Hydrodynamic Numerical Analysis of AUV Underwater Docking with Conical Docking Bay

Abstract

1. Introduction

2. Geometric Models and Numerical Methodology

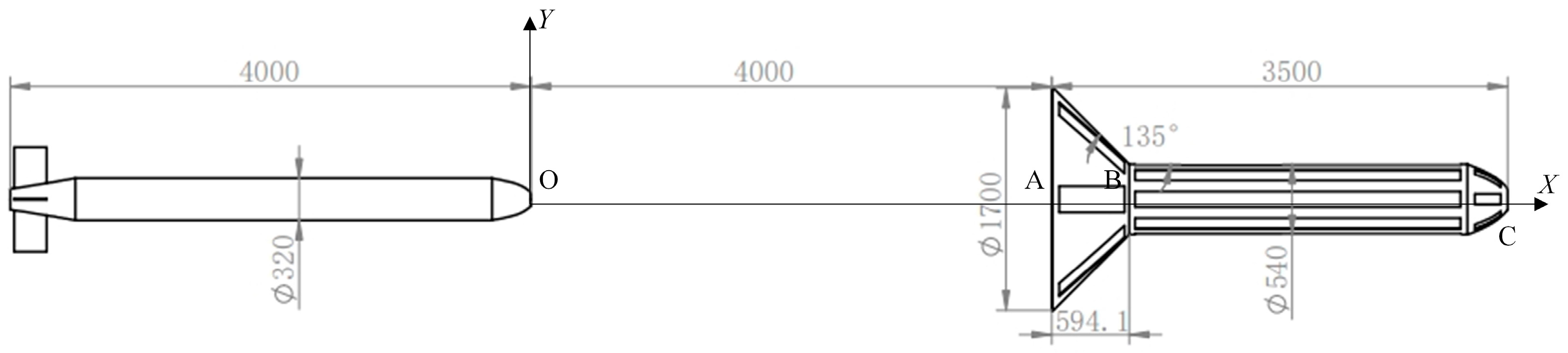

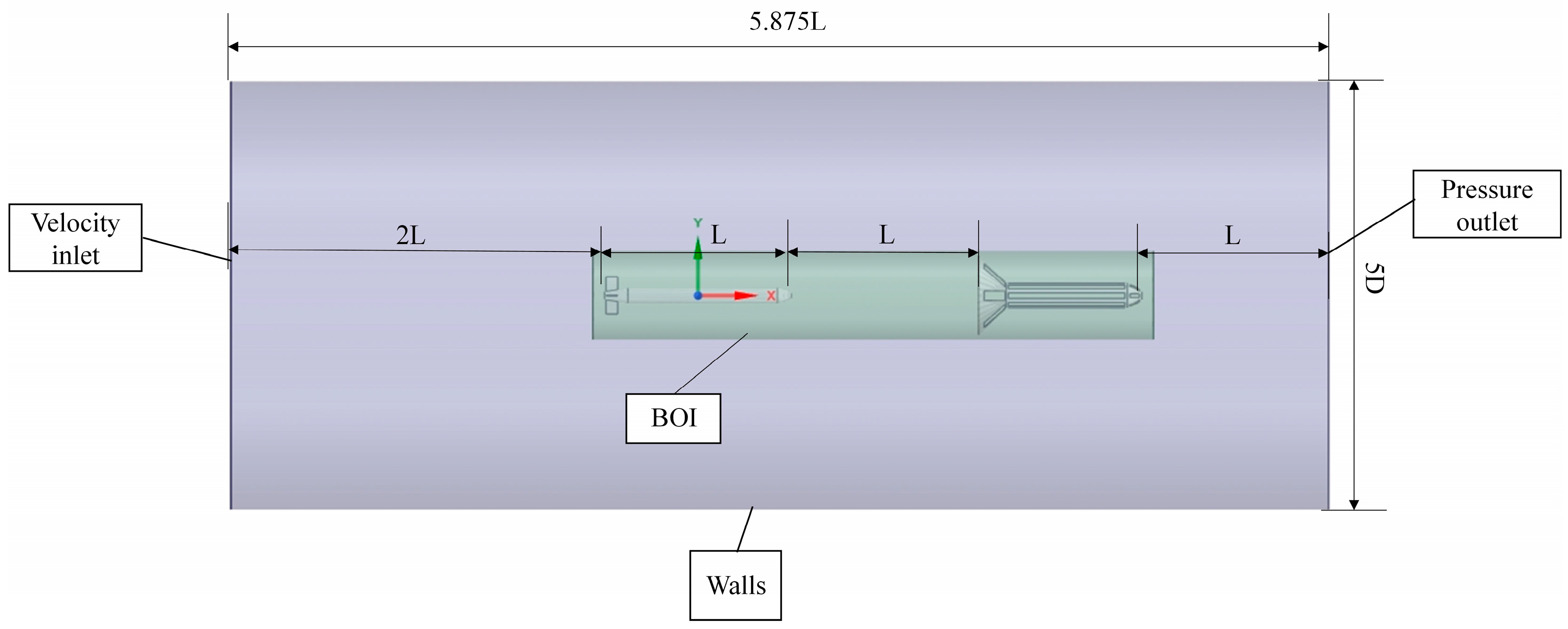

2.1. Numerical Model

2.2. Governing Equation

2.3. Boundary Condition

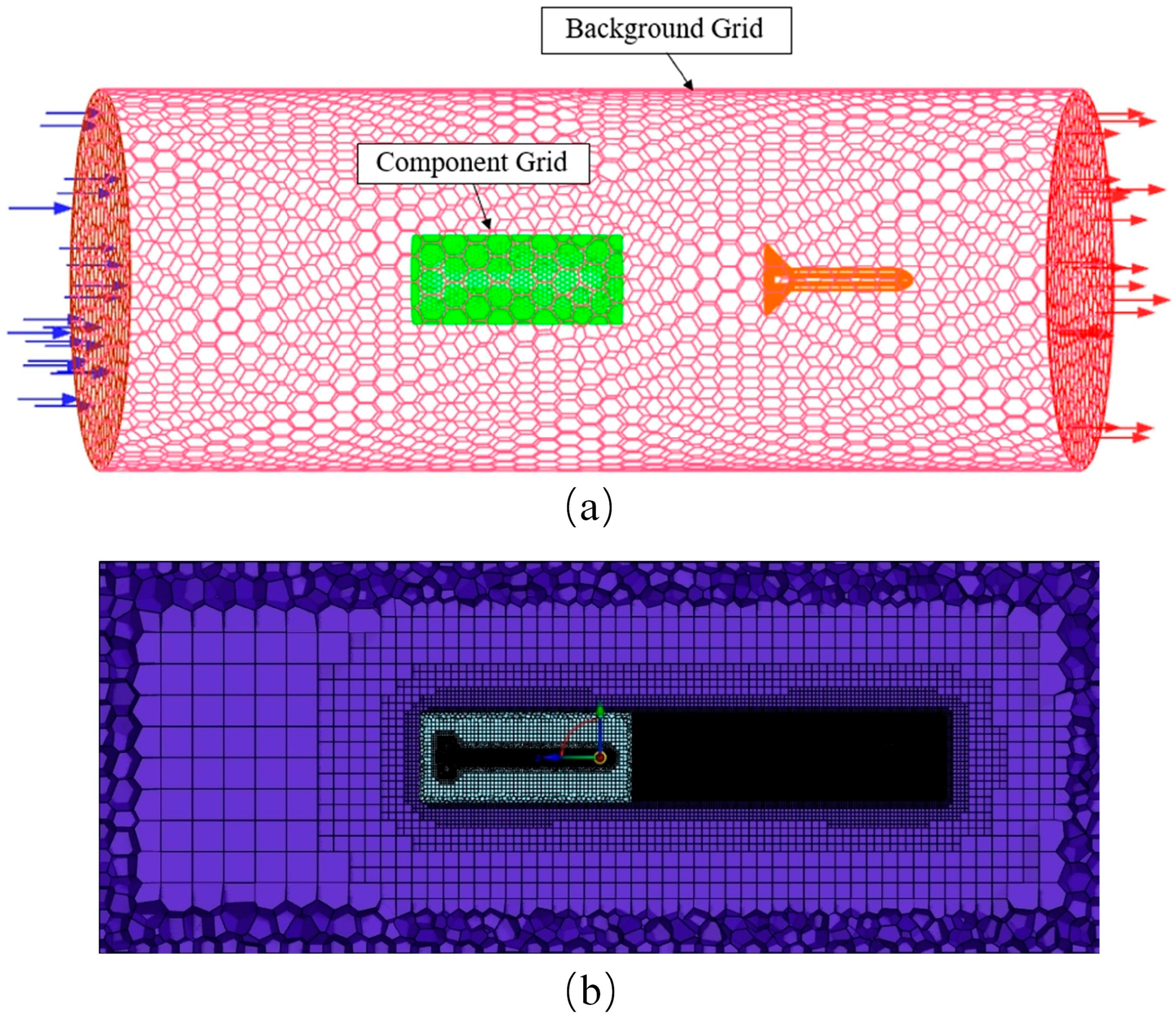

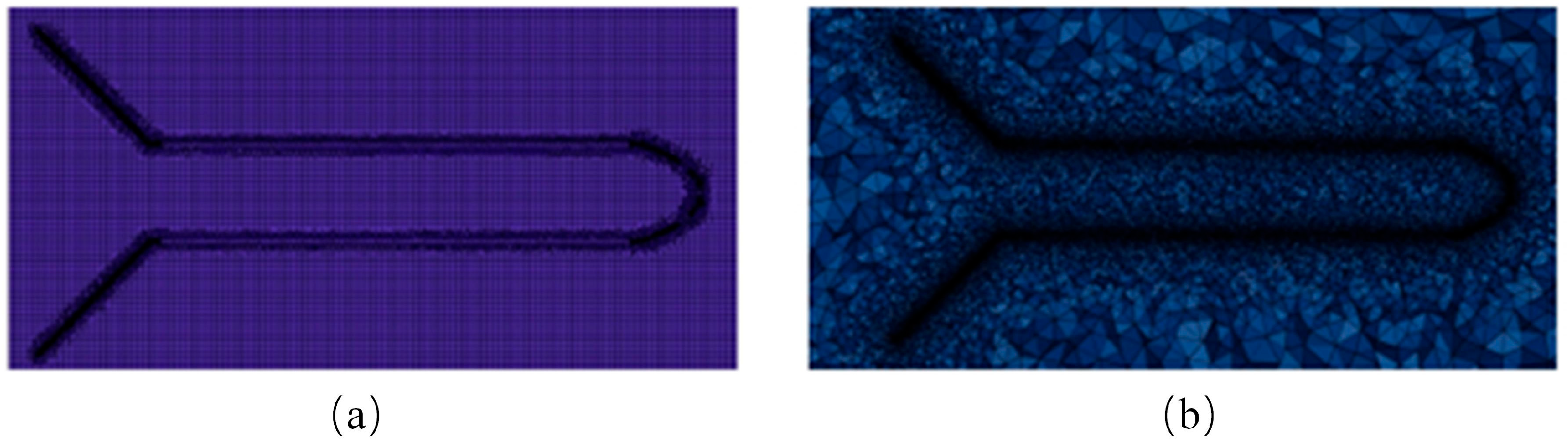

2.4. Meshing

2.5. Grid and Time-Step Dependency Study

3. Results and Discussion

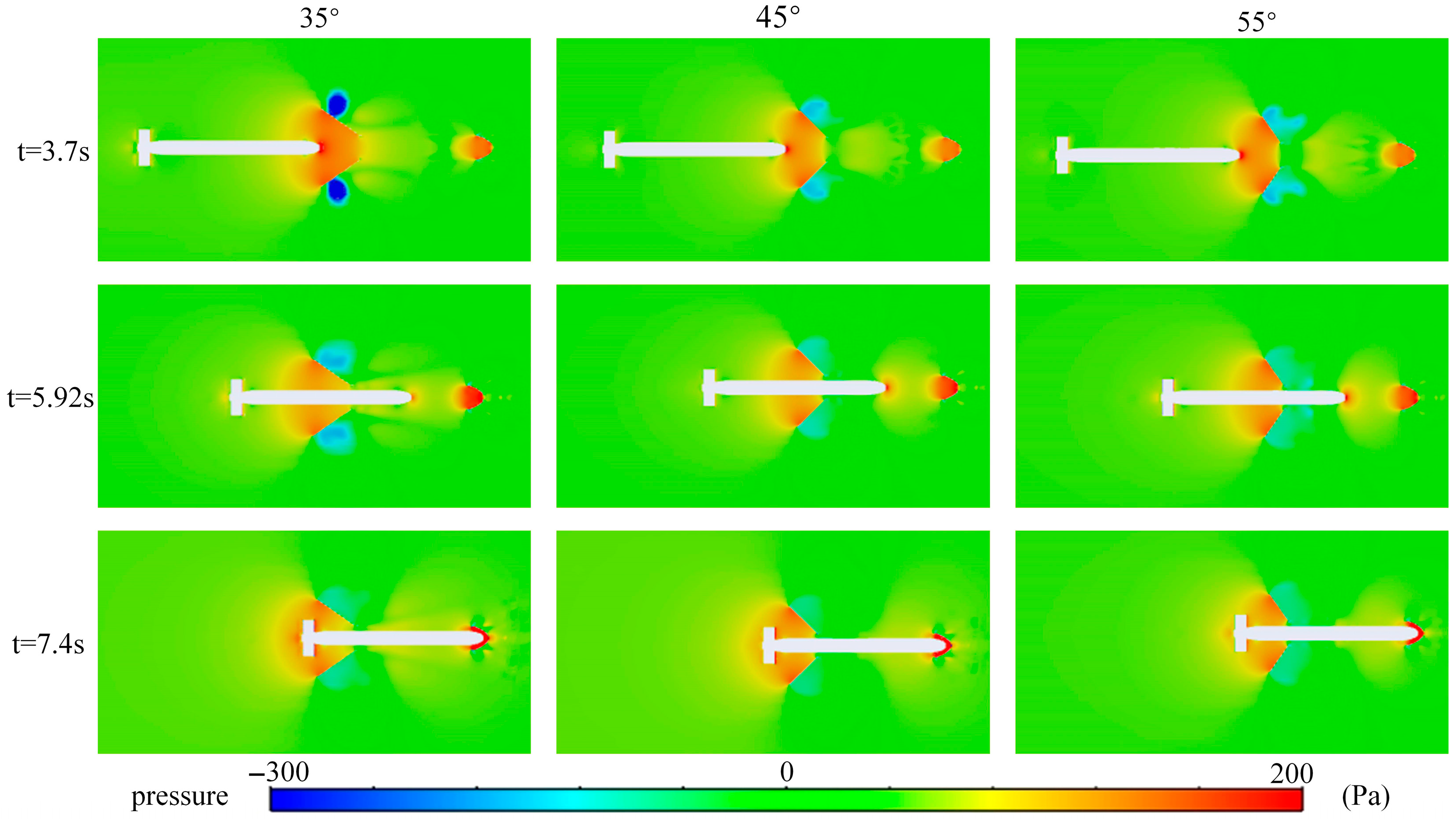

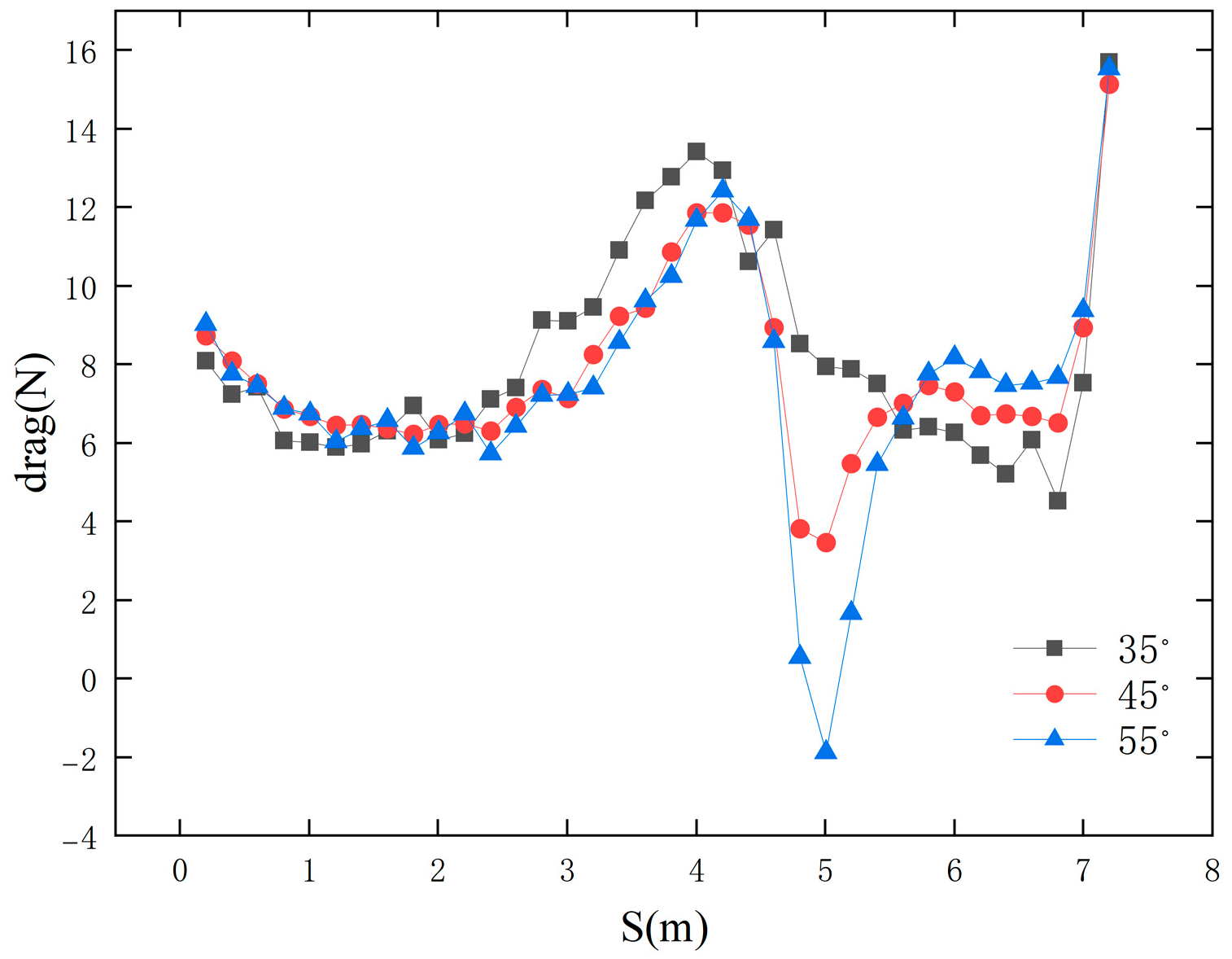

3.1. Inlet Nozzle Taper

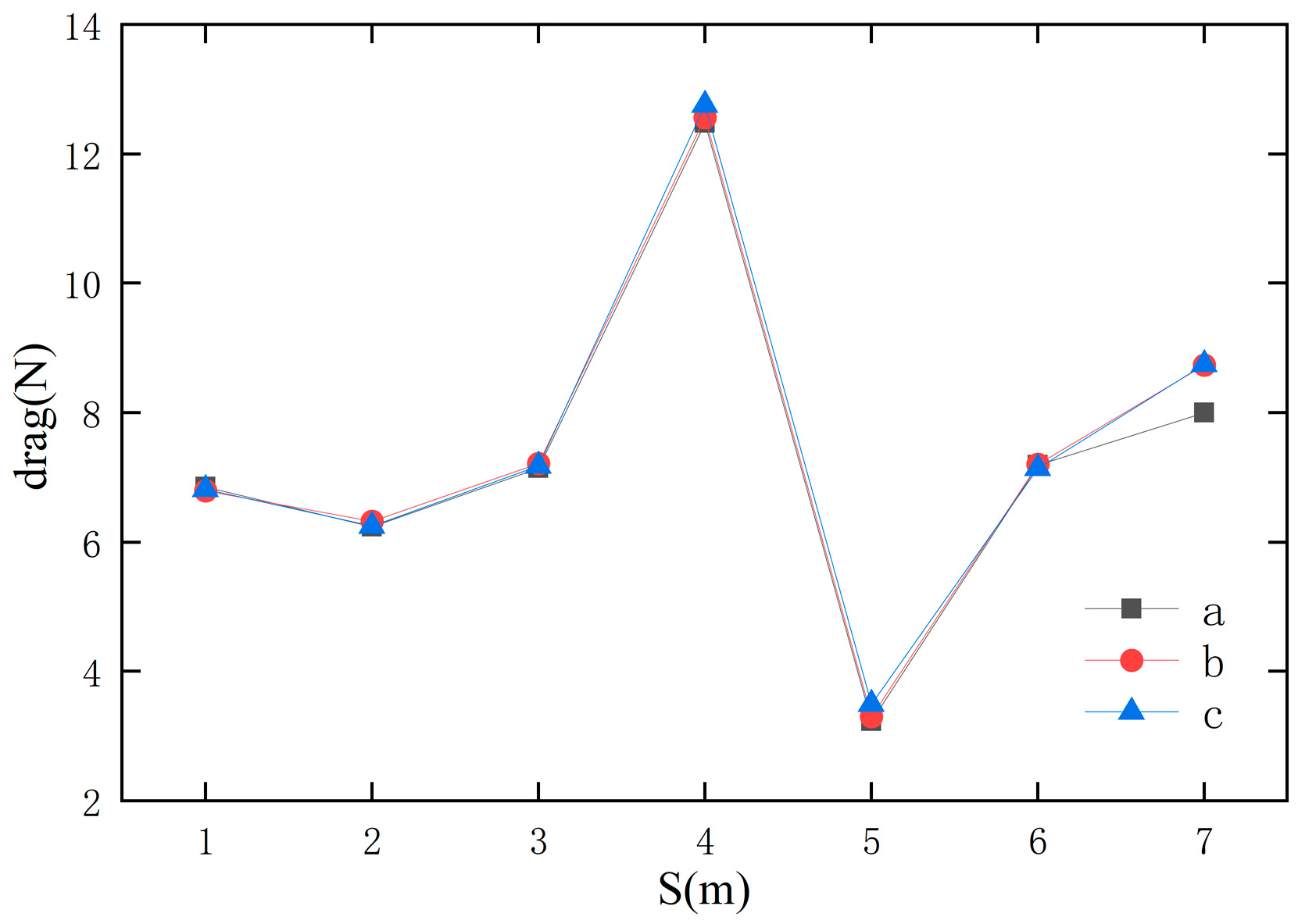

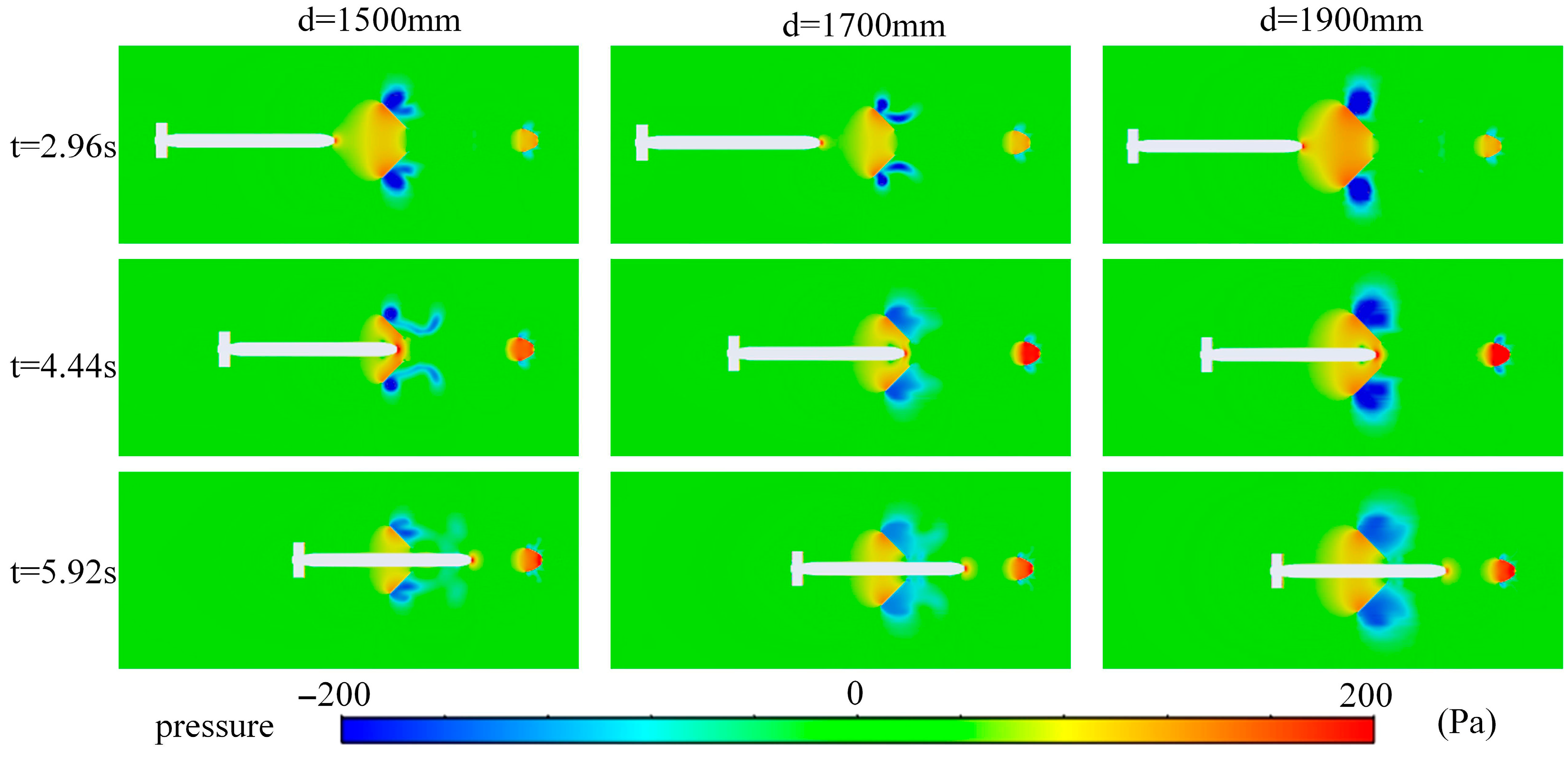

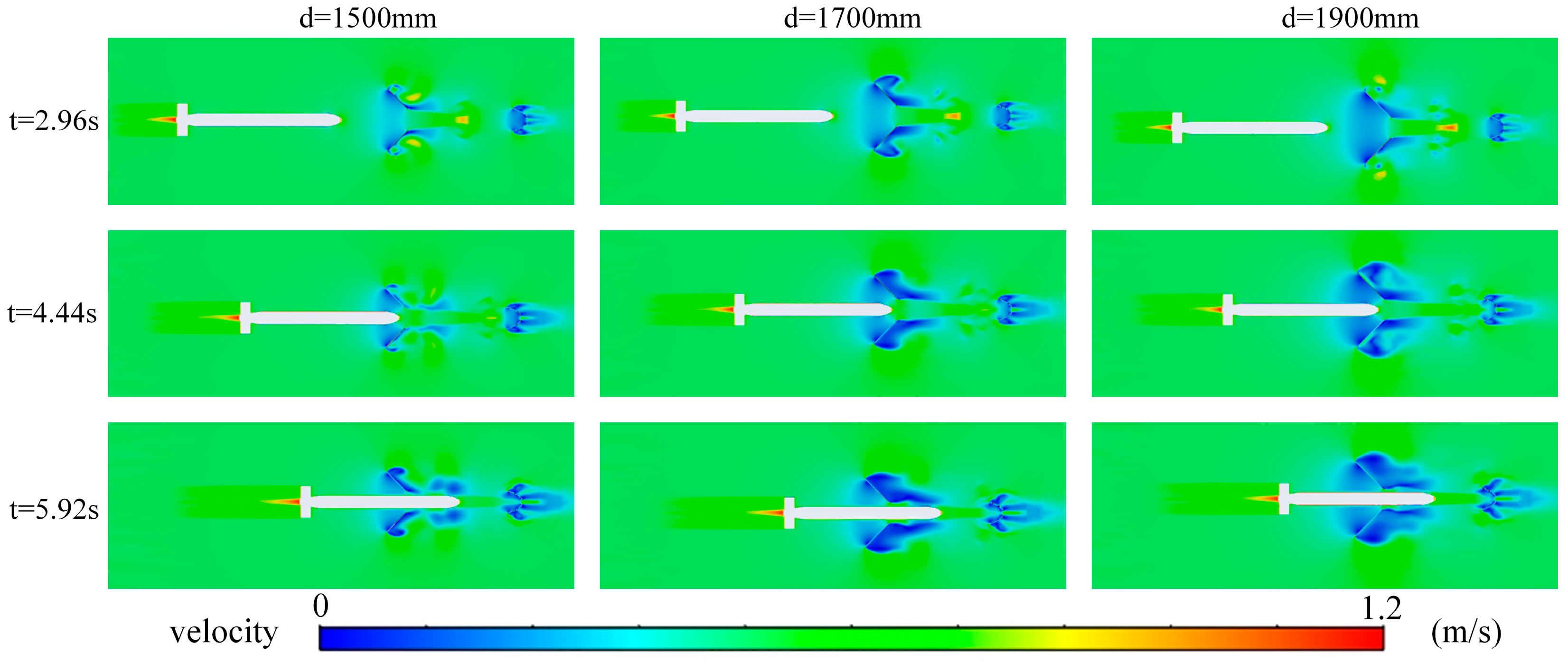

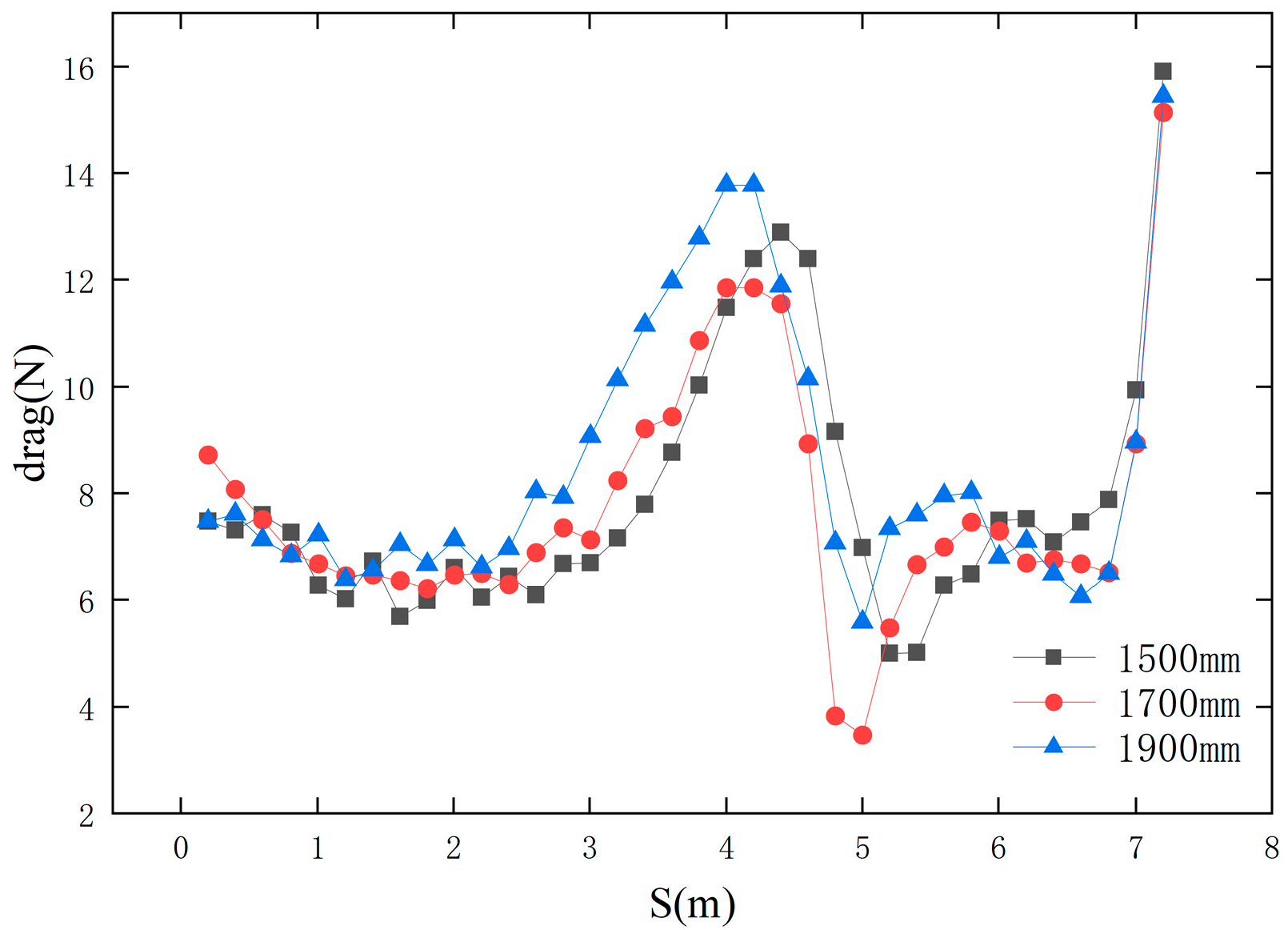

3.2. Inlet Nozzle Size

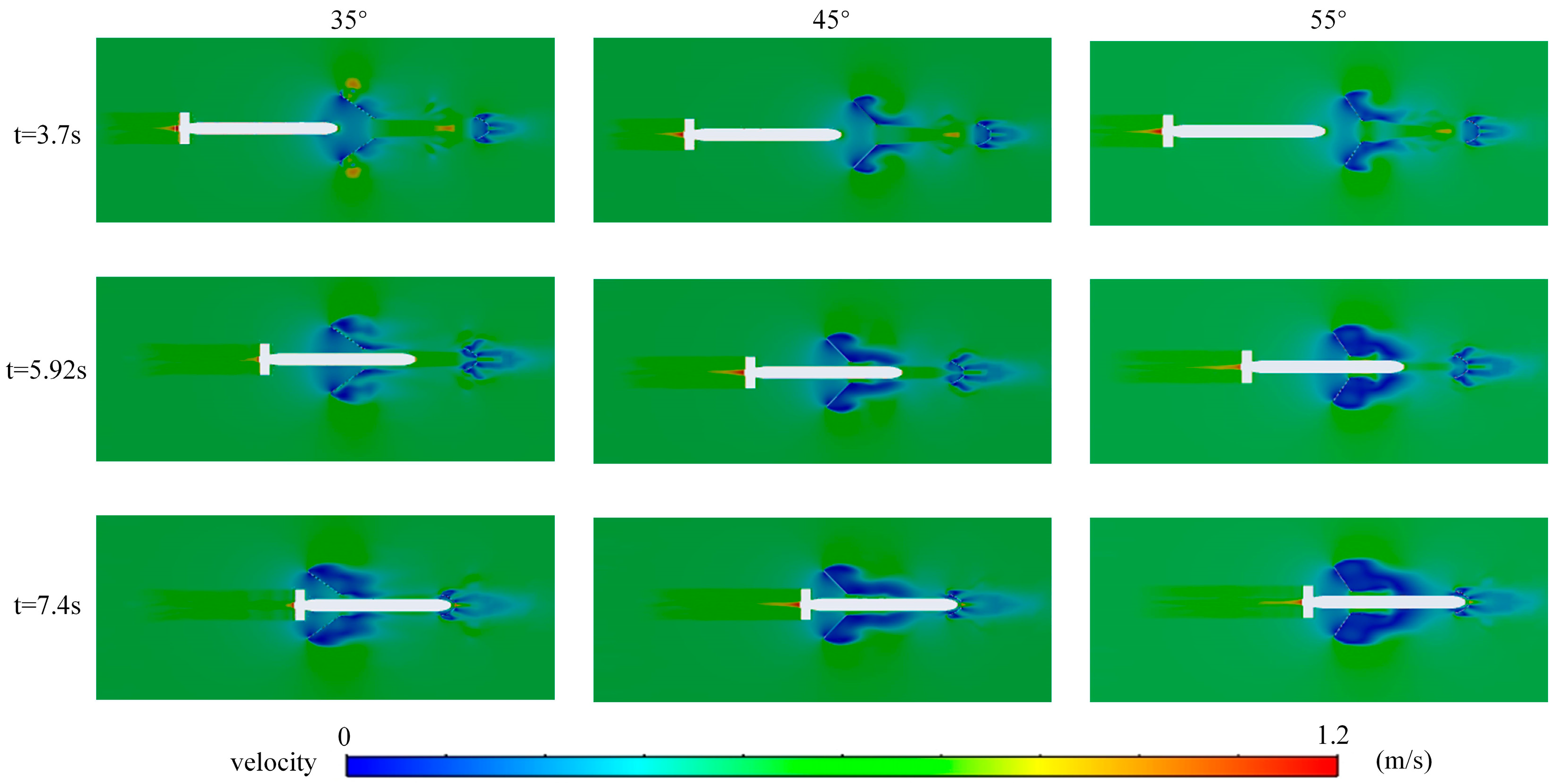

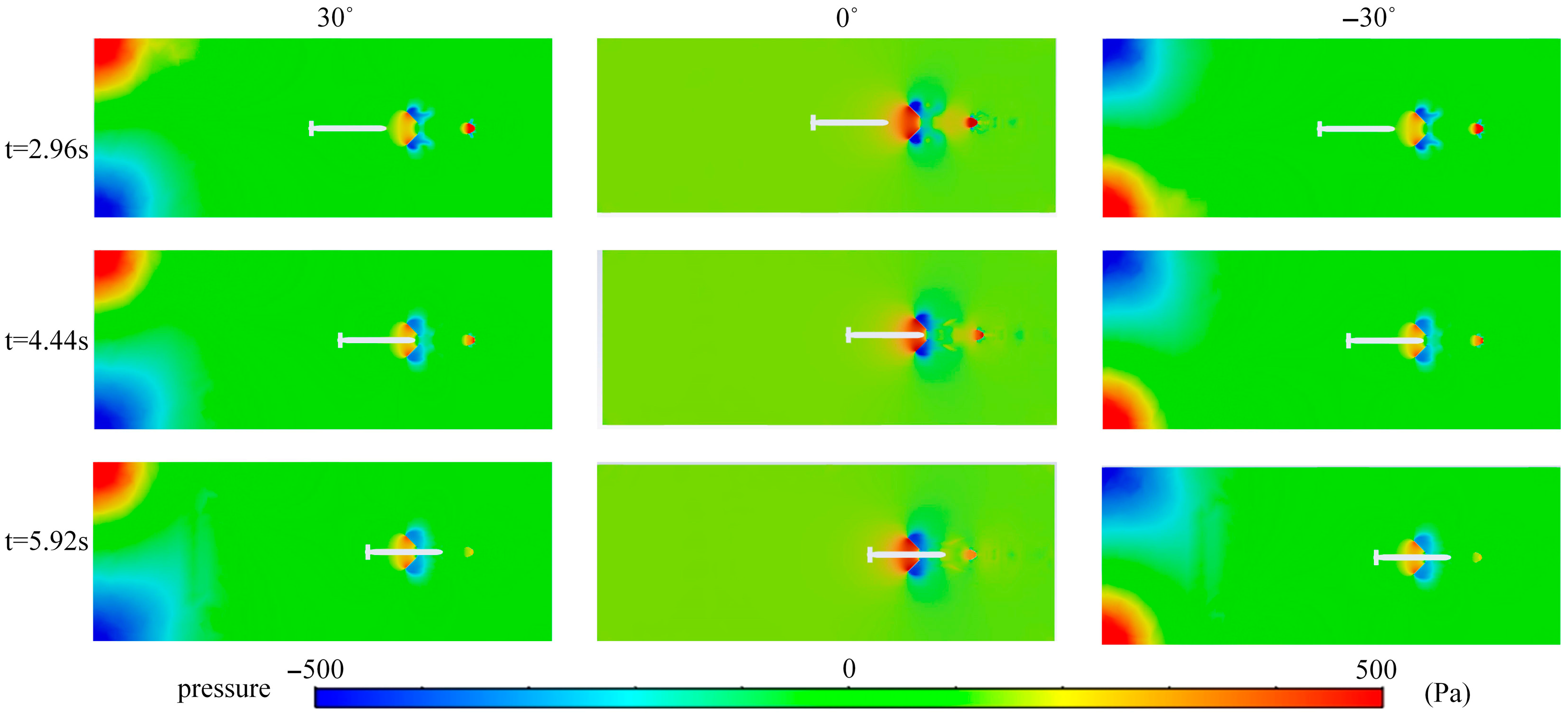

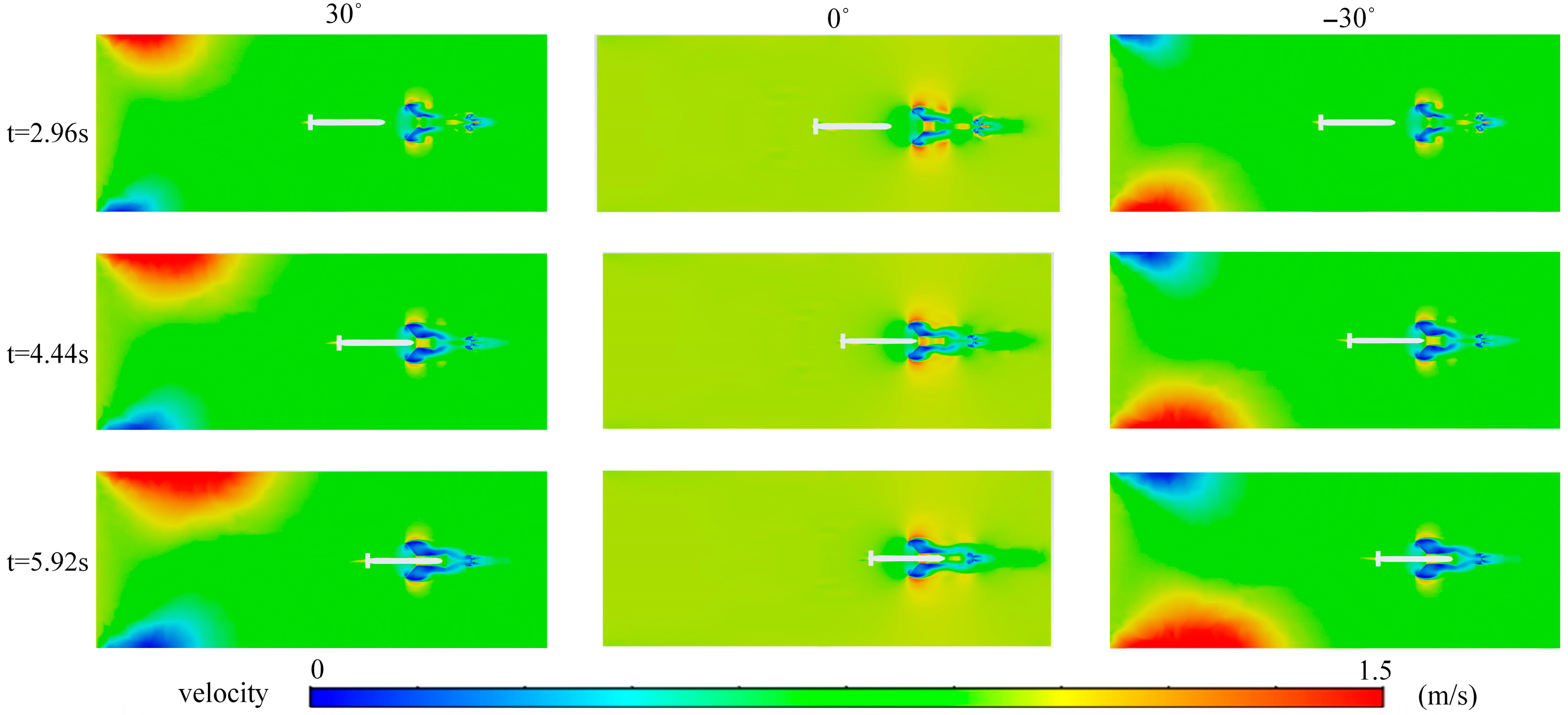

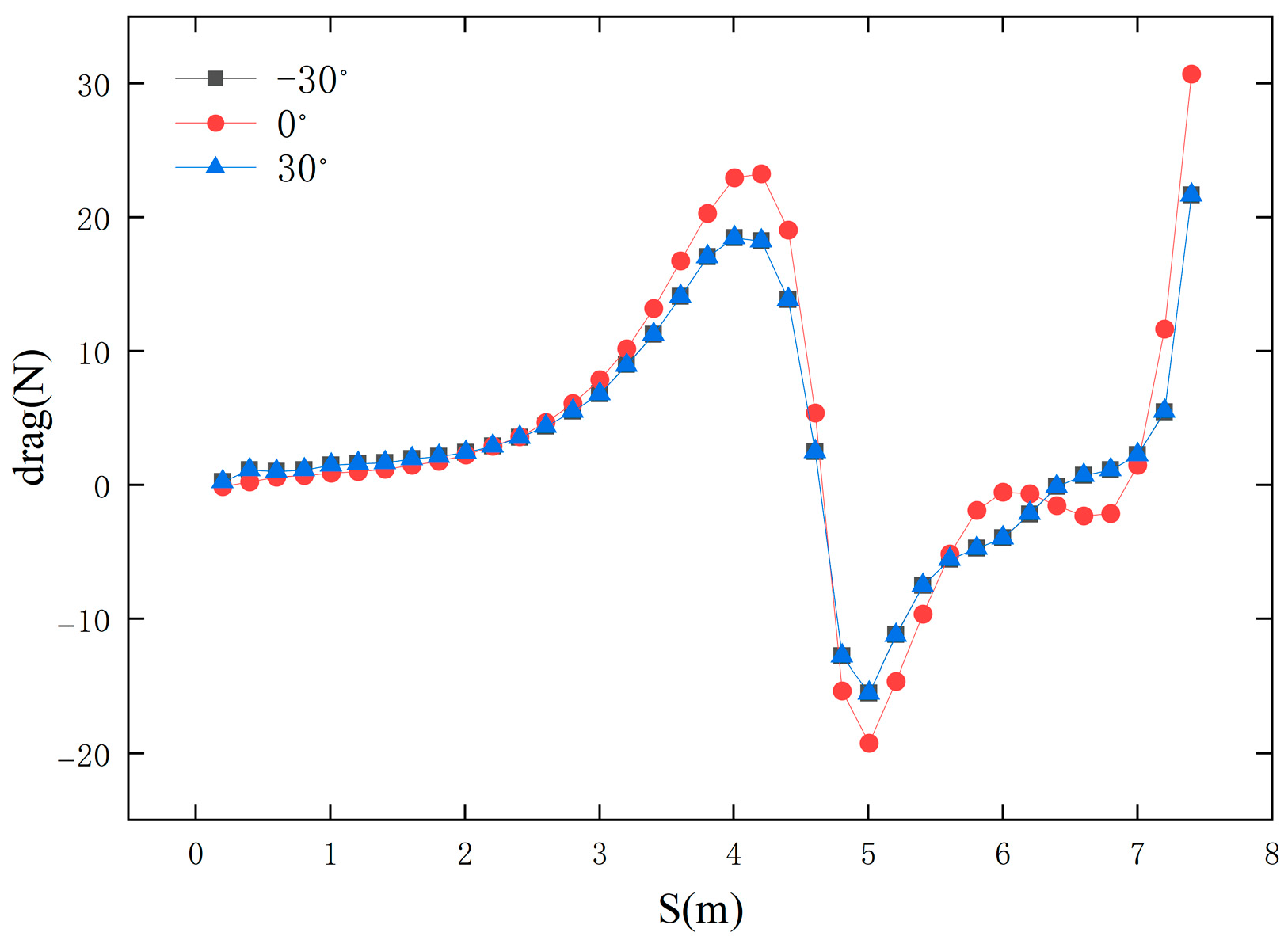

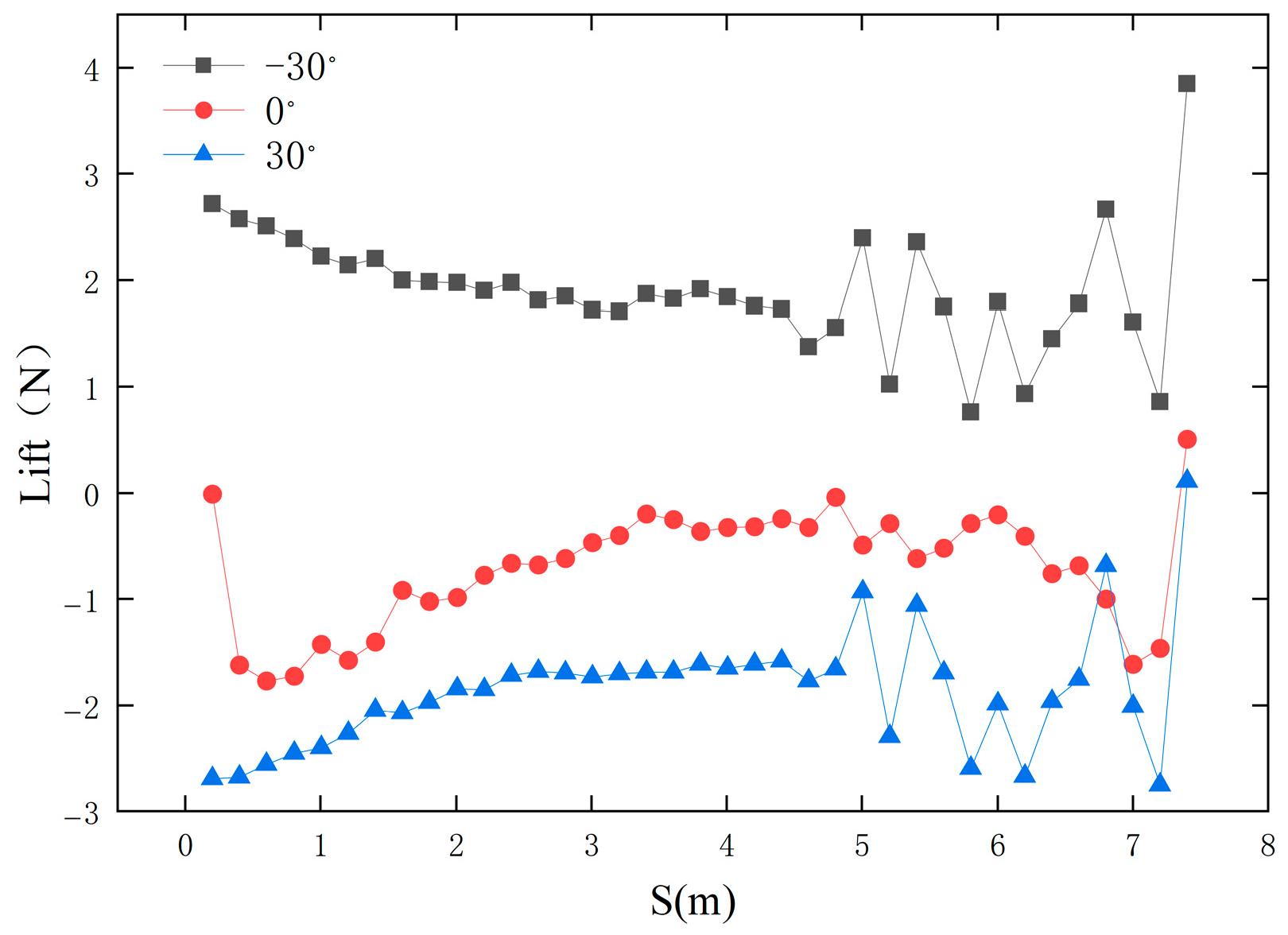

4. Effects from Ocean Currents

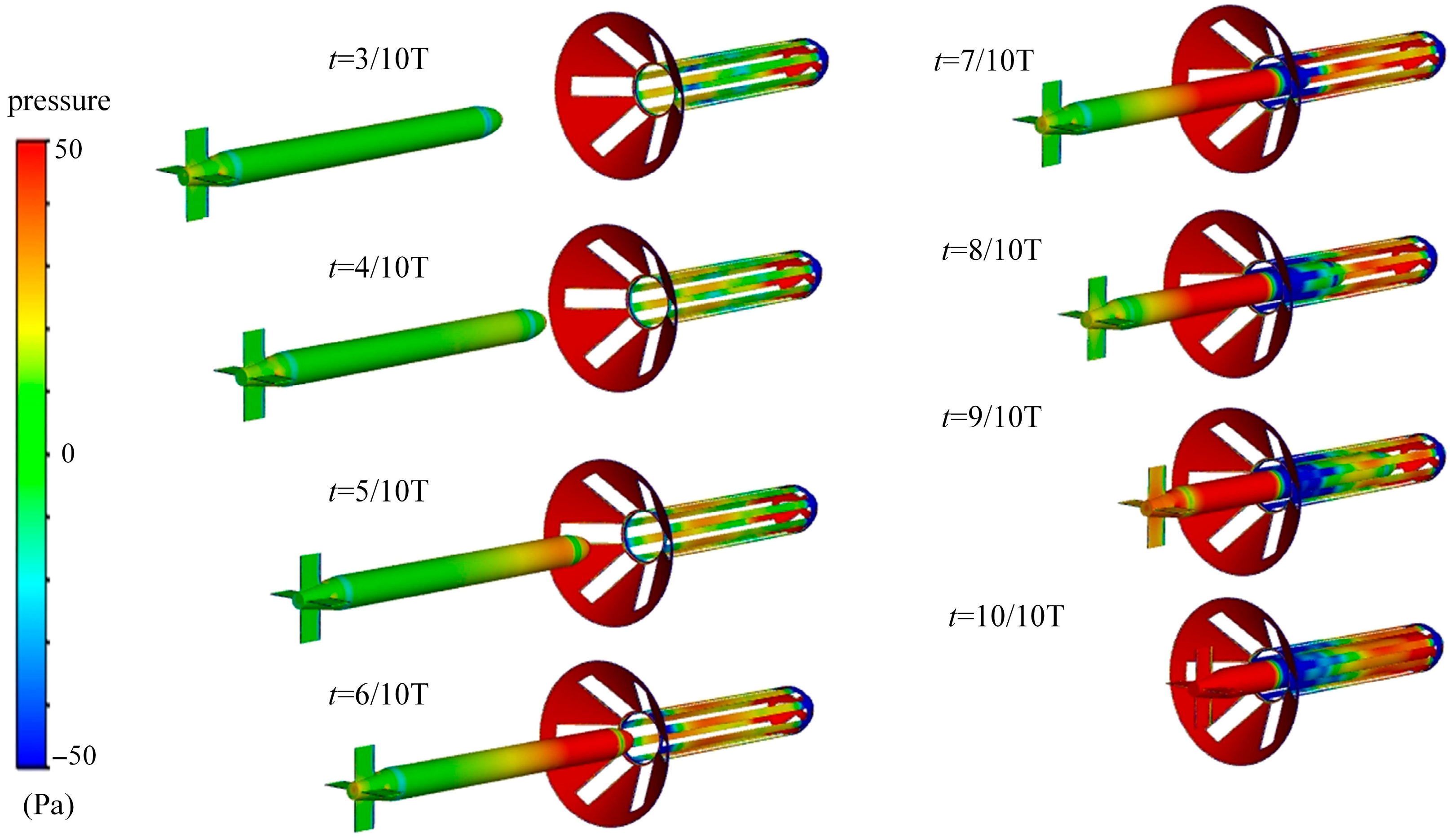

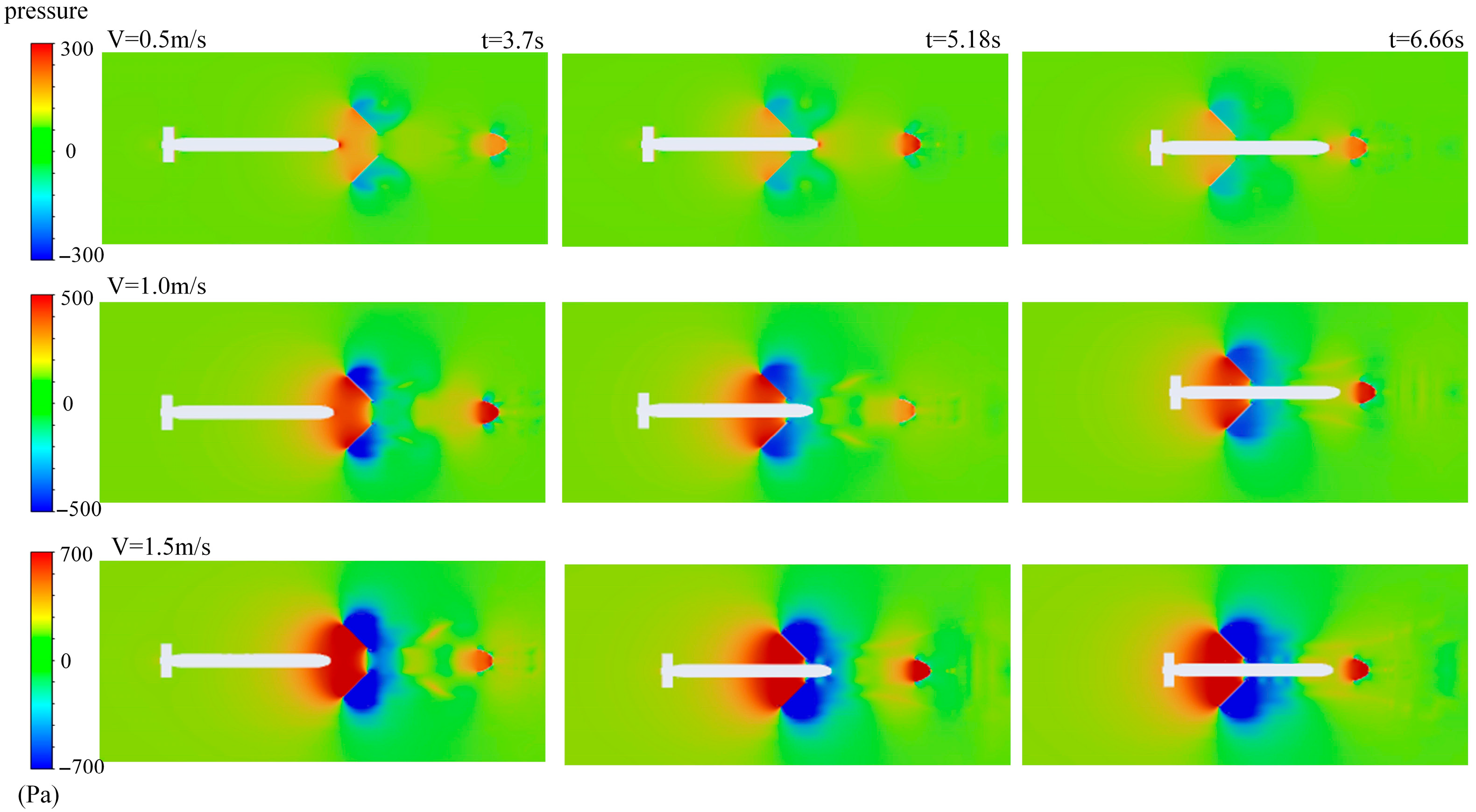

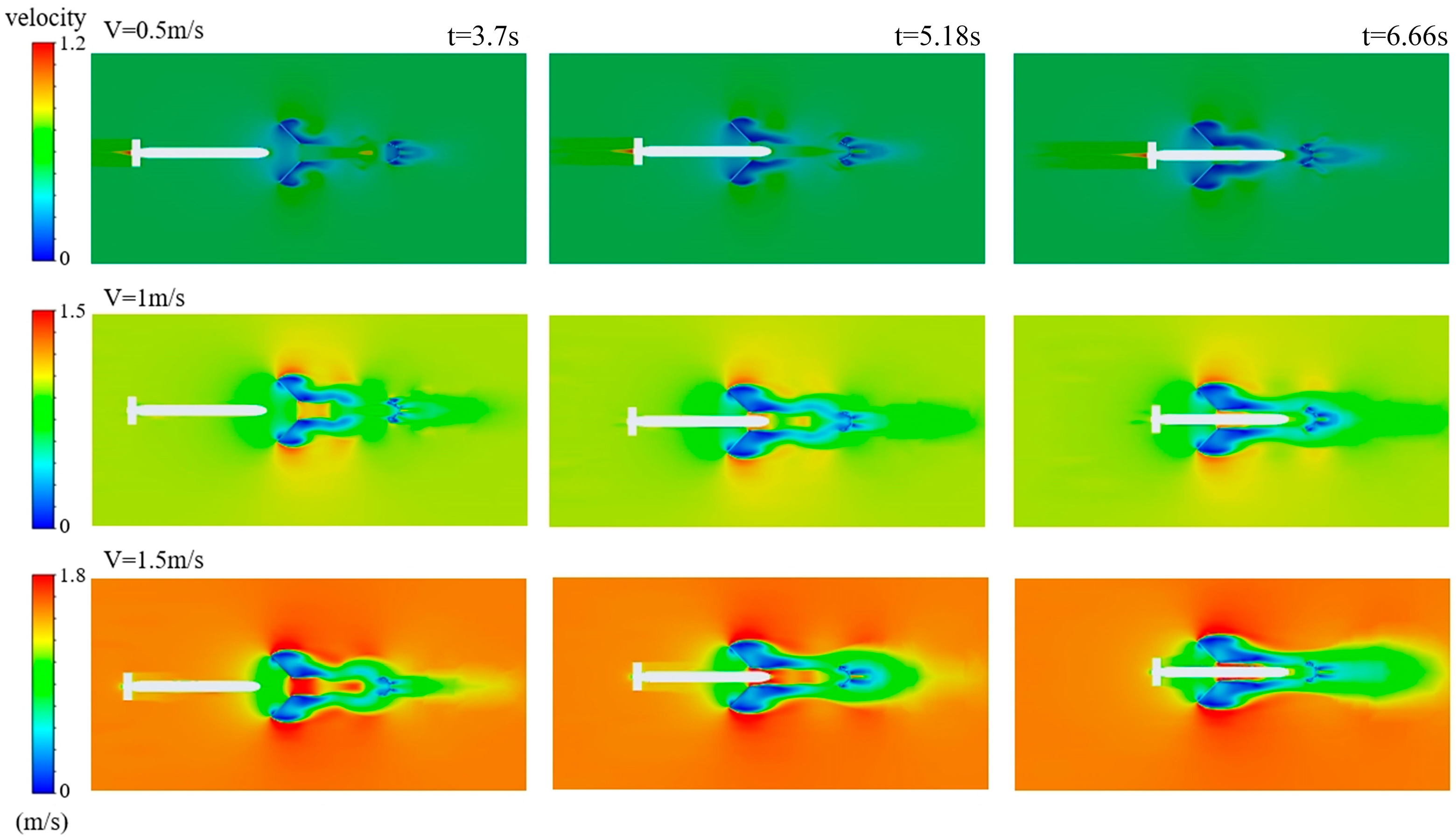

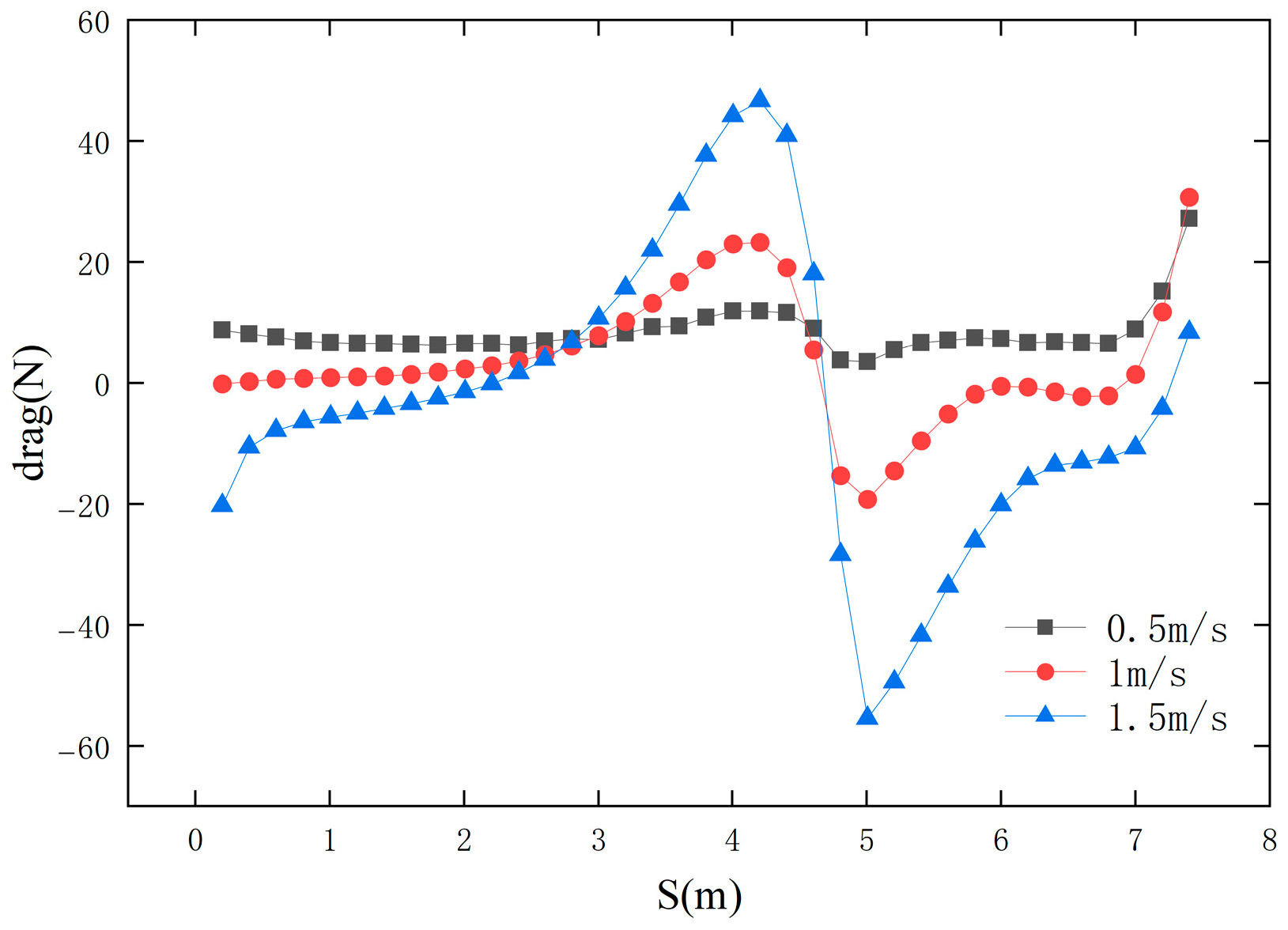

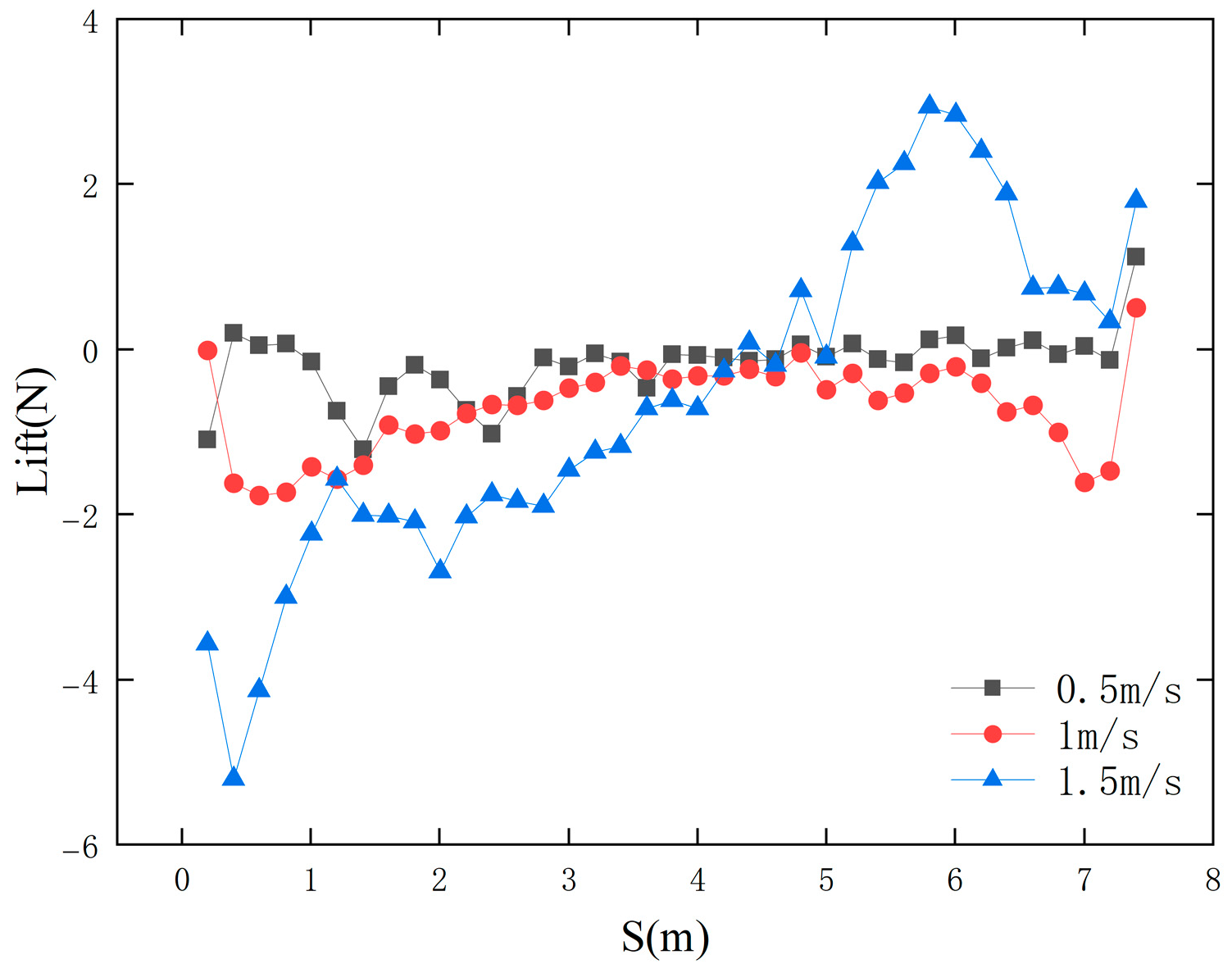

4.1. Docking Under Co-Directional Varying-Velocity Currents

4.2. Docking Under Multi-Directional Constant-Velocity Currents

5. Conclusions

- (1)

- Increasing the cone angle of the docking bay entrance (55°) significantly reduces the docking resistance of the AUV, as a larger cone angle minimizes turbulence in the flow field at the front of the docking bay and prevents the accumulation of high-pressure zones. A smaller cone angle (35°) tends to create a low-pressure zone on the rear side of the docking bay entrance, increasing the risk of fluid separation and thereby hindering the stable entry of the AUV.

- (2)

- Increasing the diameter of the docking chamber inlet (e.g., from 1500 mm to 1900 mm) will result in increased flow field resistance. A larger diameter increases the cross-sectional area of the fluid, reducing flow velocity. According to Bernoulli’s principle, this results in an increase in static pressure, thereby creating greater resistance. Conversely, a docking chamber with a smaller diameter has the lowest resistance, but an excessively small diameter may exacerbate fluid separation, thereby affecting the stability of the docking process.

- (3)

- When the ocean current velocity is consistent with the AUV’s direction of travel, resistance is minimal when the ocean current velocity is close to the AUV’s speed (1 m/s). However, when the ocean current velocity (0.5 m/s) is less than the AUV’s speed, resistance is positive during the docking process, hindering the AUV’s smooth docking. On the other hand, when the ocean current speed (1.5 m/s) exceeds the AUV’s speed, an adhesive force (thrust) appears after point B, accelerating the AUV’s docking process but also increasing the risk of collision.

- (4)

- (An increase in the direction angle of the ocean current (±30°) reduces drag during the AUV docking process, but also causes a speed difference between the upstream and downstream fields of the AUV, generating lift (upward drift) or downward pressure (downward drift). To maintain stability, the AUV must apply additional control forces to avoid significant lateral drift.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Walsh, D. Exploration and technology—Key building blocks for the new blue economy. In Preparing a Workforce for the New Blue Economy; Elsevier: Amsterdam, The Netherlands, 2021; pp. 3–16. [Google Scholar]

- Zhang, H.; Hao, L.; Wang, Y.; Liu, Y.; Wu, Z.; Wang, S.; Shao, S.; Wei, D.; Hou, W. The general design of a seafloor surveying AUV system. In Proceedings of the 2013 OCEANS-San Diego, San Diego, CA, USA, 23–27 September 2013; IEEE: Piscataway, NJ, USA, 2014; pp. 1–5. [Google Scholar]

- Liu, G.; Chen, L.; Liu, K.; Luo, Y. A swarm of unmanned vehicles in the shallow ocean: A survey. Neurocomputing 2023, 531, 74–86. [Google Scholar] [CrossRef]

- He, J.; Wen, J.; Xiao, S.; Yang, J. Multi-AUV inspection for process monitoring of underwater oil transportation. IEEE/CAA J. Autom. Sin. 2023, 10, 828–830. [Google Scholar] [CrossRef]

- Bovio, E.; Cecchi, D.; Baralli, F. Autonomous underwater vehicles for scientific and naval operations. Annu. Rev. Control 2006, 30, 117–130. [Google Scholar] [CrossRef]

- Nicholson, J.; Healey, A. The present state of autonomous underwater vehicle (AUV) applications and technologies. Mar. Technol. Soc. J. 2008, 42, 44–51. [Google Scholar] [CrossRef]

- Wang, H.; Xi, L.; Li, J.; Zhou, H. Design, construction of a small unmanned underwater vehicle. In Proceedings of the 2013 MTS/IEEE OCEANS-Bergen, Bergen, Norway, 10–14 June 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 1–6. [Google Scholar]

- Nouri, N.; Zeinali, M.; Jahangardy, Y. AUV hull shape design based on desired pressure distribution. J. Mar. Sci. Technol. 2016, 21, 203–215. [Google Scholar] [CrossRef]

- Yan, K.; Wu, L. A survey on the key technologies for underwater AUV docking. Robot 2007, 29, 267–273. [Google Scholar]

- Zhang, W.; Wu, W.; Teng, Y.; Li, Z.; Yan, Z. An underwater docking system based on UUV and recovery mother ship: Design and experiment. Ocean Eng. 2023, 281, 114767. [Google Scholar] [CrossRef]

- Szczotka, M. AUV launch & recovery handling simulation on a rough sea. Ocean Eng. 2022, 246, 110509. [Google Scholar] [CrossRef]

- Fan, S.; Liu, C.; Li, B.; Xu, Y.; Xu, W. AUV docking based on USBL navigation and vision guidance. J. Mar. Sci. Technol. 2019, 24, 673–685. [Google Scholar] [CrossRef]

- Page, B.R.; Mahmoudian, N. Simulation-driven optimization of underwater docking station design. IEEE J. Ocean. Eng. 2019, 45, 404–413. [Google Scholar] [CrossRef]

- Zhang, W.; Jia, G.; Wu, P.; Yang, S.; Huang, B.; Wu, D. Study on hydrodynamic characteristics of AUV launch process from a launch tube. Ocean Eng. 2021, 232, 109171. [Google Scholar] [CrossRef]

- Brizzolara, S.; Chryssostomidis, C. Design of an Unconventional ASV for Underwater Vehicles Recovery: Simulation of the motions for operations in rough seas. In Proceedings of the ASNE International Conference on Launch & Recovery, Linthicum, MD, USA, 14–15 November 2012. [Google Scholar]

- Sarda, E.I. Automated Launch and Recovery of an Autonomous Underwater Vehicle from an Unmanned Surface Vessel. Ph.D. Thesis, Florida Atlantic University, Boca Raton, FL, USA, 2016. [Google Scholar]

- Bai, G.; Gu, H.; Zhang, H.; Meng, L.; Tang, D. V-shaped wing design and hydrodynamic analysis based on moving base for recovery AUV. In Proceedings of the 2018 WRC Symposium on Advanced Robotics and Automation (WRC SARA), Beijing, China, 16 August 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 320–325. [Google Scholar]

- Palomeras, N.; Vallicrosa, G.; Mallios, A.; Bosch, J.; Vidal, E.; Hurtos, N.; Carreras, M.; Ridao, P. AUV homing and docking for remote operations. Ocean Eng. 2018, 154, 106–120. [Google Scholar] [CrossRef]

- Meng, L.; Lin, Y.; Gu, H.; Bai, G.; Su, T.-C. Study on dynamic characteristics analysis of underwater dynamic docking device. Ocean Eng. 2019, 180, 1–9. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, Y.; Cao, J.; Wang, B.; Li, Y. AUV docking experiments based on vision positioning using two cameras. Ocean Eng. 2015, 110, 163–173. [Google Scholar] [CrossRef]

- Lin, M.; Yang, C. Auv docking method in a confined reservoir with good visibility. J. Intell. Robot. Syst. 2020, 100, 349–361. [Google Scholar] [CrossRef]

- Vu, M.T.; Choi, H.-S.; Nhat, T.Q.M.; Nguyen, N.D.; Lee, S.-D.; Le, T.-H.; Sur, J. Docking assessment algorithm for autonomous underwater vehicles. Appl. Ocean Res. 2020, 100, 102180. [Google Scholar] [CrossRef]

- Zhang, T.; Li, D.; Yang, C. Study on impact process of AUV underwater docking with a cone-shaped dock. Ocean Eng. 2017, 130, 176–187. [Google Scholar] [CrossRef]

- Diao, J.; Li, W.; Yuan, X.; Jiang, K.; Zhao, Y. Study on influencing factors of hydrodynamics based on AUV docking with conical dock. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2023, 237, 929–939. [Google Scholar] [CrossRef]

- Diao, J.; Gao, Z.; Yuan, X. Collision dynamics in AUV docking with conical hood type dock: Influencing factors and performance analysis. Ships Offshore Struct. 2024, 19, 2130–2136. [Google Scholar] [CrossRef]

- Stokey, R.; Purcell, M.; Forrester, N.; Austin, T.; Goldsborough, R.; Allen, B.; von Alt, C. A docking system for REMUS, an autonomous underwater vehicle. In Proceedings of the Oceans’ 97. MTS/IEEE Conference Proceedings, Halifax, NS, Canada, 6–9 October 1997; IEEE: Piscataway, NJ, USA, 2002; Volume 2, pp. 1132–1136. [Google Scholar]

- Stokey, R.; Allen, B.; Austin, T.; Goldsborough, R.; Forrester, N.; Purcell, M.; Von Alt, C. Enabling technologies for REMUS docking: An integral component of an autonomous ocean-sampling network. IEEE J. Ocean. Eng. 2002, 26, 487–497. [Google Scholar] [CrossRef]

- Allen, B.; Austin, T.; Forrester, N.; Goldsborough, R.; Kukulya, A.; Packard, G.; Purcell, M.; Stokey, R. Autonomous docking demonstrations with enhanced REMUS technology. In Proceedings of the OCEANS 2006, Boston, MA, USA, 18–21 September 2006; IEEE: Piscataway, NJ, USA, 2007; pp. 1–6. [Google Scholar]

- McEwen, R.S.; Hobson, B.W.; McBride, L.; Bellingham, J.G. Docking control system for a 54-cm-diameter (21-in) AUV. IEEE J. Ocean. Eng. 2008, 33, 550–562. [Google Scholar] [CrossRef]

- Palomeras, N.; Ridao, P.; Ribas, D.; Vallicrosa, G. Autonomous I-AUV docking for fixed-base manipulation. IFAC Proc. Vol. 2014, 47, 12160–12165. [Google Scholar] [CrossRef]

- Zhang, T.; Li, D.; Lin, M.; Wang, T.; Yang, C. AUV terminal docking experiments based on vision guidance. In Proceedings of the OCEANS 2016 MTS/IEEE Monterey, Monterey, CA, USA, 19–23 September 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–5. [Google Scholar]

- Meng, L.; Lin, Y.; Gu, H.; Su, T.-C. Study on dynamic docking process and collision problems of captured-rod docking method. Ocean Eng. 2019, 193, 106624. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, H.; Yu, X.; Zhang, W.; Chen, J. Attitude constraint-based recovery for under-actuated AUVs under vertical plane control during the capture stage. Ocean Eng. 2023, 281, 115012. [Google Scholar] [CrossRef]

- Mitra, A.; Panda, J.P.; Warrior, H.V. Experimental and numerical investigation of the hydrodynamic characteristics of autonomous underwater vehicles over sea-beds with complex topography. Ocean Eng. 2020, 198, 106978. [Google Scholar] [CrossRef]

- Zhang, W.; Zeng, J.; Yan, Z.; Wei, S.; Tian, W. Leader-following consensus of discrete-time multi-AUV recovery system with time-varying delay. Ocean Eng. 2021, 219, 108258. [Google Scholar] [CrossRef]

- Wu, L.; Li, Y.; Su, S.; Yan, P.; Qin, Y. Hydrodynamic analysis of AUV underwater docking with a cone-shaped dock under ocean currents. Ocean Eng. 2014, 85, 110–126. [Google Scholar] [CrossRef]

- Meng, L.; Lin, Y.; Gu, H.; Su, T.-C. Study on the mechanics characteristics of an underwater towing system for recycling an Autonomous Underwater Vehicle (AUV). Appl. Ocean Res. 2018, 79, 123–133. [Google Scholar] [CrossRef]

- Meng, L.; Lin, Y.; Gu, H.; Su, T.-C. Study of the dynamic characteristics of a cone-shaped recovery system on submarines for recovering autonomous underwater vehicle. China Ocean Eng. 2020, 34, 387–399. [Google Scholar] [CrossRef]

- Luo, W.; Ma, C.; Jiang, D.; Zhang, T.; Wu, T. The hydrodynamic interaction between an AUV and submarine during the recovery process. J. Mar. Sci. Eng. 2023, 11, 1789. [Google Scholar] [CrossRef]

- Xu, Y.; Shi, W.; Song, Y.; Hou, H. Hydrodynamics of a Remora-inspired autonomous underwater vehicle approaching and docking to a benchmark submarine. Ocean Eng. 2024, 291, 116447. [Google Scholar] [CrossRef]

- Liu, J.; Yu, F.; He, B.; Soares, C.G. A review of underwater docking and charging technology for autonomous vehicles. Ocean Eng. 2024, 297, 117154. [Google Scholar] [CrossRef]

- Hong, L.; Fang, R.; Cai, X.; Wang, X. Numerical investigation on hydrodynamic performance of a portable AUV. J. Mar. Sci. Eng. 2021, 9, 812. [Google Scholar] [CrossRef]

- Wu, L.; Feng, X.; Hu, Z. Application of 3-D hybrid dynamic grids to simulate the flow in AUV swim-out. J. Ship Mech. 2010, 14, 717–722. [Google Scholar]

- Wu, L. Numerical Simulation on AUV Underwater Launch and Docking Based on Dynamic Hybrid Grids. Ph.D. Thesis, Graduate School of the Chinese Academy of Sciences, Beijing, China, 2009. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Li, X.; Mei, J.; Lu, D.; Tang, Y. Hydrodynamic Numerical Analysis of AUV Underwater Docking with Conical Docking Bay. J. Mar. Sci. Eng. 2025, 13, 1645. https://doi.org/10.3390/jmse13091645

Gao Y, Li X, Mei J, Lu D, Tang Y. Hydrodynamic Numerical Analysis of AUV Underwater Docking with Conical Docking Bay. Journal of Marine Science and Engineering. 2025; 13(9):1645. https://doi.org/10.3390/jmse13091645

Chicago/Turabian StyleGao, Yang, Xiaohu Li, Jianwei Mei, Daohua Lu, and Yanbing Tang. 2025. "Hydrodynamic Numerical Analysis of AUV Underwater Docking with Conical Docking Bay" Journal of Marine Science and Engineering 13, no. 9: 1645. https://doi.org/10.3390/jmse13091645

APA StyleGao, Y., Li, X., Mei, J., Lu, D., & Tang, Y. (2025). Hydrodynamic Numerical Analysis of AUV Underwater Docking with Conical Docking Bay. Journal of Marine Science and Engineering, 13(9), 1645. https://doi.org/10.3390/jmse13091645