Research on the Constitutive Relationship of the Coarse-Grained Heat-Affected Zone in Ship Thick-Plate Welded Joints of Ship Structures

Abstract

1. Introduction

2. Test Design

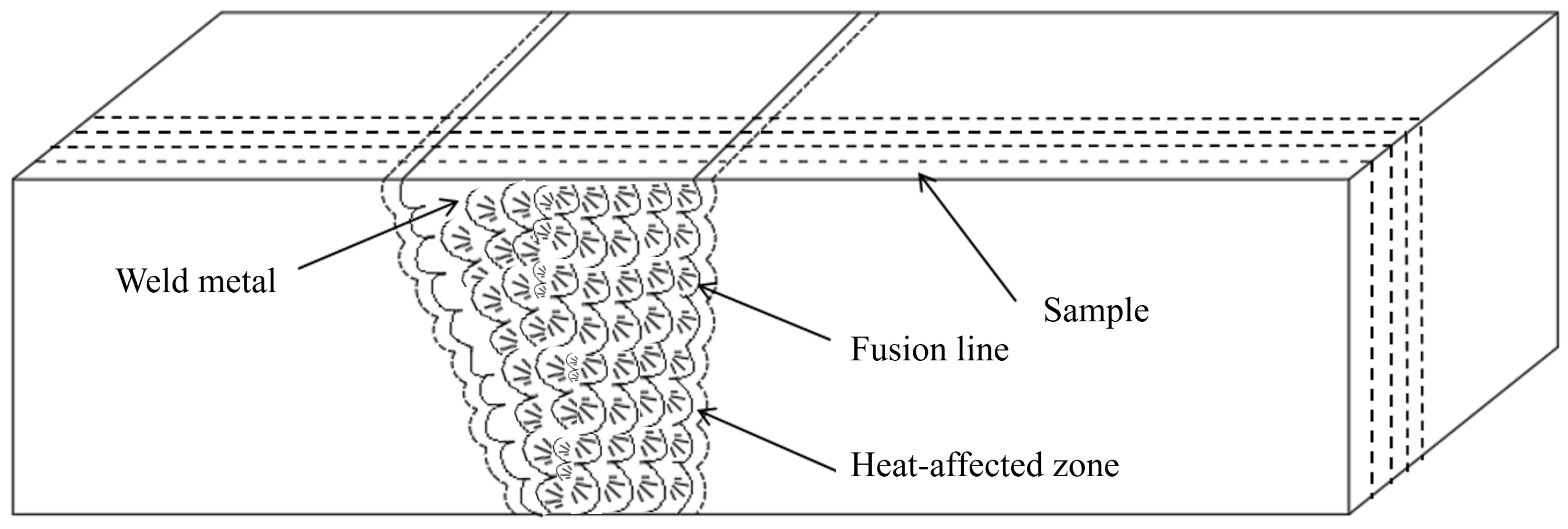

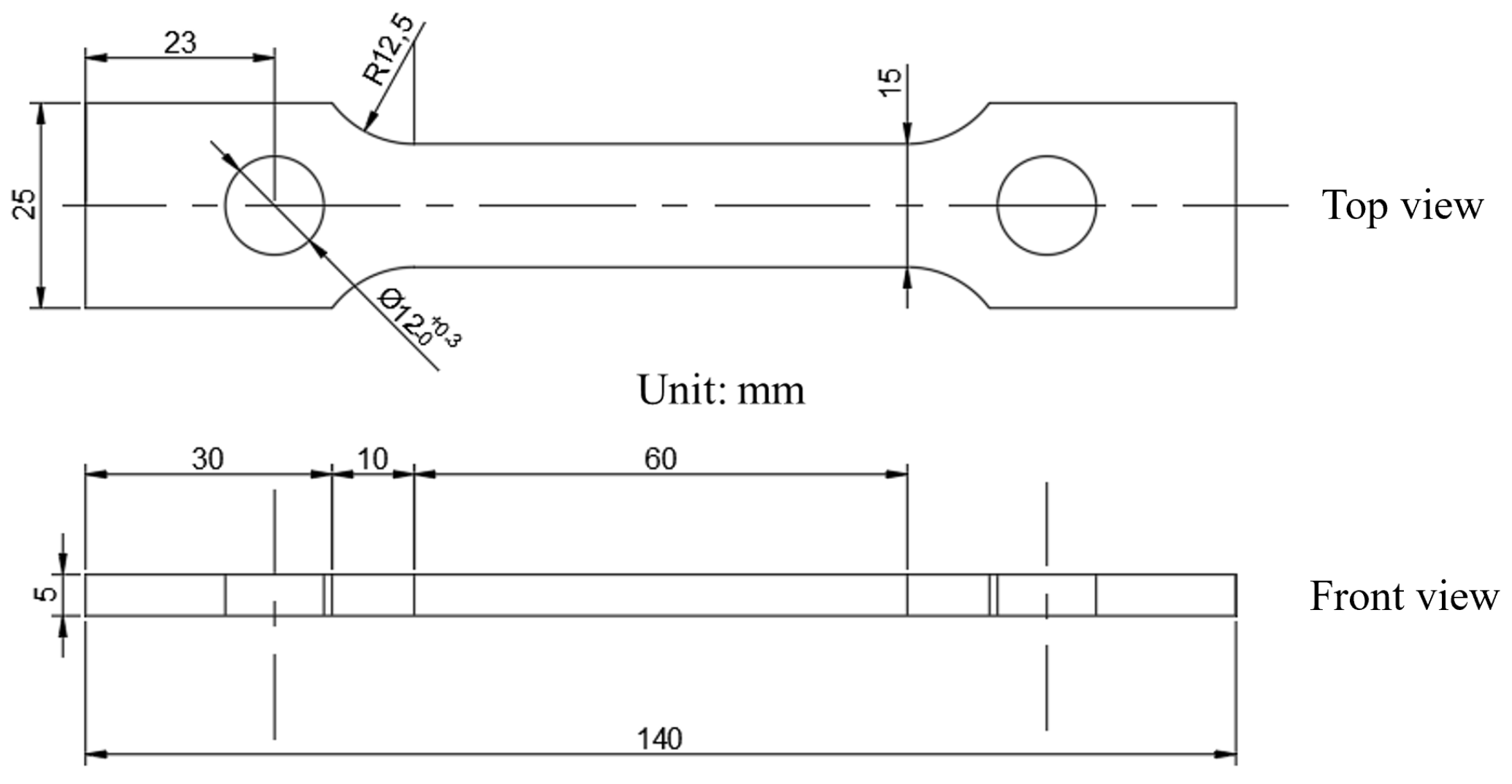

2.1. Specimen Preparation

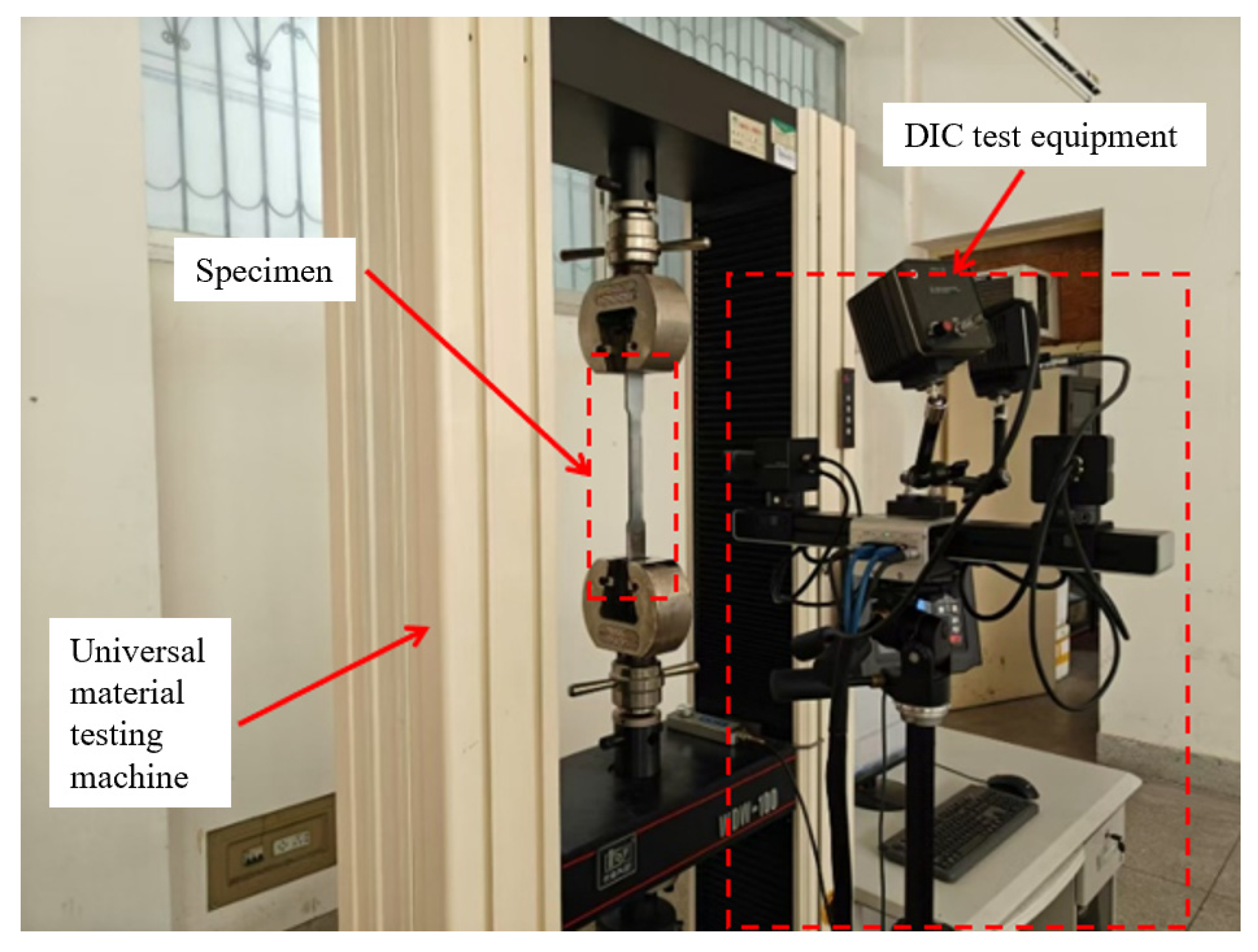

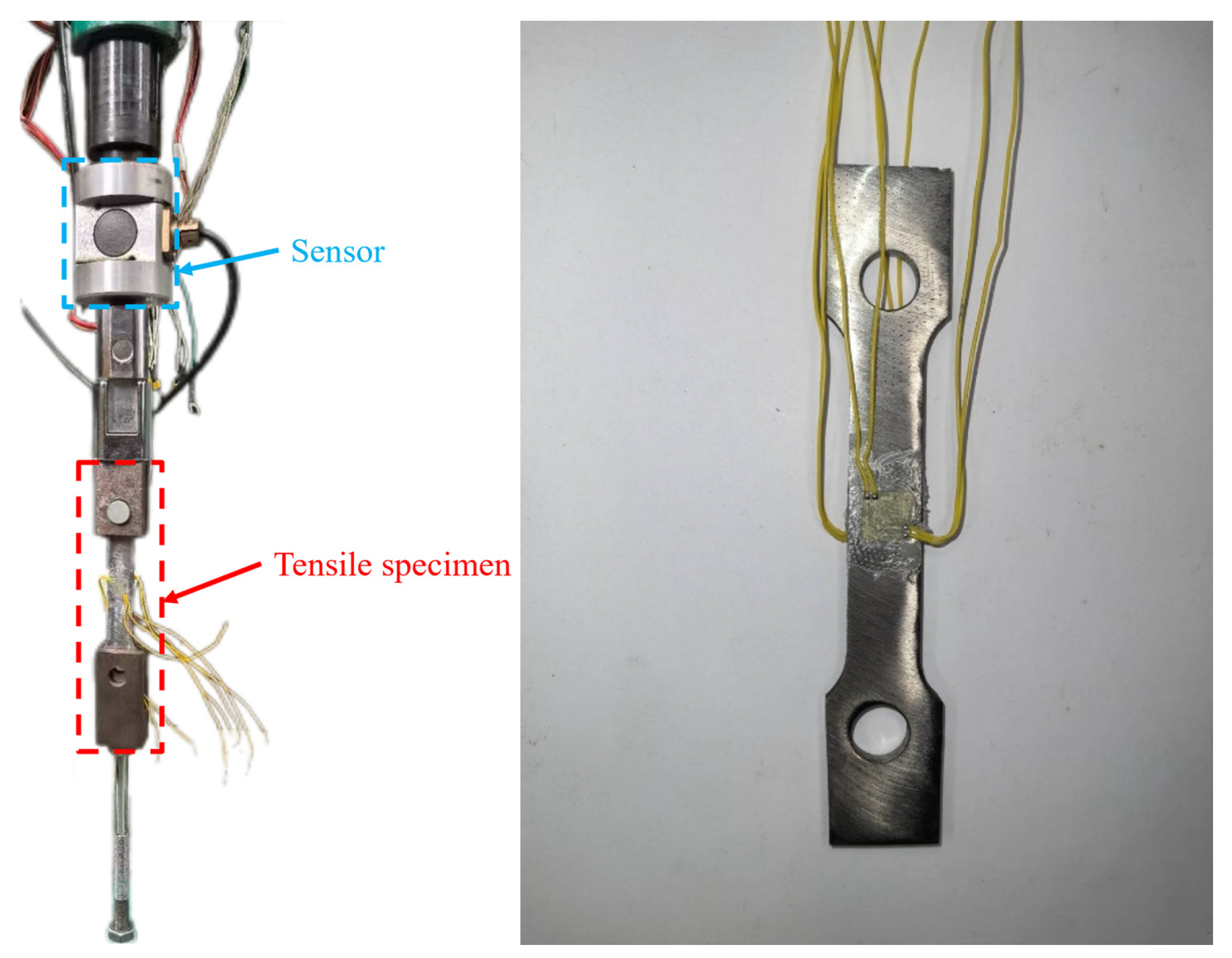

2.2. Test Equipment

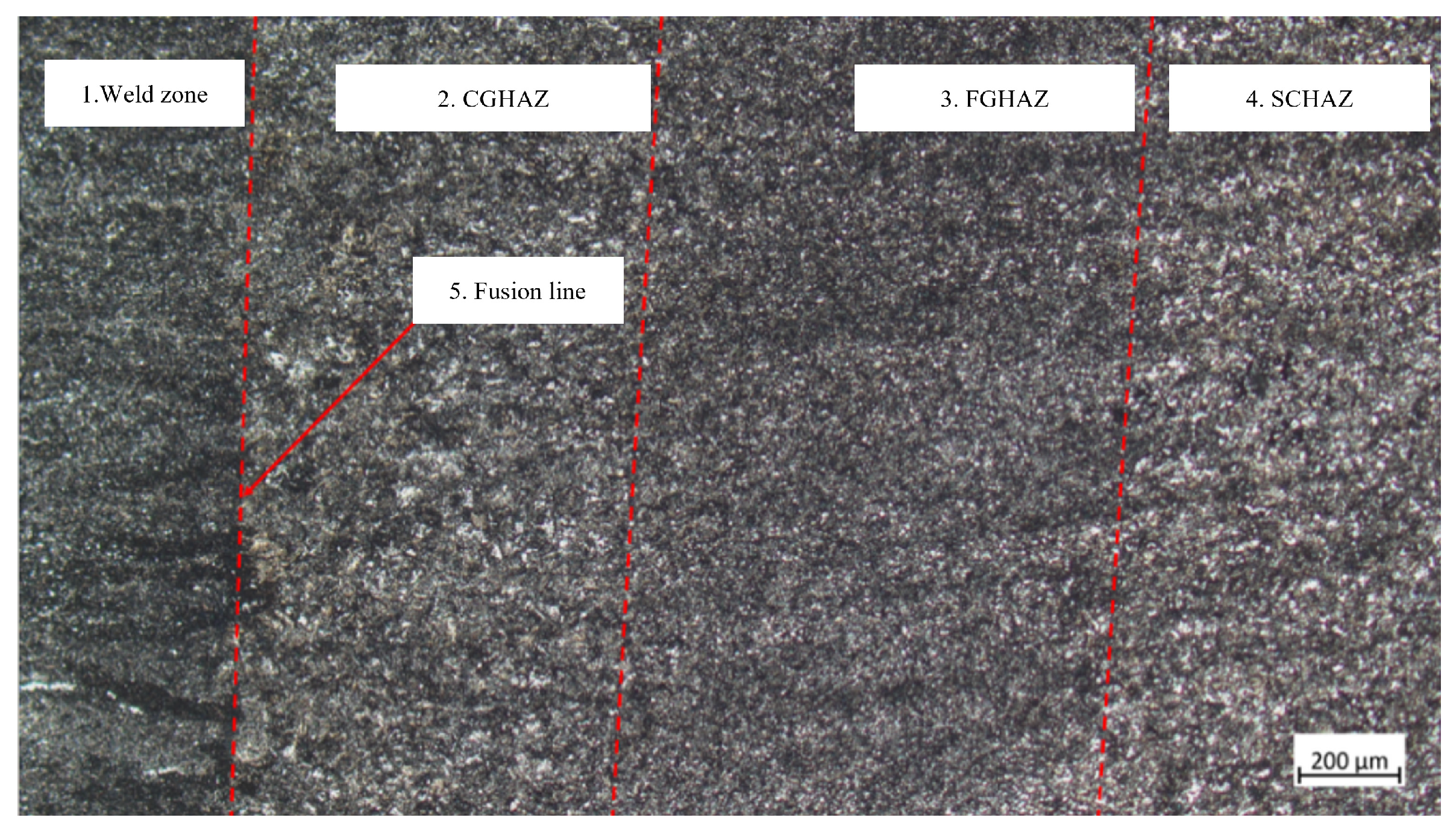

2.3. Metallographic Test of the HAZ of the Specimen

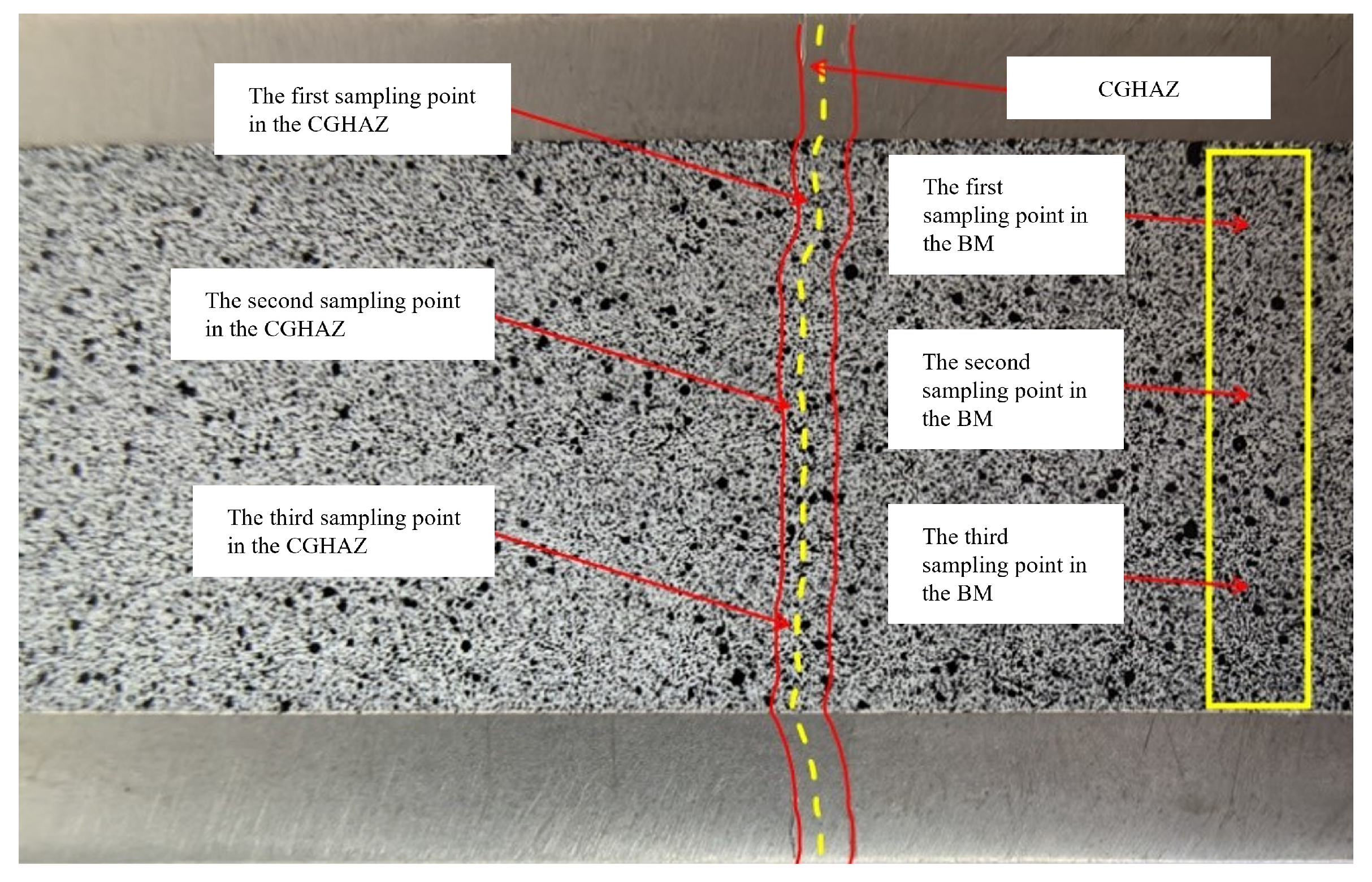

2.4. DIC Test Speckle, Spraying, and Measurement Point Selection

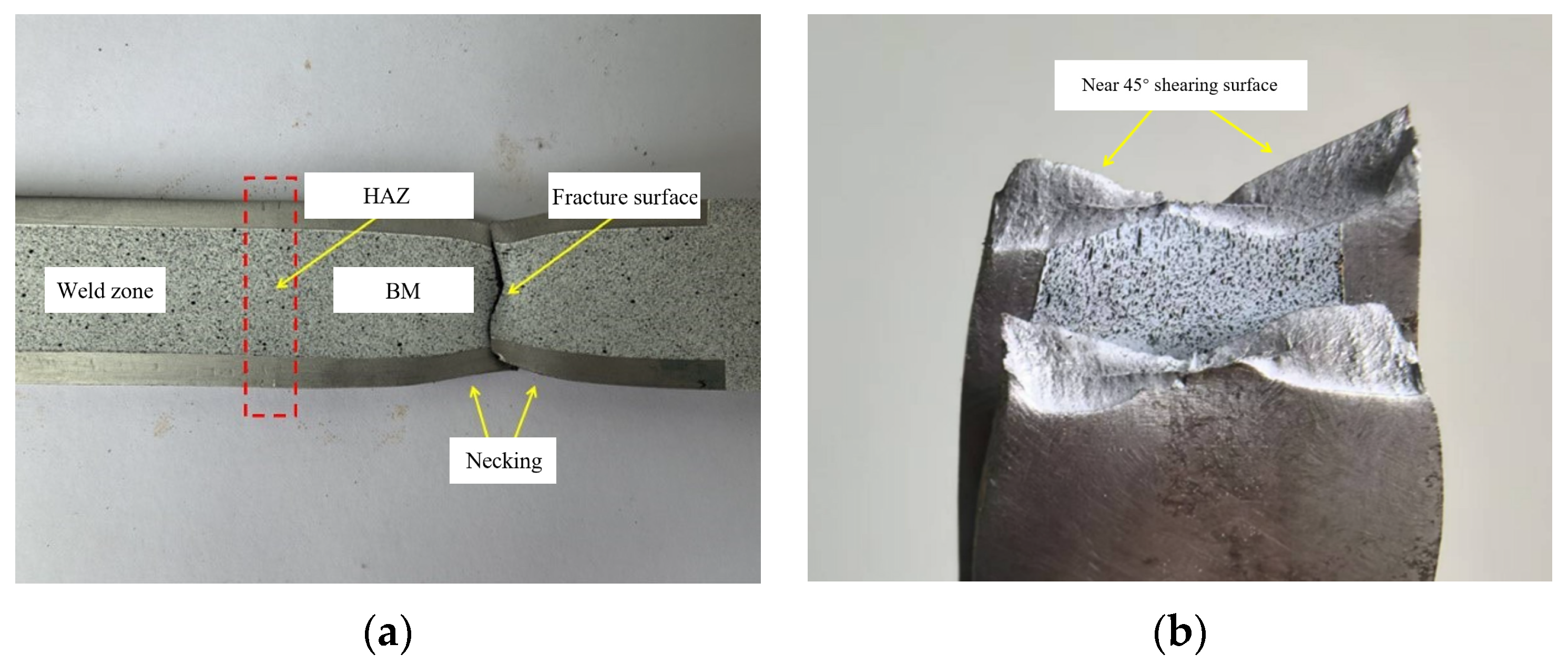

3. Test Results

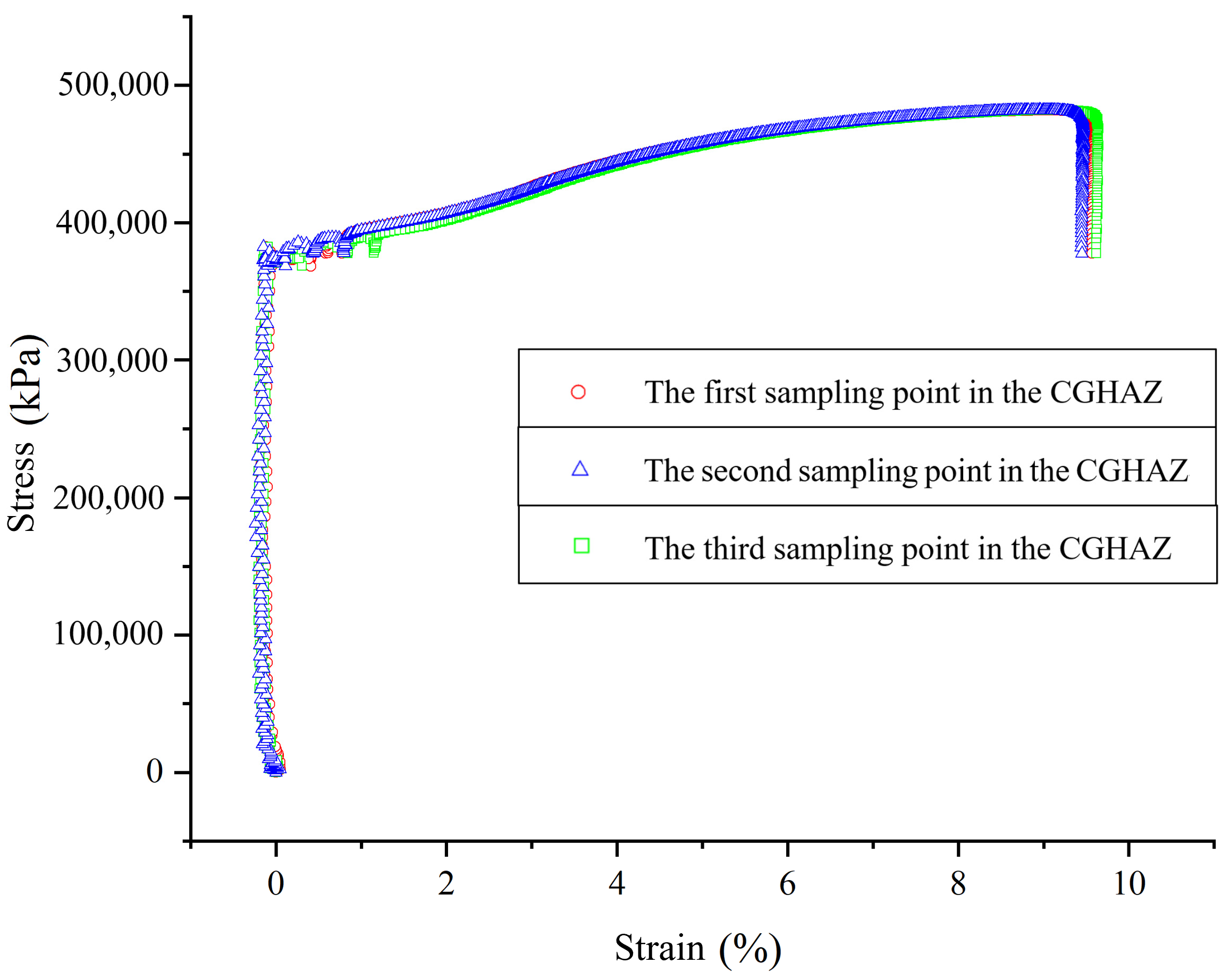

3.1. Extraction of Stress-Strain Data of the CGHAZ

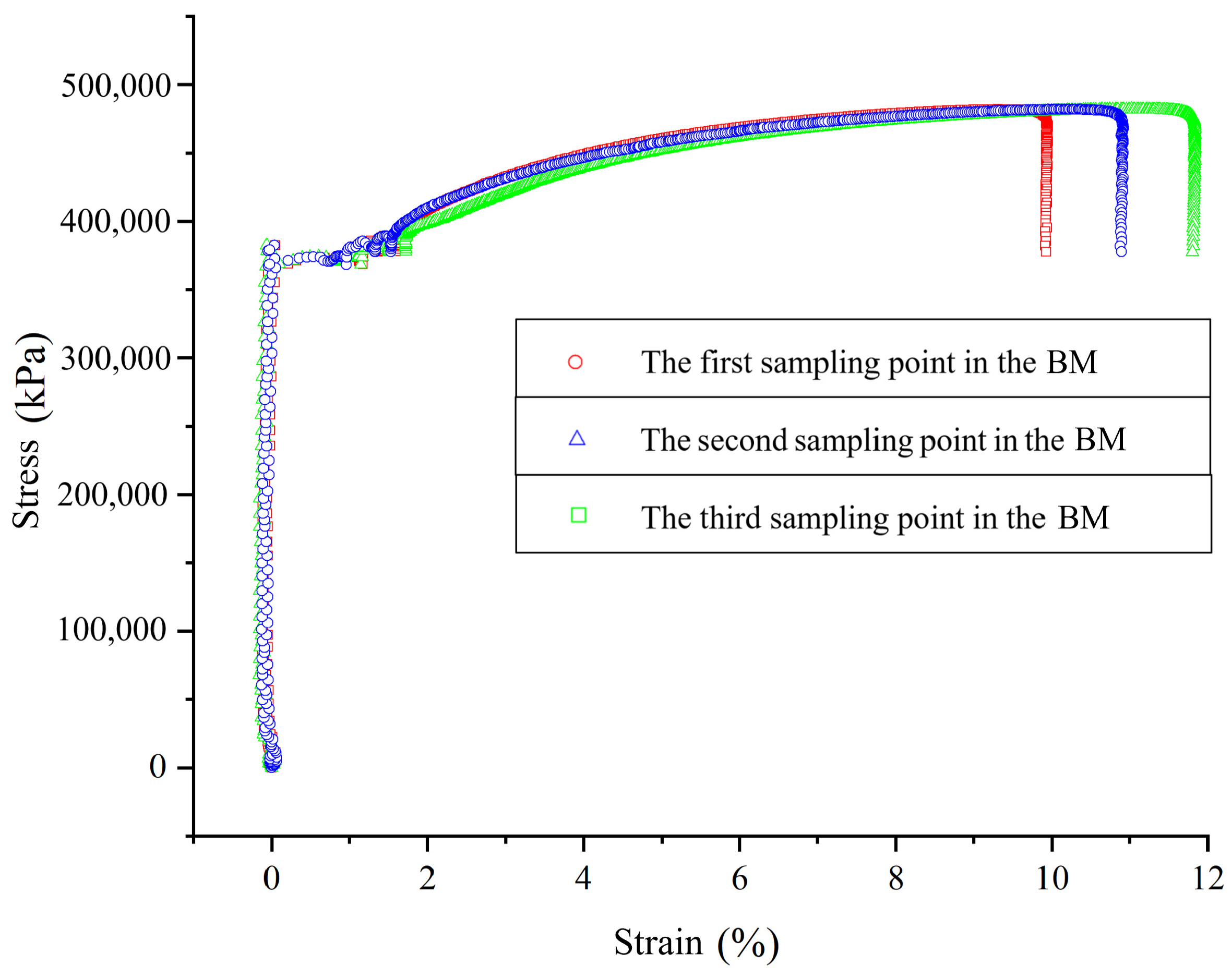

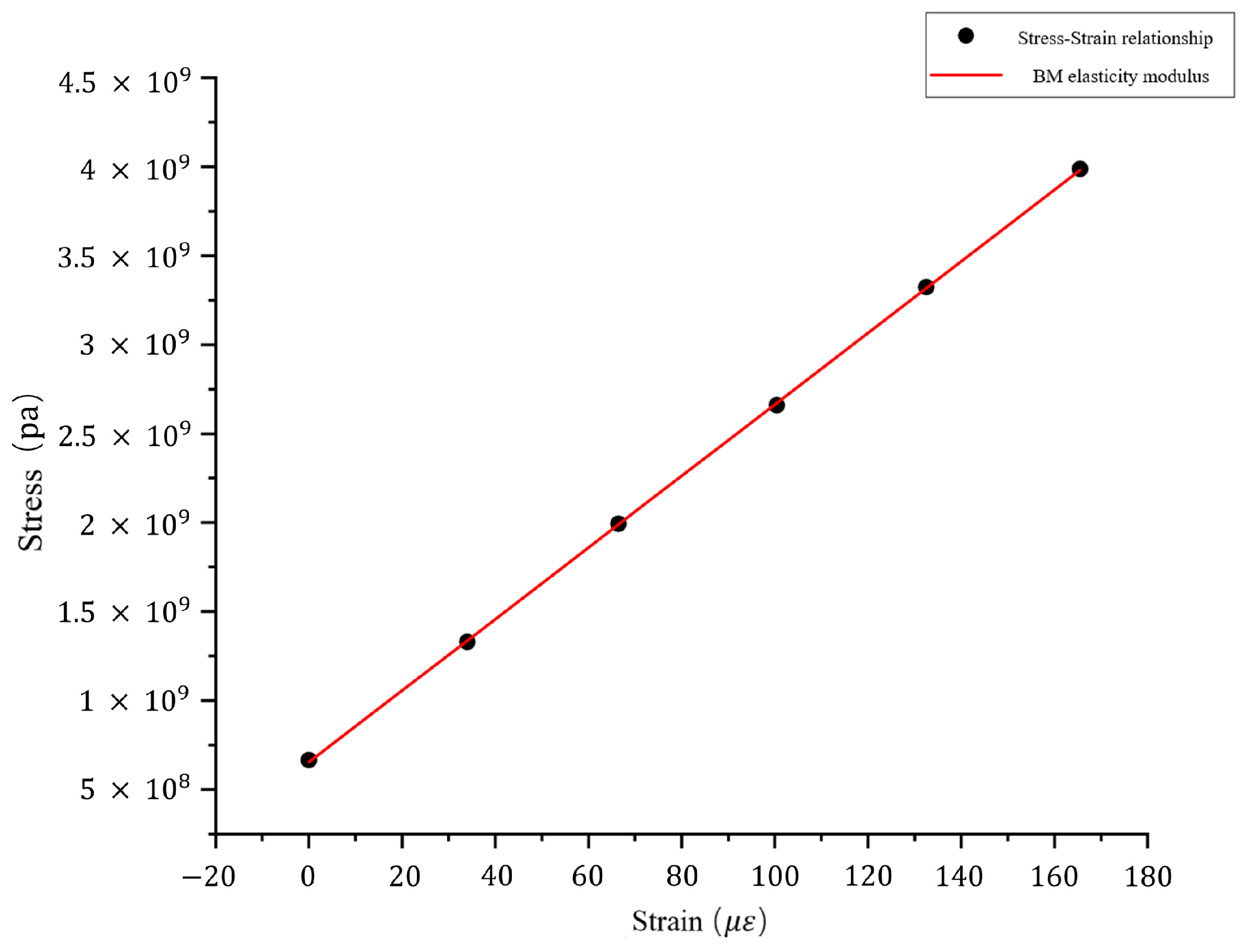

3.2. Extraction of Stress-Strain Data of the BM

4. Solution of the Constitutive Equations of the Specimen BM and CGHAZ

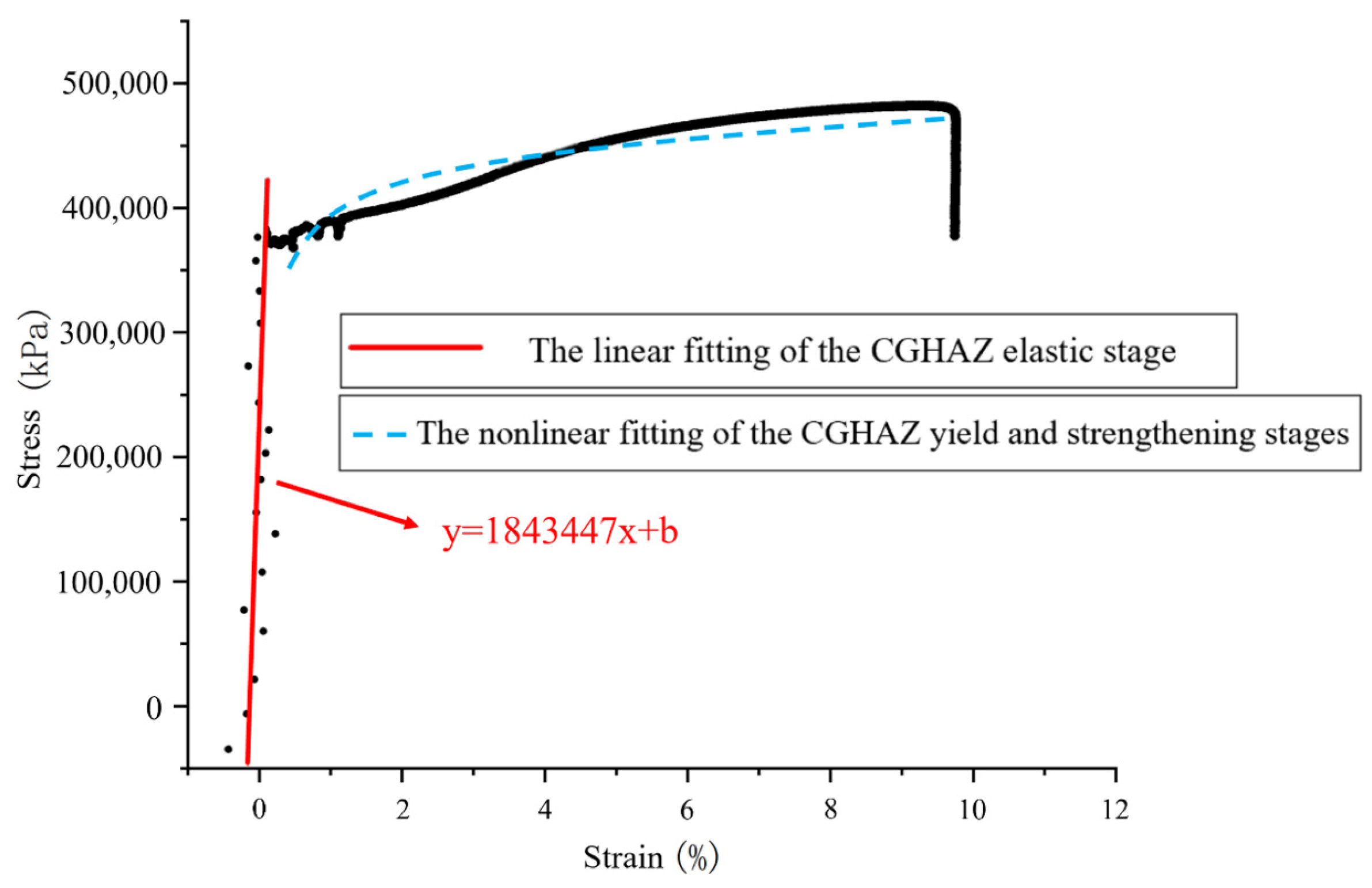

4.1. Solution of the CGHAZ Constitutive Equation

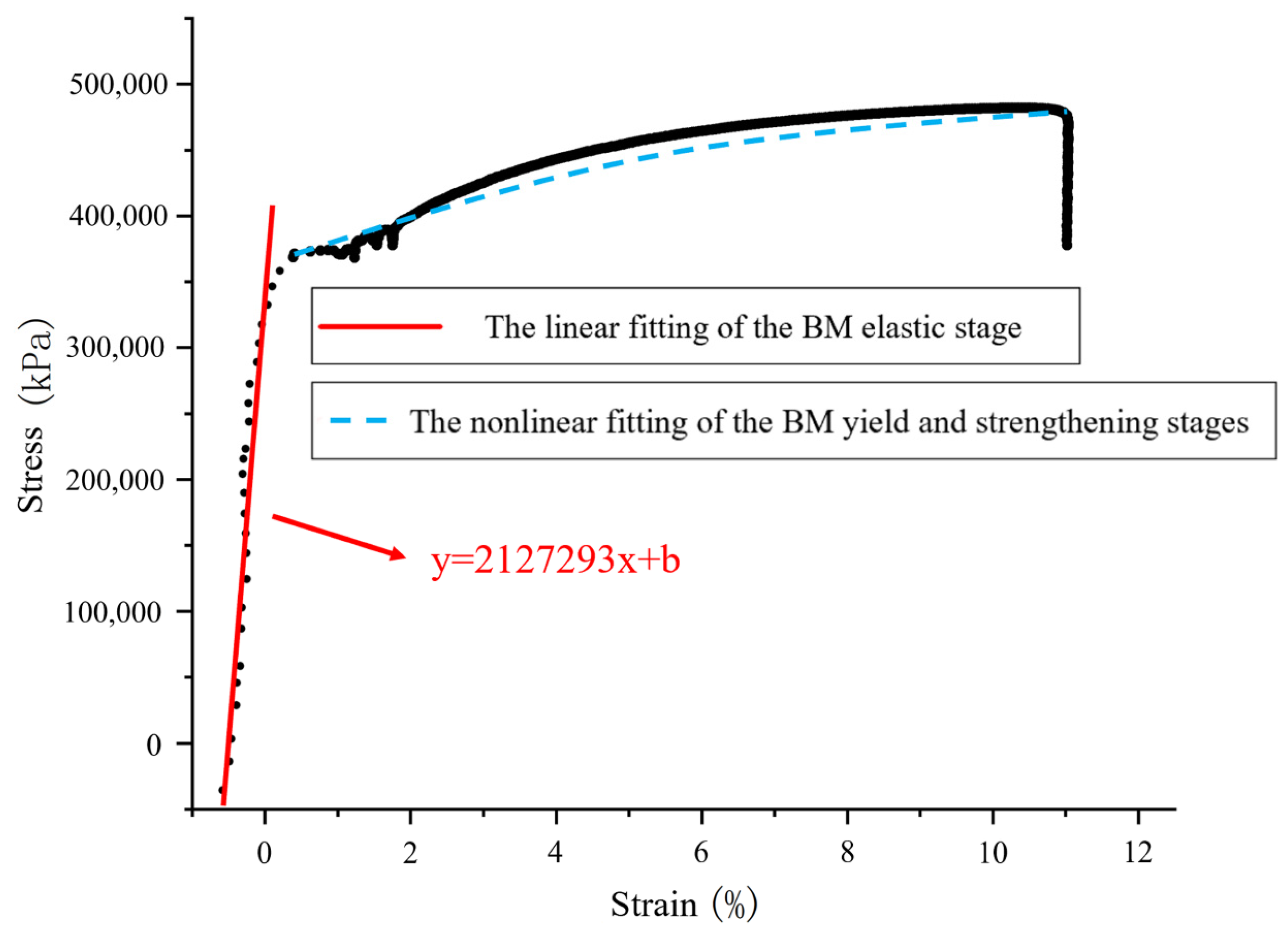

4.2. Solution of the BM Constitutive Equation

5. Comparison and Analysis of DIC Measurement Method and Traditional Force-Strain Method

6. Result Analysis

7. Conclusions

- (1)

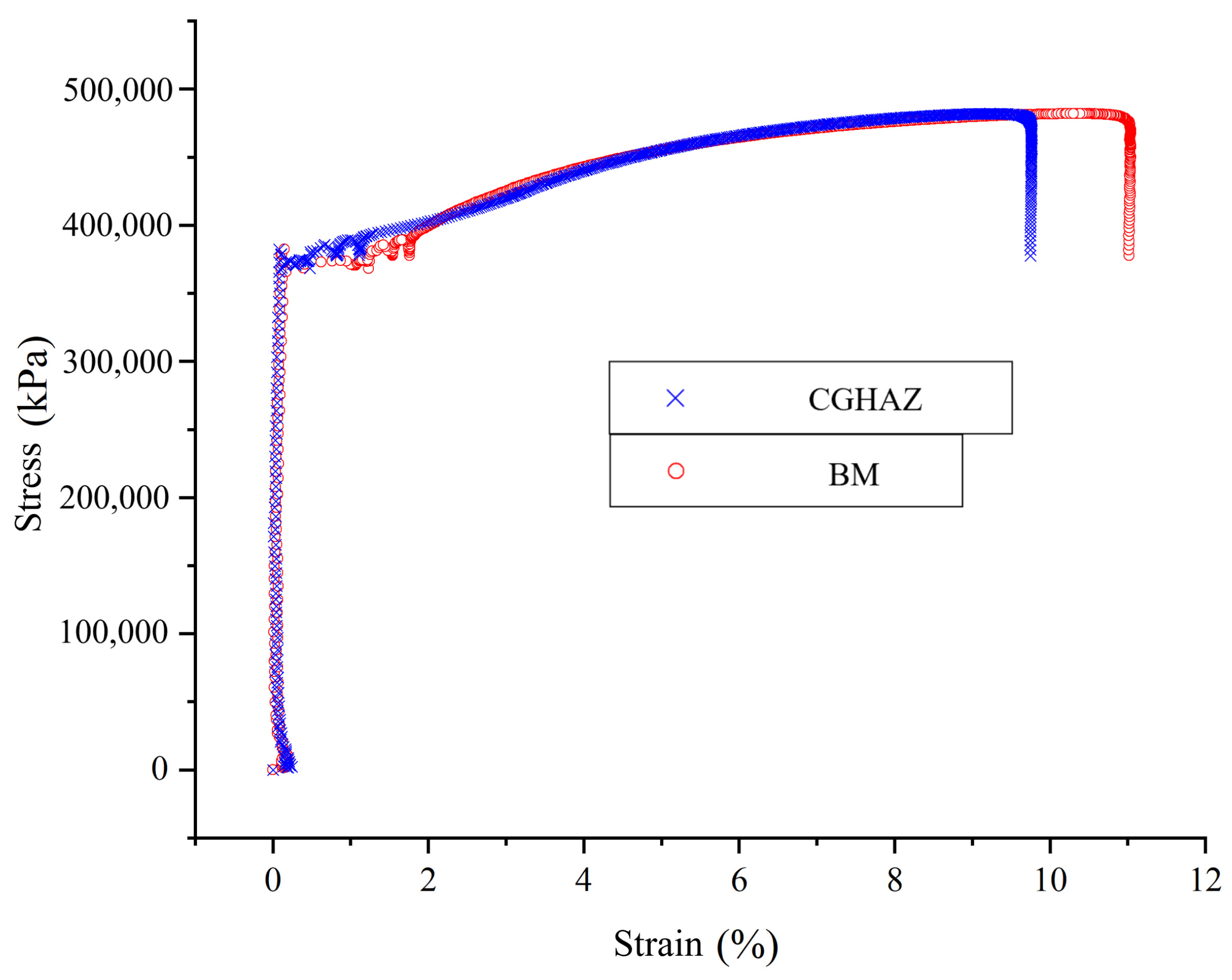

- The experimental results revealed that the CGHAZ exhibited significantly higher tensile strength than the BM, with fracture strains of 11.86% for the BM and 9.7% for the CGHAZ, indicating distinct deformation compatibility between the two regions. This anomalous strengthening effect originates from the unique microstructural characteristics of the CGHAZ: the coarse-grained structure leads to a reduced grain boundary density per unit volume. Since grain boundaries, as defect-rich regions and stress concentration sites, are preferential locations for crack nucleation, the reduced number of grain boundaries effectively suppresses microcrack initiation and propagation, thereby enhancing macroscopic tensile strength. In nonlinear mechanical analyses, it is imperative to establish a dual-material constitutive model based on strain evolution to separately characterize the deformation behavior and failure mechanisms of the CGHAZ and BM. This approach is critical for accurately predicting the mechanical performance of welded structures.

- (2)

- This study innovatively employed DIC measurement technology to construct a precise constitutive model for the CGHAZ successfully. By utilizing a non-contact, full-field strain measurement method (spatial resolution: 5 μm), this technique overcomes the technical limitations of traditional extensometers in localizing microscale CGHAZ regions. In shipbuilding practices, leveraging these precise material parameters enables designers to optimize structural layouts more rationally, such as refining plate thickness near weld zones and strategically arranging stiffeners. Such optimizations ensure structural strength and stability under diverse operational conditions, effectively mitigating safety hazards caused by insufficient consideration of CGHAZ performance. This advancement significantly enhances the safety and reliability of marine structures, providing a robust framework for engineering applications in offshore industries. In the future, interested researchers may extend the proposed methodology to studies of other materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HAZ | Heat-affected zone |

| CGHAZ | Coarse-grained heat-affected zone |

| SCHAZ | Subcritical heat-affected zone |

| FGHAZ | Fine-grained heat-affected zone |

| DIC | Digital Image Correlation |

References

- Zhang, C.Y.; Yuan, F.; Wang, N. Research on Double-sided Double-arc Welding of T-shaped Fillet Welds in Ship Thick Plates and Quality Improvement. Eng. Mach. 2023, 54, 50–60+8. [Google Scholar]

- Liu, C.; Hu, L.; Yu, L. Analysis and Reflection on Modern Ship Welding Technology. Mark. Res. Inf. 2023, 10, 163–165. [Google Scholar]

- Liu, R.; Chen, L.; Wei, Y. Microstructure simulation of TIG welding pool and heat affected zone of nickel based alloy. J. Weld. 2020, 41, 64–68+100. [Google Scholar] [CrossRef]

- Beghini, M.; Bertini, L.; Puccio, D.F. Evaluation of Mechanical Properties of Welded Joints by Small-Specimen Tests. Strain 2001, 37, 155–158. [Google Scholar] [CrossRef]

- Gan, Z.; Zhao, H.; Li, X. Research on the Properties of the Heat-Affected Zone of Low-Alloy High-Strength Steel Welding and Improvement Measures. Weld. Pipe 2024, 47, 7–16. [Google Scholar] [CrossRef]

- Yang, Q. Numerical Simulation of Temperature Field and Coarse Grain Zone Phase Content of DP78 Steel Welding Joint. Mech. Eng. Mater. 2021, 5, 91–95. [Google Scholar]

- Xiong, J.; Chen, W.; Qu, J. Analysis of the Size and Properties of the Heat-Affected Zone of 16Mn Steel MAG Welding Joint. J. Xihua Univ. Nat. Sci. Ed. 2011, 30, 85–87+101. [Google Scholar]

- Georgios, K.T.; Dimitrios, I.Z.; Dionysios, L.K. Residual Stresses and Micro-Hardness Testing in Evaluating the Heat Affected Zone’s Width of Ferritic Ductile Iron Arc Welds. Mater. Sci. Appl. 2016, 7, 73–82. [Google Scholar]

- Liu, Y.; Duan, Y.; Xin, P. Width of the Heat-Affected Zone of Fully Automatic TIP TIG Welding Joint of X70/316L Bimetallic Composite Pipe. Electr. Weld. Mach. 2015, 45, 152–156. [Google Scholar]

- Sun, Q.; Li, X.; Yao, T. Experimental Study on Crack Expansion Law of Brittle Materials under Explosive Loading Based on DIC. Explos. Shock. 2019, 39, 31–41. [Google Scholar]

- Wang, W.; Chen, Z.; Huang, S. Study on the Mechanical Properties of H60 Brass with Notches Based on DIC. Exp. Tech. Manag. 2022, 39, 72–78. [Google Scholar] [CrossRef]

- Liu, D. Evaluation of the Mechanical and Forming Properties of Laser Welding Joints of 6063 Aluminum Alloy. Master’s Thesis, Yanshan University, Qinhuangdao, China, 2021. [Google Scholar] [CrossRef]

- Li, Q.; Li, Z.; He, X. Study on the Local Mechanical Properties of Welding Joints of Zirconium-Titanium Composite Plates. Rare Met. 2020, 44, 1240–1248. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, F.; Zhang, H. Study on the Fatigue Crack Expansion Characteristics of Welded Rails Based on DIC. Electr. Weld. Mach. 2023, 53, 44–48+62. [Google Scholar]

- Rasmussen, K.J.R. Full-Range Stress-Strain Curves for Stainless Steel Alloys. J. Constr. Steel Res. 2003, 59, 47–61. [Google Scholar] [CrossRef]

- Shi, G.; Zhu, X. Research on the Constitutive Model of High-Strength Structural Steel under Monotonic Load. Eng. Mech. 2017, 34, 50–59. [Google Scholar] [CrossRef]

- GB/T 22315-2008; Metallic Materials—Test Method for Elastic Modulus and Poisson’s Ratio. China Standard Press: Beijing, China, 2008.

- Cao, Y. Advances in the Testing of Mechanical Properties of Metals. Metall. Anal. Test. (Metall. Phys. Test Sect.) 1983, 1, 45–51. [Google Scholar]

- Lan, T.; Kang, L.; Li, R. Analysis of the Mechanical Properties of Q355GNH Weathering Steel after Corrosion and Research on the Constitutive Model. Ind. Constr. 2024, 54, 49–57. [Google Scholar]

| CGHAZ | BM | Relative Differences (%) | |

|---|---|---|---|

| The elasticity modulus (GPa) | 184 ± 7 | 213 ± 5 | 13.62 |

| Yield strength (MPa) | 363 ± 9 | 373 ± 6 | 2.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Zhan, P.; Yi, T.; Zhang, S.; He, J.; Li, M. Research on the Constitutive Relationship of the Coarse-Grained Heat-Affected Zone in Ship Thick-Plate Welded Joints of Ship Structures. J. Mar. Sci. Eng. 2025, 13, 1260. https://doi.org/10.3390/jmse13071260

Xu L, Zhan P, Yi T, Zhang S, He J, Li M. Research on the Constitutive Relationship of the Coarse-Grained Heat-Affected Zone in Ship Thick-Plate Welded Joints of Ship Structures. Journal of Marine Science and Engineering. 2025; 13(7):1260. https://doi.org/10.3390/jmse13071260

Chicago/Turabian StyleXu, Linzhi, Pengyu Zhan, Tao Yi, Shukai Zhang, Jian He, and Mengzhen Li. 2025. "Research on the Constitutive Relationship of the Coarse-Grained Heat-Affected Zone in Ship Thick-Plate Welded Joints of Ship Structures" Journal of Marine Science and Engineering 13, no. 7: 1260. https://doi.org/10.3390/jmse13071260

APA StyleXu, L., Zhan, P., Yi, T., Zhang, S., He, J., & Li, M. (2025). Research on the Constitutive Relationship of the Coarse-Grained Heat-Affected Zone in Ship Thick-Plate Welded Joints of Ship Structures. Journal of Marine Science and Engineering, 13(7), 1260. https://doi.org/10.3390/jmse13071260