Application of Machine Learning for Fuel Consumption and Emission Prediction in a Marine Diesel Engine Using Diesel and Waste Cooking Oil

Abstract

1. Introduction

2. Materials and Methods

2.1. Machine Learning Approach

- Root mean square error (RMSE);

- Mean absolute error (MAE);

- Mean absolute percentage error (MAPE);

- Coefficient of determination ().

2.2. Experiment Methodology

2.3. Fuel Properties

3. Results

3.1. Model Training Results

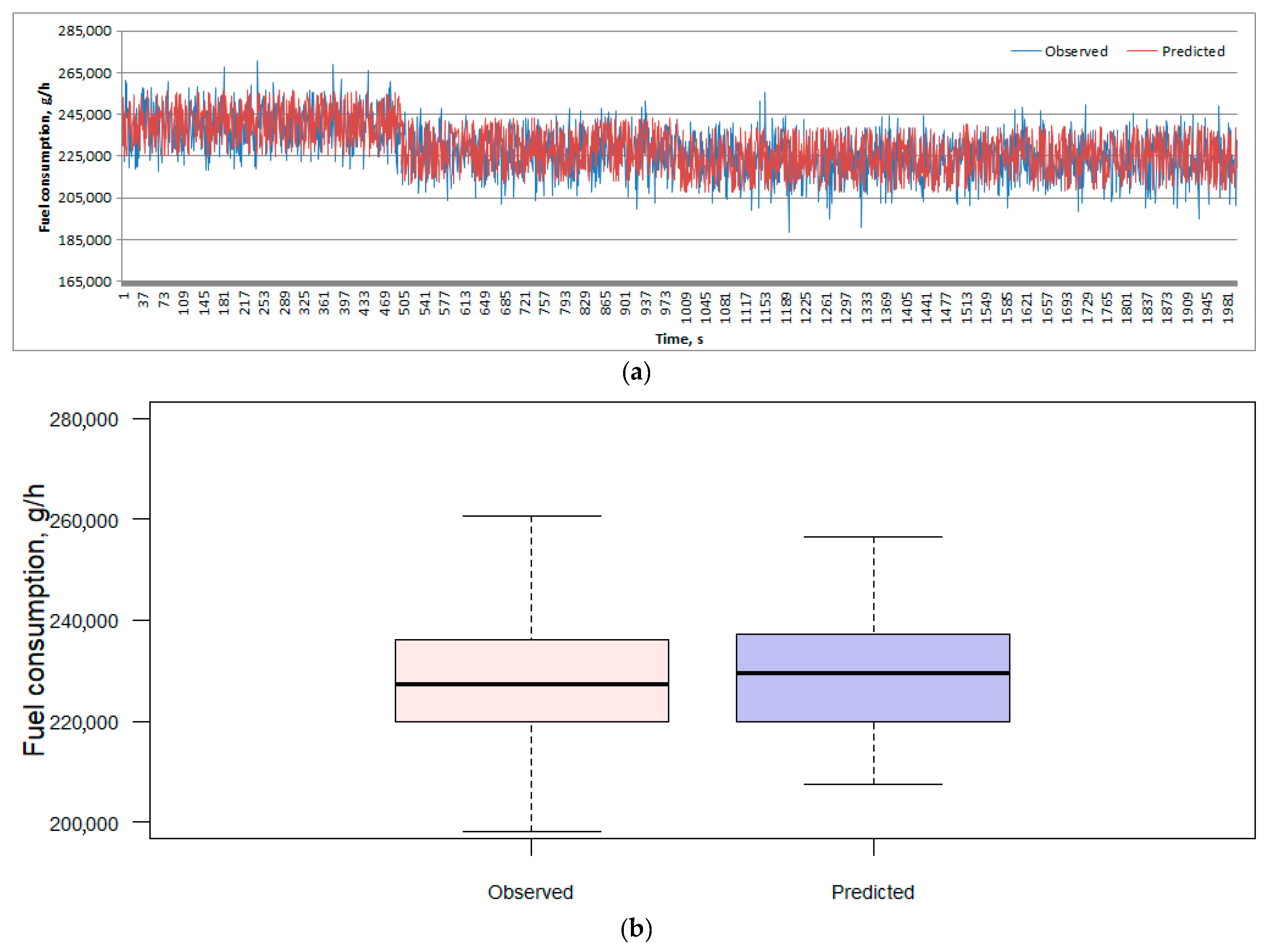

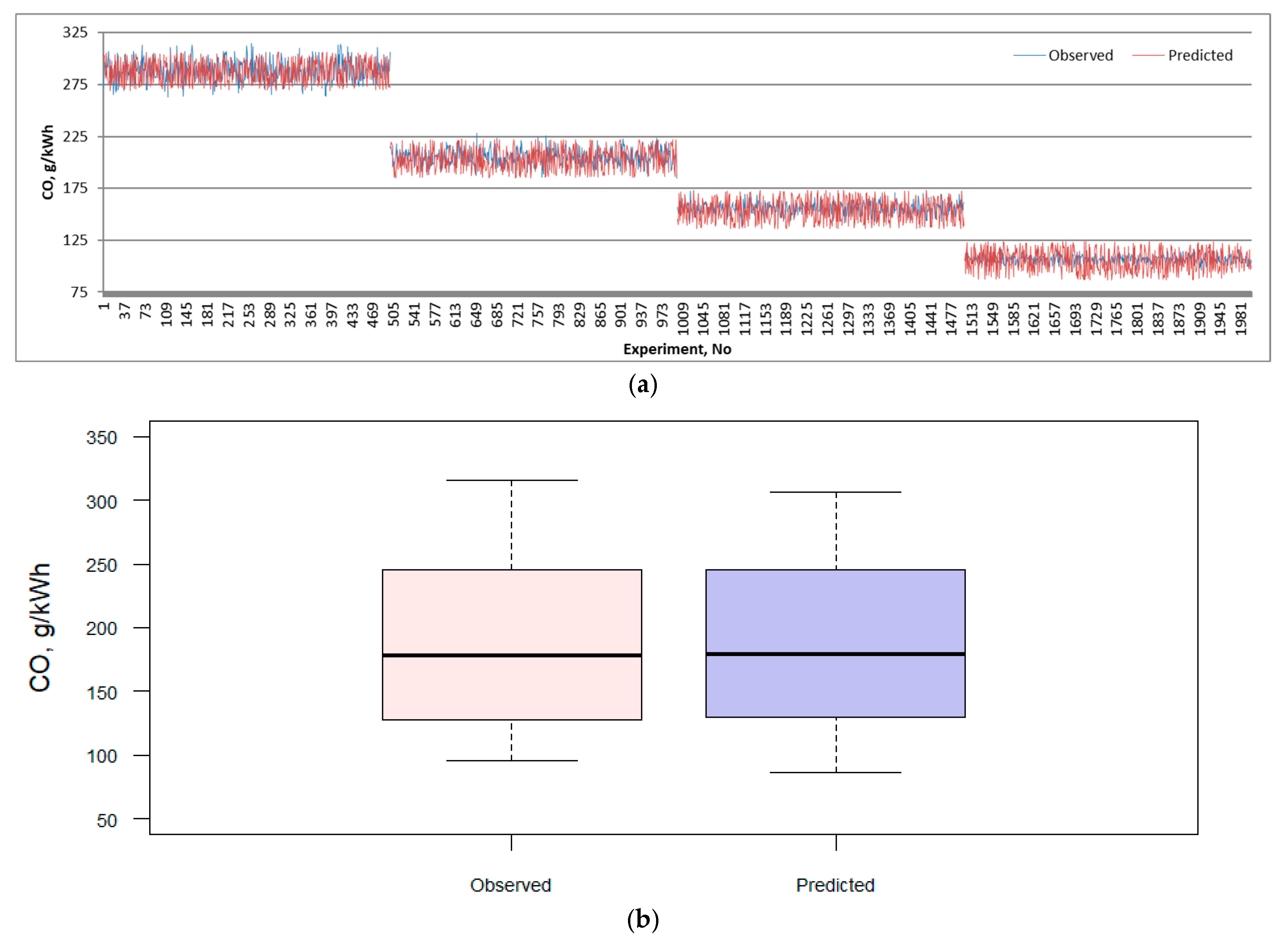

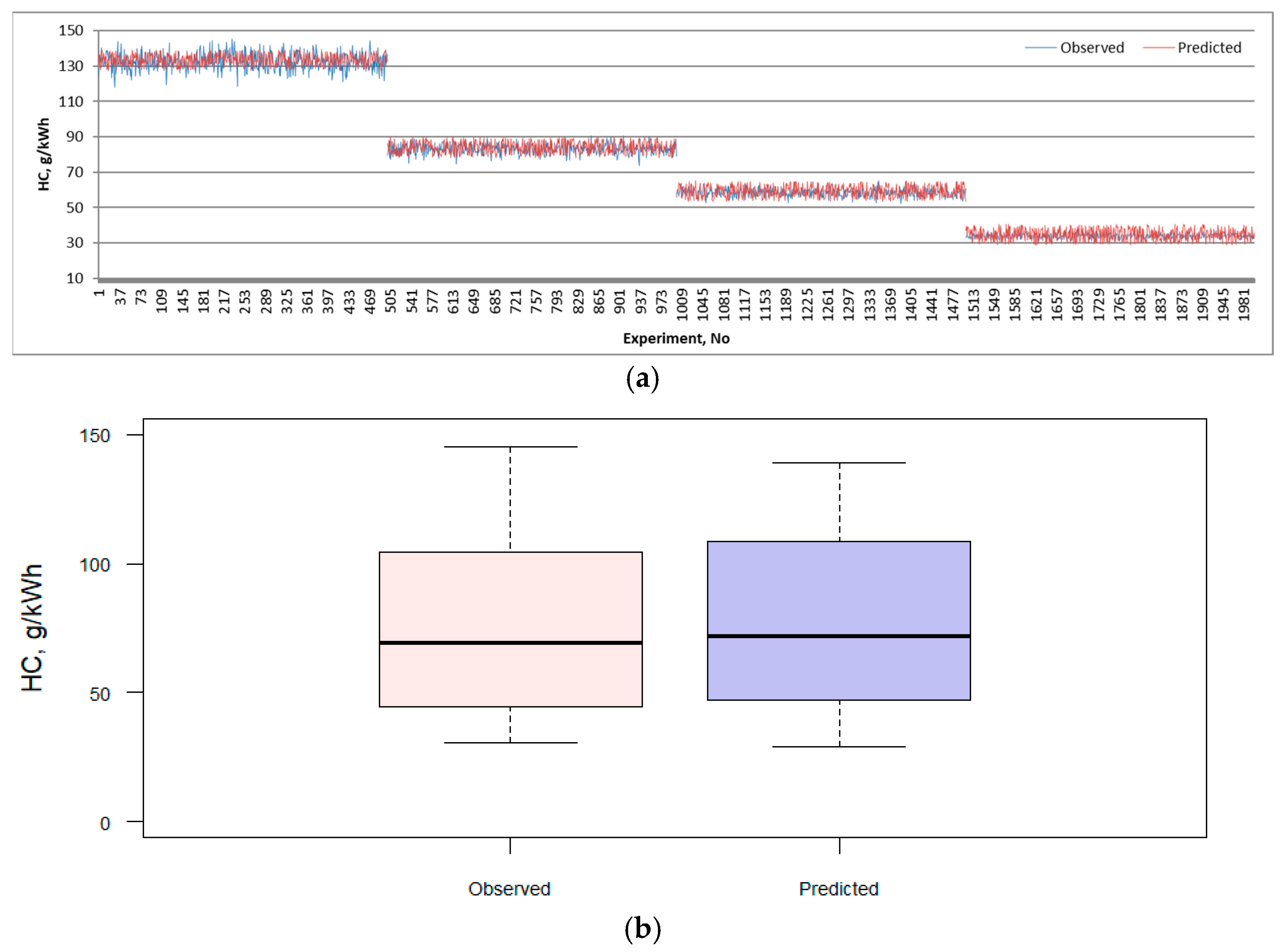

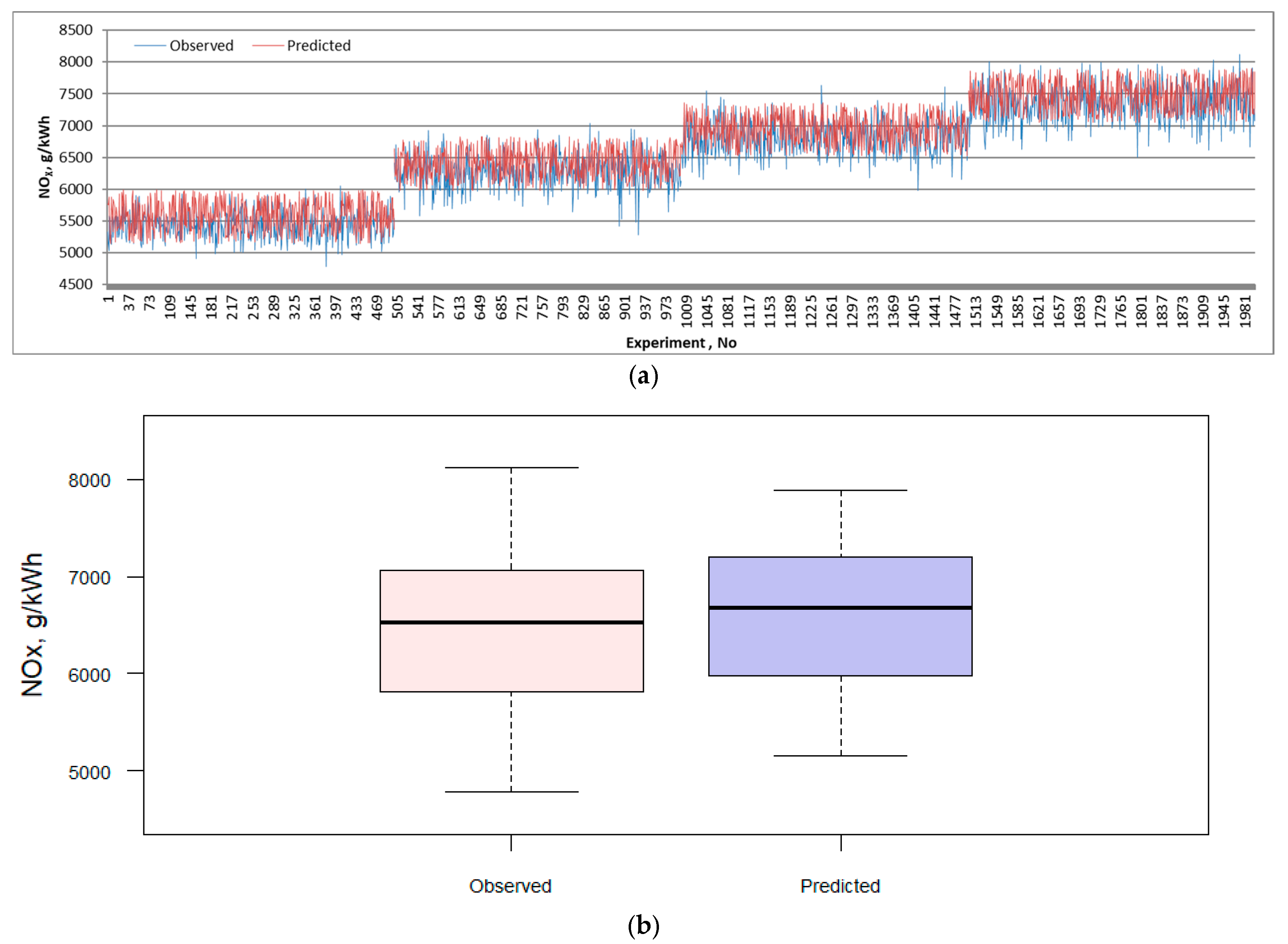

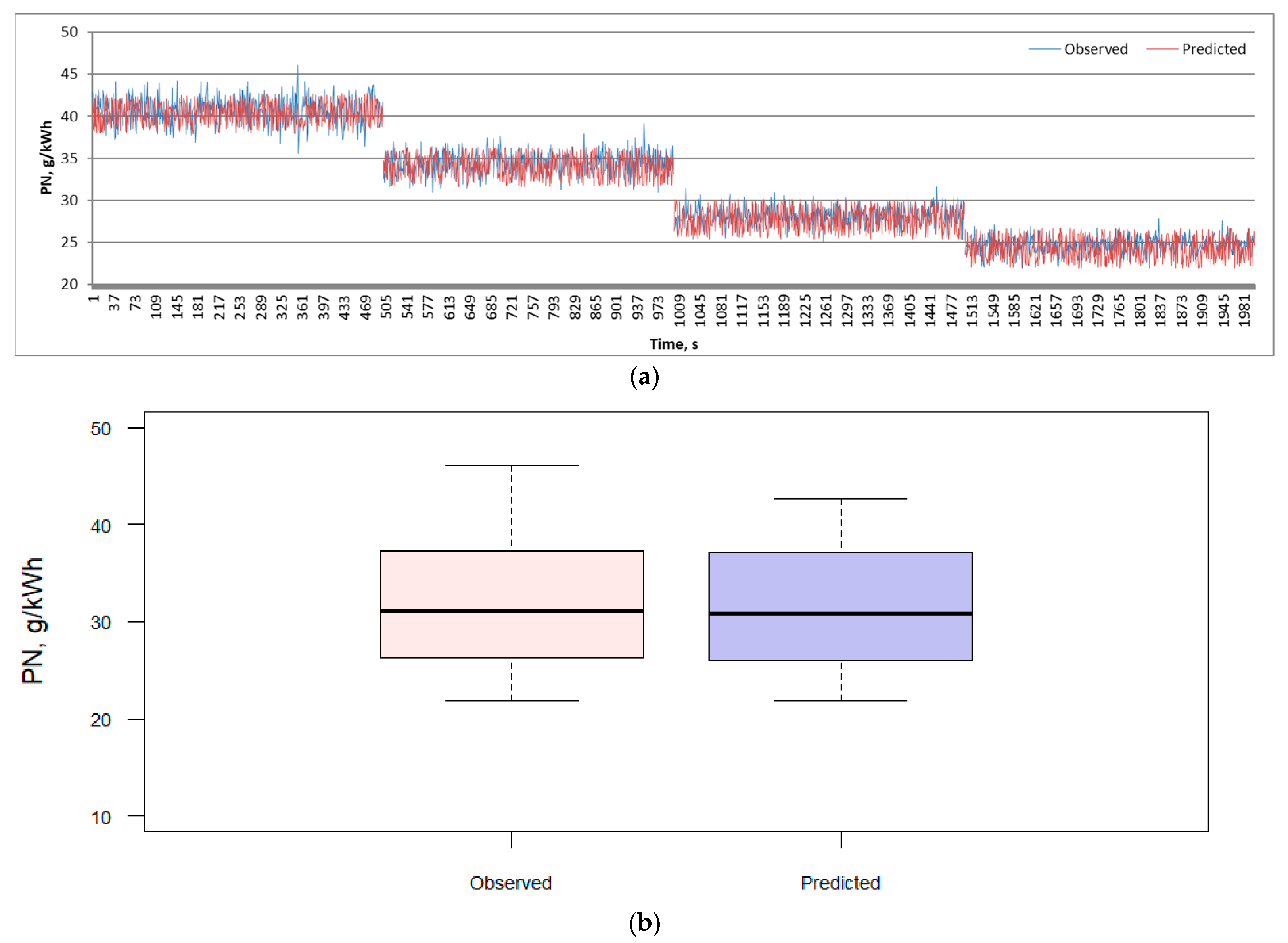

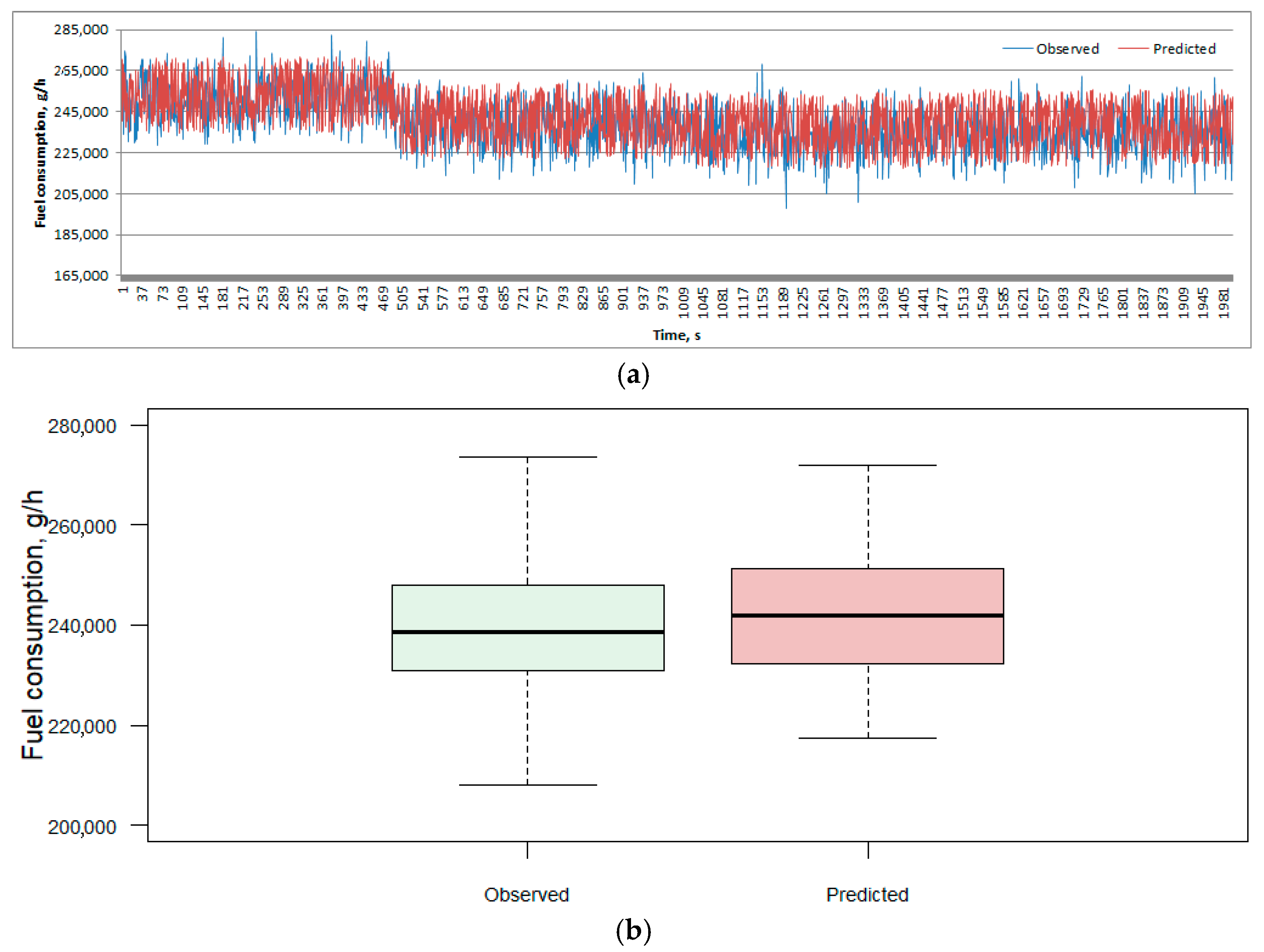

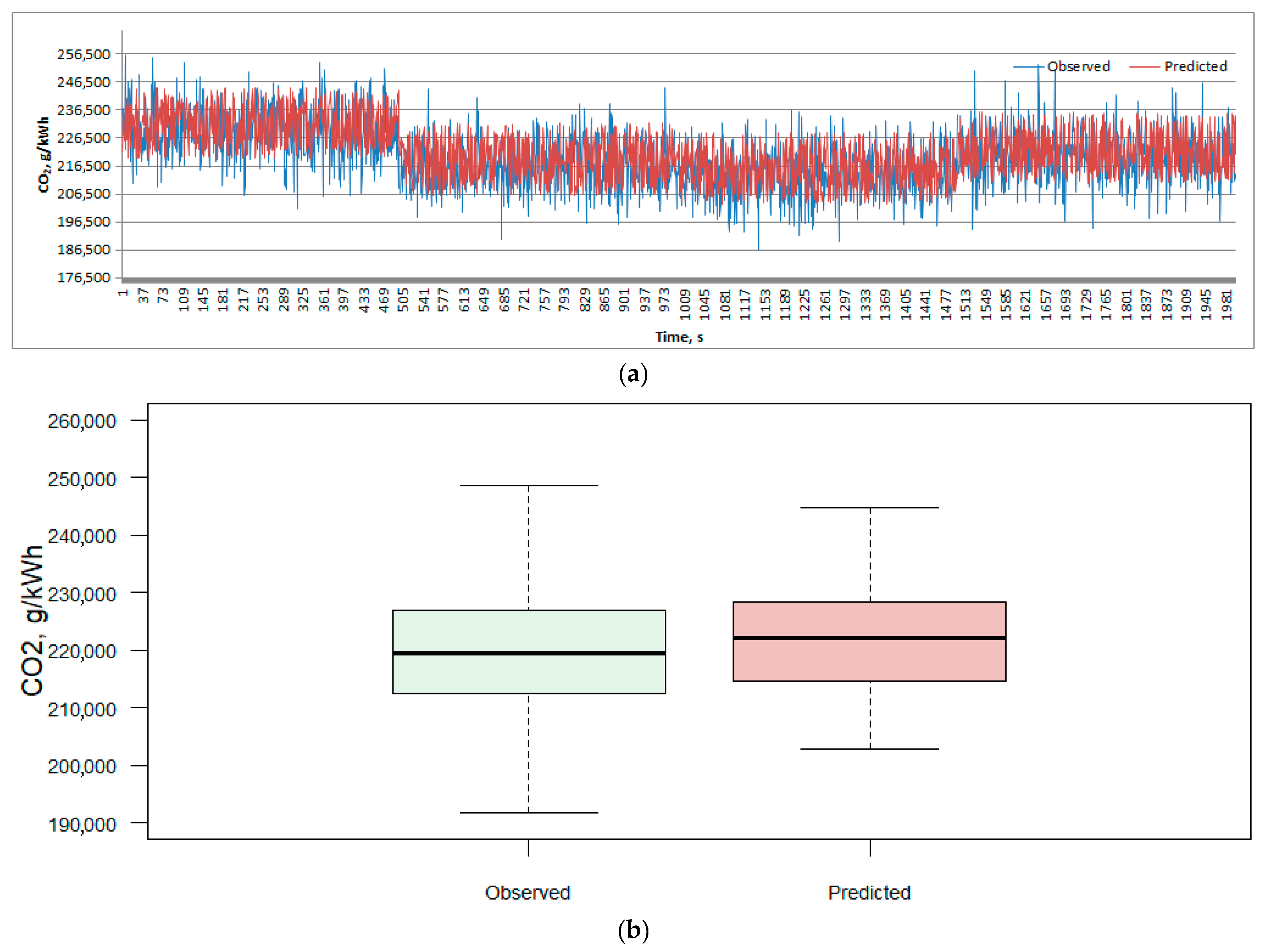

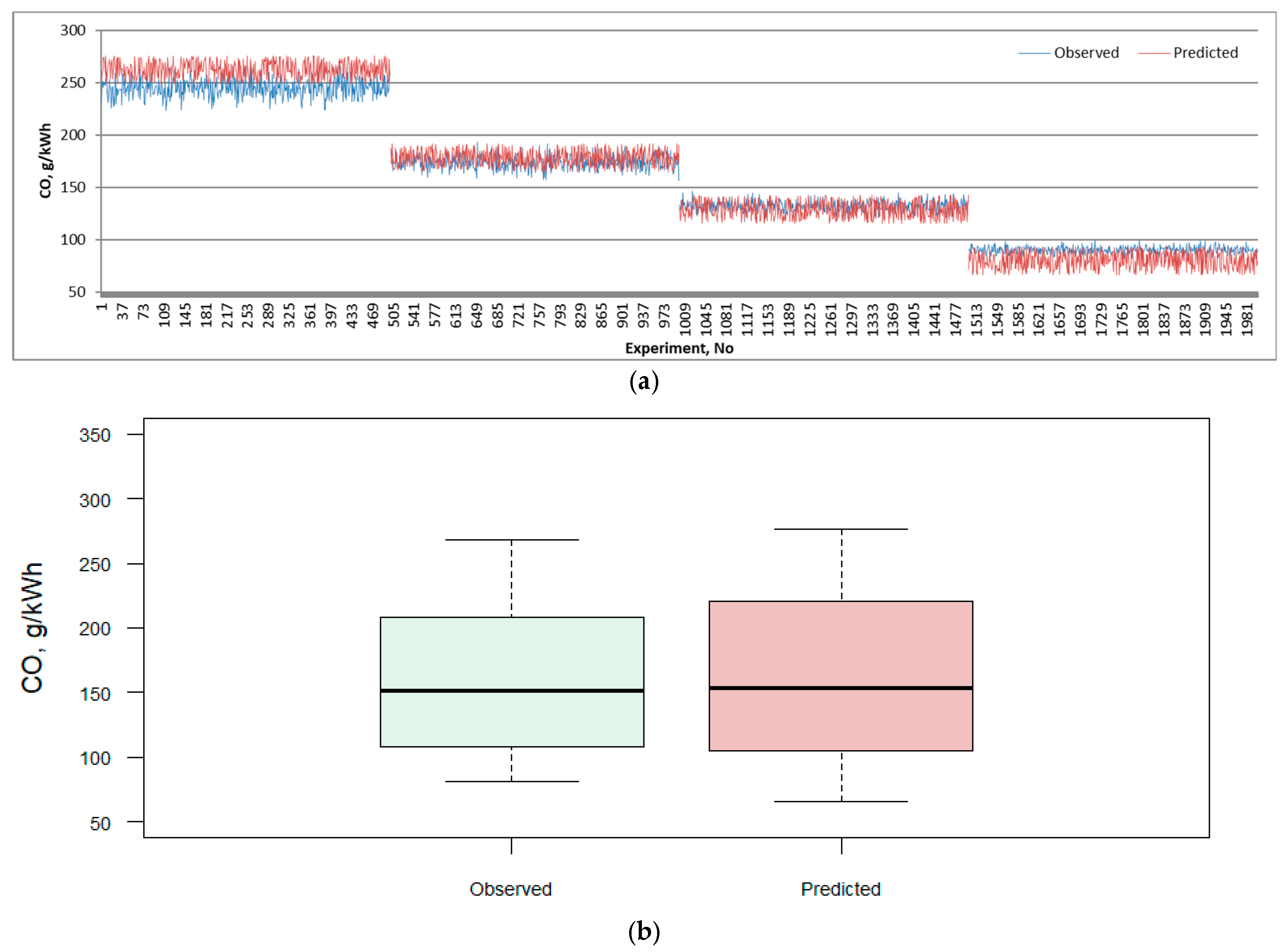

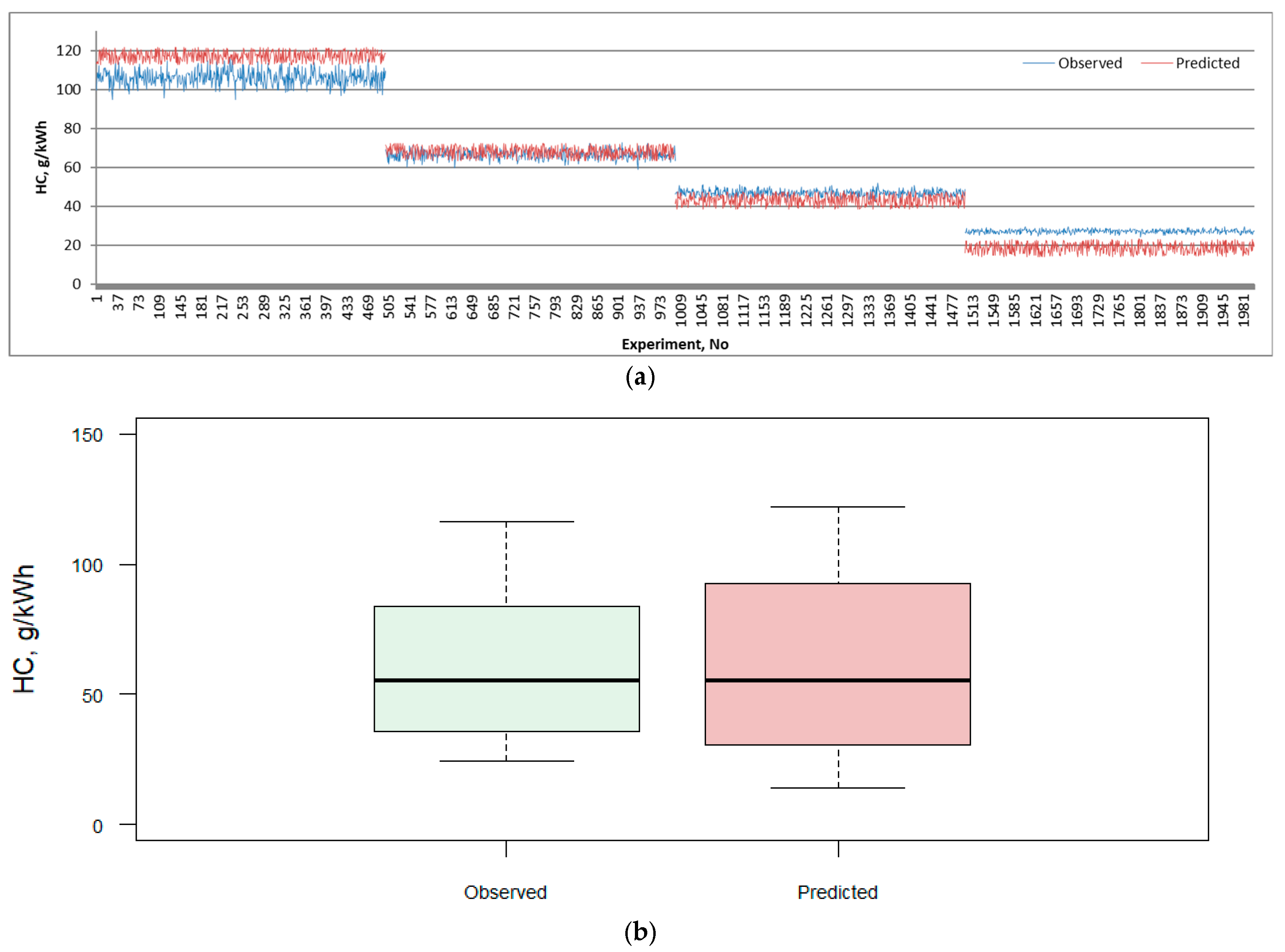

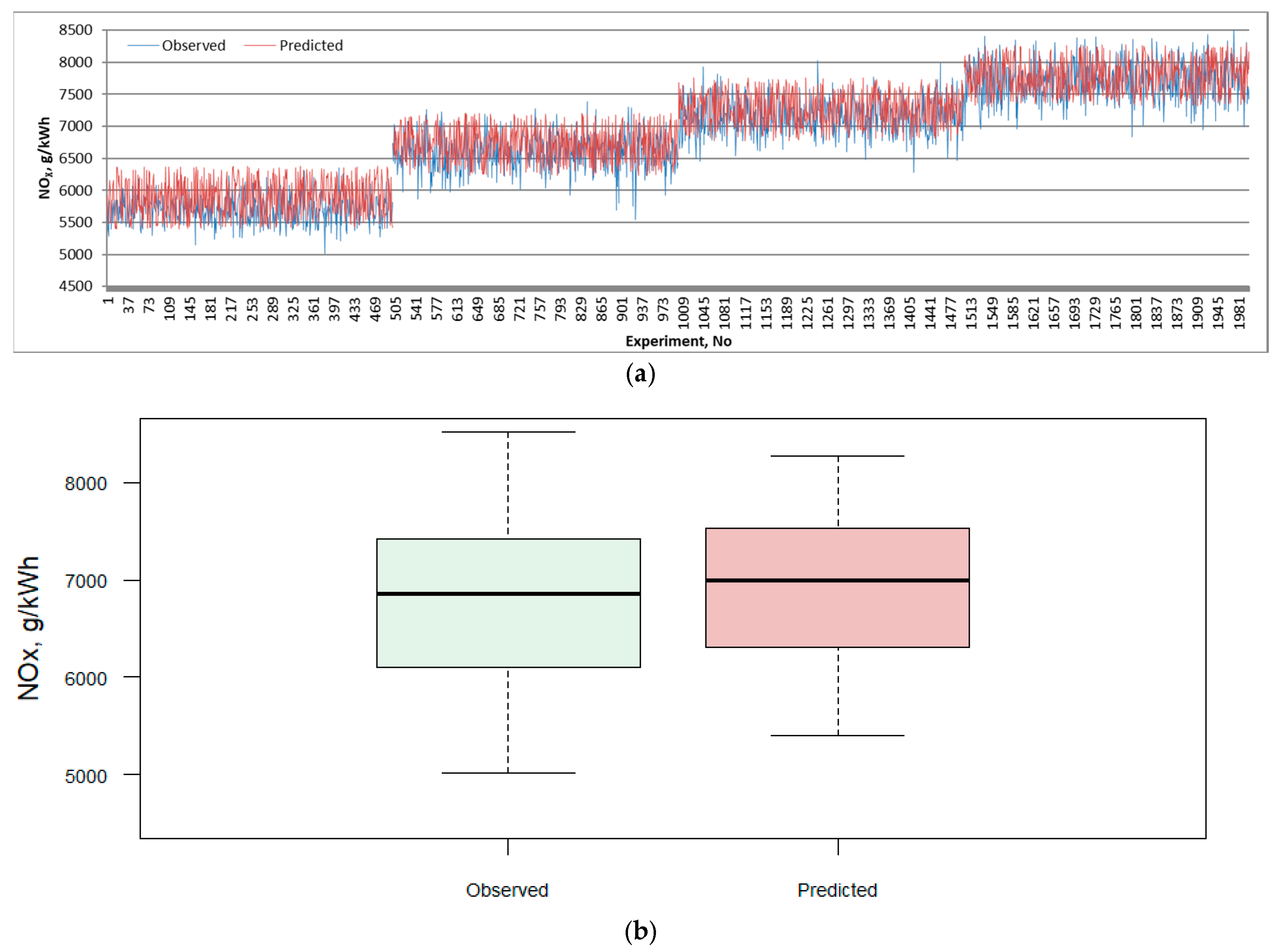

3.2. Model Testing Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, Z.; Zhang, W.; Nour, M.; Li, X.; Hung, D.L.S.; Xu, M. Interaction Mechanisms of Flash Boiling Spray with Air-Wall-Time in a SIDI Engine and Implications on Flame Propagation and Emissions Using Experimental Investigation and Machine Learning. Energy 2025, 328, 136633. [Google Scholar] [CrossRef]

- Mlynski, R.; Kozlowski, E. Selection of Level-Dependent Hearing Protectors for Use in An Indoor Shooting Range. Int. J. Environ. Res. Public Health 2019, 16, 2266. [Google Scholar] [CrossRef]

- Jovanović, V.; Janošević, D.; Marinković, D.; Petrović, N.; Djokić, R. Analysis of Influential Parameters in the Dynamic Loading and Stability of the Swing Drive in Hydraulic Excavators. Machines 2024, 12, 737. [Google Scholar] [CrossRef]

- Gu, J.; Wang, Y.; Hu, J.; Zhang, K.; Shi, L.; Deng, K. Real-Time Prediction of Fuel Consumption and Emissions Based on Deep Autoencoding Support Vector Regression for Cylinder Pressure-Based Feedback Control of Marine Diesel Engines. Energy 2024, 300, 131570. [Google Scholar] [CrossRef]

- Borucka, A.; Kozlowski, E. Mathematical Evaluation of Passenger and Freight Rail Transport as Viewed Through the COVID-19 Pandemic and the War in Ukraine Situation. Adv. Sci. Technol.-Res. J. 2024, 18, 238–249. [Google Scholar] [CrossRef]

- Žvirblis, T.; Vainorius, D.; Matijošius, J.; Kilikevičienė, K.; Rimkus, A.; Bereczky, Á.; Lukács, K.; Kilikevičius, A. Engine Vibration Data Increases Prognosis Accuracy on Emission Loads: A Novel Statistical Regressions Algorithm Approach for Vibration Analysis in Time Domain. Symmetry 2021, 13, 1234. [Google Scholar] [CrossRef]

- Odufuwa, O.Y.; Tartibu, L.K.; Kusakana, K. Artificial Neural Network Modelling for Predicting Efficiency and Emissions in Mini-Diesel Engines: Key Performance Indicators and Environmental Impact Analysis. Fuel 2025, 387, 134294. [Google Scholar] [CrossRef]

- Kumar, V.; Choudhary, A.K. Prediction of the Performance and Emission Characteristics of Diesel Engine Using Diphenylamine Antioxidant and Ceria Nanoparticle Additives with Biodiesel Based on Machine Learning. Energy 2024, 301, 131746. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Amini, M.R.; Kolmanovsky, I.; Tsutsumi, M.; Nakada, H. Modeling and Control of Diesel Engine Emissions Using Multi-Layer Neural Networks and Economic Model Predictive Control. IFAC-Pap. 2023, 56, 10696–10702. [Google Scholar] [CrossRef]

- Rohani, A.; Zareei, J.; Ghadamkheir, K.; Farkhondeh, S.A. Optimization of Engine Parameters and Emission Profiles through Bio-Additives: Insights from ANFIS Modeling of Diesel Combustion. Clean. Eng. Technol. 2025, 27, 100994. [Google Scholar] [CrossRef]

- Liu, L.; Shao, W.; Yan, Y.; Liu, D.; Zhang, J. Intelligent Self-Adaption of Marine Engine Degradation Based on a Digital-Twin Model. Energy Convers. Manag. 2025, 341, 119995. [Google Scholar] [CrossRef]

- Dişlitaş, A.N.; Yıldız, M.; Kale-Halasz, G. Digital Twin Applications in Aircraft Design Process. In Proceedings of the 3rd Cognitive Mobility Conference, Budapest, Hungary, 7–8 October 2024; Zöldy, M., Ed.; Lecture Notes in Networks and Systems. Springer Nature: Cham, Switzerland, 2025; Volume 1258, pp. 436–444, ISBN 978-3-031-81798-4. [Google Scholar]

- Gökçe, C.; Yıldız, M.; Kale-Halasz, G. VTOL Craft Controller Design and Simulation Using Digital Twin. In Proceedings of the 3rd Cognitive Mobility Conference, Budapest, Hungary, 7–8 October 2024; Zöldy, M., Ed.; Lecture Notes in Networks and Systems. Springer Nature: Cham, Switzerland, 2025; Volume 1258, pp. 401–413, ISBN 978-3-031-81798-4. [Google Scholar]

- Imanov, T.; Yildiz, M.; Teimourian, H.; Matijošius, J.; Kale, U.; Kilikevičius, A. 1D Convolutional Neural Networks Application on Aircraft Engine Thermal Performance Parameters. J. Therm. Anal. Calorim. 2025. [Google Scholar] [CrossRef]

- Park, M.-H.; Hur, J.-J.; Lee, W.-J. Prediction of Diesel Generator Performance and Emissions Using Minimal Sensor Data and Analysis of Advanced Machine Learning Techniques. J. Ocean. Eng. Sci. 2025, 10, 150–168. [Google Scholar] [CrossRef]

- Pallicheruvu, N.K.; Gnanasekaran, S. ANN-Driven Prediction of Optimal Machine Learning Models for Engine Performance in a Dual-Fuel Mode Powered by Biogas and Fish Oil Biodiesel. Energy Convers. Manag. X 2025, 25, 100827. [Google Scholar] [CrossRef]

- Dewang, Y.; Sharma, V.; Singla, Y.K. A Critical Review of Waste Tire Pyrolysis for Diesel Engines: Technologies, Challenges, and Future Prospects. Sustain. Mater. Technol. 2025, 43, e01291. [Google Scholar] [CrossRef]

- Oloruntobi, O.; Mokhtar, K.; Himawan, A.F.I.; Gohari, A.; Onigbara, V.; Rozar, N.; Balasudarsun, N.L. Economic and Environmental Assessment of Fatty-Acid-Methyl-Ester and Hydrotreated Vegetable Oil Biofuels Viability for Future Marine Engines. Bioresour. Technol. Rep. 2025, 30, 102146. [Google Scholar] [CrossRef]

- Wang, K.; Chi, Y.; Liang, H.; Jing, Z.; Li, Z.; Ma, R.; Huang, L. Carbon Emission Monitoring and Control Technology for Ships: A Review. Mar. Pollut. Bull. 2025, 219, 118219. [Google Scholar] [CrossRef]

- Li, Z.; Fei, J.; Du, Y.; Ong, K.-L.; Arisian, S. A near Real-Time Carbon Accounting Framework for the Decarbonization of Maritime Transport. Transp. Res. Part E: Logist. Transp. Rev. 2024, 191, 103724. [Google Scholar] [CrossRef]

- Marashian, A.; Böling, J.M.; Razminia, A.; Hyvönen, J.; Vettor, R.; Gustafsson, W.; Pirttikangas, M.; Björkqvist, J. Combined Engine Configuration and Speed Optimization for Fuel Savings on Cruise Ships. Ocean Eng. 2025, 322, 120387. [Google Scholar] [CrossRef]

- Mitchell, T.M. Machine Learning; McGraw-Hill Series in Computer Science; McGraw-Hill: New York, NY, USA, 1997; ISBN 978-0-07-042807-2. [Google Scholar]

- Alahmer, H.; Alahmer, A.; Alkhazaleh, R.; Al-Amayreh, M.I. Modeling, Polynomial Regression, and Artificial Bee Colony Optimization of SI Engine Performance Improvement Powered by Acetone–Gasoline Fuel Blends. Energy Rep. 2023, 9, 55–64. [Google Scholar] [CrossRef]

- Cohen, J.; Cohen, J. Applied Multiple Regression/Correlation Analysis for the Behavioral Sciences; L. Erlbaum Associates: Mahwah, NJ, USA, 2003; ISBN 978-1-4106-0626-6. [Google Scholar]

- Kozłowski, E.; Antosz, K.; Sęp, J.; Prucnal, S. Integrating Sensor Systems and Signal Processing for Sustainable Production: Analysis of Cutting Tool Condition. Electronics 2023, 13, 185. [Google Scholar] [CrossRef]

- Borucka, A.; Kozłowski, E. Modeling the Dynamics of Changes in CO2 Emissions from Polish Road Transport in the Context of COVID-19 and Decarbonization Requirements. Combust. Engines 2023, 195, 63–70. [Google Scholar] [CrossRef]

- Surblys, V.; Kozłowski, E.; Matijošius, J.; Gołda, P.; Laskowska, A.; Kilikevičius, A. Accelerometer-Based Pavement Classification for Vehicle Dynamics Analysis Using Neural Networks. Appl. Sci. 2024, 14, 10027. [Google Scholar] [CrossRef]

- Maritime Ships Database. Available online: https://directory.marinelink.com/ships/ (accessed on 20 June 2025).

- Chiavola, O.; Matijošius, J.; Palmieri, F.; Recco, E. Engine and Emission Performance of Renewable Fuels in a Small Displacement Turbocharged Diesel Engine. Energies 2024, 17, 6443. [Google Scholar] [CrossRef]

- Chiatti, G.; Chiavola, O.; Palmieri, F. Vibration and Acoustic Characteristics of a City-Car Engine Fueled with Biodiesel Blends. Appl. Energy 2017, 185, 664–670. [Google Scholar] [CrossRef]

- Rimkus, A.; Žaglinskis, J.; Stravinskas, S.; Rapalis, P.; Matijošius, J.; Bereczky, Á. Research on the Combustion, Energy and Emission Parameters of Various Concentration Blends of Hydrotreated Vegetable Oil Biofuel and Diesel Fuel in a Compression-Ignition Engine. Energies 2019, 12, 2978. [Google Scholar] [CrossRef]

- Elkelawy, M.; El Shenawy, E.A.; Bastawissi, H.A.E.; El Shennawy, I.A. The Effect of Using the WCO Biodiesel as an Alternative Fuel in Compression Ignition Diesel Engine on Performance and Emissions Characteristics. J. Phys. Conf. Ser. 2022, 2299, 012023. [Google Scholar] [CrossRef]

- Rocha-Meneses, L.; Hari, A.; Inayat, A.; Yousef, L.A.; Alarab, S.; Abdallah, M.; Shanableh, A.; Ghenai, C.; Shanmugam, S.; Kikas, T. Recent Advances on Biodiesel Production from Waste Cooking Oil (WCO): A Review of Reactors, Catalysts, and Optimization Techniques Impacting the Production. Fuel 2023, 348, 128514. [Google Scholar] [CrossRef]

- Milojević, S.; Stopka, O.; Kontrec, N.; Orynycz, O.; Hlatká, M.; Radojković, M.; Stojanović, B. Analytical Characterization of Thermal Efficiency and Emissions from a Diesel Engine Using Diesel and Biodiesel and Its Significance for Logistics Management. Processes 2025, 13, 2124. [Google Scholar] [CrossRef]

- Chiavola, O.; Matijošius, J.; Palmieri, F.; Recco, E. Effects of Renewable Fuels on the Performance and Emissions of a Small Displacement Diesel Engine for Urban Mobility; SAE International: Turin, Italy, 2024; Paper Numbers: 2024-37-0019. [Google Scholar]

- Jain, S.; Chandrappa, A.K. A Laboratory Investigation on Benefits of WCO Utilisation in Asphalt with High Recycled Asphalt Content: Emphasis on Rejuvenation and Aging. Int. J. Pavement Eng. 2023, 24, 2172577. [Google Scholar] [CrossRef]

- Foo, W.H.; Koay, S.S.N.; Chia, S.R.; Chia, W.Y.; Tang, D.Y.Y.; Nomanbhay, S.; Chew, K.W. Recent Advances in the Conversion of Waste Cooking Oil into Value-Added Products: A Review. Fuel 2022, 324, 124539. [Google Scholar] [CrossRef]

- Suardi, S.; Setiawan, W.; Nugraha, A.M.; Alamsyah, A.; Ikhwani, R.J. Evaluation of Diesel Engine Performance Using Biodiesel from Cooking Oil Waste (WCO). J. Ris. Teknol. Pencegah. Pencemaran Ind. 2023, 14, 29–39. [Google Scholar] [CrossRef]

- Outili, N.; Kerras, H.; Meniai, A.H. Recent Conventional and Non-Conventional WCO Pretreatment Methods: Implementation of Green Chemistry Principles and Metrics. Curr. Opin. Green Sustain. Chem. 2023, 41, 100794. [Google Scholar] [CrossRef]

- Chiavola, O.; Palmieri, F.; Cavallo, D.M. On the Increase in the Renewable Fraction in Diesel Blends Using Aviation Fuel in a Common Rail Engine. Energies 2023, 16, 4624. [Google Scholar] [CrossRef]

- Liao, J.; Hu, J.; Yan, F.; Chen, P.; Zhu, L.; Zhou, Q.; Xu, H.; Li, J. A Comparative Investigation of Advanced Machine Learning Methods for Predicting Transient Emission Characteristic of Diesel Engine. Fuel 2023, 350, 128767. [Google Scholar] [CrossRef]

- Gubarevych, O.; Wierzbicki, S.; Melnyk, O.; Kyrychenko, O.; Riashchenko, O. Increasing the acIncreasing the Accuracy of Calculated Indicators of Operational Reliability of Industrial Electric Motorscuracy of Calculated Indicators of Operational Reliability of Industrial Electric Motors. Eksploat. I Niezawodn. Maint. Reliab. 2025, 27, 203006. [Google Scholar] [CrossRef]

- Vrublevskyi, O.; Wierzbicki, S. Analysis of Potential Improvements in the Performance of Solenoid Injectors in Diesel Engines. Eksploat. I Niezawodn. Maint. Reliab. 2023, 25, 166493. [Google Scholar] [CrossRef]

- Schwarm, K.K.; Spearrin, R.M. Real-Time FPGA-Based Laser Absorption Spectroscopy Using on-Chip Machine Learning for 10 kHz Intra-Cycle Emissions Sensing towards Adaptive Reciprocating Engines. Appl. Energy Combust. Sci. 2023, 16, 100231. [Google Scholar] [CrossRef]

- Şahin, S. Comparison of Machine Learning Algorithms for Predicting Diesel/Biodiesel/Iso-Pentanol Blend Engine Performance and Emissions. Heliyon 2023, 9, e21365. [Google Scholar] [CrossRef] [PubMed]

- Khac, H.N.; Modabberian, A.; Zenger, K.; Niskanen, K.; West, A.; Zhang, Y.; Silvola, E.; Lendormy, E.; Storm, X.; Mikulski, M. Machine Learning Methods for Emissions Prediction in Combustion Engines with Multiple Cylinders. IFAC-Pap. 2023, 56, 3072–3078. [Google Scholar] [CrossRef]

- Aygun, H.; Dursun, O.O.; Toraman, S. Machine Learning Based Approach for Forecasting Emission Parameters of Mixed Flow Turbofan Engine at High Power Modes. Energy 2023, 271, 127026. [Google Scholar] [CrossRef]

- Zandie, M.; Ng, H.K.; Gan, S.; Muhamad Said, M.F.; Cheng, X. Multi-Input Multi-Output Machine Learning Predictive Model for Engine Performance and Stability, Emissions, Combustion and Ignition Characteristics of Diesel-Biodiesel-Gasoline Blends. Energy 2023, 262, 125425. [Google Scholar] [CrossRef]

- Khurana, S.; Saxena, S.; Jain, S.; Dixit, A. Predictive Modeling of Engine Emissions Using Machine Learning: A Review. Mater. Today Proc. 2021, 38, 280–284. [Google Scholar] [CrossRef]

- Li, B.; Ding, Y.; Ma, W.; Xiang, L.; Sui, C. A Health Condition Assessment Method for Marine Diesel Engine Turbochargers Using Zero-Dimensional Engine Model and Machine Learning. Measurement 2025, 251, 117283. [Google Scholar] [CrossRef]

- Zhang, Z.; Liang, K.; Pan, M.; Wang, H.; Sang, H.; Zhou, S.; Zhang, S.; Guan, W. Exhaust Emissions Prediction in Spark Ignition Engine Using LightGBM Optimized with the Marine Predators Algorithm. Appl. Therm. Eng. 2025, 275, 126800. [Google Scholar] [CrossRef]

- Lu, X.; Zhao, J.; Markov, V.; Grekhov, L. Deep Transfer Learning-Based Model for Real-Time Prediction of Multiple Injection Rate in Common Rail System for Marine Engine. Energy 2025, 332, 137206. [Google Scholar] [CrossRef]

- Saqib, S.; Usman, M.; Shah, A.N.; Riaz, F. A Review of the Utilization of Alternative Sources, Machine Learning, and Optimization Techniques for Spark Ignition Engines: Current Progress and Future Outlook. Results Eng. 2025, 26, 105265. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, G.; Wang, G.; Qian, D.; Shen, L. Integrated Machine Learning-Based Intelligent Optimization for Clean and Efficient Operation of Diesel Engines and Diesel Particulate Filters in Dual Modes. Process Saf. Environ. Prot. 2025, 201, 107457. [Google Scholar] [CrossRef]

- Mikulski, M.; Hunicz, J.; Duda, K.; Kazimierski, P.; Suchocki, T.; Rybak, A. Tyre Pyrolytic Oil Fuel Blends in a Modern Compression Ignition Engine: A Comprehensive Combustion and Emissions Analysis. Fuel 2022, 320, 123869. [Google Scholar] [CrossRef]

- Yuksel, O.; Bayraktar, M.; Sokukcu, M. Comparative Study of Machine Learning Techniques to Predict Fuel Consumption of a Marine Diesel Engine. Ocean. Eng. 2023, 286, 115505. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, X.; Feng, J.; Bai, S.; Li, G.; Duan, H.; Zhu, S. Challenges and Opportunities of Natural Gas Dual-Fuel Engines for Marine Applications. Fuel 2025, 400, 135808. [Google Scholar] [CrossRef]

- Al Nuaimi, H.S.; Acquaye, A.; Mayyas, A. Machine Learning Applications for Carbon Emission Estimation. Resour. Conserv. Recycl. Adv. 2025, 27, 200263. [Google Scholar] [CrossRef]

- Aggarwal, C. Recurrent Neural Networks. In Neural Networks and Deep Learning: A Textbook; Aggarwal, C.C., Ed.; Springer International Publishing: Cham, Switzerland, 2023; pp. 265–304. ISBN 978-3-031-29642-0. [Google Scholar]

- Carrington, A.M.; Fieguth, P.W.; Qazi, H.; Holzinger, A.; Chen, H.H.; Mayr, F.; Manuel, D.G. A New Concordant Partial AUC and Partial c Statistic for Imbalanced Data in the Evaluation of Machine Learning Algorithms. BMC Med. Inf. Decis. Mak. 2020, 20, 4. [Google Scholar] [CrossRef] [PubMed]

- Matijošius, J.; Rimkus, A.; Gruodis, A. Validation Challenges in Data for Different Diesel Engine Performance Regimes Utilising HVO Fuel: A Study on the Application of Artificial Neural Networks for Emissions Prediction. Machines 2024, 12, 279. [Google Scholar] [CrossRef]

- Matijošius, J.; Rimkus, A.; Gruodis, A. Prediction of the Main Environmental and Energy Characteristics of Diesel Engines Using an Artificial Neural Network for Pure Diesel Fuel, Pure Hvo, and a Mixture OF These Fuels in The Ratio 50/50 by Volume. Transp. Probl. 2024, 19, 69–82. [Google Scholar] [CrossRef]

| Emission | RMSE | MAE | MAPE | R2 | ||||

|---|---|---|---|---|---|---|---|---|

| Training | Testing | Training | Testing | Training | Testing | Training | Testing | |

| NOx | 253.2 | 270.3 | 14.2 | 18.8 | 7.6 | 10.6 | 93.6 | 91.4 |

| CO2 | 7.2 | 10.7 | 2.3 | 5.3 | 7.1 | 10.2 | 98.9 | 91.6 |

| CO | 9161.4 | 9188.8 | 85.2 | 89.6 | 8.0 | 9.3 | 906 | 88.2 |

| HC | 3.1 | 7.2 | 1.5 | 3.9 | 7.0 | 8.2 | 99.3 | 95.3 |

| PN | 1.2 | 4.8 | 1.0 | 3.1 | 7.4 | 8.6 | 96.1 | 91.2 |

| Fuel consumption | 9757.2 | 10,133.5 | 88.3 | 113.4 | 8.5 | 10.9 | 93.3 | 90.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Žvirblis, T.; Čižiūnienė, K.; Matijošius, J. Application of Machine Learning for Fuel Consumption and Emission Prediction in a Marine Diesel Engine Using Diesel and Waste Cooking Oil. J. Mar. Sci. Eng. 2025, 13, 1328. https://doi.org/10.3390/jmse13071328

Žvirblis T, Čižiūnienė K, Matijošius J. Application of Machine Learning for Fuel Consumption and Emission Prediction in a Marine Diesel Engine Using Diesel and Waste Cooking Oil. Journal of Marine Science and Engineering. 2025; 13(7):1328. https://doi.org/10.3390/jmse13071328

Chicago/Turabian StyleŽvirblis, Tadas, Kristina Čižiūnienė, and Jonas Matijošius. 2025. "Application of Machine Learning for Fuel Consumption and Emission Prediction in a Marine Diesel Engine Using Diesel and Waste Cooking Oil" Journal of Marine Science and Engineering 13, no. 7: 1328. https://doi.org/10.3390/jmse13071328

APA StyleŽvirblis, T., Čižiūnienė, K., & Matijošius, J. (2025). Application of Machine Learning for Fuel Consumption and Emission Prediction in a Marine Diesel Engine Using Diesel and Waste Cooking Oil. Journal of Marine Science and Engineering, 13(7), 1328. https://doi.org/10.3390/jmse13071328