Experimental Study on Mechanical Integrity of Cement and EICP-Solidified Soil for Scour Protection of Pile Foundations

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Soil

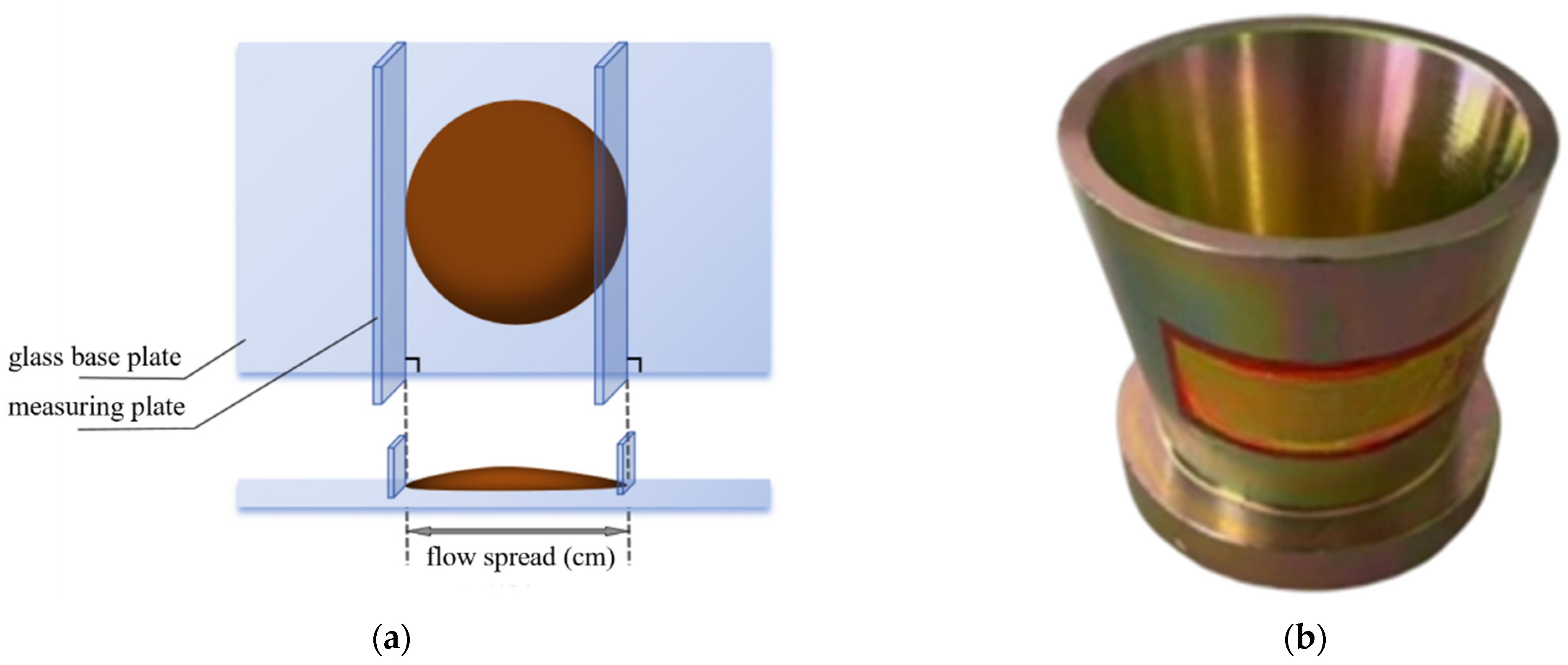

2.2. Fluidity Test Setup of Cement and ECIP-Solidified Soil

2.3. Disintegration Test Setup of Cement and ECIP-Solidified Soil

2.4. Unconfined Compression Strength Test Setup of Cement and ECIP-Solidified Soil

3. Results Analysis and Discussion

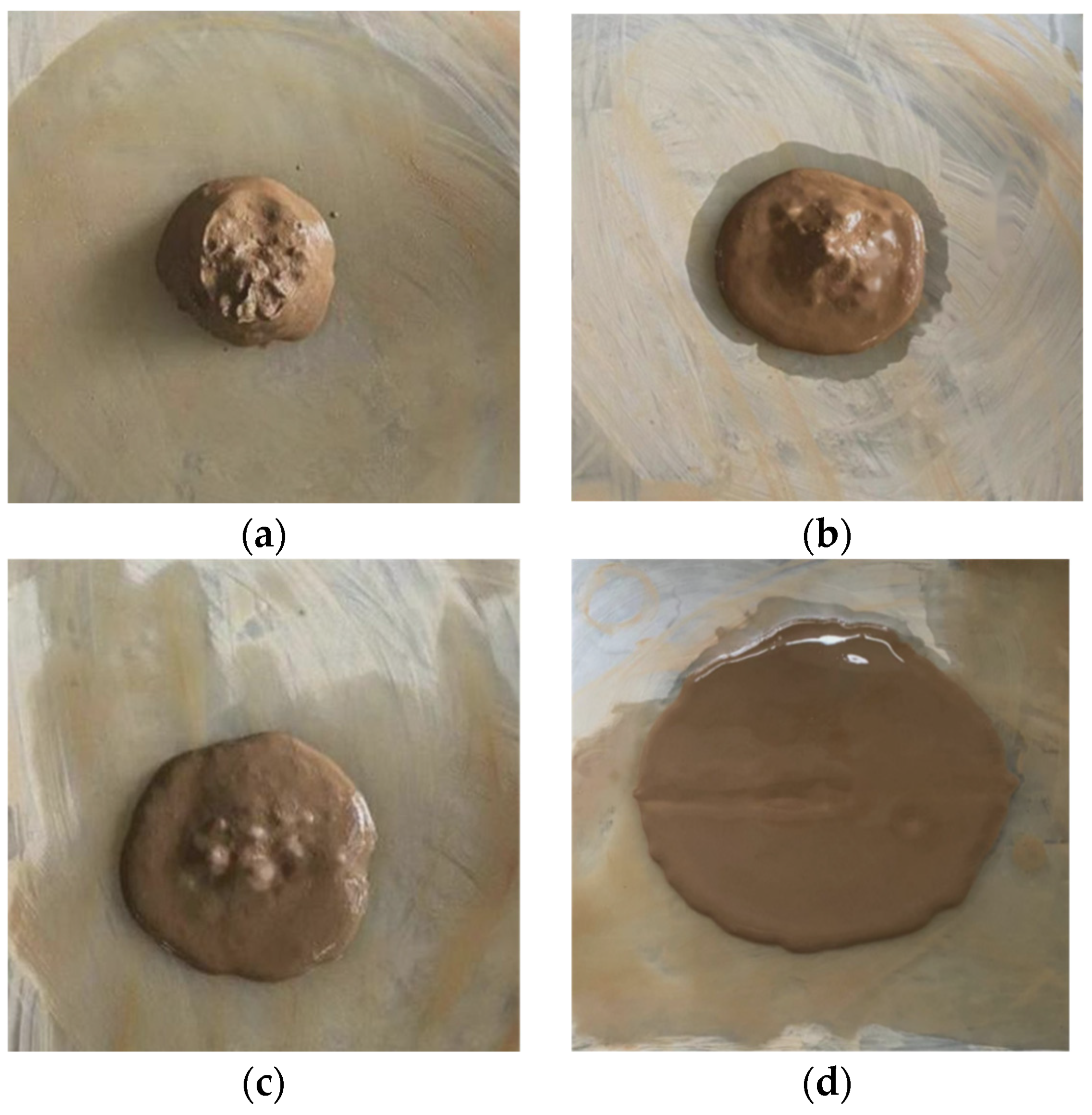

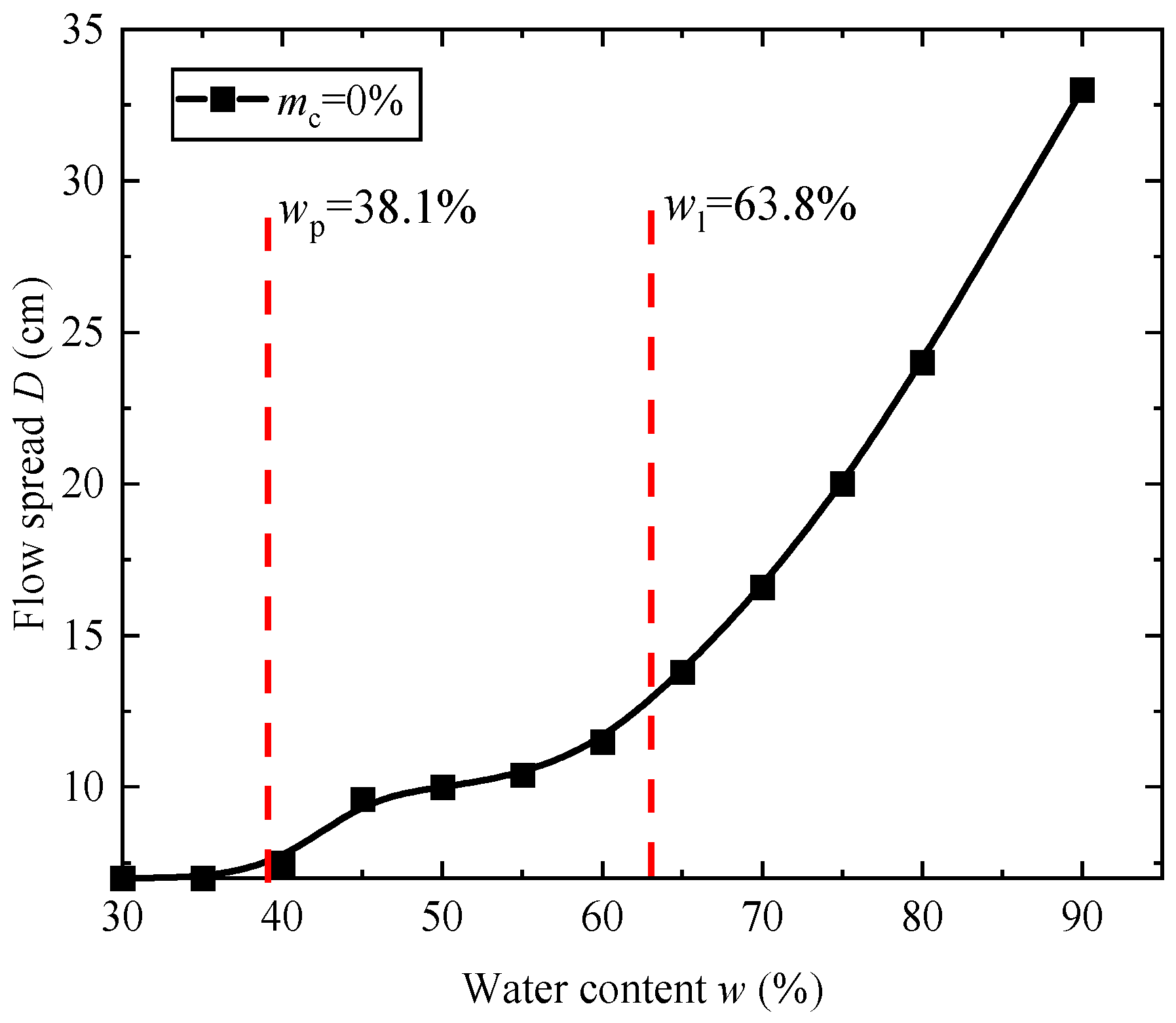

3.1. Fluidity of Original Soil

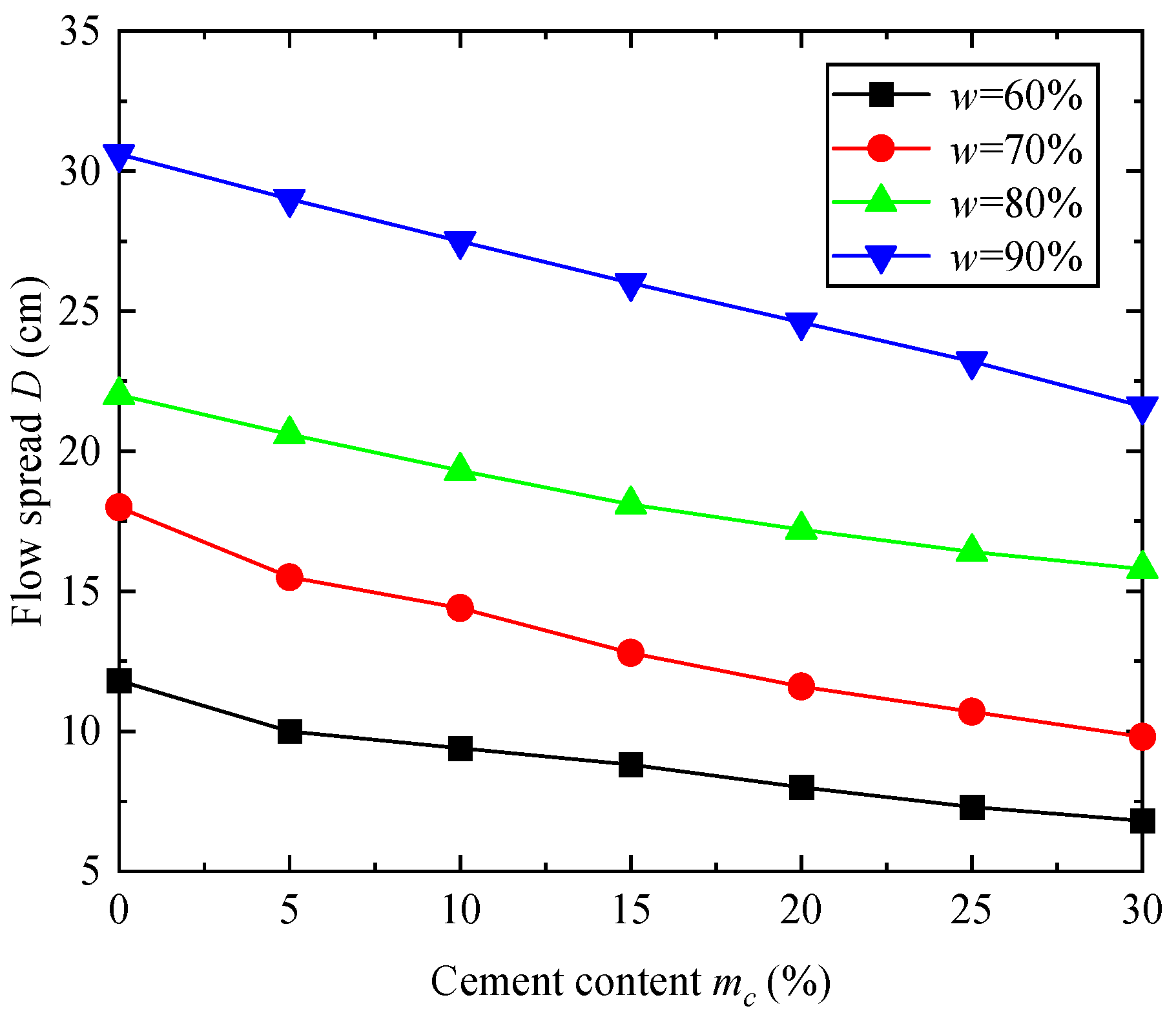

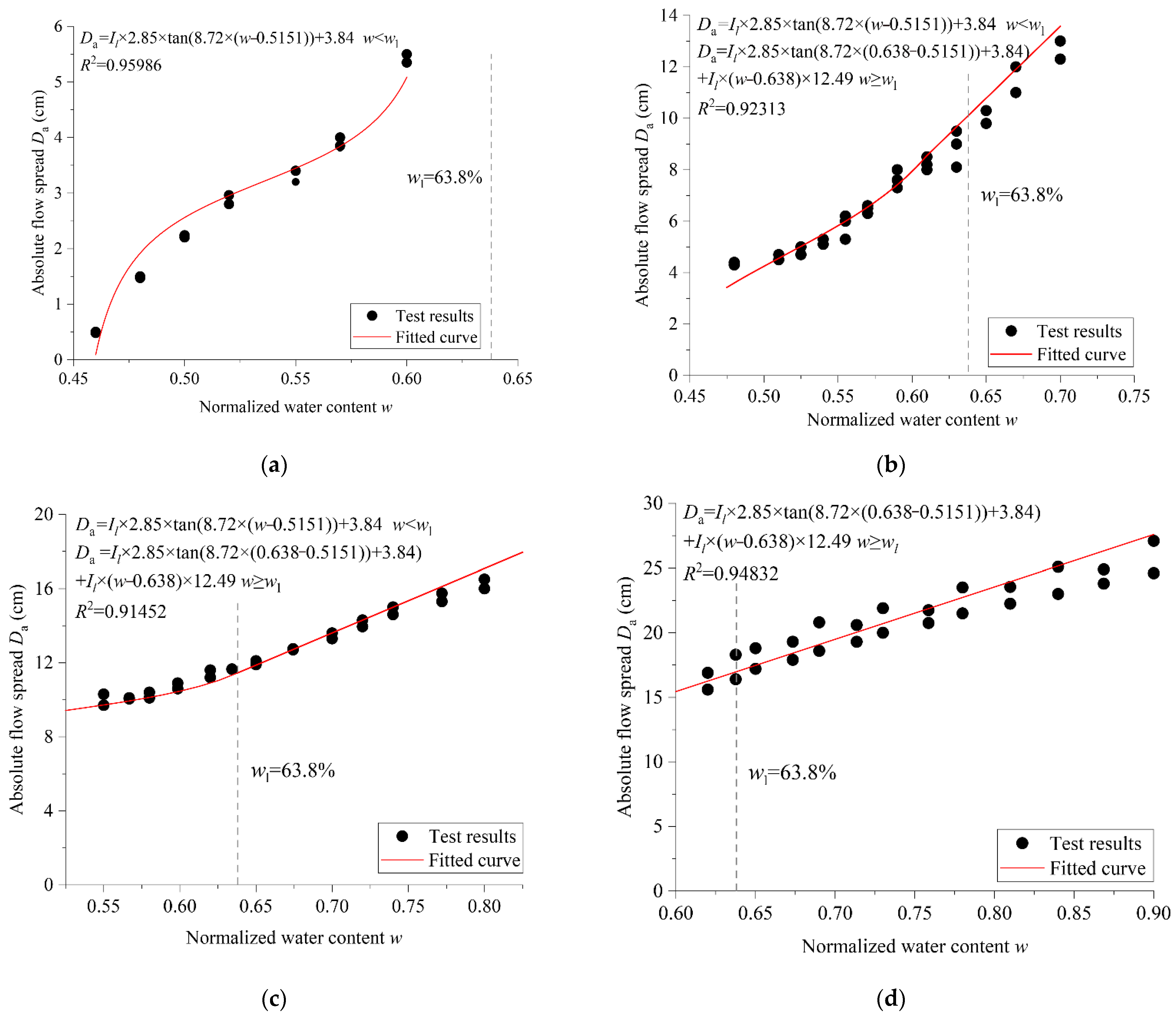

3.1.1. Fluidity of Cement-Solidified Soil

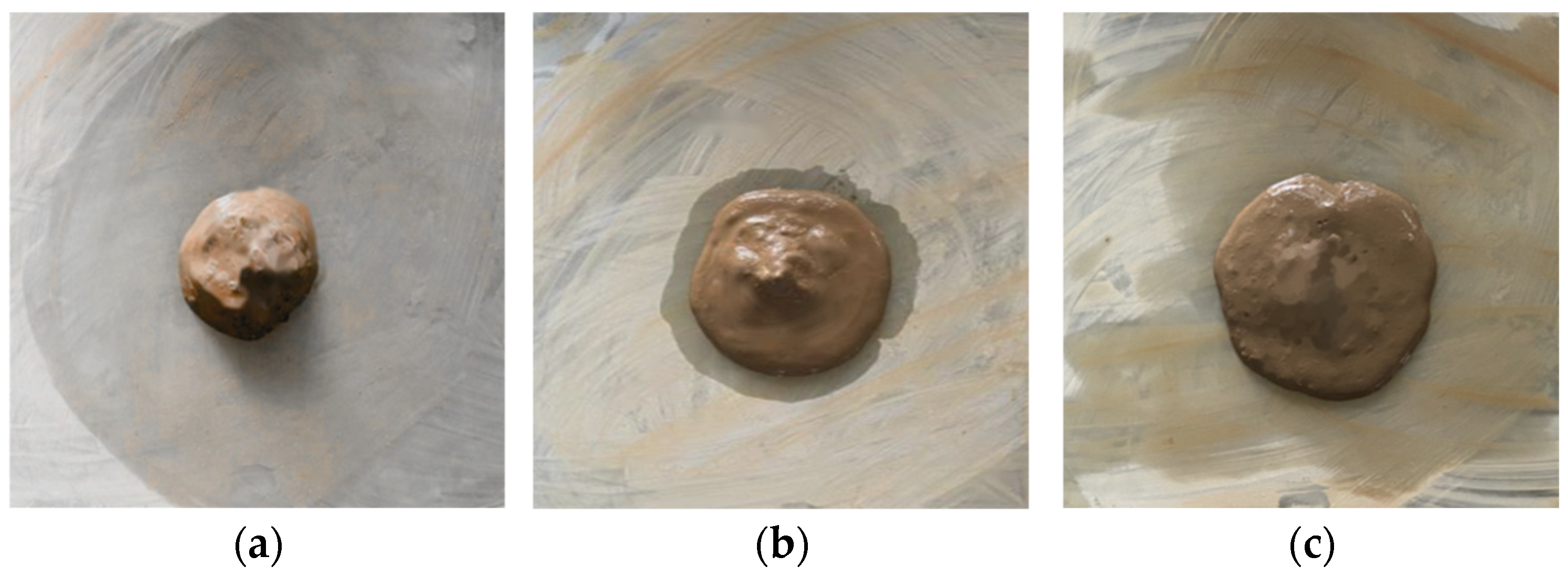

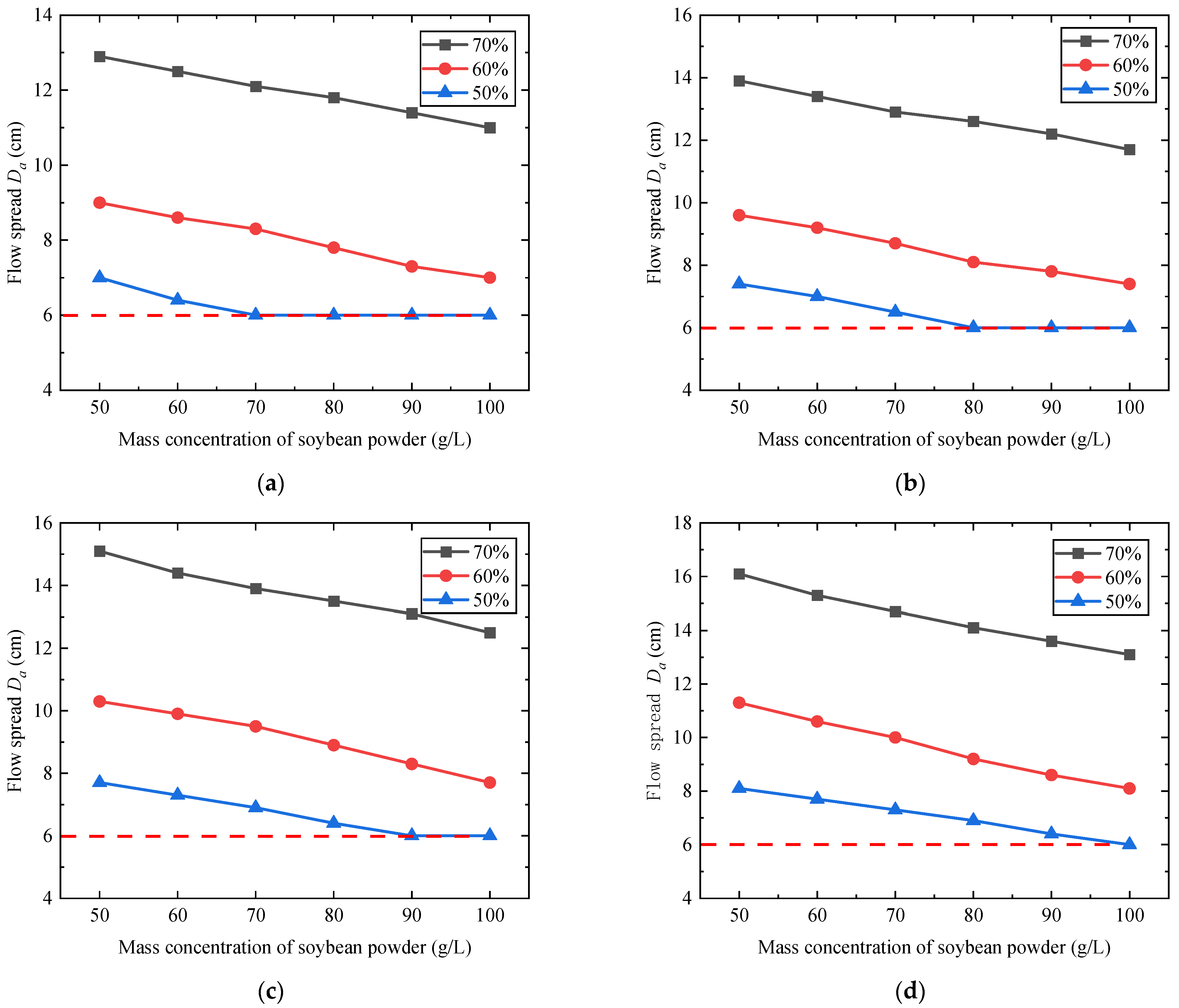

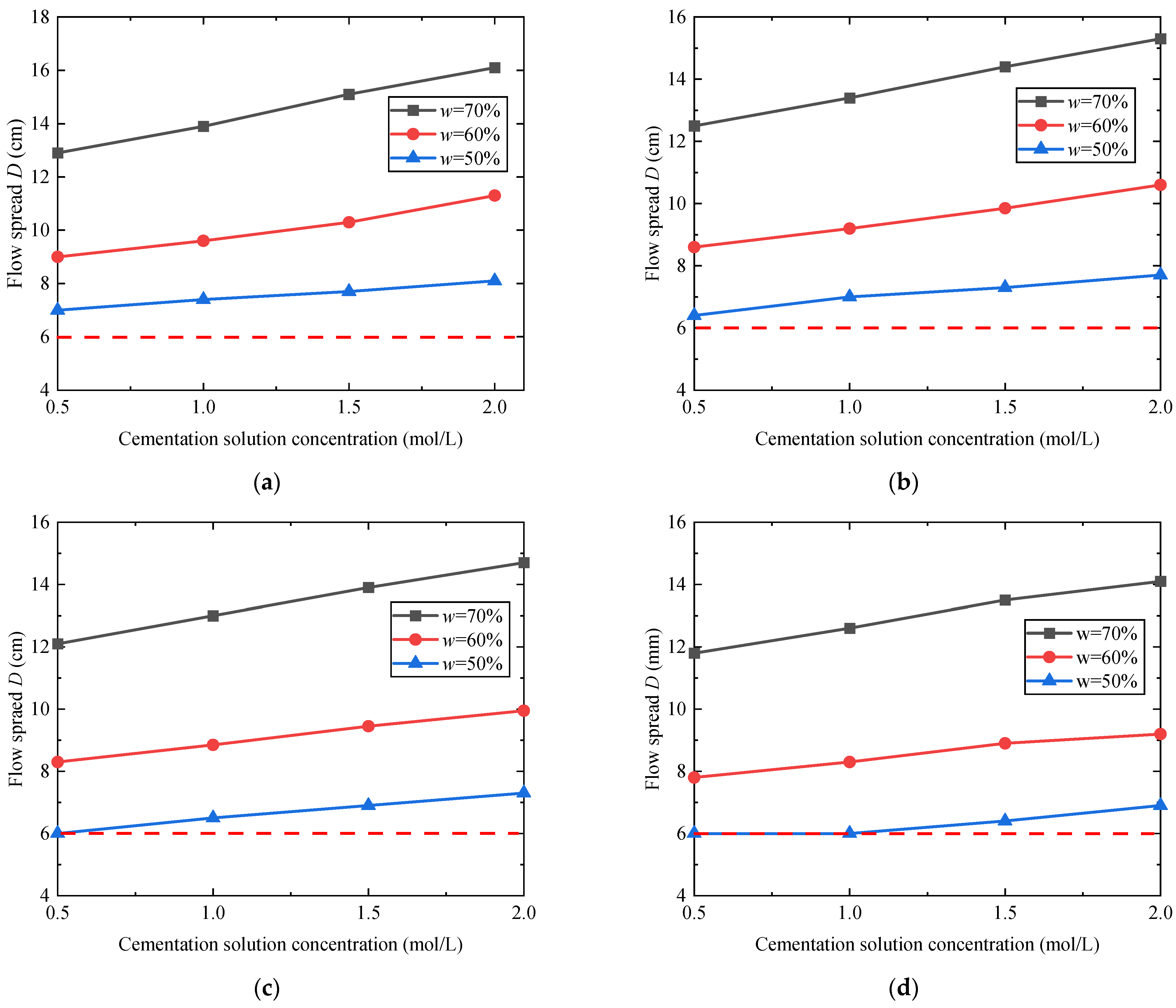

3.1.2. Fluidity of ECIP-Solidified Soil

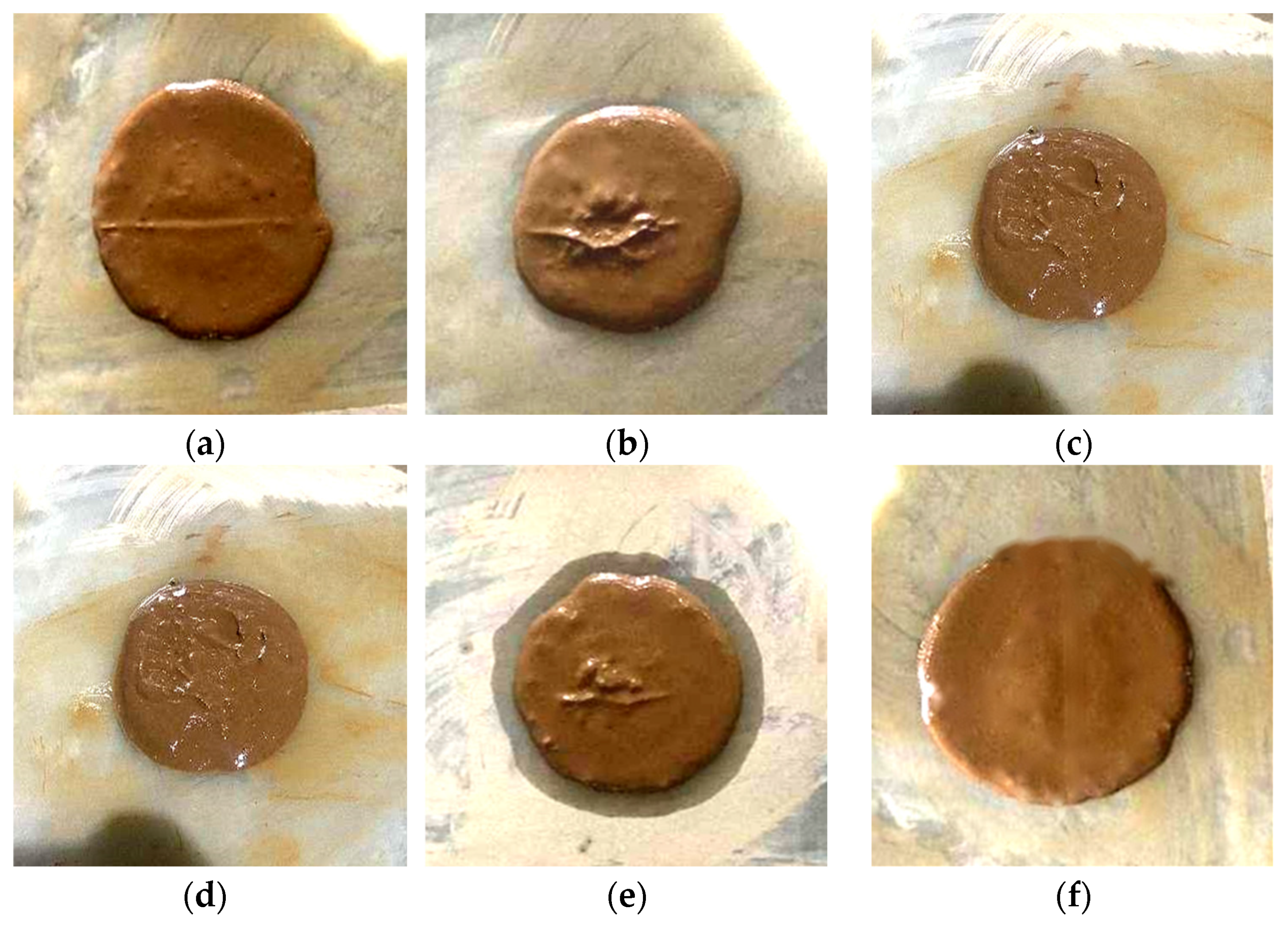

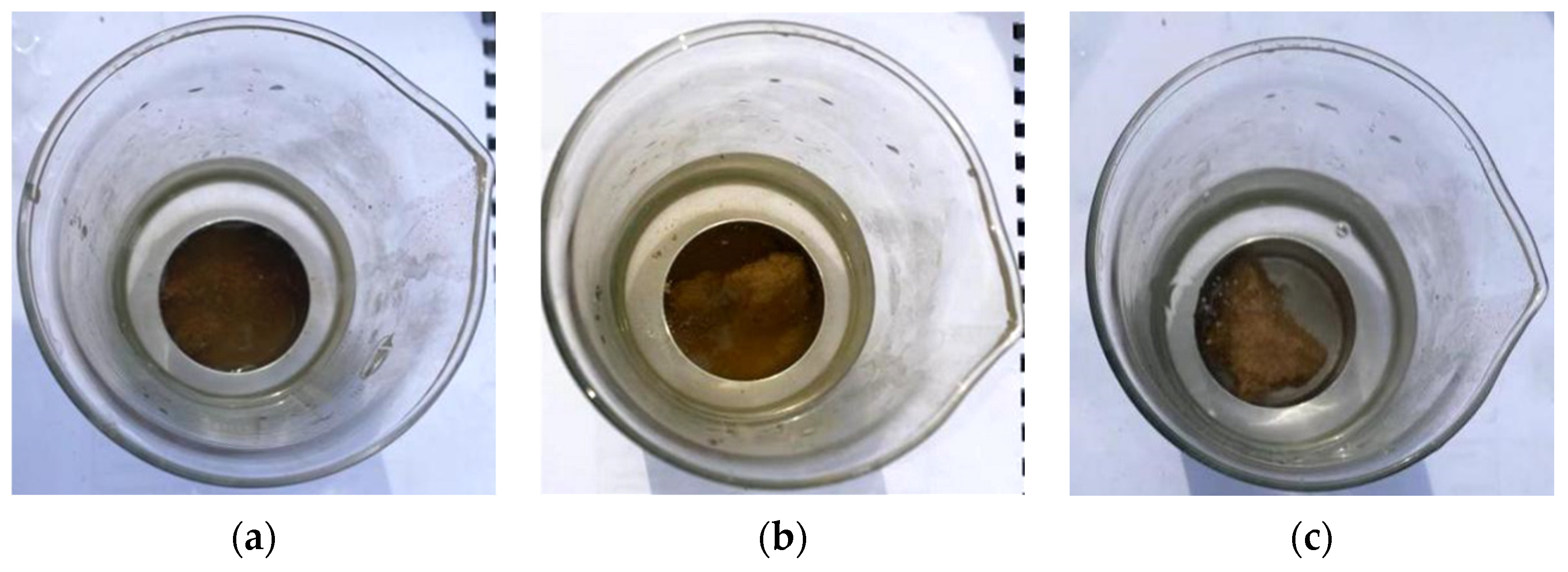

3.2. Disintegration Characteristics of Cement and ECIP-Solidified Soil

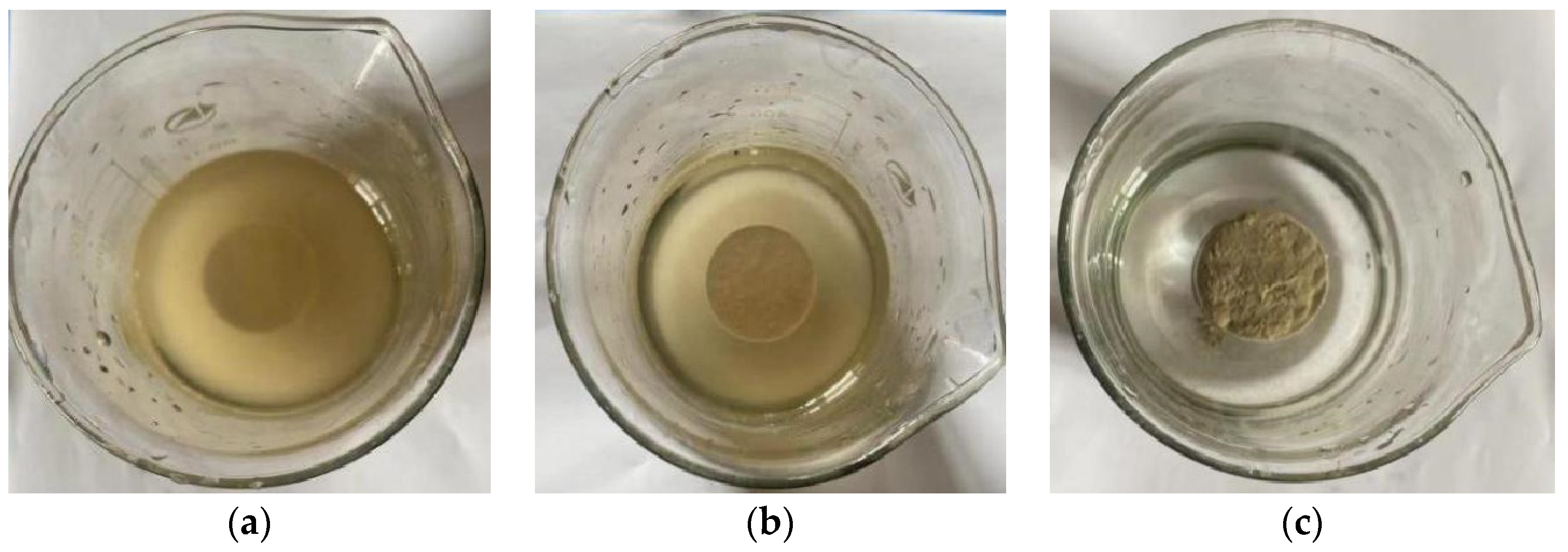

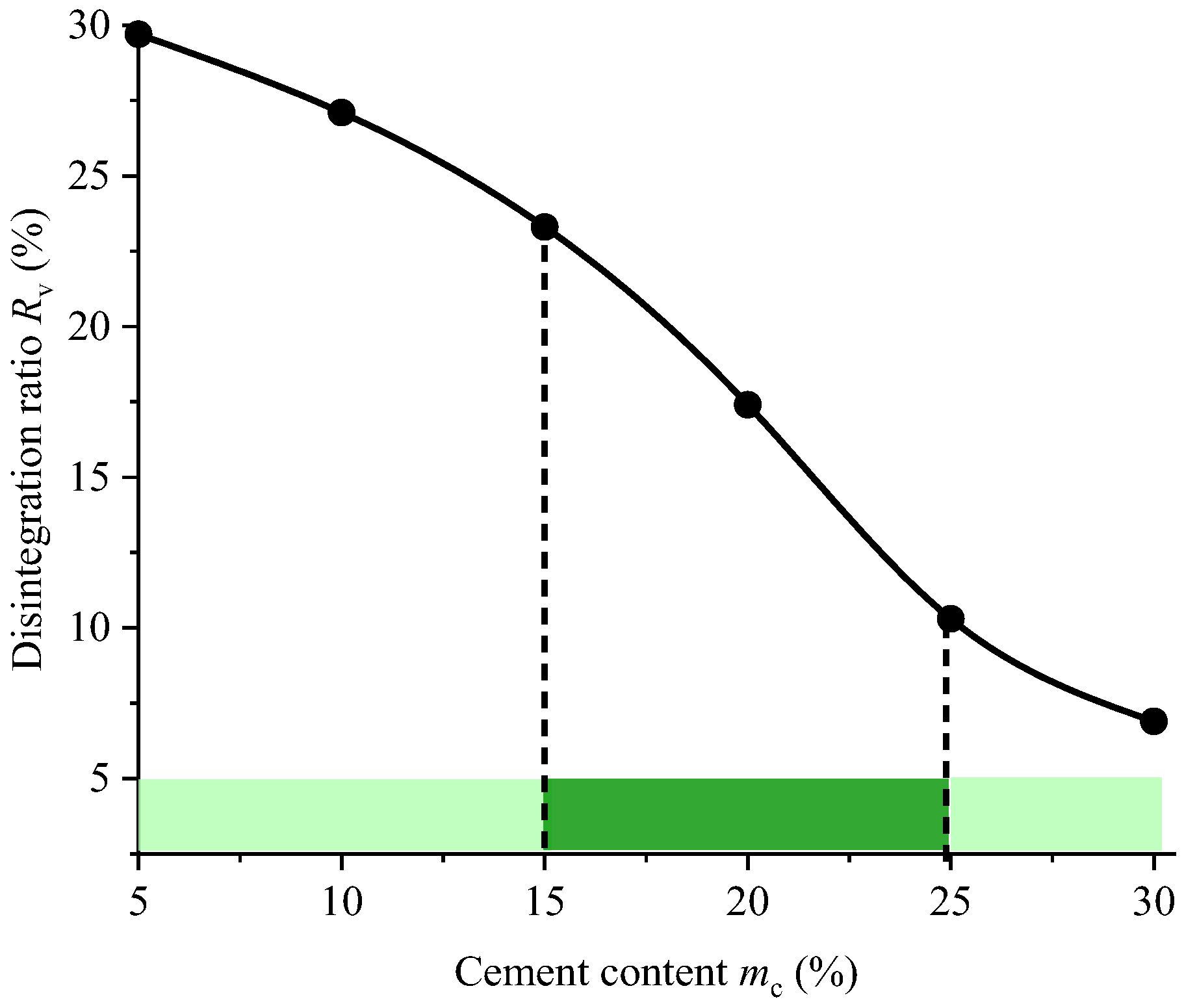

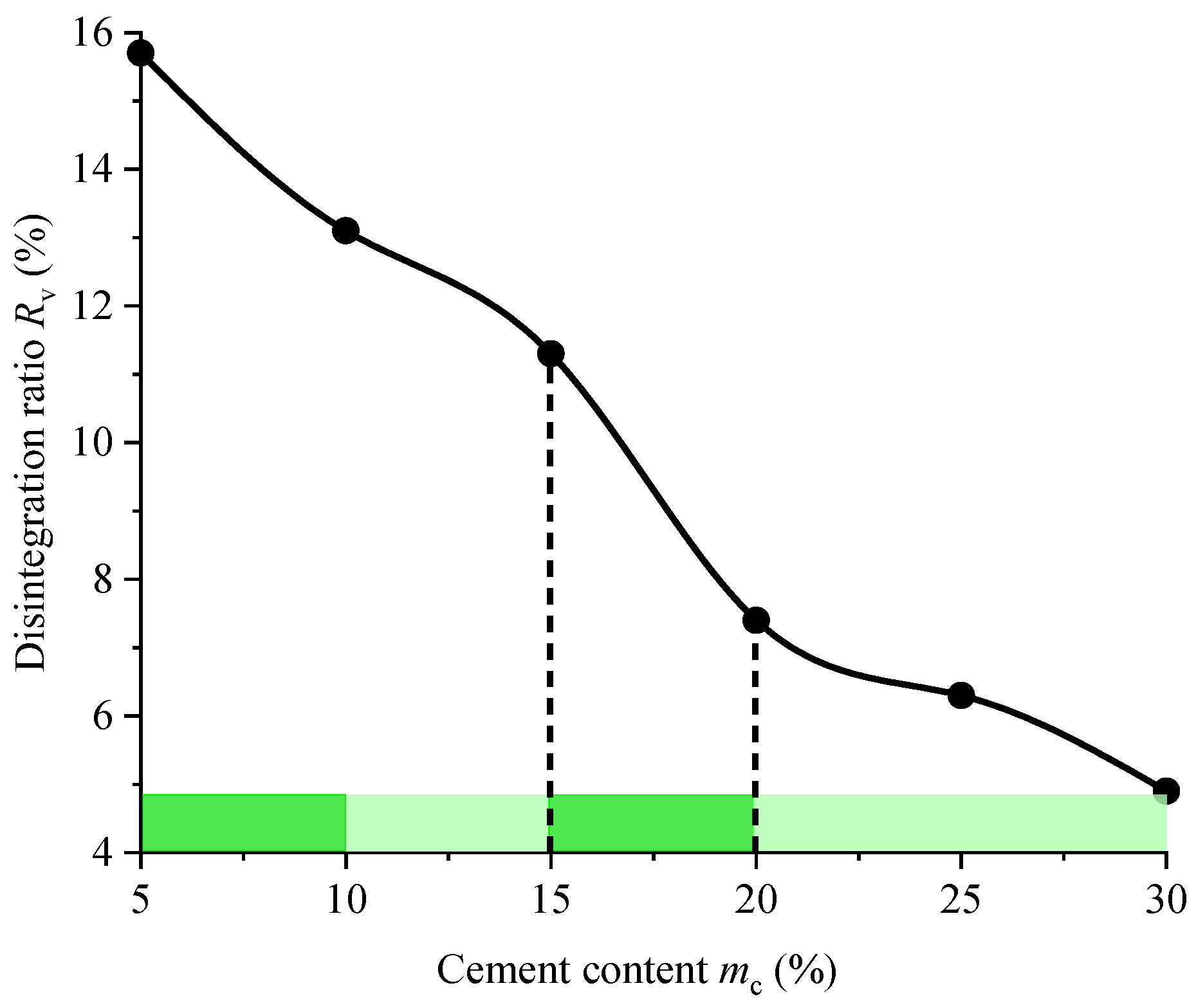

3.2.1. Disintegration Characteristics of Cement-Solidified Soil

- (1)

- Cement-solidified soil (no curing age)

- (2)

- Cement-solidified soil (curing 7 days)

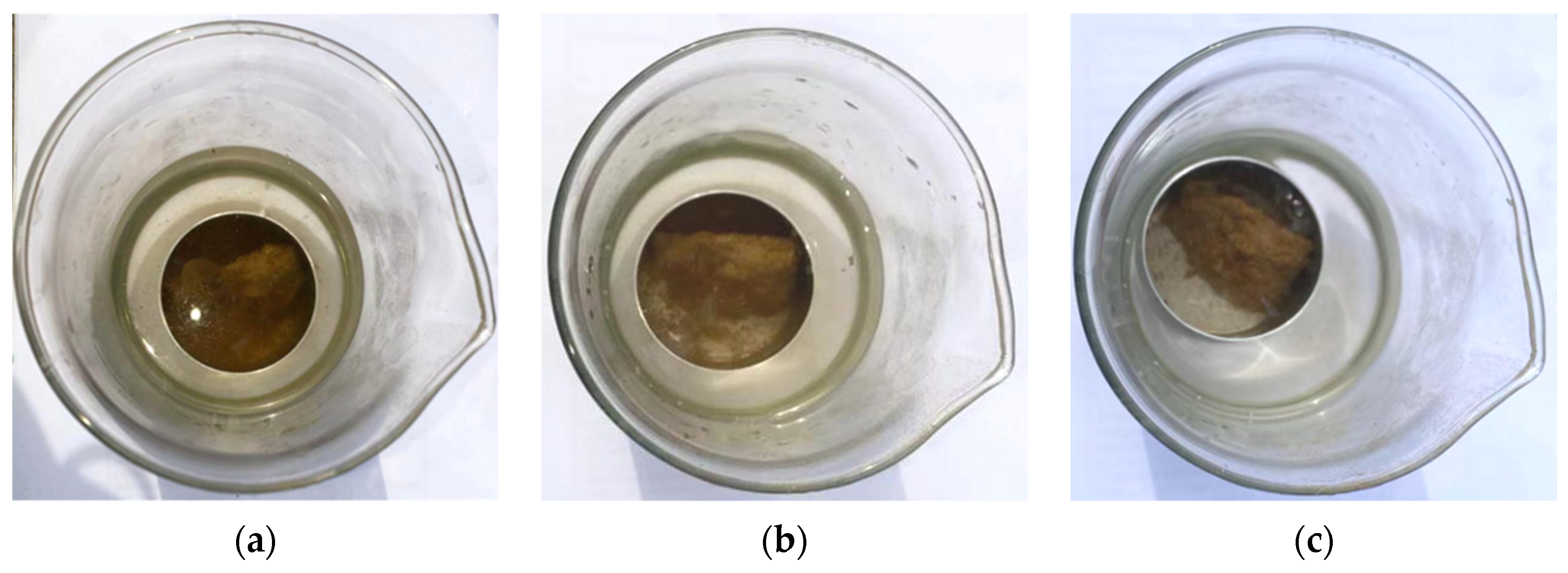

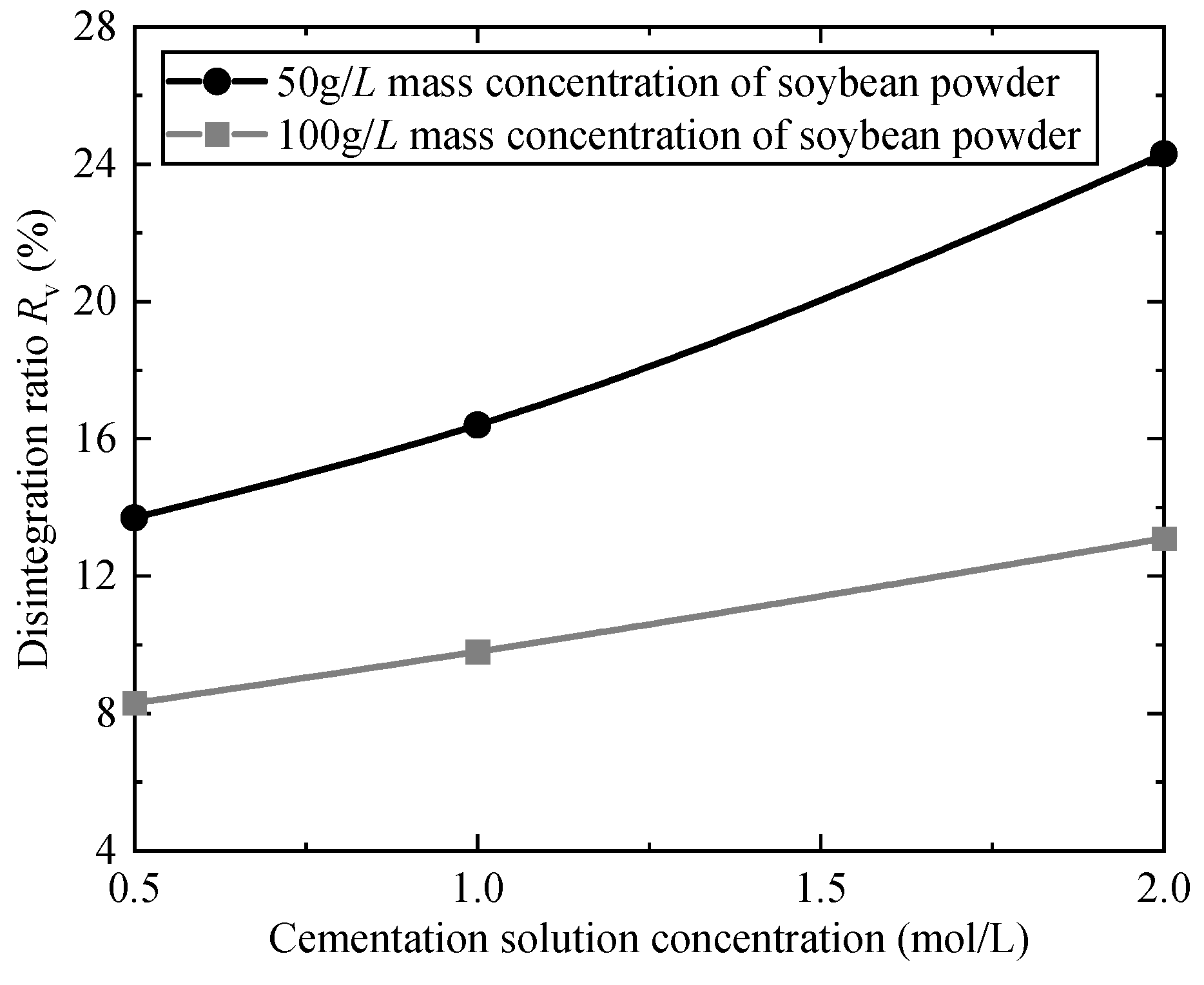

3.2.2. Disintegration Characteristics of ECIP-Solidified Soil

- (1)

- EICP-solidified soil (no curing age)

- (2)

- EICP-solidified soil (curing 7 days)

3.3. Unconfined Compression Strength of Cement and ECIP-Solidified Soil

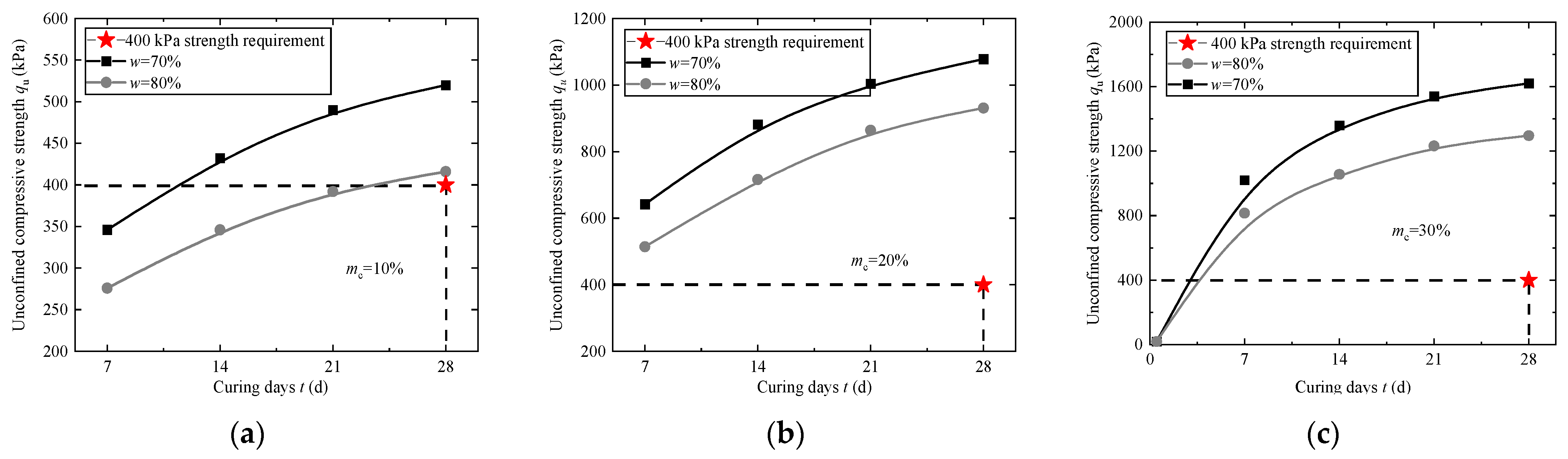

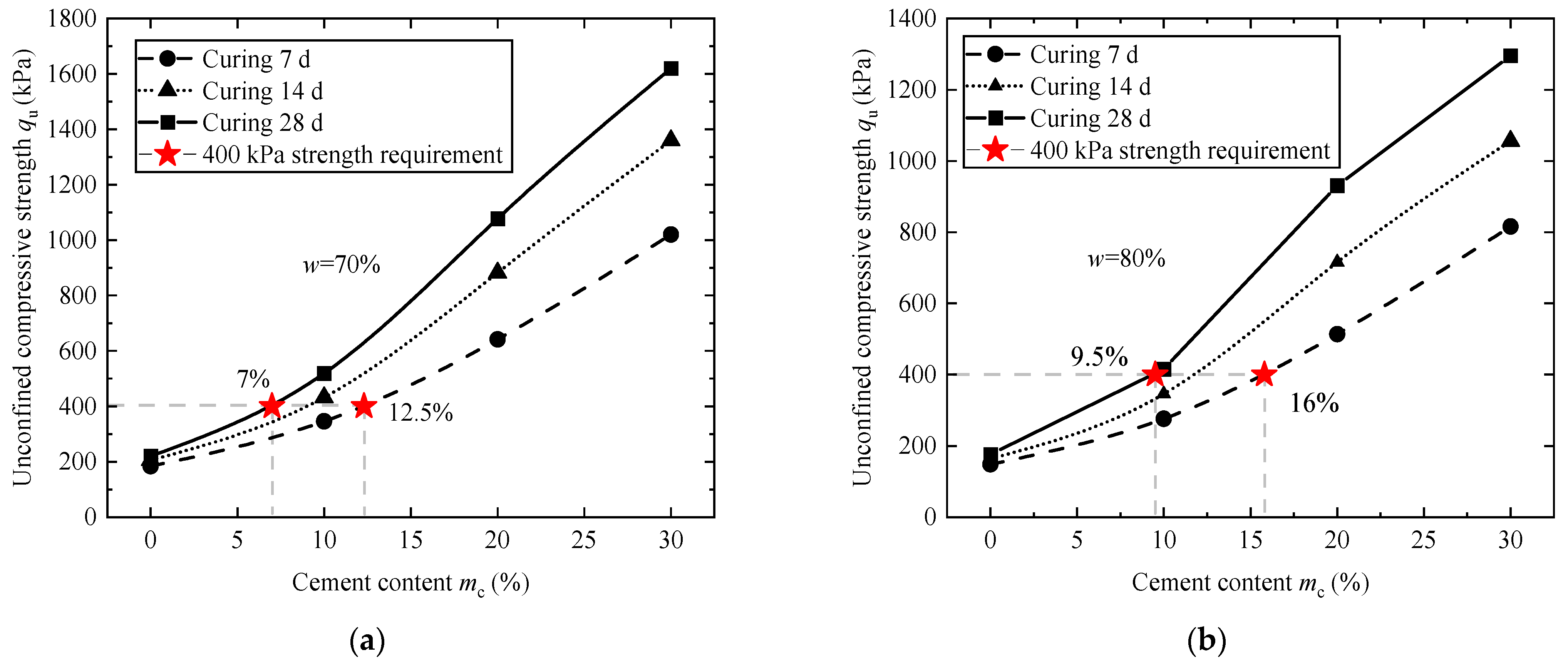

3.3.1. Unconfined Compression Strength of Cement-Solidified Soil

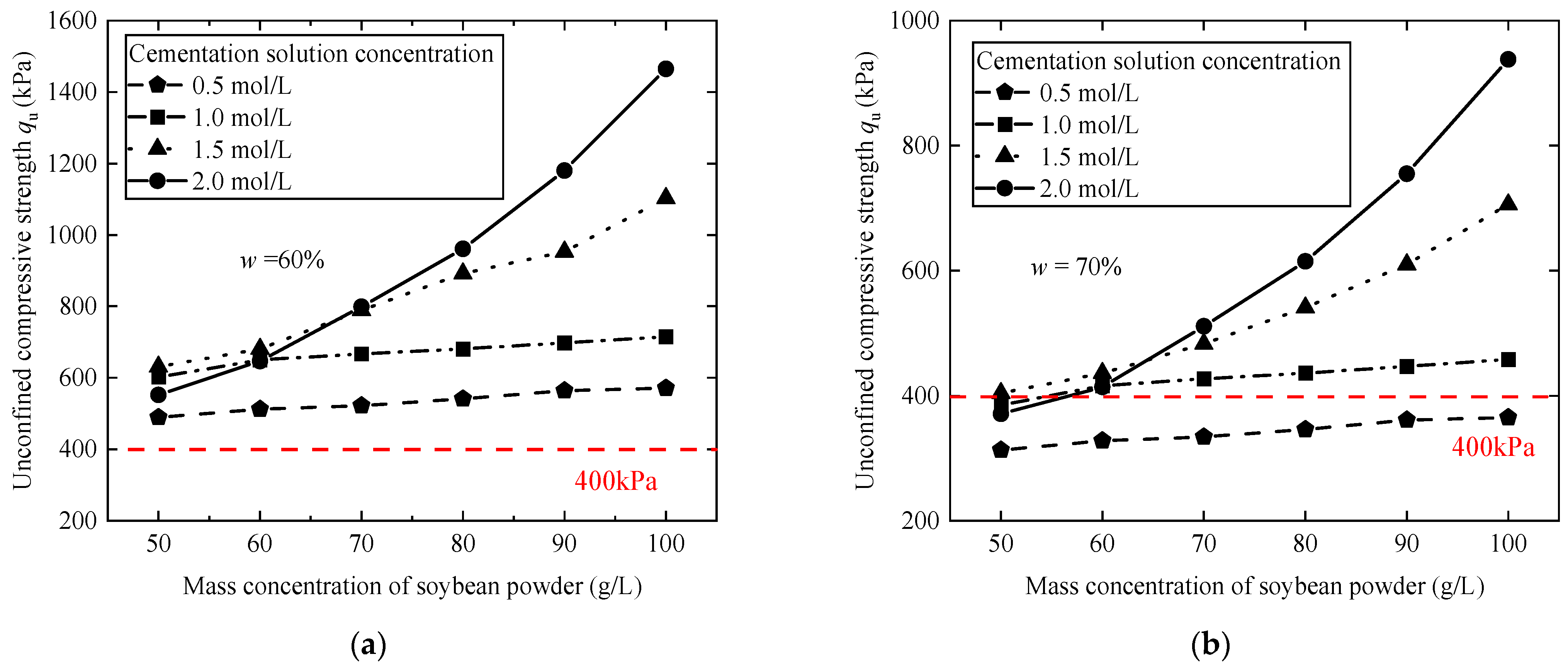

3.3.2. Unconfined Compression Strength of EICP-Solidified Soil

4. Conclusions

- (1)

- At the same initial water content, the fluidity of cement-solidified soil gradually decreases with the increase in cement content, and the rate of curve decline is first fast and then slow; for the same amount of cement added, the higher the initial water content of the solidified soil, the greater the fluidity of the solidified soil. The trend of the curve after normalization of water content is divided into three intervals.

- (2)

- At a constant cementation solution concentration, EICP-solidified soil’s fluidity decreases with higher soybean powder concentration. Higher initial water content significantly increases fluidity at the same cementation concentration. When the soybean powder concentration is constant, fluidity increases with a higher cementation solution concentration.

- (3)

- Increasing cement content during initial mixing reduces the disintegration rate of solidified soil. This decrease in disintegration rate accelerates at first and then slows down. After 7 days of curing, the disintegration rate also decreases with higher cement content, following the same trend as in the early mixing stage. The most significant improvement in anti-dispersion for 7-day-cured soil occurs at cement additions of 5–10% and 15–20%.

- (4)

- During initial mixing, EICP-solidified soil’s disintegration rate increases with a higher cementation solution concentration (at constant soybean powder concentration). As the cementation solution concentration increases, the rate of the curve increase gradually increases. After 7-day curing, disintegration decreases with higher cementation concentration. The highest reduction rate occurs below a 1.0 mol/L cementation concentration.

- (5)

- Cement-solidified soil’s strength increases with curing time, growing rapidly before 14 days then slowing. Higher initial water content reduces strength, while increased cement content boosts strength with accelerating growth. To achieve >400 kPa strength after 28-day curing, minimum cement requirements vary based on initial water content and curing duration.

- (6)

- Higher soybean powder concentration increases EICP-solidified soil strength, with faster growth at higher cementation concentrations. Increased initial water content reduces strength. As the cementation solution concentration increases, the trend in strength of EICP-solidified soil varies with different concentrations of soybean powder. Each soybean powder level has an optimal cementation concentration range that maximizes strength gain. Beyond this range, strength growth slows or decreases.

5. Limitations

6. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OuYang, H.; Gong, Z.; Zhu, M.; Liu, H.; Liu, Z.; Dai, G.; Gong, W. Numerical analysis of lateral bearing capacity of monopiles in clay, part 1: Single uniform and isotropic soil layer with strength profile su = su1× z. Comput. Geotech. 2025, 184, 107294. [Google Scholar] [CrossRef]

- Sheng, D.; Eigenbrod, K.D.; Wriggers, P. Finite element analysis of pile installation using large-slip frictional contact. Comput. Geotech. 2005, 32, 17–26. [Google Scholar] [CrossRef]

- Peng, Y.; OuYang, H.; Qin, W.; Gong, W.; Dai, G. Lateral and vertical bearing characteristics of monopile and pile groups under scour condition: Model test and calculation method. Ocean Eng. 2025, 331, 121232. [Google Scholar] [CrossRef]

- Sarmiento, J.; Guanche, R.; Losada, I.; Rosendo, E.; Guindo, A.; de Guevara, J.L. Scour processes around pile clusters of jacket foundations under steady currents. Ocean Eng. 2024, 313, 119502. [Google Scholar] [CrossRef]

- Wang, S.-Y.; Qi, W.-G.; Gao, F.-P.; Li, B.; He, B. Time development of clear-water scour around a pile foundation: Phenomenological theory of turbulence-based approach. Coast. Eng. 2024, 190, 104511. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Katkan, W.; Sirilerdwattana, W.; Rachan, R. Strength development in cement stabilized low plasticity and coarse grained soils: Laboratory and field study. Soils Found. 2006, 46, 351–366. [Google Scholar] [CrossRef]

- Abu-Farsakh, M.; Dhakal, S.; Chen, Q. Laboratory characterization of cementitiously treated/stabilized very weak subgrade soil under cyclic loading. Soils Found. 2015, 55, 504–516. [Google Scholar] [CrossRef]

- Ifediniru, C.; Ekeocha, N.E. Performance of cement-stabilized weak subgrade for highway embankment construction in Southeast Nigeria. Int. J. Geo-Eng. 2022, 13, 1. [Google Scholar] [CrossRef]

- Ardah, A.; Chen, Q.; Abu-Farsakh, M. Evaluating the performance of very weak subgrade soils treated/stabilized with cementitious materials for sustainable pavements. Transp. Geotech. 2017, 11, 107–119. [Google Scholar] [CrossRef]

- Pongsivasathit, S.; Horpibulsuk, S.; Piyaphipat, S. Assessment of mechanical properties of cement stabilized soils. Case Stud. Constr. Mater. 2019, 11, e00301. [Google Scholar] [CrossRef]

- Wei, X.; Ku, T. New design chart for geotechnical ground improvement: Characterizing cement-stabilized sand. Acta Geotech. 2020, 15, 999–1011. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Wu, Y.; Wang, C.; Liang, F. An investigation of the effect of utilizing solidified soil as scour protection for offshore wind turbine foundations via a simplified scour resistance test. J. Mar. Sci. Eng. 2022, 10, 1317. [Google Scholar] [CrossRef]

- OuYang, H.; Dai, G.; Gao, L.; Zhu, W.; Du, S.; Gong, W. Local scour characteristics of monopile foundation and scour protection of cement-improved soil in marine environment-Laboratory and site investigation. Ocean Eng. 2022, 255, 111443. [Google Scholar] [CrossRef]

- OuYang, H.; Chen, X.; Gong, Z.; Zuo, C.; Dai, G.; Gong, W. Large-scale model test study on lateral bearing characteristics of semi-rigid pile with cement-soil reinforcement under multistage loading and unidirectional multi-cycle loading in clay. Soil Dyn. Earthq. Eng. 2025, 195, 109421. [Google Scholar] [CrossRef]

- Zahri, A.M.; Zainorabidin, A. An overview of traditional and non traditional stabilizer for soft soil. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; p. 012015. [Google Scholar]

- Almajed, A.; Abbas, H.; Arab, M.; Alsabhan, A.; Hamid, W.; Al-Salloum, Y. Enzyme-Induced Carbonate Precipitation (EICP)-Based methods for ecofriendly stabilization of different types of natural sands. J. Clean. Prod. 2020, 274, 122627. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J. An experimental study on enzymatic-induced carbonate precipitation using yellow soybeans for soil stabilization. KSCE J. Civ. Eng. 2020, 24, 2026–2037. [Google Scholar] [CrossRef]

- Almajed, A.; Lateef, M.A.; Moghal, A.A.B.; Lemboye, K. State-of-the-art review of the applicability and challenges of microbial-induced calcite precipitation (MICP) and enzyme-induced calcite precipitation (EICP) techniques for geotechnical and geoenvironmental applications. Crystals 2021, 11, 370. [Google Scholar] [CrossRef]

- Saif, A.; Cuccurullo, A.; Gallipoli, D.; Perlot, C.; Bruno, A.W. Advances in enzyme induced carbonate precipitation and application to soil improvement: A review. Materials 2022, 15, 950. [Google Scholar] [CrossRef]

- Li, R.; Wu, X.; Chen, J. Numerical study on residual rate of fluidized solidified slurry in pumping for scour repair around monopile. Ocean Eng. 2023, 276, 114072. [Google Scholar] [CrossRef]

- Wu, X.-N.; Li, R.-Y.; Shu, J.; Tang, C.; Chen, J.-J.; Wang, H.-L.; Jiang, H.-L.; Wang, X. Experimental Study on Engineering Behavior of Solidified Soil for Scour Repair and Protection. China Ocean. Eng. 2024, 38, 625–635. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Beijing China Planning Publishing House: Beijing, China, 2019.

- Whiffin, V.S.; Van, P.L.A.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiology 2007, 24, 417–423. [Google Scholar] [CrossRef]

- GB/T 50080-2002; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Architecture & Building Press: Beijing, China, 2016.

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. Standards Press of China: Beijing, China, 2005.

- SL 251-2015; Code for Investigation of Natural Building Material for Water resources and Hydropower Project. China Water & Power Press: Beijing, China, 2015.

- Zhao, Q.; Li, L.; Li, C.; Li, M.D.; Amini, F.; Zhang, H.Z. Factors Affecting Improvement of Engineering Properties of MICP-Treated Soil Catalyzed by Bacteria and Urease. J. Mater. Civ. Eng. 2014, 26, 04014094. [Google Scholar] [CrossRef]

- Zhou, M.; Li, P.; Luo, X.; Shi, D.; Zhang, H. Application of solidified soil in scour protection of foundations in offshore windpower engineering. J. Waterw. Harb. 2023, 44, 264–269. [Google Scholar]

- Jiahui, C. Experimental Study on MICP Solidification of Muddy Soil. Master’s Thesis, Wuhan University of Science and Technology, Wuhan, China, 2021. [Google Scholar]

- Oste, L.A.; Temminghoff, E.J.; Riemsdijk, W.V. Solid-solution partitioning of organic matter in soils as influenced by an increase in pH or Ca concentration. Environ. Sci. Technol. 2002, 36, 208–214. [Google Scholar] [CrossRef]

- Yao, K.; Pan, Y.; Jia, L.; Yi, J.T.; Hu, J.; Wu, C. Strength evaluation of marine clay stabilized by cementitious binder. Mar. Georesour. Geotechnol. 2020, 38, 730–743. [Google Scholar] [CrossRef]

- Zhao, Q. Experimental Study on Soil Improvement Using Microbial Induced Calcite Precipitation (MICP). Ph.D. Thesis, China University of Geosciences, Beijing, China, 2014. [Google Scholar]

| Soil | Specific Gravity | Unit Weight (kN/m3) | Water Content w | Liquid Limit wl | Plastic Limit wp | Plasticity Index Ip | Liquid Index Il |

|---|---|---|---|---|---|---|---|

| silty clay | 2.74 | 16.6 | 69.3% | 63.8% | 38.1% | 25.7% | 12.1% |

| Types of Solidified Soil | Soil Initial Water Content w (%) | Cement Content mc (%) | Mass Concentration of Soybean Powder (g/L) | Cementation Solution Concentration (mol/L) |

|---|---|---|---|---|

| Cement-solidified soil | 60, 70, 80, 90 | 0, 5, 10, 15, 20, 25, 30 | / | / |

| ECIP-solidified soil | 50, 60, 70 | / | 50, 60, 70, 80, 90, 100 | 0.5, 1.0, 1.5, 2.0 |

| Types of Solidified Soil | Initial Water Content w (%) | Cement Content mc (%) | Mass Concentration of Soybean Powder (g/L) | Cementation Solution Concentration (mol/L) |

|---|---|---|---|---|

| Cement-solidified soil (no curing age) | 70 | 5, 10, 15, 20, 25, 30 | / | / |

| Cement-solidified soil (curing 7 days) | 70 | 5, 10, 15, 20, 25, 30 | / | / |

| ECIP-solidified soil (no curing age) | 60 | / | 50, 100 | 0.5, 1.0, 2.0 |

| ECIP-solidified soil (curing 7 days) | 60 | / | 50, 100 | 0.5, 1.0, 2.0 |

| Types of Solidified Soil | Initial Water Content w (%) | Cement Content mc (%) | Curing Age (d) | Mass Concentration of Soybean Powder (g/L) | Cementation Solution Concentration (mol/L) |

|---|---|---|---|---|---|

| Cement-solidified soil | 70, 80 | 0, 5, 10, 15, 20, 25, 30 | 7, 14, 21, 28 | / | / |

| ECIP-solidified soil | 60, 70 | / | 28 | 50, 60, 70, 80, 90, 100 | 0.5, 1.0, 1.5, 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, F.; Zhang, Q.; Qin, W.; Ouyang, H.; Li, Z.; Peng, Y.; Dai, G. Experimental Study on Mechanical Integrity of Cement and EICP-Solidified Soil for Scour Protection of Pile Foundations. J. Mar. Sci. Eng. 2025, 13, 1323. https://doi.org/10.3390/jmse13071323

Cao F, Zhang Q, Qin W, Ouyang H, Li Z, Peng Y, Dai G. Experimental Study on Mechanical Integrity of Cement and EICP-Solidified Soil for Scour Protection of Pile Foundations. Journal of Marine Science and Engineering. 2025; 13(7):1323. https://doi.org/10.3390/jmse13071323

Chicago/Turabian StyleCao, Feng, Qilin Zhang, Wei Qin, Haoran Ouyang, Zhiyue Li, Yutao Peng, and Guoliang Dai. 2025. "Experimental Study on Mechanical Integrity of Cement and EICP-Solidified Soil for Scour Protection of Pile Foundations" Journal of Marine Science and Engineering 13, no. 7: 1323. https://doi.org/10.3390/jmse13071323

APA StyleCao, F., Zhang, Q., Qin, W., Ouyang, H., Li, Z., Peng, Y., & Dai, G. (2025). Experimental Study on Mechanical Integrity of Cement and EICP-Solidified Soil for Scour Protection of Pile Foundations. Journal of Marine Science and Engineering, 13(7), 1323. https://doi.org/10.3390/jmse13071323