Abstract

In this paper, a connecting joint capable of underwater autonomous docking and separation is proposed, which can be used for a reconfigurable articulated underwater robot (RAU robot). The structural design, optimization, and experimental validation of the connecting joint are presented in detail. First, the concept of the RAU robot is introduced, along with its different operational modes and the application scenarios. Second, the specific structural design and basic functions of the connecting joint are described. Third, a dynamic model of the docking process between different vehicles is established and simulated by kinematic simulation software. Through discretely sampling the parameter space, the optimal parameter combination is obtained. Finally, a prototype of the connecting joint is fabricated and functional tests are conducted. The impact forces on the docking rods before and after optimization are compared. The results show that the designed connecting joint can fulfill the functional requirements for autonomous docking of the underwater robot, and the maximum impact force is reduced by 27.08% compared to the one before optimization.

1. Introduction

Numerous offshore facilities, such as oil and gas platforms, require frequent underwater inspection and maintenance [1,2], which has driven the development of new types of underwater robots with enhanced operational capabilities and extended working ranges [3,4]. Traditional Remotely Operated Vehicles (ROVs) are typically large and expensive. Their deployment process is time-consuming and the operation process has the risks of tether entanglement and collisions [5]. In contrast, conventional Autonomous Underwater Vehicles (AUVs) can perform certain underwater tasks automatically; however, most AUVs lack robotic arms that enable them to perform intervention tasks like ROVs. Although a few intervention-type AUVs equipped with manipulators have been developed in recent years, their flexibility remains limited [6,7,8,9,10,11]. Therefore, there is a growing need to develop smaller, more flexible, and more cost-effective underwater robotic systems capable of performing a wider variety of autonomous and semi-autonomous tasks.

An Underwater Snake Robot (USR) is a slender, articulated structure composed of serially connected joint modules, with the ability to swim like a biological eel. Essentially, an Underwater Swimming Manipulator (USM) is a hyper-redundant USR equipped with additional effectors. A USM is a crossover between a typical ROV/AUV and a USR, and it has the ability to perform its own locomotion and at the same time serve as a manipulator [5]. The USM shares similar hydrodynamic characteristics with traditional torpedo-shaped AUVs, making it suitable for long-distance transportation. With its flexible and slender body, it can maneuver through narrow spaces within subsea facilities to perform operational tasks. Compared to conventional ROVs, the USM exhibits superior flexibility and accessibility [12]. Moreover, the USM could function as a dexterous robotic arm that can be used as a tool and perform intervention tasks [13]. Research has also shown that USMs are more energy efficient than ROVs in almost all compared motion modes, particularly in terms of transportation cost and overall energy consumption [14]. Based on small-scale AUVs, Han [15] proposed a reconfigurable articulated underwater robot (RAU robot). The RAU robot consists of multiple modular small-scale AUV units that can not only operate collaboratively as individual vehicles but also dock together to form a unified system, which functions similarly to a USM in performing intervention tasks.

The RAU robot calls for a mechanical structure that enables reliable docking and separation among multiple small-scale AUVs, thereby allowing transformation of the RAU robot between a unified multibody AUV and several independent units. However, existing research on docking has primarily focused on capturing AUVs underwater using methods such as conical cages or robotic arms, with little attention given to docking operations between AUVs themselves [16,17]. Magnetic docking provides a practical approach for establishing underwater connections between AUVs [18]. Certain connection systems utilize electromagnets [19] or permanent magnets [20,21]. However, the force generated by electromagnets is weak. Permanent magnets may cause some unwanted interactions. Therefore, they are not suitable for AUV docking in limited spaces, typically around subsea facilities. Although several mechanical docking structures have been developed [22,23], they are not applicable to small-scale AUVs. Therefore, it is essential to develop a feasible docking structure that enables multiple small-scale AUVs to interconnect and form diverse structural configurations in underwater environments. This would enhance the sensing and intervention capabilities of small-scale AUVs, improving their overall operational performance.

This paper presents a connecting joint capable of underwater autonomous docking and separation, which can be used for a reconfigurable articulated underwater robot. The structural design of the connecting joint that enables docking between individual units is introduced, and its key parameters are optimized. Finally, the performance of the design and the effectiveness of optimization are verified through experiments. The main contributions of this paper are summarized as follows.

- 1.

- A connecting joint designed for the RAU robot is introduced. The structural design of the connecting joint for the RAU robot is developed. The underwater docking, locking, and release functions are achieved by a single motor.

- 2.

- To reduce the impact force during docking, the structural parameters of the ratchet teeth on the pawls and the docking rod are optimized with simulation. The performance of the connecting joint is experimentally validated, and the effectiveness of optimization is confirmed by impact force measurements.

The subsequent sections of this paper are organized as follows: Section 2 introduces the concept of the RAU robot and details of the structural design of its connecting joint. Section 3 presents the dynamic model and simulation-based analysis of the ratchet tooth parameters on the pawl and docking rod, leading to the identification of an optimal parameter combination. Section 4 describes the functional experiments performed on a prototype of the connecting joint, followed by impact force measurements on the docking module to validate the effectiveness of parameter optimization.

2. RAU Robot

2.1. Design Concept

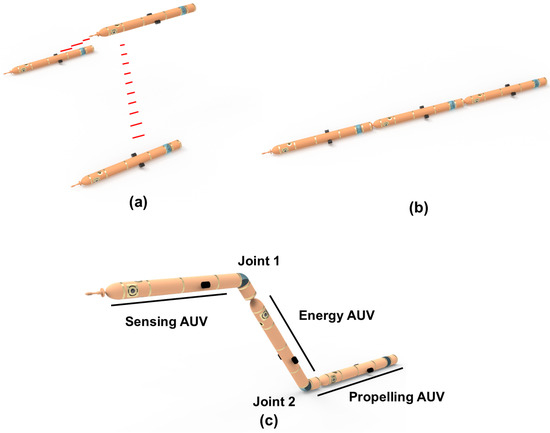

As shown in Figure 1, the RAU robot consists of multiple AUVs that can be reconfigured underwater, making it adaptable to a wide range of missions. When undocked, these AUVs, each equipped with different functional payloads, can communicate and collaborate to form a swarm for cooperative operations. During intervention missions, individual AUV units can autonomously dock with each other to form a multibody system that can function as a USM, enabling effective operations in narrow underwater environments.

Figure 1.

Conceptual diagram of the RAU robot: (a) swarm, (b) tandem layout, and (c) change into a USM.

In addition, studies by Zhang [24] and Kang [25] have demonstrated that a tandem layout is an effective configuration to reduce the resistance of a group of multiple AUVs, as shown in Figure 1b. This configuration is particularly advantageous when a task-specific AUV lacks sufficient energy to reach the target location. By forming a serial robotic assembly, auxiliary AUVs can propel the mission unit using their own energy reserves. Once the destination is reached, the task-oriented AUV detaches to complete its mission, thereby overcoming the limitations imposed by the limited energy capacity of a single AUV. Furthermore, when the task-specific AUV is replaced by a payload, the RAU robot can also be regarded as an alternative to traditional payload deployment platforms [26].

Through docking and reconfiguration, the robot expands its range of applications while maintaining the compactness of individual AUVs, thereby maximizing operational efficiency.

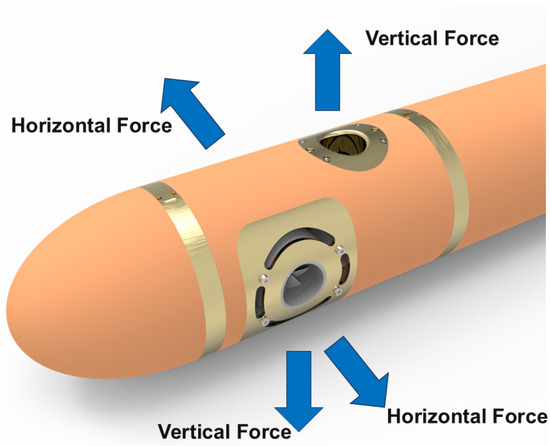

Each AUV, serving as a fundamental structural unit, is equipped with channel thrusters that provide lateral thrust for maneuvering [27]. In the standalone state, the AUV can independently adjust its horizontal and vertical positions. After docking, these thrusters act as substitutes for the motor that drives the joint in traditional USMs, enabling the control of relative positions between connected AUVs. The configuration of the channel thrusters is shown in Figure 2. Since the basic AUV has already been developed and validated experimentally [15], this paper focuses primarily on the design of the connecting joint.

Figure 2.

Channel thrusters.

2.2. Connecting Joint Design

Since the joint is responsible for connecting multiple AUVs, the parameters of every AUV unit serve as important references for the design of the connecting joint. The specifications of the basic AUV are summarized in Table 1.

Table 1.

Specification of the basic AUV.

2.2.1. Overall Design Scheme

A functional analysis of the connecting joint is presented as follows.

- 1.

- High Maneuverability

To enable multiple AUVs to operate effectively in narrow underwater environments, the connecting joint must remain compact. In addition, the joint should provide at least two passive degrees of freedom (DOFs) to enhance the flexibility of the RAU robot, offering structural support for improved maneuverability. In addition, the DOFs of the joint can be restricted by other modules, which indicates that the joint has two different statuses—constrained or unconstrained status—as shown in Figure 3.

Figure 3.

Different states of joint’s DOFs: (a) constrained status and (b) unconstrained status.

- 2.

- High Modularity

The demands of diverse missions require the RAU robot to be capable of carrying various external functional payloads according to specific operational scenarios. To support rapid integration and improve expandability, the connecting joint should minimize dependence on the installed AUV and maintain a high level of integration.

- 3.

- High Flexibility

Different missions call for different modes of the RAU robot. In order to achieve all tasks underwater, the RAU robot should be capable of autonomous underwater docking and separation, allowing smooth transitions between operational modes. Furthermore, the RAU robot should be capable of making decisions based on the underwater environment and the specific task to select the working modes.

The above functional requirements outline the design principles and specifications for the connecting joint. They can be summarized as follows:

- (1)

- The connecting joint should allow docking and locking between two different AUVs.

- (2)

- The RAU robot must have at least two passive DOFs after docking, and the joint’s DOFs can be mechanically locked or unlocked as needed.

- (3)

- The connecting joint and the AUV should utilize a unified mechanical interface.

- (4)

- RAU robot should be capable of autonomous separation into two or more AUVs when required.

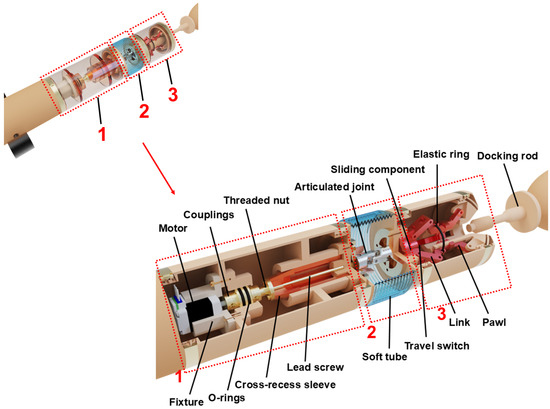

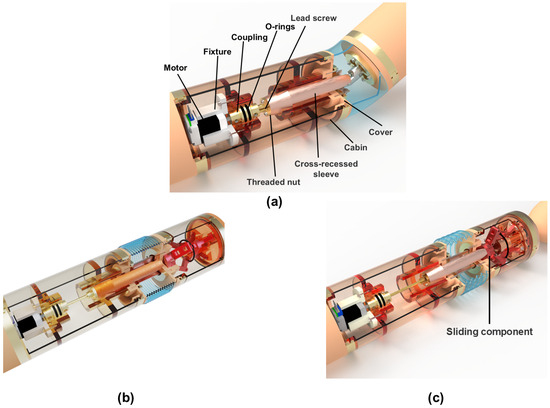

As shown in Figure 4, the designed connecting joint consists of three main components: 1—a drive module; 2—an articulated joint; and 3—a docking module. The drive module is mounted at the rear of the AUV, and it determines whether to constrain the DOFs of the joint. The angle of the joint is adjusted by the channel thrusters on the AUV. The articulated joint is structurally designed to provide two passive DOFs: pitch and yaw. The docking module enables docking and separation between different AUVs. The outer surface of the articulated joint is typically covered with a corrugated hose to minimize the influence on the hydrodynamic performance of the assembled RAU robot.

Figure 4.

Layout and internal structure of the connecting joint: 1—drive module; 2—articulated joint; and 3—docking module.

The docking rod is mounted at the front of another AUV. Docking is achieved by inserting the rod into the docking module, where it is fixed by an internal mechanism. When the RAU robot changes to USM mode, the motor inside the drive module is used to unlock the DOFs of the articulated joint. The same motor is also used to release the locking mechanism within the docking module, allowing for the separation of the individual vehicles. The internal structure of the connecting joint is shown in Figure 4.

2.2.2. Detailed Mechanism Design

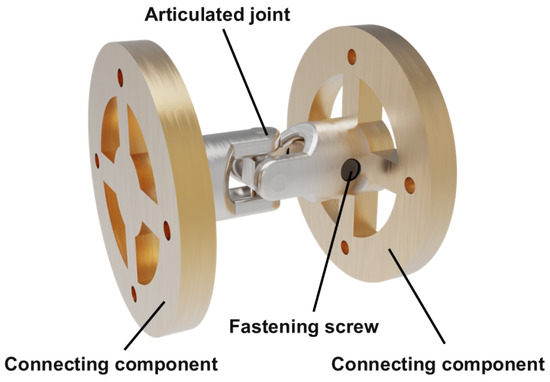

The joint is designed to provide two passive DOFs, pitch and yaw, which can be constrained by the drive module demonstrated in Figure 4. As shown in Figure 5, the main body of the articulated joint adopts a universal joint structure. This is composed of a pair of standard hinges arranged orthogonally at . Both ends of the universal joint are fixed to the connecting components using fastening screws.

Figure 5.

Structure of articulated joint.

The articulated joint is connected to both the drive module and the docking module by connecting components. Each connecting component is equipped with sector-shaped holes that allow the cross-recessed sleeve to pass through. The exterior of the joint is typically covered with a corrugated hose.

A compact stepper motor is installed inside the drive module by a fixture. A coupling is positioned within the through-hole of the drive cabin, with one end connected to the motor shaft and the other end to a lead screw. Two O-rings, embedded in the peripheral groove of the coupling, form a dynamic seal with the inner bore of the drive cabin. The cross-recessed sleeve is rigidly attached to a threaded nut, allowing them to move synchronously. The lead screw and the threaded nut form a lead screw pair that converts the rotational motion of the motor into the linear displacement of the cross-recessed sleeve. The relationship between the motor’s operating time and the preset position is calibrated by experiments. By controlling the rotation angle of the motor, the extension length of the sleeve outside the drive module can be adjusted to reach the preset position. This mechanism enables both the switch of the joint’s state and the unlocking of the docking mechanism within the docking module.

Initially, the cross-recessed sleeve is flush with one hinge of the universal joint, keeping the articulated joint in an unconstrained state, as shown in Figure 6a. When AUVs are docked or operated in straight-line mode, the cross-recessed sleeve extends outward fully through the universal joint and reaches the target position, acting as a constraint to restrict the DOFs of the joint, as shown in Figure 6b. Reversing the motor could retract the sleeve to its initial position, thus reactivating the DOFs of the joint. During separation, the sleeve extends further into the docking module to push the internal sliding component, which serves as an unlocking mechanism to release the docking rod, as shown in Figure 6c.

Figure 6.

Structure of drive module: (a) initial state, (b) outstretched state, and (c) unlocked state.

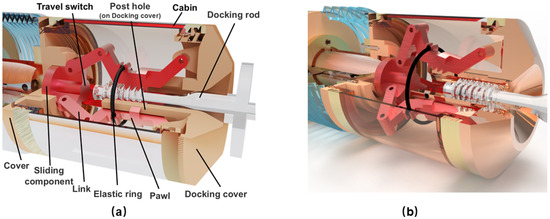

The docking module is designed to achieve both automatic locking and separation. In this design, a pawl-and-ratchet mechanism is employed to achieve automatic locking during the docking process. Three pawls are evenly distributed within the docking module, with each pawl having multiple ratchet teeth. One end of each pawl is connected to the docking cover while the other end to a sliding component by a link. The sliding component can move along a guide slot on the cover. In addition, the outside of the pawl features an annular groove. Three pawls are pulled inward by an elastic ring seated within the groove, causing them to fit tightly against the post hole on the docking cover. Once the docking rod is inserted, it passes through the post hole and engages with the ratchet teeth of the pawls, thus completing the automatic locking process, as illustrated in Figure 7a. If the docking process is successful, the rod will change the state of the travel switch on the sliding component.

Figure 7.

Structure of docking module: (a) locked state and (b) unlocked state.

Automatic separation between the docking rod and the connecting joint is achieved by actuating the cross-recessed sleeve housed within the drive module. During separation, the motor drives the sleeve further into the docking module, pushing the sliding component along the guide slot. This motion causes all the pawls to rotate simultaneously through a linkage mechanism. When the opening angle of the pawls reaches its maximum value, the pawls lose contact with the rod. Then, the docking rod detaches from the joint due to the relative motion of the two connected AUVs, thus completing the automatic separation process, as shown in Figure 7b.

During the docking process, all the pawls rotate and rebound repeatedly. Each time they rebound, the docking rod experiences a significant impact force, which is related to the magnitude of the opening angle of the pawls. Due to spatial constraints within the docking module, the size of the pawls cannot be significantly modified. Therefore, in this design, the impact force is primarily influenced by the structural parameters of the ratchet teeth. Variations in these parameters result in different levels of impact force.

3. Simulation-Based Optimization

3.1. Design Parameters and Dynamic Modeling

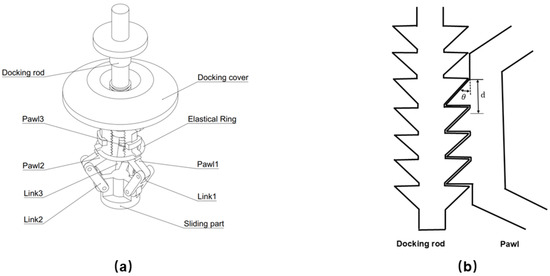

The pawls and the docking rod, each equipped with multiple ratchet teeth, experience repeated impacts during the docking process. Excessive impact forces can adversely affect the navigation capacity of both AUVs and further cause the failure of the docking process. To mitigate these effects, this study simultaneously optimizes two critical structural parameters: the tooth width (d) and the tooth angle () of the ratchet teeth on both the pawls and docking rod. These parameters significantly influence the magnitude of the peak impact force, as shown in Figure 8.

Figure 8.

Model of docking structure: (a) sketch of docking structure and (b) ratchet optimization parameters.

Before optimization, it is essential to define the ranges of feasible values for the two parameters. If the tooth width (d) is too small, the ratchet teeth may lack sufficient strength. Conversely, an excessively large d would require a reduction in the diameter of the docking rod, compromising its structural integrity and overall docking reliability. The ratchet angle () influences not only the direction of the contact force during engagement but also the geometry and mechanical performance of the teeth. Considering both strength requirements and structural size constraints, the final optimization ranges for the two parameters are defined as follows:

Tooth width (d) and tooth angle () are selected as simulation test factors, with the maximum impact force on the docking rod serving as the response variable. The grid search optimization method is used to identify the global optimum within the parameter range. Within the defined parameter space, 81 sample points are selected uniformly and discretely, resulting in 81 unique combinations of tooth width and angle.

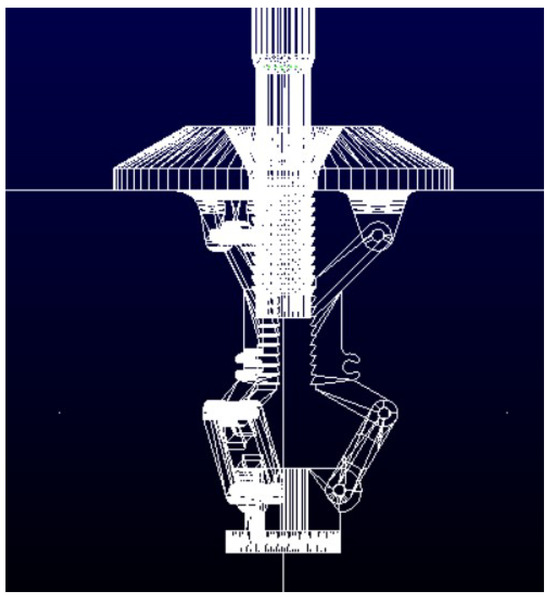

A dynamic model of the docking process was established in Adams [28], as shown in Figure 9. All components were modeled as rigid bodies with appropriate constraints. Contact forces were applied between the docking rod and each pawl. To simplify the model, the restoring force exerted by the elastic ring on the pawls was approximated as a constant, equal to the force generated when the pawls reach their maximum opening angle. The Impact function was employed to simulate three-dimensional contact and compute the resulting impact forces. It imitates the interaction as a nonlinear equivalent spring–damper system using a collision-based algorithm grounded in Hertz contact theory. The total contact force comprises two components: an elastic force due to the compression and penetration between the objects, and a damping force arising from their relative motion. The governing equation is given as follows:

Figure 9.

Adams dynamics model.

Here, k is the stiffness coefficient of the contact surfaces. The exponent e determines the contribution of the stiffness term, where larger values lead to a deeper penetration depth. denotes the critical interpenetration between the contact surfaces. c is the damping coefficient. v is the normal relative velocity at the contact point.

All components were assumed to be made of aluminum alloy. And the corresponding material properties are listed in Table 2.

Table 2.

Working condition parameter setting.

3.2. Docking Performance Analysis

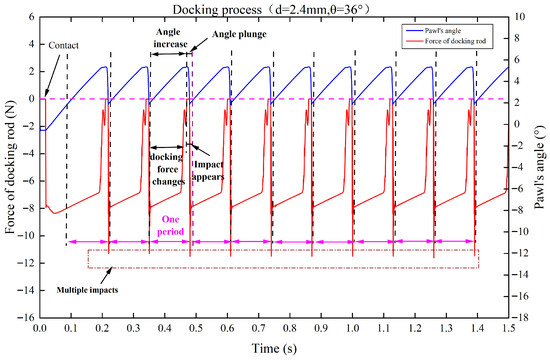

The performance of the docking is primarily characterized by the magnitude and frequency of impact forces acting on the docking rod. A dynamic simulation was conducted using a representative combination of parameters of and mm. A diagram of the impact force on the docking rod is illustrated in Figure 10. The simulation results indicate that the docking rod experienced multiple impacts during the docking process. Correspondingly, the opening angle of the pawls exhibits repeated increases followed by sharp decreases, revealing a cyclic pattern of engagement and release. A detailed analysis of this behavior is presented below:

Figure 10.

Force on the docking rod with time .

- (1)

- The docking rod and pawls feature multiple ratchet teeth. The pawls are held in close contact with the rod by the tension of an elastic ring. When the docking rod is inserted, it pushes the pawls outward, increasing their opening angle. Once a certain angle is reached, the contact between the docking rod and the pawls is momentarily lost, allowing the pawls to rebound inward under the restoring force of the elastic ring. As a result, the opening angle decreases abruptly. The presence of multiple ratchet teeth on the docking rod causes the opening angle of the pawls to increase periodically and drop abruptly throughout the docking process.

- (2)

- As the docking rod gradually enters the docking module, it exerts force on the pawls, pushing them outward and increasing their opening angle simultaneously. When the pawls separate from the docking rod, indicated by a sudden drop in their opening angle, contact is lost, and the docking rod does not experience force. Subsequently, the pawls rebound inward under the restoring force of the elastic ring, generating an impact force on the docking rod. As the docking rod continues to enter, it repeatedly engages and disengages with the first ratchet tooth on the pawls, resulting in multiple impact events. These impacts are synchronized with the cyclic variations in the opening angle of the pawls.

Due to the spatial constraints of the docking module, the overall dimensions of the pawls and the docking rod cannot be significantly modified. Therefore, this section focuses on optimizing two key parameters, the ratchet tooth width d and tooth angle , to reduce the maximum impact force on the docking rod.

3.3. Simulation Results and Analysis

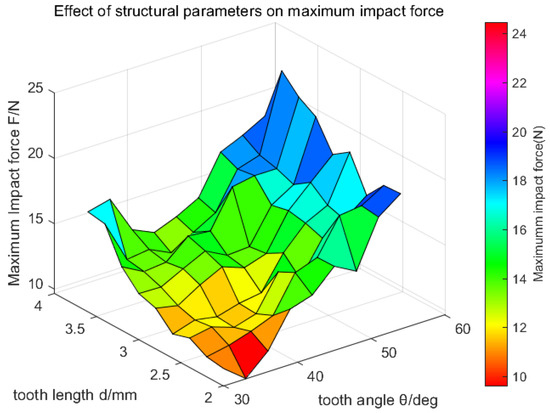

With all other ratchet tooth parameters kept constant, 81 combinations of parameters were entered into the simulation model to evaluate the corresponding impact forces on the docking rod. The simulation results were compiled, and the maximum impact forces for each combination are presented in Figure 11. The minimum impact force occurs at mm and .

Figure 11.

Influence of structural parameters on impact forces.

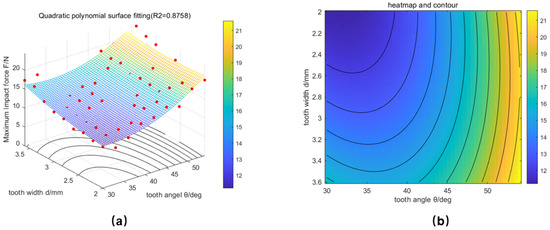

To investigate the influence of the two structural parameters on the maximum impact force, quadratic surface fitting was performed based on the simulation results. The fitted surface is shown in Figure 12, with a determination coefficient of , indicating a good level of fit. The corresponding contour map shows that the maximum impact force on the docking rod generally increases along the parameter path from to . The minimum peak impact force occurs near the combination of .

Figure 12.

Fitting surface and cloud map: (a) fitting surface and (b) heatmap and contour.

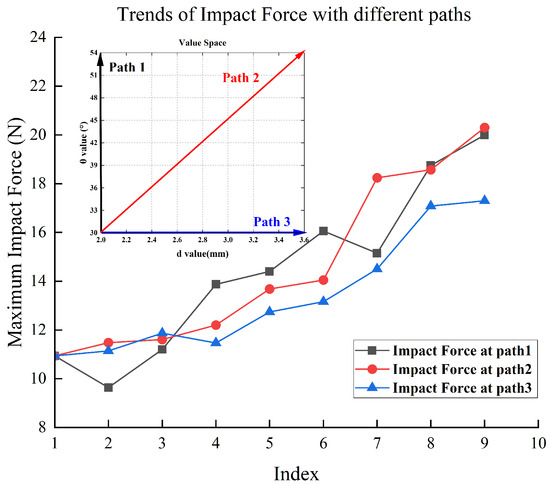

To validate the overall trend identified from the fitted surface, additional analyses were performed using data points selected along the boundaries and diagonal of the ratchet tooth parameter space. The findings are summarized as follows: (1) When the tooth angle is kept constant at , the maximum impact force on the docking rod exhibits a generally increasing trend as the tooth width d increases. (2) When and d are varied simultaneously along the diagonal of the parameter space, the maximum impact force also shows a rising trend, consistent with the fitted surface. (3) When the tooth width d is fixed at 2 mm and is varied, the simulation results similarly indicate that the maximum impact force on the docking rod increases approximately with . This is shown in Figure 13.

Figure 13.

Trends in impact forces in different directions.

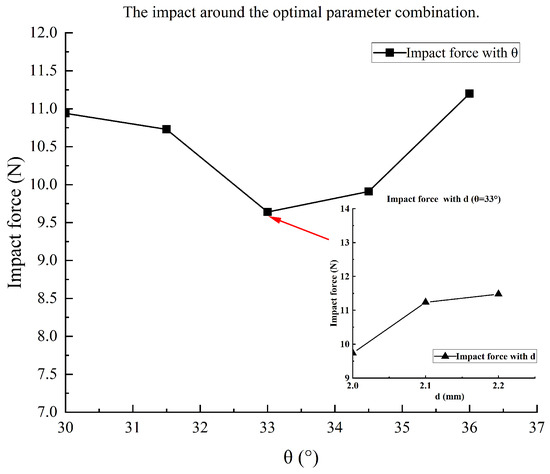

To verify the optimality of the identified combination of parameters, additional simulations were performed using midpoint values between it and adjacent sample points. Since the parameter intervals were already sufficiently small, a single-variable analysis was performed to further confirm the optimality of the selected set of parameters. First, the width d was kept constant, while the angle was varied by selecting the midpoints of the intervals 30– and 33–, namely and . Then, with kept constant, and considering that mm lies at the boundary of the parameter space, only the midpoint between 2 mm and 2.2 mm was selected for further analysis. The corresponding simulation results are presented in Figure 14.

Figure 14.

Variation in impact force with parameters near the optimal parameters.

The analysis of simulation results at the optimal point and the adjacent sample point indicates that, when d is kept constant, the maximum impact force reaches a minimum at . Any deviation from this angle, whether an increase or a decrease, results in higher impact forces. Similarly, when is fixed and d increases, the resulting impact forces exceed those obtained at mm. These results confirm that the combination represents the optimal solution within the defined parameter space.

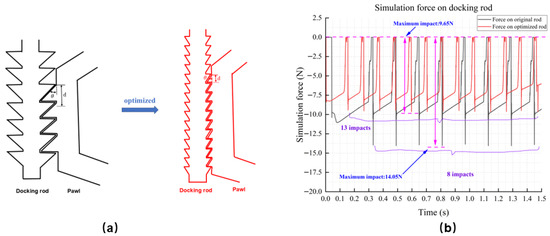

Figure 15 presents the structural configurations and simulation results of the ratchet teeth on both the pawl and docking rod before and after optimization. Before optimization, eight impact events were observed, with a maximum impact force of 14.05 N. Under the combination of the optimized parameters, the number of impact events increased to thirteen, while the peak impact force decreased to 9.64 N, representing a 31.39% reduction in the maximum impact force on the docking rod.

Figure 15.

Before and after optimization: (a) structure parameters and (b) force curve of the docking rod.

4. Experimental Validation

4.1. Functional Verification Experiment

4.1.1. Experimental Device

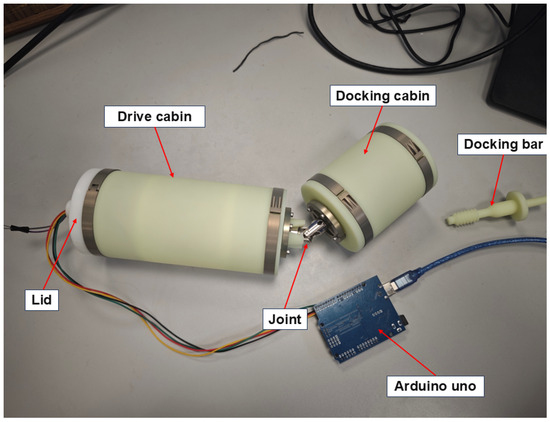

The connecting joint designed in this study consists of three primary components: the drive module, the articulated joint, and the docking module. As a critical component of the RAU robot, the joint must satisfy the following design requirements: (1) It should be directly mountable to the rear of a basic AUV and capable of achieving immediate and secure locking upon docking with another AUV. (2) It must provide at least two DOFs between the docked AUVs and allow for selective locking of these DOFs based on specific operational requirements. (3) It should enable fully autonomous separation without the need for manual intervention after the docking is completed.

Experimental tests were performed to validate the functionality of the designed connecting joint. Since only the docking rod is involved in the process, the rest of the AUV does not affect the outcome. Therefore, the docking rod was used as a substitute for the rest of the AUV in this experiment. To simplify the test and verify the feasibility of installing the connecting joint at the rear of an AUV, a lid replicating the structural parameters of the AUV’s tail section was used for installation testing. Figure 16 shows the prototype of the connecting joint and the drive unit.

Figure 16.

Prototype of connecting joint.

4.1.2. Experimental Results

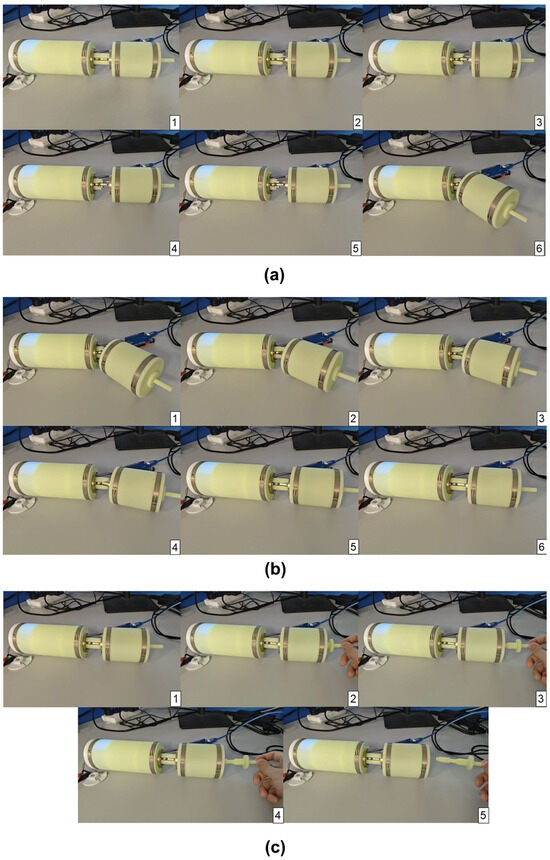

Experiments were conducted to evaluate the three primary design requirements of the connecting joint. The test results are presented in Figure 17.

Figure 17.

Connecting joint in different states: (a) relaxation of joint DOFs, (b) restriction of joint DOFs, and (c) separation state.

Figure 17a demonstrates the relaxation process of the joint DOFs. The restriction state of the DOFs is shown in a(1), where the relative position of the two modules cannot be changed, followed by the sleeve retraction process in a(2–5). Finally, as shown in a(6), the sleeve reaches the preset position and the DOFs of the joint are unlocked.

Figure 17b illustrates the reverse process. Starting from the relaxation state of the DOFs shown in b(1), the sleeve is gradually extended, as shown in b(2–5), until it reaches the preset position in b(6), resulting in the restriction of the joint DOFs.

Figure 17c shows the separation process. If the sleeve is stretched further when the DOFs of the joint are locked, then the docking rod can be removed from the docking module.

The experimental results indicate the following:

- 1.

- The connecting joint can be successfully installed at the rear of the AUV and automatically locks in place once the docking rod is inserted into the docking module.

- 2.

- The two DOFs of the articulated joint can be constrained by the motor housed within the drive module, as described in Section 2.2.2.

- 3.

- The connecting joint enables separation between different AUVs without the need for manual intervention.

These results confirm that the proposed connecting joint fully satisfies all specific functional requirements.

4.2. Impact Force Measurement Experiment

4.2.1. Impact Force Acquisition Setup

In the preceding sections, the structural parameters of the ratchet teeth on both the pawls and the docking rod were optimized through dynamic simulations conducted in Adams. The simulation results have shown a substantial reduction in the maximum impact force on the docking rod after optimization, compared to the original configuration. To validate these findings, docking module assemblies were manufactured using both pre- and post-optimization parameter sets, and the corresponding impact forces on the docking rod were measured under controlled experimental conditions.

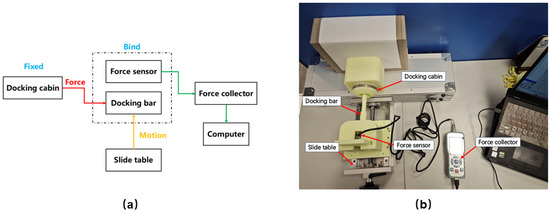

The measurement principle and experimental setup used to assess the impact force on the docking rod are illustrated in Figure 18. The docking module is securely mounted on a fixed platform. The docking rod is installed within a structural fixture positioned above a sliding table and placed in close contact with a force sensor. During the docking process, the sliding table is driven forward to simulate the motion of the docking rod. The force sensor captures the resulting impact forces on the docking rod, which are processed by a data acquisition system and transmitted to a computer for recording and analysis.

Figure 18.

Impact acquisition experiment: (a) diagram of impact acquisition experiment and (b) impact test equipment.

4.2.2. Experimental Results and Analysis

Comparison of Experimental Data

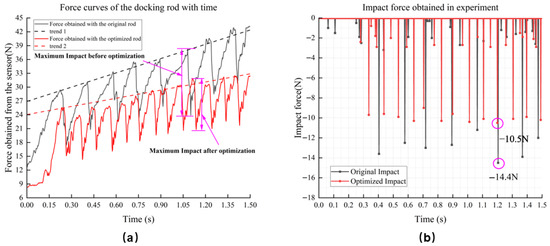

The experimental results are presented in Figure 19. Data analysis reveals a significant reduction in the maximum impact force after optimization of the ratchet tooth parameters. Specifically, the maximum impact force decreased from 14.4 N to 10.5 N, corresponding to a reduction of approximately 27.08%. Although this is lower than the reduction of 31.39% predicted by the simulation, it still represents a substantial improvement. In addition, the force needed during the docking process also showed a large decrease, as obtained from the trend line.

Figure 19.

Data before and after optimization: (a) force sensor data and (b) impact forces.

Several factors may cause the discrepancy between the experimental and simulated results. First, the prototype is fabricated using 3D printing, which typically yields lower dimensional accuracy and introduces assembly tolerances that can affect performance. Second, the materials used in the prototype differ from those assumed in the simulation, potentially leading to discrepancies in mechanical behavior and impact response. Finally, the coaxiality of the rod and docking module in the experiment is not as ideal as that in the simulation environment, so it could lead to cumulative force over time.

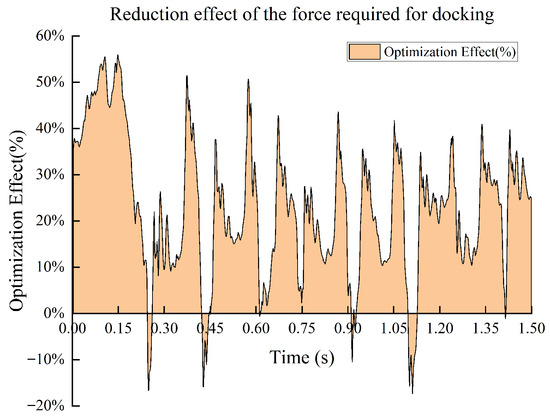

The reduction in docking force is illustrated in Figure 20. The results indicate that the average force required for docking between different AUVs decreases by approximately 22.76% compared to the pre-optimization configuration. Although some brief instances do not show any reduction, these occurrences are minor and negligible in the overall analysis.

Figure 20.

Drop in force required for docking.

Simulation Effectiveness Analysis

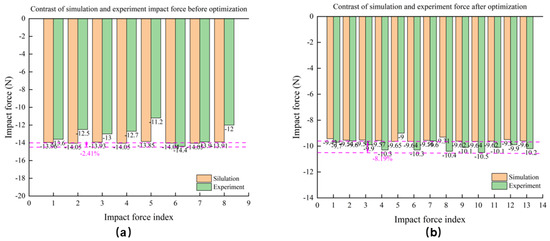

Based on simulation and experimental analyses, the optimal structural parameters for minimizing impact force were identified as a tooth width of 2 mm and a tooth angle of . The number of major impact events is consistent between the simulation and experimental results. Figure 21 presents a comparison of impact forces before and after optimization, based on both simulation and experimental data. The relative errors between simulation and experimental results are 2.41% and 8.19%, respectively—both lower than 10%. These findings demonstrate that the simulation results provide a reliable and valuable reference for practical design.

Figure 21.

Comparison of simulation and experiment: (a) before optimization and (b) after optimization.

5. Conclusions

This study presents a connecting joint capable of underwater autonomous docking and separation, which can be used for a reconfigurable articulated underwater robot. And the structural design of a connecting joint is introduced. A dynamic model is developed to optimize the structural parameters of the ratchet teeth on both the pawls and the docking rod. Subsequently, experiments are conducted to evaluate the functional performance of the design and to verify the effectiveness of parameter optimization. The main conclusions are summarized as follows.

Firstly, an RAU robot based on small-scale AUVs is introduced. It is capable of underwater reconfiguration to adapt to different environments. And the connecting joint of the RAU robot is designed to achieve underwater docking, locking, and separation using a single motor, providing essential support for the reconfiguration of the RAU robot.

Secondly, the structural parameters of the ratchet teeth on the pawls and docking rod were optimized through uniform discrete sampling. As a result, the maximum impact force on the docking rod was reduced from 14.4 N to 10.5 N, representing a reduction of approximately 27.08%. In addition, the average docking force decreased by 22.76%, confirming the effectiveness of the optimization.

Finally, the impact force measurement experiment showed relative errors of 2.41% before optimization and 8.19% after optimization compared to the simulation results, demonstrating the accuracy and reliability of the dynamic model.

To further evaluate the applicability and performance of the proposed connecting joint, the following future studies are recommended: (1) Integration with actual AUV platforms: Future work should involve installing the connecting joint on real AUVs to assess its impact on overall performance under realistic conditions. (2) Underwater docking experiments: After integration with individual AUV units, multi-AUV docking tests should be conducted to validate the feasibility and functionality of the RAU robot in real underwater environments.

Author Contributions

Conceptualization, Y.Z. and Y.Y.; methodology, Y.Z.; software, Y.Z.; validation, Y.Z., Y.Y. and Q.Z.; formal analysis, Y.Z.; investigation, Y.Z.; resources, Y.Y.; data curation, Y.Z. and Y.Y.; writing—original draft preparation, Y.Z.; writing—review and editing, Y.Y., Z.H., Z.W. and C.F.; visualization, Y.Z.; supervision, Y.Y.; project administration, Y.Y. and Y.Z.; funding acquisition, Y.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This study was sponsored by the Liaoning Revitalization Talents Program (No: XLYC2403092).

Data Availability Statement

The original contributions presented in this study are included in the article; further inquires can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ROV | Remotely Operated Vehicle |

| AUVs | Autonomous Underwater Vehicles |

| USM | Underwater Swimming Manipulator |

| USR | Underwater Snake Robot |

| RAU Robot | Reconfigurable Articulated Underwater Robot |

| DOFs | Degrees of Freedom |

References

- Reda, A.; Amaechi, C.V.; Shahin, M.A.; McKee, K.K. Field Redevelopment and Weight Shedding for Decommissioning of Offshore Facilities. J. Mar. Sci. Eng. 2024, 12, 1331. [Google Scholar] [CrossRef]

- Franka, N.; Kampmann, P. Inspection and maintenance of industrial infrastructure with autonomous underwater robots. Front. Robot. AI 2023, 10, 1240276. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Zhao, Y.; Huang, J.; Wang, F.; Chen, Y.; Luo, C.; Luo, G. Development and trends of underwater robots for inspection, maintenance and repair for offshore oil and gas platforms: A review. Sci. Technol. Rev. 2024, 42, 6–15. [Google Scholar] [CrossRef]

- Gorma, W.; Post, M.A.; White, J.; Gardner, J.; Luo, Y.; Kim, J.; Mitchell, P.D.; Morozs, N.; Wright, M.; Xiao, Q. Development of Modular Bio-Inspired Autonomous Underwater Vehicle for Close Subsea Asset Inspection. Appl. Sci. 2021, 11, 5401. [Google Scholar] [CrossRef]

- Sverdrup-Thygeson, J.; Kelasidi, E.; Pettersen, K.; Gravdahl, J. Modeling of underwater swimming manipulators. IFAC-PapersOnLine 2016, 49, 81–88. [Google Scholar] [CrossRef]

- Sverdrup-Thygeson, J.; Kelasidi, E.; Pettersen, K.Y.; Gravdahl, J.T. The underwater swimming manipulator—A bio-inspired AUV. In Proceedings of the 2016 IEEE/OES Autonomous Underwater Vehicles (AUV), Tokyo, Japan, 6–9 November 2016; pp. 387–395. [Google Scholar] [CrossRef]

- Kelasidi, E.; Liljeback, P.; Pettersen, K.Y.; Gravdahl, J.T. Innovation in Underwater Robots: Biologically Inspired Swimming Snake Robots. IEEE Robot. Autom. Mag. 2016, 23, 44–62. [Google Scholar] [CrossRef]

- Xu, P.; Zheng, J.; Wang, X.; Wang, S.; Liu, J.; Liu, X.; Xie, G.; Tao, J.; Xu, M. Design and Implementation of Lightweight AUV With Multisensor Aided for Underwater Intervention Tasks. IEEE Trans. Circuits Syst. II Express Briefs 2022, 69, 5009–5013. [Google Scholar] [CrossRef]

- Christensen, L.; Hilljegerdes, J.; Zipper, M.; Kolesnikov, A.; Hülsen, B.; Koch, C.E.S.; Hildebrandt, M.; Danter, L.C. The Hydrobatic Dual-Arm Intervention AUV Cuttlefish. In Proceedings of the OCEANS 2022, Hampton Roads, VA, USA, 17–20 October 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Pi, R.; Cieślak, P.; Ridao, P.; Sanz, P.J. TWINBOT: Autonomous Underwater Cooperative Transportation. IEEE Access 2021, 9, 37668–37684. [Google Scholar] [CrossRef]

- Kang, S.; Yu, J.; Zhang, J. Research Status of Micro Autonomous Underwater Vehicle. Robot 2023, 45, 218–237. [Google Scholar] [CrossRef]

- Lyu, F.; Xu, X.; Zha, X.; Li, Z.; Yuan, H. A Snake Eel Inspired Multi-joint Underwater Inspection Robot for Undersea Infrastructure Intelligent Maintenance. In Proceedings of the OCEANS 2022, Chennai, India, 21–24 February 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Borlaug, I.L.G.; Gravdahl, J.T.; Sverdrup-Thygeson, J.; Pettersen, K.Y.; Loria, A. Trajectory Tracking for Underwater Swimming Manipulators using a Super Twisting Algorithm. Asian J. Control 2019, 21, 208–223. [Google Scholar] [CrossRef]

- Kelasidi, E.; Pettersen, K.; Gravdahl, J. Energy efficiency of underwater robots. IFAC-PapersOnLine 2015, 48, 152–159. [Google Scholar] [CrossRef][Green Version]

- Han, T. Structural Design and Dynamic Analysis of Multi-Joint Underwater Vehicle. Master’s Thesis, Shenyang Ligong University, Shenyang, China, 2023. [Google Scholar]

- Mintchev, S.; Stefanini, C.; Girin, A.; Marrazza, S.; Orofino, S.; Lebastard, V.; Manfredi, L.; Dario, P.; Boyer, F. An underwater reconfigurable robot with bioinspired electric sense. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 1149–1154. [Google Scholar] [CrossRef]

- Liu, J.; Yu, F.; He, B.; Soares, C.G. A review of underwater docking and charging technology for autonomous vehicles. Ocean Eng. 2024, 297, 117154. [Google Scholar] [CrossRef]

- Zhang, R.; Song, T.; Sun, Q.; Guo, J. Review on underwater docking technology of AUV. Chin. J. Ship Res. 2018, 13, 43–49. [Google Scholar] [CrossRef]

- Kirby, B.T.; Aksak, B.; Campbell, J.D.; Hoburg, J.F.; Mowry, T.C.; Pillai, P.; Goldstein, S.C. A modular robotic system using magnetic force effectors. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 2787–2793. [Google Scholar] [CrossRef]

- Mintchev, S.; Ranzani, R.; Fabiani, F.; Stefanini, C. Towards Docking for Small Scale Underwater Robots. Auton. Robot. 2015, 38, 283–299. [Google Scholar] [CrossRef]

- Gilpin, K.; Kotay, K.; Rus, D. Miche: Modular Shape Formation by Self-Dissasembly. In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Rome, Italy, 10–14 April 2007; pp. 2241–2247. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Kovac, R.; Shen, W.M.; Will, P. Reconnectable joints for self-reconfigurable robots. In Proceedings of the 2001 IEEE/RSJ International Conference on Intelligent Robots and Systems. Expanding the Societal Role of Robotics in the the Next Millennium (Cat. No.01CH37180), Maui, HI, USA, 29 October–3 November 2001; Volume 1, pp. 584–589. [Google Scholar] [CrossRef]

- Dunbabin, M.; Vasilescu, I.; Corke, P.; Rus, D. Experiments with Cooperative Networked Control of Underwater Robots. In Experimental Robotics: The 10th International Symposium on Experimental Robotics; Springer: Berlin/Heidelberg, Germany, 2008; pp. 463–470. [Google Scholar] [CrossRef]

- Zhang, D.; Pan, G.; Shi, Y.; Wang, P.; Chao, L. Investigation of the resistance characteristics of a multi-AUV system. Appl. Ocean. Res. 2019, 89, 59–70. [Google Scholar] [CrossRef]

- Kang, S.; Yu, J.; Zhang, J.; Jin, Q.; Hu, F. Direct Route Drag Prediction of Chain-structured Underwater Vehicle Based on Neural Network Optimized by Particle Swarm Optimization. J. Mech. Eng. 2019, 55, 29–39. [Google Scholar] [CrossRef]

- Song, J.; Shen, H.; Liu, J.; Yao, L.; He, B. Design and CFD simulation analysis of a multistage separable AUV. Ocean. Eng. 2019, 37, 107–116. [Google Scholar] [CrossRef]

- Guo, J.; Yang, Y.; Wang, C.; Hu, Z.; Zheng, Q.; Fan, C. Multiparameter Collaborative Optimization and Analysis of the Non-Penetrating Tunnel Thruster. J. Mar. Sci. Eng. 2024, 12, 1960. [Google Scholar] [CrossRef]

- Xu, L.; Hu, Z.; Yang, Y.; Wang, C. Study on Engagement Characteristics of Gear Overrunning Clutch of Aquatic-aerial Amphibious Propellers. China Mech. Eng. 2023, 34, 1126–1133. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).