Abstract

Floating solar technology has gained significant attention as part of the global expansion of renewable energy due to its potential for installation in underutilized water bodies. Several countries, including the Netherlands, have initiated efforts to extend this technology from inland freshwater applications to open offshore environments, particularly within offshore wind farm areas. This development is motivated by the synergistic benefits of increasing site energy density and leveraging the existing offshore grid infrastructure. The deployment of offshore floating photovoltaic (OFPV) systems involves assembling multiple modular units in a marine environment, introducing operational risks that may give rise to safety concerns. To mitigate these risks, weather windows must be considered prior to the task execution to ensure continuity between weather-sensitive activities, which can also lead to additional time delays and increased costs. Consequently, optimizing marine logistics becomes crucial to achieving the cost reductions necessary for making OFPV technology economically viable. This study employs a simulation-based approach to estimate the installation duration of a 5 MWp OFPV plant at a Dutch offshore wind farm site, started in different months and under three distinct risk management scenarios. Based on 20 years of hindcast wave data, the results reveal the impacts of campaign start months and risk management policies on installation duration. Across all the scenarios, the installation duration during the autumn and winter period is 160% longer than the one in the spring and summer period. The average installation durations, based on results from 12 campaign start months, are 70, 80, and 130 days for the three risk management policies analyzed. The result variation highlights the additional time required to mitigate operational risks arising from potential discontinuity between highly interdependent tasks (e.g., offshore platform assembly and mooring). Additionally, it is found that the weather-induced delays are mainly associated with the campaigns of pre-laying anchors and platform and mooring line installation compared with the other campaigns. In conclusion, this study presents a logistics modeling methodology for OFPV systems, demonstrated through a representative case study based on a state-of-the-art truss-type design. The primary contribution lies in providing a framework to quantify the performance of OFPV installation strategies at an early design stage. The findings of this case study further highlight that marine installation logistics are highly sensitive to local marine conditions and the chosen installation strategy, and should be integrated early in the OFPV design process to help reduce the levelized cost of electricity.

1. Introduction

Solar photovoltaic (PV) systems have sustained tremendous growth in the renewable energy sector, driven by their competitive levelized cost of electricity (LCOE) compared to other technologies [1]. By mid-century, the global cumulative installed capacity of solar PV is estimated to grow 13-fold from the current capacity of 1.6 TW, contributing 40% of global on-grid electricity generation [2,3].

Despite this promising growth, concerns about land availability for utility-scale installation have been intensifying in many regions [4]. Specifically speaking, it requires approximately 1 of open land area for every 200 MWp of modern PV system installation [5], which poses a significant barrier in countries where land is either scarce or costly, such as the Netherlands [6]. This challenge has sparked interest in developing floating solar PV technology, where solar energy systems are installed on water surfaces using floaters and mooring systems. The technology opens up opportunities to utilize water bodies for solar PV installation, which has currently been commercialized in inland freshwater environments such as lakes, reservoirs and ponds in various regions [7].

Driven by the fact that offshore area has great potential for solar PV installation [8], offshore floating PV (OFPV) technology has recently gained momentum in research and development. Although deploying systems in offshore environments is expected to incur higher capital and operational costs, the synergies of implementing a hybrid system incorporating different types of renewable energy assets are suggested to enhance the economic effectiveness [9,10]. The co-location of offshore solar and wind technologies allows for synergies both in power production and resource sharing. Specifically speaking, the energy yield per unit area increases while the production profile also becomes smoother with a positive impact on grid stability [11]. Furthermore, the shared use of grid infrastructure (e.g., export cables, substations) and marine resources (e.g., vessels, access equipment, port space) between solar and wind farms can further reduce costs, provided that sufficient cooperation and coordination are established between the plant owners, operators, and service providers.

However, OFPV technology is still in its early development stage. Offshore environments present harsher conditions compared to inland freshwater systems, leading to various design challenges [12]. These include the reliability of structures under complex and extreme loads from waves and wind, saltwater corrosion of components, and reduced power performance due to the suboptimal tilt angle of panels [13]. As a result, OFPV technology requires a much more resilient and sophisticated design to ensure reliable operation in offshore conditions, especially in regions with relatively high wave exposure such as the North Sea.

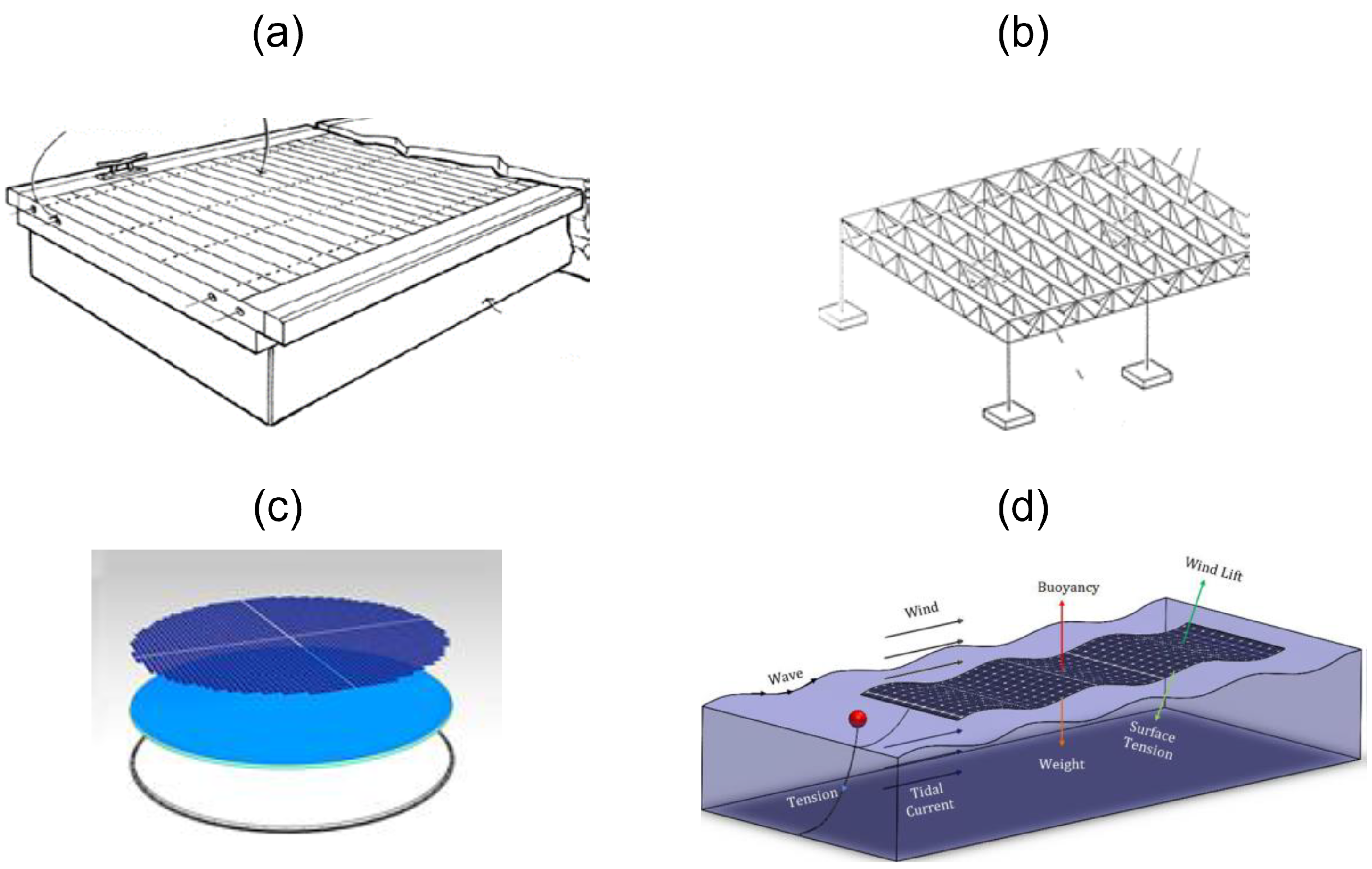

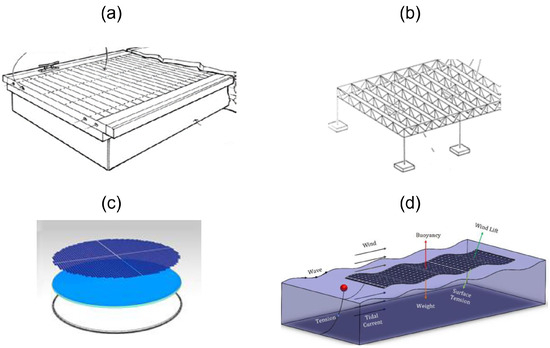

Currently, various types of OFPV systems are under development, with four major design concepts existing in the market as shown in Figure 1. Several designs have reached technology readiness levels (TRLs) around 6 to 7, where prototype systems are tested on a pilot scale in the offshore environment [14,15,16,17].

Figure 1.

Schematics of different OFPV design concepts: (a) pontoon type, (b) truss type, (c) fish farm type, (d) soft and flex type [18].

Next to the ongoing development of OFPV design, marine logistics during installation and maintenance campaigns are becoming a notable research topic due to the complexities of conducting activities on floating bodies in the offshore environment. Offshore operations are generally more costly, time-consuming, and risk-laden compared to onshore activities [19]. A recent study highlights that almost 30% of the life-cycle cost of OFPV systems arises from activities carried out during the installation phase [20].

The installation of OFPV systems typically involves several key phases, including site preparation, floater delivery, structural assembly, deployment of the mooring system, cable routing, installation of electrical equipment, grid connection, and commissioning [21]. While the logistics share similarities with other offshore infrastructures, the operation of modular OFPV system assembly at offshore sites remains a developing practice within the industry. In particular, marine assembly operations require executing a sequence of complex activities under harsh offshore conditions, such as towing, maneuvering, positioning and mooring [22], where inappropriate planning of these activities may introduce operational risks that create safety hazards for personnel and also cause extra time delays as well as cost overruns. In the field of offshore logistics, several modeling approaches have been adopted to evaluate marine operations subject to weather dependencies [23,24,25]. However, relevant studies of marine assembly logistics of OFPV remain particularly scarce given the relatively nascent state of the technology. This limited body of literature combined with OFPV installation being a life-cycle cost driver [20] underscores the urgent need for early-stage research and modeling efforts to optimize offshore processes, identify key challenges and propose cost-effective solutions.

Thus, the goal of this study is to demonstrate how a discrete-event simulation (DES) approach commonly applied in offshore logistics modeling can be applied to address the existing knowledge gap in OFPV installation logistics within both academia and industry. The modeling methodology, presented through a case study, is intended to support stakeholders involved in the design and construction of OFPV systems and contribute to lower uncertainty around OFPV marine logistics. To the best of the authors’ knowledge, this is the first study addressing OFPV marine operations in detail using the DES approach. Overall, this study has the following aims:

- Demonstrate the feasibility of using a discrete-event simulation approach to quantitatively assess offshore logistics for OFPV systems.

- Present a case study with generalized and representative input parameters to support reproducibility and future research.

- Provide insights into the effects of various risk management policies on the performance of OFPV installation campaigns.

2. Methodology

This section begins by presenting the logistic model used in the study. Subsequently, the scope of the case study is outlined, describing details of the site location and design of the reference OFPV plant and weather data, which is then followed by the illustration of installation logistics and the associated operational risks. Afterward, the definition of three simulation scenarios, each representing a different risk management policy, is explained. Finally, the limitations of the study are discussed.

2.1. Logistics Modeling

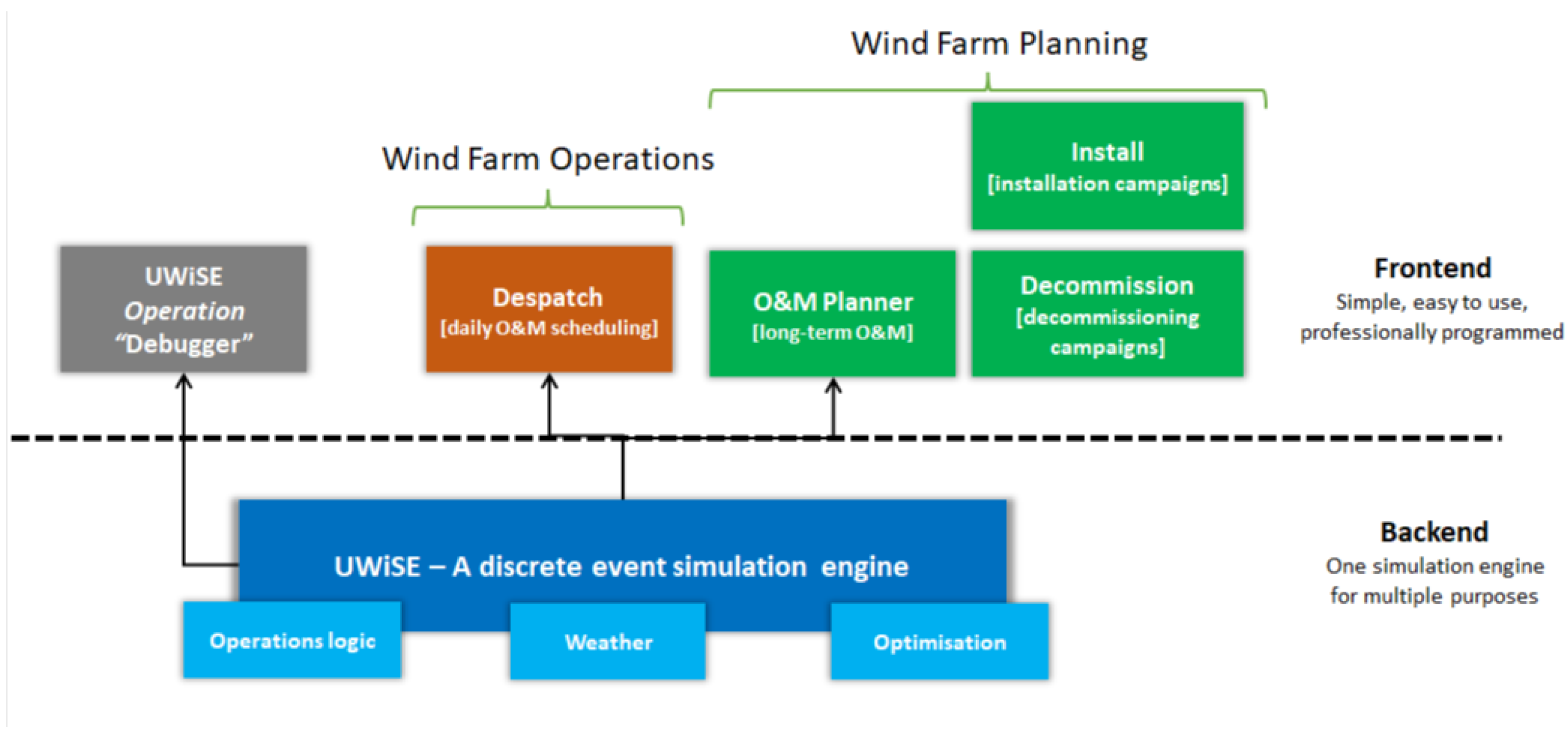

In this study, a high-fidelity logistic modeling platform, named UWiSE [26], has been used to evaluate the installation campaign of a 5MWp OFPV system under weather-dependent constraints. UWiSE integrates multiple modules designed to simulate the logistics of offshore renewable energy assets, such as offshore wind and OFPV farms, across various life-cycle phases, including installation, operation and maintenance (O&M), and decommissioning [27,28]. Figure 2 provides an overview of the UWiSE software platform (latest version released as of 2024), where the Install module has been used in this study.

Figure 2.

Overview of UWiSE software platform [27].

UWiSE employs a discrete-event simulation (DES) approach to model logistical processes as a sequence of user-defined events occurring at specific time points. Events such as vessel transit from port to site, loading operations and component installations each impact the system’s state, allowing for the assessment of performance metrics including installation time, resource utilization, power production and downtime losses. This approach is particularly valuable in logistics, as it facilitates detailed analysis of dynamic processes and supports optimization of resource allocation and workflow efficiency.

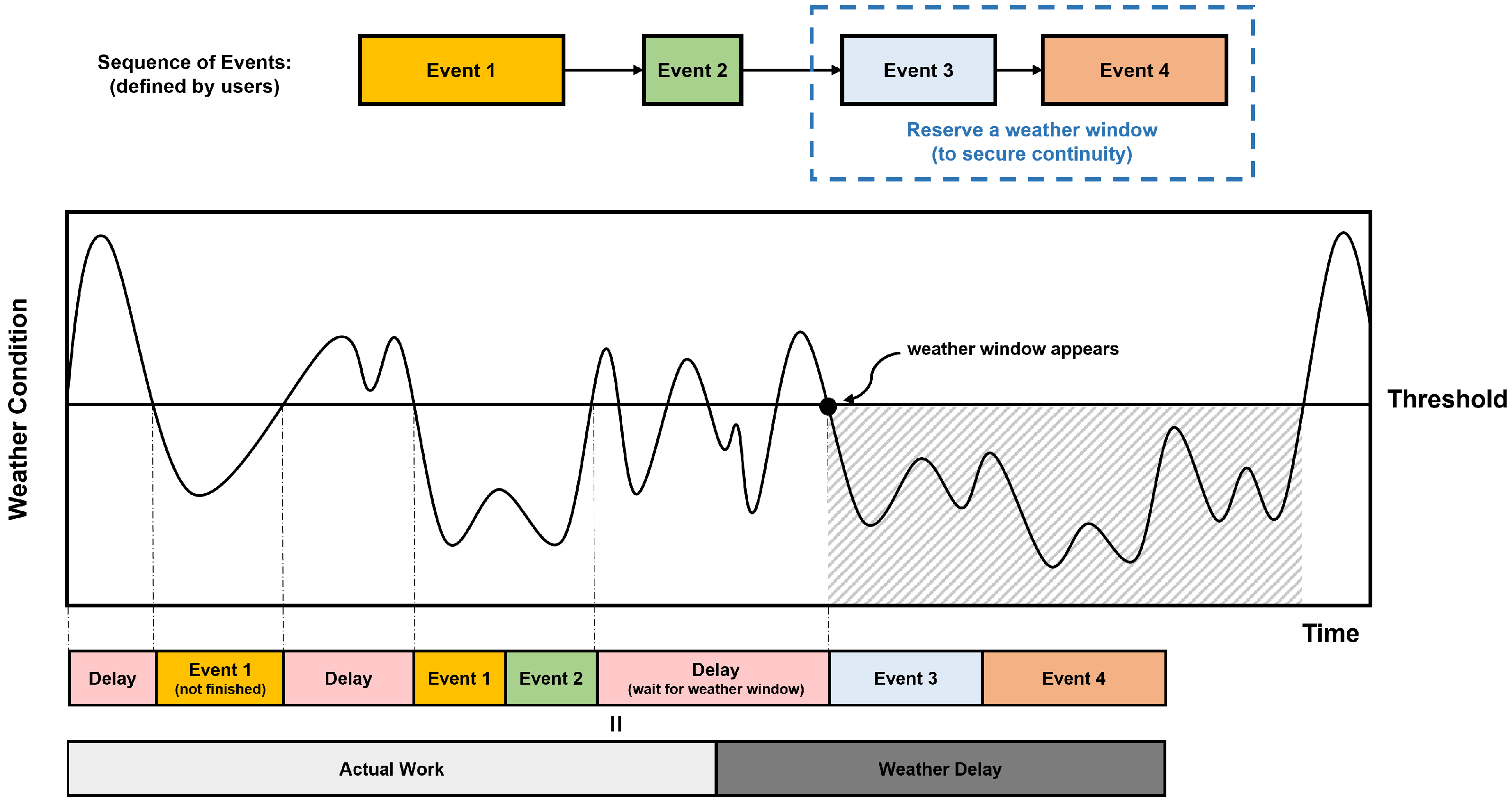

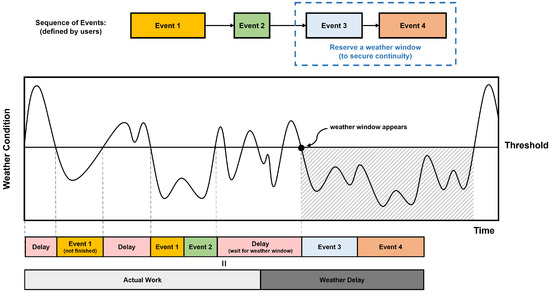

Figure 3 provides a schematic overview of how UWiSE Install calculates installation duration in the context of weather dependencies. In the example shown, an installation campaign consists of four operational steps (viewed as events in the model), each defined by its duration and a threshold on its operational weather conditions. Events occur in accordance with their sequence, where each of their execution periods is logged as “actual work”. In circumstances where weather conditions exceed the set thresholds, the event is delayed, where the additional time of waiting is logged as a “weather delay”.

Figure 3.

Schematic diagram of the duration calculation in the UWiSE Install module.

Some events are especially interdependent, meaning that they must be completed in sequence without interruption (e.g., Events 3 and 4 should proceed consecutively without delay, as shown in Figure 3). In such cases, a weather window is allocated to ensure continuity between these events. Ultimately, the total installation duration is calculated as the sum of the actual work and weather delays, highlighting the effects of weather dependencies on logistics. Furthermore, the model incorporates multiple years of hourly time series of wind and wave data to quantify the annual uncertainty in weather conditions.

2.2. Case Study

- Site

Hollandse Kust West (HKW) is a 176 offshore wind development zone designated by the Dutch government, located approximately 50–70 km off the west coast of the Netherlands. A total of 2.1 GW of offshore wind capacity is planned to be installed, divided into three sites (HKW VI, VII, and VIII) [29]. Tenders for sites VI and VII were issued in 2022, and the wind farms are currently under construction. Site VII is selected as a case study, as the winning bid for this site includes the installation of a 5 MWp OFPV pre-commercial demonstration plant featuring an elevated platform concept developed by the Dutch company SolarDuck [30]. The platform is planned to be assembled at the Port of IJmuiden and will subsequently be towed to the designated offshore site.

- OFPV Design

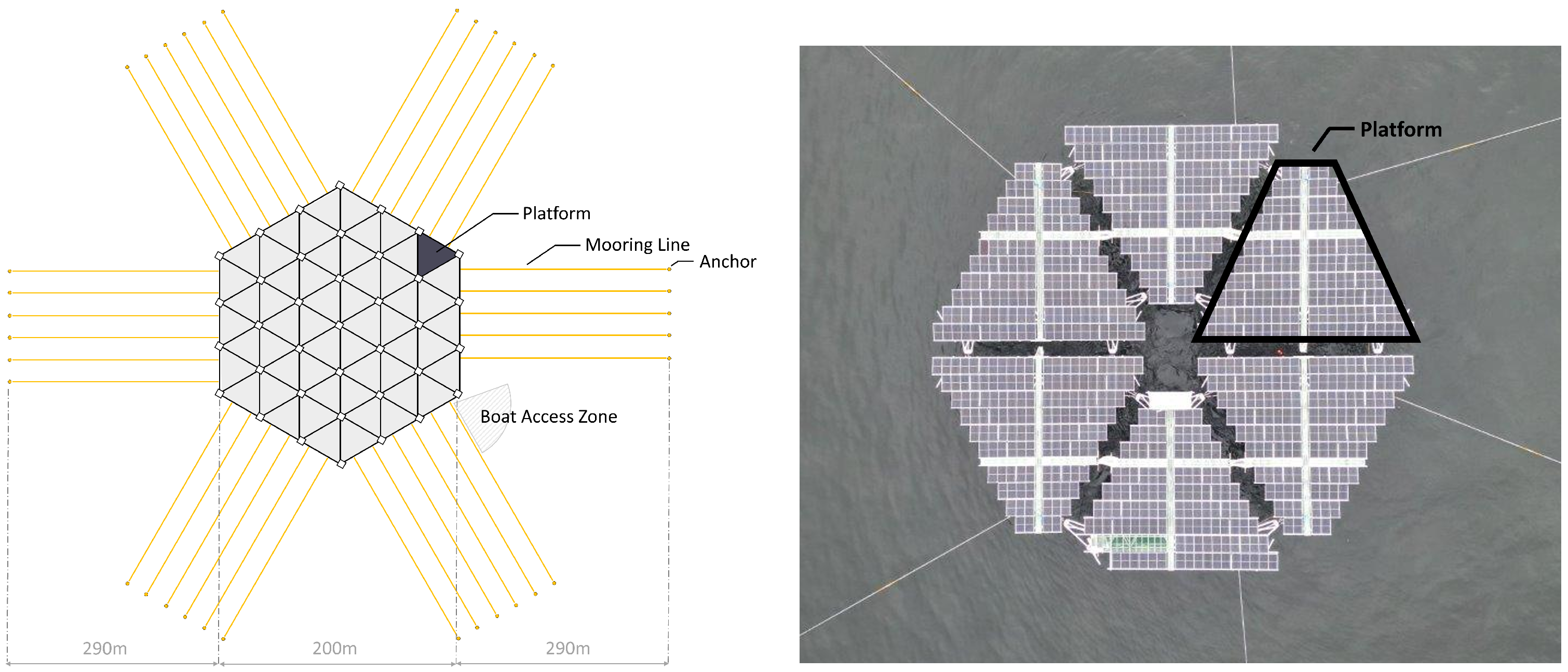

SolarDuck’s OFPV plant concept is a modular design consisting of multiple triangular-shaped and elevated (truss-type) floating platforms, engineered to withstand extreme weather conditions in the North Sea. In this study, a preliminary design of a 5 MWp plant developed by SolarDuck is considered, where 54 triangular platforms are connected to form a large hexagonal plant with three platforms at each edge, as illustrated in Figure 4. The design of each platform will be based on the 520 kWp scaled prototype developed in the Merganser pilot project [31], although with expected changes based on the lessons learned during the pilot.

Figure 4.

(Left) Schematic representation of the truss-type OFPV plant designed by SolarDuck with a capacity of 5 MWp, comprising 54 floating platforms, 35 mooring lines, and 35 anchors. (Right) The OFPV plant with an installed capacity of 520 kWp developed in the Merganser pilot project that has been installed at the North Sea testing site [31].

The solar panels and the electrical equipment (e.g., inverters, inter-platform cables, transformer, etc.) will be distributed on top of the platforms, which are then supported by an elevated truss structure. The structure is mainly made of aluminum, standing approximately 10 m above the waterline, which is designed to prevent direct contact with slamming waves. The buoyancy of the structure is provided by vertical aluminum floats, where the structure is interconnected by multiple large gas cylinders that offer damping to mitigate wave-induced relative motions. The system will be stabilized on the water’s surface by connecting it to the seabed through multiple mooring lines and anchors.

- Wave Data

The viability of offshore installation activities is largely affected by the local sea state. In fact, as for every offshore activity, the effects of waves and relative motions need to be carefully considered when defining operational method statements to guarantee the safety of personnel, as well as the integrity of the asset, vessels and equipment used. Moreover, installation activities require suitable weather windows to be defined to safeguard the structural integrity of the different sub-assemblies, which are typically more susceptible to wave-induced loads than the fully assembled system.

Given that, at the time of this study, detailed information on the system’s hydrodynamic design and on the specific vessels to be used was not available to the authors, wave periods, current directions, mooring layouts, and vessel orientations have been ignored in this study. Instead, sea state dependencies have been modeled simply as a function of the significant wave height parameter (Hs), which is a common metric for the preliminary evaluation of offshore method statements [32].

For this case study, 20 years’ worth of hourly hindcast Hs data at the offshore site location ranging from 1996 to 2015 has been collected from the publicly available North Sea Wave Database [33]. The multiple years of data have been used to quantify the uncertainty in the expected local sea state.

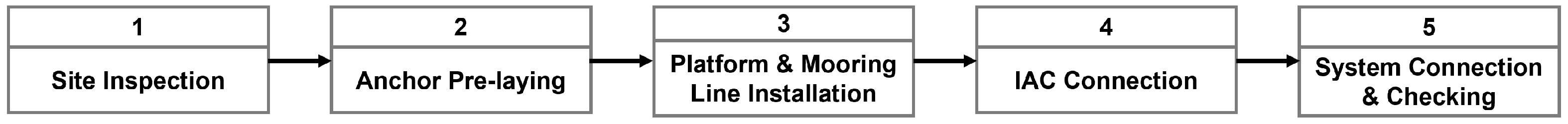

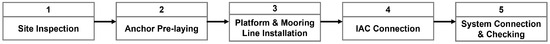

2.3. OFPV Installation Logistics

This study considers the installation of a single 5 MWp OFPV plant. The simulation scope covers the main offshore campaigns that are relevant to the logistics of marine assembly, as depicted in Figure 5. These include site inspection, anchor pre-laying, platform and mooring line installation, and inter-array cable (IAC) connection as well as system connection and checking before commissioning. However, installation campaigns for the balance of plants, offshore substations, IACs and export cables are excluded from the scope. Moreover, onshore logistics, such as component manufacturing, transportation to the port and platform pre-assembly, are beyond this study’s focus.

Figure 5.

Scope of the OFPV installation logistic simulations.

The high-level sequence and description of the activities in each offshore campaign considered are described below. For each campaign, detailed method statements outlining the step sequences, durations, required resources, operational limits, and weather windows have been defined and used as input to the discrete-event simulations. Due to their design-specific nature, the detailed method statements are a sensitive part of SolarDuck’s intellectual property and are not reported here. For the sake of clarity, a generic method statement table is reported in Appendix A to outline the type and format of input used in the simulations. It should be noted that the installation method modeled in this study is based on 2023 knowledge levels.

- Site Inspection: In this campaign, a survey vessel equipped with a multibeam sonar is deployed to measure the water depth in high resolution, obtain a three-dimensional picture of the seabed, and gather information on the topsoil’s characteristics for preparing pre-laying activities.

- Anchor Pre-laying: This campaign aims to pre-lay anchors on the seabed for later connection to mooring lines. An anchor-handling tug (AHT) is used to transport, deploy and pre-load 3 anchors per trip (limited by the vessel’s capacity). There are 35 anchors to be pre-laid, resulting in 12 trips between the port and offshore site to complete the campaign.

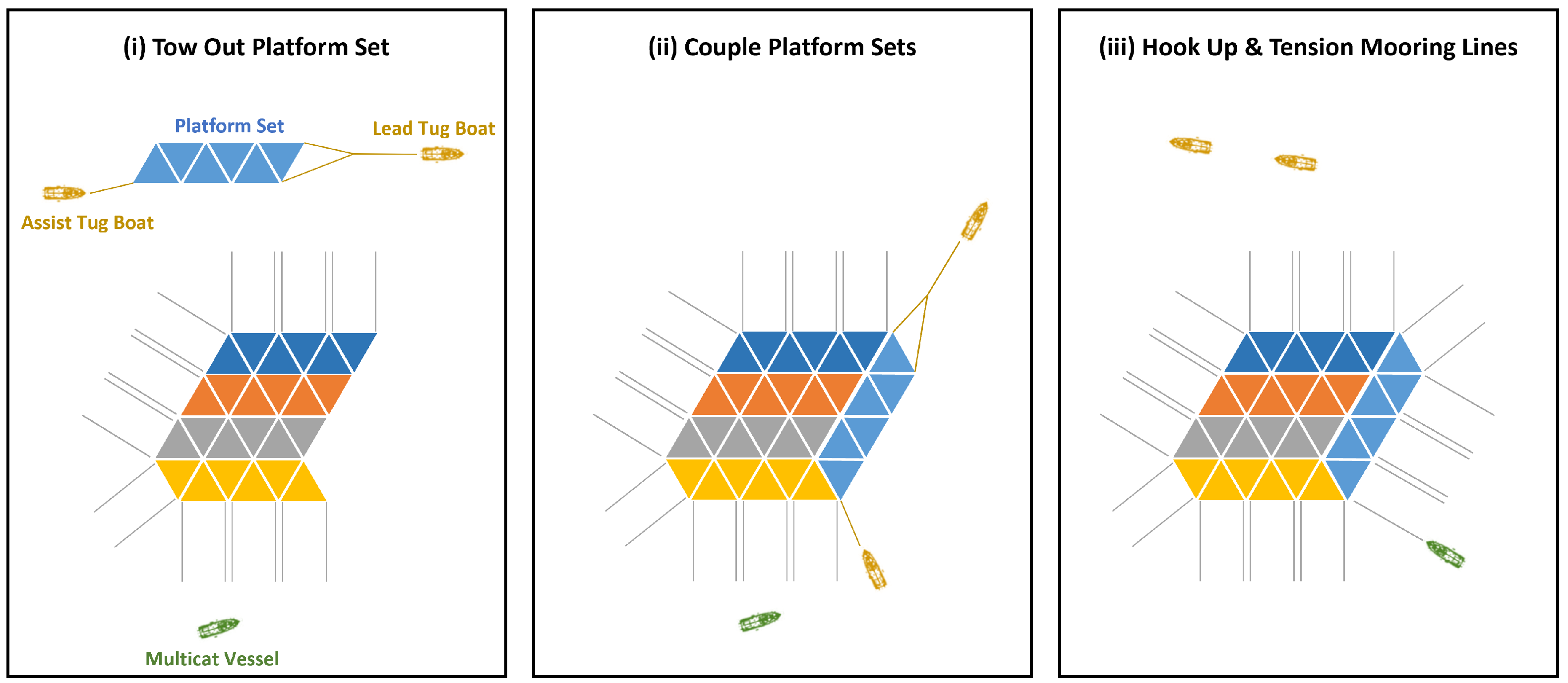

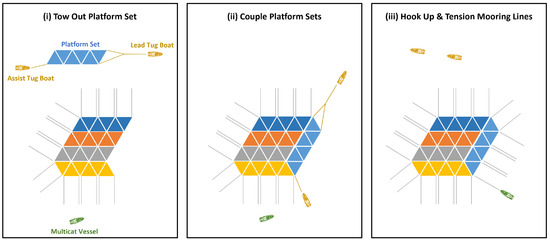

- Platform and Mooring Line Installation: This campaign involves the on-site coupling of the platforms forming the OFPV plant and the connection of mooring lines to both the set of interconnected platforms and the pre-laid anchors. As depicted in Figure 6, the campaign comprises three primary operations: (i) towing a pre-assembled platform set to the site, maneuvering it into place, (ii) offshore coupling of contiguous platform sets, and (iii) hooking up and tensioning of mooring lines. It is assumed that each pre-assembled platform set consists of six individual platforms connected at the port’s quayside before the start of this campaign. Each platform set is then towed to the site by two tugboats (TBs). Towing operations are assumed to be performed in series (i.e., platform sets are towed one after the other, and the towing of the next set only starts once coupling and mooring operations on the former set are completed).

Figure 6. Schematic sketch of the offshore operations for the platform and mooring line installation campaign.Upon arrival at the site, the platform set is coupled with previously installed platform sets, starting from the second trip onward. Simultaneously, a multicat vessel (MV) is deployed to attach and tension mooring lines to the plant’s sub-assembly (consisting of platform sets already towed and coupled offshore). The entire campaign involves the installation of 9 platform sets and 35 mooring lines, necessitating 9 trips between the port and the site to complete the 5 MWp plant’s assembly.

Figure 6. Schematic sketch of the offshore operations for the platform and mooring line installation campaign.Upon arrival at the site, the platform set is coupled with previously installed platform sets, starting from the second trip onward. Simultaneously, a multicat vessel (MV) is deployed to attach and tension mooring lines to the plant’s sub-assembly (consisting of platform sets already towed and coupled offshore). The entire campaign involves the installation of 9 platform sets and 35 mooring lines, necessitating 9 trips between the port and the site to complete the 5 MWp plant’s assembly. - IAC Connection: This campaign connects the OFPV plant to the IAC (assumed to already be installed at the site). A cable-laying vessel (CLV) is deployed to perform the task, which consists of the CLV traveling to the site, retrieving the IAC and connecting it to the plant.

- System Connection and Checking: This campaign connects the remaining electrical systems of the OFPV plant (incl. inverters, transformer, SKID, inter-platform and string cables, etc.) and carries out final system checks before commissioning. A crew transfer vessel (CTV) is deployed to transfer personnel to the site on a scheduled basis to complete the campaign.

2.4. Marine Operational Risks

Marine assembly operation is subjected to continuous wave movement, where several key steps must be executed below a certain threshold of wave height. For instance, deploying and laying anchors would demand personnel to work close to the water, where high waves potentially jeopardize personnel’s safety. Similarly, towing platforms in large waves causes excessive rolling and pitching motion of tugboats, potentially resulting in operational loss of control or damages on platforms. Precise platform maneuvering and coupling also become challenging as wave-induced deviations can lead to errors or equipment damage. Running and connecting mooring lines would require controlled tension, and unstable waves can induce dynamic fluctuations, compromising alignment and attachment security.

Moreover, disruptions between interdependent steps can also introduce unforeseen risks that cause extra time and cost for installation campaigns. For example, a pause between platform maneuvering and coupling would allow platforms and vessels to drift under environmental forces such as wind, waves, and currents. Even minor shifts can misalign the positioned platforms, complicating the following coupling step and increasing the risks of positioning errors or collisions.

To minimize operational risks mentioned above, it is essential not only to define wave height thresholds for individual activities but also to allocate an extended weather window prior to the operational sequence to ensure continuity between tasks.

2.5. Scenario Definition

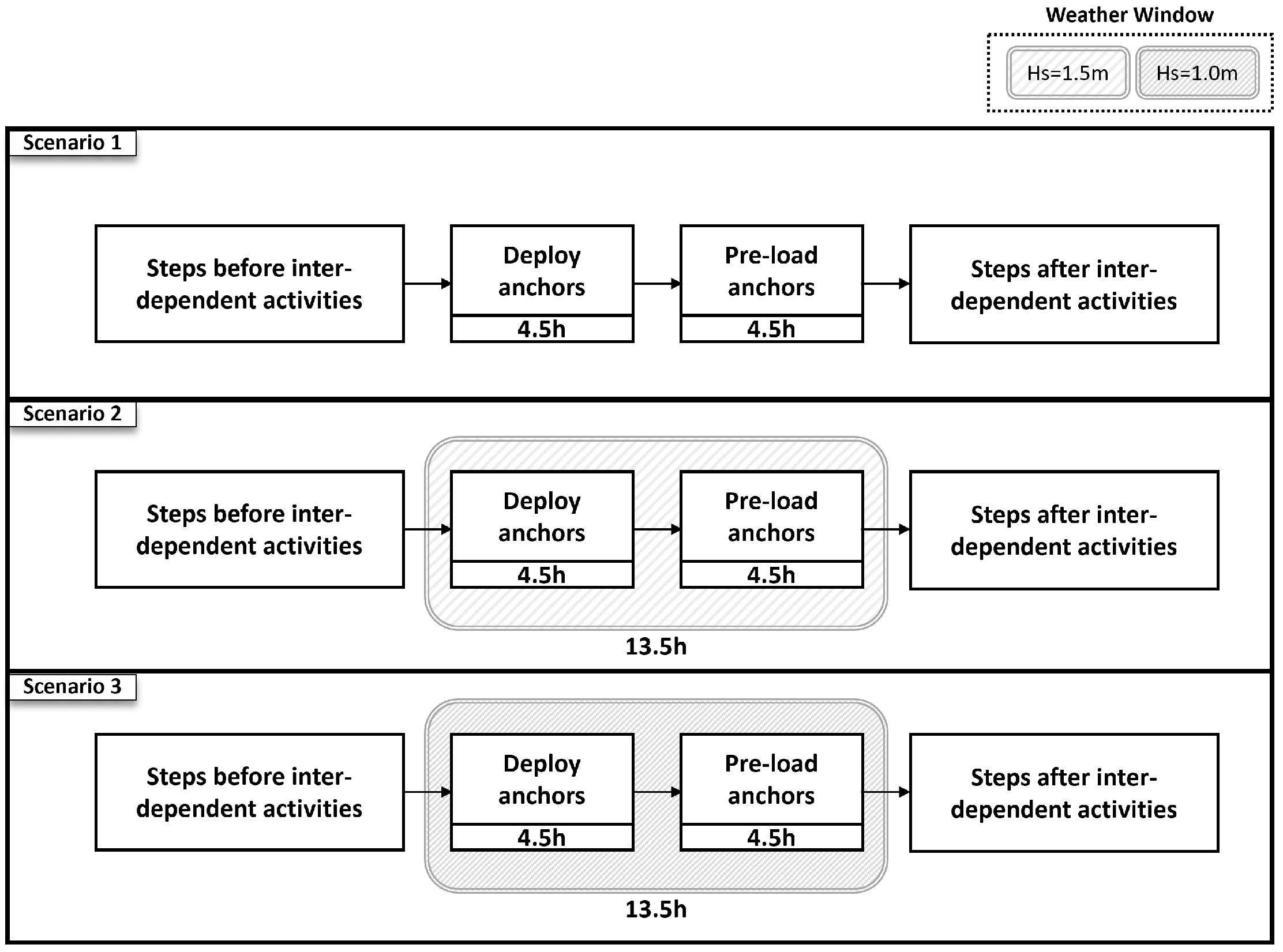

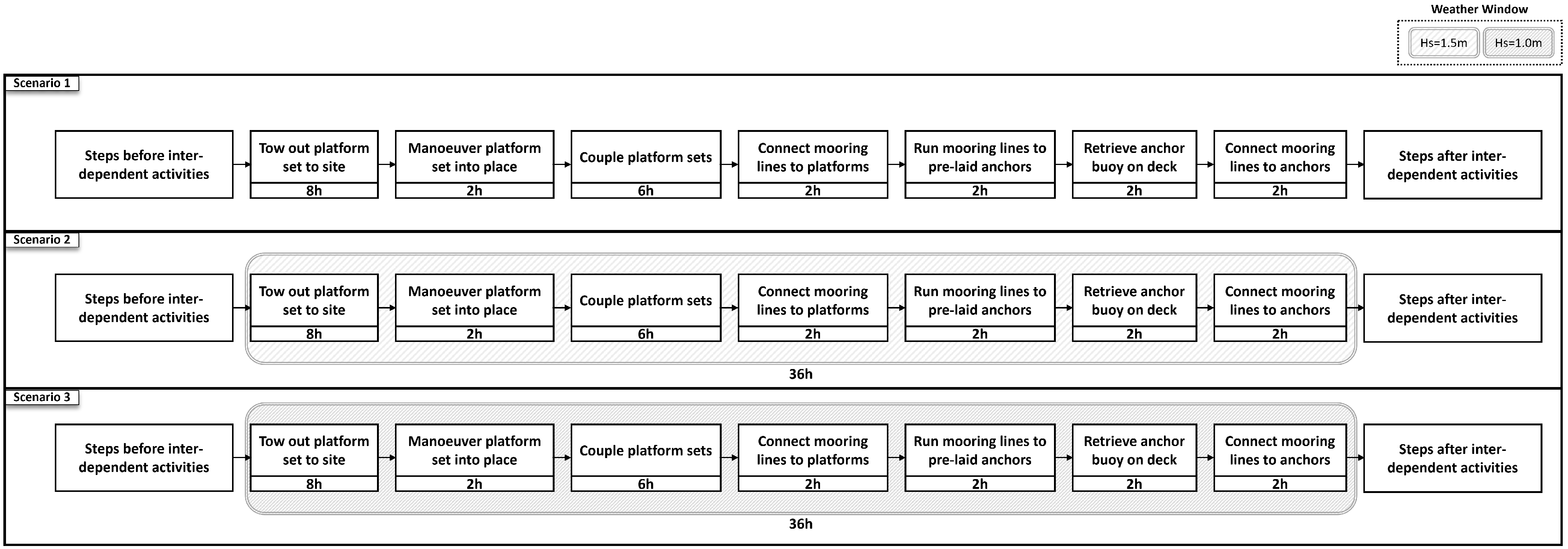

To mitigate weather-induced risks and to further support decision-making in OFPV installation, three scenarios with alternative risk management strategies were modeled, as summarized in Table 1. These three scenarios represent increasingly conservative policies that result in progressively lower operational risks.

Table 1.

Overview of the simulation scenarios representing different risk management policies. A contingency period is suggested to be included in weather windows to cover the uncertainty in weather forecast based on a common marine operation standard [32].

Figure 7 and Figure 8 illustrate the major operational steps for the anchor pre-laying and platform and mooring line installation campaigns, and how the weather window criteria are applied to the sequences of interdependent steps under different risk management scenarios.

Figure 7.

Key operational steps of anchor pre-laying, with different weather window criteria applied under various risk management scenarios.

Figure 8.

Key operational steps of platform and mooring line installation, with different weather window criteria applied under various risk management scenarios.

In the figures, gray blocks denote the required weather windows, with the corresponding durations annotated below and Hs thresholds indicated in the legend. For example, before deploying and pre-loading anchors in Scenario 1, no weather window is enforced. In contrast, Scenarios 2 and 3 apply weather windows of 13.5 h (which includes 50% of the contingency period on top of its operational period), with Hs thresholds of 1.5 m and 1.0 m, respectively. These windows aim to ensure that critical interdependent steps can proceed without interruption, thereby supporting safe and continuous execution.

It is noted that this study assumes Hs of 1.5 m as a general threshold for each operational step executed in a marine environment, while the exact threshold can vary between different installation methods, equipment and OFPV designs in practice.

2.6. Key Limitations

Several important limitations should be acknowledged to correctly interpret the scope and applicability of the results presented in this study:

1. Site- and Design-Specific Context: This study presents results based on a representative case involving a specific location and truss-type OFPV design. The metrics evaluated in this study may vary significantly with different site conditions, technological configurations, and project-specific assumptions. As such, the results cannot be generalized to other sites or OFPV designs. That said, the proposed modeling approach is project-agnostic and can be applied to any offshore site, OFPV design or installation strategy as site characteristics, installation method statements, deployed resources, and metocean conditions and limitations are configurable inputs. Given appropriate input data, the same framework can be readily applied to simulate other OFPV installation scenarios.

2. Exclusion of Quantitative Cost Assessment: Due to the commercial sensitivity of input data provided by an industry partner, a detailed cost analysis is beyond the scope of this study. Instead, qualitative discussions are offered to reflect upon potential implications on LCOE and design decisions. Importantly, the presented logistical metrics remain valuable for identifying performance drivers and operational bottlenecks relevant to stakeholders.

3. Limited Reproducibility: While detailed proprietary method statements cannot be disclosed, a high-level description of the operational strategy is provided, including identification of key interdependencies in the logistics chain. Although this restricts full replication of the results of this case study, the methodology and outcomes presented offer valuable insights into the structure and sequencing of OFPV marine operations, which are deemed relevant to the OFPV industry and the scientific community. Future research may further build on this framework considering open or generic project data to guarantee reproducibility and explore broader applicability across different OFPV concepts and site conditions.

3. Results

In this section, simulation results obtained with the logistics model and inputs defined in Section 2 are presented. Installation duration is considered a key performance indicator (KPI) in this study, which aims to quantify the impacts of weather dependencies on OFPV installation campaigns.

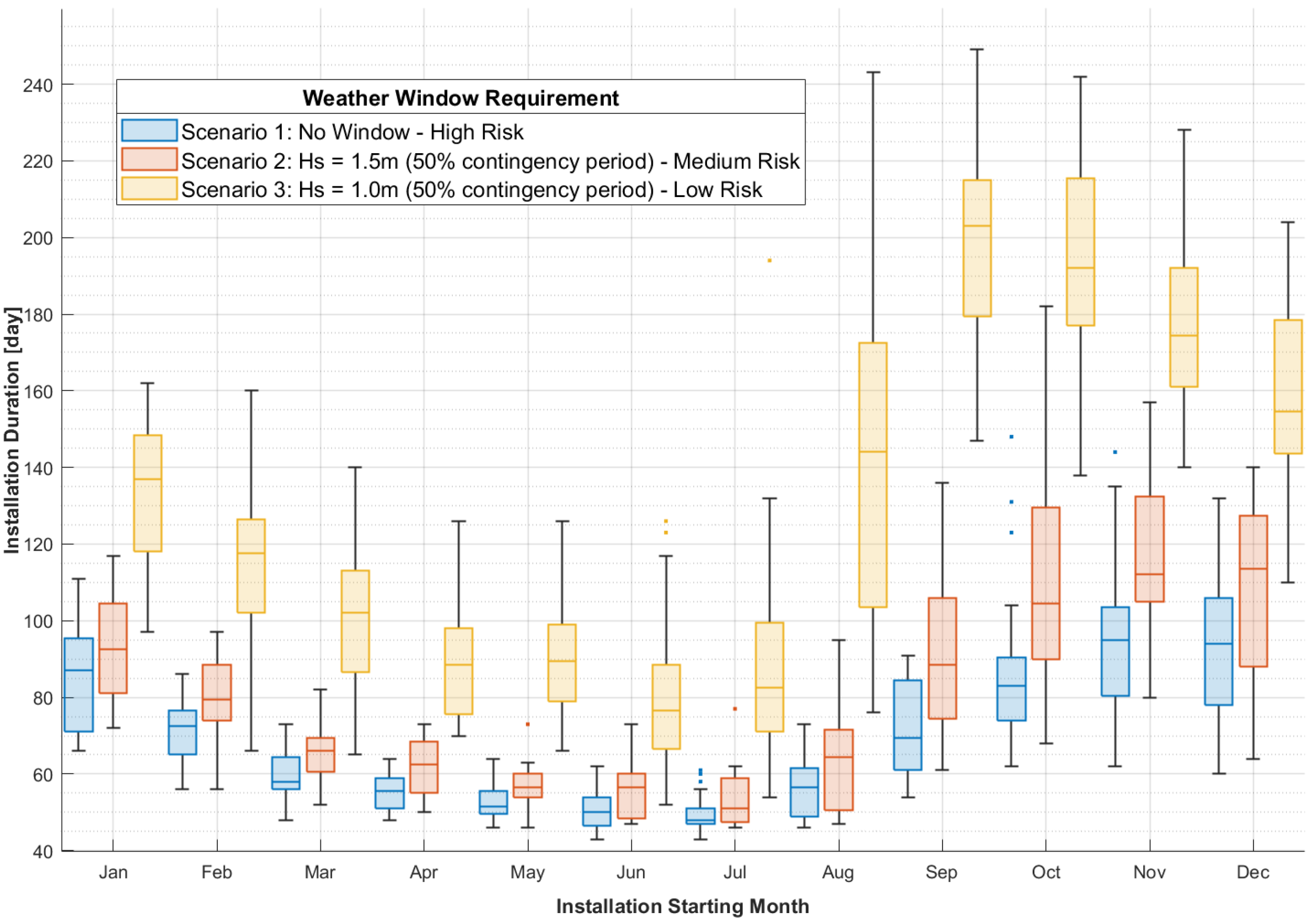

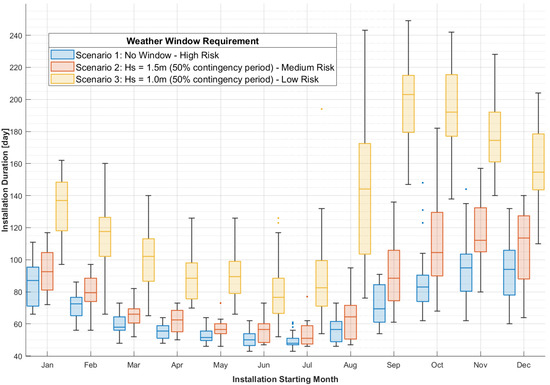

The relationship between the installation duration and the campaign starting month for the three different scenarios is illustrated in Figure 9. Each boxplot represents the statistical analysis of 20 simulation results, each generated using identical inputs but distinct wave data collected from 1996 to 2015 (as defined in Section 2.2). The resulting variability due to weather uncertainty is depicted in the boxplot, which shows the first quartile (bottom of the box), median (middle line), the third quartile (top of the box), minimum and maximum excluding outliers (lower and upper whiskers), and outliers (dots). Specifically speaking, outliers are defined as data points that deviate more than 1.5 times the interquartile range (i.e., the difference between the third and the first quartile) above the first or below the third quartile. The definition of outliers aims to reduce the bias in the statistical measures and ensure that they are not skewed by infrequent extreme events.

Figure 9.

Installation duration under different starting months for the 3 scenarios. Each start month per scenario is simulated using 20 different years of weather data, where its statistical analysis is represented by a boxplot using different colors representing the different scenarios. Each scenario represents a distinct risk management policy as defined in Table 1.

In total, 12 boxplots are generated for each scenario to characterize the installation duration trend across 12 different possible campaign start months. The first day of each month is simulated to represent the corresponding month. Additionally, results for the three scenarios are compared, with Scenarios 1, 2 and 3 representing progressively more conservative operational risk management policies, as defined previously in Section 2.

3.1. Seasonal Influence on Installation Duration

The results reveal substantial variability in installation duration depending on the campaign starting month. For instance, in Scenario 1, the duration ranges from 50 days in July to 96 days in November. On average, campaigns initiated during autumn and winter (September to February) experience durations 160% longer than those beginning in spring and summer (March to August). The interquartile range during the winter months is also approximately 200% wider, indicating greater uncertainty and operational risk.

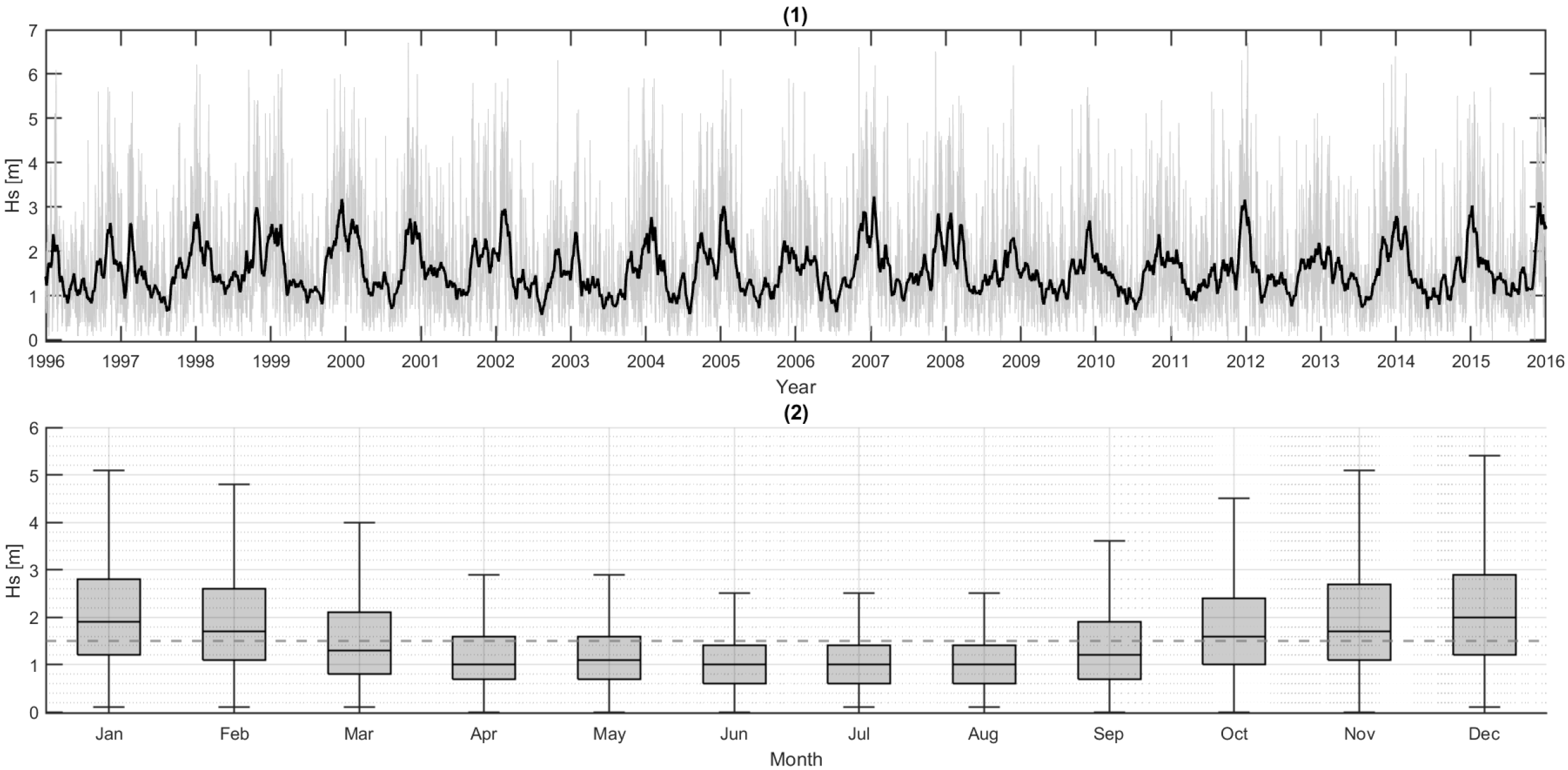

This variation reflects the pronounced impact of seasonal wave conditions on marine operations. Figure 10 illustrates the variability of significant wave height at the site throughout the year. Notably, harsher wave conditions are observed during winter months between October and February, explaining the seasonal sensitivity of the installation campaign duration (Figure 9). For example, the drastic +70% increase in the median installation duration of Scenario 3 between July and August is explained by the low probability of finding weather windows with significant wave height (Hs) lower than 1 m in the months of October, November, and December where the median Hs exceeds 1.5 m. Although this study isolates wave conditions as the sole environmental driver, it is important to note that other real-world factors, such as vessel availability and crew scheduling, may amplify seasonal effects and introduce additional logistical constraints.

Figure 10.

Site-specific Hs data for the years 1996 to 2015 collected from the North Sea Wave Database [33]. (1) The hourly time series is sketched in gray with the daily moving average marked in black. (2) Monthly variation in Hs, where each boxplot represents statistical analysis from 20 years of data. Outliers are excluded from the boxplots. The dashed line represents the Hs threshold of 1.5 m that is assumed for all the marine operational activities.

3.2. Impact of Risk Management Policies

Table 2 presents a comparison of average installation durations across the three scenarios, each reflecting a different risk management policy. As anticipated, stricter policies correspond to longer installation durations. Scenario 1 (least stringent) results in an average of 70 days, Scenario 2 in 80 days, and Scenario 3 (most stringent) in 130 days. Notably, the relationship between policy stringency and installation duration is nonlinear. Introducing 50% contingency weather windows with an Hs threshold of 1.5 m (from Scenario 1 to 2) increases the duration by only approximately 10 days. In contrast, tightening the Hs threshold from 1.5 m to 1.0 m for these extended windows (from Scenario 2 to 3) results in a substantially larger increase of around 50 days. These findings highlight the critical importance of carefully calibrating wave height constraints in the definition of weather windows for effective risk management, to strike a balance between operational continuity and overall installation efficiency.

Table 2.

Average installation duration at different starting months for the three scenarios (unit: day).

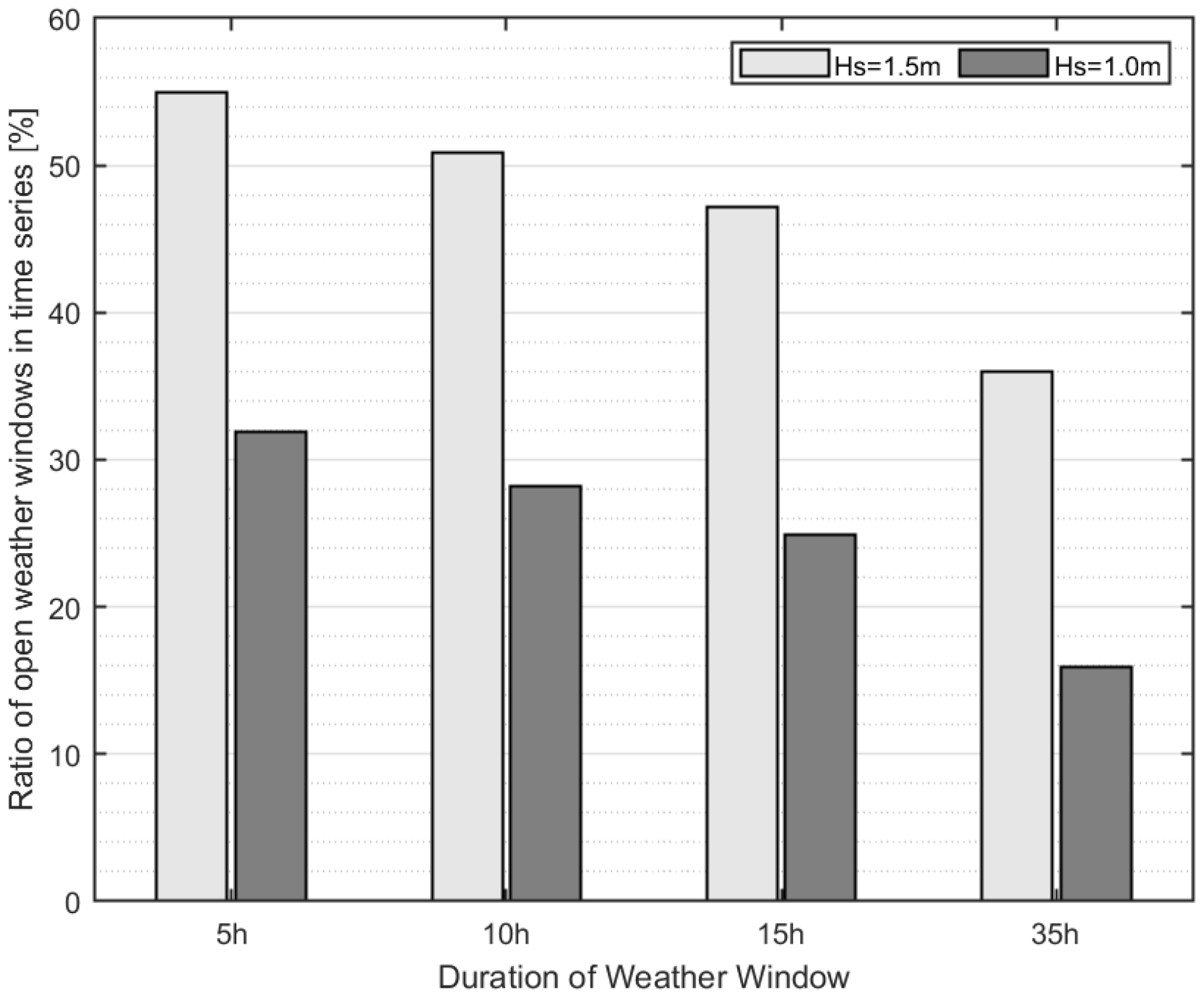

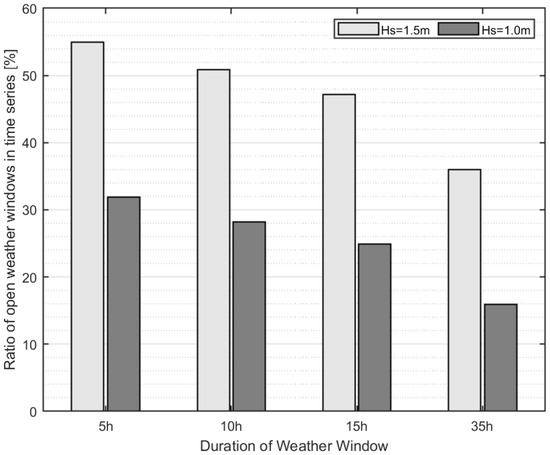

3.3. Sensitivity of Operational Windows

To better characterize the relationship between weather criteria and operational feasibility, the ratio of open weather windows is calculated and shown in Figure 11. This ratio represents the proportion of time intervals that satisfy the specified weather window criteria relative to the total number of intervals considered in the simulation. The results reveal that the Hs threshold (between 1.5 m and 1.0 m) exerts a greater influence on accessibility than the duration of the weather window, particularly for window lengths less than 35 h. For instance, increasing the window duration from 5 to 10 h at a constant Hs threshold of 1.5 m reduces the open window ratio from 55% to approximately 50%. In contrast, tightening the Hs threshold from 1.5 m to 1.0 m while keeping the window duration fixed at 5 h leads to a more pronounced reduction, from 55% to around 30%. This nonlinear relationship persists across various window lengths and explains the sharp increase in installation duration observed in Scenario 3, where the combination of a strict Hs threshold of 1.0 m and extended window requirements significantly restricts operational feasibility.

Figure 11.

Ratio of open weather windows under different weather window conditions based on a 20-year time series of site-specific weather data.

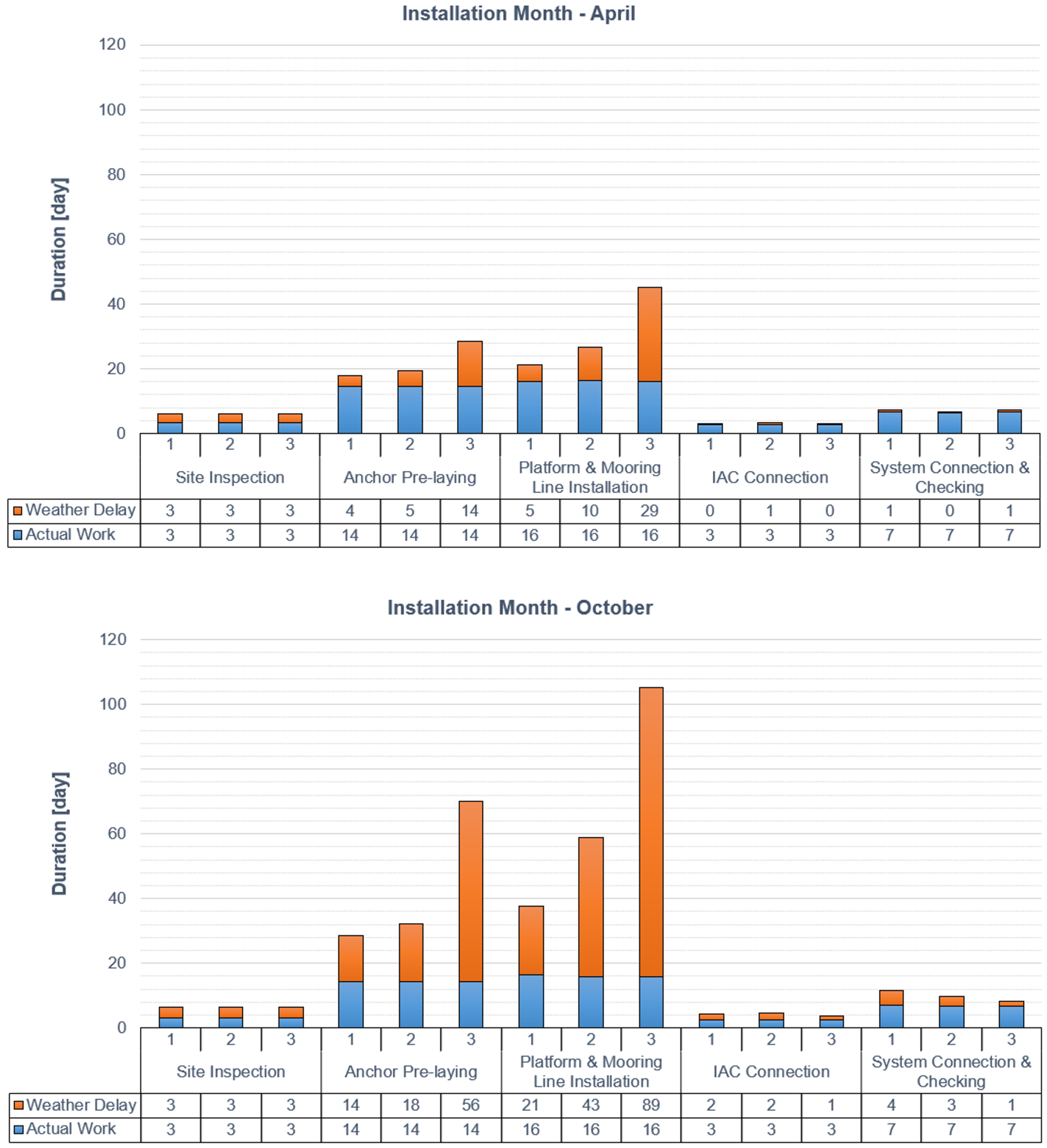

3.4. Campaign-Level Breakdown of Weather Delays

A breakdown of installation duration by campaign type is presented in Figure 12, distinguishing between weather delays and working time. April (representing moderate conditions) and October (representing harsh conditions) are selected as two representative start months. Across all scenarios and both seasons, the anchor pre-laying and platform and mooring line installation campaigns consistently account for the majority of weather delays, contributing over 75% of the total. This concentration is attributable to the complex and interdependent nature of operations within these campaigns (as discussed in Section 2.5). For instance, the platform and mooring line installation involves numerous sequential and interdependent tasks that must be executed continuously to ensure safe operation, all governed by restrictive Hs thresholds of 1.5–2.0 m. The cumulative impact of weather-induced interruptions across these tightly coupled steps leads to extended campaign durations.

Figure 12.

Breakdown of the duration for each installation campaign for the three scenarios. The bar from left to right for each campaign refers to Scenarios 1, 2 and 3, respectively.

These two campaigns also exhibit the strongest sensitivity to risk management policies. In April, for example, the total weather delay for these campaigns increases from 9 days in Scenario 1 to 15 days in Scenario 2 and 43 days in Scenario 3. In contrast, all other campaigns experience relatively stable delays of approximately 4 days, regardless of scenario. This indicates that the effects of tightening weather windows are not evenly distributed, but rather concentrated in campaigns with high wave sensitivity and task interdependence. Under harsher wave conditions in October, delays increase even more dramatically. The weather delay associated with these two campaigns grows from 35 days in Scenario 1 to 61 days in Scenario 2 and 145 days in Scenario 3. These results confirm that both seasonal conditions and risk policy stringency can amplify operational delays, particularly for those wave-sensitive tasks in the anchor pre-laying and platform and mooring line installation campaigns.

In conclusion, the concentration of weather delays in these two campaigns underscores the importance of carefully tailored risk management policies that specifically address weather-sensitive operations. To mitigate these delays, future installation strategies or technologies should aim to achieve the following:

- Accelerate working speed to reduce the overall duration of operational sequences.

- Minimize interdependencies between sequential tasks.

- Loosen weather constraints for critical steps where safety permits.

3.5. Reflection of Impact on Cost

Although this study does not present a cost analysis due to the sensitivity of proprietary project-specific cost structures, the modeled installation durations clearly suggest significant implications for the project economics. In particular, weather-induced delays can substantially increase installation-related capital expenditures (CAPEX), especially in offshore projects where vessel chartering and operational standby costs are high. These delays not only increase direct installation costs but can also contribute to broader schedule overruns, potentially affecting financing terms and project returns by delaying revenues from electricity generation, and increasing health and safety risks due to longer time spent offshore.

Given that installation logistics are highly sensitive to weather conditions, and the cost of marine operations is both time-dependent and site-specific, these factors should be explicitly considered during early-stage design and planning. As installation costs are paid before the project starts generating revenues and complex offshore operations involving personnel (as well as expensive equipment) are a major risk factor for new technology projects like OFPV, the elements addressed in this study are expected to affect the bankability of an OFPV project, resulting in a high impact on its LCOE. Therefore, it is recommended that design iterations incorporate sufficiently detailed installation CAPEX modeling (including weather-contingent logistics), to enable more accurate and risk-aware financial projections for OFPV development.

While a full cost–benefit analysis lies beyond the scope of this work, evaluating the impact of installation CAPEX on the LCOE of an OFPV project is deemed a priority for future work. Similarly, a quantitative assessment of the cost–benefit profile of integrating site-specific installation modeling activities with different fidelity levels in OFPV design iterations would be a valuable thread for future research.

Finally, due to the highly sensitive nature of cost data, especially in this early stage of OFPV technology development where commercial viability is still under investigation, the definition of open-access reference OFPV designs similar to those developed for offshore wind (e.g., [34,35]) is deemed highly beneficial to enable independent cost assessments to be performed and included in studies like the present one.

4. Conclusions

This study has demonstrated a methodology using the discrete-event simulation (DES) approach to quantify the impacts of weather dependencies on OFPV installation campaigns, using installation duration as a key performance indicator (KPI). A case study is presented involving a 5 MWp truss-type OFPV plant, proposed for installation at a North Sea location approximately 50–70 km from the Port of IJmuiden. Hindcast wave data spanning 20 years is utilized for multiple simulations to characterize the uncertainty of results introduced by the variability of weather conditions every year. Additionally, three scenarios are compared, with Scenarios 1 to 3 representing increasingly stringent risk management policies, using progressively stricter significant wave height (Hs) criteria for defining contingency periods.

By simulating across different campaign start months, the study highlights that the timing of when the campaigns are initiated significantly impacts the resulting installation duration. Campaigns starting in the months with harsher wave conditions, where the Hs operational threshold is more likely to be exceeded, result in more delays and thereby prolonged installation duration. In Scenario 1, where the least stringent risk management policy is deployed, the shortest installation duration is 50 days with a start month of July, while the longest duration is as long as 96 days with a start month of November. This variability of installation duration with different start months also underscores the susceptibility of OFPV installation to wave conditions. On average, across all the scenarios, the installation duration in the autumn and winter period (from September to February) is 160% longer than the spring and summer period (from March to August).

In this study, a few tasks that must be performed in sequence and without interruption are identified. Any interruption between these activities can potentially cause unforeseen operational risks (e.g., incomplete mooring of a sub-assembly). To mitigate these risks, extended weather windows are applied to ensure that favorable weather conditions persist across the sequence of operations, achieving continuity between the tasks. In Scenario 1, only individual weather windows are used for each task. In contrast, Scenarios 2 and 3 utilize extended weather windows covering multiple interdependent tasks, with Hs thresholds of 1.5 m and 1.0 m, respectively. Comparing the three scenarios, it is found that the installation duration, averaged across 12 start months, is 70, 80 and 130 days for Scenarios 1 to 3, respectively. This result outlines the additional installation duration required to mitigate the operational risks. Moreover, it is found that the difference between Scenarios 3 and 2 (e.g., 50 days) is much greater than that between Scenarios 2 and 1 (e.g., 10 days). This effect highlights the sensitivity of weather window availability to the Hs threshold, particularly when it falls between 1.0 and 1.5 m. Accordingly, the advancement in installation methods, equipment, or OFPV designs that enables operational threshold further below an Hs of 1.5 m is anticipated to enhance the operational efficiency significantly.

The analysis also indicates that weather-induced delays are primarily associated with the anchor pre-laying and platform and mooring line installation campaigns. For instance, in April, these two campaigns account for 75%, 80%, and 90% of weather delays for Scenarios 1 to 3, respectively. This substantial proportion of delays arises from the wave-sensitive and complex nature of tasks involved, such as towing, maneuvering, and coupling platforms. Furthermore, weather delays in these two campaigns demonstrate a heightened sensitivity to risk management policies compared to the other campaigns. In April, for example, these two campaigns experience weather delays of 9, 15, and 43 days in Scenarios 1, 2, and 3, respectively, while overall delays from the other campaigns remain constant at 4 days across all the scenarios. This finding highlights that operational risks associated with task discontinuities are largely concentrated in these two campaigns. It is important to highlight that while stricter weather windows could help mitigate such risks, an overly conservative approach may also introduce unnecessary delays.

5. Future Work

To the best of the authors’ knowledge, this is the first published work addressing the logistical challenges associated with the offshore installation of a large OFPV plant. The logistics strategy considered in the analysis is an early design based on 2023 knowledge levels that provides valuable insights into the time impact of the different campaigns required for the installation of a 5MW elevated truss-type OFPV plant. Due to the nascent stage of OFPV technology, installation strategies are expected to offer ample room for optimization. The insights gained in this study shall be used to steer future research and development activities aimed at optimizing installation plans and procedures to ultimately reduce project risks, duration and costs.

As large windows are required for the intermediate steps until completion of the full hexagon, future work should consider the survivability limits of the plant’s sub-assemblies to ensure that the installation is “offshore-proof” after each intermediate step. In fact, the time aspect of activities such as maritime handling, additional mooring, etc., has a relevant influence on the weather risks associated with incomplete hexagons and should be taken into account. Expanding on this study’s findings, where a single 5 MWp OFPV plant is modeled, future research should focus on optimizing installation strategies for large-scale OFPV farms. Simulations should explore both parallel and sequential installation of multiple OFPV units to assess potential economies of scale and logistical efficiencies. Additionally, investigating installation strategies for hybrid renewable energy systems, such as those incorporating offshore wind farms, presents a promising but unexplored research area. Given the shared logistical requirements, including vessels, technicians, and operational bases, coordinated installation campaigns could potentially improve logistical efficiency by optimizing vessel and resource allocation. Furthermore, a comprehensive cost–benefit analysis, taking into account both direct installation costs and asset downtime losses due to late commissioning, is essential to strike an optimal balance between time and cost efficiency. Finally, applying the methodology to assess diverse OFPV designs and geographical regions with varying wave conditions would provide valuable insights into installation strategies adapted to specific environmental contexts.

From a broader perspective, the authors would like to stress the need for generic open-access reference OFPV designs (including high-level installation logistics) to work around the commercial sensitivity of design-specific cost data that prevents the evaluation of OFPV installation CAPEX and the quantification of its expected impact on the LCOE.

Author Contributions

L.-J.H. set up the model, conducted the discrete-event simulations, prepared the initial manuscript draft, and revised the manuscript based on reviewers’ feedback. S.M. reviewed the model setup and outputs, supported L.-J.H. in reviewing, debugging, and interpreting interim results, and edited the manuscript by providing critical feedback and suggestions for improvement. M.d.J. reviewed and provided feedback on the initial manuscript draft. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been supported by the Top Sector Energy subsidy for energy innovation Demonstratie Energie- en Klimaatinnovatie (DEI+) from the Dutch Ministerie van Klimaat en Groene Groei.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Access to the data presented in this work may be granted upon request.

Acknowledgments

The authors acknowledge the Dutch Ministerie van Klimaat en Groene Groei for supporting this study as part of the DEI+ Pilot Merganser project Task 1.2.4. A special acknowledgment also goes to the consortium partner and project coordinator SolarDuck for their active involvement in the definition of this case study and the thorough review of this manuscript.

Conflicts of Interest

None of the authors has any competing interests.

Abbreviations

| AHT | Anchor-handling tug |

| CLV | Cable-laying vessel |

| CTV | Crew transfer vessel |

| DES | Discrete-event simulation |

| IAC | Inter-array cable |

| KPI | Key performance indicator |

| LCOE | Levelized cost of electricity |

| MV | Multicat vessel |

| OFPV | Offshore floating photovoltaic |

| O&M | Operation and maintenance |

| TRL | Technology readiness level |

| TB | Two tugboat |

Appendix A

This appendix outlines the method statement input format as well as the main assumptions used in the modeling of the OFPV installation campaign. A method statement consists of a sequence of operational steps, each defined by its duration referred to as the planned operation period () in [32], maximum allowable Hs limit, and a reserved weather window equal to the operation reference period () defined in [32]. Table A1 depicts the standard format of the method statement input used to define every offshore campaign simulated.

Table A1.

Example of a basic and generic method statement input table.

Table A1.

Example of a basic and generic method statement input table.

| ID | Operational Step | Duration () [h] | Max Hs [m] | Weather Window () [h] |

|---|---|---|---|---|

| 1-1 | Mobilize vessel | 24 | - | - |

| 1-2 | Load technicians on vessel at port | 1 | - | - |

| 1-3 | Vessel travels to site | (calculated) 1 | 2.0 | 1.5 |

| 1-4 | Work 2 | 1.5 | 1.5 | |

| 1-5 | Vessel travels back to port | (calculated) 1 | 2.0 | 1.5 |

| 1-6 | Unload technicians at port | 1 | - | - |

| 1-7 | Demobilize survey vessel | 24 | - | - |

1 transit durations are calculated based on travel distance and vessel cruise speed. 2 may consist of multiple sub-steps with their own weather limits depending on the operation (e.g., deck operations, load technicians on OFPV, etc.).

The following general assumptions have been made when defining the method statement of every simulated campaign:

- The vessel (any kind) traveling step is limited by an Hs of 2.0 m.

- The marine operational step is limited by an Hs of 1.5 m.

- The CTV personnel transferring step is limited by an Hs of 1.5 m, while the wave direction and period were neglected in this analysis.

- A weather window with a 50% margin is reserved for the step that has an Hs limit.

- The duration of vessel mobilization or demobilization is 24 h.

- The duration of technician loading or unloading is 1 h.

- The vessel traveling time is calculated based on distance and the average speed of the vessel.

- The survivability of the intermediate installations of platform sets is assumed to be sufficiently high, allowing the overarching weather window for the entire towing and coupling campaign to be neglected. However, the OFPV platform can only withstand design Hs conditions after the full hexagonal configuration is established, which necessitates identifying a sufficiently large weather window across the whole operation. Given that the towing and assembly campaign spans approximately 10 days, approaching the reliability limits of weather forecasts, contingency measures are essential to mitigate the risk of unexpected harsh weather conditions, such as storms, during real-world operation.

References

- International Renewable Energy Agency. Renewable Power Generation Costs in 2022. 2023. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2023/Aug/IRENA_Renewable_power_generation_costs_in_2022.pdf (accessed on 29 July 2025).

- International Energy Agency Photovoltaic Power Systems Programme. Snapshot of Global PV Markets 2024. 2024. Available online: https://iea-pvps.org/wp-content/uploads/2024/04/Snapshot-of-Global-PV-Markets-1.pdf (accessed on 29 July 2025).

- DNV. Energy Transition Outlook 2023. 2023. Available online: https://www.dnv.com/energy-transition-outlook/download (accessed on 29 July 2025).

- SolarPower Europe. Global Market Outlook for Solar Power 2023–2027. 2023. Available online: https://www.solarpowereurope.org/insights/outlooks/global-market-outlook-for-solar-power-2023-2027/detail (accessed on 29 July 2025).

- Solar Energy UK. Why Are Solar PV Panels Getting Bigger? Solar Energy UK. 2021. Available online: https://solarenergyuk.org/why-are-solar-pv-panels-getting-bigger/ (accessed on 29 July 2025).

- Bhambhani, A. Netherlands Discussing Space for Solar PV. Taiyang News. 2023. Available online: https://taiyangnews.info/markets/netherlands-discussing-space-for-solar-pv (accessed on 29 July 2025).

- Huang, G.; Tang, Y.; Chen, X.; Chen, M.; Jiang, Y. A comprehensive review of floating solar plants and potentials for offshore applications. J. Mar. Sci. Eng. 2023, 11, 2064. [Google Scholar] [CrossRef]

- Silalahi, D.F.; Blakers, A. Global atlas of marine floating solar PV potential. Solar 2023, 3, 416–433. [Google Scholar] [CrossRef]

- Pérez-Collazo, C.; Greaves, D.; Iglesias, G. A review of combined wave and offshore wind energy. Renew. Sustain. Energy Rev. 2015, 42, 141–153. [Google Scholar] [CrossRef]

- Zheng, X.; Zheng, H.; Lei, Y.; Li, Y.; Li, W. An offshore floating wind–solar–aquaculture system: Concept design and extreme response in survival conditions. Energies 2020, 13, 604. [Google Scholar] [CrossRef]

- López, M.; Rodríguez, N.; Iglesias, G. Combined floating offshore wind and solar PV. J. Mar. Sci. Eng. 2020, 8, 576. [Google Scholar] [CrossRef]

- Liu, G.; Guo, J.; Peng, H.; Ping, H.; Ma, Q. Review of recent offshore floating photovoltaic systems. J. Mar. Sci. Eng. 2024, 12, 1942. [Google Scholar] [CrossRef]

- Oliveira-Pinto, S.; Stokkermans, J. Marine floating solar plants: An overview of potential, challenges and feasibility. Proc. Inst. Civ. Eng.-Marit. Eng. 2020, 173, 120–135. [Google Scholar] [CrossRef]

- Oceans of Energy. North Sea 1. 2020. Available online: https://oceansofenergy.blue/north-sea-1/ (accessed on 29 July 2025).

- SolarDuck. Merganser Pilot. 2024. Available online: https://solarduck.tech/merganser-pilot/ (accessed on 29 July 2025).

- Ocean Sun. Kyrholmen Project. 2018. Available online: https://oceansun.no/project/kyrholmen/ (accessed on 29 July 2025).

- Steitz, C. Dutch Developer Secures Funds for Flexible Floating Solar Pilot in North Sea. PV Magazine. 2022. Available online: https://www.pv-magazine.com/2022/12/02/dutch-developer-secures-funds-for-flexible-floating-solar-pilot-in-north-sea/ (accessed on 29 July 2025).

- Stolk, M.J.; Lenssen, N. Challenges and Potential for Offshore Solar: An Overview of Challenges and the Potential of Offshore Floating Solar Energy Development. Zon op Water. 2022. Available online: https://zonopwater.nl/u/files/Challenges%20and%20potential%20for%20offshore%20solar%202022.pdf (accessed on 29 July 2025).

- Walpita, H.L.; Roosloot, N.; Otnes, G.; Aarseth, B.L.; Selj, J.; Nysted, V.S.; Marstein, E.S. Operation and Maintenance of Floating PV Systems: A Review. IEEE J. Photovoltaics 2025, 15, 400–415. [Google Scholar] [CrossRef]

- Cordal-Iglesias, D.; Fernández-Mira, D.; Filgueira-Vizoso, A.; Guillén-Díaz, T.; Robalo-Cabrera, I.; Alcayde, A.; Montoya, F.G.; García-Diez, A.I.; Graña-López, M.A.; Puime-Guillén, F.; et al. CAPEX and OPEX of floating offshore photovoltaic farms: The case of study of the Mediterranean area of the Iberian Peninsula. In Proceedings of the International Conference on Renewable Energies and Power Quality (ICREPQ’24), Bilbao, Spain, 26–28 June 2024; Available online: https://www.icrepq.com/icrepq24/376-24-cordal.pdf (accessed on 29 July 2025).

- World Bank Group. Where Sun Meets Water: Floating Solar Handbook for Practitioners. World Bank. 2019. Available online: https://documents1.worldbank.org/curated/en/418961572293438109/pdf/Where-Sun-Meets-Water-Floating-Solar-Handbook-for-Practitioners.pdf (accessed on 29 July 2025).

- Bai, Y.; Bai, Q. Subsea Engineering Handbook. Gulf Professional Publishing. 2012. Available online: https://www.sciencedirect.com/book/9781856176897/subsea-engineering-handbook (accessed on 29 July 2025).

- Torres, E.S.; Thies, P.R.; Lawless, M. Offshore logistics: Scenario planning and installation modeling of floating offshore wind projects. Asme Open J. Eng. 2023, 2, 021013. [Google Scholar] [CrossRef]

- Muhabie, Y.T.; Rigo, P.; Cepeda, M.; de Almeida D’Agosto, M.; Caprace, J.D. A discrete-event simulation approach to evaluate the effect of stochastic parameters on offshore wind farms assembly strategies. Ocean. Eng. 2018, 149, 279–290. [Google Scholar] [CrossRef]

- Díaz, H.; Guedes Soares, C. Approach for installation and logistics of a floating offshore wind farm. J. Mar. Sci. Eng. 2022, 11, 53. [Google Scholar] [CrossRef]

- TNO Unified Windfarm Simulation Environment. Available online: https://uwise.tno.nl/ (accessed on 29 July 2025).

- Mancini, S.; Bloothoofd, J.; Dighe, V.; van der Mijle Meijer, H. Development and verification of a discrete-event simulation tool for high-fidelity modelling of offshore wind and solar farm decommissioning campaigns. J. Phys. Conf. Ser. 2024, 2745, 012010. [Google Scholar] [CrossRef]

- Dighe, V.V.; Huang, L.J.; Montfort, J.H.; Serraris, J.J. Improving O&M Simulations by Integrating Vessel Motions for Floating Wind Farms. J. Mar. Sci. Eng. 2024, 12, 1948. [Google Scholar] [CrossRef]

- Netherlands Enterprise Agency. Hollandse Kust (West) Wind Farm Zone. 2024. Available online: https://www.noordzeeloket.nl/en/functions-and-use/offshore-wind-energy/free-passage-shared-use/hollandse-kust-west-wind-farm-zone/ (accessed on 29 July 2025).

- SolarDuck Press Release: HKW VII. Available online: https://solarduck.tech/wp-content/uploads/2022/11/SolarDuck-Press-release-HKW-VII-Nov-11-2022-v1.pdf (accessed on 29 July 2025).

- SolarDuck. SolarDuck and RWE Successfully Install Offshore Floating Solar Pilot Merganser Off Dutch Coast. 2024. Available online: https://solarduck.tech/solarduck-and-rwe-successfully-install-offshore-floating-solar-pilot-merganser-off-dutch-coast/ (accessed on 29 July 2025).

- DNV. DNV-ST-N001: Marine Operations and Marine Warranty. Det Norske Veritas (DNV). 2021. Available online: https://www.dnv.com/energy/standards-guidelines/dnv-st-n001-marine-operations-and-marine-warranty/ (accessed on 29 July 2025).

- North Sea Wave Database. Available online: https://zenodo.org/records/3773256 (accessed on 29 July 2025).

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development (No. NREL/TP-500-38060); National Renewable Energy Lab.(NREL): Golden, CO, USA, 2009; Available online: https://docs.nrel.gov/docs/fy09osti/38060.pdf (accessed on 29 July 2025).

- Gaertner, E.; Rinker, J.; Sethuraman, L.; Zahle, F.; Anderson, B.; Barter, G.; Abbas, N.; Meng, F.; Bortolotti, P.; Skrzypinski, W.; et al. Definition of the IEA 15-Megawatt Offshore Reference Wind Turbine. Available online: https://www.nrel.gov/docs/fy20osti/75698.pdf (accessed on 29 July 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).