Berth Efficiency Under Risk Conditions in Seaports Through Integrated DEA and AHP Analysis

Abstract

1. Introduction

2. Literature Overview

2.1. A Literature Overview of the Risk Management System in the Port

- -

- dependence of strategic long-term contracts on rented resources (warehouses, port machinery, …);

- -

- difference between the purpose of the area defined by the spatial planning documentation for the port area and the character of the activities performed in that area;

- -

- development of alternative (competitive) logistic routes which could attract cargo passing through a concrete port or cargo from that port’s hinterland area;

- -

- a delay in fulfilling preconditions to serve ships in accordance with the ongoing development trends in the shipping industry: absence of on-shore power supply connections and lack of facilities for supplying ships with alternative fuels. In general, a delay in adjusting business activities in a port to changed national and international regulations, etc.

2.2. A Literature Overview of Port Efficiency

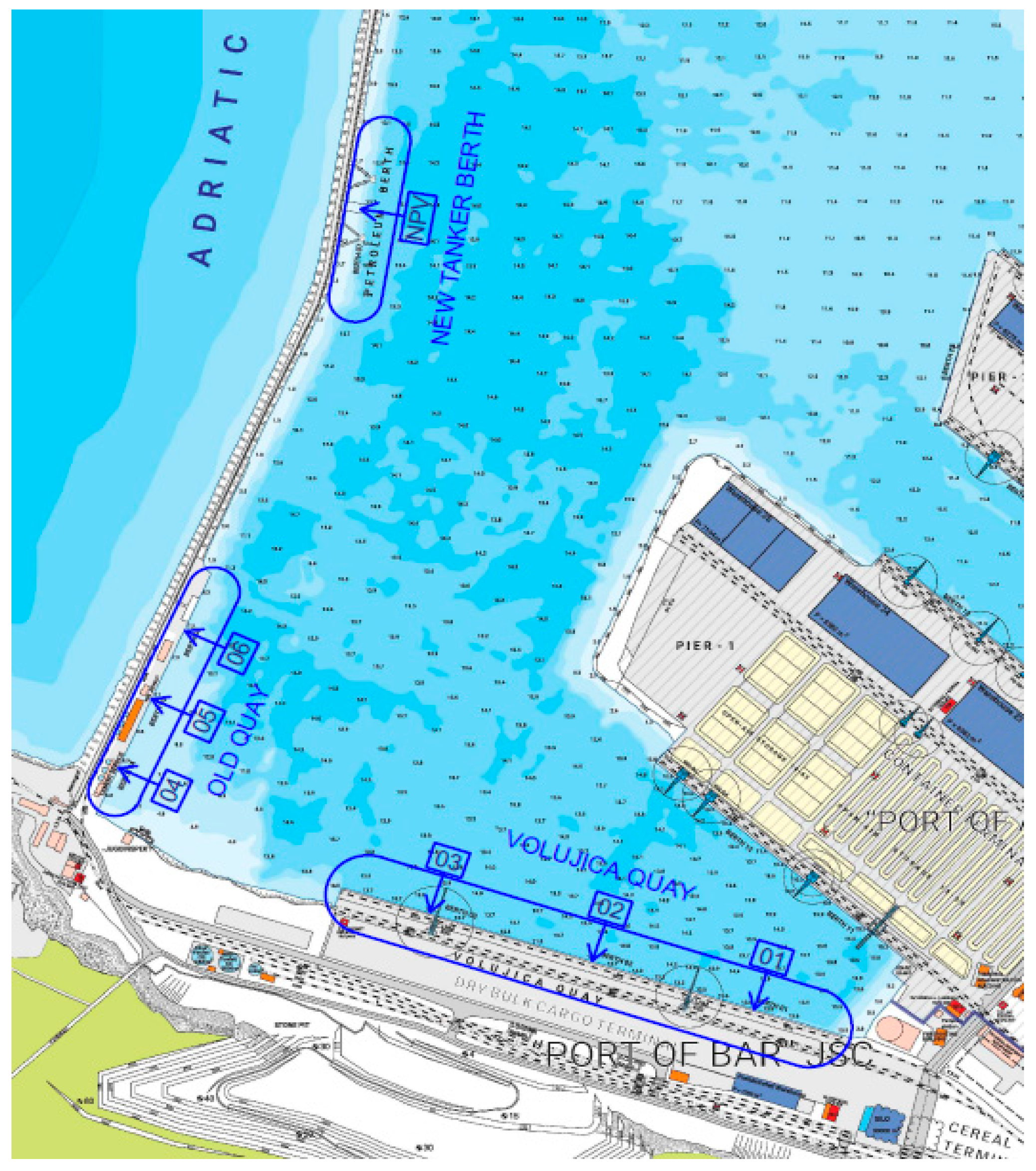

3. Description of a Port Where the Analysis Is Performed

4. Methodology

4.1. Data Envelopment Analysis (DEA)

4.1.1. Identification of the Decision-Making Units (DMUs)

4.1.2. Selection of the Input and Output Variables

- -

- daily wages, C01-1 (EUR) of workers directly engaged in the cargo handling operation;

- -

- port machinery costs, C01-2 (EUR) used in the cargo handling process: depending on the type of the cargo handling operation and type of the cargo, this component of costs is a sum of following items (related to the used types of the port machinery): fuel costs, electric power costs, depreciation costs, and cost of periodical inspection by authorized external body (fulfillment of safety requirements);

- -

- costs of personal safety equipment, C01-3 (EUR) of workers directly engaged in the cargo handling process;

- -

- costs of fire truck, C01-4 (EUR) used for preventive purposes in the handling operation with liquid bulk cargoes (oil derivatives);

- -

- costs of insurance of workers directly engaged in the cargo handling process, C01-5 (EUR);

- -

- costs of using a protective dam, C01-6 (EUR), against spills of oil derivatives during handling operations.

4.1.3. Analyzed Period

4.1.4. Data Series

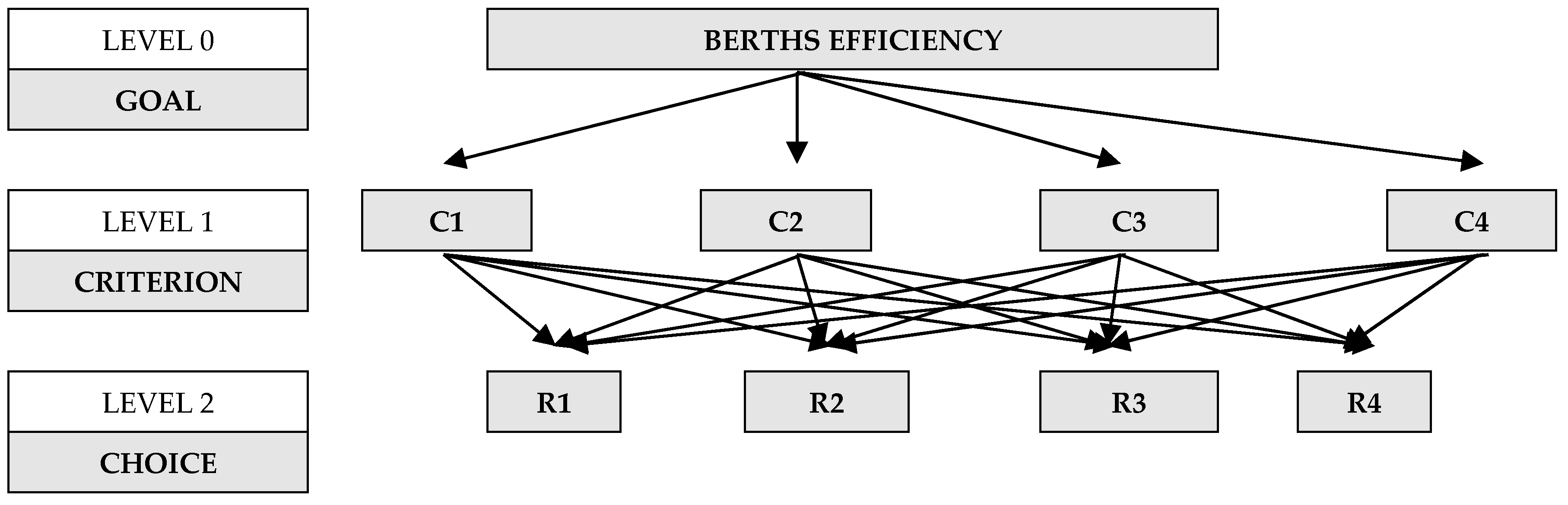

4.2. AHP (Analytic Hierarchy Process) Method

- (A)

- Defining the goal

- (B)

- Defining selection criteria and variants (alternatives)

- -

- criterion 1—C1: number of engaged workers;

- -

- criterion 2—C2: berth length;

- -

- criterion 3—C3: water depth;

- -

- criterion 4—C4: operation costs.

- (C)

- Defining the hierarchical analysis model

- (D)

- Pair-wise comparison and consistency test

- -

- creating a reciprocal (comparative) matrix (using Saati’s fundamental scale of absolute numbers);

- -

- summing each column of the reciprocal (comparison) matrix;

- -

- obtaining the normalized relative weights;

- -

- calculating principal eigen value λmax—the summation of the products between each element of the eigen vector and the sum of columns of the reciprocal (comparison) matrix);

- -

- calculating Consistency Index, CI—a measure of deviation or degree of consistency using the following equation: CI = (λmax − n)/(n − 1), where λmax—principal eigen value; n—number of items for comparison;

- -

- calculating Consistency Ratio, CR—based on the values of Consistency Index, CI, and Random Consistency Index, RI (table values), according to the number of items to be compared, n; for the analyzed case, n = 4 ⇒ RI = 0.9; if the value of CR is under 0,10, then the made evaluation is consistent.

- (E)

- Calculate the global weights

respect to the goal) × (relative weight of the variant (alternat.)–domain of

risks Mi based on criterion cj, from compar. matrix with respect to criterion cj)

- (F)

- Final ranking of alternatives.

5. Results

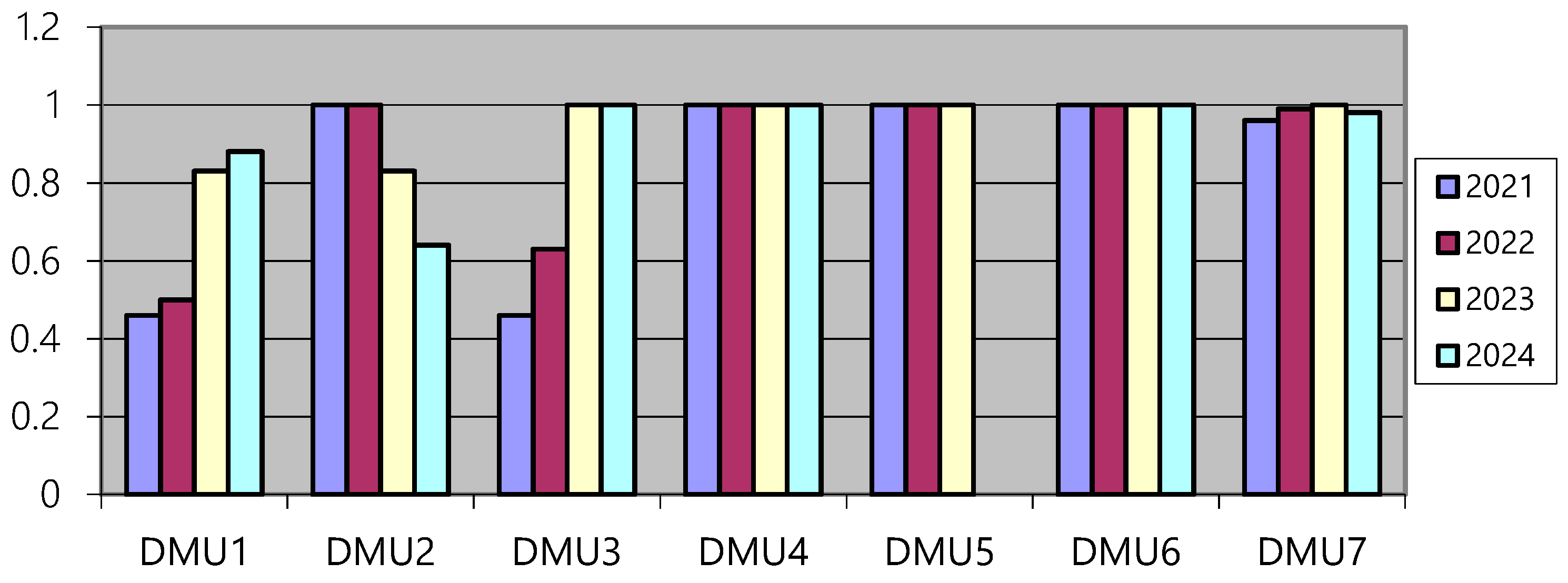

5.1. Efficiency Scores for Defined DMUs (Berths)

5.2. Intensity of Impact of Risks on Berths’ Efficiency

5.2.1. Pair-Wise Comparisons and Consistency Tests—Level 1 and Level 2 of the Hierarchy Framework

5.2.2. Overall Composite Weights (Synthesizing Results) and Final Ranking

6. Discussion

- -

- Rank 1: Variant (alternative) 1, R1—operational risks—overall composite weight: 0.3546 (35.46%);

- -

- Rank 2: Variant (alternative) 3, R3—safety risks—overall composite weight share: 0.2845 (28.45%);

- -

- Rank 3: Variant (alternative) 2, R2—technical risks—overall composite weight: 0.2399 (23.99%);

- -

- Rank 4: Variant (alternative) 4, R4—environmental risks—overall composite weight: 0.1209 (12.09%).

- -

- related to the Variant (alternative) 1, R1—operational risks: to improve management supervision and internal controls; to improve planning of the cargo handling process (optimization of allocation of resources), to improve parameters of the cargo handling process realization (increasing productivity, minimization/elimination of working process interruptions, …); etc.

- -

- related to Variant (alternative) 3, R3—safety risks: to optimize health and safety procedures; to optimize usage of personal protective equipment; to minimize period of exposure and mode of exposure of workers; to carry out, strictly in line with the related regulation, all necessary safety inspections of the port infrastructure, port superstructure, port machinery by the authorized external bodies; to implement the safety management system which involves preventive measures referred on all persons within the port area (port workers, customers, service providers, ship’s crew, …); etc.

- -

- related to Variant (alternative) 2, R2—technical risks: to optimize the level of qualification of maintenance personnel; to optimize implemented maintenance policies; to optimally carry out preventive and corrective maintenance of all port technical systems, etc.

- -

- related to Variant (alternative) 4, R4—environmental risks: to establish the optimal environmental management system which will prevent negative impacts/different environmental aspects: emissions to air (cargo handling operations, port machinery, ships, open areas, …), spillages to water (from ships, from the port territory), spillages to soil; generation of waste; usage of resources (electricity, water); noise pollution; relation with the local community; etc.

- -

- according to criterion 1—C1: number of workers engaged in the cargo handling process, has the rank “3”, with a weight of 0.2260 (22.60%);

- -

- according to criterion 2—C2: berth length, has the rank “1”, with a weight of 0.4196 (41.96%);

- -

- according to criterion 3—C3: water depth, has the rank “2”, with a weight of 0.2748 (27.48%);

- -

- according to criterion 4—C4: operation costs, has the rank “1”, a weight of 0.4429 (44.29%).

- -

- according to criterion 1—C1: number of workers engaged in the cargo handling process, has the rank “1”, with a weight of 0.4774 (47.74%);

- -

- according to criterion 2—C2: berth length, has the rank “3”, with a weight of 0.1955 (19.55%);

- -

- according to criterion 3—C3: water depth, has the rank “4”, with a weight of 0.1394 (13.94%);

- -

- according to criterion 4—C4: operation costs, has the rank “3”, a weight of 0.2131 (21.31%).

- -

- according to criterion 1—C1: number of workers engaged in the cargo handling process, has the rank “3”, with a weight of 0.1893 (18.93%);

- -

- according to criterion 2—C2: berth length, has the rank “2”, with a weight of 0.2477 (24.77%);

- -

- according to criterion 3—C3: water depth, has the rank “1”, with a weight of 0.3873 (38.73%);

- -

- according to criterion 4—C4: operation costs, has the rank “2”, a weight of 0.2376 (23.76%).

- -

- according to criterion 1—C1: number of workers engaged in the cargo handling process, has the rank “4”, with a weight of 0.1073 (10.73%);

- -

- according to criterion 2—C2: berth length, has the rank “4”, with a weight of 0.1371 (13.71%);

- -

- according to criterion 3—C3: water depth, has the rank “3”, with a weight of 0.1981 (19.81%);

- -

- according to criterion 4—C4: operation costs, has the rank “4”, with a weight of 0.1065 (10.65%).

- -

- Variant (alternative) 3, R3—safety risks, according to criterion 1—C1: number of workers engaged in the cargo handling process: weight of 0.4774 (47.74%);

- -

- Variant (alternative) 1, R1—operational risks, according to criterion 4—C4: operation costs: weight of 0.4429 (44.29%);

- -

- Variant (alternative) 1, R1—operational risks, according to criterion 2—C2: berth length: weight of 0.4196 (41.96%);

- -

- Variant (alternative) 2, R2—technical risks, according to criterion 3—C3: water depth: weight of 0.3873 (38.73%).

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References and Note

- Nagi, A.; Schroeder, M.; Kersten, W. Risk Management in Seaports: A Community Analysis at the Port of Hamburg. Sustainability 2021, 13, 8035. [Google Scholar] [CrossRef]

- Parra, N.M.; Nagi, A.; Kersten, W. Risk Assessment Methods in Seaports: A Literature Review. In Publications of the HAZARD Project 24; HAZARD Project: Turku, Finland, 2018. [Google Scholar] [CrossRef]

- Sarkar, B.D.; Shankar, R.; Kar, A.K. Severity analysis and risk profiling of port logistics barriers in the Industry 4.0 era. Benchm. Int. J. 2022, 30, 3253–3280. [Google Scholar] [CrossRef]

- Do Bagus, M.R.; Hanaoka, S. Interdependency patterns of potential seaport risk factors in relation to supply chain disruption in Indonesia. J. Shipp. Trade 2023, 8, 6. [Google Scholar] [CrossRef]

- Marsh, J.L.T. Specialty, Global Marine & Cargo Practice, Ports & Terminals: Risk Challenges and Solutions. Available online: https://www.marsh.com (accessed on 20 July 2024).

- Alzate, P.; Isaza, G.A.; Toro, E.M.; Jaramillo-Garzón, J.A.; Hernandez, S.; Jurado, I.; Hernandez, D. Operational efficiency and sustainability in smart ports: A comprehensive review. Mar. Syst. Ocean Tech. 2024, 19, 120–131. [Google Scholar] [CrossRef]

- European Commission. Europe’s Seaports 2030: Challenges Ahead, Brussels. 2013. Available online: https://europe.eu//commission/presscorner/detail/en/memo_13_448 (accessed on 15 October 2024).

- Bulletin Fall 352. 2016. Available online: https://repositorio.cepal.org/server/api/core/bitstreams/1e9d475e-70e5-41a2-a1c9-7d8b7351db4d/content (accessed on 22 October 2024).

- Hanson, S.E.; Nicholls, R.J. Demand for ports to 2050: Climate policy, growing trade and the impacts of sea-level rise. Earth’s Futur. 2020, 8, e2020EF001543. [Google Scholar] [CrossRef]

- Deloitte Inc. Port 2050 Scenarios Update Final Report. 2015. Available online: https://deloitte.relayto.com/e/monitor-deloitte-final-report-dfjz70sqtnhl5 (accessed on 28 October 2024).

- Taneja, P.; Walker, W.; Ligteringen, H.; Van Schuylenburg, M. Future scenarios, Implications for port planning. In Proceedings of the WCTRS Conference, Antwerp, Belgium, 7–9 May 2009; Available online: https://www.researchgate.net/publication/284150234_Future_scenario’s_Implications_for_port_planning (accessed on 3 November 2024).

- Haezendonck, E. Port Strategy for Sustainable Development; MDPI AG: Basel, Switzerland, 2021. [Google Scholar] [CrossRef]

- Wahyni, S. Innovation in Port Development The Quad Helix Model. In Infrastructure Investment in Indonesia: A Focus on Ports; Open Book Publishers: Cambridge, UK, 2019; Available online: http://books.openedition.org/obp/11468?lang=en (accessed on 30 October 2024).

- Allen, C.H. Future Ports Scenarios for 21st Century Port Strategic Planning. J. Transp. Law Log. Pol. 2011, 79, 80–137. [Google Scholar] [CrossRef]

- Ukić-Boljat, H.; Vilke, S.; Grubišić, N.; Maglić, L. Application of multi-criteria analysis for the introduction of green port management practices: An evaluation of energy efficient mobility in nautical ports. Sci. J. Mar. Univ. Szczec. 2021, 65, 72–83. [Google Scholar] [CrossRef]

- Taljaard, S.; Weerts, S. Towards Sustainable Port Development in the Western Indian Ocean. Scenario Analysis; United Nations Environment Programme, Nairobi Convention Secretariat and Council for Scientific & Industrial Research: Nairobi, Kenya, 2023; Available online: https://www.nairobiconvention.org/clearinghouse/sites/default/files/WIOSUS~2.PDF (accessed on 11 October 2024).

- International Association of Ports and Harbours (IAPH). Risk and Resilience, Guidelines for Ports. 2020. Available online: https://sustainableworldports.org/wp-content/uploads/IAPH-Risk-and-Resilience-Guidelines-for-Ports-BD.pdf (accessed on 10 November 2024).

- Mokhtari, K. Advanced Risk Management in Offshore Terminals and Marine Ports. Ph.D. Thesis, Liverpool Logistics, Offshore and Marine Research Institute, Liverpool John Moores University, Liverpool, UK, 2011. Available online: https://researchonline.ljmu.ac.uk/id/eprint/6094/1/549427.pdf (accessed on 1 August 2024).

- Wang, B.; Chin, K.S.; Su, Q. Risk management and market structures in seaport–dry port systems. Mar. Econ. Log. 2022, 24, 114–137. [Google Scholar] [CrossRef]

- Camus, P.; Tomás, A.; Díaz-Hernández, G.; Rodríguez, B.; Izaguirre, C.; Losada, I. Probabilistic assessment of port operation downtimes under climate change. Coast Eng. 2019, 147, 12–24. [Google Scholar] [CrossRef]

- Yin, J.; Khan, R.U.; Wang, X.; Asad, M. A data-centered multi-factor seaport disruption risk assessment using Bayesian networks. Ocean Eng. 2024, 308, 118338. [Google Scholar] [CrossRef]

- Available online: https://www.iso.org/standard/65694.html (accessed on 1 October 2024).

- John, P.; Christie, J.S.; Ircha, M.C. Port Risk Management Strategy. 2014. Available online: https://ctrf.ca/wp-content/uploads/2014/07/13JohnChristieIrchaPortRiskManagement.pdf (accessed on 23 November 2024).

- Risk Management ISO 31000. Available online: https://www.iso.org/files/live/sites/isoorg/files/store/en/PUB100426.pdf (accessed on 17 August 2024).

- Vaughan, E.J.; Elliott, C.M. Fundamentals of Risk and Insurance; Wiley: Hoboken, NJ, USA, 1978; Available online: https://books.google.me/books/about/Fundamentals_of_Risk_and_Insurance.html?id=RdbuAAAAMAAJ&redir_esc=y (accessed on 2 October 2024).

- Kristiansen, S. Maritime Transportation: Safety Management and Risk Analysis; Elsevier Butterworth-Heinemann: Amsterdam, The Netherlands, 2005; Available online: https://books.google.me/books/about/Maritime_Transportation.html?id=-O57NcHhkLMC&redir_esc=y (accessed on 4 November 2024).

- Sihem, S.; Noumen, R. Port risk assessment in container terminals: The case of Tunisia. Int. J. Transp. Dev. Integr. 2020, 4, 42–50. [Google Scholar] [CrossRef]

- Kadir, Z.A.; Mohammad, R.; Othman, N.; Amrin, A.; Muhtazaruddin, M.N.; Abu-Bakar, S.H.; Muhammad-Sukki, F. Risk management framework for handling and storage of cargo at major ports in Malaysia towards port sustainability. Sustainability 2020, 12, 516. [Google Scholar] [CrossRef]

- Ministarstvo finansija. Smjernice za uspostavljanje i sprovodjenje procesa upravljanja rizicima u subjektima javnog sektora (Ministry of Finance. Guidelines for Establishing and Performing Risk Management Process in the Public Sector), Podgorica. 2015. Available online: https://www.gov.me/dokumenta/1838ca0c-9f68-4fca-b721-bed22b42be15 (accessed on 3 December 2024).

- Woodruff, J.M. Consequence and likelihood in risk estimation: A matter of balance in UK health and safety risk assessment practice. Saf. Sci. 2005, 43, 345–353. [Google Scholar] [CrossRef]

- Kadir, Z.A.; Mohammad, R.; Othman, N. An Advanced Risk Matrix Analysis Approach for Safety Evaluation at Major Ports in Malaysia. J. Adv. Res. Bus. Manag. St. 2020, 18, 31–41. [Google Scholar]

- Yang, T.; Hung, C.-C. Multi-Attribute Decision Making Methods for Plant Layout Design Problem. Robot. Comput. Manuf. 2007, 23, 126–137. [Google Scholar] [CrossRef]

- Janowicz, K.; Pauling, J. Risk Assessment, Management, and Mitigation for Port and Marine Terminals Projects; AAPA Cargo Optimization: Wollongong, Australia, 2016; Available online: https://www.aapa-ports.org/files/SeminarPresentations/2016Seminars/2016CargoOptimization/Kat%20J.pdf (accessed on 2 October 2024).

- Nagi, A.; Indorf, M.; Kersten, W. Bibliometric analysis of risk management in seaports. Proc. Hambg. Int. Conf. Logist. (HICL) 2017, 23, 491–521. [Google Scholar] [CrossRef]

- Yang, Y.-C. Risk management of Taiwan’s maritime supply chain security. Saf. Sci. 2011, 382–393. [Google Scholar] [CrossRef]

- Mabrouki, C.; Bellabdaoui, A.; Mousrij, A. Risk Analysis and Assessment by Multicriteria Approach Based in RO-RO Port Terminal. Case Study. Int. J. Comp. Sci. Iss. 2013, 10, 37–45. [Google Scholar]

- Dias, G.C.; Leal, I.C.; Rébula de Oliveira, U. Supply chain risk management at seaport container terminals. Gest. Prod. 2019, 26, 1–14. [Google Scholar] [CrossRef]

- Procedure “opi sg hse 001 ups r03”, HSE Risk Management and Reporting; Professional Operating Instruction; Eni Montenegro: Podgorica, Montenegro, 2020.

- Bazaras, D.; Palšaitis, R. Risk Management in Sea Ports—Insights and Trends; Lecture Notes in Networks and Systems; Springer: Berlin/Heidelberg, Germany, 2020; pp. 268–274. [Google Scholar] [CrossRef]

- Pallis, P.L. Port risk management in container terminals. Trans. Res. Proc. 2017, 25, 4411–4421. [Google Scholar] [CrossRef]

- Dorofee, A.J.; Walker, J.A.; Alberts, C.J.; Higuera, R.P.; Murphy, R.L.; Wiliams, R.C. Continuous Risk Management Guidebook; Carnegie Mellon University: Pittsburgh, PA, USA, 1996; Available online: https://www.scirp.org/reference/referencespapers?referenceid=133334 (accessed on 10 September 2024).

- Hudson Trident. Risk Assessment Factors in Port Security. 2019. Available online: https://portalcip.org/wp-content/uploads/2019/08/9-Assessing-Risk-and-Port-Security-05062019.pdf (accessed on 12 November 2024).

- Risk Management in the Customs Context. Available online: https://www.wcoomd.org/-/media/wco/public/global/pdf/topics/enforcement-and-compliance/activities-and-programmes/risk-management-and-intelligence/risk-management-compendium-volume-1.pdf?la=en (accessed on 29 October 2024).

- Procedure “pro hse 013 eni spa r01”, Radiological Risk Management; Eni Montenegro: Podgorica, Montenegro, 2020.

- Trbojevic, V.M.; Carr, B.J. Risk based methodology for safety improvements in ports. J. Hazard. Mater. 2000, 71, 467–480. [Google Scholar] [CrossRef] [PubMed]

- IEC/FDIS 31010; Risk Management—Risk Assessment Techniques. IEC: Geneva, Switzerland, 2009. Available online: https://bambangkesit.wordpress.com/wp-content/uploads/2015/12/iso-31010_risk-management-risk-assessment-techniques.pdf (accessed on 1 December 2024).

- Alyami, H.; Lee, P.T.-W.; Yang, Z.; Riahi, R.; Bonsall, S.; Wang, J. An advanced risk analysis approach for container port safety evaluation. Mar. Pol. Manag. 2014, 41, 634–650. [Google Scholar] [CrossRef]

- Juliza, H.; Anggiat, H.O.S. Identify The Operational Risk of the Port by the Risk Breakdown Structure (RBS) Method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 505, 012012. [Google Scholar] [CrossRef]

- Hashemi, H.; Mousavi, S.M.; Tavakkoli-Moghaddam, R.; Gholipour, Y. Compromise Ranking Approach with Bootstrap Confidence Intervals for Risk Assessment in Port Management Projects. J. Manag. Eng. 2013, 29, 334–344. [Google Scholar] [CrossRef]

- Juttner, U.; Peck, H.; Christopher, M. Supply chain risk management. Int. J. Log. Res. App. 2003, 6, 197–210. [Google Scholar] [CrossRef]

- Vilko, J.; Ritala, P. Service Supply Chain Risk Management. Oper. Supp. Ch. Manag. 2014, 7, 114–120. [Google Scholar] [CrossRef]

- Klein, R.J.T.; Nicholls, R.J.; Thomalla, F. Resilience to natural hazards: How useful is this concept? Glob. Environ. Chang. B Environ. Hazards 2003, 5, 35–45. [Google Scholar] [CrossRef]

- Procedure “SLT TG 005 r01”; Health Technical Guideline, Health Risk Assessment. Eni Montenegro: Podgorica, Montenegro, 2020.

- Climate-Smart Risk Management for Ports. Available online: https://climate.copernicus.eu/climate-smart-risk-management-ports (accessed on 2 October 2024).

- Available online: https://www.iso.org/en/contents/news/2023/01/a-net-zero-logistics-sector.html (accessed on 21 November 2024).

- European Environment Agency. European Climate Risk Assessment, Chapter 1 (Contributing: Marc Zebisch (EURAC)). 2024. Available online: https://www.eea.europa.eu/publications/european-climate-risk-assessment/european-climate-risk-assessment-report-unedited/view (accessed on 5 September 2024).

- European Commission. COM(2024) 91 Final. Communication from the Commission to the European Parliament, The Council, The European Economic and Social Committee and the Committee of the Regions. Managing Climate Risks—Protecting People and Prosperity. 2024. Available online: https://climate.ec.europa.eu/document/download/b04a5ed8-83da-4007-9c25-1323ca4f3c92_en?filename=communication_on_managing_climate_risks_en.pdf (accessed on 3 September 2024).

- Van Houtven, G.; Gallaher, M.; Woollacott, J.; Decker, E. Act Now or Pay Later: The Costs of Climate Inaction for Ports and Shipping. RTI International. 2022. Available online: https://www.edf.org/sites/default/files/press-releases/RTI-EDF%20Act%20Now%20or%20Pay%20Later%20Climate%20Impact%20Shipping.pdf (accessed on 17 September 2024).

- Verschuur, J.; Pant, R.; Koks, E.; Hall, J. A systemic risk framework to improve the resilience of port and supply-chain networks to natural hazards. Marit. Econ. Logist. 2022, 24, 489–506. [Google Scholar] [CrossRef]

- Burns, M.G. Port Management and Operations; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar] [CrossRef]

- Chang, C.-H.; Xu, J.; Song, D.-P. An analysis of safety and security risks in container shipping operations: A case study of Taiwan. Saf. Sci. 2014, 63, 168–178. [Google Scholar] [CrossRef]

- ICS Maritime Barometer Report 2022–2023; International Chamber of Shipping: London, UK. 2023. Available online: https://www.ics-shipping.org/wp-content/uploads/2023/05/ICS-Barometer-2022-2023-updated.pdf (accessed on 22 November 2024).

- UNCTAD. Port Risk Management and Resilience-Building Toolbox. Available online: https://resilientmaritimelogistics.unctad.org/guidebook/5-port-risk-management-and-resilience-building-toolbox (accessed on 12 November 2024).

- Marine Risk Management: Best Practice. Available online: https://www.abpmer.co.uk/blog/marine-risk-management-best-practice/ (accessed on 18 November 2024).

- Available online: https://www.hsestudyguide.com/iso-45001-risk-assessment-matrix/ (accessed on 24 October 2024).

- Available online: https://www.iso.org/standard/63062.html (accessed on 27 November 2024).

- Drzavna revizorska insitucija (Montenegrin State Audit Institution). Pravilnik o identifikovanju, mjerenju, procjeni i upravljanju rizicima (Rulebook on Identification, Measuring, Estimating and Managing Risks), Podgorica. 2022. Available online: https://dri.co.me/doc/Pravilnik%20o%20identifikovanju,mjerenju,procjeni%20i%20upravljanju%20rizicima.pdf (accessed on 2 December 2024).

- Available online: https://www.iso.org/standard/72140.html (accessed on 30 November 2024).

- Jomthanachai, S.; Wong, W.-P.; Lim, C.-P. An Application of Data Envelopment Analysis and Machine Learning Approach to Risk Management. IEEE Access 2021, 9, 85978–85994. [Google Scholar] [CrossRef]

- Hatami-Marbini, A.; Asu, J.O.; Hafeez, K.; Khoshnevis, P. DEA-driven risk management framework for oil supply chains. Soc.-Econ. Plan. Sci. 2024, 95, 101996. [Google Scholar] [CrossRef]

- Rausand, M. System Reliability Theory Models, Statistical Methods, and Applications; Wiley: Hoboken, NJ, USA, 2004; Available online: https://www.ntnu.edu/documents/624876/1277590549/chapt03-fmeca.pdf/ecf0c289-bc19-492f-88ef-6a197ad4a9f1 (accessed on 18 August 2024).

- Rekabi, M. Failure Mode, Effects and Criticality Analysis (FMECA). 2024. Available online: https://www.ors-consulting.com/failure-mode-effects-and-criticality-analysis-fmeca (accessed on 19 August 2024).

- Introduction to Failure Mode, Effects & Criticality Analysis (FMECA). Available online: https://quality-one.com/fmeca/ (accessed on 23 July 2024).

- The Comprehensive Guide to FMECA in Reliability Engineering and Risk Assessment. Available online: https://www.modla.co/blog/guide-to-fmeca-in-reliability-engineering-and-risk-assessment (accessed on 31 July 2024).

- La Fata, C.M.; Giallanza, A.; Micale, R.; La Scalia, G. Improved FMECA for effective risk management decision making by failure modes classification under uncertainty. Eng. Fail. Anal. 2022, 135, 106163. [Google Scholar] [CrossRef]

- Available online: https://www.gov.me/dokumenta/a6a538b0-4884-45fc-8ab8-2240af84c805 (accessed on 12 November 2024).

- Available online: https://osha.europa.eu/en/legislation/guidelines/guidance-risk-assessment-work (accessed on 1 August 2024).

- The OSH Framework Directive. Available online: https://osha.europa.eu/en/legislation/directives/the-osh-framework-directive/the-osh-framework-directive-introduction (accessed on 4 August 2024).

- European Directives on Safety and Health at Work. Available online: https://osha.europa.eu/en/safety-and-health-legislation/european-directives (accessed on 2 September 2024).

- Available online: https://osha.europa.eu/en/safety-and-health-legislation (accessed on 1 September 2024).

- EU Strategic Framework on Health and Safety at Work 2021–2027. Available online: https://osha.europa.eu/en/safety-and-health-legislation/eu-strategic-framework-health-and-safety-work-2021-2027 (accessed on 1 September 2024).

- Workplaces, Equipment, Signs, Personal Protective Equipment. Available online: https://osha.europa.eu/en/legislation/directives/workplaces-equipment-signs-personal-protective-equipment (accessed on 4 September 2024).

- Exposure to Chemical Agents and Chemical Safety. Available online: https://osha.europa.eu/en/legislation/directives/exposure-to-chemical-agents-and-chemical-safety (accessed on 5 September 2024).

- Exposure to Physical Hazards. Available online: https://osha.europa.eu/en/legislation/directives/exposure-to-physical-hazards (accessed on 6 September 2024).

- Exposure to Biological Agents. Available online: https://osha.europa.eu/en/legislation/directives/exposure-to-biological-agents (accessed on 4 September 2024).

- Provisions on Workload, Ergonomic and Psychosocial Risks. Available online: https://osha.europa.eu/en/legislation/directives/provisions-on-workload-ergonomical-and-psychosocial-risks (accessed on 4 September 2024).

- Sector Specific and Worker Related Provisions. Available online: https://osha.europa.eu/en/legislation/directives/sector-specific-and-worker-related-provisions (accessed on 5 September 2024).

- National Legislation on Safety and Health at Work. Available online: https://osha.europa.eu/en/safety-and-health-legislation/national-legislation-safety-and-health-work (accessed on 2 September 2024).

- Migda, N.S. Using the quality management system for risk management by the seaport administration. SHS Web Conf. 2023, 164, 00042. [Google Scholar] [CrossRef]

- Munawaroh, M.; Weerawat, W. Evaluation Efficiency of Indonesian Seaports: Data Envelopment Analysis. In Proceedings of the 10th International Conference on Operations and Supply Chain Management, Wellington, New Zealand, 14–16 December 2020; Available online: https://www.journal.oscm-forum.org/journal/proceeding/conf_paper/oscm-conf-evaluation-efficiency-of-indonesian-seaports-data-envelopment-analysis (accessed on 11 June 2024).

- Madeueke, U.A. Measuring and Benchmarking Efficiency and Productivity Levels of Liquid Bulk Terminal Operations Using a DEA and OEE Approach Considering Nigeria’s Atlas Cove Jetty and Depot Facility. Master’s Thesis, Erasmus University Rotterdam, Rotterdam, The Netherlands, 2012. Available online: https://thesis.eur.nl (accessed on 31 August 2024).

- Kaiser, E.; Pathomsiri, S.; Haghani, A. Developing Measures of Us Ports Productivity and Performance: Using DEA and FDH Approaches. In Proceedings of the 47th Annual Transportation Research Forum, New York, NY, USA, 23–25 March 2006; p. 208013. [Google Scholar] [CrossRef]

- Lin, Y.; Yan, L.; Wang, Y.-M. Performance Evaluation and Investment Analysis for Container Port Sustainable Development in China: An Inverse DEA Approach. Sustainability 2019, 11, 4617. [Google Scholar] [CrossRef]

- Role of Technology in Enhancing Port Efficiency. Available online: https://www.visiwise.co/blog/enhancing-port-efficiency/ (accessed on 9 October 2024).

- Abudu, R.; Zheng, S.; Thompson, E.A. Port Adaptation and Efficiency: An Empirical Study of Ghanaian Ports. Int. J. Reg. Dev. 2021, 8, 1–36. [Google Scholar] [CrossRef]

- Quansah, N.E. Impact of Privatization In Ports: Measuring Efficiency through Data Envelopment Analysis and Key Performance Indicators. Master’s Thesis, World Maritime University, Digital Repository of the World Maritime University, Sweden, Europe, 2008. Available online: https://commons.wmu.se/cgi/viewcontent.cgi?article=1329&context=all_dissertations (accessed on 20 October 2024).

- Oyewole, F.O.; Enyioko, N. Influence of Private Port on Efficiency of Ports in Nigeria. SSRN Electr. J. 2023. [Google Scholar] [CrossRef]

- Mazaheri, A. How the ISPS Code Affects Port and Port Activities. Master’s Thesis, University College of Borås School of Engineering, Boras, Sweden, 2008. Available online: https://www.diva-portal.org/smash/get/diva2:1310768/FULLTEXT01.pdf (accessed on 16 July 2024).

- Yen, B.T.H.; Huang, M.-J.; Lai, H.-J.; Cho, H.-H.; Yi-Ling Huang, Y.-L. How smart port design influences port efficiency—A DEA-Tobit approach. Res. Transp. Bus. Manag. 2023, 46, 100862. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, L.; Meng, Q. Evaluating port efficiency dynamics: A risk-based approach. Transp. Res. Part B Methodol. 2022, 166, 333–347. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kim, C. Effect of Risk Management on Port and Regional Economic Performance Prod. Oper. Manag. Soc. 2023, 34, 81–95. [Google Scholar] [CrossRef]

- Kornher, L.; Sakyi, D.; Tannor, L.L. “When you need it quick, let us ship it right”: On the importance of port efficiency and service quality to comply with food trade standards in Ghana. Rev. World Econ. 2024, 161, 231–255. [Google Scholar] [CrossRef]

- Saruchera, F. Determinants of effective high-risk cargo logistics at sea ports: A case study. J. Transp. Supply Chain Manag. 2020, 14, a488. [Google Scholar] [CrossRef]

- Diallo, M.L.; Vaz, A.; Ghadiri, S.M. Factors that influence a container terminal competitiveness from he shipping lines’ perspective: A case of Conakry Container Terminal. J. Marit. Logist. 2023, 3, 1–23. [Google Scholar] [CrossRef]

- Boakye, G.; Li, Y.; Asare, E. Determination of the Efficiency of Port Performance and Productivity Based on Data Envelopment Analysis in the West Africa Sub-region. Ind. J. Sci. Technol. 2021, 14, 3396–3406. [Google Scholar] [CrossRef]

- Port of Bar, Documentation of the Development Department, 2021.

- Wang, C.-N.; Nguyen, N.-A.; Fu, H.-P.; Hsu, H.-P.; Dang, T.-T. Efficiency Assessment of Seaport Terminal Operators Using DEA Malmquist and Epsilon-Based Measure Models. Axioms 2021, 10, 48. [Google Scholar] [CrossRef]

- Kuosmanen, T.; Kortelainen, M. Data Envelopment Analysis in Environmental Valuation: Environmental Performance, Eco-Efficiency and Cost-Benefit Analysis. 2004. Available online: https://econwpa.ub.uni-muenchen.de (accessed on 18 October 2024).

- Sherman, H.D.; Zhu, J. Data Envelopment Analysis Explained. In Service Productivity Management; Springer: Boston, MA, USA, 2006. [Google Scholar] [CrossRef]

- Jablonský, J. A Spreadsheet Based System for DEA Models. 2008. Available online: https://mcdm.ue.katowice.pl (accessed on 22 July 2024).

- Park, R.-K.; De, P. An Alternative Approach to Efficiency Measurement of Seaports. In Port Management. Palgrave Readers in Economics; Haralambides, H.E., Ed.; Palgrave Macmillan: London, UK, 2015. [Google Scholar] [CrossRef]

- Nguyen, H.-O.; Chang, Y.-T.; Chin, A.T.H.; Tongzon, J. Measuring port efficiency using bootstrapped DEA: The case of Vietnamese ports. Marit. Policy Manag. 2015, 43. [Google Scholar] [CrossRef]

- González, M.M.; Trujillo, L. Efficiency Measurement in the Port Industry: A Survey of the Empirical Evidence. J. Transp. Econ. Polic. 2009, 43, 157–192. Available online: https://www.jstor.org (accessed on 12 July 2024).

- Nwanosike, F.; Tipi, N.; Warnock-Smith, D. Benchmarking the operational efficiency of Nigeria seaport terminals using Data Envelopment Analysis (DEA). In Proceedings of the 18th International Symposium on Logistics (ISL 2013); Pawar, K.S., Rogers, H., Eds.; Resilient Supply Chains in an Uncertain Environment, Centre for Concurrent Enterprise, Nottingham University Business School: Nottingham, UK, 2013; pp. 383–390. Available online: https://oro.open.ac.uk/74776/ (accessed on 14 July 2024).

- Ewertowska, A. Systematic Tools Based on Data Envelopment Analysis for the Life Cycle Sustainbility Evaluation of Technologies. Doctoral Thesis, Universitat Rovira i Virgili, Taragona, Spain, 2017. Available online: https://www.tesisenred.net (accessed on 22 November 2024).

- Dewarlo, O. DEA Window Analysis for Measuring Port Performances Efficiency of Four Islands Countries Located in West Indian Ocean Countries. Am. J. Ind. Bus. Manag. 2019, 9, 2098–2111. [Google Scholar] [CrossRef]

- Kammoun, R. The Technical Efficiency of Tunisian Ports: Comparing Data Envelopment Analysis and Stochastic Frontier Analysis Scores. Logist. Sustain. Transp. 2018, 9, 73–84. [Google Scholar] [CrossRef]

- Taboada, G.L.; Seruca, I.; Sousa, C.; Pereira, Á. Exploratory Data Analysis and Data Envelopment Analysis of Construction and Demolition Waste Management in the European Economic Area. Sustainability 2020, 12, 4995. [Google Scholar] [CrossRef]

- Pjevčević, D.; Radonjić, A.; Hrle, Z.; Čolić, V. DEA Window Analysis for Measuring Port Efficiencies in Serbia. Promet–Traffic Transp. 2012, 24, 63–72. [Google Scholar] [CrossRef]

- Barros, C.P. A Benchmark Analysis of Italian Seaports Using Data Envelopment Analysis. Marit. Econ. Logist. 2006, 8, 347–365. [Google Scholar] [CrossRef]

- Li, W.; Miller-Hooks, E. Understanding the implications of port-related workforce shortages on global maritime performance through the study of a carrier alliance. Marit. Econ. Logist. 2023, 25, 452–478. [Google Scholar] [CrossRef]

- Iswandi; Gunarto, M.; Andriyansah. Analysis Of Factors that Influence the Performance of Employees in Boarding and Unloading of Ship Goods in the Port. J. Eduvest. 2024, 4, 5500–5510. [Google Scholar] [CrossRef]

- Moros-Daza, A.; Jubiz-Diaz, M. Labour force management in maritime ports: A comprehensive systematic literature review. Heliyon 2024, 10, e31401. [Google Scholar] [CrossRef]

- Ozguven, E.E.; Altinel, K.; Gullu, R.; Otay, E.N. Quay Length Optimization Using a Stochastic Knapsack Model. J. Waterw. Port Coastal Ocean Eng. 2013, 139, 424–435. [Google Scholar] [CrossRef]

- Chargui, K.; Zouadi, T.; El Fallahi, A.; Reghioui, M.; Aouam, T. Berth and quay crane allocation and scheduling with worker performance variability and yard truck deployment in container terminals. Transp. Res. Part E Logist. Transp. Rev. 2021, 154, 102449. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Zhen, L. Berth and quay cranes allocation problem with on-shore power supply assignment in container terminals. Comput. Ind. Eng. 2024, 188, 109910. [Google Scholar] [CrossRef]

- Grubisic, N.; Maglic, L. Optimization Process for Berth and Quay-Crane Assignment in Container Terminals with Separate Piers. Athen. J. Techol. Eng. 2018, 5, 53–68. [Google Scholar] [CrossRef]

- Javanshir, H.; Seyed-Alizadeh Ganji, S.R. Optimal Allocation of Ships to Quay Length in Container Ports. J. Ind. Syst. Eng. 2010, 3, 275–290. [Google Scholar]

- Li, X.; Wu, Z.; Shen, W. Addressing Challenges in Port Depth Analysis: Integrating Machine Learning and Spatial Information for Accurate Remote Sensing of Turbid Waters. Sensors 2024, 24, 3802. [Google Scholar] [CrossRef]

- Chen, C.; Delefortrie, G.; Lataire, E. Effects of water depth and speed on ship motion control from medium deep to very shallow water. Ocean. Eng. 2021, 231, 109102. [Google Scholar] [CrossRef]

- Mateo-Pérez, V.; Corral-Bobadilla, M.; Ortega-Fernández, F.; Rodríguez-Montequín, V. Determination of Water Depth in Ports Using Satellite Data Based on Machine Learning Algorithms. Energies 2021, 14, 2486. [Google Scholar] [CrossRef]

- Ray, A. The Optimum Depth of Water in a Port; Staff working paper; no. SWP 67; World Bank: Washington, DC, USA, 1970; Available online: http://documents.worldbank.org/curated/en/786331468739289516 (accessed on 15 March 2025).

- Hoyt, R.E.; Liebenberg, A.P. The value of Enterprise Risk Management. J. Risk Insur. 2011, 78, 795–822. [Google Scholar] [CrossRef]

- Eling, M.; Wirfs, J. What are the actual costs of cyber risk events? Eur. J. Oper. Res. 2019, 272, 1109–1119. [Google Scholar] [CrossRef]

- Hallegatte, S. Modeling the Role of Inventories and Heterogeneity in the Assessment of the Economic Costs of Natural Disasters. Risk Anal. 2013, 34, 152–167. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Ng, A.K.; Lee, P.T.-W.; Wang, T.; Qu, Z.; Rodrigues, V.S.; Pettit, S.; Harris, I.; Zhang, D.; Lau, Y.-Y. Risk and cost evaluation of port adaptation measures to climate change impacts. Transp. Res. Part D Transp. Environ. 2018, 61, 444–458. [Google Scholar] [CrossRef]

- Berechman, J.; Tseng, P.-H. Estimating the environmental costs of port related emissions: The case of Kaohsiung. Transp. Res. Part D Transp. Environ. 2012, 17, 35–38. [Google Scholar] [CrossRef]

- Bichou, K. The ISPS Code and The Cost of Port Compliance: An Initial Logistics and Supply Chain Framework for Port Security Assessment and Management. Marit. Econ. Logist. 2004, 6, 322–348. [Google Scholar] [CrossRef]

- Bichou, K. Risk-Based Cost Assessment of Maritime and Port Security. In Proceedings of the Conference: Security and Environmental Sustainability of Multimodal Transport; Springer: Dordrecht, The Netherlands, 2010; pp. 183–2011. Available online: https://link.springer.com/chapter/10.1007/978-90-481-8563-4_11 (accessed on 22 August 2024).

- Grainger, A. Trade and customs compliance costs at ports. Marit. Econ. Logist. 2014, 16, 467–483. [Google Scholar] [CrossRef]

- Zhang, Y.; Jasmine Siu, J.; Lee Lam, L. Estimating the economic losses of port disruption due to extreme wind events. Ocean Coast. Manag. 2015, 116, 300–310. [Google Scholar] [CrossRef]

- Loh, H.S.; Thai, V.V. Cost Consequences of a Port-Related Supply Chain Disruption. Asian J. Shipp. Logist. 2015, 31, 319–340. [Google Scholar] [CrossRef]

- Hudoyo, C.P.; Latief, Y.; Sagita, L. Development of WBS (Work Breakdown Structure) Risk Based Standard for Planning Cost Estimation at Port Project. IOP Conf. Ser. Earth Environ. Sci. 2019, 258, 012051. [Google Scholar] [CrossRef]

- Talas, R.; David, A.; Menachof, D.A. The efficient trade-off between security and cost for sea ports: A conceptual model. Int. J. Risk Assess. Manag. 2009, 13, 46–59. [Google Scholar] [CrossRef]

- Tichavska, M.; Tovar, B. External costs from vessel emissions at port: A review of the methodological and empirical state of the art. Trans. Rev. 2017, 37, 383–402. [Google Scholar] [CrossRef]

- Lambert, J.H. Risk-Cost-Benefit Analysis for Port Environmental Security Investments. In Managing Critical Infrastructure Risks. NATO Science for Peace and Security Series C: Environmental Security; Linkov, I., Wenning, R.J., Kiker, G.A., Eds.; Springer: Dordrecht, The Netherlands, 2007; pp. 299–307. [Google Scholar] [CrossRef]

- Jugović, A.; Slišković, M.; Vukić, L. Concept of external costs calculation in the ports: Environmental Impacts. Tehn. Vjes. 2018, 25 (Suppl. 2), 495–502. [Google Scholar] [CrossRef]

- Gómez-Fuster, J.M.; Pilar Jiménez, P. Probabilistic risk modelling for port investments: A practical approach. Case Stud. Transp. Policy 2020, 8, 822–831. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, Y.; Li, T. Port Cargo Throughput Forecasting Based on Combination Model. In Proceedings of the 2016 Joint International Information Technology, Mechanical and Electronic Engineering Conference, Xi’an, China, 4–5 September 2016. [Google Scholar] [CrossRef]

- Eskafi, M.; Kowsari, M.; Dastgheib, A.; Ulfarsson, G.F.; Taneja, P.; Thorarinsdottir, R.I. Mutual information analysis of the factors influencing port throughput. Mar. Bus. Rev. 2021, 6, 129–146. [Google Scholar] [CrossRef]

- Jansen, M. Forecasting Container Cargo Throughput in Ports. Master’s Thesis, Erasmus University Rotterdam, Erasmus School of Economics Urban, Port and Transport Economics, Rotterdam, The Netherlands, 2014. Available online: https://thesis.eur.nl (accessed on 29 March 2025).[Green Version]

- Sun, L.; Tan, D.-R. Research on probability distribution of port cargo throughput. J. Mar. Sci. Appl. 2008, 7, 65–68. [Google Scholar] [CrossRef]

- Zhang, H. Analysis of Influencing Factors of Coastal Port Cargo Throughput in China from Economic Aspect. Master’s Thesis, Digital Repository of the World Maritime University, Malmö, Sweden, 2014. Available online: https://commons.wmu.se/cgi/viewcontent.cgi?article=2861&context=all_dissertations (accessed on 31 March 2025).[Green Version]

- Makoa, P.; Dávid, A.; Oleic, A.B. Possibilities of increasing the throughput of ports. Trans. Res. Proc. 2021, 55, 426–433. [Google Scholar] [CrossRef]

- Cuong, T.N.; Long, L.N.B.; Kim, H.-S.; Sam-Sang You, S.-S. Data analytics and throughput forecasting in port management systems against disruptions: A case study of Busan Port. Marit. Econ. Logist. 2022, 25, 61–89. [Google Scholar] [CrossRef]

- Morales-Ramírez, D.; Gracia, M.D.; Mar-Ortiz, J. Forecasting national port cargo throughput movement using autoregressive models. Case Stud. Transp. Policy 2025, 19, 101322. [Google Scholar] [CrossRef]

- Awah, P.C.; Nam, H.; Kim, S. Short Term Forecast of Container Throughput: New Variables Application for the Port of Douala. J. Mar. Sci. Eng. 2021, 9, 720. [Google Scholar] [CrossRef]

- Obasi, C.C. Assessment of the Impact of Cargo Throughput on Port Productivity in Warri Seaport, Delta State, Nigeria. Ann. Rev. Res. 2022, 7, 555714. [Google Scholar] [CrossRef]

- Georgoulas, D.; Koliousis, I.; Papadimitriou, S. An AHP enabled port selection multi-source decision support system and validation: Insights from the ENIRISST project. J. Shipp. Trade 2023, 8, 16. [Google Scholar] [CrossRef]

- Lee, S.-W.; Song, J.-M.; Park, S.-J.; Sohn, B.-R. A Study on the Comparative Analysis of Port Competitiveness Using AHP. KMI Int. J. Marit. Aff. Fish. 2014, 6, 053–071. [Google Scholar] [CrossRef]

- Satoglu, S.I.; Türkekul, İ. Selection of Material Handling Equipment using the AHP and MOORA. J. Tek. Ind. 2021, 22, 113–124. [Google Scholar] [CrossRef]

- Maletič, D.; Nagyová, A.; Gomišček, B.; Maletič, M. Framework Development of an Asset Manager Selection Based on Risk Management and Performance Improvement Competences. Safety 2021, 7, 10. [Google Scholar] [CrossRef]

- Mattioli, R.; Levy-Bencheton, C. Methodologies for the Identification of Critical Information Infrastructure Assets and Services, Guidelines for Charting Electronic Data Communication Networks; European Union Agency for Network and Information Security: Athens, Greece, 2014; Available online: https://op.europa.eu/en/publication-detail/-/publication/e8b32529-fae9-495c-8494-e7e6cf6e014e/language-en (accessed on 12 January 2025).

- Saaty, R.W. The Analytic Hierarchy Process—What it is and how it is used. Math. Mod. 1987, 9, 161–176. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Yücel, M.E.; Yurtören, C. Determination of Risk Factors Caused by Ships in Port Planning. Int. J. Environ. Geoinform. (IJEGEO) 2019, 6, 254–263. [Google Scholar] [CrossRef]

- Yuliantini, Y.; Thamrin, M.; Candra Susanto, P. Determination of Shipping Safety by Maintenance, Ship Construction, Weather, and Human Resource Competence: In a Literature Review. Dinasti Int. J. Educ. Manag. Soc. Sci. 2024, 5, 2358–2368. [Google Scholar] [CrossRef]

- Li, C.; Zhao, J.; Ding, G.; Zhang, K.; Li, W.; Li, Y.; Wang, Y.; Wen, J. The Study of Risk Assessment Method for Ship Berthing Based on the “Human-Ship-Environment” Synergy. J. Mar. Sci. Eng. 2024, 12, 2022. [Google Scholar] [CrossRef]

- Hsu, W.-K.K. Assessing the Safety Factors of Ship Berthing Operations. J. Navig. 2014, 68, 576–588. [Google Scholar] [CrossRef]

- Khan, R.U.; Yin, J.; Mustafa, F.S.; Anning, N. Risk assessment for berthing of hazardous cargo vessels using Bayesian networks. Ocean Coast. Manag. 2021, 210, 105673. [Google Scholar] [CrossRef]

- Thévenin, M. Climate Risks to Global Seaports Operations. Available online: https://www.i4sea.com/blog/climate-risks-to-global-ports-operations (accessed on 21 March 2025).

- Chou, C.C. Modelling and simulation of ship collisions in port and coastal waters. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2021, 235, 737–749. [Google Scholar] [CrossRef]

- Ma, J.; Liu, T.; Zhu, Z.; Zhou, Y. Research on Ship Collision Risk Calculation in Port Navigation Waters Based on Ising Model and AIS Data. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2024, 10. [Google Scholar] [CrossRef]

- Li, M.; Mou, J.; Chen, P.; Chen, L.; Gelder, V. Real-time collision risk based safety management for vessel traffic in busy ports and waterways. Ocean Coast. Manag. 2023, 234, 106471. [Google Scholar] [CrossRef]

- Yu, H.; Meng, Q.; Fang, Z.; Liu, J.; Xu, L. A review of ship collision risk assessment, hotspot detection and path planning for maritime traffic control in restricted waters. J. Navig. 2022, 75, 1337–1363. [Google Scholar] [CrossRef]

- Marino, M.; Cavallaro, L.; Castro, E.; Musumeci, R.E.; Martignoni, M.; Roman, F.; Foti, E. New frontiers in the risk assessment of ship collision. Ocean Eng. 2023, 274, 113999. [Google Scholar] [CrossRef]

- Park, S.; Yeo, J.; Kyonghan Lee, K. Developing a Ship Collision Risk Assessment Model with Internal and External Factors: Focused on South Korea Maritime Environment. J. Adv. Transp. 2024, 2024, 5062203. [Google Scholar] [CrossRef]

- Goerlandt, F. Risk Analysis for Vessel Accident Prevention in Marine Areas: An Accident-Theoretic Perspective on Spatial Aspects of Risk. In Area-Based Management of Shipping; Chircop, A., Goerlandt, F., Pelot, R., Aporta, C., Eds.; Springer: Cham, Germany, 2024. [Google Scholar] [CrossRef]

- Zhou, Y.; Du, W.; Liu, J.; Li, H.; Grifoll, M.; Song, W.; Zheng, P. Determination of Ship Collision Avoidance Timing Using Machine Learning Method. Sustainability 2024, 16, 4626. [Google Scholar] [CrossRef]

- Wang, D.; Yan Jing, Y. Ship collision risk analysis in port waters integrating GRA algorithm and BPNN. Transp. Saf. Environ. 2025, 7, tdaf012. [Google Scholar] [CrossRef]

- Ma, X.; Shi, G.; Shi, J.; Liu, J. A framework of marine collision risk identification strategy using AIS data. J. Navig. 2023, 76, 525–544. [Google Scholar] [CrossRef]

- Zhu, Q.; Xi, Y.; Weng, J.; Han, B.; Hu, S.; Ge, Y.-E. Intelligent ship collision avoidance in maritime field: A bibliometric and systematic review. Expert Syst. Appl. 2024, 252, 124148. [Google Scholar] [CrossRef]

- Lee, D.-H. A Study on Multi-ship Avoidance System for Unmanned Surface Vehicles Using the Quaternion Ship Domain and Collision Risk Index. J. Ocean Eng. Technol. 2025, 39, 103–121. [Google Scholar] [CrossRef]

| Topics Analyzed/Researched | Key Findings | References |

|---|---|---|

| Definition of a risk | Risk is the effect of uncertainty on achieving the objectives, often quantified as the Likelihood of the occurrence (L) of an event multiplied by its Impact (I) (L × I). This means that risk can be managed by reducing the likelihood or the impact of the related uncertainty (harmful events: the loss, injury, or other adverse consequences). | [22,23,24,25,26,27,28,29,30,31] |

| Risk management process: definition, phases, objectives | Risk management is a decision-making process that involves identifying, analyzing, and mitigating risk measurement results. Risk management in ports plays an important role in mitigating and preventing possible accidents and disruptions. Guidance for the definition of the risk management process and risk tolerability criteria is referred to as People, Social Context, Environment, Assets, Operations, and Reputation. There is no specific risk management method or framework to cope with all existing and potential threats and hazards in a port. | [32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49] |

| Classification of risks | Different approaches to risk classification are implemented, from very general approaches (e.g., internal, external, hidden, or man-made and natural) to a very detailed risk classification in a port. | [1,2,5,17,18,27,36,47,50,51,52,53,54,55,56,57,58,59,60,61] |

| Risk probability and severity matrix | Risks can be mapped using a risk severity and probability matrix. It helps ensure that risks receive differentiated management attention and allocated resources. For estimating the occurrence frequency of a risk in a risk matrix, verbal expressions such as very low, low, medium, high, and very high can be used. In addition, to estimate the consequence impact, the following linguistic variables can be used: slight, minor, moderate, critical, and catastrophic. | [18,38,62,63,64,65,66] |

| Risk registry | A risk registry is a record of risks, current controls, additional required controls, and responsibility for control activities. The process of creating a risk register consists of five steps: setting goals, identifying risks, assessing risks, responding to risks, and monitoring and reporting. | [29,63,67] |

| Techniques for assessing risks | The methods frequently used for risk assessment are brainstorming, checklists, hazard analysis and critical control, scenario analysis, business impact analysis, failure mode effect analysis (FMEA), failure mode effect and criticality analysis (FMECA), fault tree analysis, cause-and-effect analysis, Markov analysis, Monte Carlo simulation, Analytical Hierarchal Process (AHP) method, … | [18,36,46,68,69,70,71,72,73,74,75] |

| Regulation | Risk management in a port has to be based on the national and international—domain-specific—regulations. In the literature sources used are defined elements of the national (in Montenegro) and international regulations, which are used as a base for the structuring and functioning of a risk management system in the field of safety and health at work. | [76,77,78,79,80,81,82,83,84,85,86,87,88] |

| Object of Research/Findings | Reference |

|---|---|

| Object of research: A new methodology to quantify the efficiency dynamics of a port over time. Findings: An optimization-based approach for efficiency measurement under uncertainty and a risk-based index to measure the efficiency of any operating unit. | [100] |

| Object of research: Risk management in the maritime supply chain. Findings: When supply chain risk increases, efficiency significantly goes down, even when the maritime supply chain is very good. | [101] |

| Object of research: The importance of port efficiency and service quality. Findings: Exporting firms have a positive willingness to pay for a reduction in the handling time. Findings emphasize the importance of trade facilitation measures in improving port efficiency and service quality. | [102] |

| Object of research: Determinants of effective high-risk cargo (HRC) handling at seaports. Findings: The study confirmed the correlation between HRC training and the level of knowledge of risk mitigation and emergency procedures, documentation understanding, and regulations adherence. | [103] |

| Object of research: Impact of port efficiency on a nation’s ability to compete internationally. Findings: Port terminal efficiency and the quality of services are the most important factors in selecting a container terminal, followed by port charges, hinterland connections, and port location. | [104] |

| Volujica Quay—berths: 01, 02, 03 | Total length: 555 m; individual length of berths: 185 m; Water depth: 14 m |

| Old Quay—berths: 04, 05, 06 | Total length: 280 m; individual length of berths: 93 m; Water depth: 5 m–7.2 m; |

| New Tanker Berth–07 (NPV) | Maximum ship’s LOA: 200 m; Water depth: 13.5 m |

| DMUi | Purpose/Main Activities Carried Out |

|---|---|

| DMU1—berth 01 | loading/unloading operations with dry bulk cargo (grain, bauxite, salt) |

| DMU2—berth 02 | loading/unloading operations with dry bulk cargo (copper concentrate, coal, iron ore) |

| DMU3—berth 03 | loading/unloading operations with dry bulk cargo (crushed stone, iron scrap) |

| DMU4—berth 04 | unloading operations with dry bulk cargo (cement in bulk) |

| DMU5—berth 05 | loading operations with liquid bulk cargo (acetic acid) |

| DMU6—berth 06 | loading/unloading operations with liquid bulk cargo (oil derivatives) |

| DMU7—berth 07 | unloading operations with liquid bulk cargo (oil derivatives) |

| The Object of the Research | Reference |

|---|---|

| To measure the extent to which specific firms have implemented Enterprise Risk Management (ERM) programs. | [133] |

| To consider a broad range of cyber risk events and actual cost data. To identify cyber losses from an operational risk database and analyze these with appropriate methods. | [134] |

| To assess indirect natural disaster losses and to analyze their drivers. | [135] |

| A risk and cost evaluation methodology that can be applied to the analysis of port climate change adaptation measures in situations where data uncertainty is high. | [136] |

| To estimate the emission costs of ships and trucks in a port, focusing mainly on particular matter and volatile organic compounds. | [137] |

| The various economic approaches to risk management and cost control in shipping are reviewed. | [138] |

| The issues of risk-based models and procedural costs in the context of maritime and port security. | [139] |

| A review of the costs associated with trade and customs procedures at seaports (trade and customs compliance costs). | [140] |

| To develop an approach for estimating the economic losses of port disruptions induced by extreme wind events. | [141] |

| To quantitatively measure the impact of a port-related threat on supply chains and thus highlight the importance of port-related supply chain disruption management. | [142] |

| Developing Work Breakdown Structure (WBS) standardization on port projects and identifying risks that may occur during project implementation, and considering them in the cost estimation process. | [143] |

| A conceptual model that ports can follow to ensure that efficient security investment decisions are made to reduce the exposure to terrorist and other unlawful activities. | [144] |

| To identify the Impact Pathway Approach (IPA) as the best-practice bottom-up methodology for calculating site-specific external costs derived from shipping air emissions. | [145] |

| Addressing situations in which the decision space of risk management is large and combinatorial, engaging the decision-maker in the allocation of resources to the security, robustness, and resilience of critical infrastructures. | [146] |

| Internalization of external costs related to air pollution in the ports. | [147] |

| A general methodology for including risk analysis in an economic–financial analytical model of a port investment project. | [148] |

| DMUi | Year | Output | Inputs | |||

|---|---|---|---|---|---|---|

| Annual Throughput (t) (×103) | Number of Directly Engaged Workers (×103) | Berth Length (m) (×103) | Water Depth (m) (×103) | Direct Operation Costs (EUR) (×103) | ||

| Berth 01 | 2021 | 156.74 | 0.49 | 0.185 | 0.014 | 34.31 |

| 2022 | 182.68 | 0.58 | 0.185 | 0.014 | 39.98 | |

| 2023 | 343.07 | 1.08 | 0.185 | 0.014 | 75.09 | |

| 2024 | 306.1 | 0.97 | 0.185 | 0.014 | 67 | |

| Berth 02 | 2021 | 662.58 | 1.08 | 0.185 | 0.014 | 175.68 |

| 2022 | 1084.76 | 1.76 | 0.145 | 0.014 | 287.62 | |

| 2023 | 323.6 | 0.53 | 0.145 | 0.014 | 85.8 | |

| 2024 | 204.59 | 0.33 | 0.185 | 0.014 | 54.25 | |

| Berth 03 | 2021 | 78.19 | 0.25 | 0.06 | 0.014 | 34.57 |

| 2022 | 663.76 | 2.15 | 0.185 | 0.014 | 293.47 | |

| 2023 | 816.16 | 2.64 | 0.185 | 0.014 | 360.86 | |

| 2024 | 527.5 | 1.71 | 0.155 | 0.014 | 233.23 | |

| Berth 04 | 2021 | 126.7 | 0.09 | 0.093 | 0.006 | 3.61 |

| 2022 | 123.48 | 0.09 | 0.093 | 0.006 | 3.52 | |

| 2023 | 138.17 | 0.1 | 0.093 | 0.006 | 3.94 | |

| 2024 | 105.61 | 0.08 | 0.093 | 0.006 | 3.01 | |

| Berth 05 | 2021 | 30.06 | 0.02 | 0.093 | 0.007 | 0.77 |

| 2022 | 2.22 | 0.002 | 0.093 | 0.007 | 0.057 | |

| 2023 | 1.1 | 0.001 | 0.093 | 0.007 | 0.028 | |

| 2024 | 0 | 0 | 0.093 | 0.007 | 0 | |

| Berth 06 | 2021 | 176.6 | 0.1 | 0.093 | 0.009 | 10.05 |

| 2022 | 169.71 | 0.09 | 0.093 | 0.009 | 9.66 | |

| 2023 | 214.05 | 0.12 | 0.093 | 0.009 | 12.18 | |

| 2024 | 188.44 | 0.1 | 0.093 | 0.009 | 10.72 | |

| Berth 07 | 2021 | 50.47 | 0.027 | 0.198 | 0.013 | 2.87 |

| 2022 | 83.11 | 0.045 | 0.198 | 0.013 | 4.73 | |

| 2023 | 30.32 | 0.016 | 0.198 | 0.013 | 1.73 | |

| 2024 | 20.14 | 0.011 | 0.198 | 0.013 | 1.15 | |

| Risk Category | Description |

|---|---|

| Operational risks | Lack of management supervision, errors, poor internal controls; the risks generated during the operational planning process, loading/unloading and storage of cargo, … [36]; the risk of loss arising from the failure or inadequacy of internal processes, poor work culture, etc. [48]. |

| Technical risks | In adequate maintenance policies caused by the absence of preventive and corrective maintenance, lack of qualified maintenance personnel, lack of adequate stocks of spare parts, insufficient standardization of equipment types, … [18]. |

| Safety risks | Poor health and safety procedures; port safety is affected by multiple factors related to design, installation, operation, and maintenance [47]; there are five key factors that influence the effects of potential health hazards [53]: type of health hazard, time period of exposure, level of exposure (dose), mode of exposure (e.g., contact, inhalation, or ingestion), individual susceptibility, etc. Domains of people safety risks: port workers, customers, service providers, ship’s crew, … [18]. |

| Environmental risks | Resilience is widely seen as a desirable system property in mitigating environmental risks [52]; ship emissions, dredging, oils spills, chemical contaminants, ballast waters, noise pollution, alien species, … [27]; the port environment is endangered by ports’ hinterland, ports’ activities and operations, and ships activities; ports pollution may also result from ship accidents, accidents in ports, land activities, ship bunkering, noises, garbage, dust, dredging, port maintenance, ship air pollution, traffic congestion, sewage etc. [18]. |

| DMUi, Berths | 2021 | 2022 | 2023 | 2024 | ||||

|---|---|---|---|---|---|---|---|---|

| Score | Rank | Score | Rank | Score | Rank | Score | Rank | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) |

| 01 | 0.4632 | 6 | 0.5019 | 7 | 0.8291 | 7 | 0.8806 | 5 |

| 02 | 1 | 1 | 1 | 1 | 0.8309 | 6 | 0.6405 | 6 |

| 03 | 0.4597 | 7 | 0.6119 | 6 | 1 | 1 | 1 | 1 |

| 04 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 05 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 7 |

| 06 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 07 | 0.9638 | 5 | 0.9882 | 5 | 1 | 1 | 0.9828 | 4 |

| Reciprocal Matrices | Characteristic Parameters and Consistency Tests | |||||

|---|---|---|---|---|---|---|

| Level 1 of the hierarchy framework—goal | ||||||

| Criterion | C1 | C2 | C3 | C4 | Priority Vector | Principal Eigen vector: λmax = 4.1427; Consistency Index, CI = 0.0476; Random value of consistency index, RI = 0.9; Consistency ratio, CR = 0.0528; Consistency ratio is under 0.10, which means that the performed evaluation is consistent. |

| C1 | 1.00 | 3.00 | 3.00 | 0.50 | 0.3095 | |

| C2 | 0.33 | 1.00 | 2.00 | 0.33 | 0.1496 | |

| C3 | 0.33 | 0.50 | 1.00 | 0.33 | 0.1052 | |

| C4 | 2.00 | 3.00 | 3.00 | 1.00 | 0.4357 | |

| sum | 3.66 | 7.50 | 9.00 | 2.16 | 1.0000 | |

| Level 2 of the hierarchy framework—criterion 1 | ||||||

| Criterion | R1 | R2 | R3 | R4 | Priority Vector | Principal Eigen vector: λmax = 4.2437; Consistency Index, CI = 0.0812; Random value of consistency index, RI = 0.9; Consistency ratio, CR = 0.0903; Consistency ratio is under 0.10, which means that the performed evaluation is consistent. |

| R1 | 1.00 | 2.00 | 0.33 | 2.00 | 0.2260 | |

| R2 | 0.50 | 1.00 | 0.33 | 3.00 | 0.1893 | |

| R3 | 3.00 | 3.00 | 1.00 | 3.00 | 0.4774 | |

| R4 | 0.50 | 0.33 | 0.33 | 1.00 | 0.1073 | |

| sum | 5.00 | 6.33 | 1.99 | 9.00 | 1.0000 | |

| Level 2 of the hierarchy framework—criterion 2 | ||||||

| Criterion | R1 | R2 | R3 | R4 | Priority Vector | Principal Eigen vector: λmax = 4.2515; Consistency Index, CI = 0.0838; Random value of consistency index, RI = 0.9; Consistency ratio, CR = 0.0932; Consistency ratio is under 0.10, which means that the performed evaluation is consistent. |

| R1 | 1.00 | 3.00 | 2.00 | 2.00 | 0.4196 | |

| R2 | 0.33 | 1.00 | 2.00 | 2.00 | 0.2477 | |

| R3 | 0.50 | 0.50 | 1.00 | 2.00 | 0.1955 | |

| R4 | 0.50 | 0.50 | 0.50 | 1.00 | 0.1371 | |

| sum | 2.33 | 5.00 | 5.50 | 7.00 | 1.0000 | |

| Level 2 of the hierarchy framework—criterion 3 | ||||||

| Criterion | R1 | R2 | R3 | R4 | Priority Vector | Principal Eigen vector: λmax = 4.1353; Consistency Index, CI = 0.0451; Random value of consistency index, RI = 0.9; Consistency ratio, CR = 0.0501; Consistency ratio is under 0.10, which means that the performed evaluation is consistent. |

| R1 | 1.00 | 0.50 | 2.00 | 2.00 | 0.2748 | |

| R2 | 2.00 | 1.00 | 2.00 | 2.00 | 0.3873 | |

| R3 | 0.50 | 0.50 | 1.00 | 0.50 | 0.1397 | |

| R4 | 0.50 | 0.50 | 2.00 | 1.00 | 0.1981 | |

| sum | 4.00 | 2.50 | 7.00 | 5.50 | 1.0000 | |

| Level 2 of the hierarchy framework—criterion 4 | ||||||

| Criterion | R1 | R2 | R3 | R4 | Priority Vector | Principal Eigen vector: λmax = 4.2383; Consistency Index, CI = 0.0794; Random value of consistency index, RI = 0.9; Consistency ratio, CR = 0.0883; Consistency ratio is under 0.10, which means that the performed evaluation is consistent. |

| R1 | 1.00 | 3.00 | 2.00 | 3.00 | 0.4429 | |

| R2 | 0.33 | 1.00 | 2.00 | 2.00 | 0.2376 | |

| R3 | 0.50 | 0.50 | 1.00 | 3.00 | 0.2131 | |

| R4 | 0.33 | 0.50 | 0.33 | 1.00 | 0.1065 | |

| sum | 2.16 | 5.00 | 5.33 | 9.00 | 1.0000 | |

| C1 | C2 | C3 | C4 | Composite Weight | |

|---|---|---|---|---|---|

| R1 | 0.2260 | 0.4196 | 0.2748 | 0.4429 | 0.3546 |

| R2 | 0.1893 | 0.2477 | 0.3873 | 0.2376 | 0.2399 |

| R3 | 0.4774 | 0.1955 | 0.1397 | 0.2131 | 0.2845 |

| R4 | 0.1073 | 0.1371 | 0.1981 | 0.1065 | 0.1209 |

| 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| DMUi–berths | Parameter | Trends by Intervals (Values of Output and Inputs ×103) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2021–2022 | 2022–2023 | 2023–2024 | ||||||||

| 01 | Efficiency score | 0.4632 | + | 0.5019 | 0.5019 | + | 0.8291 | 0.8291 | + | 0.8806 |

| Output—Throughput | 156.74 | + | 182.68 | 182.68 | + | 343.07 | 343.07 | - | 306.10 | |

| Input 1—Workers | 0.49 | + | 0.58 | 0.58 | + | 1.08 | 1.08 | - | 0.97 | |

| Input 2—Berth length | 0.185 | = | 0.185 | 0.185 | = | 0.185 | 0.185 | = | 0.185 | |

| Input 3—Water depth | 0.014 | = | 0.014 | 0.014 | = | 0.014 | 0.014 | = | 0.014 | |

| Input 4—Direct costs | 34.31 | + | 39.98 | 39.98 | + | 75.09 | 75.09 | - | 67 | |

| 02 | Efficiency score | 1 | = | 1 | 1 | - | 0.8309 | 0.8309 | - | 0.6405 |

| Output—Throughput | 662.58 | + | 1084.76 | 1084.76 | - | 323.60 | 323.60 | - | 204.59 | |

| Input 1—Workers | 1.08 | + | 1.76 | 1.76 | - | 0.53 | 0.53 | - | 0.33 | |

| Input 2—Berth length | 0.185 | - | 0.145 | 0.145 | = | 0.145 | 0.145 | + | 0.185 | |

| Input 3—Water depth | 0.014 | = | 0.014 | 0.014 | = | 0.014 | 0.014 | = | 0.104 | |

| Input 4—Direct costs | 175.68 | + | 287.62 | 287.62 | - | 85.80 | 85.80 | - | 54.25 | |

| 03 | Efficiency score | 0.4597 | + | 0.6119 | 0.6119 | + | 1 | 1 | = | 1 |

| Output—Throughput | 78.19 | + | 663.79 | 663.79 | + | 816.16 | 816.16 | - | 527.50 | |

| Input 1—Workers | 0.25 | + | 2.15 | 2.15 | + | 2.64 | 2.64 | - | 1.71 | |

| Input 2—Berth length | 0.060 | + | 0.185 | 0.185 | = | 0.185 | 0.185 | - | 0.155 | |

| Input 3—Water depth | 0.014 | = | 0.014 | 0.014 | = | 0.014 | 0.014 | = | 0.014 | |

| Input 4—Direct costs | 34.57 | + | 295.47 | 295.47 | + | 360.86 | 360.86 | - | 233.23 | |

| 04 | Efficiency score | 1 | = | 1 | 1 | = | 1 | 1 | = | 1 |

| Output—Throughput | 126.70 | - | 123.48 | 123.48 | + | 138.17 | 138.17 | - | 105.61 | |

| Input 1—Workers | 0.09 | = | 0.09 | 0.09 | + | 0.10 | 0.10 | - | 0.08 | |

| Input 2—Berth length | 0.093 | = | 0.093 | 0.093 | = | 0.093 | 0.093 | = | 0.093 | |

| Input 3—Water depth | 0.006 | = | 0.006 | 0.006 | = | 0.006 | 0.006 | = | 0.006 | |

| Input 4—Direct costs | 3.61 | - | 3.52 | 3.52 | + | 3.94 | 3.94 | - | 3.01 | |

| 05 | Efficiency score | 1 | = | 1 | 1 | = | 1 | 1 | - | 0 |

| Output—Throughput | 30.06 | - | 2.22 | 2.22 | - | 1.10 | 1.10 | - | 0 | |

| Input 1—Workers | 0.02 | - | 0.002 | 0.002 | - | 0.001 | 0.001 | - | 0 | |

| Input 2—Berth length | 0.093 | = | 0.093 | 0.093 | = | 0.093 | 0.093 | = | 0.093 | |

| Input 3—Water depth | 0.007 | = | 0.007 | 0.007 | = | 0.007 | 0.007 | = | 0.007 | |

| Input 4—Direct costs | 0.77 | - | 0.057 | 0.057 | - | 0.028 | 0.028 | - | 0 | |

| 06 | Efficiency score | 1 | = | 1 | 1 | = | 1 | 1 | = | 1 |

| Output—Throughput | 176.6 | - | 169.71 | 169.71 | + | 214.05 | 214.05 | - | 188.44 | |

| Input 1—Workers | 0.1 | - | 0.09 | 0.09 | + | 0.12 | 0.12 | - | 0.1 | |

| Input 2—Berth length | 0.093 | = | 0.093 | 0.093 | = | 0.093 | 0.093 | = | 0.093 | |

| Input 3—Water depth | 0.009 | = | 0.009 | 0.009 | = | 0.009 | 0.009 | = | 0.009 | |

| Input 4—Direct costs | 10.05 | - | 9.66 | 9.66 | + | 12.18 | 12.18 | - | 10.72 | |

| 07 | Efficiency score | 0.9638 | + | 0.9882 | 0.9882 | + | 1 | 1 | - | 0.9828 |

| Output–Throughput | 50.47 | + | 83.11 | 83.11 | - | 30.32 | 30.32 | - | 20.14 | |

| Input 1—Workers | 0.027 | + | 0.043 | 0.043 | - | 0.016 | 0.016 | - | 0.011 | |

| Input 2—Berth length | 0.198 | = | 0.198 | 0.198 | = | 0.198 | 0.198 | = | 0.198 | |

| Input 3—Water depth | 0.013 | = | 0.013 | 0.013 | = | 0.013 | 0.013 | = | 0.013 | |

| Input 4—Direct costs | 2.87 | + | 4.73 | 4.73 | - | 1.73 | 1.73 | - | 1.15 | |

—Trends are not balanced.

—Trends are not balanced.Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Đelović, D.; Aleksić, M.; Iker, O.; Chalaris, M. Berth Efficiency Under Risk Conditions in Seaports Through Integrated DEA and AHP Analysis. J. Mar. Sci. Eng. 2025, 13, 1324. https://doi.org/10.3390/jmse13071324

Đelović D, Aleksić M, Iker O, Chalaris M. Berth Efficiency Under Risk Conditions in Seaports Through Integrated DEA and AHP Analysis. Journal of Marine Science and Engineering. 2025; 13(7):1324. https://doi.org/10.3390/jmse13071324

Chicago/Turabian StyleĐelović, Deda, Marinko Aleksić, Oto Iker, and Michail Chalaris. 2025. "Berth Efficiency Under Risk Conditions in Seaports Through Integrated DEA and AHP Analysis" Journal of Marine Science and Engineering 13, no. 7: 1324. https://doi.org/10.3390/jmse13071324

APA StyleĐelović, D., Aleksić, M., Iker, O., & Chalaris, M. (2025). Berth Efficiency Under Risk Conditions in Seaports Through Integrated DEA and AHP Analysis. Journal of Marine Science and Engineering, 13(7), 1324. https://doi.org/10.3390/jmse13071324