1. Introduction

Tidal energy converters, such as tidal turbines, harness the energy of tidal currents and convert it into a usable form of energy, typically electricity. Developing tidal turbines helps enrich the energy mix with a renewable and predictable form of energy. Only in certain specific areas are the tidal currents strong enough to be exploited. To optimize cost and power, tidal turbines are likely to be installed on tidal farms [

1]. At present, there is no industrial-scale tidal farm in operation; however, projects involving the deployment of turbines are being implemented. These projects are poised to establish the foundation for the development of industrial farms. This work is part of such a project, the OceanQuest project. OceanQuest’s technology is the HydroQuest turbine, a vertical-axis, bottom-mounted device, as shown in

Figure 1.

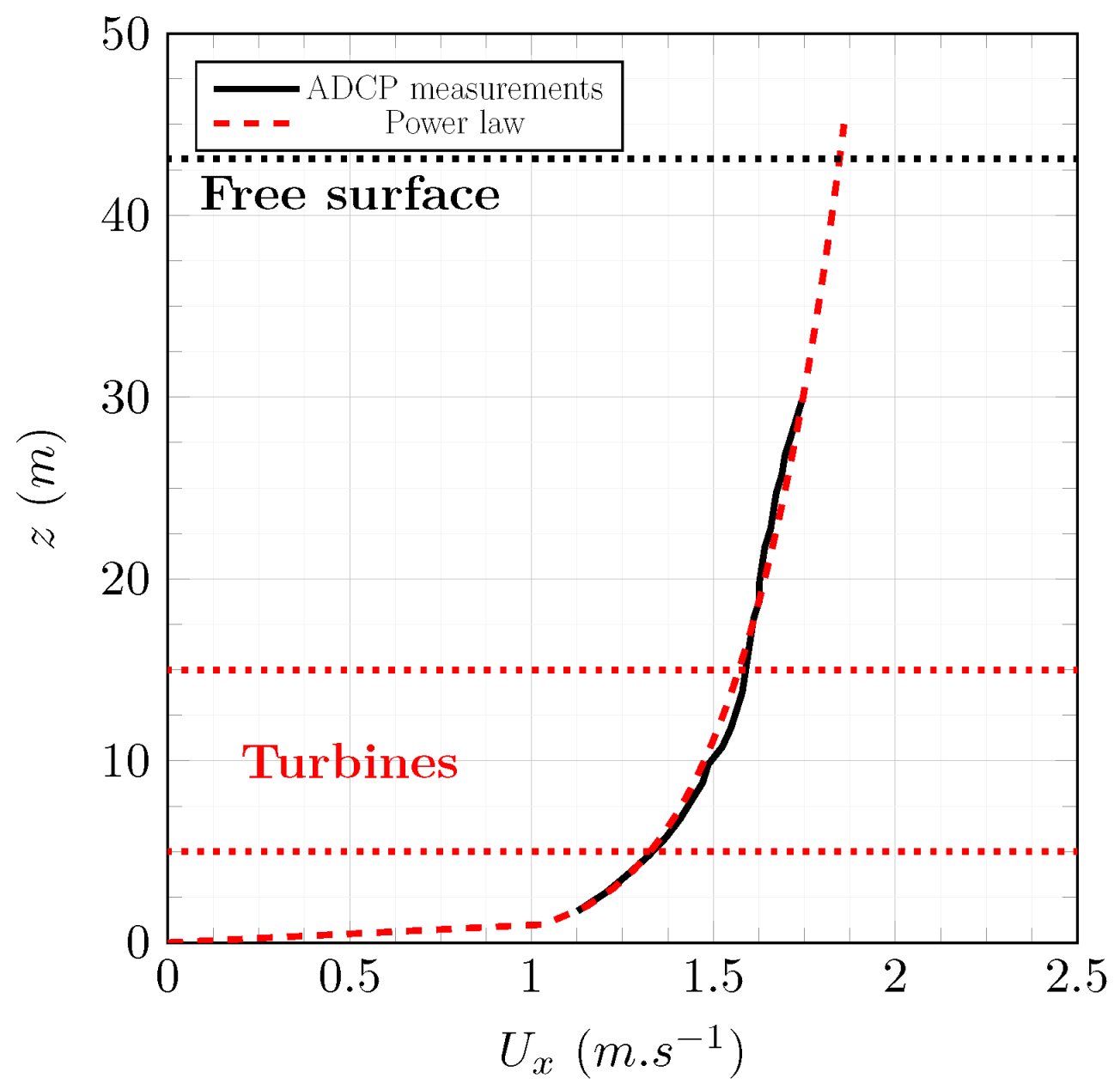

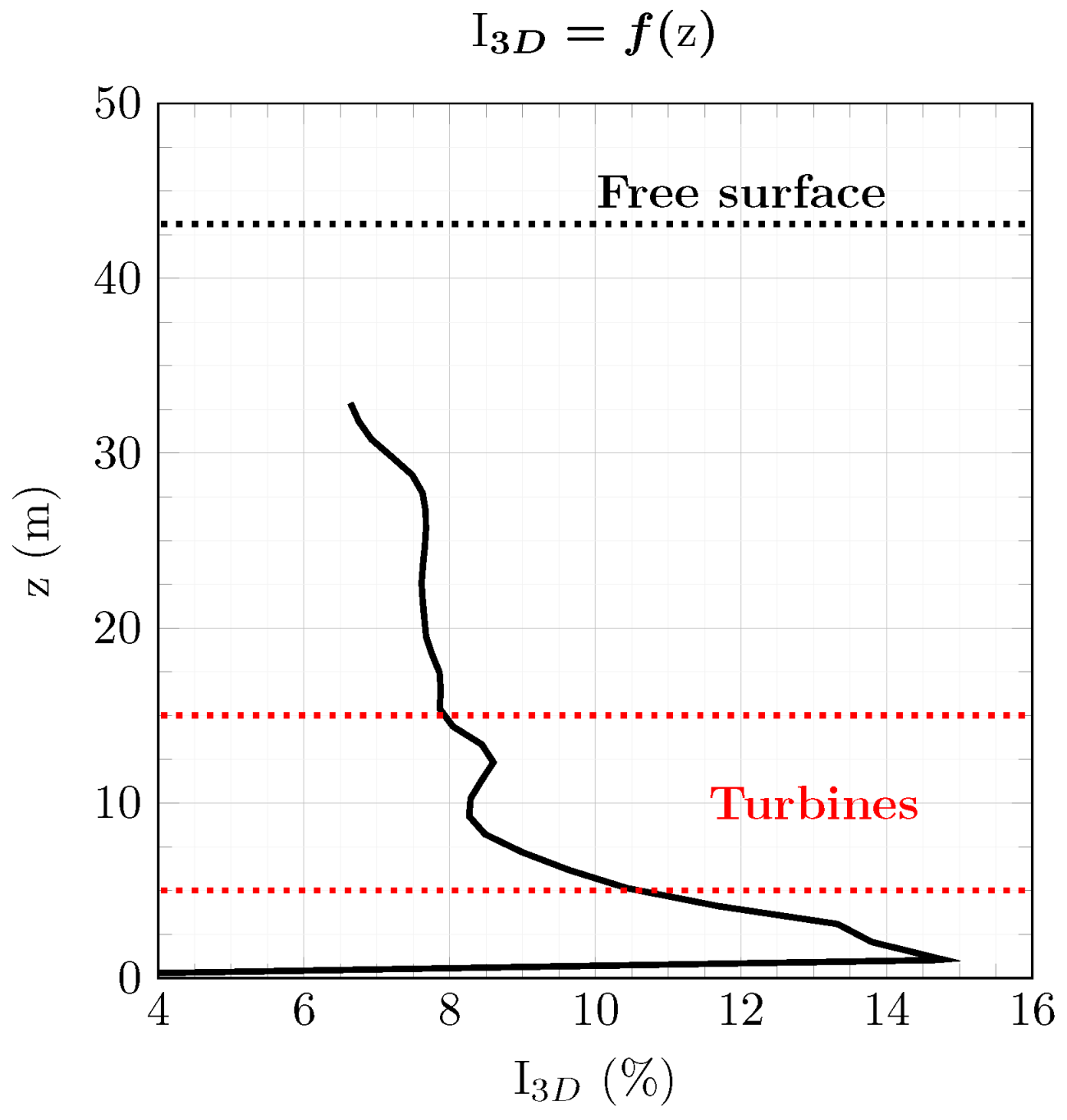

Prior to undertaking a comprehensive examination of the numerous studies on tidal turbines, it is essential to provide a synopsis of the environmental context within which these turbines operate. Although highly localized, tidal sites can be found on almost every continent on Earth. Most of them are exposed to wind and waves [

2,

3]. These surface disturbances propagate through the water column and influence the flow. As shown in the analysis of in situ measurements in [

4], sea states greatly affect load fluctuations without changing the average value. The bottom roughness also affects the stream and generates a high level of ambient turbulence of up to

[

5]. The ambient turbulence is site-specific and should be considered with great care when studying the implementation of a tidal site [

2]. Turbulence characteristics and vortex size have also been shown to be affected by local roughness and may differ from one place to another within the same site [

6,

7,

8]. Ambient turbulence influences the behavior of tidal turbines. Experimental and numerical studies have been performed on both vertical-axis tidal turbines (VATTs) and horizontal-axis tidal turbines (HATTs) to assess their effects [

1,

9,

10,

11]. From these investigations, turbulence was found to accelerate wake recovery, reduce the average power coefficient, and increase the load fluctuations. Investigations on tidal turbine arrays should therefore take this phenomenon into account.

In order to study tidal turbines and their environments, three possible approaches are available. The first and most cumbersome is in situ deployment, which has been successfully used to test prototypes and measure tidal flow characteristics [

2]. This approach provides extremely valuable data but is expensive and very localized within tidal areas. Flume tank experiments are also used to test various tidal turbine technologies [

11,

12]. Access to the flow surrounding the turbines facilitates the acquisition of comprehensive and sophisticated statistics on flow and turbine behavior [

13]. The main disadvantages of these approaches are the scale effects and the possible unrealistic blockage of the flow by the device. Experimental approaches are often used along with Computational Fluid Dynamics (CFD) approaches. It is acknowledged that numerical methods require experimentation for validation; nevertheless, these methods facilitate the creation of a full-scale model.

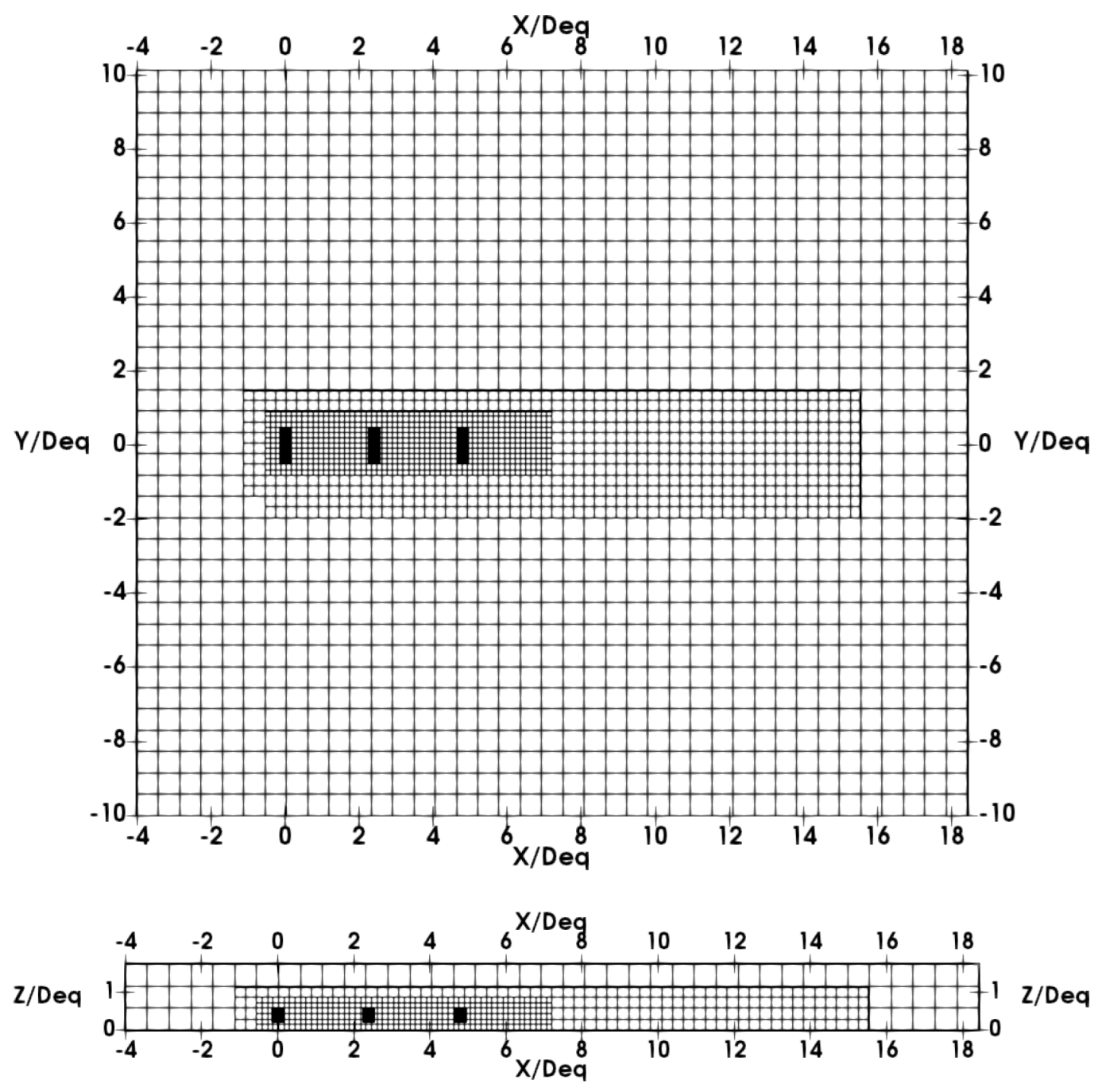

CFD VATT modeling techniques can be sorted into different categories based on increasing complexity and computational costs. The least expensive way to model turbines within a CFD simulation is the actuator cylinder approach coupled with the Reynolds-Averaged Navier–Stokes (RANS) solver [

14]. This approach can be used to model large-scale arrays but can be inaccurate when complex and unsteady flows are considered. On the other side of the spectrum are blade-resolved simulations [

15]. These approaches are the most accurate. Using state-of-the-art blade-resolved CFD, the authors of [

15] were able to model two VATT models interacting. Even with access to large HPC centers, the computational cost of blade-resolved CFD is prohibitive when considering an array of more than two turbines. An interesting alternative is the Actuator Line Model (ALM) coupled with Large Eddy Simulation (LES) [

16,

17]. While less expensive than blade-resolved approaches, ALM–LES enables an unsteady description of the flow and tracking of the blades.

Due to its ability to capture unsteady phenomena, the ALM–LES method has been used to study advanced turbine behavior such as blade fatigue in HATT arrays [

18]. When combined with a seabed morphology boundary condition, ALM–LES can model full-scale tidal turbines at actual tidal sites [

19]. Regarding VATTs, [

20,

21] extensively examined the influence of ALM parameters on the accuracy of the model. Their findings are therefore extremely valuable for setting up a robust ALM–LES model. These investigations suggest that ALM–LES is an interesting tool for studying small arrays of full-scale vertical-axis tidal turbines.

Tidal turbine technology is not as well-established as wind turbine technology, and there are almost as many turbine technologies as there are manufacturers. Because these technologies behave differently, studies are required to optimize each design. The VATT in question here, the HydroQuest tidal turbine, has its own particularities and features four counter-rotating rotors distributed across two columns. The behavior of this specific turbine has been studied in model-scale experiments [

11], in which unsteady upstream conditions were considered. A full-scale HydroQuest VATT was studied in [

16] under various turbulent upstream conditions. To the best of the authors’ knowledge, no study has examined the interaction between multiple VATTs with counter-rotating rotors under realistic upstream conditions. The aforementioned setup includes complex interactions between unsteady phenomena and turbines. In light of the existing literature, ALM–LES appears to be a suitable methodology.

The ALM–LES method is implemented here within the Lattice Boltzmann Method (LBM) to calculate flow. The LBM is an efficient unsteady, weakly compressible CFD method that is well-suited for modeling large areas [

8,

22]. It also has low dissipation, making it well-suited for modeling the advection and dissipation of wakes. In the case of submerged water flow, simulations are well below the LBM compressibility limits. The LBM code is the PaLaBoS library [

23]. ALM–LBM–LES is used in this paper to study full-scale HydroQuest turbines. Ambient turbulence is accounted for by generating a realistic turbulent boundary layer upstream of the turbines using a Synthetic Eddy Method (SEM) [

24]. To avoid introducing too many unknown sources of disruption, the free surface and rough bottom are disregarded. Interactions between turbines are studied for six layouts with up to four turbines. The spacing and arrangement of the elements along the streamwise direction vary between cases. The analysis focuses on how the flow and power output are influenced by the relative distances and positions of the turbines. This paper is organized as follows.

Section 2 introduces the numerical models, turbine specifications, and arrangements.

Section 3 investigates the averaged flow and power, as well as the morphology of the wake.

Section 4 presents the conclusions and perspectives.

Figure 1.

HydroQuest/CMN tidal turbine tested at Paimpol-Bréhat (Brittany, France). Reproduced with permission from HydroQuest [

25], 2022.

Figure 1.

HydroQuest/CMN tidal turbine tested at Paimpol-Bréhat (Brittany, France). Reproduced with permission from HydroQuest [

25], 2022.

3. Results and Discussion

In this section, the results from the simulations of the aligned scenarios (

) and the staggered scenarios (

) are presented and discussed. The simulations were run for 530 s before calculating the statistics. This duration is approximately one channel flow-through time for the

and

scenarios. The statistics were sampled over 244 s, with a frequency of 190 Hz. According to [

38], a minimum of 20 turbine revolutions is required to average the data. With a TSR of

, it took the turbine approximately 11 s to complete a single revolution. In 244 s, the turbine completed 21 revolutions, which is more than what is recommended by [

38]. For all layouts, the focus is primarily on the wake velocity, then on the power output, and finally on the wake morphology.

3.1. Computational Effort

Table 3 summarizes the computational effort required for the six ALM–LBM–LES simulations. All computations were carried out on the CRIANN (Centre Régional d’Informatique et d’Applications du Numériques de Normandie) cluster Myria

3.

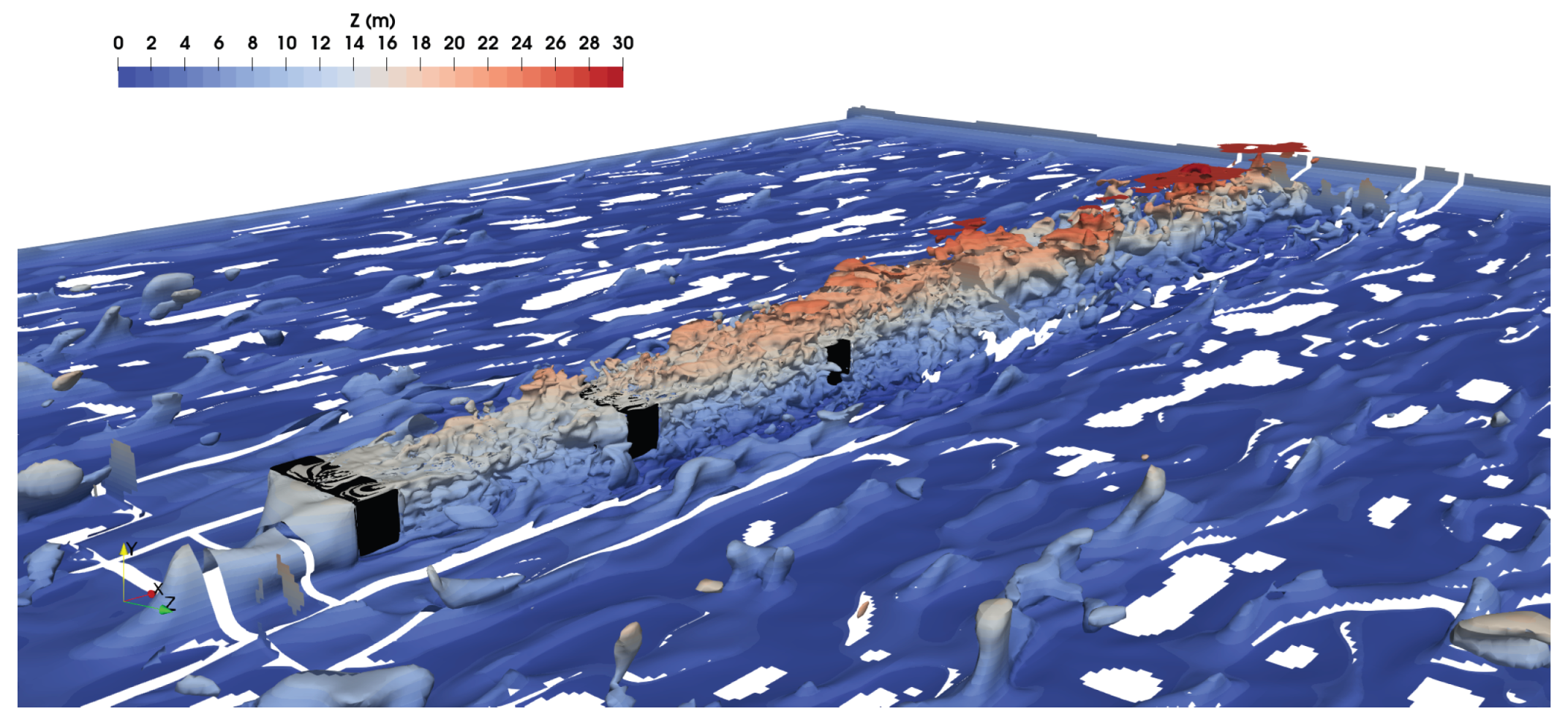

3.2. Wake Velocity

An instantaneous 3D view of the streamwise velocity for the

scenario is shown in

Figure 8. Since this scenario has the largest spacing between turbines, it is interesting to note that downstream turbines are located in areas affected by the wake. Moreover, it was qualitatively observed that the ambient vortices had a size on the same order of magnitude as the turbines, reflecting the prescribed SEM vortex length of 8 m. Because of the computational cost of this study, the simulations were not run long enough to compute advanced statistics, such as autocorrelation, which could have provided a quantitative estimation of the actual size of the vortices.

Investigating how turbine spacing affects the wake can be tedious, as the wake is a 3D, unsteady phenomenon that occupies a large volume. To obtain a global view of the wake with a manageable amount of data, a limited set of quantities was selected. The averaged axial velocity deficit was plotted along the turbine centerline for all scenarios. The velocity deficit is defined as

.

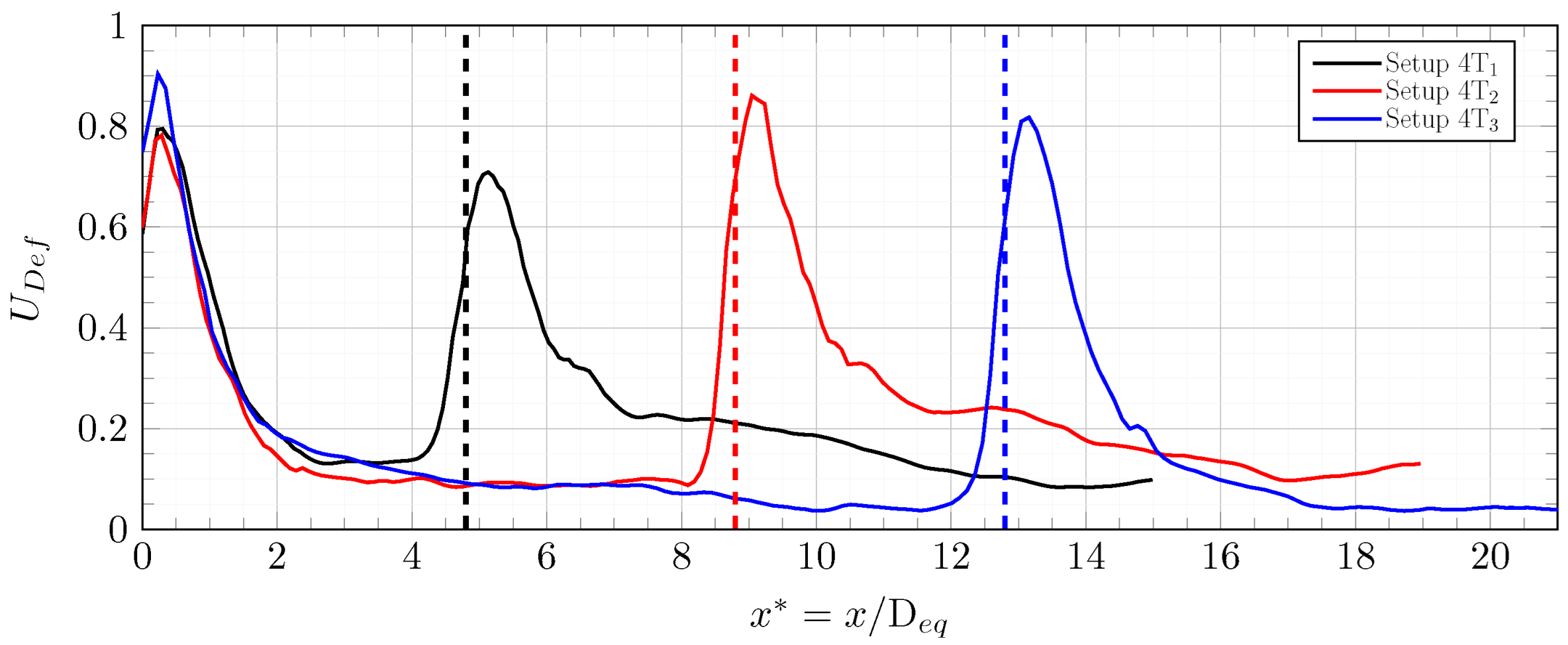

Figure 9 shows the velocity deficits for the

scenarios. In all scenarios, wake recovery is not achieved between turbines, and downstream turbines are always located in regions with reduced velocity. Also, the velocity deficit upstream of the third turbine is greater than that upstream of the second turbine. This was observed across all three scenarios. The velocity deficit accumulates with each successive turbine, as also observed by [

14]. After approximately 1

, the velocity recovery follows a linear trend, with a similar trend observed across all cases and turbines. This behavior is examined in more detail later in this section. The peak velocity deficit at each turbine varies depending on the turbine and the scenario, and no consistent trend was observed (see

Figure 9). As the statistical line passes through the interior of the stator, the quantities calculated at the turbine location have little physical meaning.

In the

scenarios, the turbines are not aligned, so two figures are needed to show the velocity deficit along the x-direction.

Figure 10 shows

for central turbines 1 and 4. The velocity deficit upstream of turbine 4s varies significantly across scenarios. For the

scenario, the wake of turbine 1 almost fully recovered, so its influence on turbine 4 should be minimal. As in the

scenarios, a linear trend was observed in the far wake of each turbine.

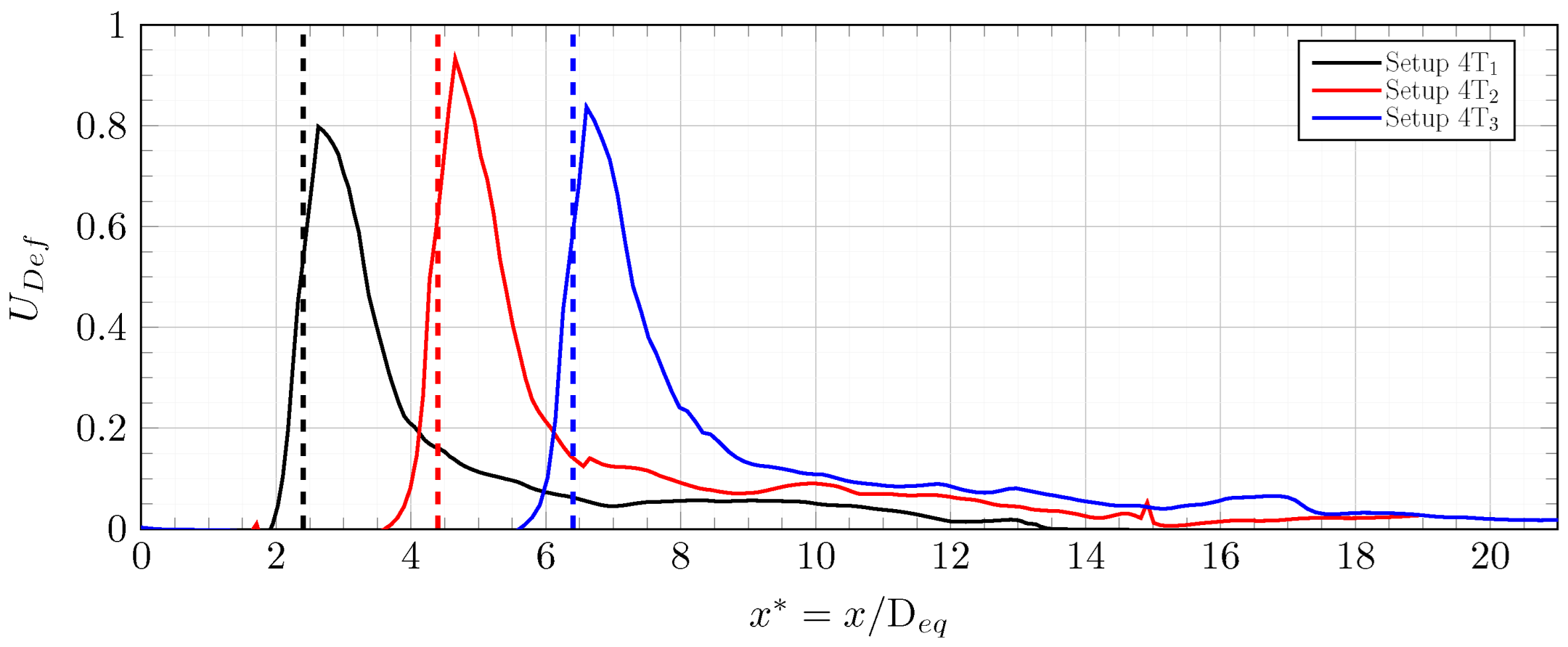

Figure 11 shows

for lateral turbines 2 and 3, and no clear differences between the scenarios are visible. More differences may appear in integral quantities, such as the power coefficient, or in the 3D plots of the wakes examined in the following sections.

For better comparison between arrays, two additional figures are included.

Figure 12 shows the wake downstream of the last turbine in the

and

scenarios. As noted previously, all velocity deficit plots exhibit a linear trend after approximately 1

. All scenarios are highly similar, with one exception: the velocity deficit downstream of turbine 4 in the

scenario is significantly lower than in the other scenarios. This is consistent with the results in

Figure 10.

Figure 13 compares the wake of turbine 4s in the

scenarios with the wake of turbine 2 in the

scenario. Indeed, turbine 2 in the

scenario is isolated and almost undisturbed. As seen in

Figure 13, the wake of turbine 4 in the

scenario is almost identical to that of an undisturbed turbine.

The results in

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13 suggest that the spacing between turbines and the number of turbines in the array do not significantly affect the velocity deficit downstream of the array. This remains true up to a critical spacing, beyond which the wake of an upstream turbine can fully recover. In such a scenario, the velocity deficit downstream of the array is similar to that of an isolated turbine. This critical spacing lies between 200 m and 300 m. As shown in

Figure 10, the corresponding critical velocity deficit upstream of the turbine falls within the range

.

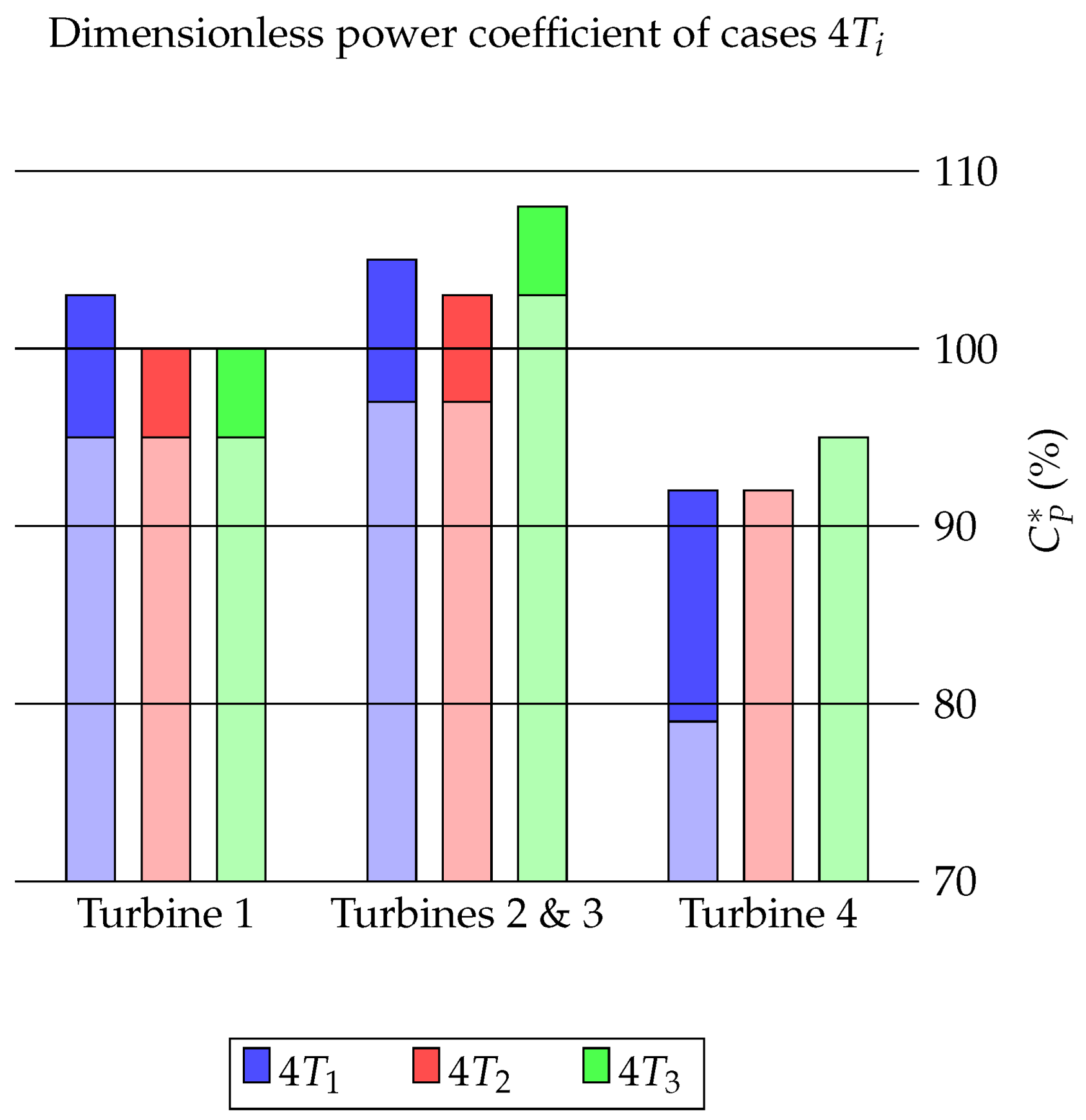

3.3. Turbine Power

In this section, the average power coefficients of the turbines in the

and

scenarios are investigated. The power coefficients are made dimensionless by dividing the power coefficient of each turbine by that of the first turbine of the corresponding layout,

or

, as shown in Equation (

9).

A distinction is made between top rotors and bottom rotors. In the figures below, the power coefficients of the bottom rotors are shown in dull colors, while those of the top rotors are shown in bright colors. The power coefficients for the

scenarios are shown in

Figure 14. Across all scenarios, turbine 1s have the highest

values and turbine 3s have the lowest. The loss in

for turbine 3s is substantial. All turbine 3s have

values approximately

lower than those of turbine 1s. This is consistent with the results in

Section 3.2, where an accumulation of the velocity deficit for downstream turbines was observed. The top rotors of turbines 1 and 2 have higher

values than the bottom rotors. This is likely due to the upstream boundary layer shown in

Figure 6. The difference in

between the top and bottom rotors is more pronounced for turbine 2s than for turbine 1s. No difference is observed for turbine 3s. Further insight into these two observations is given in

Section 3.4, based on the velocity deficit maps. Turbine 1 in the

scenario generates slightly less power than turbine 1 in the

scenario, which generates less power than turbine 1 in the

scenario. This difference could be due to how the array affects flow blockage, but it is also small enough to fall within the method’s margin of error.

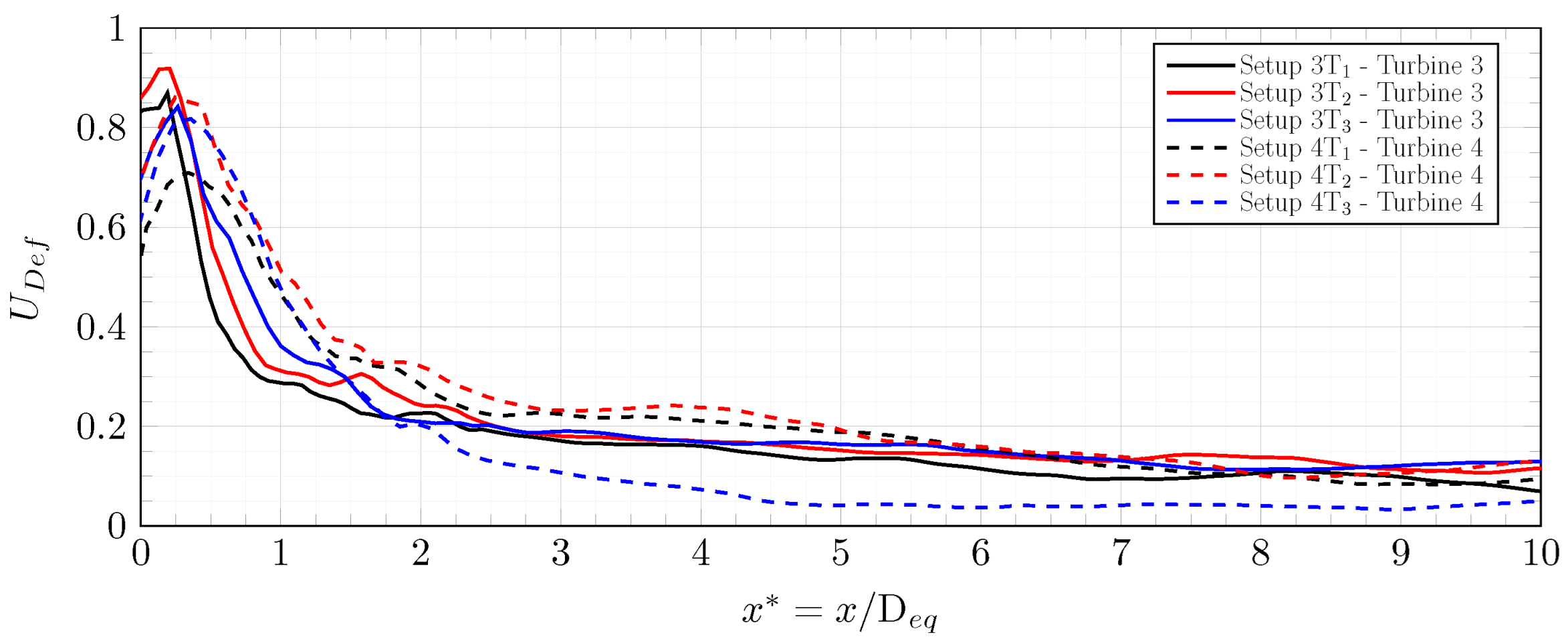

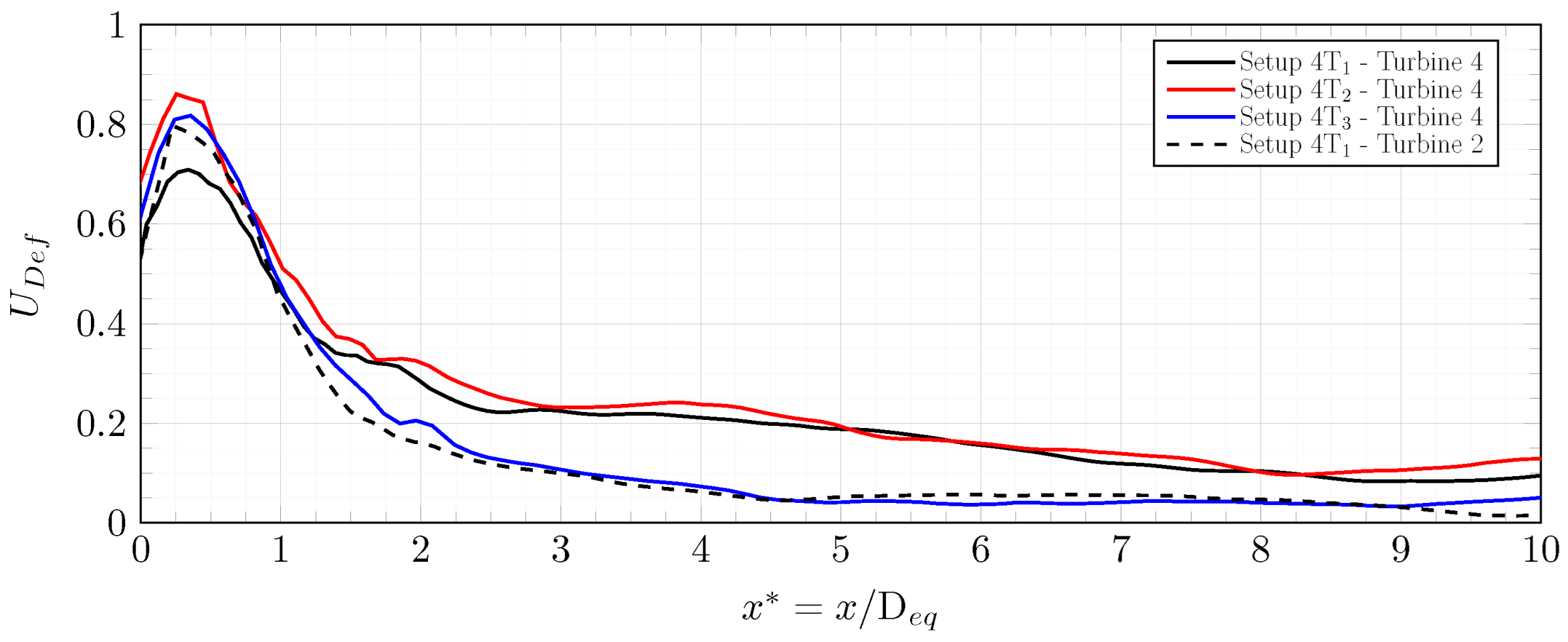

Figure 15 depicts the

values for the turbines in the

scenarios. The power coefficients of all turbines fall within a narrower range compared to the

scenarios. The lowest power is observed in the bottom rotor of turbine 4 in the

scenario and is around

. Turbines 2 and 3 have higher

values than turbine 1 and seem to benefit from the staggered configuration. The flow likely accelerates when bypassing the first turbines in the arrays, a known phenomenon in wind and tidal farms [

14]. The gain in power is highest in the

scenario, with an

increase in

. No difference between the top and bottom rotors is observed for turbine 4s, except in the

scenario. This is likely due to interactions between turbines and the expansion of the wake.

Section 3.4 provides a more detailed analysis of this phenomenon.

Lin et al., (2024) [

15] modeled two aligned VATTs using blade-resolved LES. By testing various distances between turbines, they observed that the power coefficient of the second turbine was halved when the distance between turbines was 10 diameters. In our case, the greatest reduction in power occurred in the

scenario, where the power coefficient of the second turbine decreased by 40%. In this scenario, the distance between turbines was 50 m, equivalent to two

or

D. In addition to technological differences, Ref. [

15] used a constant velocity inlet with no turbulence, which was not the case here. Turbulence is known to reduce the wake recovery distance. For example, in [

1], the influence of the distance between two aligned HATTs was examined. Two inflow conditions were tested: one with a turbulence intensity of 3% and the other with 15%. With a distance of 12 D between turbines and a turbulence intensity of 3%, the power coefficient of the second turbine was reduced by 50%. However, with a distance of 6 D and a turbulence intensity of 15%, the reduction was only 20%. This could explain why, despite the shorter spacing compared to [

15], the power coefficient reduction in our study was smaller.

It is worth noting that turbine 4s in the scenarios and turbine 2s in the scenarios have similar power coefficients. All are located in the wake of a single turbine. These observations are consistent with the velocity deficit upstream of these turbines, which lies between 10 and .

3.4. Wake Morphology

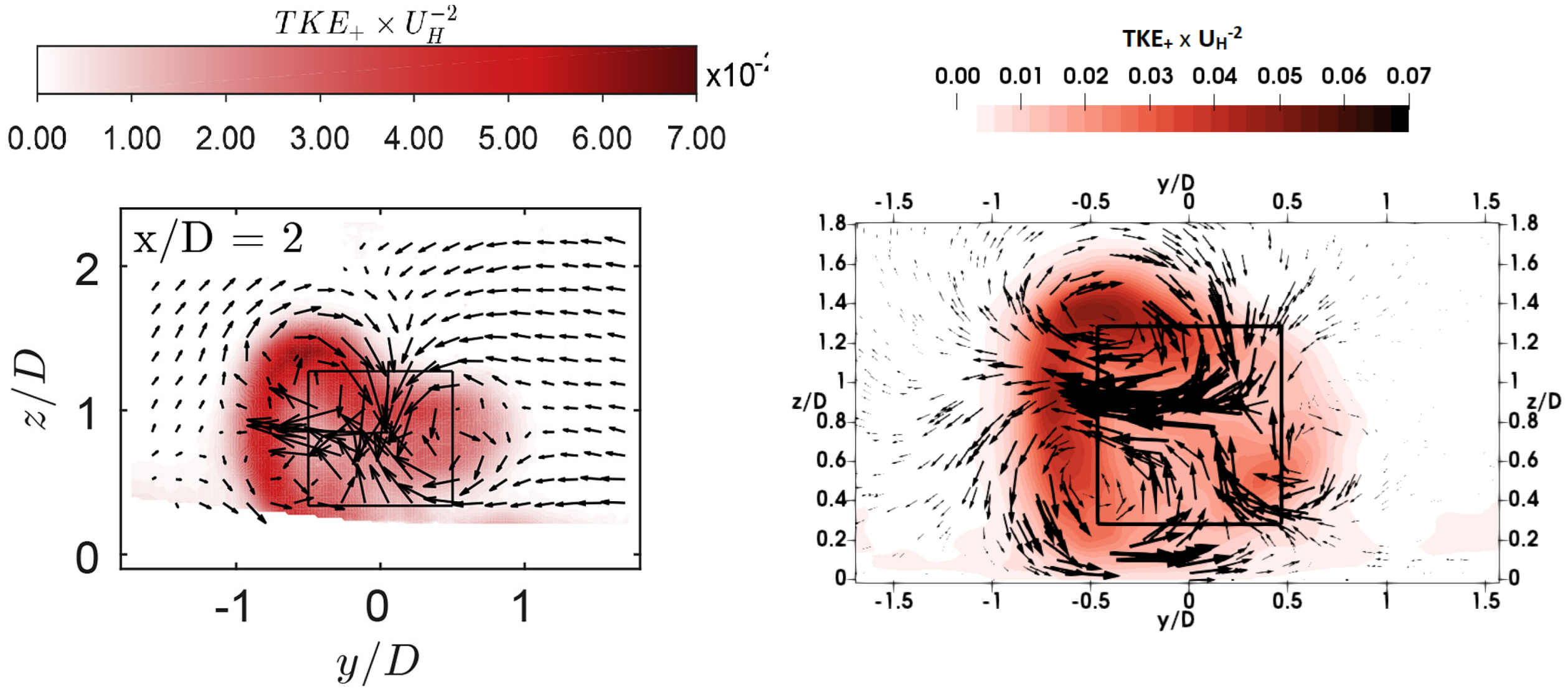

Grondeau et al., (2019) [

16] studied the wake of a single HydroQuest turbine, identical to the one modeled here. To observe the shape of the wake, the average flow field was sliced with planes normal to

at several downstream distances. Two counter-rotating vortices were observed in the wake of the same turbine using this approach. A similar procedure was used in the

and

scenarios.

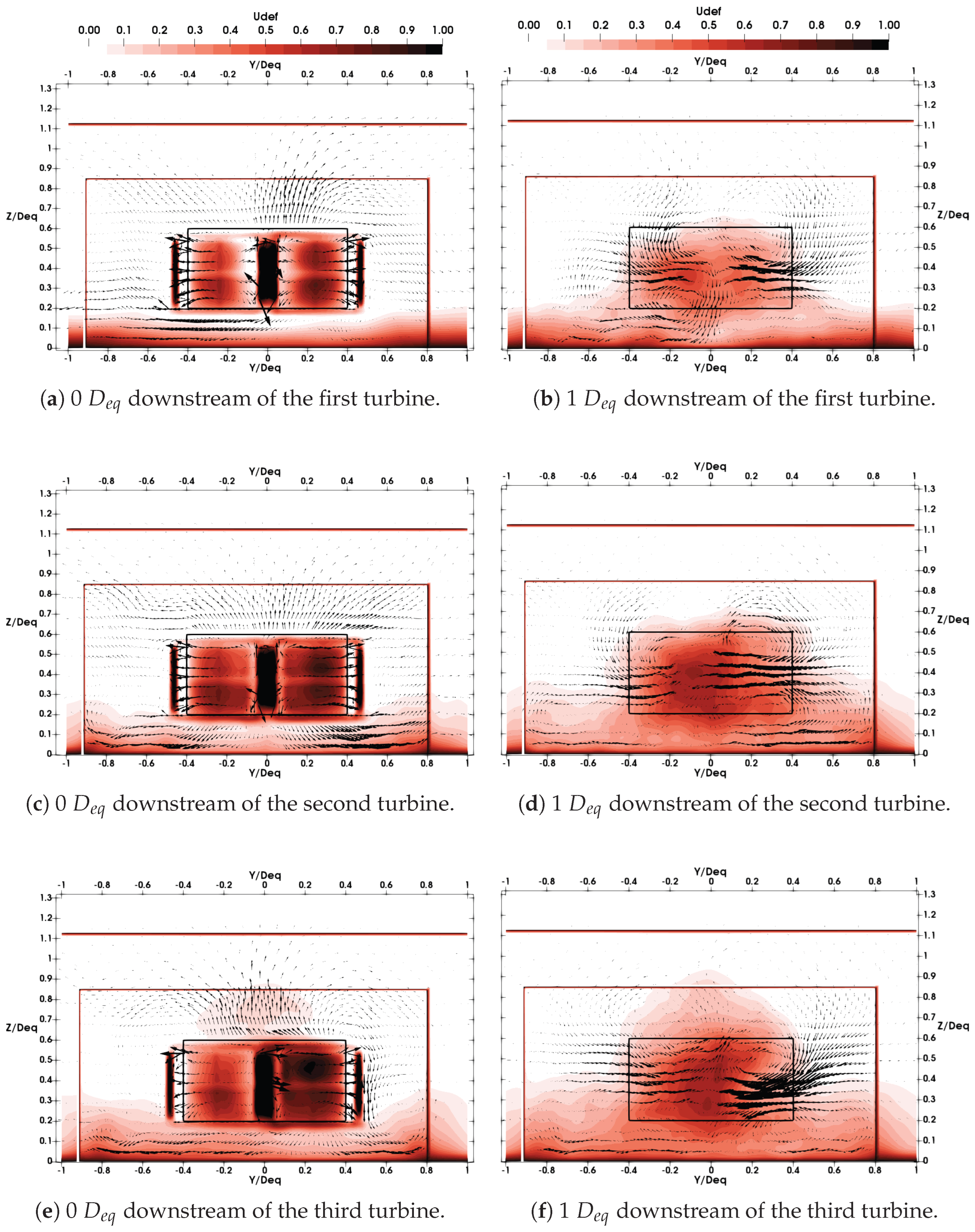

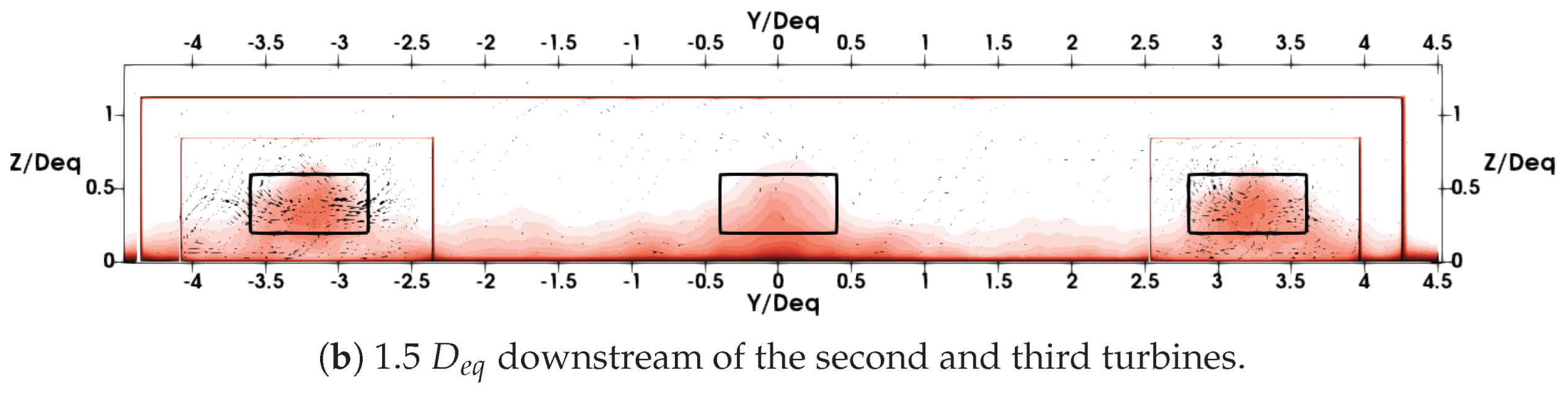

3.4.1. Wake Morphology for the Aligned Setup

Starting with the most compact scenario (

), the velocity deficit was plotted at two downstream distances for each turbine:

(turbine location) and

. Recall that the spacing between turbines in this case is 50 m, or 2

.

Figure 16a,b show the results for the first turbine;

Figure 16c,d show the results for the second turbine; and

Figure 16e,f show the results for the third and most downstream turbine. Looking at

Figure 16a,c,e, the influence of upstream turbines on the second and third turbines is apparent. The boundary layer is thicker at the locations of turbines 2 and 3.

Figure 16b,d,f depict the velocity deficit in the wakes of the turbines. The influence of upstream turbines on downstream turbines is even more noticeable. Counter-rotating vortices are observed, as reported in [

16]. Top vortices have their centers located at the top of the turbine footprint, at about a quarter of the turbine width from the center. The intensity of the top vortices increases for the second and third turbines, modifying the shape of the wake. This stretches the bottom vortices toward the sides, although it has limited influence on the overall wake width, which is relatively similar between the second and third turbines. The most significant effect is the upward stretching of the wake toward the free surface.

The second aligned scenario (

), with a spacing between turbines of 100 m, is shown in

Figure 17a–f. Differences can still be observed at the turbine locations, and the boundary layer is thicker for downstream turbines. The shapes of the wakes of turbines 1 and 2, as shown in

Figure 17b,d, are similar. The main differences are that the wake footprint is larger and the velocity deficit is more pronounced for turbine 2. Only the wake of turbine 3 is stretched significantly upward.

The averaged velocity field for the

scenario, with a spacing between turbines of 150 m, is shown in

Figure 18a–f. There is little difference between the boundary layers at the turbine locations. Additionally, the velocity fields shown in

Figure 18c,e are almost identical. The wakes of turbines 2 and 3 are no longer mushroom-shaped but instead more rectangular, like that of turbine 1. Between turbines 2 and 3, the wake footprint spreads in the y- and z-directions, and the velocity deficit increases. The intensity of the counter-rotating vortices does not seem to increase between turbines.

The distance between turbines significantly affects the morphology of the wake. For spacings below 150 m, the counter-rotating vortices become more intense with each successive turbine. This greatly affects the shape of the wake by stretching it toward the surface, which can be seen in

Figure 19. A 3D wake animation for the

scenario, based on the isocontour of the Lambda-2 criterion, is provided in the

Supplementary Materials. Because only three turbines were modeled here, the effect on the array was limited. These vortices have also been described in experimental studies [

32,

39,

40]. As explained in [

32], the counter-rotating vortex pairs originate from the

velocity gradient in the z-direction (see the original work for more details). Thus, an increase in this gradient for downstream turbines may cause the intensification of the vortices. Across all

scenarios, the wake footprint of the first turbine does not seem to extend beyond the turbine footprint. This is not the case for the wakes of turbines 2 and 3, consequently, turbine 3s are fully embedded in the velocity deficit region, whereas turbine 2s are not. Turbine 1s are only influenced by the upstream boundary layer. So, it is likely that the bottom and top rotors of turbine 3s experience a more uniform vertical velocity profile than those of turbines 1 and 2 due to the mixing caused by the wake. This may explain why the difference in

between the top and bottom rotors, as discussed in

Section 3.3, vanishes between turbines 2 and 3.

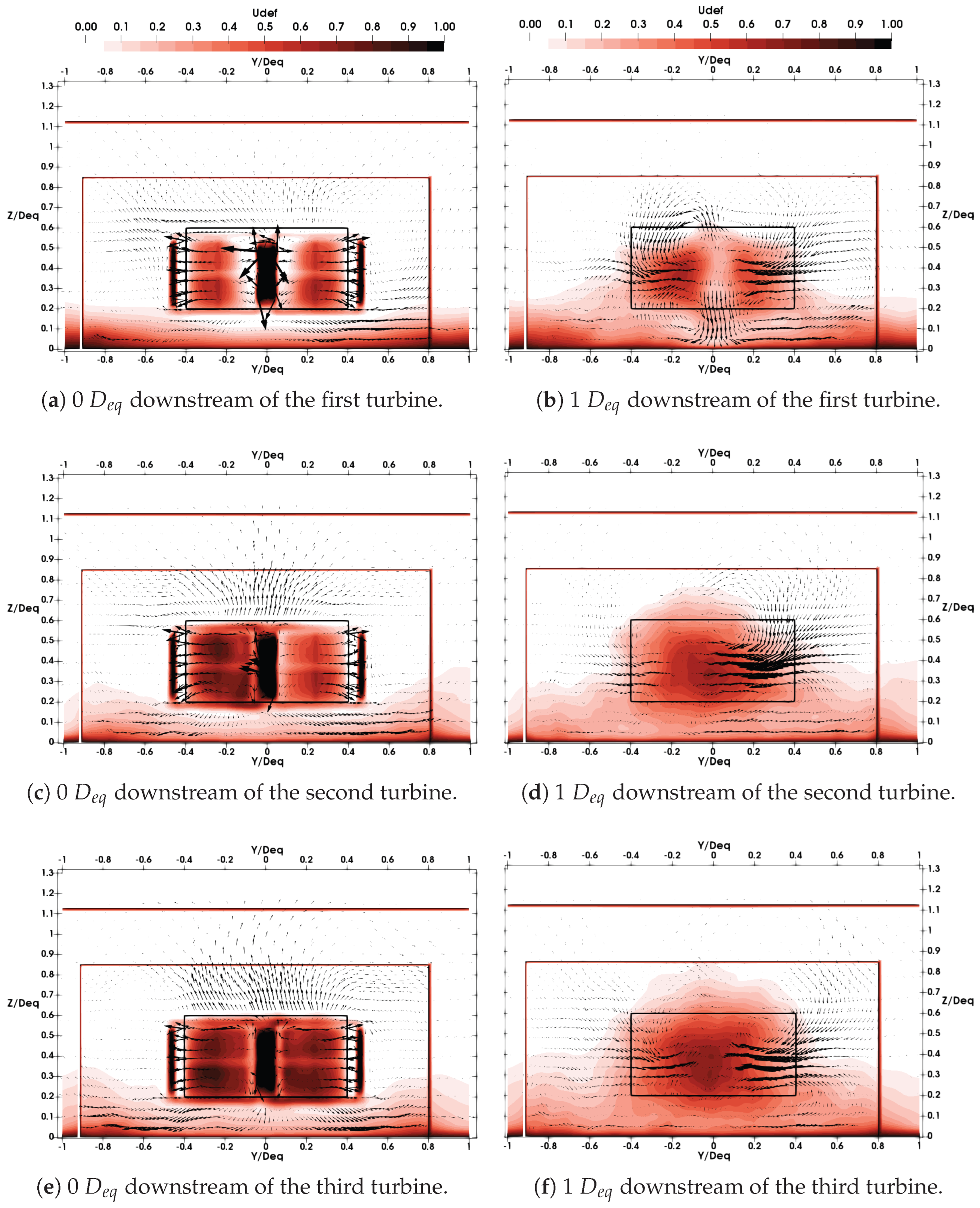

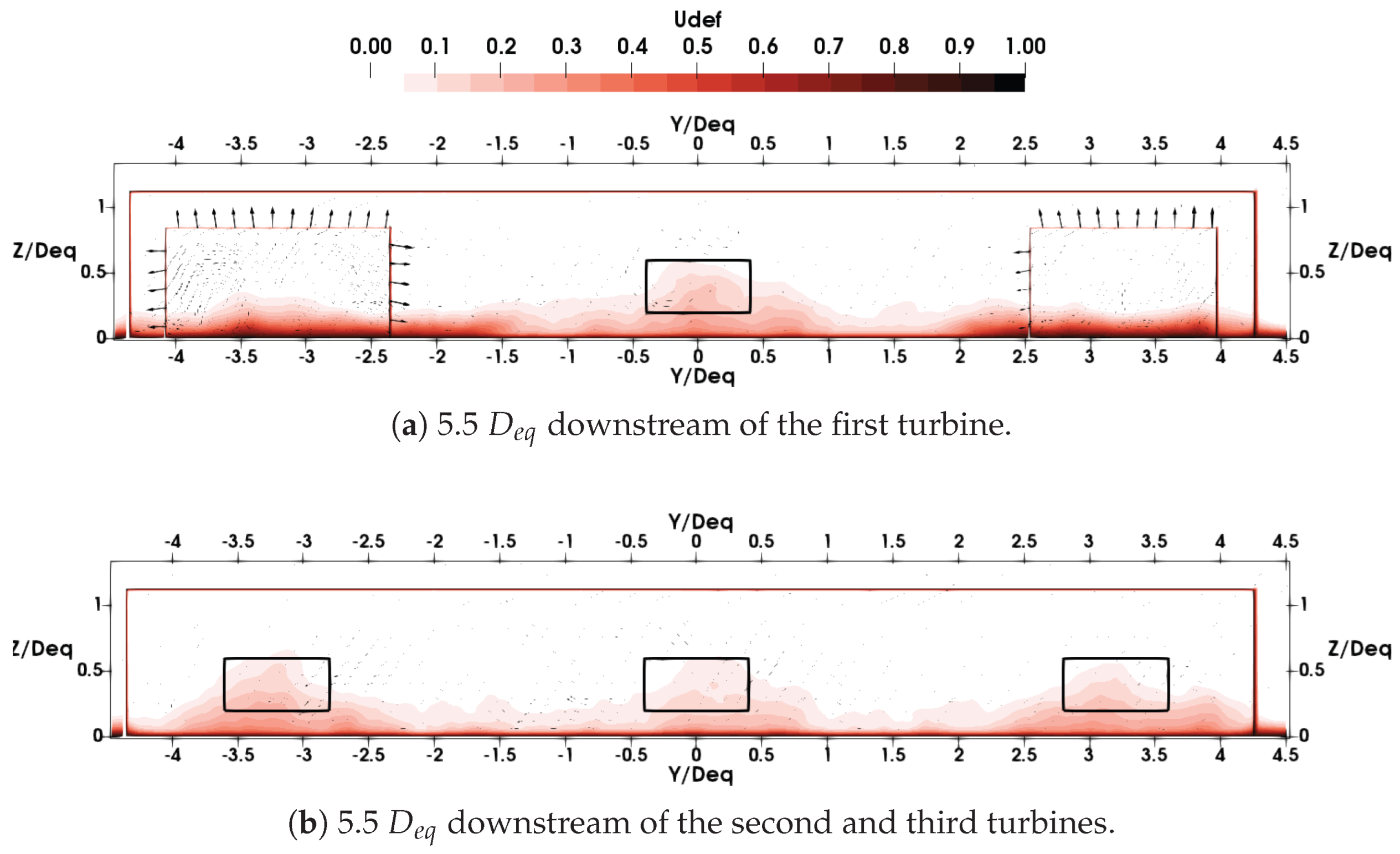

3.4.2. Wake Morphology for the Staggered Setup

The procedure described at the beginning of

Section 3.4 was applied to the

scenarios. For the

scenario, the average velocity deficit is shown in

Figure 20 at

downstream of the first turbine and

downstream of the second and third turbines. This corresponds to

upstream of the second, third and fourth turbines. In

Figure 20a, the wake of the first turbine does not expand vertically beyond the turbine footprint. The wake is slightly wider than the turbine footprint but does not exceed

in the y-direction. The counter-rotating vortices can be seen. As shown in

Figure 20b, the wake of the first turbine creates a strong velocity deficit gradient in the z-direction. The velocity deficit is different between the top and the bottom of the turbine footprint and is estimated to be approximately

.

Figure 21a shows the velocity deficit

upstream of turbines 2 and 3, or

downstream of turbine 1. The wake expansion in the vertical direction is still restricted to the turbine footprint. In the y-direction, the wake expands up to

. No counter-rotating vortex is visible.

Figure 21b shows the velocity deficit

upstream of turbine 4, or

downstream of turbines 2 and 3. The wakes of turbines 1, 2, and 3 are distinct from one another. The wake of turbine 1 covers all of turbine 4’s projected area. The difference in the velocity deficit between the top and bottom of turbine 4 is below

.

Figure 22a,b show the average axial velocity deficit

upstream of turbines 2 and 3 and

upstream of turbine 4, respectively. This corresponds to

downstream of turbine 1 and turbines 2 and 3, respectively. The wake of turbine 1 expands beyond

in the y-direction. As shown in

Figure 22b, the wakes of turbines 1, 2, and 3 are still

apart. The wake of turbine 1 is visible and covers most of turbine 4’s area, and the velocity deficit is almost uniform.

In

Section 3.3, it was noted that in the

and

scenarios, the power coefficients of the top and bottom rotors of turbine 4s were identical. In the

scenario, a difference of

was identified. This variation is likely attributable to disparate vertical velocity gradients present at the turbine locations. This gradient was relatively low for turbine 4s in the

and

scenarios, while it was higher in the

scenario. It was also noted in

Section 3.3 that turbines within the second row benefited from the blockage produced by turbine 1. This resulted in higher

values. As shown in the velocity deficit maps, the wakes of turbine 1s keep expanding in the y-direction. This would explain why the increase in

was greater in the

scenario. This was not the case in the

and

scenarios, where the

values of turbines 2 and 3 were close but the wake expansion differed. The vertical expansion of all the wakes of the

turbines was limited to the turbine footprints. This outcome was significantly different from that of the

scenarios, where the vertical expansion was amplified for multiple aligned turbines situated at distances less than 150 m from each other.

4. Conclusions and Outlook

ALM–LBM–LES simulations of realistic full-scale VATTs arranged into small arrays were performed. A total of six layouts were investigated: three aligned configurations with three turbines ( scenarios) and three staggered configurations with four turbines ( scenarios). The distances between consecutive aligned turbines were 50, 100, 150 m in the scenarios, and 100, 200, 300 m in the scenarios. All simulations used the same turbulent upstream boundary condition, generating a realistic inflow. The average velocity deficit along the turbine centerline was analyzed, as well as the average power coefficient and the shape of the wake.

It was observed that the centerline velocity deficit downstream of the array was not influenced by the number of turbines and that arrays

,

, and

exhibited similar wakes. The distance between turbines appeared to have a greater influence. Indeed, the wake in the

scenario differed significantly from the others. It was suggested that, in this scenario, there was a critical spacing of between 200 m and 300 m that led to a quasi-full recovery of the flow. This resulted in the far wake of the array being identical to that of a single turbine. The influence of different turbulence intensities on the far wake of a single HydroQuest VATT was assessed in [

16] using the same numerical approach. The impact on both the velocity deficit and the shape of the wake was observed. Consequently, the observations in this paper may be affected by local variations in turbulence characteristics, such as those caused by seabed morphology.

The impact of the distance between turbines on the average power coefficient was evident. For a distance between turbines greater than 100 m, the second turbine only lost power to the first turbine in the array. The accumulation of the velocity deficit between turbines led to a significant drop in efficiency of around for the third turbines in the arrays. Across all scenarios, the mixing in the wake from upstream turbines reduced the velocity gradient in the vertical direction. This translated into smaller differences in between the top and bottom rotors of downstream turbines. The lateral turbines benefited from the staggered configuration with a maximal increase in of compared to the first turbine in the array.

Observing the shape of the wake, it was suggested that the counter-rotating vortices created by the turbine became more intense with each passing turbine for a spacing below 150 m. Among the consequences was a stretching of the wake toward the free surface. When the spacing was equal to or greater than 150 m, this phenomenon was no longer observed.

These observations can be used to design more practical guidelines for these specific arrays:

To optimize power output and allow for flow recovery, aligned turbines should be kept at least 300 m apart, or 12 equivalent diameters.

A lateral spacing of 70 m, or equivalent diameters, in the lateral direction is enough to prevent the wake from merging.

A staggered configuration can increase power production due to the blocking effect.

Because counter-rotating vortices tend to increase the turbine footprint, the evolution of counter-rotating vortex pairs should be predicted.

In this paper, an integral length scale was chosen to match the observed integral length at the Alderney Race tidal site. However, significantly changing this scale would likely affect the results. For example, studies in the wind turbine sector, such as [

41], have observed phenomena linking large-scale vortices of turbulent flows to wake meandering. Future studies could focus on the influence of this parameter.

As discussed in the introduction, free-surface waves affect load fluctuations and are therefore important for fatigue predictions. Including extreme events, such as storms, in our model could provide valuable data for designing the turbine’s structure.

Understanding the influence of turbulence, layouts, and the fact that turbulence varies within a site, a similar study incorporating the actual seabed morphology of a tidal site would give valuable information on how a small farm would perform. Such a study could focus on how the seabed’s morphology locally affects the wake and load fluctuations.