Numerical Investigation on Erosion Characteristics of Archimedes Spiral Hydrokinetic Turbine

Abstract

1. Introduction

2. Mathematical Model

3. Numerical Computational Model

3.1. CFD Modeling

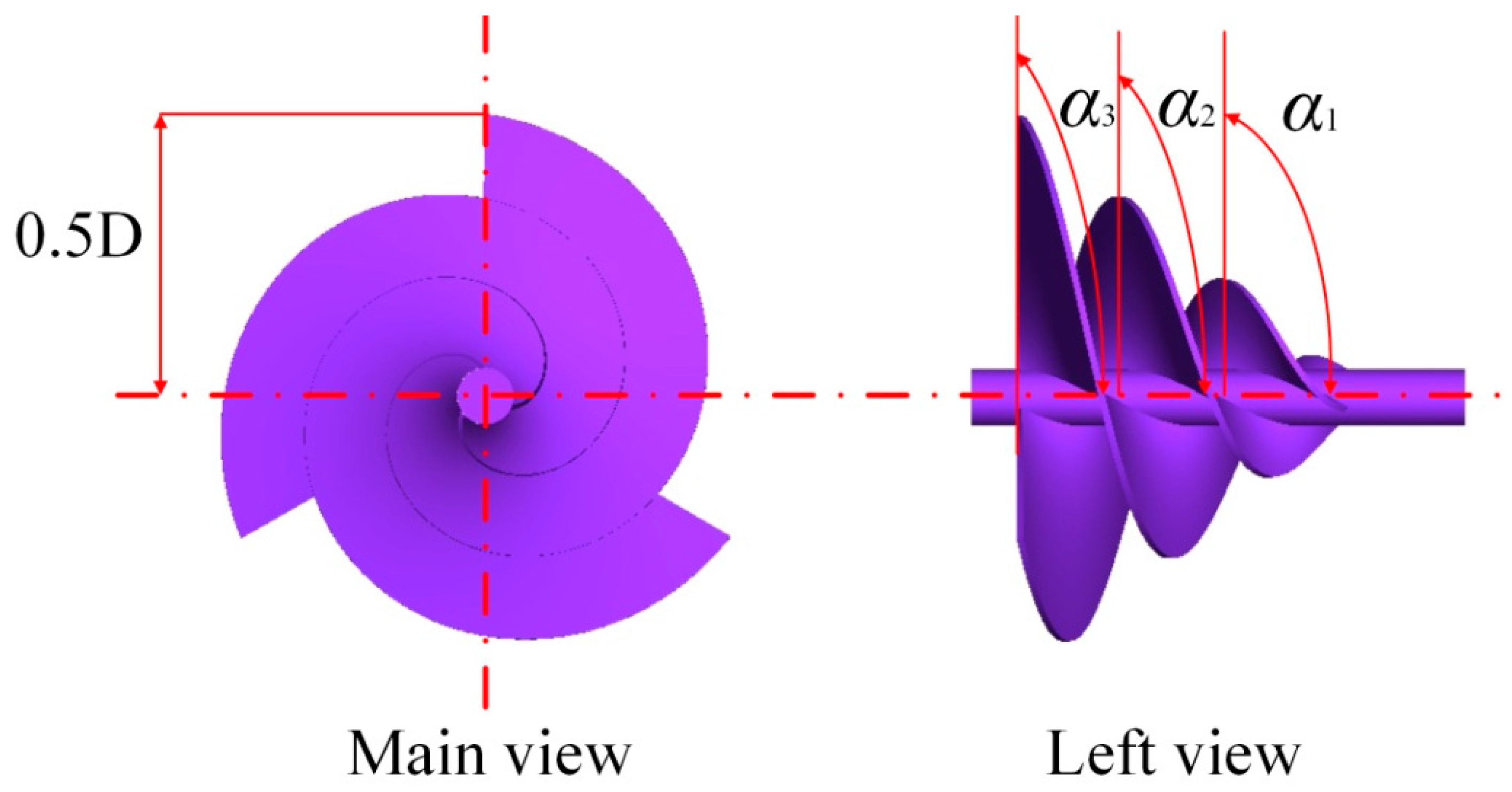

3.2. Geometry of the ASHT

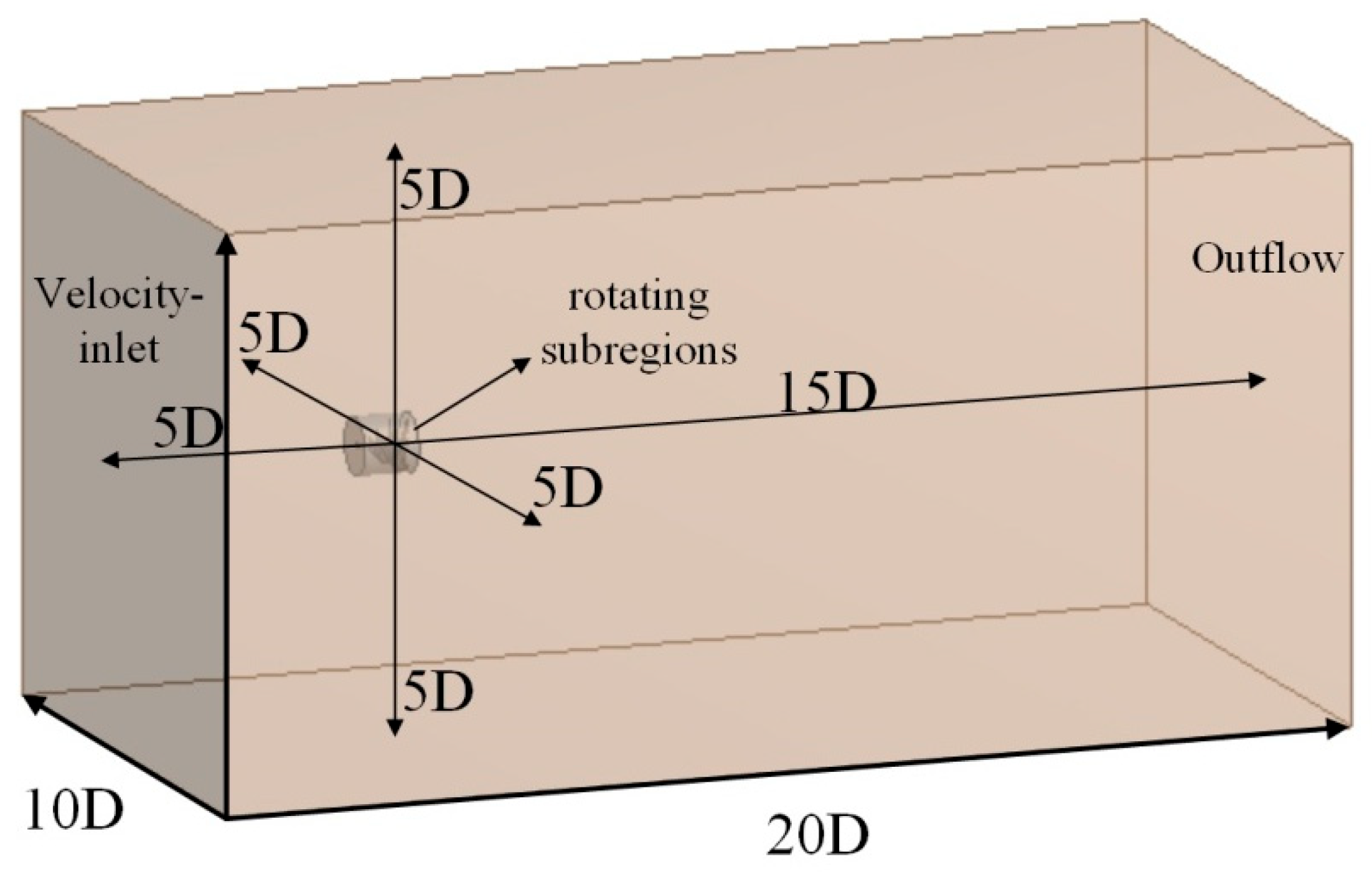

3.3. Computational Domain

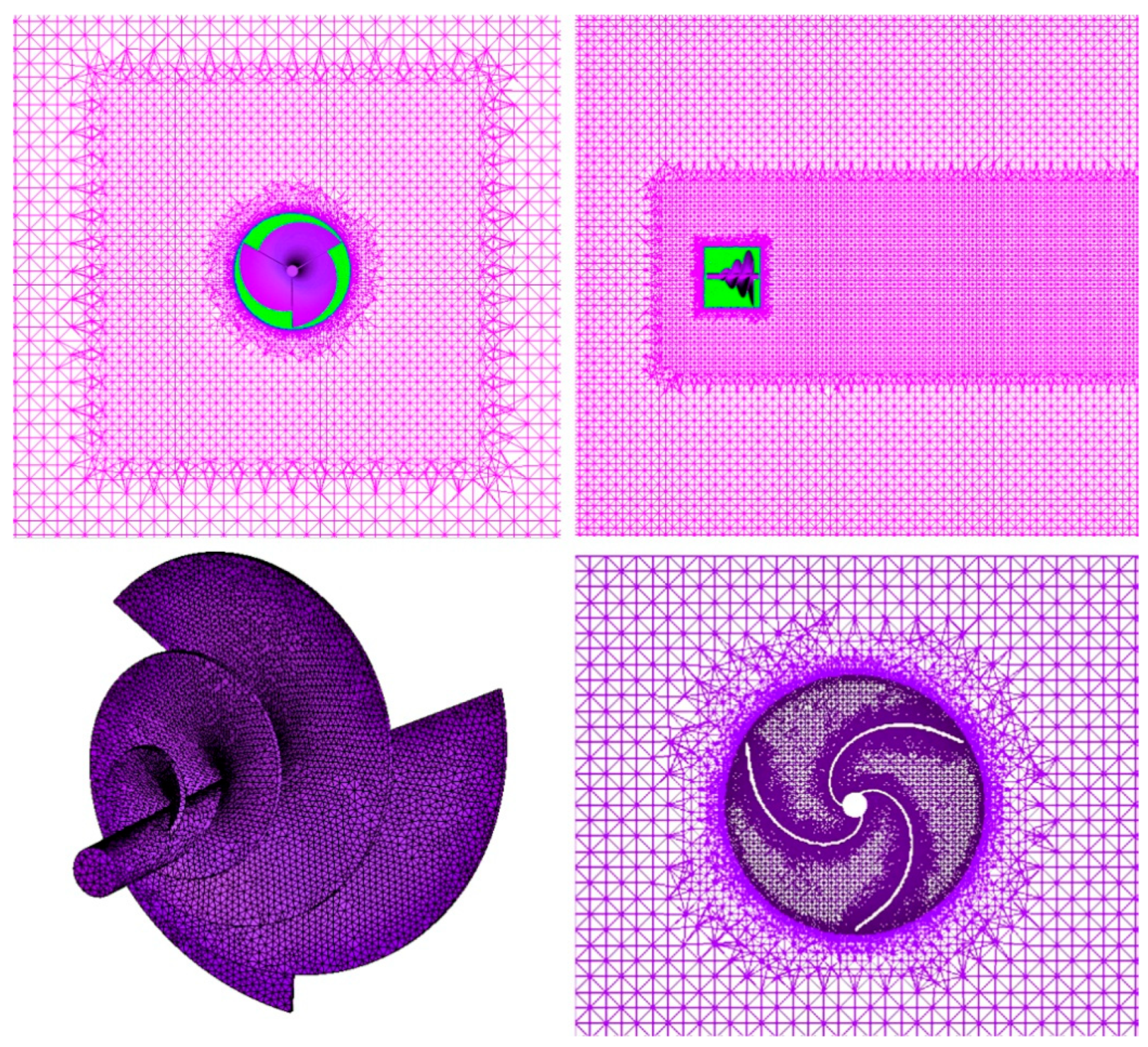

3.4. Computational Mesh

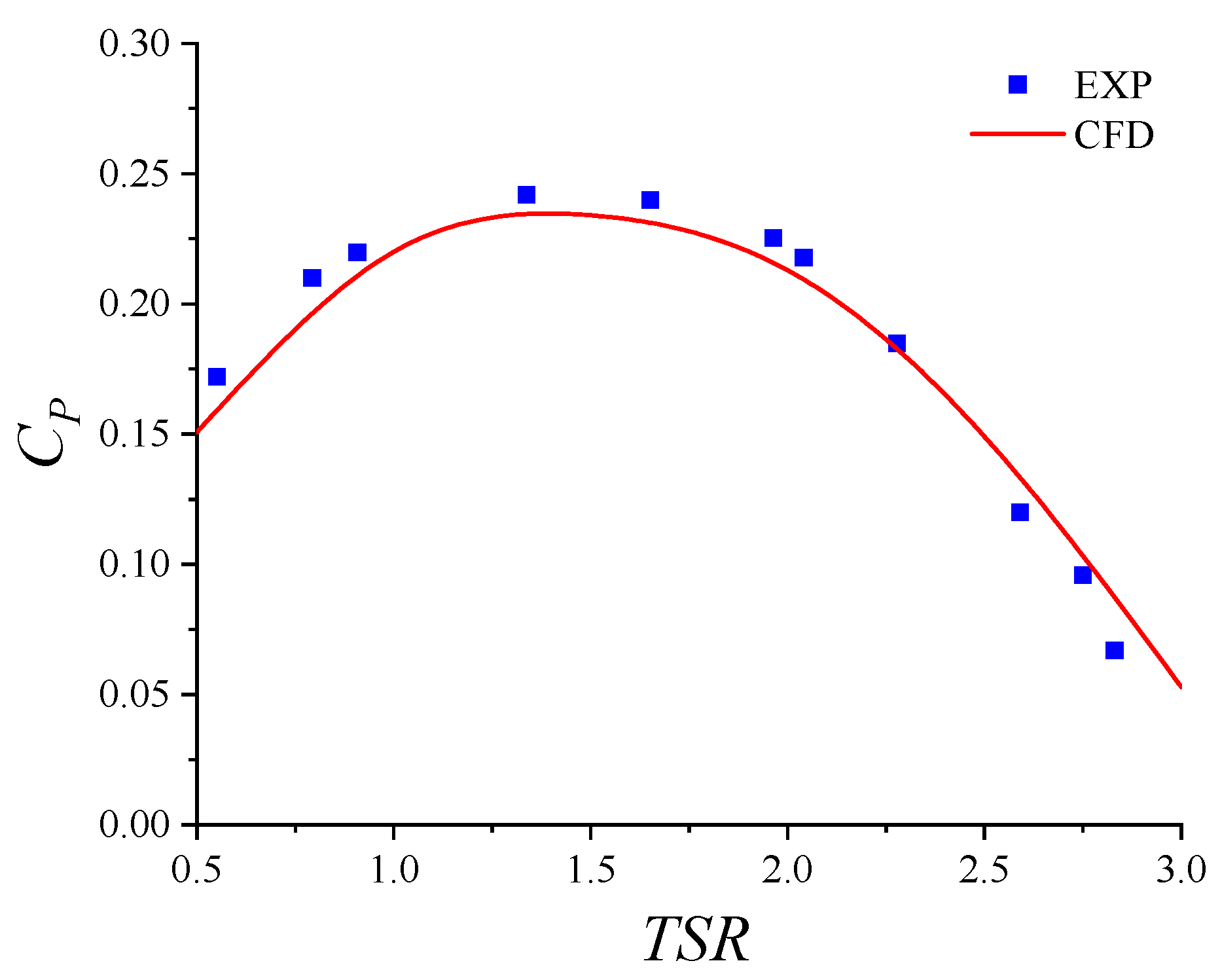

3.5. Model Validation

4. Results

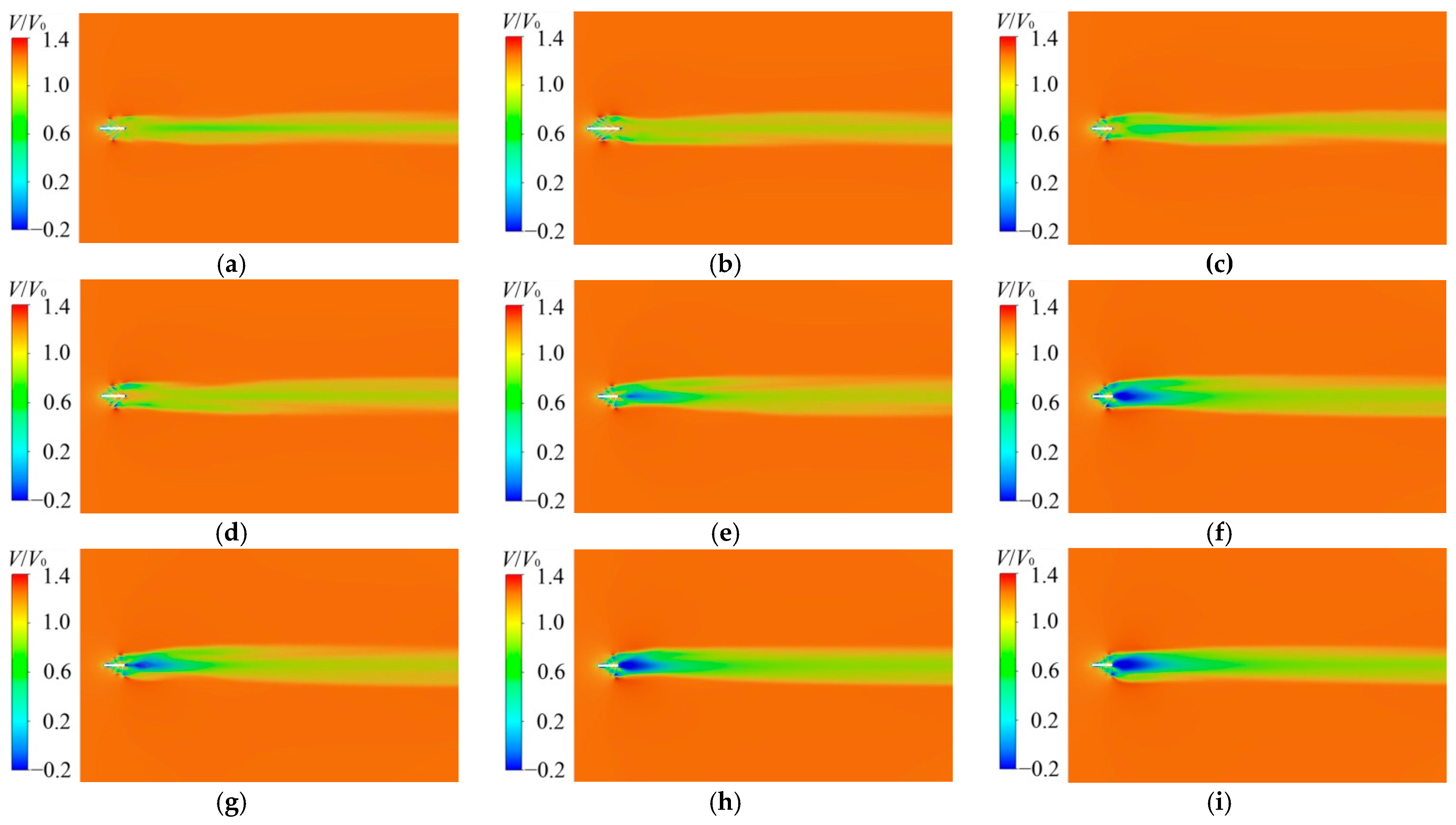

4.1. Flow Field Analysis

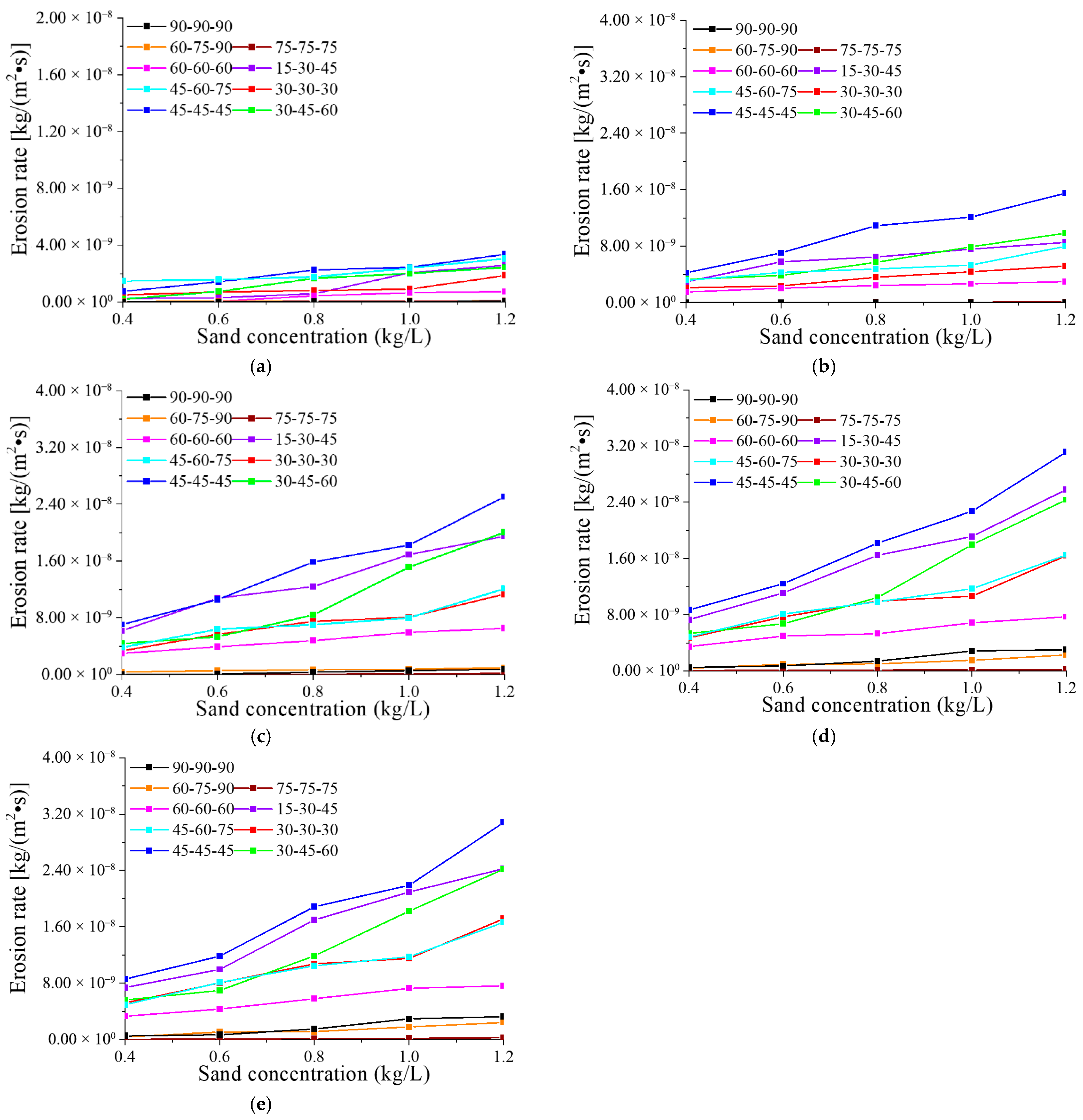

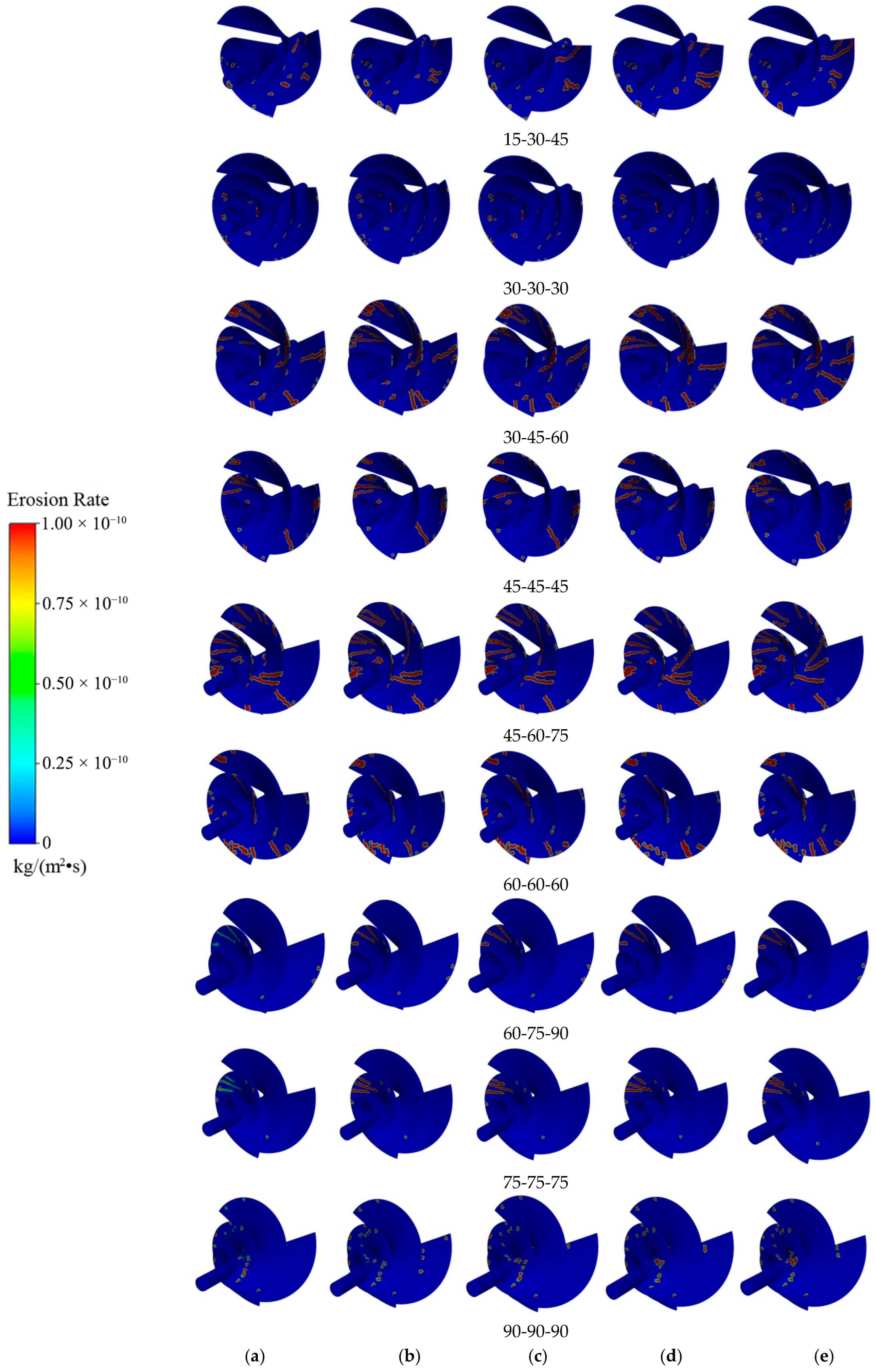

4.2. Effect of Sand Concentration on Erosion Rate

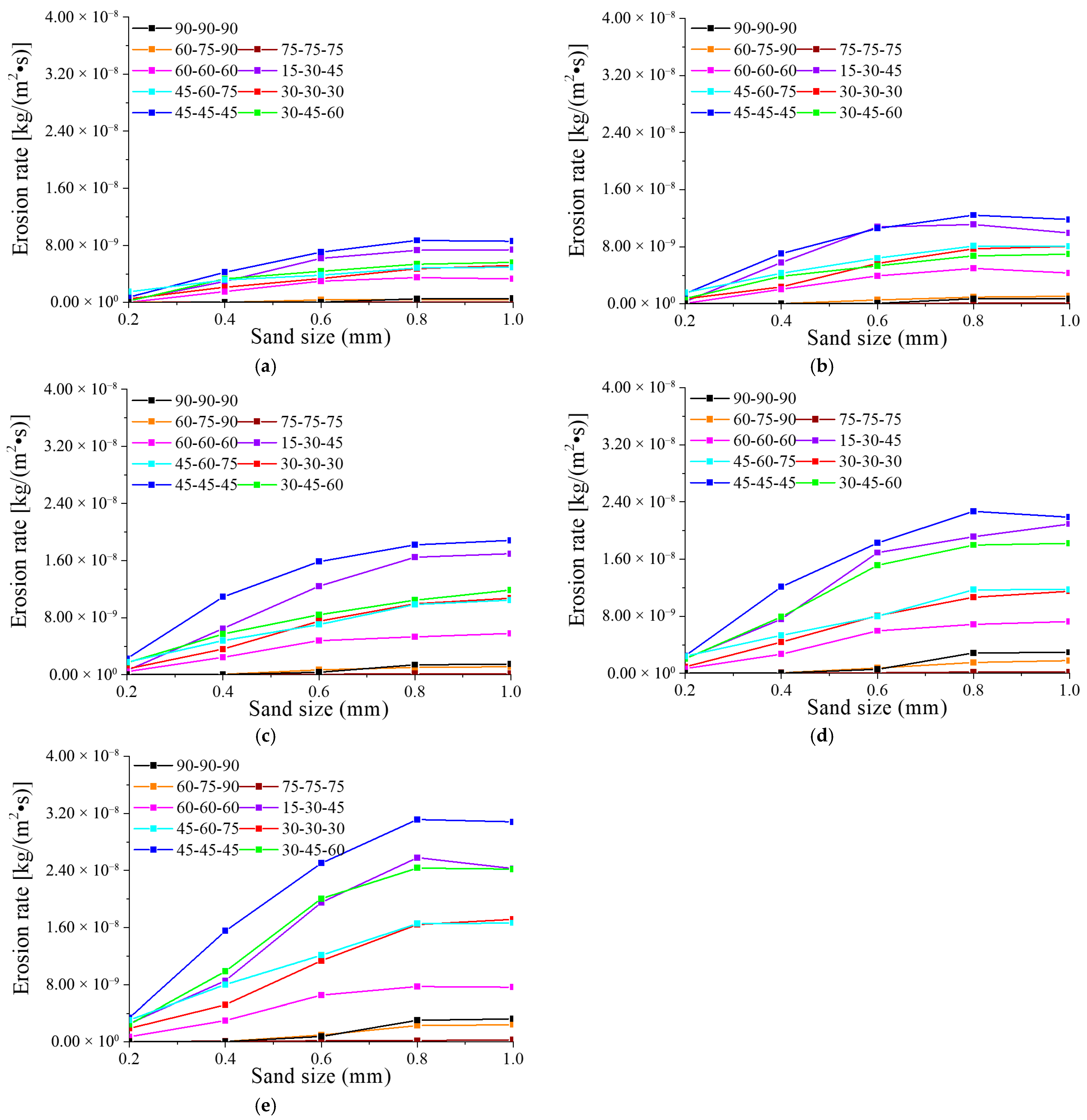

4.3. Effect of Sand Size on Erosion Rate

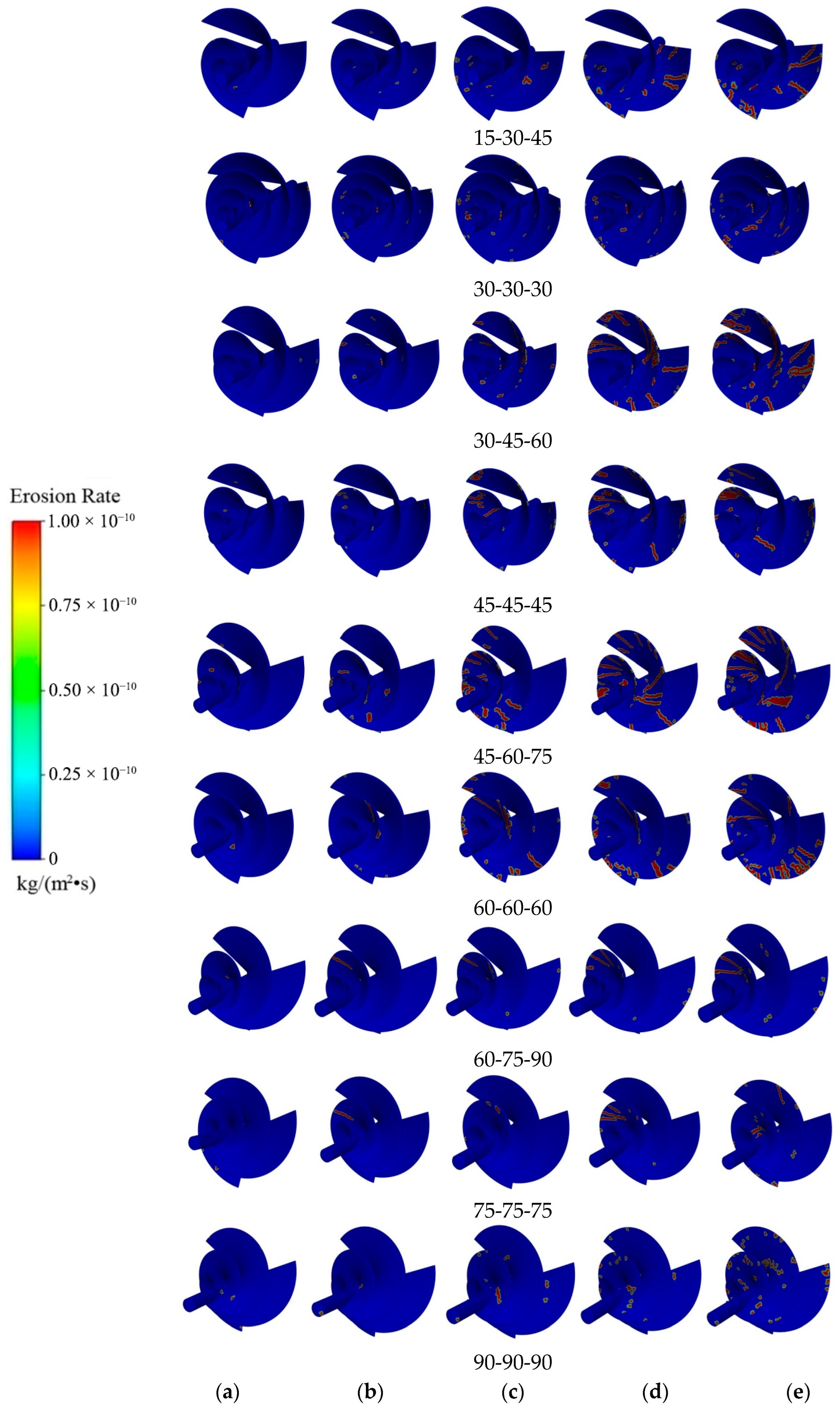

5. Discussion

6. Conclusions

- (1)

- All ASHT configurations exhibit consistent flow field patterns, characterized by high-velocity regions near the blade tips and low-velocity zones with flow separation near the hub—attributed to wake effects. Blade angle significantly affects flow heterogeneity: small angles reduce flow resistance and turbulence, thereby minimizing low-velocity regions near the hub; large angles enhance flow separation and expand wake regions, even resulting in reverse flow.

- (2)

- Erosion rate increases linearly with sand concentration for all configurations and sand sizes, due to a proportional rise in particle impact frequency. As concentration increases, erosion zones expand from the blade tip edges toward mid-span regions and areas adjacent to the hub. This expansion stabilizes once sand concentration exceeds 0.8 kg/L.

- (3)

- Erosion rate demonstrates non-linear growth with increasing sand size. For particles smaller than 0.6 mm, the erosion rate increases rapidly and nearly linearly, owing to improved boundary layer penetration and higher kinetic energy per impact. For particles larger than 0.6 mm, the growth rate declines as a result of a “momentum–quantity trade-off”: although individual particles carry greater momentum, the total number of particles—and thus impact events—decreases, leading to a plateau in erosion rate.

- (4)

- Blade angle significantly influences erosion rate in a tiered relationship: medium angles > small angles > large angles. Medium angles promote an optimal balance between normal and tangential impact components, maximizing material removal. In contrast, large angles produce predominantly normal impacts, which limit erosion due to insufficient tangential action for material removal. Small angles result in reduced erosion efficiency because of weaker plastic deformation and limited fragment generation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hussain, J.; Rittmann, B.E. Algae as a source of renewable energy: Opportunities, challenges, and recent developments. Sustain. Energy Fuels 2023, 7, 2515–2544. [Google Scholar] [CrossRef]

- Imbayah, I.; Hasan, M.; El-Khozondare, H.; Khalee, M.; Alsharif, A.; Ahmed, A.A. Review paper on green hydrogen production, storage, and utilization techniques in Libya. J. Sol. Energy Sustain. Dev. 2024, 13, 1–21. [Google Scholar] [CrossRef]

- Matos, T.; Rocha, J.L.; Martins, M.S.; Gonçalves, L.M. Enhancing Sea Wave Monitoring Through Integrated Pressure Sensors in Smart Marine Cables. J. Mar. Sci. Eng. 2025, 13, 766. [Google Scholar] [CrossRef]

- Manolache, A.I.; Andrei, G. A comprehensive review of multi-use platforms for renewable energy and aquaculture integration. Energies 2024, 17, 4816. [Google Scholar] [CrossRef]

- Reddy, K.B.; Bhosale, A.C.; Saini, R.P. Performance parameters of lift-based vertical axis hydrokinetic turbines-A review. Ocean Eng. 2022, 266, 113089. [Google Scholar] [CrossRef]

- Zhang, D.; Guo, P.; Wang, H.; Hu, Q.; Li, J.; Shams, A. Multi-objective optimization of a banki hydrokinetic turbine for deep-sea power supply: Experimental and numerical investigation. J. Clean. Prod. 2024, 441, 140953. [Google Scholar] [CrossRef]

- Satrio, D.; Utama, I.K.A.P. Experimental investigation into the improvement of self-starting capability of vertical-axis tidal current turbine. Energy Rep. 2021, 7, 4587–4594. [Google Scholar] [CrossRef]

- Gao, R.J.; Chen, J.H.; Zhang, J.J.; Zhou, S.Y.; Xu, H.F.; Wu, J.D.; Qian, X.H. Hydrodynamic study on energy capturing performance of horizontal axis blades under sub-low speed tidal current. China Ocean Eng. 2020, 34, 374–386. [Google Scholar] [CrossRef]

- Bakırcı, M.; Yılmaz, S. Theoretical and computational investigations of the optimal tip-speed ratio of horizontal-axis wind turbines. Eng. Sci. Technol. Int. J. 2018, 21, 1128–1142. [Google Scholar] [CrossRef]

- Suntivarakorn, R.; Wanchat, S.; Monatrakul, W. An experimental study of electricity generation using a horizontal spiral turbine. Energy Procedia 2016, 100, 532–536. [Google Scholar] [CrossRef]

- Monatrakul, W.; Suntivarakorn, R. Effect of blade angle on turbine efficiency of a Spiral Horizontal Axis Hydro Turbine. Energy Procedia 2017, 138, 811–816. [Google Scholar] [CrossRef]

- Song, K.; Kang, Y. Fluid-Structure Interactions Analysis of a Drag-Type Horizontal Axis Hydraulic Turbine. J. Phys. Conf. Ser. 2022, 2404, 012001. [Google Scholar] [CrossRef]

- Monatrakul, W.; Senawong, K.; Sritram, P.; Suntivarakorn, R. A Comparison Study of Hydro-Compact Generators with Horizontal Spiral Turbines (HSTs) and a Three-Blade Turbine Used in Irrigation Canals. Energies 2023, 16, 2267. [Google Scholar] [CrossRef]

- Zhang, D.; Guo, P.; Cheng, Y.; Hu, Q.; Li, J. Analysis of blockage correction methods for high-solidity hydrokinetic turbines: Experimental and numerical investigations. Ocean Eng. 2023, 283, 115185. [Google Scholar] [CrossRef]

- Badawy, Y.E.; Nawar, M.A.; Attai, Y.A.; Mohamed, M. Co-enhancements of several design parameters of an archimedes spiral turbine for hydrokinetic energy conversion. Energy 2023, 268, 126715. [Google Scholar] [CrossRef]

- Zhang, D.; Guo, P.; Qian, Y.; Qiao, H.; Li, J. Analysis and optimization of a deep-water in-situ power generation system based on novel ductless Archimedes screw hydrokinetic turbines. Renew. Energy 2024, 225, 120235. [Google Scholar] [CrossRef]

- Song, K.; Huan, H.T.; Wei, L.C.; Liu, C.X. A comparative study of hydrodynamic performance between ducted and non-ducted Archimedes spiral hydrokinetic turbines. Ocean Eng. 2024, 306, 118087. [Google Scholar] [CrossRef]

- Song, K.; Huan, H.T.; Wei, L.C.; Liu, C.X. Investigation of the effect of blade angle of Archimedes spiral hydrokinetic turbine based on hydrodynamic performance and entropy production theory. Ocean Eng. 2025, 324, 120731. [Google Scholar] [CrossRef]

- Song, K.; Huan, H.T.; Wei, L.C.; Liu, C.X. Enhancing the Performance of Novel Archimedes Spiral Hydrokinetic Turbines Utilizing Blade Winglets in Deep-Sea Power Generation for Autonomous Underwater Vehicles. Drones 2025, 9, 72. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, H.; Lin, Y.; Gu, Y.; Wang, S. Numerical investigation of the erosion behavior in blades of tidal current turbine. J. Renew. Sustain. Energy 2022, 14, 044502. [Google Scholar] [CrossRef]

- Padhy, M.K.; Saini, R.P. Study of silt erosion on performance of a Pelton turbine. Energy 2011, 36, 141–147. [Google Scholar] [CrossRef]

- Zhou, W.; Chai, J.; Xu, Z.; Cao, C.; Wu, G.; Yao, X. Numerical simulation of solid-liquid two-phase flow and wear prediction of a hydraulic turbine high sediment content. Exp. Tech. 2023, 47, 281–293. [Google Scholar] [CrossRef]

- Pereira, G.C.; de Souza, F.J.; de Moro Martins, D.A. Numerical prediction of the erosion due to particles in elbows. Powder Technol. 2014, 261, 105–117. [Google Scholar] [CrossRef]

- Mansouri, A.; Arabnejad, H.; Shirazi, S.A.; McLaury, B.S. A combined CFD/experimental methodology for erosion prediction. Wear 2015, 332–333, 1090–1097. [Google Scholar] [CrossRef]

- Ying, L.L.; Yao, Y.; Lai, F.; Liu, J.; Ge, W.; Yao, Y. Suspended sediment simulation and water purification scheme research of turbid archipelago. In Proceedings of the OCEANS 2016, Shanghai, China, 10–13 April 2016; pp. 1–5. [Google Scholar]

- Sareen, A.; Sapre, C.A.; Selig, M.S. Effects of leading edge erosion on wind turbine blade performance. Wind Energy 2014, 17, 1531–1542. [Google Scholar] [CrossRef]

- Wang, J.; Gao, J.; Zhang, Y.; Cui, H. Analysis of the Sand Erosion Effect and Wear Mechanism of Wind Turbine Blade Coating. Energies 2024, 17, 413. [Google Scholar] [CrossRef]

- Eisenberg, D.; Laustsen, S.; Stege, J. Wind turbine blade coating leading edge rain erosion model: Development and validation. Wind Energy 2018, 21, 942–951. [Google Scholar] [CrossRef]

- Herring, R.; Dyer, K.; Martin, F.; Ward, C. The increasing importance of leading edge erosion and a review of existing protection solutions. Renew. Sustain. Energy Rev. 2019, 115, 109382. [Google Scholar] [CrossRef]

- Peng, W.; Cao, X. Numerical simulation of solid particle erosion in pipe bends for liquid–solid flow. Powder Technol. 2016, 294, 266–279. [Google Scholar] [CrossRef]

- McLaury, B.S.; Shirazi, S.A.; Shadley, J.R.; Rybicki, E.F. Modeling erosion in chokes. ASME-Publ.-Fed 1996, 236, 773–782. [Google Scholar]

- Shen, Z.; Chu, W.; Li, X.; Dong, W. Sediment erosion in the impeller of a double-suction centrifugal pump–A case study of the Jingtai Yellow River Irrigation Project, China. Wear 2019, 422–423, 269–279. [Google Scholar] [CrossRef]

- Grant, G.; Tabakoff, W. Erosion prediction in turbomachinery resulting from environmental solid particles. J. Aircr. 1975, 12, 471–478. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Zahari, N.M.; Zawawi, M.H.; Sidek, L.M.; Mohamad, D.; Itam, Z.; Ramli, M.Z.; Rashid, M. Introduction of discrete phase model (DPM) in fluid flow: A review. In AIP Conference Proceedings; AIP Publishing LLC: New York, NY, USA, 2018; p. 020234. [Google Scholar]

- Chang, P.; Xu, G.; Zhou, F.; Mullins, B.; Abishek, S. Comparison of underground mine DPM simulation using discrete phase and continuous phase models. Process Saf. Environ. Prot. 2019, 127, 45–55. [Google Scholar] [CrossRef]

- Lawson, M.J.; Li, Y.; Sale, D.C. Development and verification of a computational fluid dynamics model of a horizontal-axis tidal current turbine. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; pp. 711–720. [Google Scholar]

- Moshfeghi, M.; Shams, S.; Hur, N. Aerodynamic performance enhancement analysis of horizontal axis wind turbines using a passive flow control method via split blade. J. Wind Eng. Ind. Aerodyn. 2017, 167, 148–159. [Google Scholar] [CrossRef]

- Al-Dabbagh, M.A.; Yuce, M.I. Numerical evaluation of helical hydrokinetic turbines with different solidities under different flow conditions. Int. J. Environ. Sci. Technol. 2019, 16, 4001–4012. [Google Scholar] [CrossRef]

- Moshfeghi, M.; Song, Y.J.; Xie, Y.H. Effects of near-wall grid spacing on SST-K-ω model using NREL Phase VI horizontal axis wind turbine. J. Wind Eng. Ind. Aerodyn. 2012, 107–108, 94–105. [Google Scholar] [CrossRef]

- Kamal, A.M.; Nawar, M.A.; Attai, Y.A.; Mohamed, M.H. Blade design effect on Archimedes Spiral Wind Turbine performance: Experimental and numerical evaluations. Energy 2022, 250, 123892. [Google Scholar] [CrossRef]

- Kumar, P.; Singal, S.K.; Gohil, P.P. A technical review on combined effect of cavitation and silt erosion on Francis turbine. Renew. Sustain. Energy Rev. 2024, 190, 114096. [Google Scholar] [CrossRef]

- Patel, K.; Desai, J.; Chauhan, V.; Charnia, S. Development of Francis turbine using computational fluid dynamics. In Proceedings of the 11st Asian International Conference on Fluid Machinery and 3rd Fluid Power Technology Exhibition, Chennai, India, 21–23 November 2011; pp. 1–3. [Google Scholar]

- Noon, A.A.; Kim, M.H. Erosion wear on Francis turbine components due to sediment flow. Wear 2017, 378–379, 126–135. [Google Scholar] [CrossRef]

| Description Value | Value |

|---|---|

| Fluid density | 1025 kg/m3 |

| Wall material | carbon steel |

| Wall density | 7850 |

| Sand density | 2650 |

| Sand shape | Spherical |

| Mesh | Total Cells | CP | Relative Error% |

|---|---|---|---|

| 1 | 2,957,912 | 0.195 | 2.50 |

| 2 | 3,819,823 | 0.200 | 0.99 |

| 3 | 4,275,311 | 0.202 | 0.98 |

| 4 | 5,131,234 | 0.204 | 0.49 |

| 5 | 6,297,235 | 0.205 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, K.; Huan, H.; Wei, L.; Wang, Y. Numerical Investigation on Erosion Characteristics of Archimedes Spiral Hydrokinetic Turbine. J. Mar. Sci. Eng. 2025, 13, 1707. https://doi.org/10.3390/jmse13091707

Song K, Huan H, Wei L, Wang Y. Numerical Investigation on Erosion Characteristics of Archimedes Spiral Hydrokinetic Turbine. Journal of Marine Science and Engineering. 2025; 13(9):1707. https://doi.org/10.3390/jmse13091707

Chicago/Turabian StyleSong, Ke, Huiting Huan, Liuchuang Wei, and Yongli Wang. 2025. "Numerical Investigation on Erosion Characteristics of Archimedes Spiral Hydrokinetic Turbine" Journal of Marine Science and Engineering 13, no. 9: 1707. https://doi.org/10.3390/jmse13091707

APA StyleSong, K., Huan, H., Wei, L., & Wang, Y. (2025). Numerical Investigation on Erosion Characteristics of Archimedes Spiral Hydrokinetic Turbine. Journal of Marine Science and Engineering, 13(9), 1707. https://doi.org/10.3390/jmse13091707