Shore-Based Constant Tension Mooring System Performance and Configuration Study Based on Cross-Domain Collaborative Analysis Method

Abstract

1. Introduction

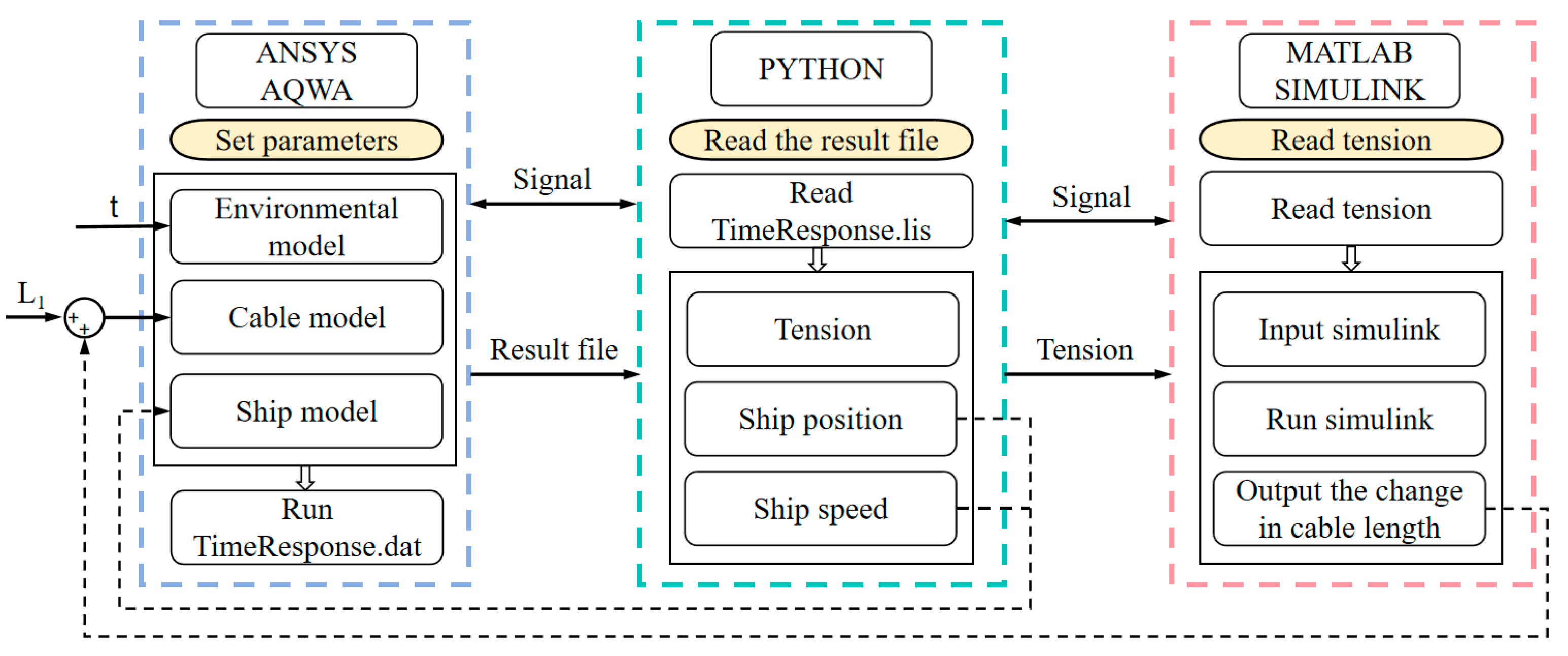

2. System Design and Operating Principles

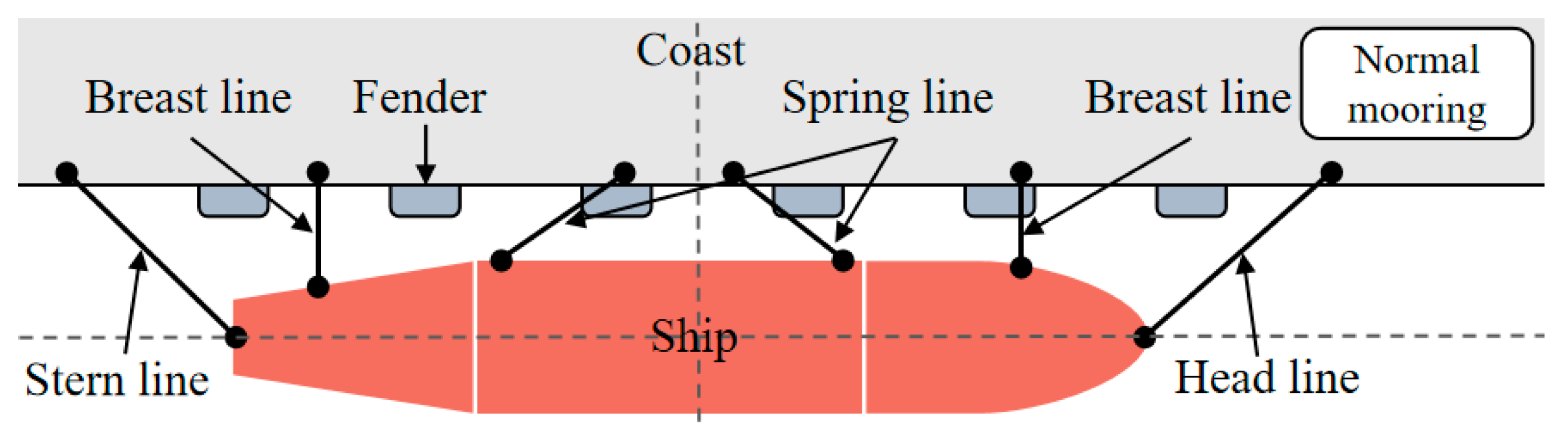

2.1. Purpose of System Design

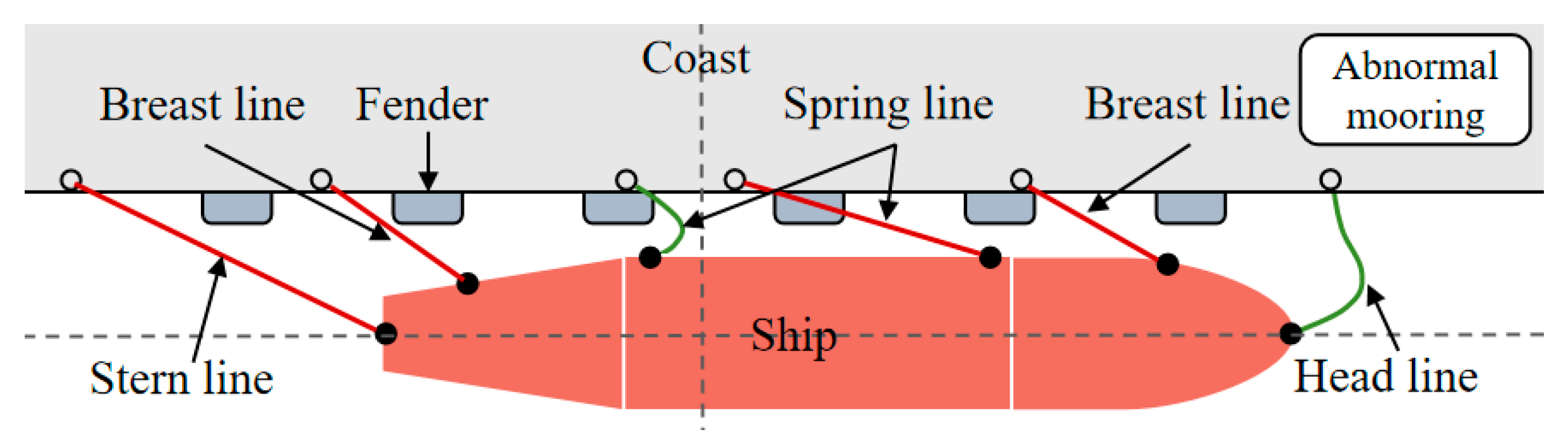

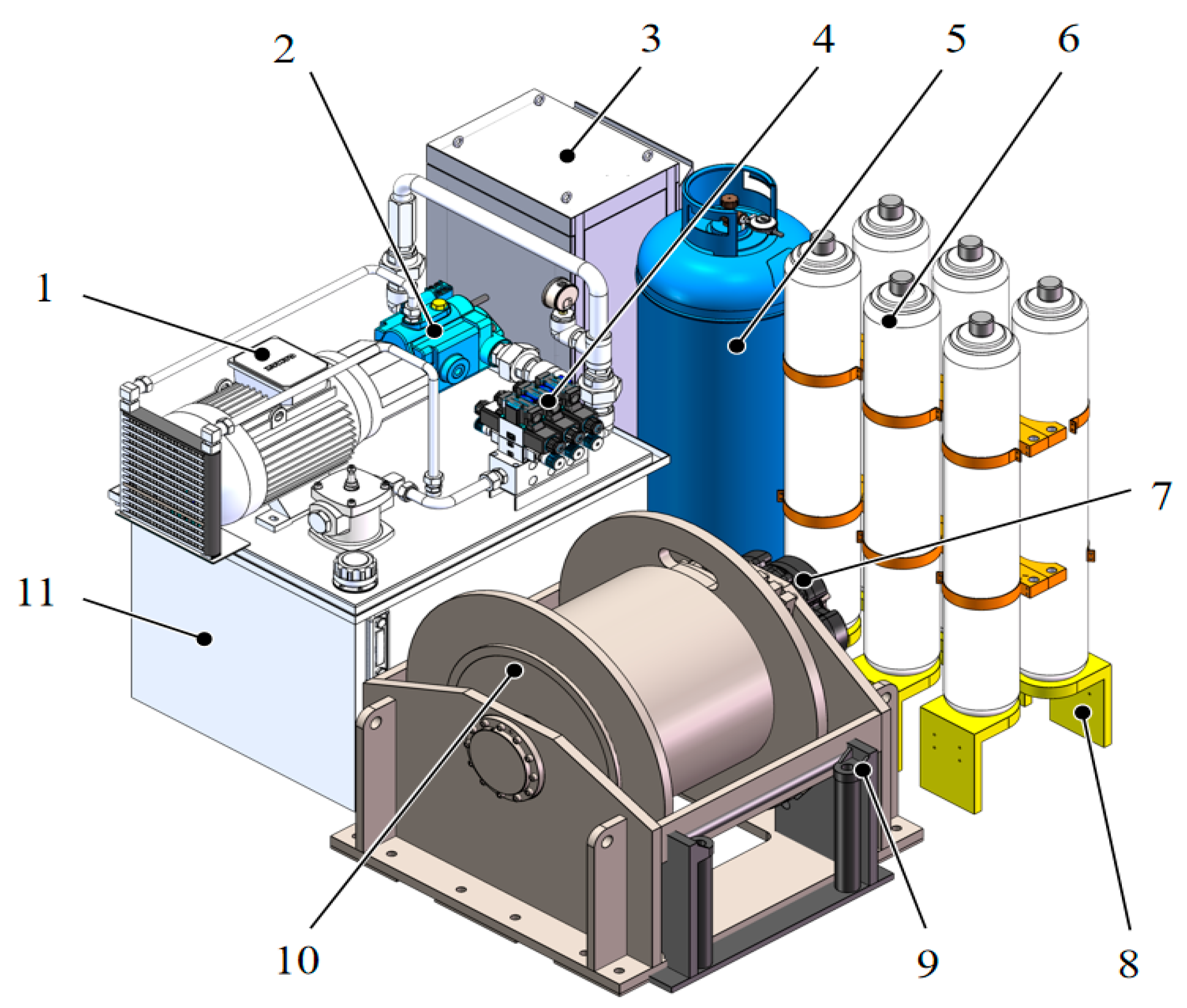

2.2. Design of Constant Tension Mooring System

2.3. Mathematical Model of the Mooring System

2.4. Mathematical Model of a Ship

3. Numerical Simulation and Analysis

3.1. Numerical Simulation Parameter Setting

3.1.1. Wave Load Modeling

3.1.2. Wind Load Modelling

3.1.3. Flow Load Modeling

3.1.4. Parameter Setting

3.2. Analysis of Bollard Force

4. Results and Discussion

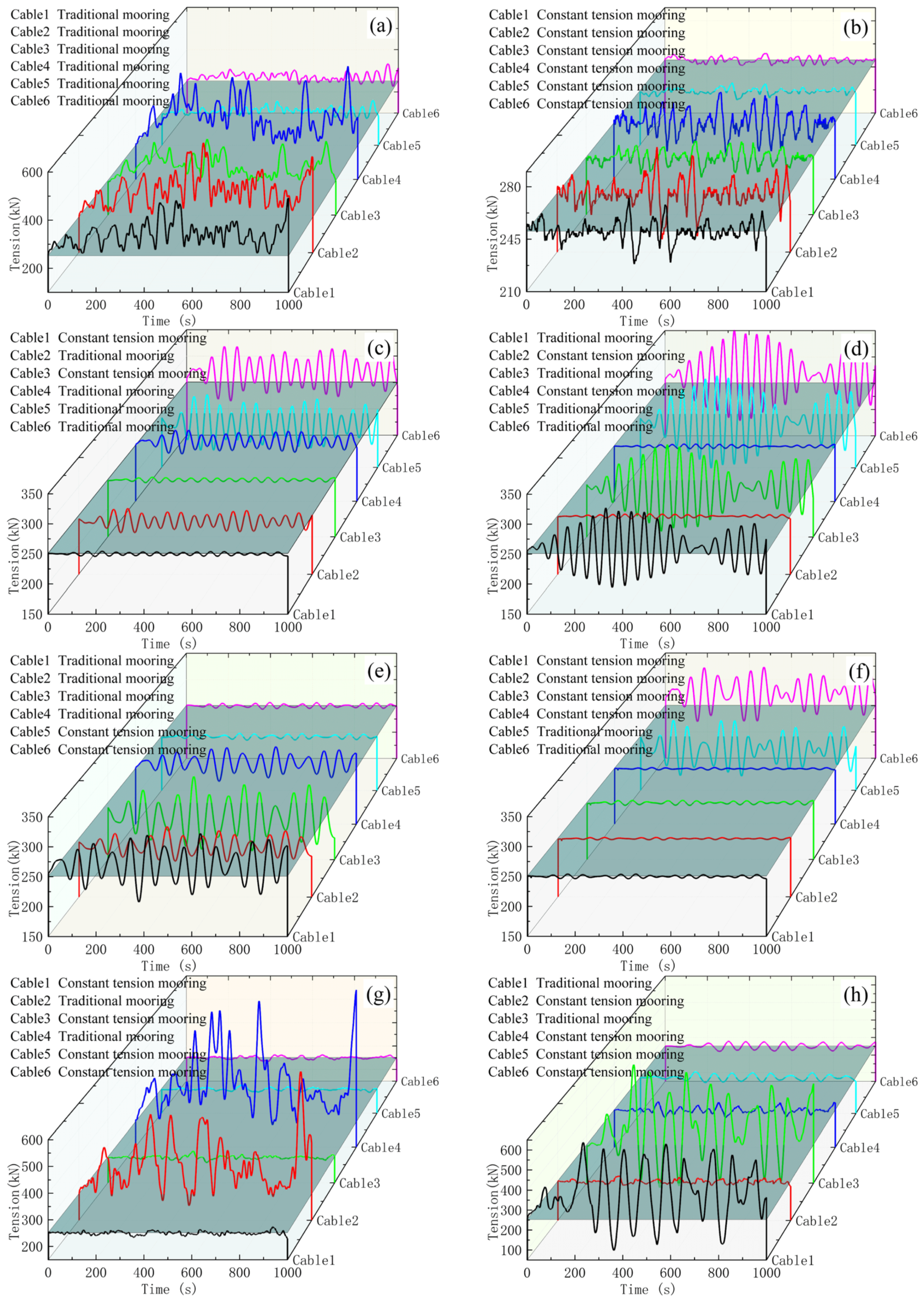

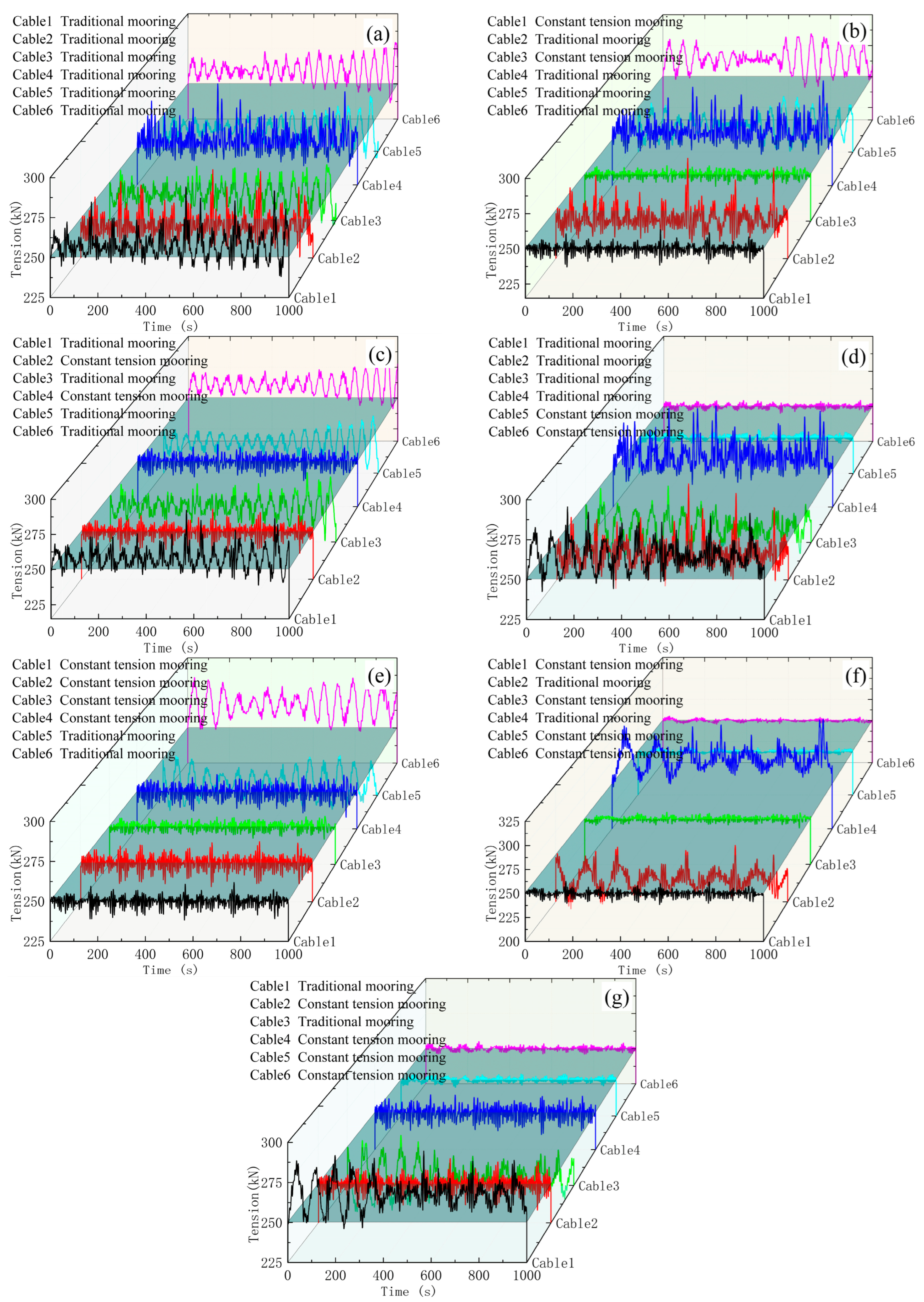

4.1. Optimization Analysis of Cable Tension

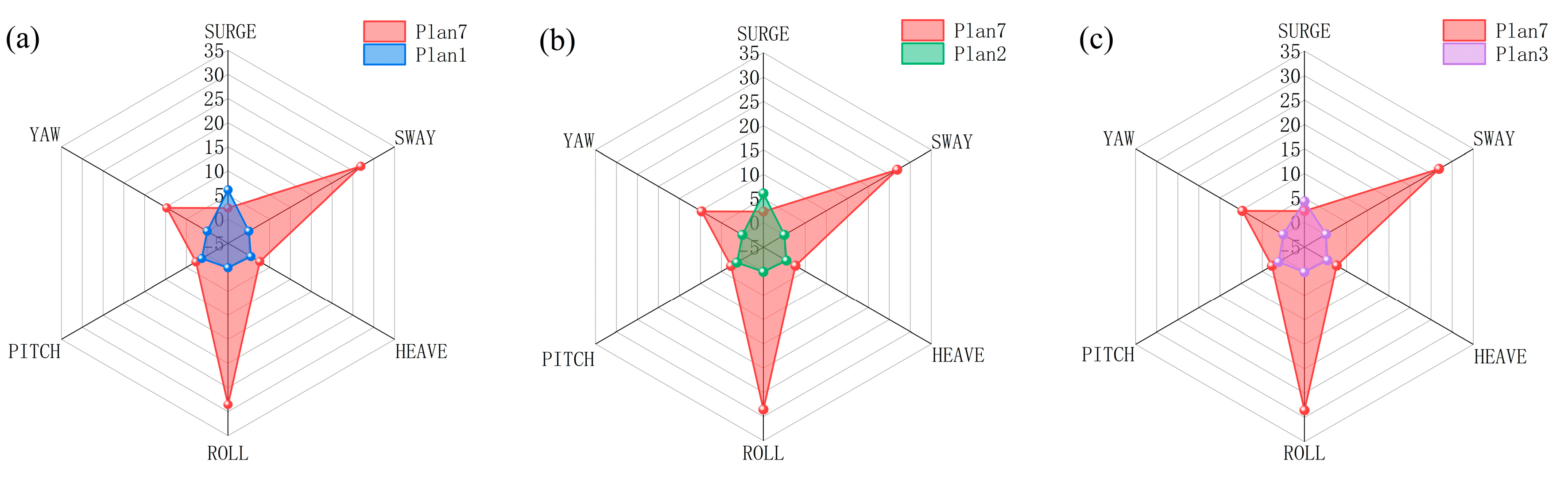

4.2. Optimization Analysis of Ship Stability

4.3. Results and Prospects

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Qm | hydraulic motor output flow |

| Cim | internal leakage coefficient |

| Com | external leakage coefficient |

| Pb | system back pressure |

| Ph | pressure of the high-pressure pipeline |

| Pl | low-pressure pipeline backpressure |

| P0 | Initial pressure |

| P1 | System pressure under working condition 1 |

| P2 | System pressure under working condition 2 |

| Dm | hydraulic motor flow |

| θm | hydraulic motor angle of rotation |

| Vs | hydraulic motor single-cavity volume |

| V0 | volume of the accumulator at the initial time |

| V1 | volume of the accumulator at the beginning of the mooring |

| V2 | volume of the skin bladder in the adjusted accumulator |

| Bm | equivalent viscous damping coefficient |

| D | diameter of the winch |

| Fc | tension on the cable |

| n | gear ratio of the reducer |

| Ti | input torque of the hydraulic motor |

| QRH | quick-release hook device |

| SWL | safe working load |

| WLL | working load limit |

Appendix A

| Symbol | Units | Physical Meanings |

|---|---|---|

| m3/s | Real-time output flow of the hydraulic motor | |

| m3/s | Hydraulic motor internal leakage coefficient | |

| m3/s | Hydraulic motor leakage coefficient | |

| MPa | High-pressure pipeline working pressure | |

| MPa | Back pressure of the low-pressure pipeline | |

| m3/rad | Theoretical flow rate of the hydraulic motor | |

| ° | The rotation angle of the hydraulic motor | |

| m3 | Hydraulic motor single-chamber volume | |

| N/m2 | Effective volume modulus of the hydraulic motor | |

| kg·m2 | Total rotational inertia of the system | |

| N·m·s/rad | Equivalent viscous damping coefficient | |

| N·m | Output torque during system load | |

| MPa | The pre-charging pressure of the accumulator | |

| m3 | The initial volume of the body shell | |

| MPa | Pressure in the accumulator during mooring | |

| m3 | The volume of the bag when it is moored | |

| MPa | Pressure after the accumulator is adjusted | |

| m3 | The volume after the body suit adjustment | |

| m3 | The volume of the oil in the accumulator | |

| m3/s | The flow rate of the input or output of the accumulator | |

| N | Real-time tension of the cable | |

| N·m | The torque acting on the hydraulic motor |

References

- Ahmed, Y.A.; Hasegawa, K. Automatic ship berthing using artificial neural network trained by consistent teaching data using nonlinear programming method. Eng. Appl. Artif. Intell. 2013, 26, 2287–2304. [Google Scholar] [CrossRef]

- Paulauskas, V.; Paulauskas, D. Research on work methods for tugs in ports. Transport 2011, 26, 310–314. [Google Scholar] [CrossRef]

- Khan, R.U.; Yin, J.; Mustafa, F.S.; Anning, N. Risk assessment for berthing of hazardous cargo vessels using Bayesian networks. Ocean Coast. Manag. 2021, 210, 105673. [Google Scholar] [CrossRef]

- Kuzu, A.C.; Akyuz, E.; Arslan, O. Application of fuzzy fault tree analysis (FFTA) to maritime industry: A risk analysing of ship mooring operation. Ocean Eng. 2019, 179, 128–134. [Google Scholar] [CrossRef]

- Sokukcu, M.; Sakar, C. Risk analysis of collision accidents during underway STS berthing maneuver through integrating fault tree analysis (FTA) into Bayesian network (BN). Appl. Ocean Res. 2022, 126, 103290. [Google Scholar] [CrossRef]

- OCIMF. Mooring Equipment Guidelines (MEG4), 4th ed.; Witherby Seamanship International Ltd.: London, UK, 2018; pp. 3–12. [Google Scholar]

- International Maritime Organization (IMO). Revised Guidance on Shipboard Towing and Mooring Equipment (MSC.1/Circ.1175/Rev.1); International Maritime Organization: London, UK, 2020. [Google Scholar]

- Jeong, J.S.; Lee, D.S.; Kim, Y.B.; Lee, K.S. Modeling and control allocation for ship berthing system design. In Proceedings of the ICCAS 2010, Gyeonggi-do, Republic of Korea, 27–30 October 2010; pp. 195–200. [Google Scholar]

- Liu, X.; Ren, W.; Zhang, Q.; Zhang, S.H. Research of Marine Simulator Cables’ Mathematical Models. Adv. Mater. Res. 2014, 889, 551–554. [Google Scholar]

- Wu, L.; Yang, J.; Xiang, Z.; Liu, M.; Li, M.; Di, Y.; Jiang, H.; Dai, C.; Ji, X. An intelligent monitoring system for the force characteristics of floating bollards in a ship lock. J. Mar. Sci. Eng. 2023, 11, 1948. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, L.; Ding, S.; Li, F. Numerical simulation of moored ships in level ice considering dynamic behavior of mooring cable. Mar. Struct. 2025, 99, 103716. [Google Scholar] [CrossRef]

- Yan, K.; Zhang, S.; Oh, J.; Seo, D.-W. A review of progress and applications of automated vacuum mooring systems. J. Mar. Sci. Eng. 2022, 10, 1085. [Google Scholar] [CrossRef]

- Nazligul, Y.E.; Yazir, D. Comparison of automated mooring systems against existing mooring systems by using the IF-TOPSIS method. Ocean Eng. 2023, 285, 115269. [Google Scholar] [CrossRef]

- Wang, K.; Chu, Y.; Huang, S.; Liu, Y. Preliminary design and dynamic analysis of constant tension mooring system on a 15 MW semi-submersible wind turbine for extreme conditions in shallow water. Ocean Eng. 2023, 283, 115089. [Google Scholar] [CrossRef]

- Chen, Q.; Li, W.; Wang, X.; Yu, J.; Jafarzadeh, S.; Li, Y.; Li, S.; Zhang, W.; Chen, G. Development of a dynamic model for a constant tension winch. In Proceedings of the OCEANS 2015-MTS/IEEE Washington, Washington, DC, USA, 19–22 October 2015; pp. 1–4. [Google Scholar]

- Chen, Q.; Li, W.; Chen, G. FUZZY P+ ID controller for a constant tension winch in a cable laying system. IEEE Trans. Ind. Electron. 2016, 64, 2924–2932. [Google Scholar] [CrossRef]

- Zhu, P.; Zhang, Q.; Zhao, Z.; Yang, B. BP fuzzy neural network PID based constant tension control of traction winch. Meas. Control 2023, 56, 857–873. [Google Scholar] [CrossRef]

- Kery, S. Dynamic modeling of ship-to-ship and ship-to-pier mooring performance. Mar. Technol. Soc. J. 2018, 52, 87–93. [Google Scholar] [CrossRef]

- Van der Molen, W.; Scott, D.; Taylor, D.; Elliott, T. Improvement of mooring configurations in Geraldton Harbour. J. Mar. Sci. Eng. 2015, 4, 3. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, X.; Chen, J.; Liu, R.; Sun, J.; Si, Y. Catenary mooring length control for motion mitigation of semi-submersible floating wind turbines. J. Mar. Sci. Eng. 2024, 12, 628. [Google Scholar] [CrossRef]

- Tahar, A.; Halkyard, J.; Steen, A.; Finn, L. Float over installation method—Comprehensive comparison between numerical and model test results. J. Offshore Mech. Arct. Eng. 2006, 128, 256. [Google Scholar] [CrossRef]

- Sun, L.; Taylor, R.E.; Choo, Y.S. Multi-body dynamic analysis of float-over installations. Ocean Eng. 2012, 51, 1–15. [Google Scholar] [CrossRef]

- Ma, Y.; Yuan, L.; Zan, Y.; Huang, F. Numerical simulation of float-over installation for offshore platform. J. Mar. Sci. Appl. 2018, 17, 79–86. [Google Scholar] [CrossRef]

- Kwak, H.; Jung, S.; Oh, S.; Kwon, Y.; Nam, B.; Kim, N.; Lee, K.; Sung, H. Assessment of docking operation during float-over installation on jacket structure. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Honolulu, HI, USA, 10–15 June 2018; p. ISOPE-I-18-057. [Google Scholar]

- Liu, N.; Qu, P.; Chen, S.; Shen, W.; Zhang, L.; Zhang, Z.; Li, N. Design and Analysis of Rotary Constant Tension Mooring Device. In Proceedings of the 2024 IEEE International Conference on Mechatronics and Automation (ICMA), Tianjin, China, 4–7 August 2024; pp. 178–182. [Google Scholar]

- Wang, L.; Liu, N.; Wang, S.; Chen, S. Study on cable tension characteristics of shore-based constant tension mooring systems under the coupling effect of wind, wave, and current. J. Offshore Mech. Arct. Eng. 2024, 146, 051704. [Google Scholar] [CrossRef]

- Rosa-Santos, P.; Taveira-Pinto, F.; Veloso-Gomes, F. Experimental evaluation of the tension mooring effect on the response of moored ships. Coast. Eng. 2014, 85, 60–71. [Google Scholar] [CrossRef]

- Figuero, A.; Sande, J.; Peña, E.; Alvarellos, A.; Rabuñal, J.R.; Maciñeira, E. Operational thresholds of moored ships at the oil terminal of inner port of A Coruña (Spain). Ocean Eng. 2019, 172, 599–613. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, W.; Wang, H.; Zhang, Y.; Liu, X. Digital Hydraulic Motor Characteristic Analysis for Heavy-Duty Vehicle Traction. Actuators 2025, 14, 11. [Google Scholar] [CrossRef]

- Low, Y.M.; Langley, R.S. Time and frequency domain coupled analysis of deepwater floating production systems. Appl. Ocean Res. 2006, 28, 371–385. [Google Scholar] [CrossRef]

- Kurian, V.J.; Ng, C.Y.; Liew, M.S. Effect of Short-Crested Waves on the Dynamic Responses of Truss SPAR Platforms. In Proceedings of the Twenty-third International Offshore and Polar Engineering Conference, Anchorage, AK, USA, 30 June–5 July 2013. [Google Scholar]

- Barltrop, N.D.P. Floating Structures: A Guide for Design and Analysis, 1st ed.; Oilfield Publications Limited (OPL): Ledbury, UK, 1998. [Google Scholar]

- Randall, R.E. Elements of Ocean Engineering, 2nd ed.; Society of Naval Architects: Jersey City, NJ, USA, 2010; pp. 20–24. [Google Scholar]

- Ziylan, K.; Nas, S. A quasi-static mooring analysis approach for berthed ships. Ocean. Eng. 2024, 309, 118488. [Google Scholar] [CrossRef]

- Costas, R.; Figuero, A.; Sande, J.; Pena, E.; Guerra, A. The influence of infragravity waves, wind, and basin resonance on vessel movements and related downtime at the Outer Port of Punta Langosteira, Spain. Appl. Ocean Res. 2022, 129, 103370. [Google Scholar] [CrossRef]

- López, M.; Iglesias, G. Long wave effects on a vessel at berth. Appl. Ocean Res. 2014, 47, 63–72. [Google Scholar] [CrossRef]

- van Deyzen, A.F.; Beimers, P.; Van der Lem, J.; Messiter, D.; de Bont, J.A. To improve the efficiency of ports exposed to swell. In Proceedings of the Australasian Coasts & Ports Conference, Auckland, New Zealand, 15–18 September 2015; pp. 919–926. [Google Scholar]

- Gao, F.; Tang, Y.; Hu, C.; Xie, X. Research on a Ship Mooring Motion Suppression Method Based on an Intelligent Active Anti-Roll Platform. Appl. Sci. 2023, 13, 7979. [Google Scholar] [CrossRef]

- Shi, X.-Y.; Zhang, N.-C.; Chen, C.-P.; Jiang, H.-Z.; Cui, L. Experimental Study of characteristics of motions of a large mooring ship in long-period waves. J. Mar. Sci. Technol. 2014, 22, 15. [Google Scholar]

| Parameters Meanings | Reference Number |

|---|---|

| Length (m) | 192 |

| Wide (m) | 30.8 |

| Depth (m) | 11 |

| Coordinate (X, Y, Z) | (−1.326, 0, 10) |

| Tonnage (Kg) | 45,000,000 |

| Rxx, Ryy, Rzz | 8.84, 48, 48 |

| Lateral windward area (m2) | 2700 |

| Longitudinal windward area (m2) | 650 |

| Parameters | Normal Sea Conditions | Extreme Sea Conditions |

|---|---|---|

| Wind spectrum | NPD | NPD |

| Wind speed (m/s) | 4.4 | 11 |

| Wind reference height (m) | 10 | 10 |

| Wave spectrum | JONSWAP | JONSWAP |

| Surface velocity (m/s) | 0.8 | 2.1 |

| Bottom velocity (m/s) | 0.3 | 0.3 |

| Significant wave height (m) | 0.8 | 4.5 |

| Gamma | 1.55 | 1.6 |

| Peak wave period (s) | 6.67 | 9 |

| Start Period (s) | 0.94795 | 1.90917 |

| Finish Period (s) | 7.73931 | 15.47511 |

| Plan | Plan 1 | Plan 2 | ||||||||||||||||

| Name | FMAX (kN) | FAVG (kN) | FSD (kN) | FMAX (kN) | FAVG (kN) | FSD (kN) | ||||||||||||

| Angle | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 |

| Cable1 | 278 | 296 | 322 | 263 | 265 | 269 | 8 | 9 | 25 | 273 | 292 | 327 | 257 | 258 | 259 | 6 | 7 | 29 |

| Cable2 | 251 | 287 | 271 | 240 | 243 | 237 | 4 | 8 | 13 | 253 | 267 | 254 | 250 | 250 | 249 | 1 | 5 | 2 |

| Cable3 | 251 | 262 | 297 | 233 | 235 | 226 | 9 | 9 | 29 | 259 | 268 | 313 | 240 | 242 | 237 | 7 | 7 | 34 |

| Cable4 | 267 | 293 | 290 | 257 | 260 | 260 | 4 | 9 | 14 | 252 | 263 | 254 | 250 | 250 | 250 | 0.7 | 5 | 2 |

| Cable5 | 253 | 256 | 256 | 250 | 250 | 249 | 1 | 2 | 3 | 260 | 260 | 321 | 240 | 240 | 236 | 8 | 7 | 38 |

| Cable6 | 253 | 255 | 256 | 250 | 250 | 250 | 1 | 2 | 3 | 283 | 281 | 351 | 260 | 260 | 236 | 8 | 7 | 38 |

| Plan | Plan3 | Plan 4 | ||||||||||||||||

| Name | FMAX (kN) | FAVG (kN) | FSD (kN) | FMAX (kN) | FAVG (kN) | FSD (kN) | ||||||||||||

| Angle | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 |

| Cable1 | 251 | 264 | 254 | 250 | 250 | 249 | 0.5 | 3 | 2 | 284 | 295 | 637 | 267 | 268 | 376 | 8 | 8 | 13 |

| Cable2 | 251 | 288 | 263 | 242 | 245 | 240 | 3 | 8 | 10 | 252 | 266 | 280 | 250 | 250 | 250 | 0.9 | 5 | 10 |

| Cable3 | 252 | 257 | 254 | 250 | 250 | 250 | 0.7 | 3 | 2 | 250 | 258 | 675 | 229 | 230 | 342 | 9 | 9 | 15 |

| Cable4 | 262 | 296 | 278 | 255 | 258 | 257 | 3 | 9 | 10 | 252 | 262 | 297 | 250 | 250 | 251 | 0.7 | 5 | 16 |

| Cable5 | 252 | 259 | 280 | 236 | 236 | 230 | 7 | 9 | 27 | 253 | 254 | 282 | 250 | 250 | 250 | 1 | 2 | 14 |

| Cable6 | 278 | 285 | 318 | 264 | 264 | 269 | 6 | 9 | 25 | 253 | 255 | 279 | 250 | 250 | 250 | 1 | 2 | 14 |

| Plan | Plan 5 | Plan 6 | ||||||||||||||||

| Name | FMAX (kN) | FAVG (kN) | FSD (kN) | FMAX (kN) | FAVG (kN) | FSD (kN) | ||||||||||||

| Angle | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 | 0 | 45 | 90 |

| Cable1 | 253 | 263 | 274 | 250 | 250 | 250 | 0.8 | 4 | 6 | 252 | 262 | 254 | 250 | 250 | 250 | 0.7 | 3 | 2 |

| Cable2 | 249 | 262 | 723 | 222 | 224 | 364 | 8 | 10 | 10 | 253 | 264 | 252 | 250 | 250 | 250 | 0.9 | 5 | 1 |

| Cable3 | 252 | 257 | 275 | 250 | 250 | 250 | 0.9 | 3 | 6 | 252 | 257 | 254 | 250 | 250 | 250 | 0.8 | 3 | 2 |

| Cable4 | 302 | 323 | 789 | 277 | 279 | 407 | 9 | 13 | 11 | 252 | 262 | 252 | 250 | 250 | 250 | 0.7 | 5 | 1 |

| Cable5 | 253 | 255 | 267 | 250 | 250 | 250 | 1 | 2 | 6 | 253 | 253 | 280 | 233 | 233 | 226 | 9 | 9 | 23 |

| Cable6 | 254 | 256 | 263 | 250 | 250 | 250 | 1 | 2 | 6 | 287 | 286 | 324 | 267 | 267 | 273 | 9 | 9 | 24 |

| Angle | Name | Cable1 | Cable2 | Cable3 | Cable4 | Cable5 | Cable6 |

|---|---|---|---|---|---|---|---|

| 0° | FMAX (kN) | 294 | 282 | 262 | 294 | 263 | 283 |

| FAVG (kN) | 258 | 247 | 243 | 256 | 241 | 260 | |

| FSD (kN) | 8 | 8 | 7 | 8 | 7 | 7 | |

| 45° | FMAX (kN) | 296 | 284 | 265 | 292 | 263 | 282 |

| FAVG (kN) | 258 | 247 | 243 | 256 | 241 | 260 | |

| FSD (kN) | 8 | 8 | 8 | 8 | 7 | 7 | |

| 90° | FMAX (kN) | 492 | 569 | 433 | 609 | 308 | 333 |

| FAVG (kN) | 340 | 369 | 315 | 383 | 258 | 271 | |

| FSD (kN) | 49 | 64 | 43 | 77 | 15 | 18 |

| Plan | FMAX (kN) | Red (%) | FAVG (kN) | Red (%) |

|---|---|---|---|---|

| Plan 1 | 928 | 74.9 | 440 | 76.6 |

| Plan 2 | 1218 | 67.0 | 479 | 74.6 |

| Plan 3 | 933 | 74.7 | 466 | 75.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, N.; Qu, P.; Chen, S.; Chen, H.; Wang, S. Shore-Based Constant Tension Mooring System Performance and Configuration Study Based on Cross-Domain Collaborative Analysis Method. J. Mar. Sci. Eng. 2025, 13, 1385. https://doi.org/10.3390/jmse13081385

Liu N, Qu P, Chen S, Chen H, Wang S. Shore-Based Constant Tension Mooring System Performance and Configuration Study Based on Cross-Domain Collaborative Analysis Method. Journal of Marine Science and Engineering. 2025; 13(8):1385. https://doi.org/10.3390/jmse13081385

Chicago/Turabian StyleLiu, Nan, Peijian Qu, Songgui Chen, Hanbao Chen, and Shoujun Wang. 2025. "Shore-Based Constant Tension Mooring System Performance and Configuration Study Based on Cross-Domain Collaborative Analysis Method" Journal of Marine Science and Engineering 13, no. 8: 1385. https://doi.org/10.3390/jmse13081385

APA StyleLiu, N., Qu, P., Chen, S., Chen, H., & Wang, S. (2025). Shore-Based Constant Tension Mooring System Performance and Configuration Study Based on Cross-Domain Collaborative Analysis Method. Journal of Marine Science and Engineering, 13(8), 1385. https://doi.org/10.3390/jmse13081385