Effect of the Pore Distribution of Fishing Tanks on Hydrodynamic Characteristics Under the Wave Action

Abstract

1. Introduction

- (1)

- The influence of the opening ratio on the motion response and mooring line forces was analyzed. The opening ratio was defined as the percentage of the pore area divided by the side area. Different perforation areas had distinct effects on the motion response and mooring line forces.

- (2)

- The effect of the asymmetric pore distribution in different locations was investigated. The findings also indicated that the effects of pore distribution were greater than those of the opening ratio. The results demonstrated that an asymmetric pore distribution in the windward and leeward sides of the vessel had an impact on the roll motion and the flow velocity near the pores. It is beneficial for enhancing the water circulation in the aquaculture tank.

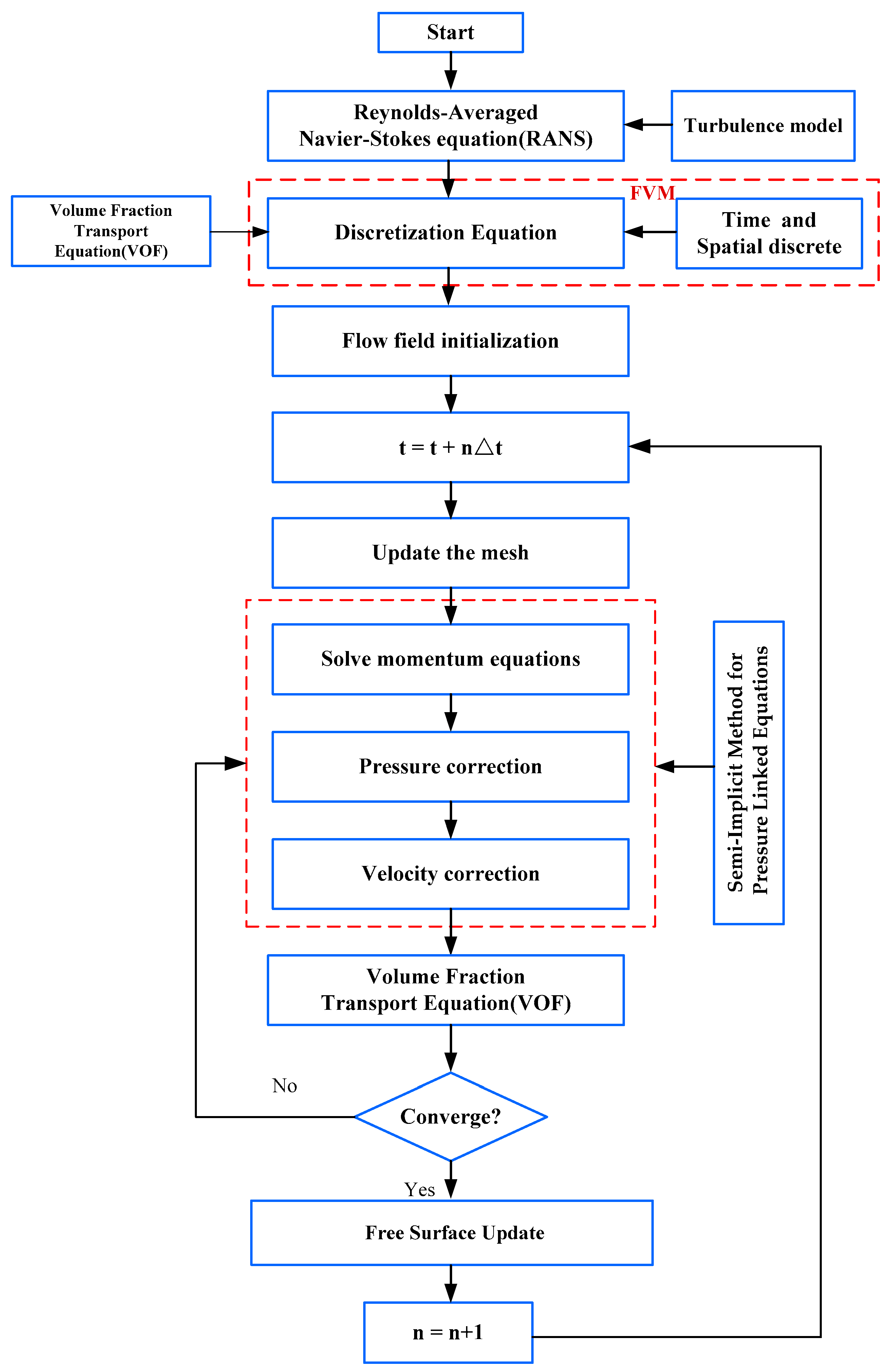

2. The Mathematical Model

2.1. The Definition of the Problem

2.2. Governing Equations

2.3. Free Surface Modeling

2.4. Turbulence Model

3. Numerical Simulation Setup

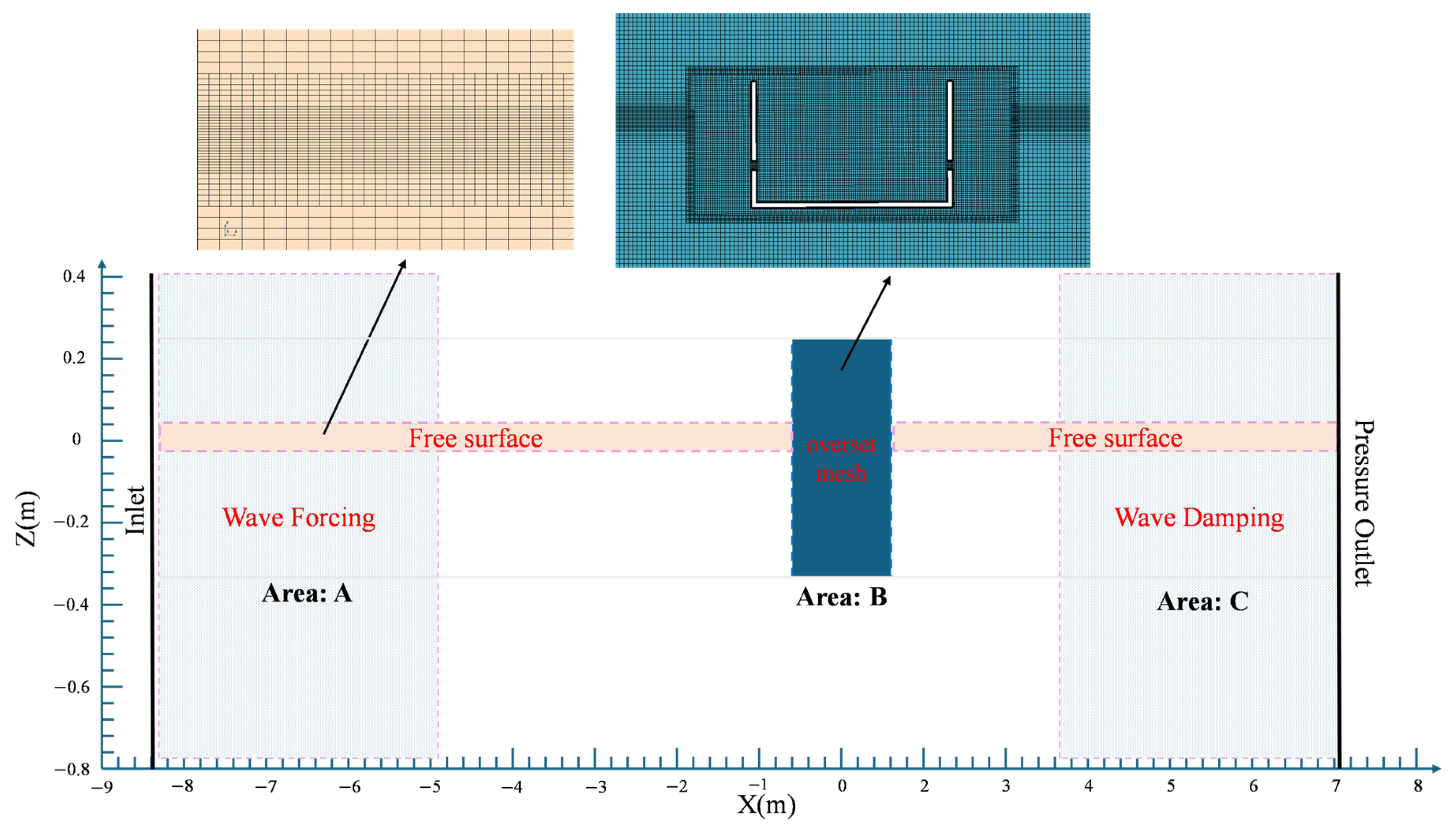

3.1. Numerical Model Setup

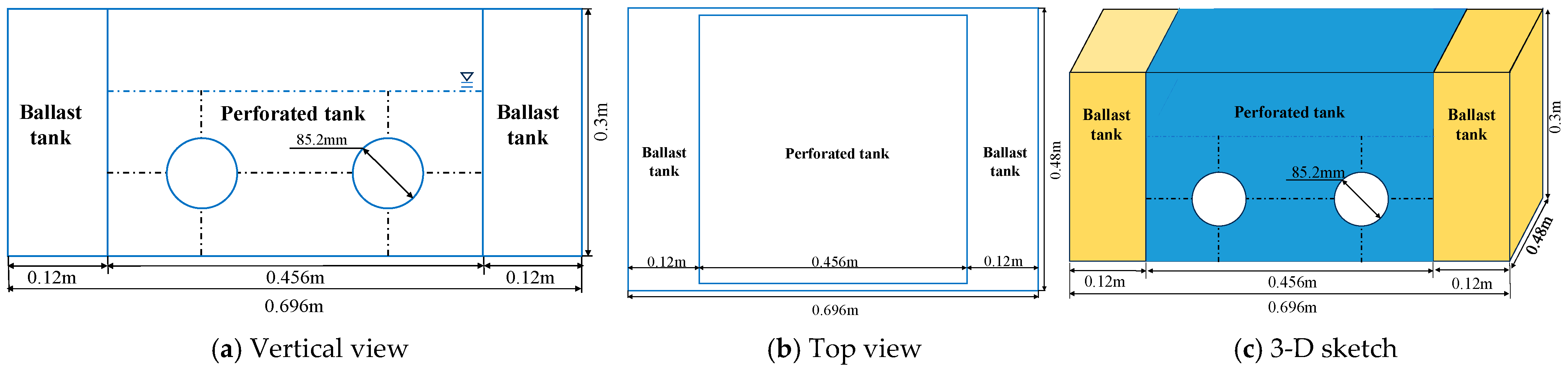

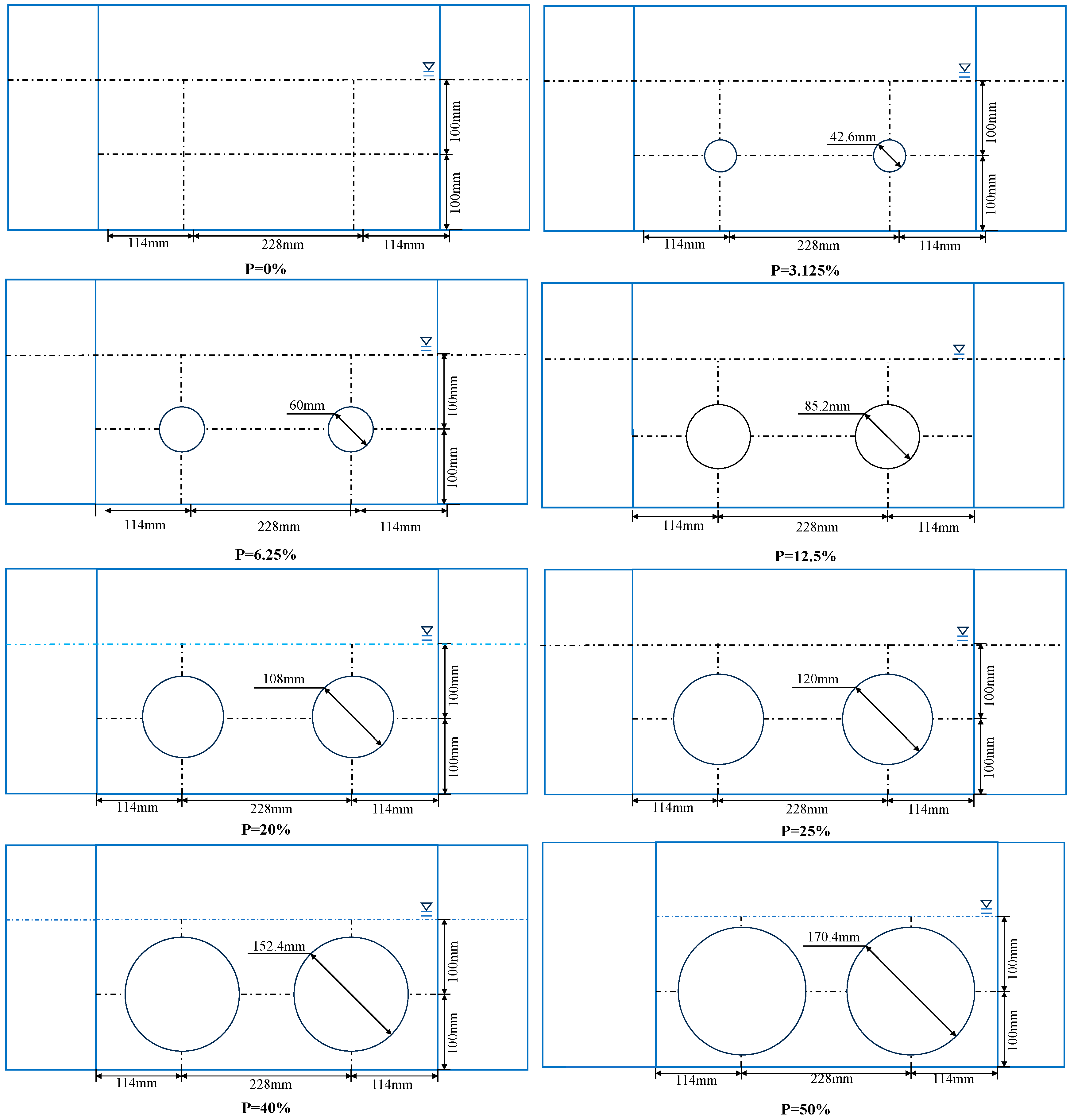

3.2. The Setup of the Perforated Fishing Tank

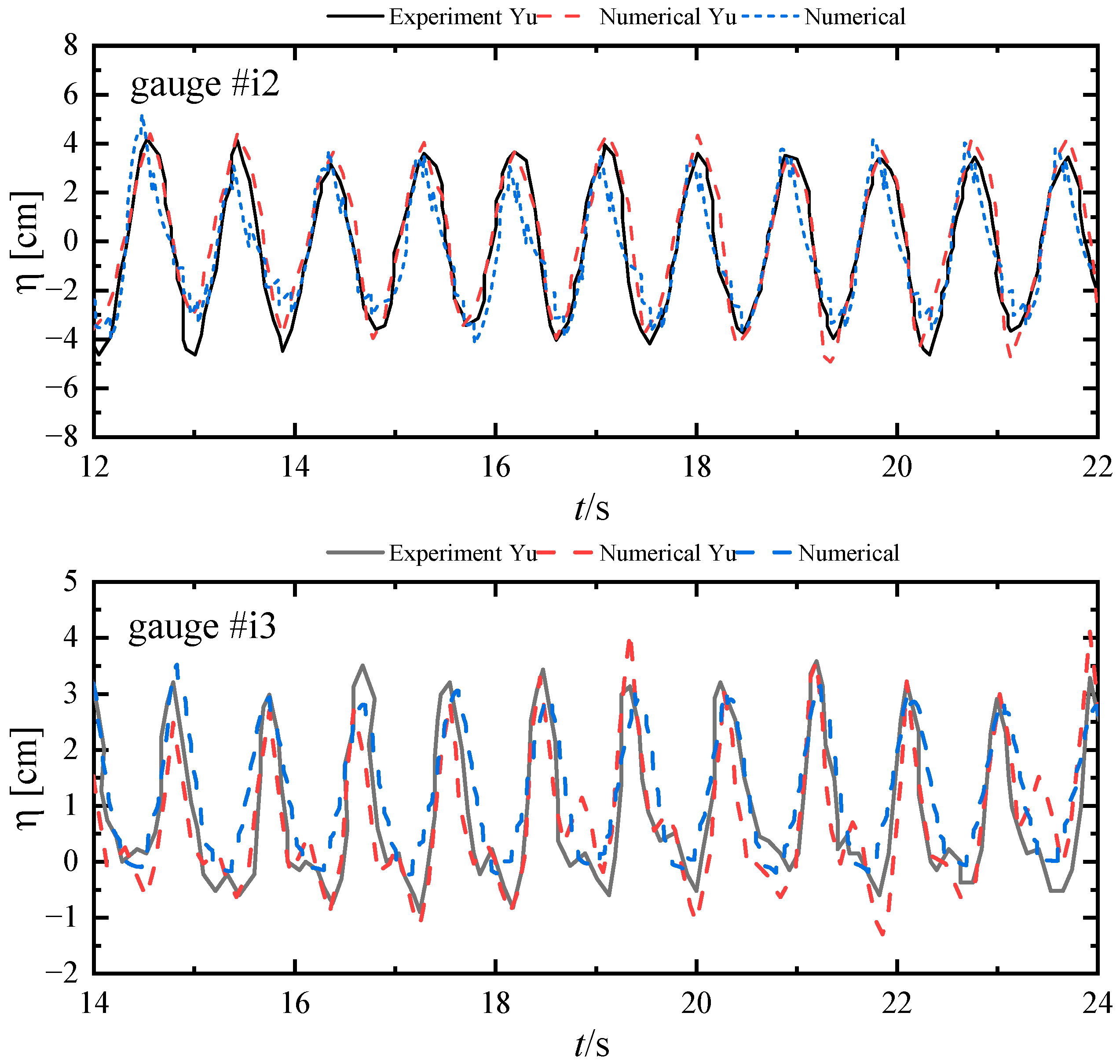

4. Model Validation

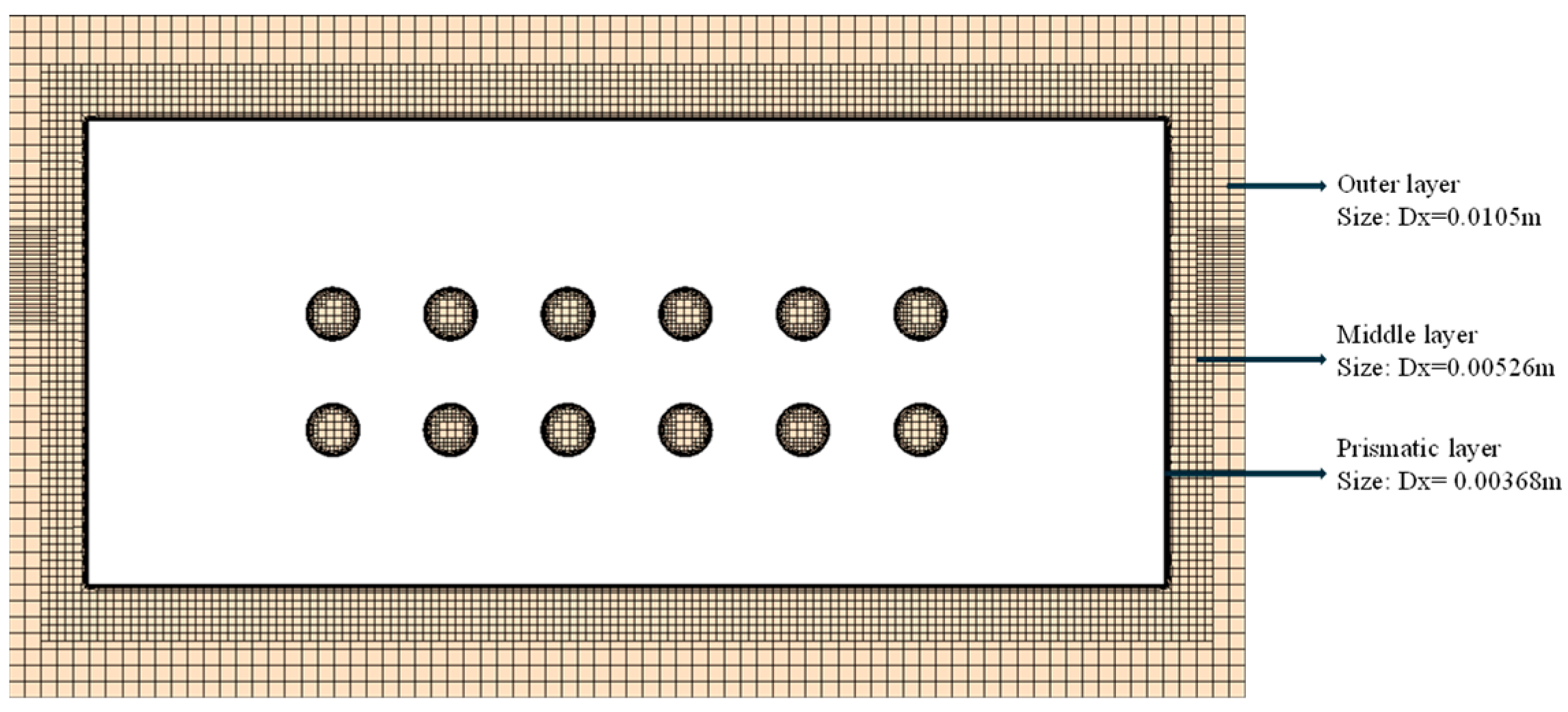

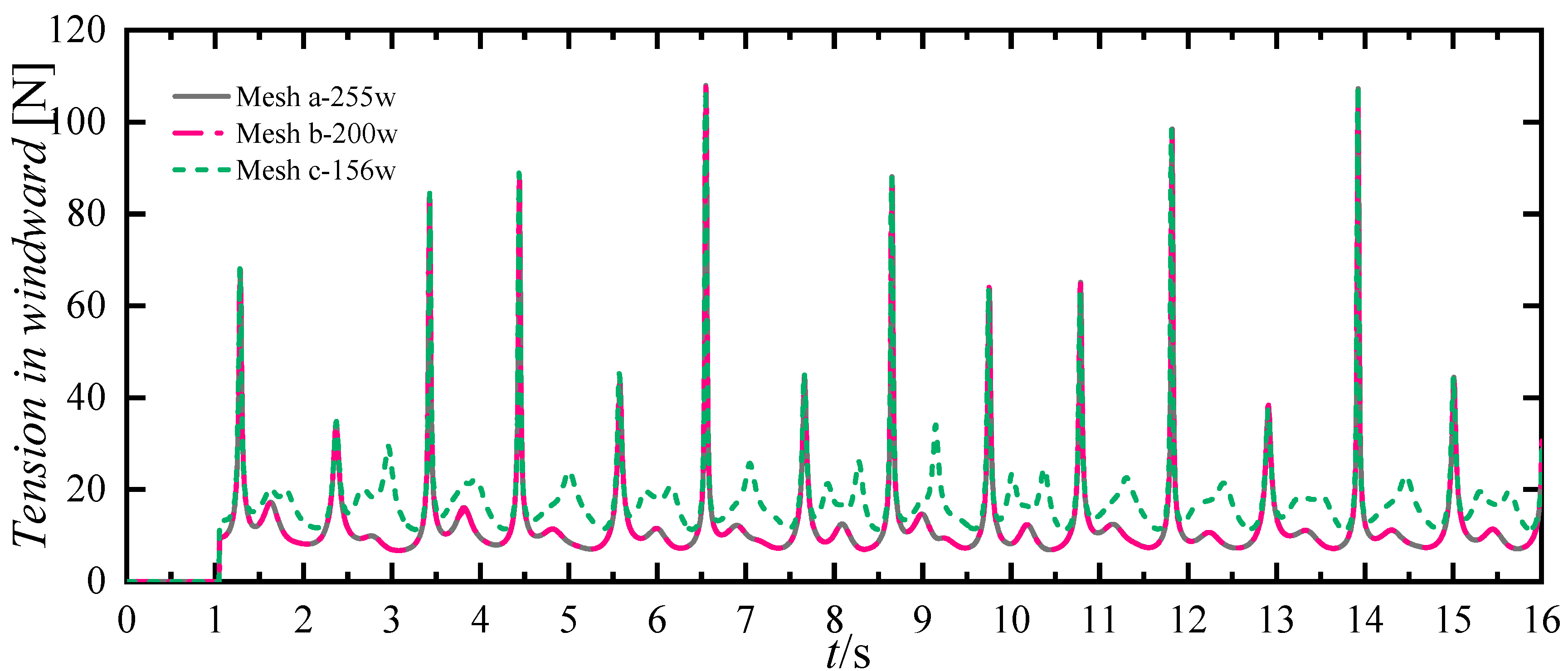

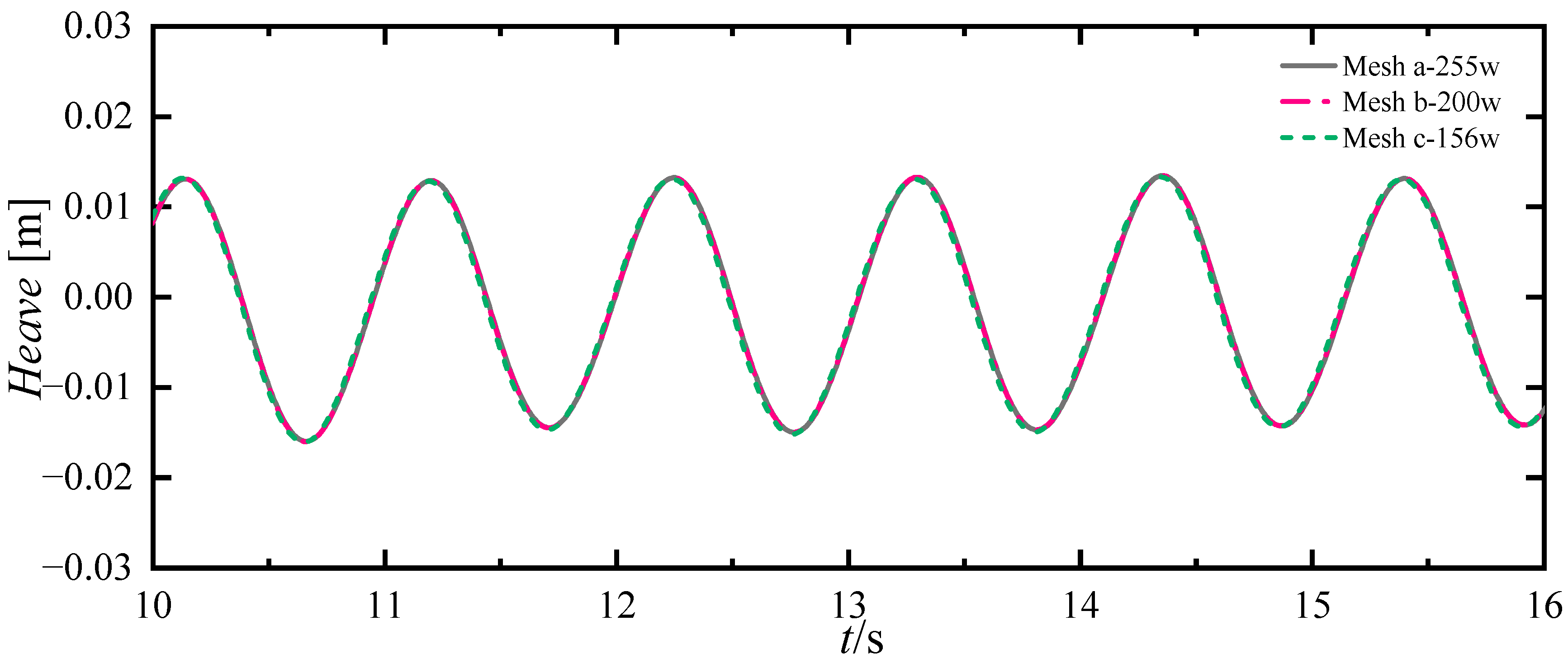

4.1. Validation of Tank Model Mesh

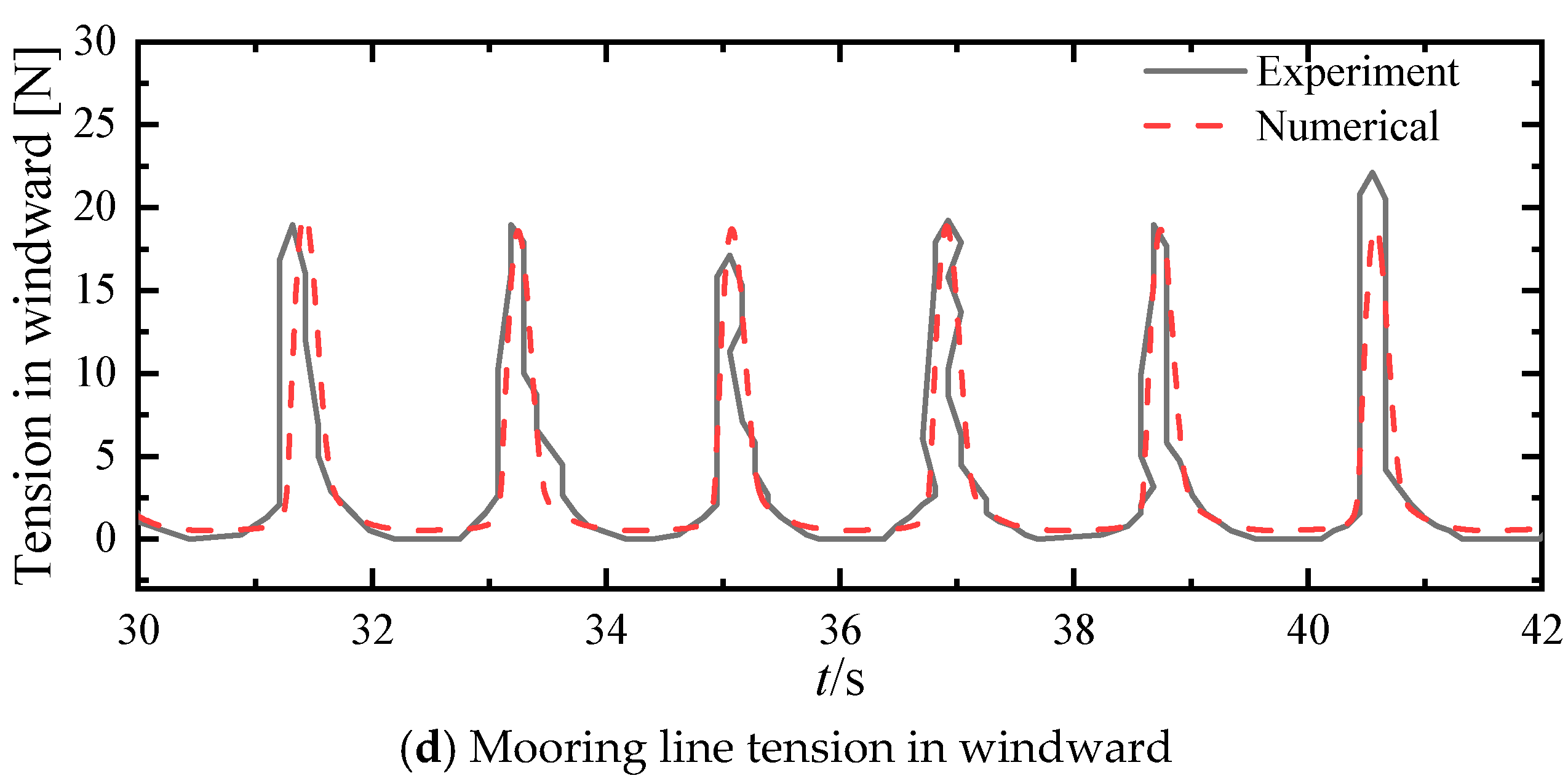

4.2. Validation of Floating Liquid Tank

5. Results and Analysis

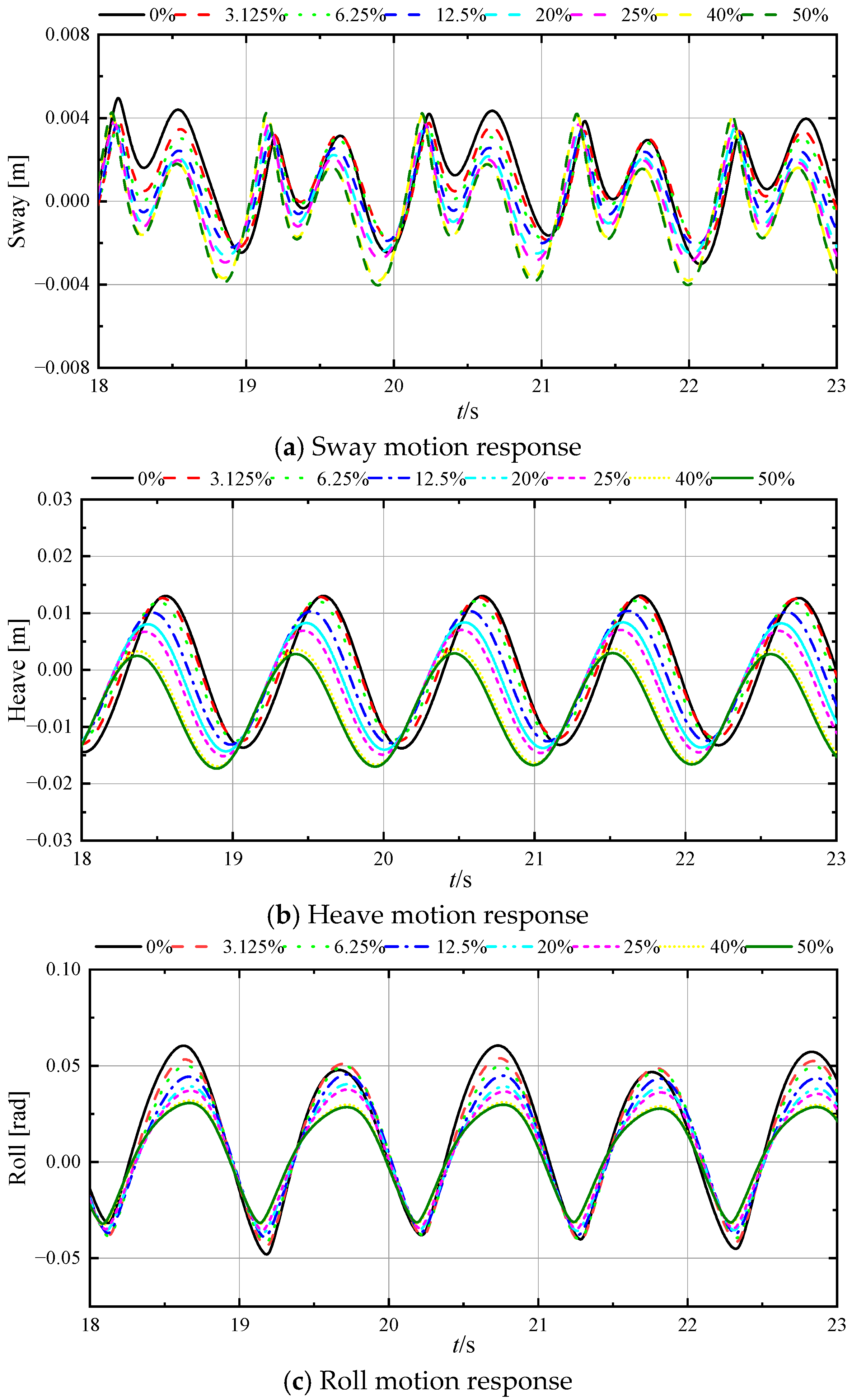

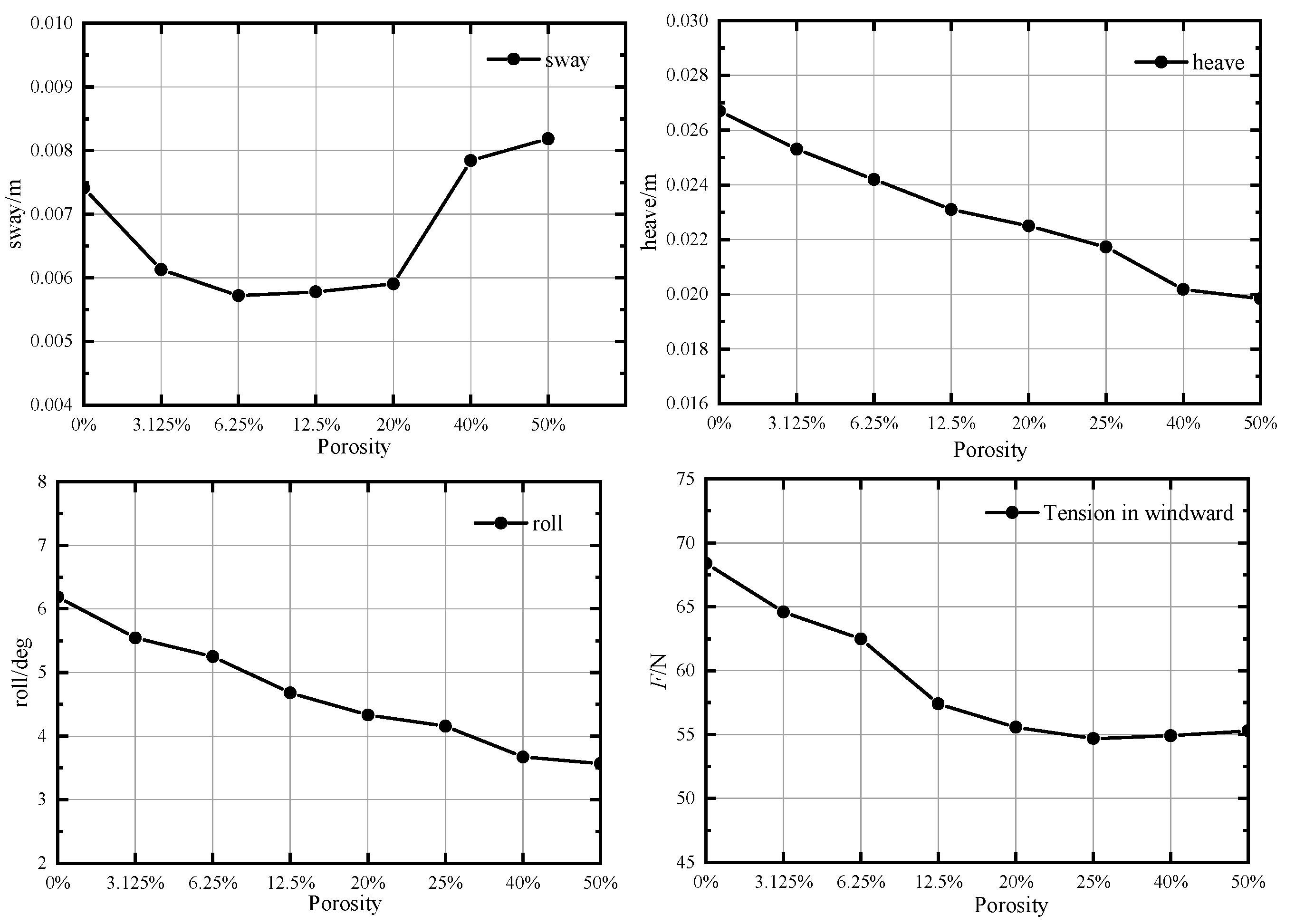

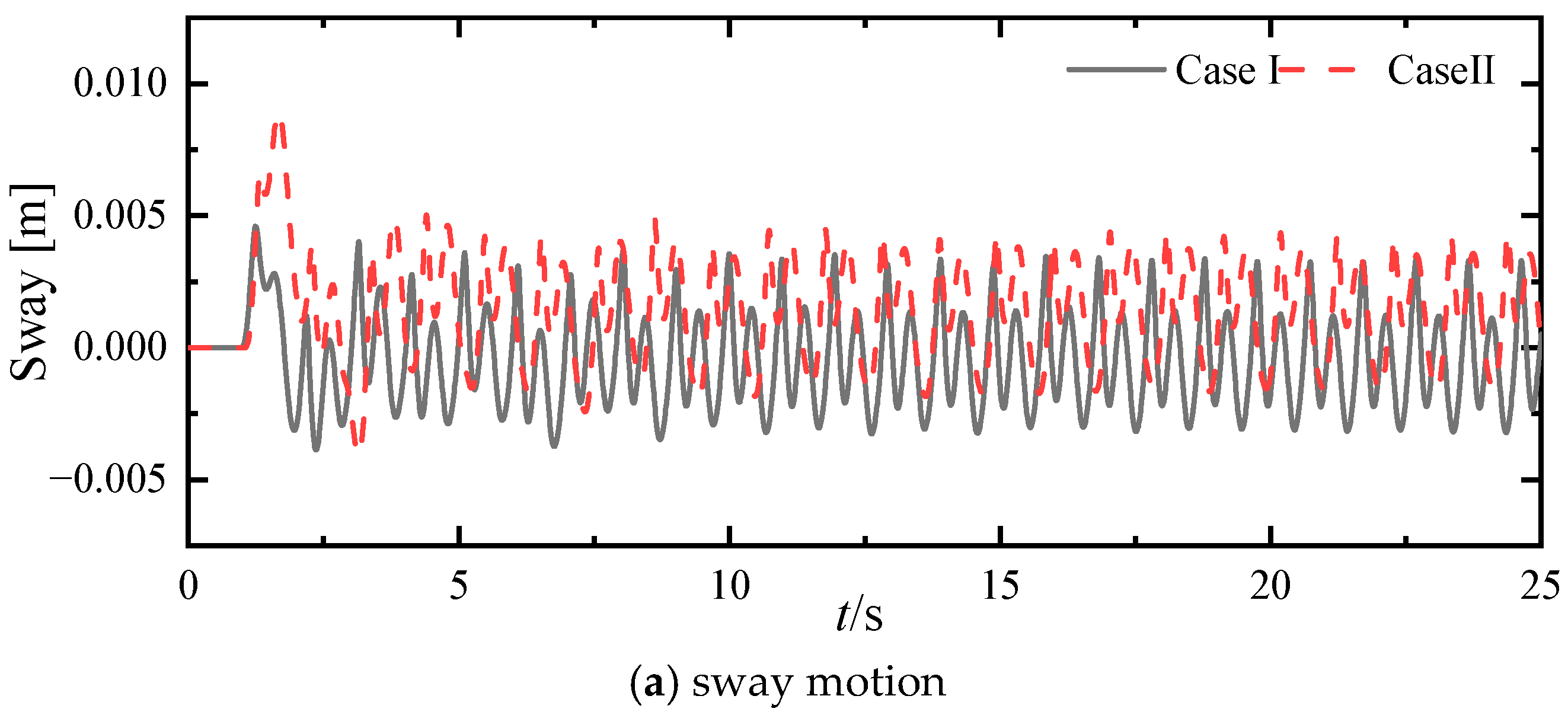

5.1. Analysis of the Effect of Opening Ratio on the Motion Response and Mooring Tension

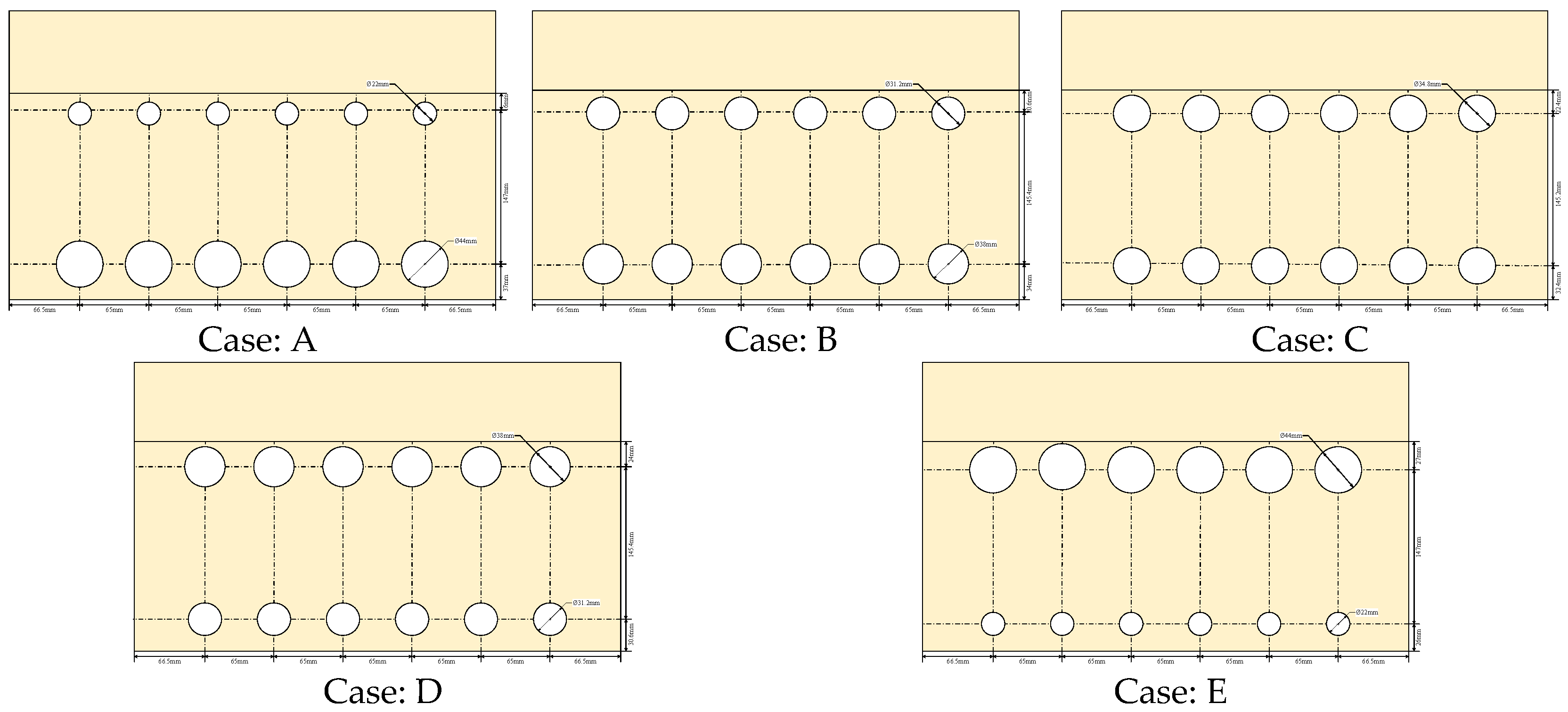

5.2. Analysis of Asymmetric Openings Along the Water Depth Direction

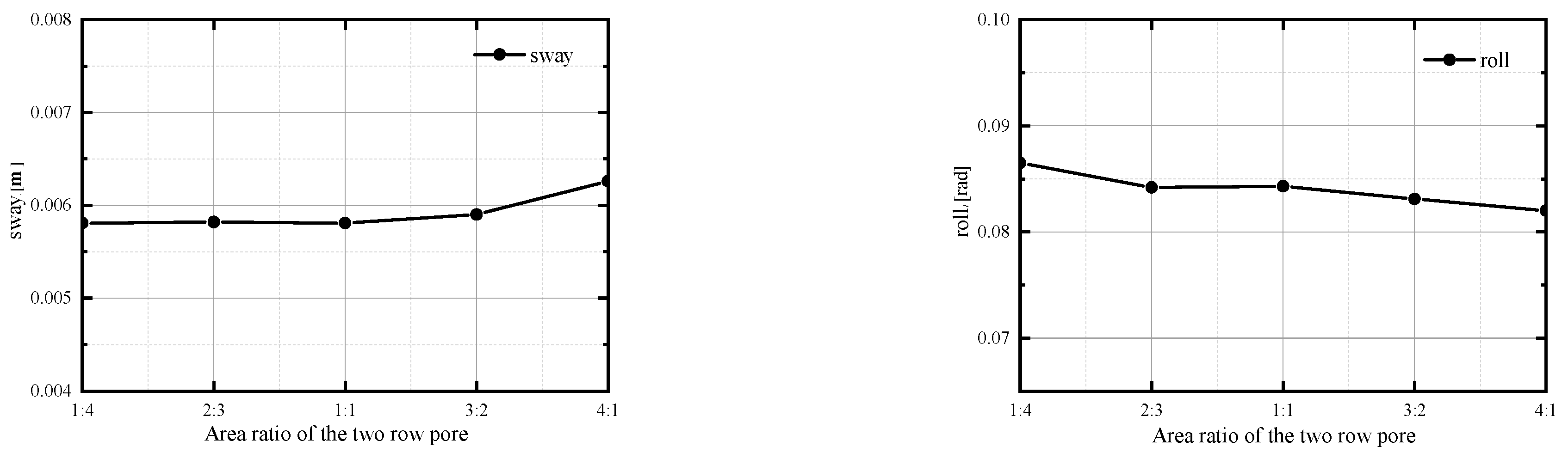

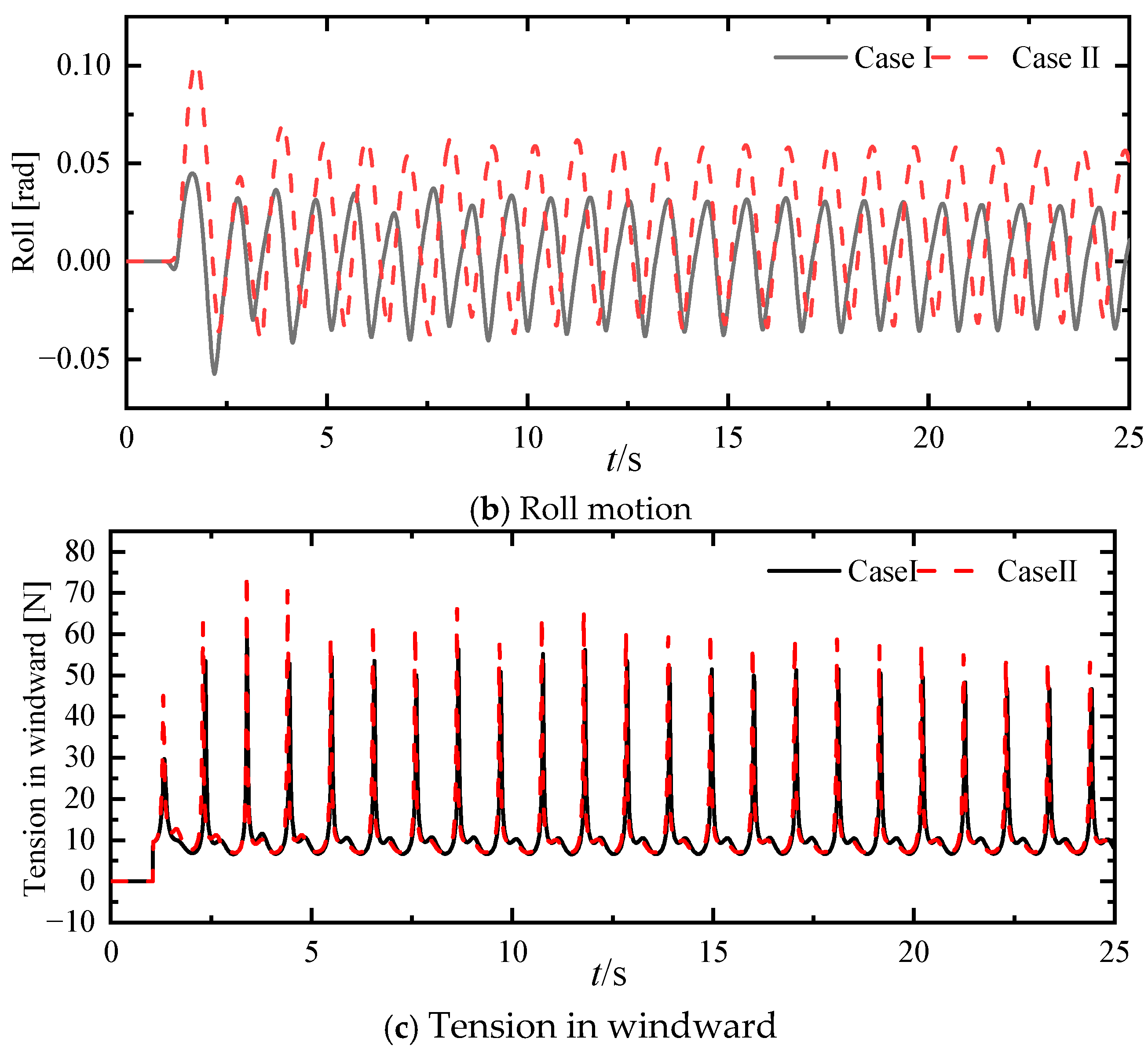

5.2.1. Motion Response and Mooring Force

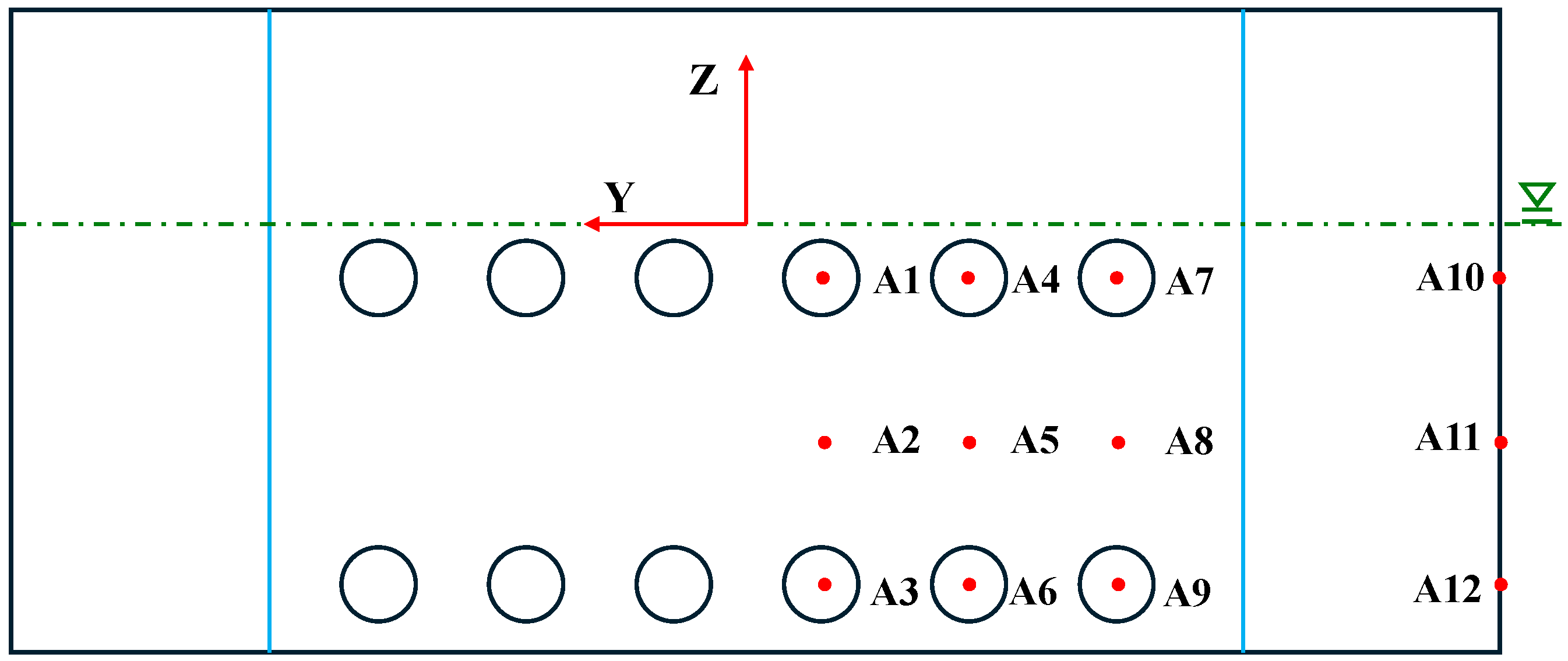

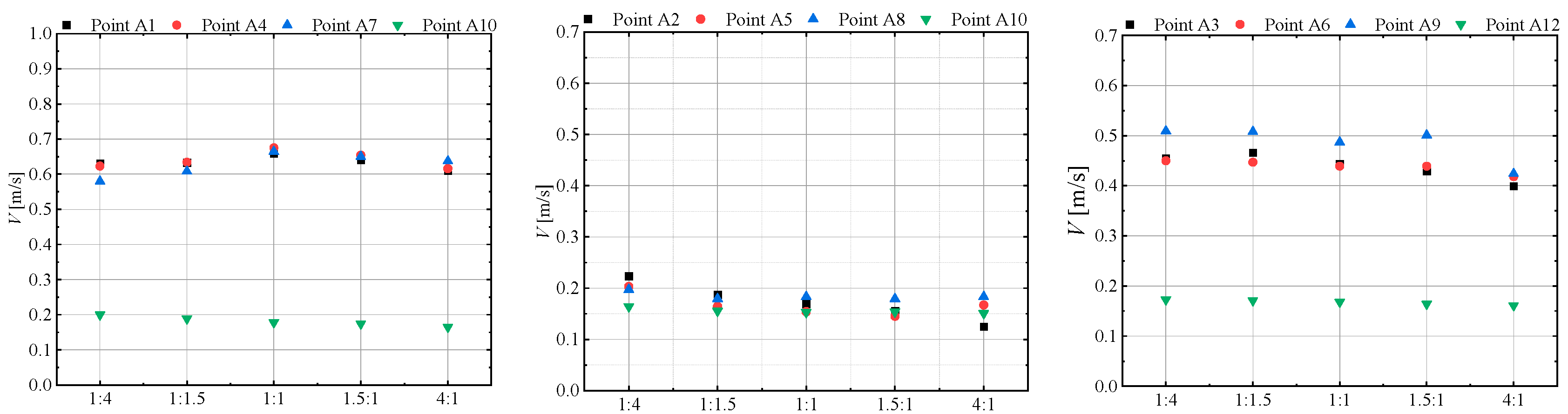

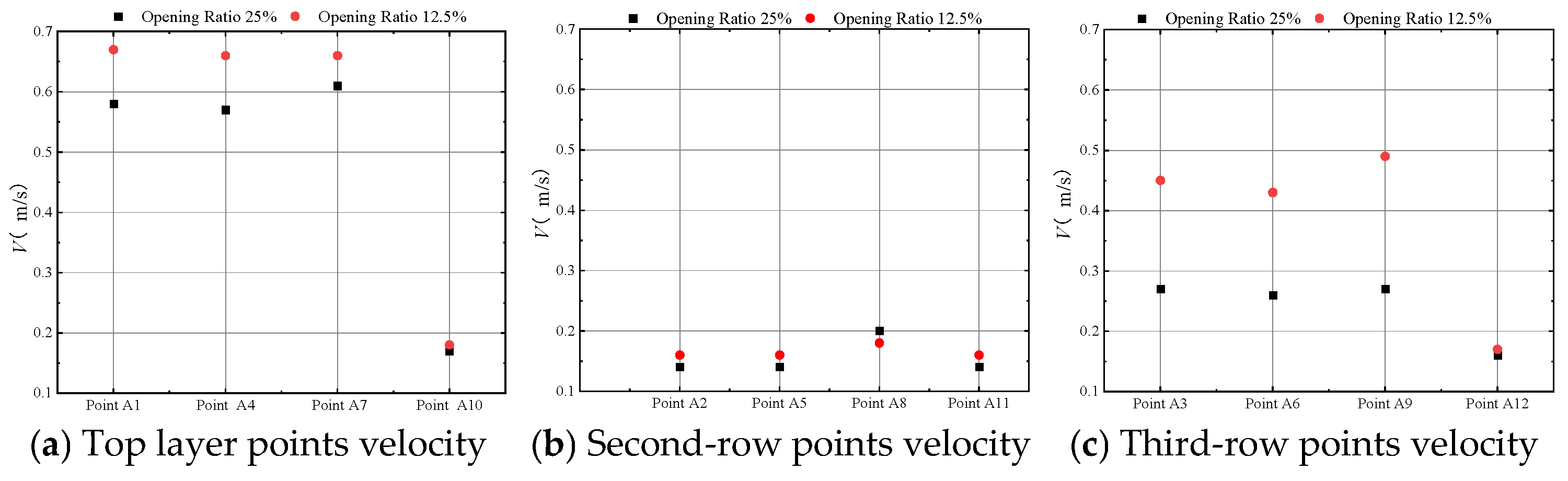

5.2.2. Velocity

5.3. Analysis of Asymmetric Openings in Windward and Leeward Regions

6. Summary and Outlook

- (1)

- Perforation design generally enhances hydrodynamic performance compared to fully enclosed tanks. At 50% porosity, motion response decreased significantly: heave amplitude reduced from 26.7 mm to 19.8 mm (25.8% reduction), and roll amplitude decreased from 6.19° to 3.56° (42.4% reduction). Mooring tension followed the same trend, indicating that perforation effectively reduces motion response and mooring loads, thereby improving hydrodynamic performance.

- (2)

- Depth-based perforation distribution exhibits limited influence on motion response. Different vertical configurations minimally affected sway and roll motions (a mere 7.63% difference in roll), with an even smaller impact on the heave (only 5.2% difference). This finding is inconsistent with the initial hypothesis that vertically asymmetric pore distribution would significantly alter the flow field.

- (3)

- The asymmetric perforation (in windward/leeward sides) exerts a significantly greater influence on motion, internal flow velocity, and water exchange efficiency. Its impact on motion response, internal flow velocity, and water exchange efficiency substantially exceeds that of vertical distribution. Quantitatively, flow velocity variations at first-row measurement points reached 5.8–15.8% across porosity ratios, while third-row points showed a sharp increase to 6.25–81.5%.

- (4)

- An asymmetric perforation design on the windward and leeward sides effectively regulates local flow velocity and establishes directional flow channel forms. By regulating local velocities to establish directional flow channels, this design achieved 5.8–15.8% velocity differences at top-row points under specific conditions (25% and 12.5% porosity). This configuration simultaneously enhances water exchange efficiency while reducing motion response and mooring tension, representing an effective strategy for hydrodynamic optimization. Adjusting asymmetry levels improves exchange efficiency while ensuring structural stability and reduced mooring loads. This approach challenges the conventional porosity-centric design paradigm, offering novel insights for engineering optimization of tank perforation structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Holmer, M. Environmental issues of fish farming in offshore waters: Perspectives, concerns and research needs. Aquacult. Environ. Interac. 2010, 1, 57–70. [Google Scholar] [CrossRef]

- Hvas, M.; Folkedal, O.; Oppedal, F. Fish welfare in offshore salmon aquaculture. Rev. Aquacult. 2020, 13, 836–852. [Google Scholar] [CrossRef]

- Naylor, R.L.; Hardy, R.W.; Buschmann, A.H. A 20-year retrospective review of global aquaculture. Nature 2021, 591, 551–563. [Google Scholar] [CrossRef]

- Tao, Y.W.; Zhu, R.Q.; Gu, J.Y. Experimental and numerical investigation of the hydrodynamic response of an aquaculture vessel. Ocean Eng. 2023, 279, 114505. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Guan, C.T.; Bi, C.W. Experimental investigations on hydrodynamic responses of a semi-submersible offshore fish farm in waves. J. Mar. Sci. Eng. 2019, 7, 238. [Google Scholar] [CrossRef]

- Chu, Y.I.; Wang, C.M.; Park, J.C.; Lader, P.F. Review of cage and containment tank designs for offshore fish farming. Aquaculture 2020, 519, 734928. [Google Scholar] [CrossRef]

- Nobakht-Kolur, F.; Zeinoddini, M.; Ghalebi, A. Hydrodynamic forces in marine- fouled floating aquaculture cages: Physical modelling under irregular waves. J. Fluid Struct. 2021, 105, 103331. [Google Scholar] [CrossRef]

- Nobakht-Kolur, F.; Zeinoddini, M.; Aalami Harandi, M.M.; Abi, F.A.; Jadidi, P. Effects of soft marine fouling on wave-induced forces in floating aquaculture cages: Physical model testing under regular waves. Ocean Eng. 2021, 238, 109759. [Google Scholar] [CrossRef]

- Bi, C.W.; Zhao, Y.P.; Sun, X.X.; Zhang, Y.; Guo, Z.X.; Wang, B.; Dong, G.H. An efficient artificial neural network model to predict the structural failure of high density polyethylene offshore net cages in typhoon waves. Ocean Eng. 2020, 196, 106793. [Google Scholar] [CrossRef]

- Kristiansen, D.; Lader, P.; Jensen, Ø.; Fredriksson, D. Experimental study of an aquaculture net cage in waves and current. China Ocean Eng. 2015, 29, 325–340. [Google Scholar] [CrossRef]

- Xu, T.J.; Dong, G.H.; Tang, M.F.; Liu, J.; Guo, W.J. Experimental Analysis of Hydrodynamic Forces on Net Panel in Extreme Waves. Appl. Ocean Res. 2021, 107, 102495. [Google Scholar] [CrossRef]

- Jiang, Z.Q.; Bi, C.W.; Xin, L.X. Dynamic responses of a semi-submersible integrated wind-energy-aquaculture structure under regular and irregular waves. Aquacult. Eng. 2024, 106, 102412. [Google Scholar] [CrossRef]

- Dong, G.H.; Guo, S.A.; Bi, C.W. Numerical study on the flow characteristics of an integrated fish cage based on the monopile offshore wind turbine foundation. Aquacult. Eng. 2024, 107, 102458. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Bi, C.W.; He, S.Y.; Huang, L.Y. Numerical analysis of the hydrodynamic response of an aquaculture-cage group in offshore wind farm. Ocean Eng. 2024, 309, 118404. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, J.; He, D.; Wang, K.; Liu, Y.; Zhi, J. Hydrodynamic characteristics and internal flow field of a perforated fishing vessel under wave conditions. Ocean Eng. 2024, 314, 119611. [Google Scholar] [CrossRef]

- Li, B.B.; Liu, Z.Q.; Liang, H. BEM modeling for the hydrodynamic analysis of the perforated fish farming vessel. Ocean Eng. 2023, 285, 115225. [Google Scholar] [CrossRef]

- Xue, B.; Zhao, Y.P.; Liu, Y.; Cheng, Y. Flow characteristics of an aquaculture vessel with perforated sideboards at various incidence angles. Biosyst. Eng. 2023, 234, 108–124. [Google Scholar] [CrossRef]

- Xue, B.; Liu, Y.; Ren, X.; Chen, C.; Zhao, Y. Influence of perforation placement on the hydrodynamics of a culture tank onboard a self-exchange aquaculture vessel. Biosyst. Eng. 2024, 245, 106–121. [Google Scholar] [CrossRef]

- Cui, M.C.; Wang, J.; Guo, X.Y. Numerical Analysis of Flow Field Characteristics in a Tank of Aquaculture Vessel under Rolling Motion. Shipbuild. China 2020, 61, 204–215, (In Chinese with English Abstract). [Google Scholar]

- Cui, M.; Li, Z.; Zhang, C.; Guo, X. Statistical investigation into the flow field of closed aquaculture tanks aboard a platform under periodic oscillation. Ocean Eng. 2022, 248, 110677. [Google Scholar] [CrossRef]

- Wang, G.; Martin, T.; Huang, L.Y.; Bihs, H. Numerical investigation of the hydrodynamics of a submersible steel-frame offshore fish farm in regular waves using CFD. Ocean Eng. 2022, 256, 111528. [Google Scholar] [CrossRef]

- Weller, H.G.; Tabor, G.; Jasak, H.; Fureby, C. A tensorial approach to computational continuum mechanics using object oriented techniques. Comput. Phys. 1998, 12, 620–631. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, Y.D.; Zhang, W. Effect of the pore parameters of the perforated baffle on the control of liquid sloshing. Ocean Eng. 2024, 302, 12. [Google Scholar] [CrossRef]

- Gorle, J.M.R.; Terjesen, B.F.; Summerfelt, S.T. Influence of inlet and outlet placement on the hydrodynamics of culture tanks for Atlantic salmon. Int. J. Mech. Sci. 2020, 188, 105944. [Google Scholar] [CrossRef]

- Jones, W.P.; Launder, B.E. The Prediction of Laminarization with Two-Equation Model of Turbulence. Int. J. Heat Mass Tran. 1972, 15, 301–314. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The Numerical Computation of Turbulent Flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- STAR CCM+ User Guide Version 2020.1.0. Siemens PLM Software Inc.: Plano, TX, USA, 2020; pp. 1–12117.

- Kim, J.; O’Sullivan, J.; Read, A. Ringing analysis of a vertical cylinder by Euler overlay method. In Proceedings of the ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012; pp. 855–866. [Google Scholar] [CrossRef]

- Baquet, A.; Kim, J.; Huang, Z. Numerical modeling using CFD and potential wave theory for three-hour nonlinear irregular wave simulations. In Proceedings of the ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering, Trondheim, Norway, 25–30 June 2017. V001T01A002. [Google Scholar] [CrossRef]

- Yu, H. Numerical and Experimental Study on Hydrodynamic Performance of Moored Floating Liquid Storage Tank. Master’s Thesis, Dalian University of Technology, Dalian, China, 2018. (In Chinese with English Abstract). [Google Scholar]

| Case | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Opening Ratio | 0.0% | 3.125% | 6.25% | 12.5% | 20% | 25% | 40% | 50% |

| Height | 0.04 m | |||||||

| Period | 1.05 s | |||||||

| Type | Diameter of the Upper Opening Row | Diameter of the Lower Row | Area of the Upper Opening Row | Area of the Lower Opening Row | The Ratio of the Upper and Lower Opening Row |

|---|---|---|---|---|---|

| Case A | 22.0 mm | 44.0 mm | 380 mm2 | 1521 mm2 | 1:4.0 |

| Case B | 31.2 mm | 38.0 mm | 765 mm2 | 1134 mm2 | 1:1.5 |

| Case C | 34.8 mm | 34.8 mm | 951 mm2 | 951 mm2 | 1:1.0 |

| Case D | 38.0 mm | 31.2 mm | 1134 mm2 | 765 mm2 | 1.5:1 |

| Case E | 44.0 mm | 22.0 mm | 1521 mm2 | 380 mm2 | 4.0:1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, X.; Yu, X.; Yang, J.; Huo, F. Effect of the Pore Distribution of Fishing Tanks on Hydrodynamic Characteristics Under the Wave Action. J. Mar. Sci. Eng. 2025, 13, 1619. https://doi.org/10.3390/jmse13091619

Ma X, Yu X, Yang J, Huo F. Effect of the Pore Distribution of Fishing Tanks on Hydrodynamic Characteristics Under the Wave Action. Journal of Marine Science and Engineering. 2025; 13(9):1619. https://doi.org/10.3390/jmse13091619

Chicago/Turabian StyleMa, Xiaojian, Xiao Yu, Jian Yang, and Fali Huo. 2025. "Effect of the Pore Distribution of Fishing Tanks on Hydrodynamic Characteristics Under the Wave Action" Journal of Marine Science and Engineering 13, no. 9: 1619. https://doi.org/10.3390/jmse13091619

APA StyleMa, X., Yu, X., Yang, J., & Huo, F. (2025). Effect of the Pore Distribution of Fishing Tanks on Hydrodynamic Characteristics Under the Wave Action. Journal of Marine Science and Engineering, 13(9), 1619. https://doi.org/10.3390/jmse13091619