1. Introduction

Piping systems on maritime vessels play a vital role, functioning as the essential “vascular system” by enabling the transfer of mass flow, momentum flow, and energy flow, which is crucial for maintaining the operational efficiency of the vessels [

1,

2]. The operation of these systems inevitably results in the generation of large vibration and loud noise. Therefore, the topic of how to reduce the noise and vibration has been the attracting attention of many researchers from the past few decades to the presents [

3,

4,

5,

6]. The integration of flexible inserts within the piping system presents a dual advantage; it serves to isolate and/or mitigate structural vibrations and noise while accommodating displacements caused by pressure surges and vibrations between the equipment and the piping [

7,

8]. Conventional flexible inserts predominantly employ rubber as the load-bearing material or combine rubber with a metal wire mesh to enhance tensile strength [

9]. However, the inclusion of a metal wire mesh may inadvertently increase the structural stiffness of the flexible insert, which contradicts the goal of achieving effective vibration damping and noise reduction.

The honeycomb structure, recognized for its advanced material properties, demonstrates remarkable attributes such as a high strength-to-weight ratio, specific stiffness, structural stability, and energy absorption capabilities. Furthermore, honeycomb sandwich structures with extensive design flexibility, allowing for optimized matching designs through adjustments in structural parameters and the incorporation of reinforcing fillers [

10,

11], have shown significant vibration-damping and noise-reduction capabilities. The incorporation of honeycomb structures as core materials in the fabrication of sandwich composite pipes and shell structures retains their inherent high specific strength, high specific stiffness, and high specific energy absorption rate [

12]. Moreover, the characteristic of zero Poisson’s ratio (ZPR) prevents a substantial increase in effective stiffness in the horizontal direction by limiting vertical contraction or expansion, resulting in the ZPR honeycomb’s resistance to radial movement under axial forces [

13]. Consequently, honeycomb structures exhibiting ZPR are more advantageous in terms of structural stability compared to other honeycomb configurations, making them particularly suitable for incorporation into flexible inserts designs. Unfortunately, there is a significant dearth of research on flexible inserts made of a honeycomb structure.

The dynamic characteristics of fluid-filled pipelines significantly influence the efficacy of vibration and acoustic mitigation strategies. Numerous studies have been conducted to develop methodologies for calculating the dynamic characteristics of such pipelines. For instance, Tijsseling et al. and Vardy et al. employed the characteristics method to investigate extended water hammer models and beam models, with a particular emphasis on fluid–structure interaction (FSI) and cavitation phenomena during transient vibrations in freely suspended horizontal pipelines [

14,

15]. In a subsequent study, Dai et al. applied the transfer matrix method to evaluate the natural frequencies, frequency response functions, and instabilities in both straight and bent three-dimensional fluid-filled pipes [

16]. Li et al. explored the fluid–structure coupling characteristics of fluid-filled straight and branched pipes through the transfer matrix method, analyzing the impact of support configurations, structural performance, and fluid parameters on the dynamic response and natural frequencies of the pipelines [

17,

18]. El-Sayed et al. utilized both the variational iteration method and the transfer matrix method to investigate the free vibration of multi-span fluid-filled pipelines [

19]. These analytical and numerical methods for assessing the vibrations of fluid-filled pipelines take into account the geometry and material properties of the pipeline shells, as well as the characteristics of the working medium. However, the application of these pipeline vibration calculation methods becomes impractical when the pipelines are equipped with flexible vibration-insulating inserts and hydrodynamic noise attenuators, which are specifically designed to mitigate vibration and hydrodynamic noise [

20]. The flexible inserts integrated into the pipelines exhibit diverse and complex structures, and they are often constructed from materials that differ from those of the pipelines. Current calculation methods for determining the dynamic properties of flexible inserts in fluid-filled pipelines do not yield reliable results across a wide frequency range. Consequently, obtaining accurate calculations of the impedance of the flexible inserts is crucial for conducting reliable vibration and noise analyses of actual fluid-filled pipelines.

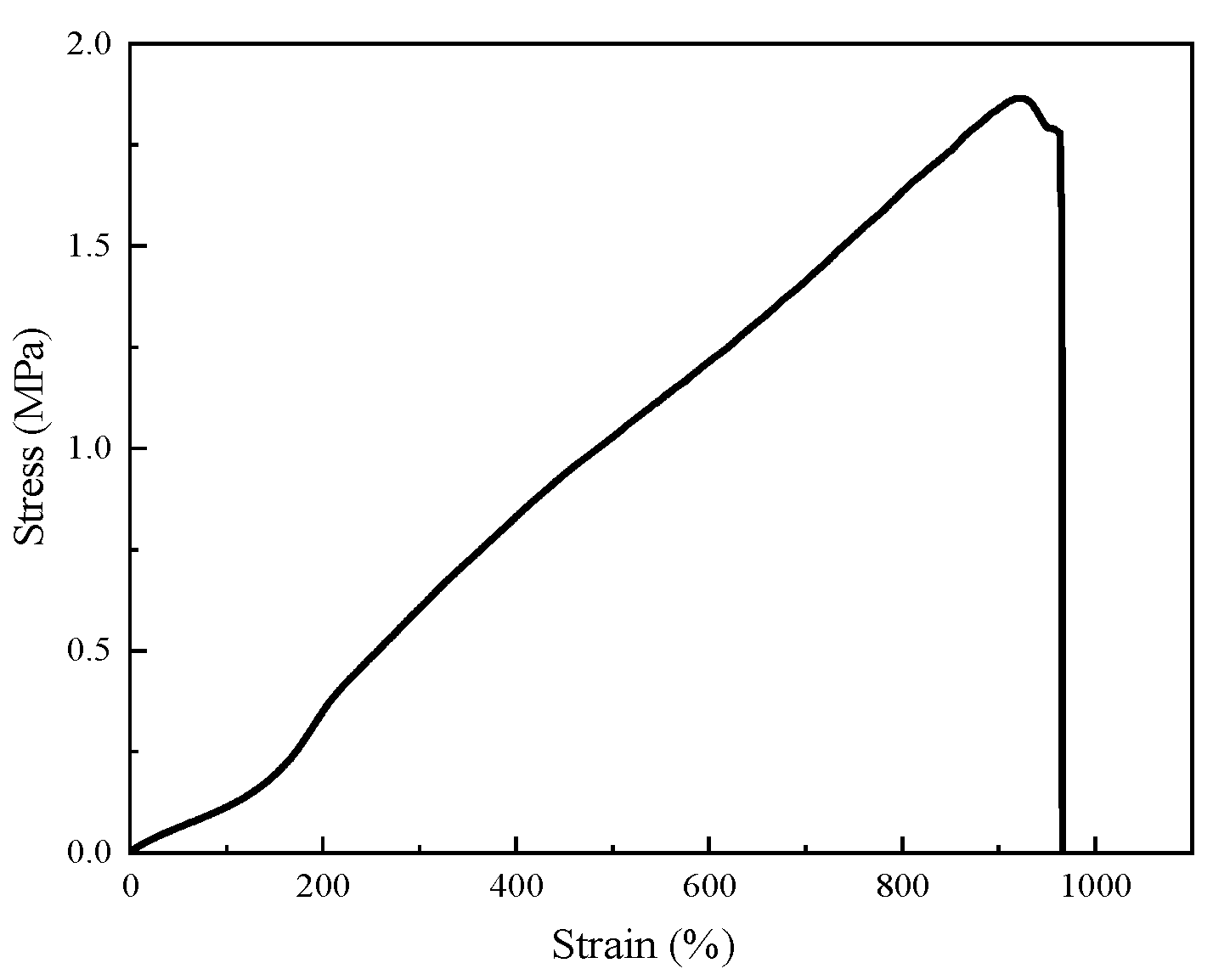

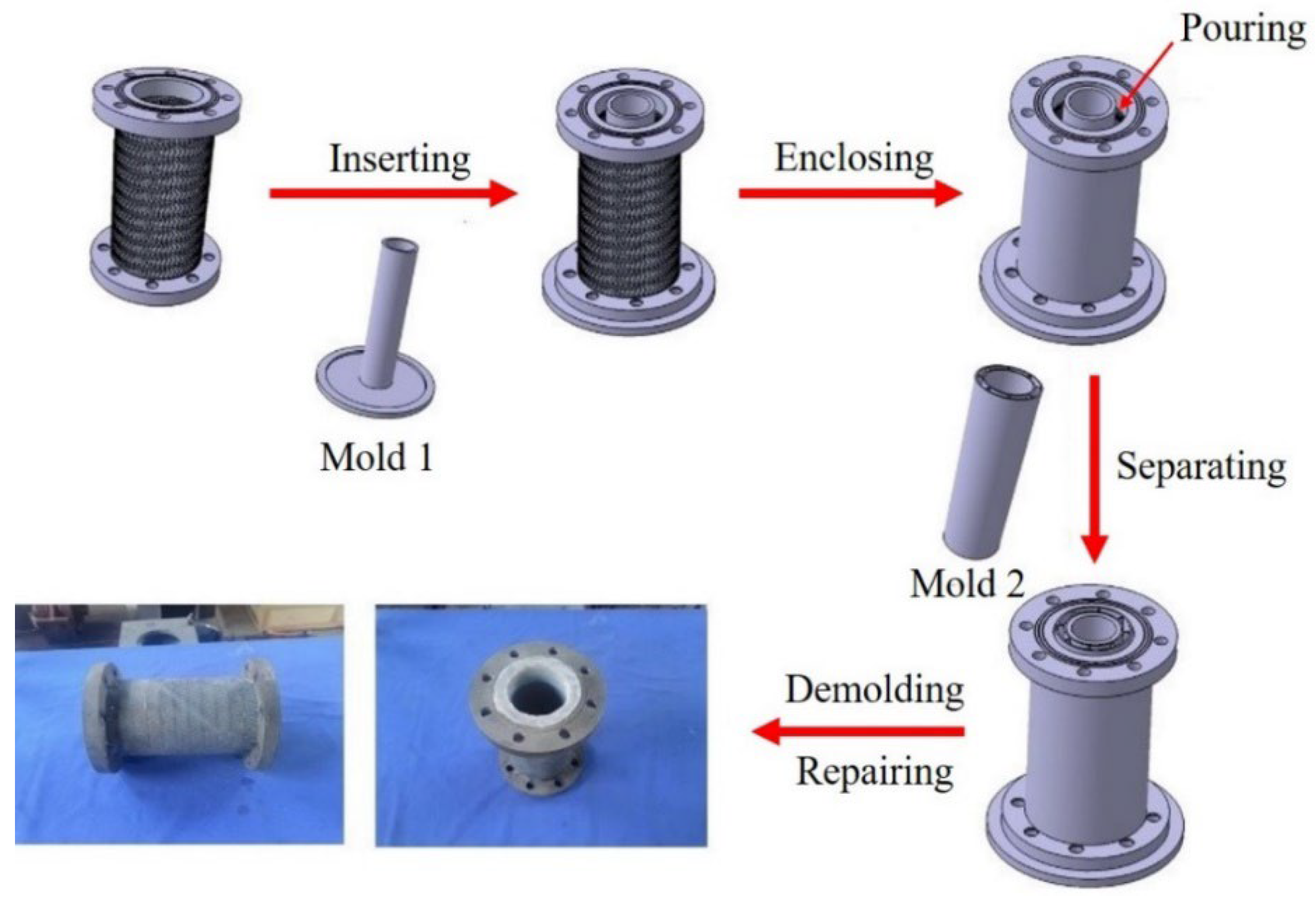

In the present work, a novel sandwich flexible insert (NSFI) has been introduced, distinguished by its innovative design that departs from traditional flexible insert configurations. The NSFI consists of three distinct layers: the inner and outer layers are constructed from elastic materials, while the middle layer incorporates a honeycomb structure characterized by a ZPR. The impedance of the NSFI with fluid is examined utilizing the FSI four-equation model. The paper is structured into five sections.

Section 1 provides a succinct introduction.

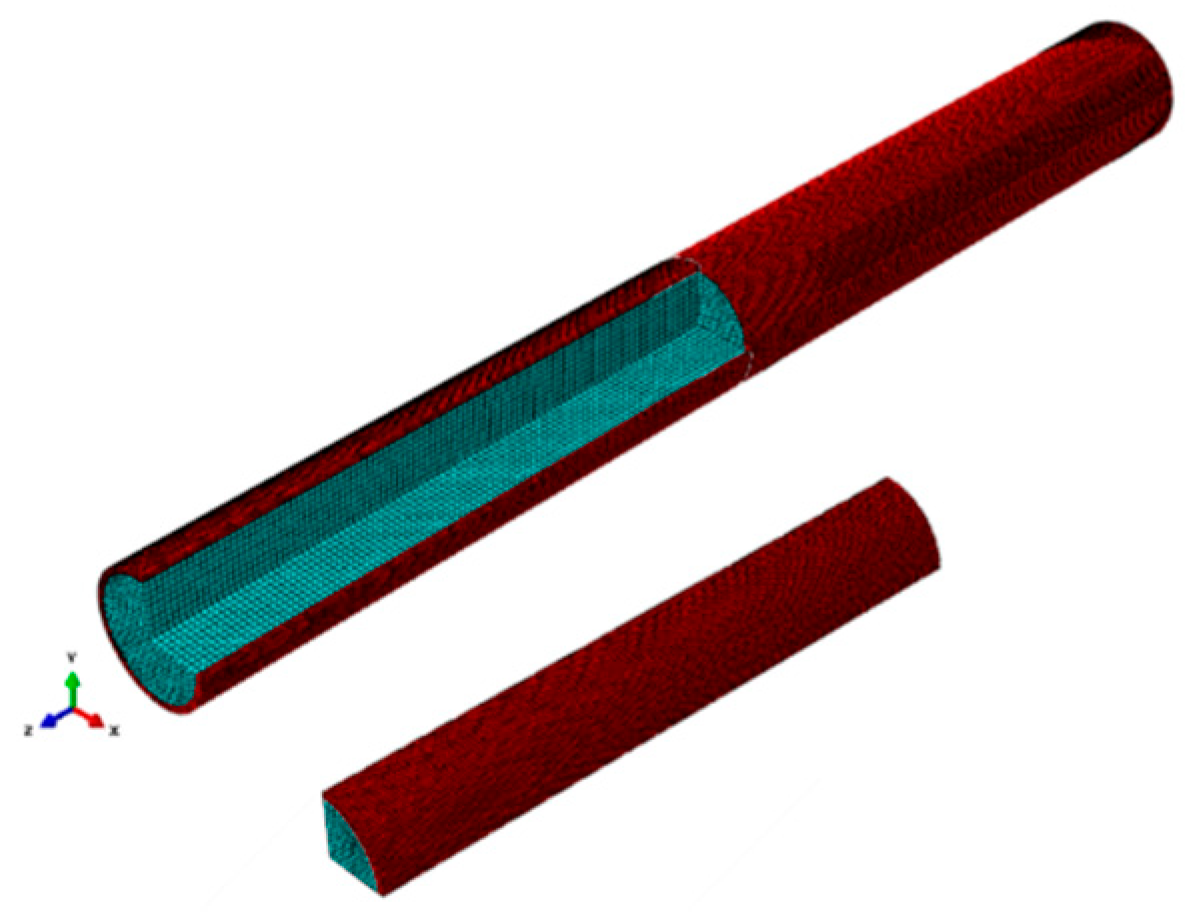

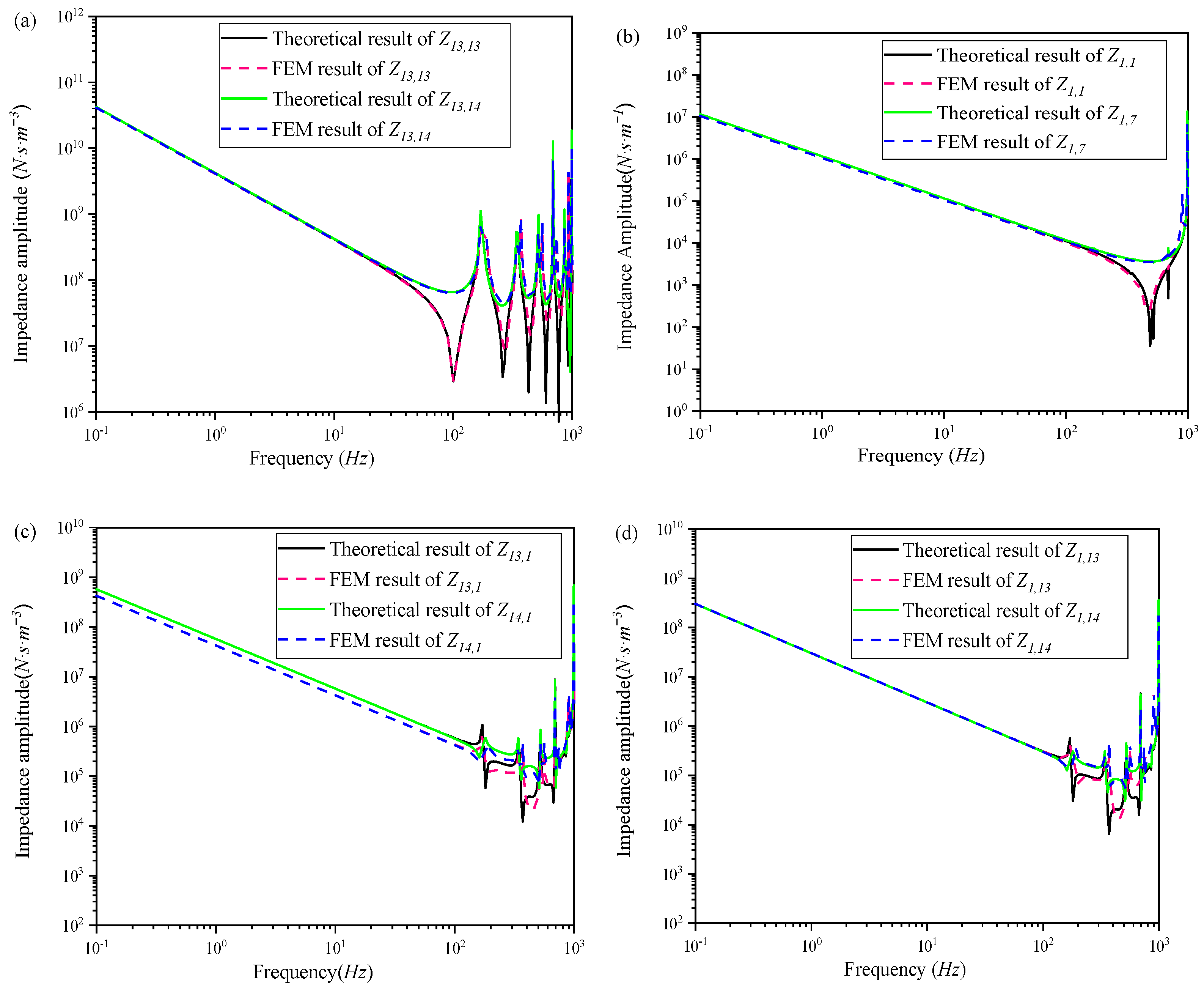

Section 2 delineates the governing equations for axial coupling pertinent to the fluid-filled NSFI. In

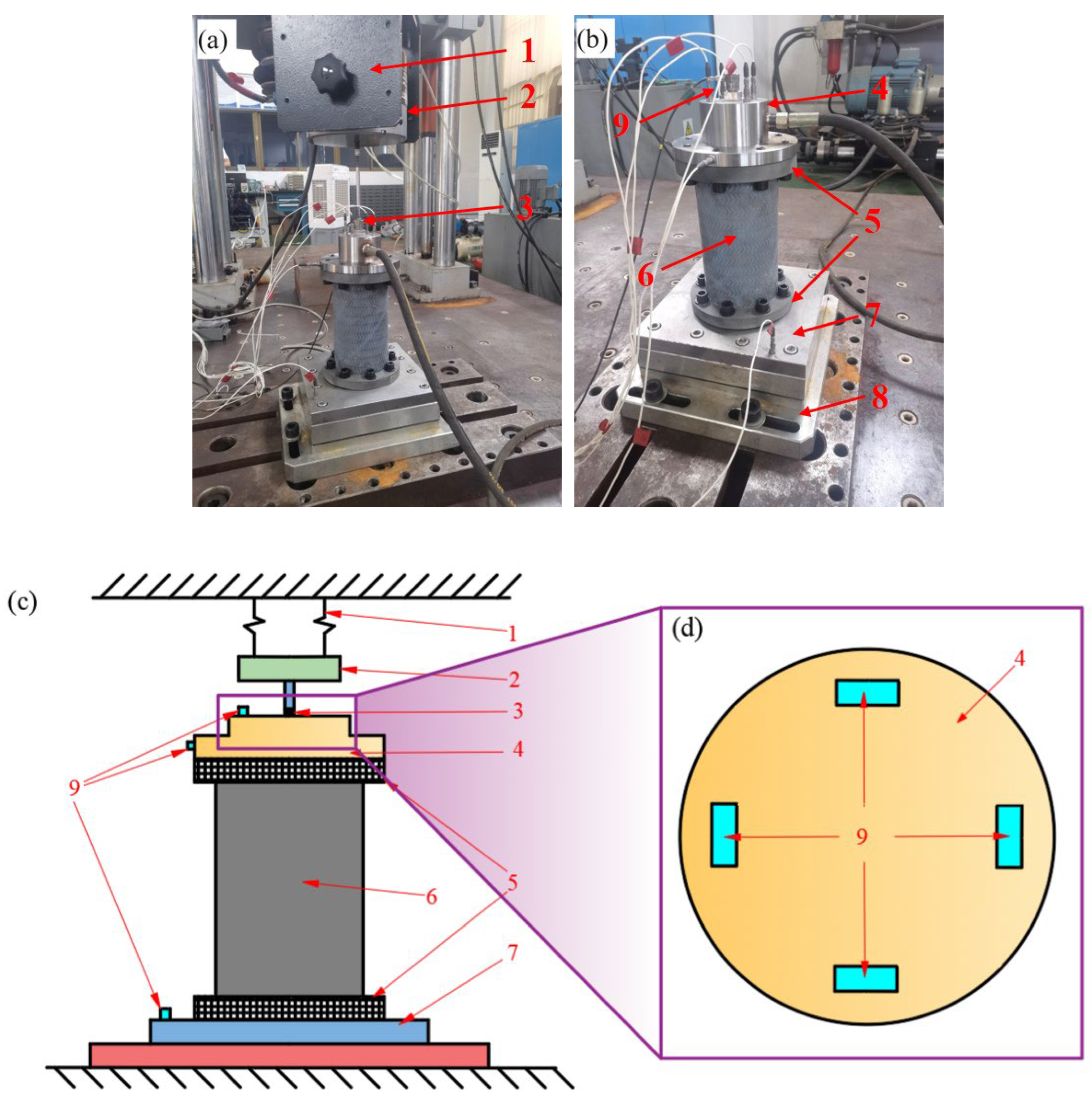

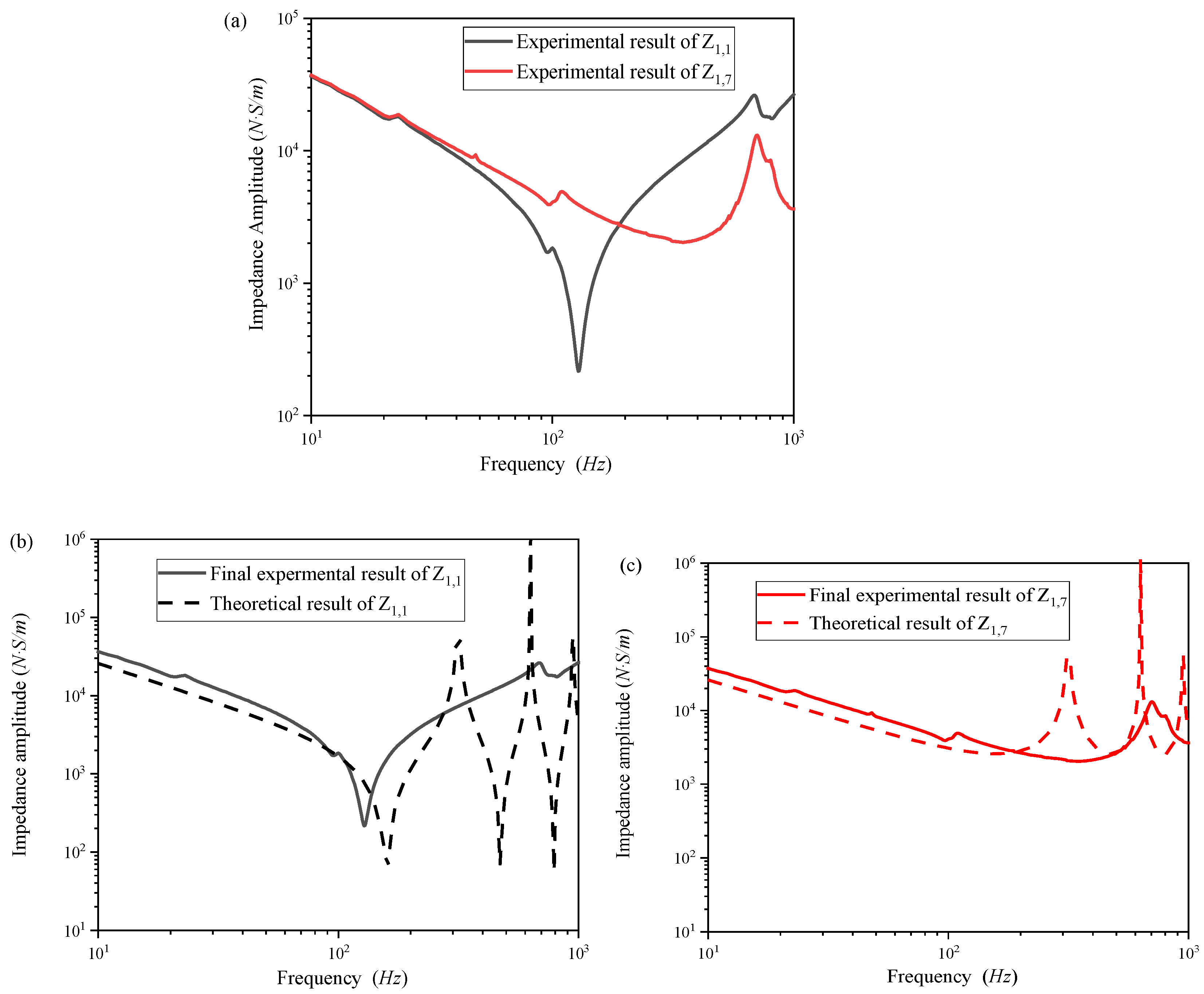

Section 3, the validity of these governing equations is established through finite element method (FEM) analysis and experimental validation.

Section 4 conducts a parametric analysis to investigate the influence of geometric parameters on the impedance of the fluid-filled NSFI. Finally,

Section 5 presents a brief summary of the findings and proposes avenues for future research.

2. Governing Equations

The NSFI consists of three distinct layers, with both the inner and outer layers composed of elastic and isotropic materials of equal thickness. The middle layer is characterized by a honeycomb structure featuring ZPR.

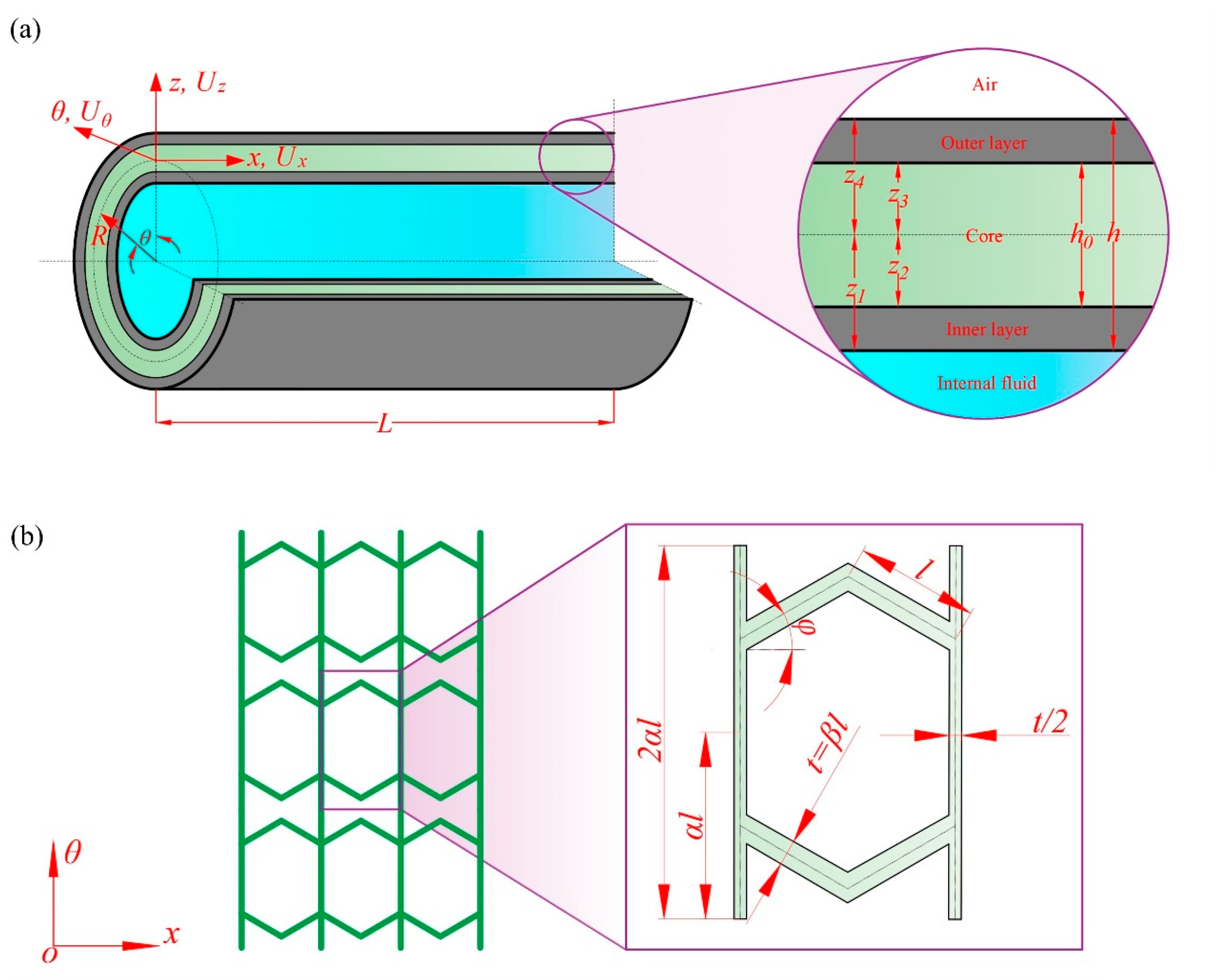

Figure 1 shows the schematic sketch and the coordinate system of the NSFI, where the radius of middle surface is denoted as

R, the thickness as

h, and the length as

L. An orthogonal coordinate system (

z,

x, and

θ) is established at the middle surface. The deformations of the point at the middle surface of the insert wall are denoted as

Ux,

Uθ, and

Uz, corresponding to the

x,

θ, and

z directions, respectively. Coordinates (

Zk,

k = 1, 2, 3, 4) are defined for each layer as depicted in

Figure 1a, with

Z1 =

h/2;

Z2 =

h0/2;

Z3 = −

h0/2; and

Z4 = −

h/2.

Figure 1b depicts the ZPR honeycomb core and outlines the geometrical parameters of its unit cell. Here,

φ is the internal angles,

l represents the length of diagonal walls,

2αl represents the length of vertical walls, and

t = βl represents the thickness of sloping walls. The parameters

α and

β correspond to the aspect ratio and the cell wall thickness ratios, respectively. The notations of variables in the NSFI are given as listed in

Table 1.

For the sake of simplicity, it is assumed that the materials constituting the isotropic portions are uniform, characterized by an elastic modulus

E, density

ρt, and Poisson’s ratios

μ. The material properties of the honeycomb structure are elaborated in Ref. [

21]:

where

and

ρc are elastic modulus and density of raw materials used in the honeycomb core, respectively.

The basic membrane shell theory is applicable for analyzing the dynamics of a liquid-filled pipe wall in the context of long wave propagation. For long waves, the wavelength (λ) is much larger than the pipe radius (R, i.e., λ >> R), such that radial deformation is negligible, and bending stresses and moments have minimal influence on the overall dynamics. This approach thus emphasizes in-plane stresses (axial and circumferential) while neglecting bending effects, as noted by Tijsseling et al. [

22]. Furthermore, the radial inertia of the flexible insert wall and the viscous friction of the internal fluid are not taken into account. Consequently, the forces exerted on the insert wall are depicted in

Figure 2 and must adhere to the following conditions:

where

P is the internal fluid pressure distribution in

z direction,

Nx and

Nθ are axial stress and circumferential stress of the insert wall, and

I denotes the mass moment of inertia. The calculation of these parameters can be performed utilizing classical shell theory in conjunction with Hamilton’s principle, as elaborated in the work of Song et al. [

21]:

where

k = 1, 2, 3;

k = 1 or 3 stands for the inner or outer layer;

k = 2 stands for the core layer, and

By substituting Equation (3) into Equation (2), the equation for continuous motion of the internal fluid can be derived:

By combining Equation (5) with the circumferential stress of the insert wall and subsequently eliminating the variable w, the following equation can be obtained:

Multiply both sides of the equation by the area of the insert wall, and Equation (6) can be rewritten as follows:

where

Ap is the area of the internal fluid.

By taking the partial derivative of the above formula with respect to time, we obtain

According to the equation of continuous motion of fluid

where

Ev is the bulk modulus of the fluid in the rigid insert,

uf is the longitudinal displacement of the fluid,

A = π*

R2 is the nominal area of the insert, and satisfy

Combining Equations (5), (9), and (10), the equation of continuous motion of the internal fluid can be rewritten as follows:

where

is the corrected volume modulus of fluid, and can be expressed as

The coupling of Equations (8) and (11) indeed reflects the mutual interaction between internal fluid and the insert wall. By integrating those equations and mutual boundary conditions, the FSI four-equation model of the NSFI can be derived:

where

Assuming that the axial vibrations of both the insert wall and the internal liquid exhibit simple harmonic motion, it is feasible to obtain a simultaneous solution of the coupled fluid–structure system equations in wave form, based on linearized assumptions and periodic motion [

23]. The resulting eigenvalues and mode shapes can be derived for pertinent fluid and structural variables without the necessity of employing finite element approximations. Consequently, the solution to the governing Equation (13) along the axial coordinate can be articulated as follows:

Equation (13) can be reformulated as follows:

From the expression above, we can derive a quartic equation in terms of

λ:

where

Therefore, the longitudinal wave numbers

λ1 and

λ2 for the insert wall and internal fluid considering the Poisson coupling can be determined:

where

.

The general solution of Equation (13) through linear superposition can be obtained:

where

Ai (

i = 1, 2, 3, 4) are constants, and

In alignment with the definition of impedance for pipeline components, as outlined by Popkov et al. [

20], the axial state variables at each end of the flexible inserts, in conjunction with the impedance matrix, are expressed in the following manner:

where

and

Af is the cross-section of internal fluid.

Then the input mechanical impedance at the input end is obtained as

The input mechanical impedance at the output end is obtained as

The input acoustic impedances are

The transfer mechanical impedances are

The transfer acoustic impedances are

The input mechanical–acoustic impedances are

The transfer mechanical–acoustic impedances are

The input acoustic–mechanical impedances are

The transfer acoustic–mechanical impedances are

4. Results and Discussion

The theoretical formula was implemented in a Matlab program to calculate the axial impedance of the NSFI. This section investigates the influence of varying the geometric dimensions of the NSFI and the structural parameters of the honeycomb core on the dynamic characteristics of the NSFI.

Table 5 enumerates the geometric dimensions of the NSFI, the structural parameters of the honeycomb core, and the material properties employed in the parametric analysis. All results, unless specified otherwise, are based on the data provided in

Table 5.

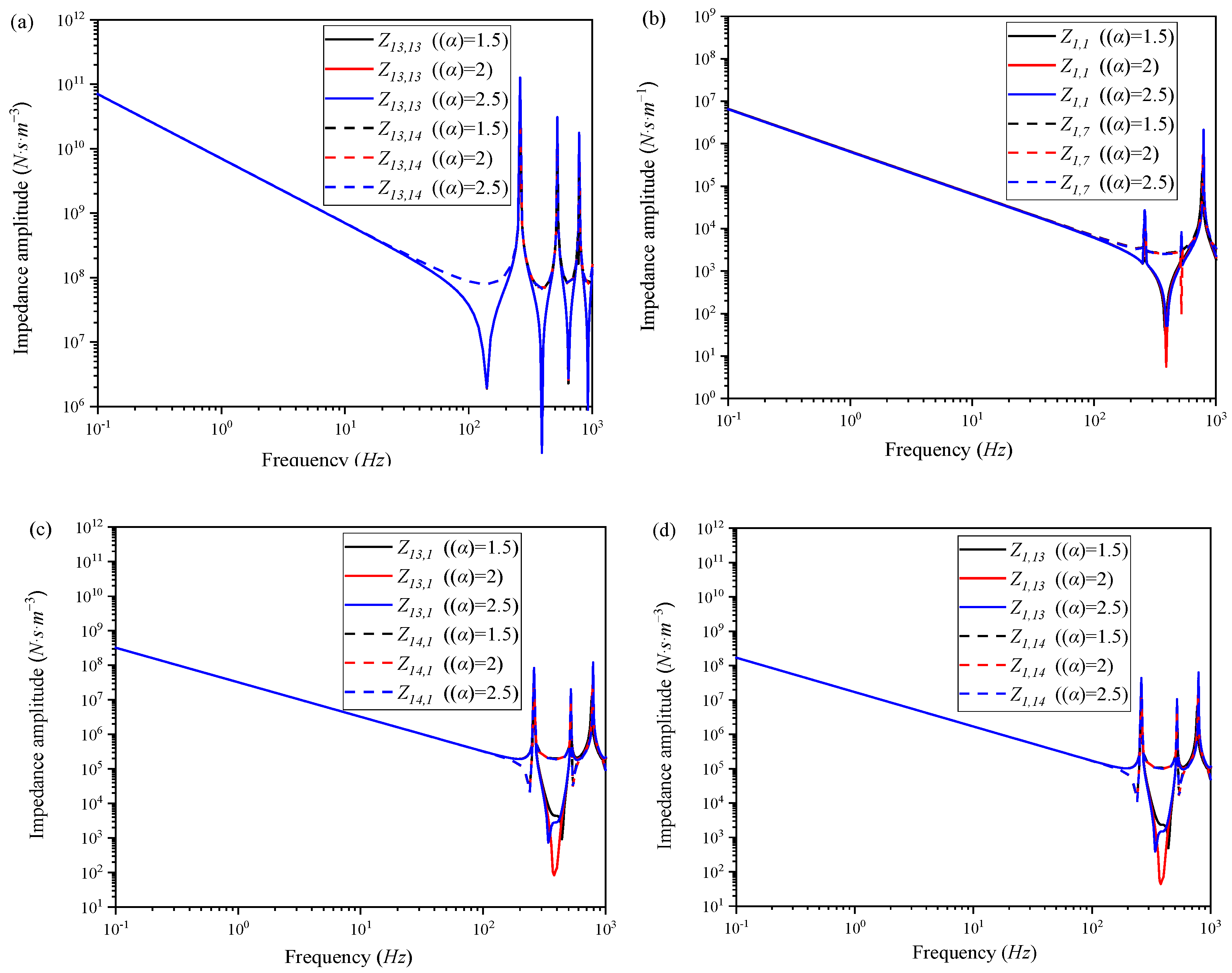

Figure 10,

Figure 11,

Figure 12 and

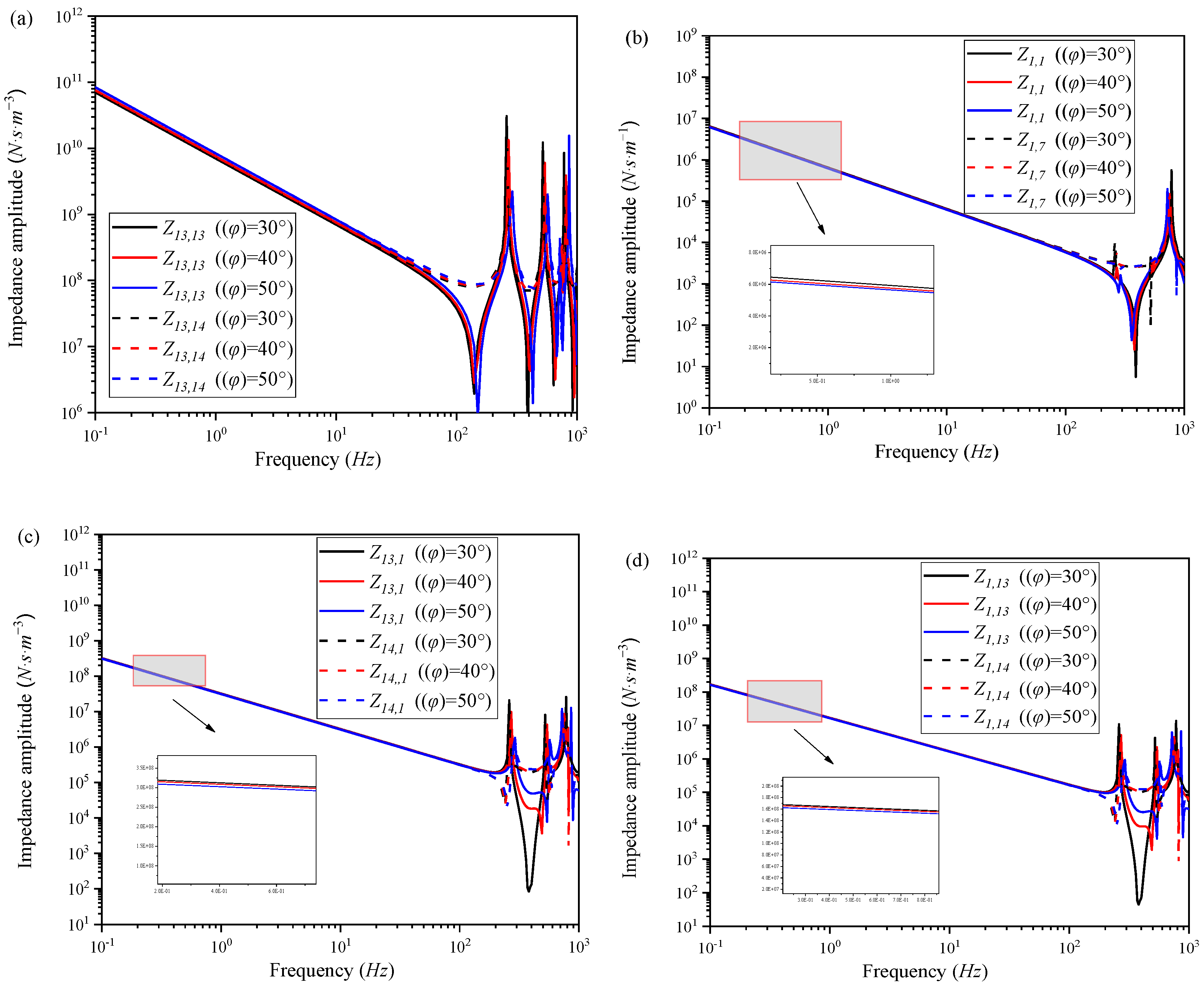

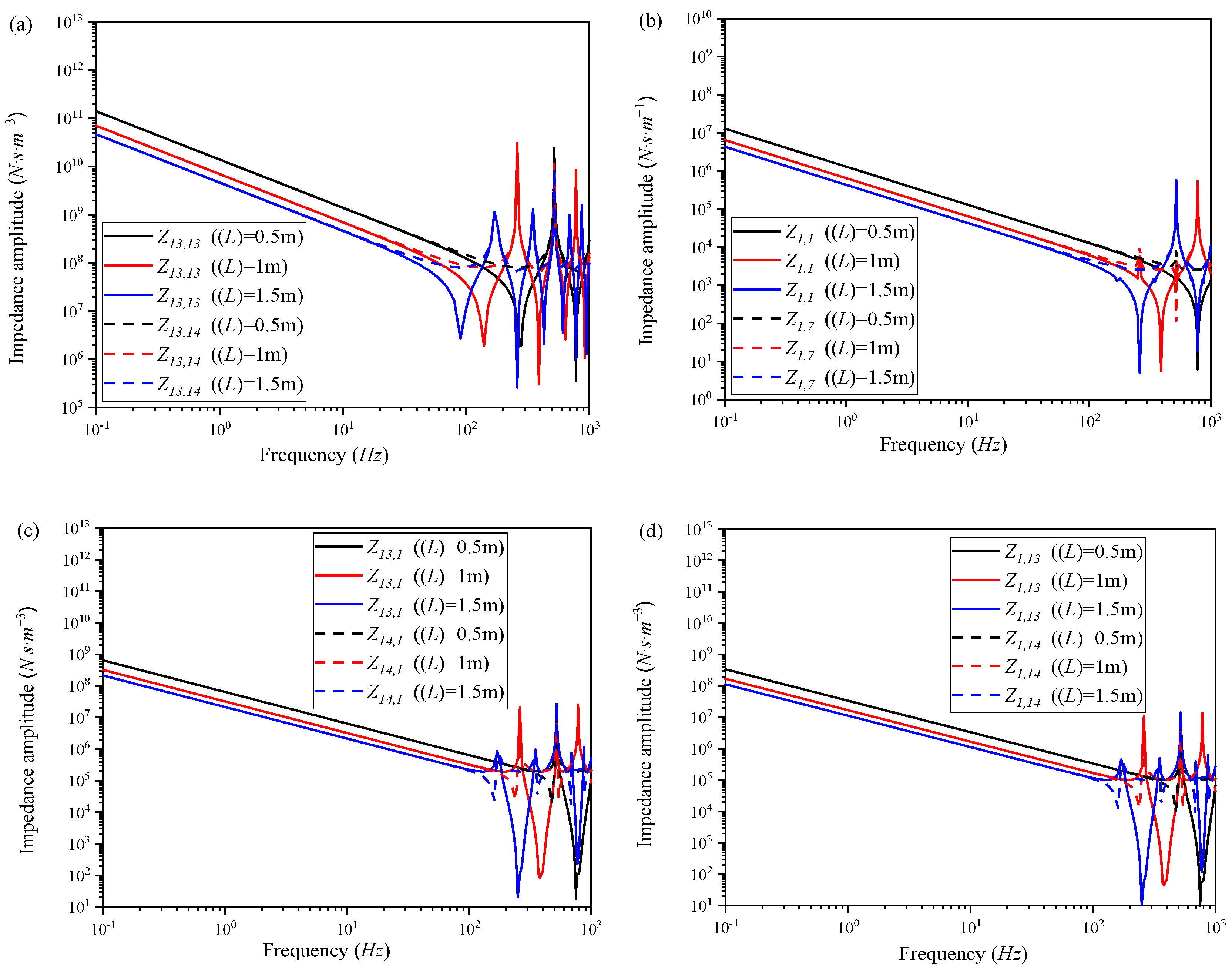

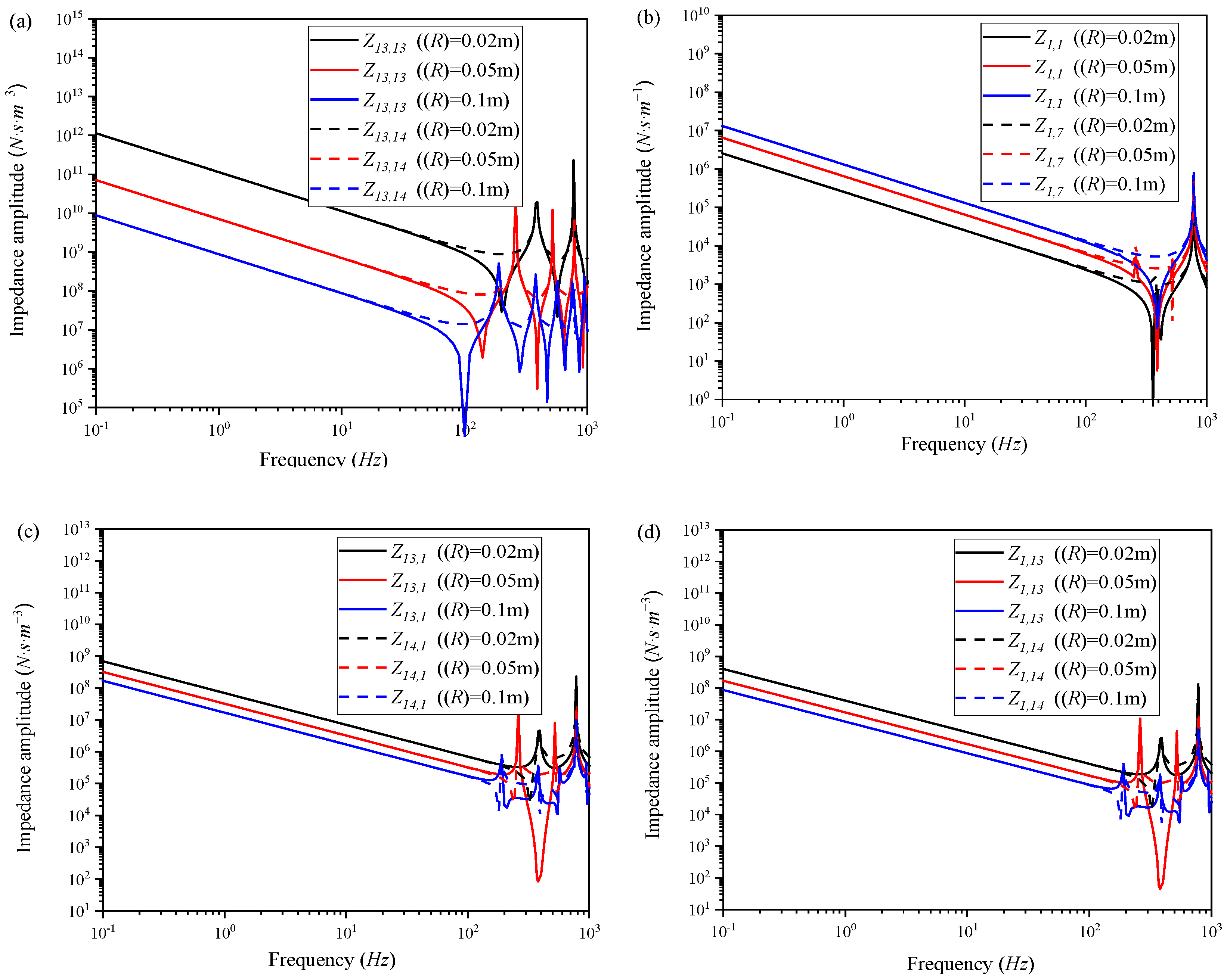

Figure 13 delineate the influence of the structural parameters of the honeycomb core on the dynamic characteristics of the NSFI.

Figure 14 and

Figure 15 illustrate the impact of geometrical parameters on the impedance of the NSFI.

Figure 10 illustrates that

α has a negligible effect on both acoustic and mechanical impedance. However, it significantly affects the coupling impedance. An increase in α correlates with a marked reduction in the first anti-resonance frequency for both input mechanical–acoustic and acoustic–mechanical impedances.

Figure 11 demonstrates the effect of

β on the impedance of the fluid-filled NSFI, revealing that both resonance and anti-resonance frequencies increase as

β rises. In the low-frequency range, the magnitudes of acoustic and mechanical impedances increase with

β, while the magnitudes of mechanical–acoustic and acoustic–mechanical impedances decrease. The elevation of

β contributes to an overall increase in the stiffness of the NSFI [

21]. At lower frequencies, enhanced stiffness results in a more rigid NSFI, producing a greater reaction force even with minimal displacements, thereby augmenting mechanical impedance. Additionally, as stiffness increases, the NSFI exhibits a higher acoustic propagation speed, leading to an elevated acoustic impedance.

Figure 12 explores the effect of

φ on impedance, revealing that an increase in

φ leads to a decrease in the resonance and anti-resonance frequencies of mechanical impedance, whereas those of acoustic impedance, acoustic–mechanical, and mechanical–acoustic impedance escalate. Furthermore, with an increase in

φ, the magnitude of the acoustic impedance increases, while the magnitudes of mechanical impedance, acoustic–mechanical impedance, and mechanical–acoustic impedance decrease in the low-frequency range.

Figure 13 investigates the effect of h0, demonstrating that an increase in

h0 leads to a decrease in the resonance and anti-resonance frequencies of mechanical impedance. Conversely, the frequencies for acoustic impedance, acoustic–mechanical, and mechanical–acoustic impedance increase. Within the low-frequency domain, a progressive increase in

h0 results in a higher magnitude of acoustic impedance, while the magnitudes for mechanical, acoustic–mechanical, and mechanical–acoustic impedance decrease. The increased

φ and

h0 can weaken the core layer’s enhancement effect on the NSFI’s global rigidity, leading to the decline of the global bending rigidity of the NSFI. At this point, the enhancement effect of the core layer as the upper and lower panel spacing on overall bending stiffness of the NSFI is weakened, resulting in the reduction in the overall bending stiffness and mechanical impedance of the NSFI. In addition, the density of the elastic and isotropic materials is less than that of this NSFI’s core. When h is given a definite value, an increase in core thickness h0 leads to the reduction in the inner and outer layer thickness. In other words, an increase in h0 will augment the overall mass of the NSFI, leading to an increase in both acoustic propagation speed and acoustic impedance.

Figure 14 illustrates the impact of

L on the axial impedance of the fluid-filled NSFI. The data presented in the graph indicates that an increase in

L corresponds to a reduction in both the resonance and anti-resonance frequencies. Additionally, within the low-frequency range, the amplitude of the impedance diminishes with an increase in

L. As shown in

Figure 15, an increase in

R is associated with a decrease in the resonance and anti-resonance frequencies for acoustic, mechanical–acoustic, and acoustic–mechanical impedance, whereas the frequencies for mechanical impedance remain relatively unchanged. Additionally, in the low-frequency range, an increase in

R results in a decrease in the magnitudes of acoustic, mechanical–acoustic, and acoustic–mechanical impedance, while the magnitude of mechanical impedance experiences an increase.

In fluid-filled pipelines, the resistance induced by viscosity generates a frictional interaction between the internal fluid and the pipe wall, a phenomenon referred to as friction coupling [

25,

26]. Sudden alterations in the direction of the fluid at specific fittings lead to what is known as connection coupling. In the case of bent pipes with non-circular cross-sections, the forced redirection of the fluid results in pressure fluctuations, which produce a “straightening” effect identified as Bourdon coupling. Generally, in scenarios characterized by medium to low frequencies, the influence of friction coupling on the dynamic response of pipeline systems is minimal and frequently overlooked. However, at elevated frequencies, the formation of a boundary layer engenders a “collective state”, thereby complicating the relationship between fluid friction and vibration frequency considerably. Friction coupling and Poisson coupling are fundamental behaviors within pipeline systems that significantly affect overall system dynamics, while connection coupling and Bourdon coupling primarily influence localized regions. The effect of friction coupling on the response of the pipeline system is relatively minor, whereas connection coupling and Poisson coupling exert a more pronounced influence on the system’s dynamics, with Bourdon coupling impacting only the bends. Therefore, in straight pipelines devoid of branches, both connection and Bourdon couplings are absent, rendering Poisson coupling the predominant factor in the fluid–structure interaction within the pipeline system.

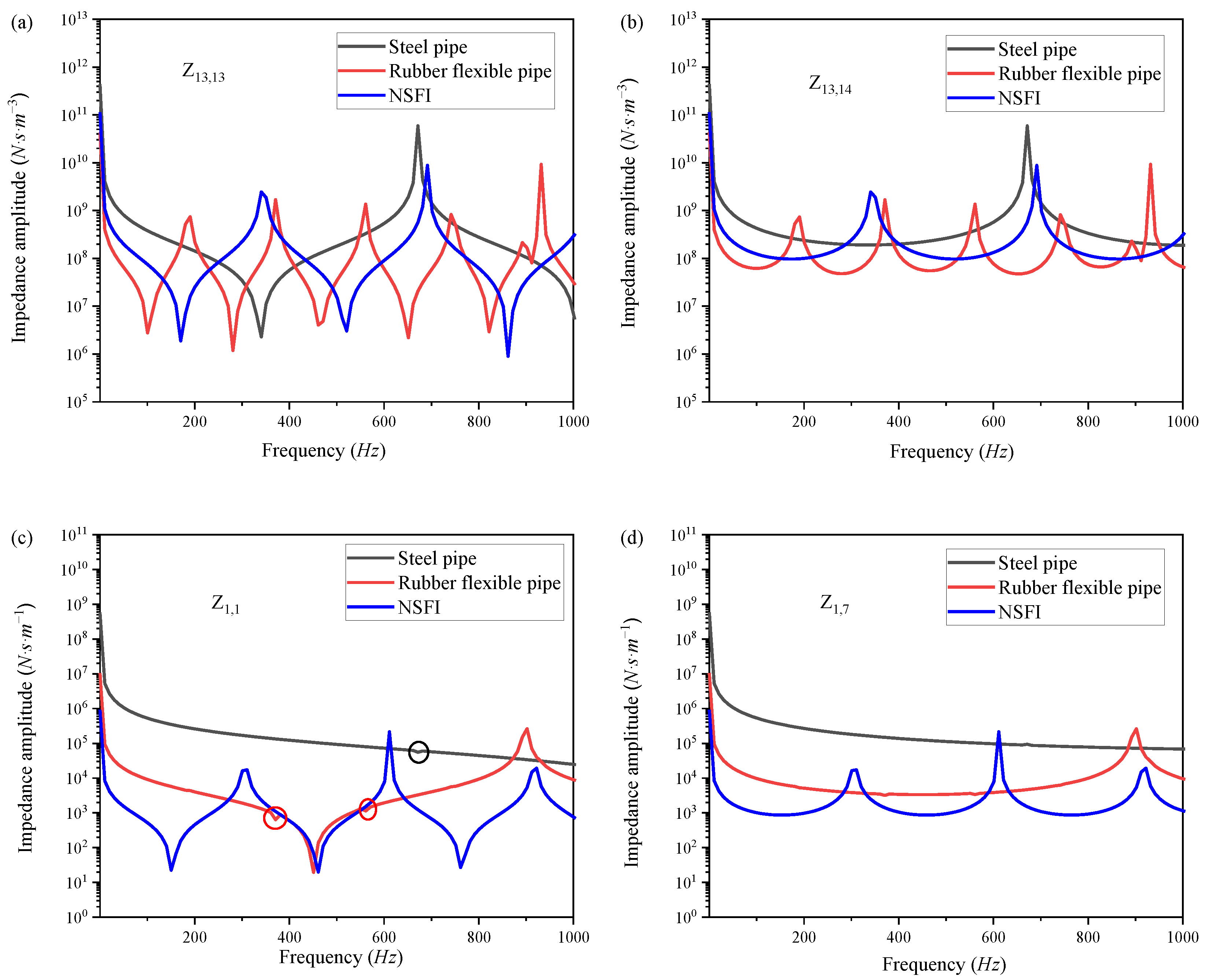

Figure 16 presents a comparative analysis of the impedance characteristics of the NSFI with those of steel pipes and rubber flexible pipes as the parameter h0 approaches h. It is observed that within the low-frequency range, the magnitudes of both acoustic and mechanical impedance for steel pipes surpass those of both the rubber flexible pipe and the NSFI. Notably, while the acoustic impedance of the rubber flexible pipe is lower than that of the NSFI, its mechanical impedance is comparatively higher. Furthermore, the resonance and anti-resonance frequencies associated with steel pipes are elevated relative to those of both the rubber flexible pipe and the NSFI. In the case of rubber flexible pipes, the resonance and anti-resonance frequencies for acoustic impedance are lower than those of the NSFI, whereas the mechanical impedance frequencies are higher. Additionally, the magnitude-frequency curves for mechanical impedance of both steel and rubber flexible pipes display several minor spikes, which can be attributed to the FSI characteristics between the pipe wall and the internal fluid [

27]. Moreover, compared to rigid pipelines, the differences in density and sound speed between the walls of flexible inserts and the internal fluids are less marked, enhancing the acoustic vibration coupling effect. The vibrations of the insert wall induce vibrations in the internal fluid, while the pulsations of the internal fluid result in radial deformation and axial changes in the pipe wall, as noted by Tijsseling et al. [

28]. This phenomenon is particularly pronounced in elbow-shaped flexible conduits, which significantly affects the lateral vibrations of the pipeline. As depicted in

Figure 16, the absence of spikes in the NSFI curve as

h0 approaches h suggests that the structure and the longitudinal waves of the fluid operate independently, with no occurrence of Poisson coupling. Despite theoretical frameworks that conceptualize the honeycomb core as an anisotropic homogeneous shell structure, the NSFI presents an innovative solution to the challenges posed by Poisson coupling in piping systems. It is important to note that honeycomb cores are typically regarded as homogeneous orthotropic materials, as their equivalent properties can be predicted irrespective of the complexity of their internal structures.

5. Conclusions

In the paper, a NSFI was developed, featuring a distinctive three-layer configuration comprising elastic inner and outer layers, along with a honeycomb core exhibiting a zero Poisson’s ratio, which is intended to effectively isolate and/or mitigate vibrations and noise on piping system. An effective theoretical prediction of dynamic characteristics for the fluid-filled NSFI was derived based on the FSI four-equation model. The theoretical predictions were subsequently validated through finite element analysis and experimental results, alongside comparisons with existing literature. The primary conclusions are listed as follows:

(1) The results of the parametric analysis show that various geometric parameters exert differential influences on axial impedance, thus facilitating the customization of impedance characteristics through parameter adjustments. For example, the parameter α has a negligible effect on the impedance of the fluid-filled NSFI. In contrast, an increase in the parameter β correlates with an elevation in both the resonant and anti-resonant frequencies of the pipeline, resulting in increased acoustic and mechanical impedance at lower frequencies. Concurrently, both mechanical–acoustic and acoustic–mechanical impedances exhibit a decline. Additionally, an increase in the parameter φ leads to higher resonant and anti-resonant frequencies of acoustic impedance, while the corresponding frequencies for mechanical impedance decrease.

(2) The amplitude–frequency curves of mechanical impedance for steel pipes and rubber flexible pipes display several minor spikes, attributed to the FSI characteristics between the pipe wall and the internal fluid. However, as h0 approaches h, the amplitude–frequency curve of the NSFI’s mechanical impedance is devoid of these spikes, indicating that the longitudinal waves within the structure and the fluid operate independent, with no Poisson coupling occurring. This observation suggests a novel approach for mitigating Poisson coupling effects.

It should also be noted that the FSI four-equation model is founded upon a beam model. Beam models may oversimplify the intricate interactions and dynamic behaviors of materials and structures, resulting in inaccuracies in predicting anti-resonance frequencies and impedance amplitudes at elevated frequencies. In future work, a more sophisticated model that incorporates the actual material properties and structural details of the NSFI is necessary, including the effects of 3D printing integration and the actual material distribution within the honeycomb core. Furthermore, adjustments to the experimental setups may be warranted to better isolate the characteristics of the NSFI from the contributions of the measurement apparatus, thereby ensuring more precise impedance measurements.