave more reliably when extrapolating beyond the training set. Likewise, physics-informed neural networks and other constraint-based AI frameworks represent a path forward for ensuring that AI predictions honor fundamental laws (such as conservation of mass or energy) by design, thereby improving trustworthiness and applicability in safety-critical naval design problems. This review also highlights the potential of generative AI models (e.g., GANs and diffusion models) to augment the design space exploration. They can produce innovative hull or structural configurations that human designers might not conceive, serving as a creative assistant in the design process. The convergence of generative techniques with physics knowledge (for example, a GAN that generates hull forms that are then evaluated by a physics-based module) could lead to powerful design frameworks that push the boundaries of traditional naval architecture.

Looking ahead, several future research directions emerge from this review. First, there is a need for the development of generalizable AI frameworks for ship design. Many current studies address very specific problems (a particular ship type or a single performance metric) with bespoke models. Future efforts should focus on creating methods that can be adapted or extended to different ship classes, operating conditions, and design objectives with minimal retraining. This might involve modular AI architectures or meta-learning approaches that can transfer knowledge from one design context to another. Second, the incorporation of domain physics and expert knowledge into AI remains a rich avenue—whether through physics-informed networks, multi-fidelity modeling (combining low- and high-fidelity simulations), or embedding expert rules into learning algorithms. Such incorporation will improve model robustness and acceptance by practicing engineers. Thirdly, the development of hybrid human-AI design loops is an important area: rather than replacing naval architects, AI systems should complement human expertise, for instance by quickly narrowing down options that human designers then scrutinize and refine. Achieving this will require user-friendly AI tools and visualization techniques so that designers can interact with and understand AI suggestions. Additionally, addressing the practical barriers identified (data availability, validation, and implementation in real industry settings) is crucial for future progress. Efforts to establish robust validation frameworks (e.g., standardized benchmark datasets, evaluation metrics, and perhaps challenge problems for ship design AI) would greatly help in objectively comparing methods and ensuring that reported improvements are meaningful. Similarly, fostering data-sharing initiatives or public repositories of experimental/operational data could alleviate the chronic data scarcity that hinders many AI projects in the maritime field. Collaboration between academia and industry will be key to translating academic innovations into practice; pilot projects and case studies that demonstrate AI-driven design in real ship development projects can build confidence and provide lessons on integration challenges. Finally, as computing technology advances, it opens the door for more computationally intensive AI techniques to be routinely used in ship design. This review anticipates that optimization and search processes that were previously too slow (e.g., high-dimensional design space exploration with Monte Carlo simulations) might become tractable by combining AI surrogates with brute-force computing power. This will enable more exhaustive and ambitious design optimization than was previously possible, leading to better-performing and more innovative ship designs.

To sum it up, the current state of AI in ship design is one of rich possibilities balanced by practical considerations. There is a toolkit of AI models available, each with demonstrated benefits, from improving hull resistance predictions and structural weight optimization to enabling real-time decision support, and the prudent selection or combination of these tools is essential. The overarching recommendation is that engineers should select AI methods in a context-aware manner, guided by the specifics of the design problem and with an eye to the trade-off between accuracy, interpretability, and resource requirements. The future of this field will likely be defined by greater integration of AI with domain knowledge (making AI tools more aware of naval architecture principles) and by the creation of flexible, generalizable frameworks that can handle the inherently complex, multidisciplinary nature of ship design. By pursuing hybrid models, incorporating physics, and striving for generalizability and robustness, researchers can address current limitations and pave the way for AI techniques to become a mainstream, trusted part of the ship designer’s toolkit. The ultimate goal is to bridge the gap between academic innovation and practical application, ensuring that advances in AI truly translate into safer, more efficient, and more innovative ship designs in the years to come.

This review analyzed published studies investigating the implementations of AI in the ship design process. A variety of studies were reviewed, and the key findings and trends were identified and discussed. This analysis demonstrated that the interest in ship design optimization exhibited an exponential increase in the last decade. AI-driven methodologies, such as generative design algorithms, surrogate models, and evolutionary optimization, provide powerful capabilities for rapidly exploring and identifying superior ship designs. These approaches significantly enhance efficiency, allowing naval architects to optimize performance, sustainability, and cost-effectiveness in the early stages of the design process. However, there are still challenges that the maritime industry needs to overcome before they can fully utilize AI.

However, practical implementation remains constrained by data availability, computational limitations, and the absence of robust validation frameworks. To fully realize AI’s potential within the maritime industry, future research must prioritize addressing these gaps. Key recommended areas for further study include developing comprehensive validation standards, enhancing data quality and accessibility, improving computational efficiency, and fostering integration methods that combine AI techniques with conventional engineering expertise. Ultimately, by overcoming these barriers, the maritime industry can harness AI’s full potential, leading to the creation of innovative, sustainable, and highly efficient vessels capable of meeting the demanding operational and environmental standards of the future.