Force Element Analysis of Vortex-Induced Vibration Mechanism of Three Side-by-Side Cylinders at Low Reynolds Number

Abstract

1. Introduction

2. Computational Setup and Formulation

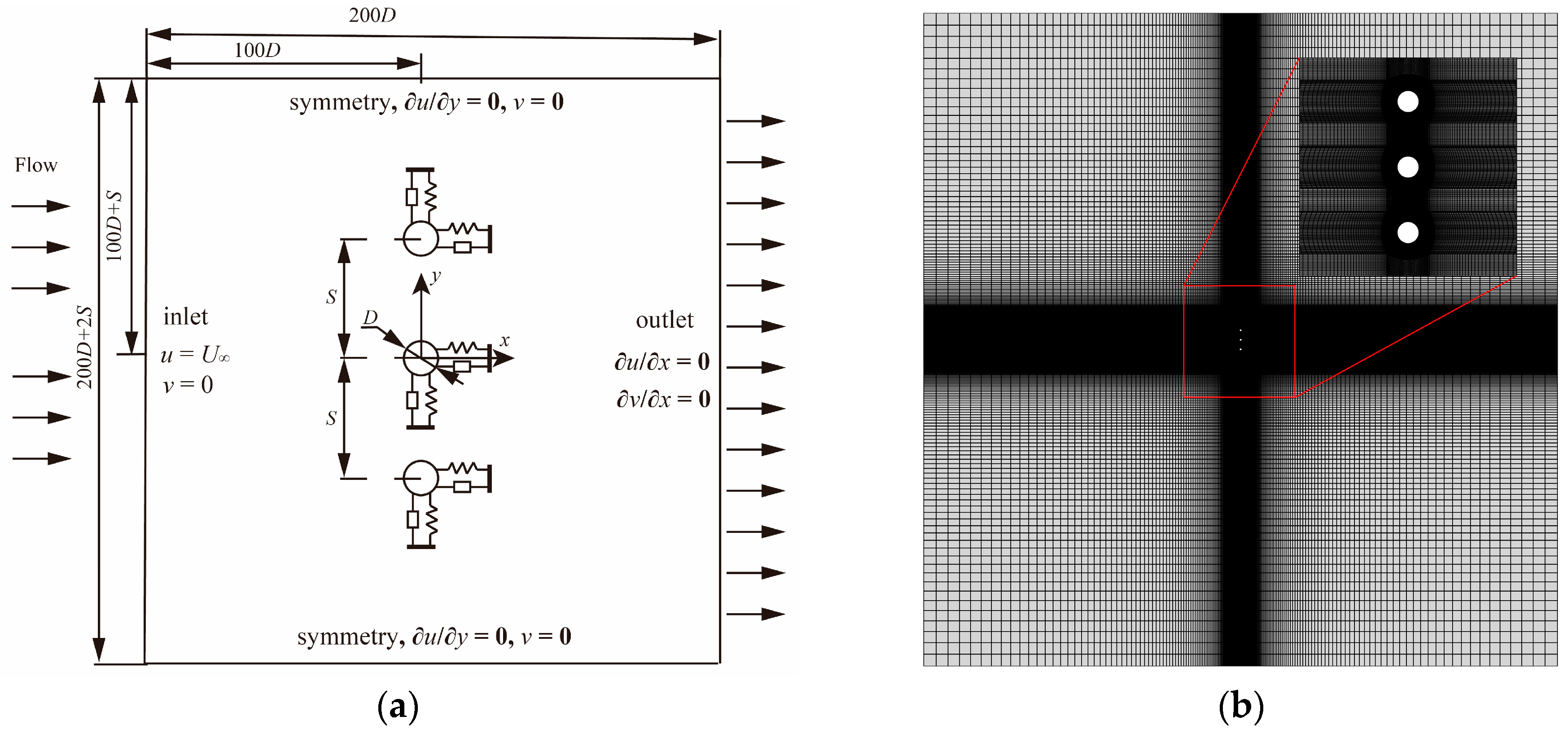

2.1. Physical Model

2.2. Numerical Methods

2.2.1. Governing Equations

2.2.2. Force Element Formula

2.2.3. Vibration Governing Equations

2.3. Independence Verification

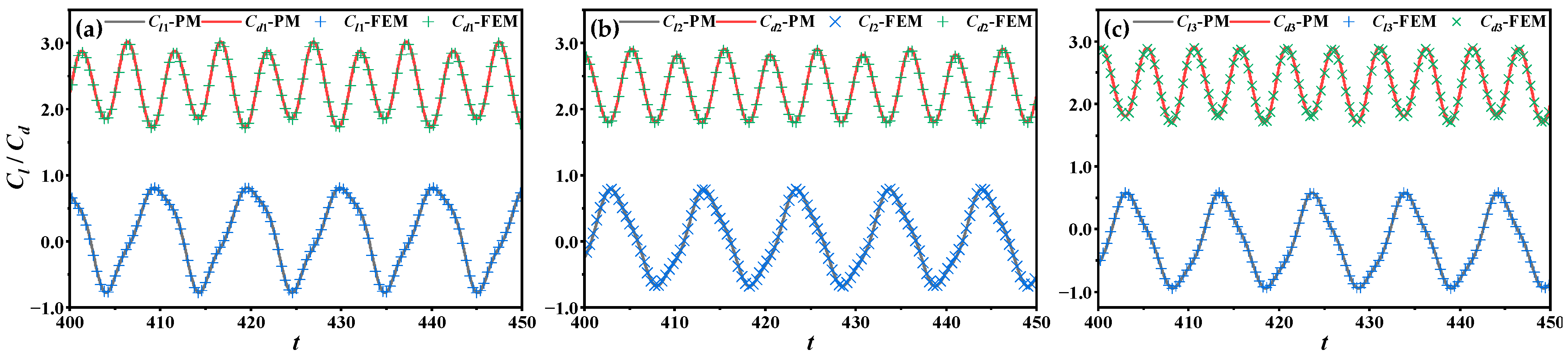

2.3.1. Method Validation

2.3.2. Grid and Time-Step Independence Verification

3. Results and Discussions

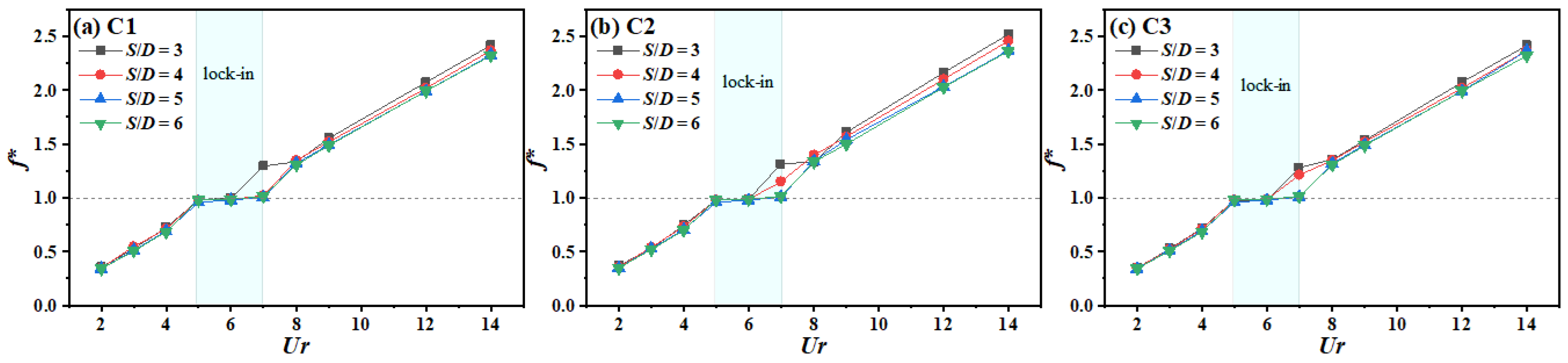

3.1. Frequency and Amplitude Response Analysis

3.1.1. Frequency Response

3.1.2. Amplitude Response

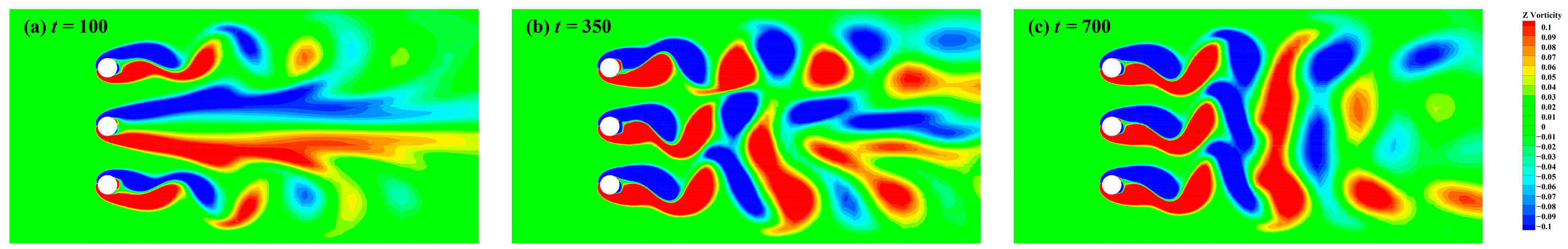

3.2. Wake Characteristic Analysis

3.2.1. Steady-State Evolution Mode

- Tri-stage (I) (TS(I))

- Bi-Stage (BS)

- Tri-Stage (II) (TS(II))

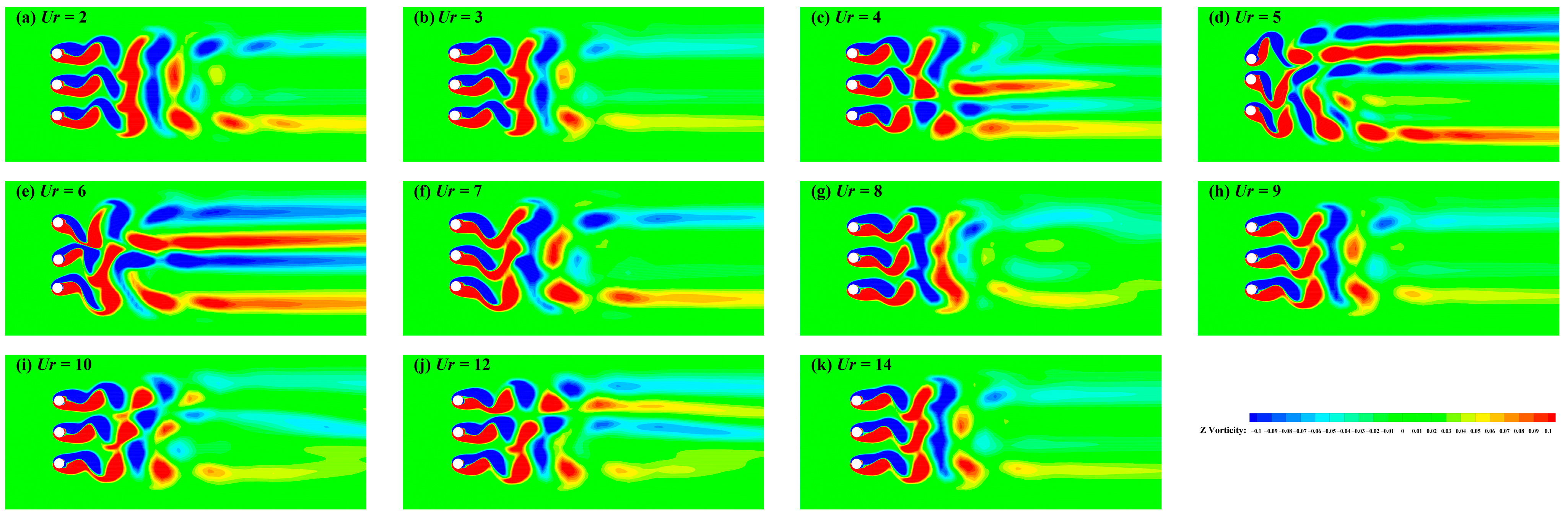

3.2.2. Wake Patterns at S/D = 3

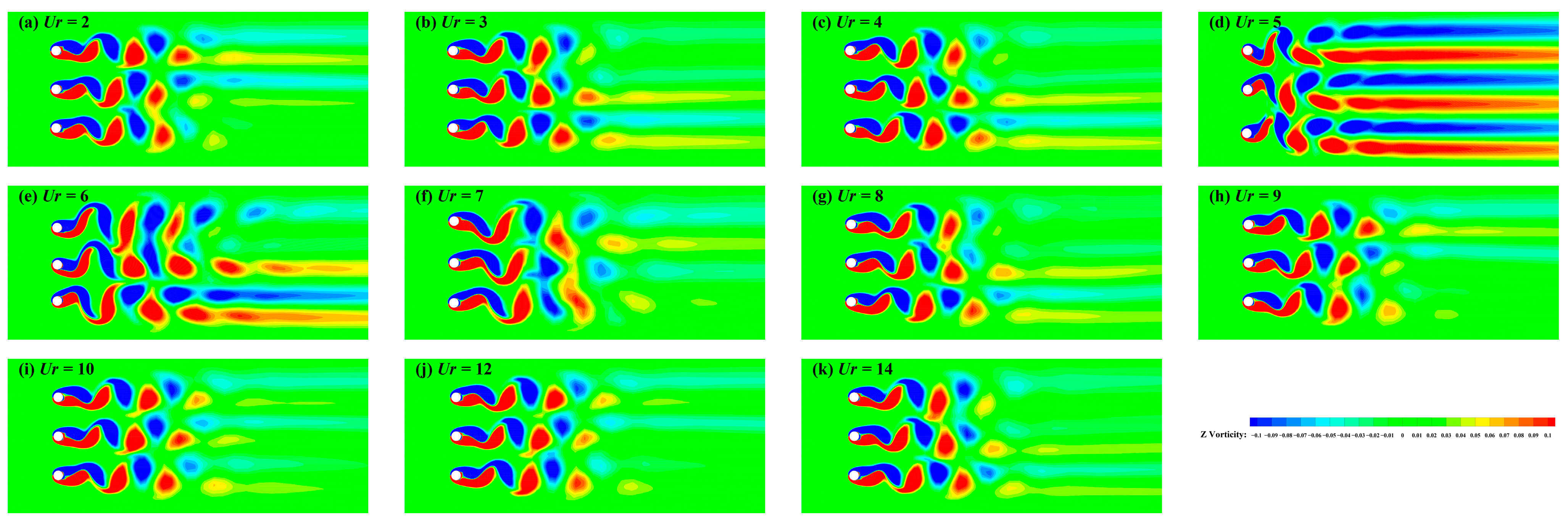

3.2.3. Wake Patterns at S/D = 4

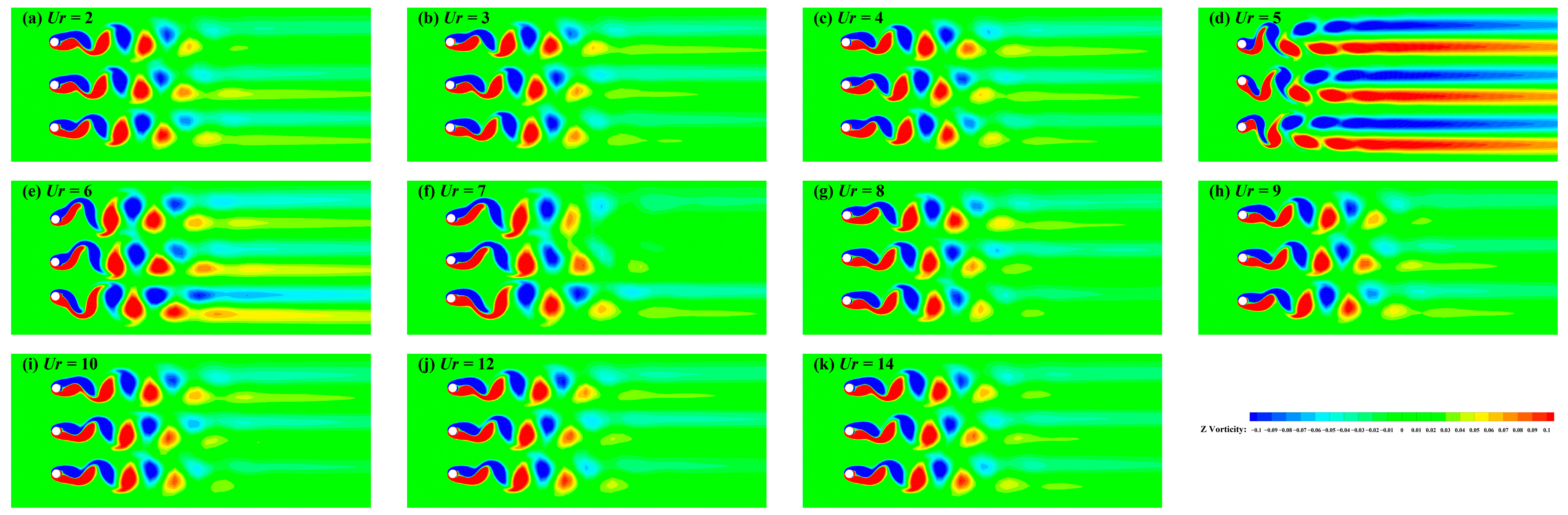

3.2.4. Wake Patterns at S/D = 5

3.2.5. Wake Patterns at S/D = 6

3.2.6. Wake Patterns Conclusions

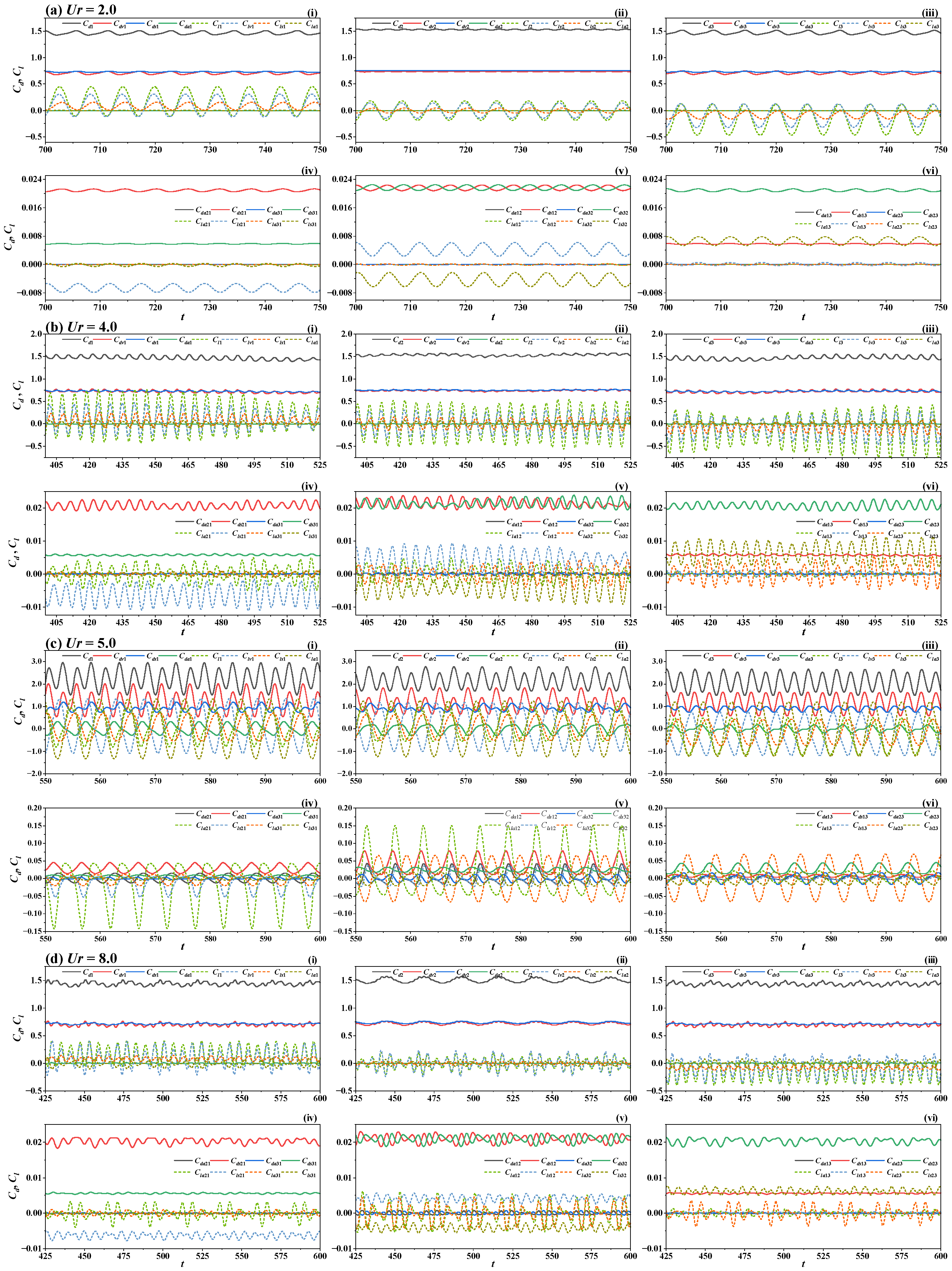

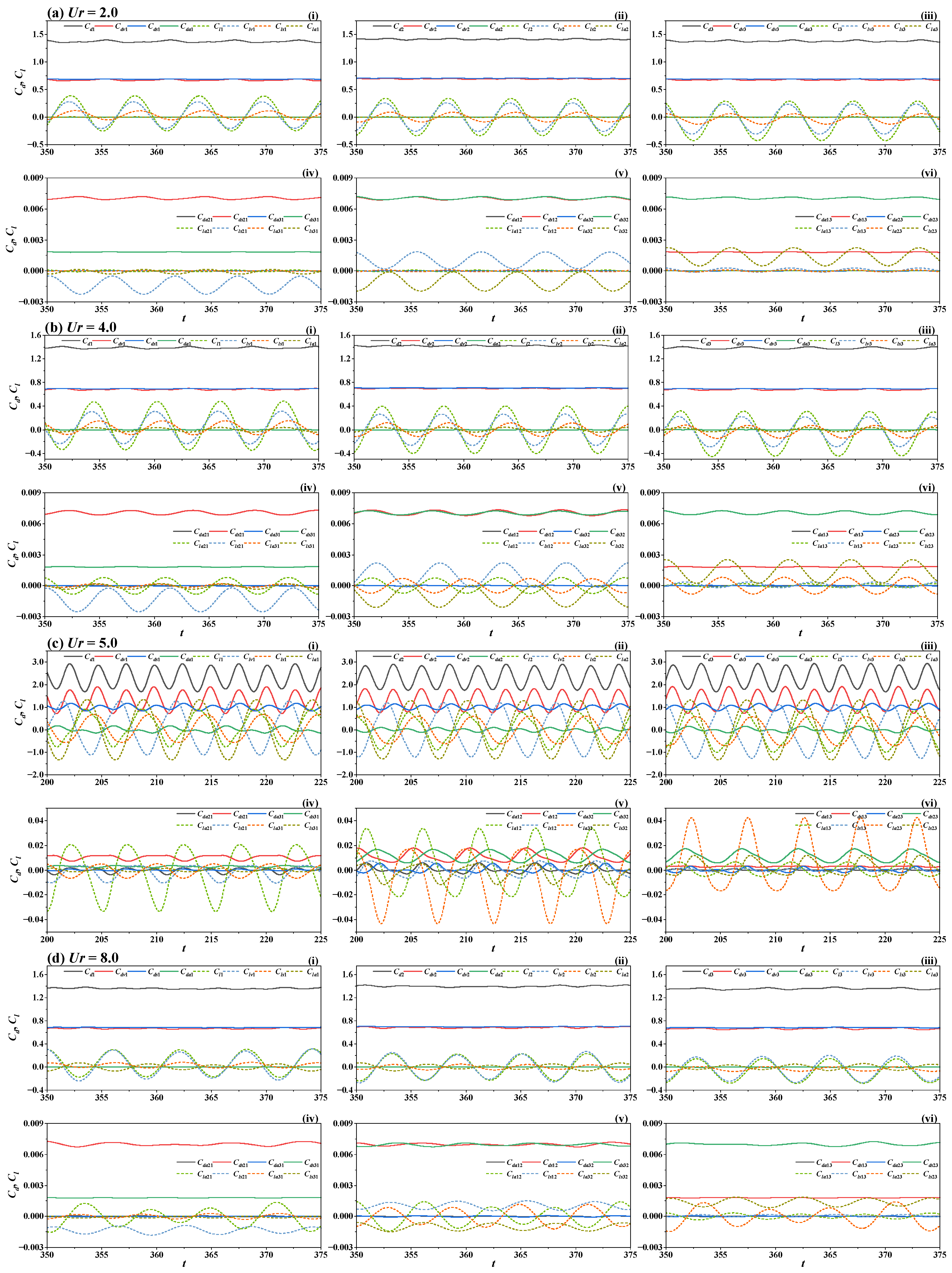

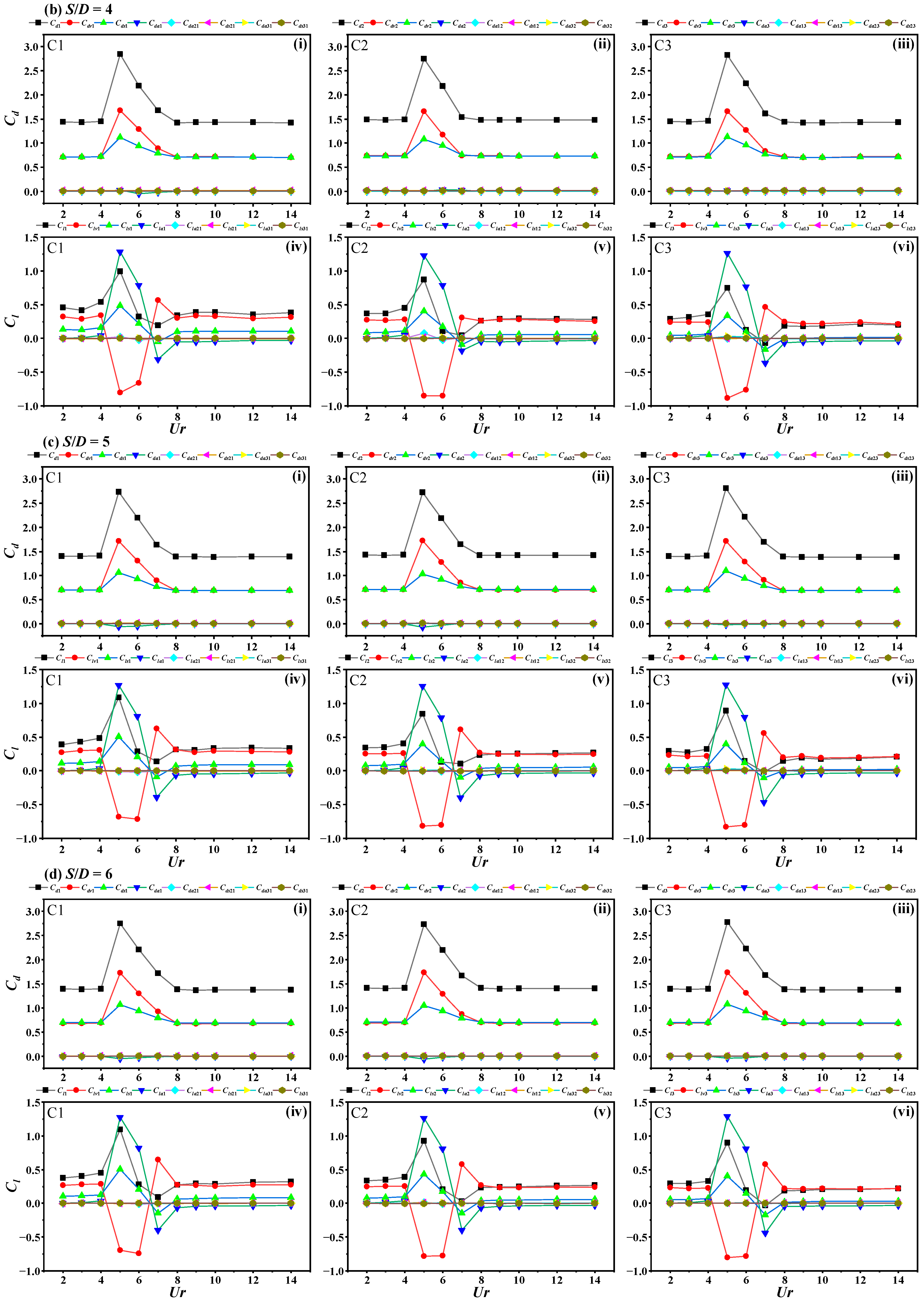

3.3. Hydrodynamic Coefficients Analysis

3.3.1. Hydrodynamic Analysis at S/D = 3

3.3.2. Hydrodynamic Analysis at S/D = 4

3.3.3. Hydrodynamic Analysis at S/D = 5

3.3.4. Hydrodynamic Analysis at S/D = 6

3.3.5. Force Contribution Analysis

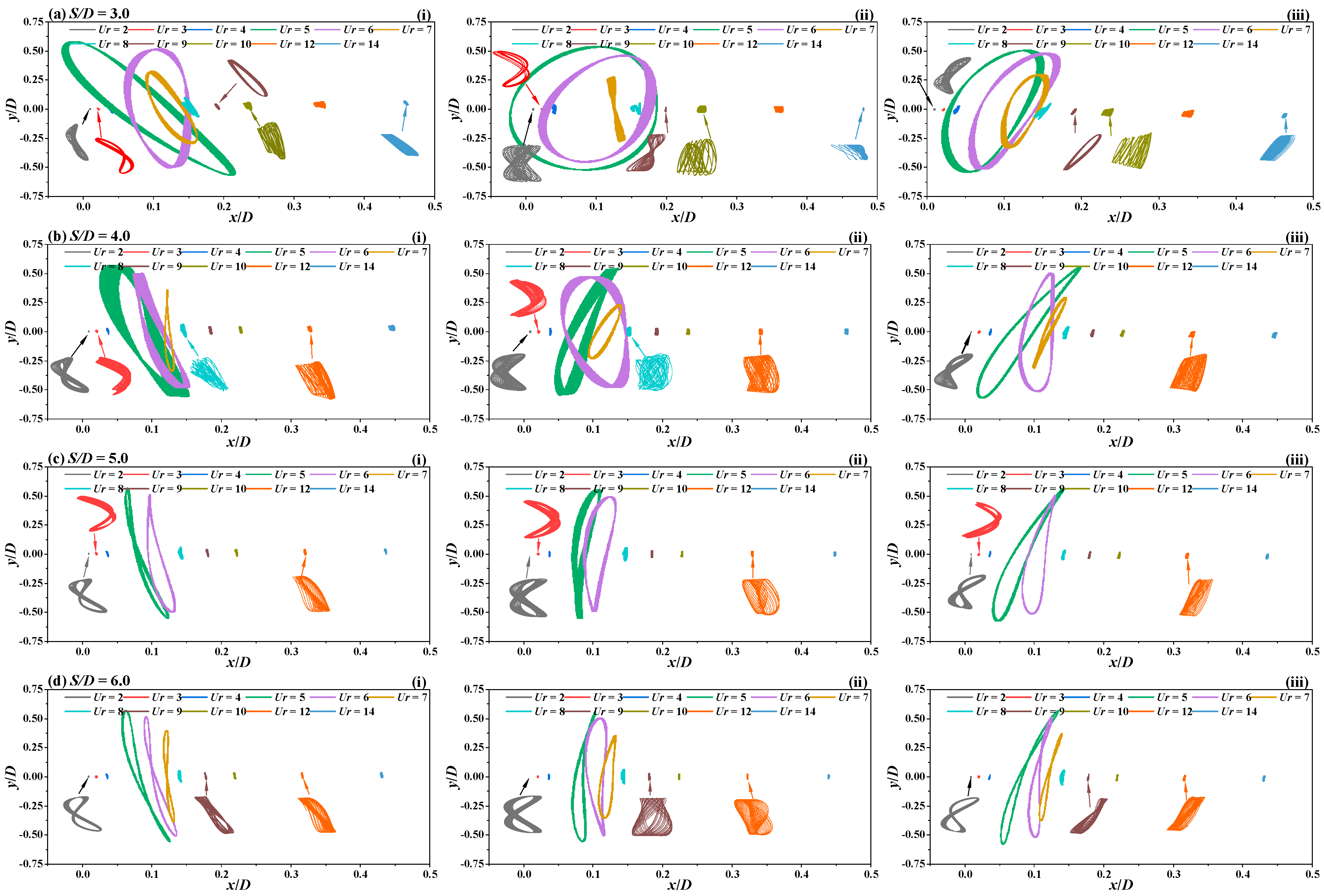

3.4. Motion Trajectory Analysis

3.4.1. Motion Trajectory Modes

3.4.2. Comprehensive Analysis of Motion Trajectories

4. Conclusions

- The excitation phenomenon of cylinders at different spacing ratios exhibits three vibration regions. A “pseudo-lock-in” phenomenon occurs at S/D = 3 and Ur = 7. As the spacing ratio increases, inter-cylinder interferences weaken, and the “lock-in” region broadens. On the initial branch (IB) and desynchronization region (DB), the amplitudes of cylinders are small. Cylinders are significantly influenced by contributions from the volume vorticity force and surface vorticity force in the flow field. When approaching the “lock-in” region (near Ur = 4), the surface acceleration force increases substantially, amplifying vibration amplitudes and significantly enhancing the interaction forces on the adjacent cylinders. Concurrently, phase differences (phase shifts) emerge among the lift and drag force components, accompanied by a “multi-frequency” phenomenon, leading to irregular and disordered motion trajectories. Within the “lock-in” region, cross-flow vibration responses intensify. The surface acceleration force and volume vorticity force dominate with comparable magnitudes but opposite phases. Inter-cylinder interactions are primarily governed by the surface acceleration forces of adjacent cylinders. Here, the “multi-frequency” behavior in lift/drag coefficients diminishes, exhibiting distinct periodic variations, and cylinder motion trajectories become stable and regular.

- Compared to two side-by-side cylinders, the wake patterns of three side-by-side cylinders are mainly categorized into four types. Overall, wake patterns are dominated by in-phase asynchronous (IA) and out-of-phase asynchronous (OA). At smaller spacings, in-phase asynchronous (IA) and in-phase synchronous (IS) prevail. As the spacing ratio increases, vortex shedding is primarily governed by in-phase synchronous (IS) and out-of-phase synchronous (OS). At S/D = 3, mutual interference between cylinders’ wakes is intense, resulting in four distinct wake patterns across different Ur. When S/D increases to 4, inter-cylinder interference decreases, resembling the wake of a single cylinder undergoing VIV. For S/D > 4, wake patterns behind each cylinder match those of a single cylinder under VIV. Additionally, when adjacent cylinders exhibit in-phase synchronization (IS), their wakes tend to merge.

- Unlike two side-by-side cylinders, the inclusion of a middle cylinder introduces complexity. The forces on the middle cylinder may randomly synchronize with one side cylinder or remain asynchronous with both. This results in more intricate surface interaction forces. Smaller spacing ratios amplify these forces, leading to time history curves of hydrodynamic forces dominated by multi-frequency oscillations. Three distinct stages emerge at smaller spacing ratios, while only two stages occur at larger spacing ratios.

- At small spacing, when Ur is large, the proximity of cross-flow and in-line vibration frequencies results in elliptical motion trajectories. Near the “lock-in” region (transition region), trajectories become disordered due to a “multi-frequency” phenomenon. As S/D increases, the top and bottom cylinders exhibit “figure-eight” trajectories similar to a single cylinder. The middle cylinder, influenced by both upper and lower cylinders, predominantly displays “bounded figure-eight” or “bounded random” motion trajectories outside the “lock-in” region.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sumner, D. Two circular cylinders in cross-flow: A review. J. Fluids Struct. 2010, 26, 849–899. [Google Scholar] [CrossRef]

- Zhao, M. Flow induced vibration of two rigidly coupled circular cylinders in tandem and side-by-side arrangements at a low Reynolds number of 150. Phys. Fluids 2013, 25, 123601. [Google Scholar] [CrossRef]

- Bao, Y.; Zhou, D.; Tu, J.H. Flow characteristics of two in-phase oscillating cylinders in side-by-side arrangement. Comput. Fluids 2013, 71, 124–145. [Google Scholar] [CrossRef]

- Chen, W.; Ji, C.; Xu, D. Vortex-induced vibrations of two side-by-side circular cylinders with two degrees of freedom in laminar cross-flow. Comput. Fluids 2019, 193, 104288. [Google Scholar] [CrossRef]

- Zhang, H.J.; Zhou, Y. Effect of unequal cylinder spacing on vortex streets behind three side-by-side cylinders. Phys. Fluids 2001, 13, 3675–3686. [Google Scholar] [CrossRef]

- Zhou, Y. Vortical structures behind three side-by-side cylinders. Exp. Fluids 2003, 34, 68–76. [Google Scholar] [CrossRef]

- Kang, S. Numerical study on laminar flow over three side-by-side cylinders. KSME Int. J. 2004, 18, 1869–1879. [Google Scholar] [CrossRef]

- Ul Islam, S.; Rahman, H.; Ying, Z.C.; Saha, S.C. Comparison of wake structures and force measurements behind three side-by-side cylinders. J. Braz. Soc. Mech. Sci. 2016, 38, 843–858. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, C.; Zhao, M.; Wang, L.; Zhu, R. Experimental investigation on flow past two and three side-by-side inclined cylinders. J. Fluids Eng. 2020, 142, 011201. [Google Scholar] [CrossRef]

- Sooraj, P.; Khan, M.H.; Sharma, A.; Agrawal, A. Wake analysis and regimes for flow around three side-by-side cylinders. Exp. Therm. Fluid Sci. 2019, 104, 76–88. [Google Scholar] [CrossRef]

- More, B.S.; Dutta, S.; Gandhi, B.K. Flow around three side-by-side square cylinders and the effect of the cylinder oscillation. J. Fluids Eng. 2020, 142, 021303. [Google Scholar] [CrossRef]

- Ali, M.H.; Munir, A.; Zhao, M. Numerical investigation of flow across three co-rotating cylinders in side-by-side arrangement. Phys. Fluids 2023, 35, 113601. [Google Scholar] [CrossRef]

- Song, M.; Guo, S.; Xu, H.; Tao, W.; Lei, J.; Chang, C.C. Force Element Analysis in Vortex-Induced Vibrations of Side-by-Side Dual Cylinders: A Numerical Study. J. Mar. Sci. Eng. 2024, 12, 1529. [Google Scholar] [CrossRef]

- Chang, C.C.; Yang, S.H.; Chu, C.C. A many-body force decomposition with applications to flow about bluff bodies. J. Fluid Mech. 2008, 600, 95–104. [Google Scholar] [CrossRef]

- Chang, C.C. Potential flow and forces for incompressible viscous flow. Proc. R. Soc. A-Math. Phy. 1992, 437, 517–525. [Google Scholar]

- Hsieh, C.T.; Kung, C.F.; Chang, C.C.; Chu, C.C. Unsteady aerodynamics of dragonfly using a simple wing-wing model from the perspective of a force decomposition. J. Fluid Mech. 2010, 663, 233–252. [Google Scholar] [CrossRef]

- Luo, X.G.; Gao, A.K.; Lu, X.Y. Enhanced performance of a self-propelled flexible plate by a uniform shear flow and mechanism insight. Phys. Fluids 2023, 35, 021903. [Google Scholar] [CrossRef]

- Chen, W.; Ji, C.; Alam, M.M.; Williams, J.; Xu, D. Numerical simulations of flow past three circular cylinders in equilateral-triangular arrangements. J. Fluid Mech. 2020, 891, A14. [Google Scholar] [CrossRef]

- Cui, Z.; Zhao, M.; Teng, B. Vortex-induced vibration of two elastically coupled cylinders in side-by-side arrangement. J. Fluid Struct. 2014, 44, 270–291. [Google Scholar] [CrossRef]

- Thapa, J.; Zhao, M.; Cheng, L.; Zhou, T. Three-dimensional simulations of flow past two circular cylinders in side-by-side arrangements at right and oblique attacks. J. Fluid Struct. 2015, 55, 64–83. [Google Scholar] [CrossRef]

- Zdravkovich, M.M. Review of flow interference between two circular cylinders in various arrangements. J. Fluid Eng. 1977, 99, 618–633. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, H.J.; Yiu, M.W. The turbulent wake of two side-by-side circular cylinders. J. Fluid Mech. 2002, 458, 303–332. [Google Scholar] [CrossRef]

- Alam, M.M.; Moriya, M.; Sakamoto, H. Aerodynamic characteristics of two side-by-side circular cylinders and application of wavelet analysis on the switching phenomenon. J. Fluid Struct. 2003, 18, 325–346. [Google Scholar] [CrossRef]

- Chen, W.; Ji, C.; Xu, W.; Liu, S.; Campbell, J. Response and wake patterns of two side-by-side elastically supported circular cylinders in uniform laminar cross-flow. J. Fluid Struct. 2015, 55, 218–236. [Google Scholar] [CrossRef]

- Kim, H.J.; Durbin, P.A. Investigation of the flow between a pair of circular cylinders in the flopping regime. J. Fluid Mech. 1988, 196, 431–448. [Google Scholar] [CrossRef]

- Williamson, C.H.K. Evolution of a single wake behind a pair of bluff-bodies. J. Fluid Mech. 1985, 159, 1–18. [Google Scholar] [CrossRef]

- Bishop, R.E.D.; Hassan, A.Y. The lift and drag forces on a circular cylinder in a flowing fluid. R. Soc. Lond. Proc. 1964, 277, 32–50. [Google Scholar]

- Zdravkovich, M.M. Modification of vortex shedding in the synchronization range. J. Fluid Eng. 1982, 104, 513–517. [Google Scholar] [CrossRef]

| St1 | St2 | St3 | d1 | d2 | d3 | |

|---|---|---|---|---|---|---|

| Kang (2004) [7] | 0.177 | 0.183 | 0.177 | 1.479 | 1.553 | 1.479 |

| Ali et al. (2023) [12] | 0.178 | 0.184 | 0.178 | 1.481 | 1.544 | 1.480 |

| Present study | 0.178 | 0.184 | 0.178 | 1.480 | 1.546 | 1.480 |

| Mesh | Element | ∆t* | Cl1,RMS | Cl2,RMS | Cl3,RMS | Ay1* | Ay2* | Ay3* | Total Time |

|---|---|---|---|---|---|---|---|---|---|

| M1 | 60,000 | 0.0025 | 0.6615 | 0.5832 | 0.6643 | 0.5673 | 0.5557 | 0.5691 | 180 h |

| M2 | 101,600 | 0.0025 | 0.6748 | 0.5865 | 0.6661 | 0.5662 | 0.5570 | 0.5715 | 203 h |

| M3 | 162,500 | 0.0025 | 0.6722 | 0.5977 | 0.6698 | 0.5696 | 0.5575 | 0.5707 | 235 h |

| M4 | 221,400 | 0.0025 | 0.6752 | 0.6006 | 0.6699 | 0.5683 | 0.5567 | 0.5702 | 305 h |

| M3 | 162,500 | 0.00125 | 0.6662 | 0.5977 | 0.6637 | 0.5718 | 0.5577 | 0.5704 | 576 h |

| M3 | 162,500 | 0.005 | 0.6944 | 0.6032 | 0.6805 | 0.5644 | 0.5552 | 0.5746 | 151 h |

| Ur | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S/D | ||||||||||||

| 3 | TS(I) | TS(I) | BS | BS | BS | TS(I) | TS(I) | TS(I) | BS | BS | TS(I) | |

| 4 | BS | BS | BS | BS | BS | TS(II) | BS | BS | BS | BS | BS | |

| 5 | BS | BS | BS | BS | BS | TS(II) | BS | BS | BS | BS | BS | |

| 6 | BS | BS | BS | BS | BS | BS | BS | BS | BS | BS | BS | |

| Inter-Cylinder | Ur | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S/D | |||||||||||||

| C1–C2 | 3 | IS | IS | IS | OA | OA | IS | IS | IS | OA | OS | IA | |

| 4 | OA | IA | IA | OA | IA | OA | IA | OA | OA | IA | IA | ||

| 5 | OS | OA | OA | IA | IA | IA | OA | IA | OS | IA | IA | ||

| 6 | IS | OS | OA | OA | IS | IA | IS | OA | IA | OA | IS | ||

| C2–C3 | 3 | IS | IS | OS | IA | IA | IA | IS | IA | OA | IA | IA | |

| 4 | IA | OA | OA | OA | OS | IA | OA | IA | OA | OA | OA | ||

| 5 | IS | IA | IA | OA | OS | OS | IA | OA | IS | IA | OA | ||

| 6 | OS | IA | IA | IA | OS | OA | OS | IA | OA | IA | IS | ||

| C1–C3 | 3 | IS | IS | OS | OA | OA | IA | IS | IA | OS | OA | IA | |

| 4 | OA | OS | OA | IA | OA | OA | OS | OS | OA | OS | OS | ||

| 5 | OS | OS | OS | OS | OA | OA | OS | OS | OS | OS | OS | ||

| 6 | OS | OA | OS | OS | OS | OS | OS | OS | OS | OS | OA | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, S.-X.; Song, M.-T.; Lei, J.-C.; Xu, H.-L.; Chang, C.-C. Force Element Analysis of Vortex-Induced Vibration Mechanism of Three Side-by-Side Cylinders at Low Reynolds Number. J. Mar. Sci. Eng. 2025, 13, 1446. https://doi.org/10.3390/jmse13081446

Guo S-X, Song M-T, Lei J-C, Xu H-L, Chang C-C. Force Element Analysis of Vortex-Induced Vibration Mechanism of Three Side-by-Side Cylinders at Low Reynolds Number. Journal of Marine Science and Engineering. 2025; 13(8):1446. https://doi.org/10.3390/jmse13081446

Chicago/Turabian StyleGuo, Su-Xiang, Meng-Tian Song, Jie-Chao Lei, Hai-Long Xu, and Chien-Cheng Chang. 2025. "Force Element Analysis of Vortex-Induced Vibration Mechanism of Three Side-by-Side Cylinders at Low Reynolds Number" Journal of Marine Science and Engineering 13, no. 8: 1446. https://doi.org/10.3390/jmse13081446

APA StyleGuo, S.-X., Song, M.-T., Lei, J.-C., Xu, H.-L., & Chang, C.-C. (2025). Force Element Analysis of Vortex-Induced Vibration Mechanism of Three Side-by-Side Cylinders at Low Reynolds Number. Journal of Marine Science and Engineering, 13(8), 1446. https://doi.org/10.3390/jmse13081446