Numerical Investigation of Offshore CCUS in Deep Saline Aquifers Using Multi-Layer Injection Method: A Case Study of the Enping 15-1 Oilfield CO2 Storage Project, China

Abstract

1. Introduction

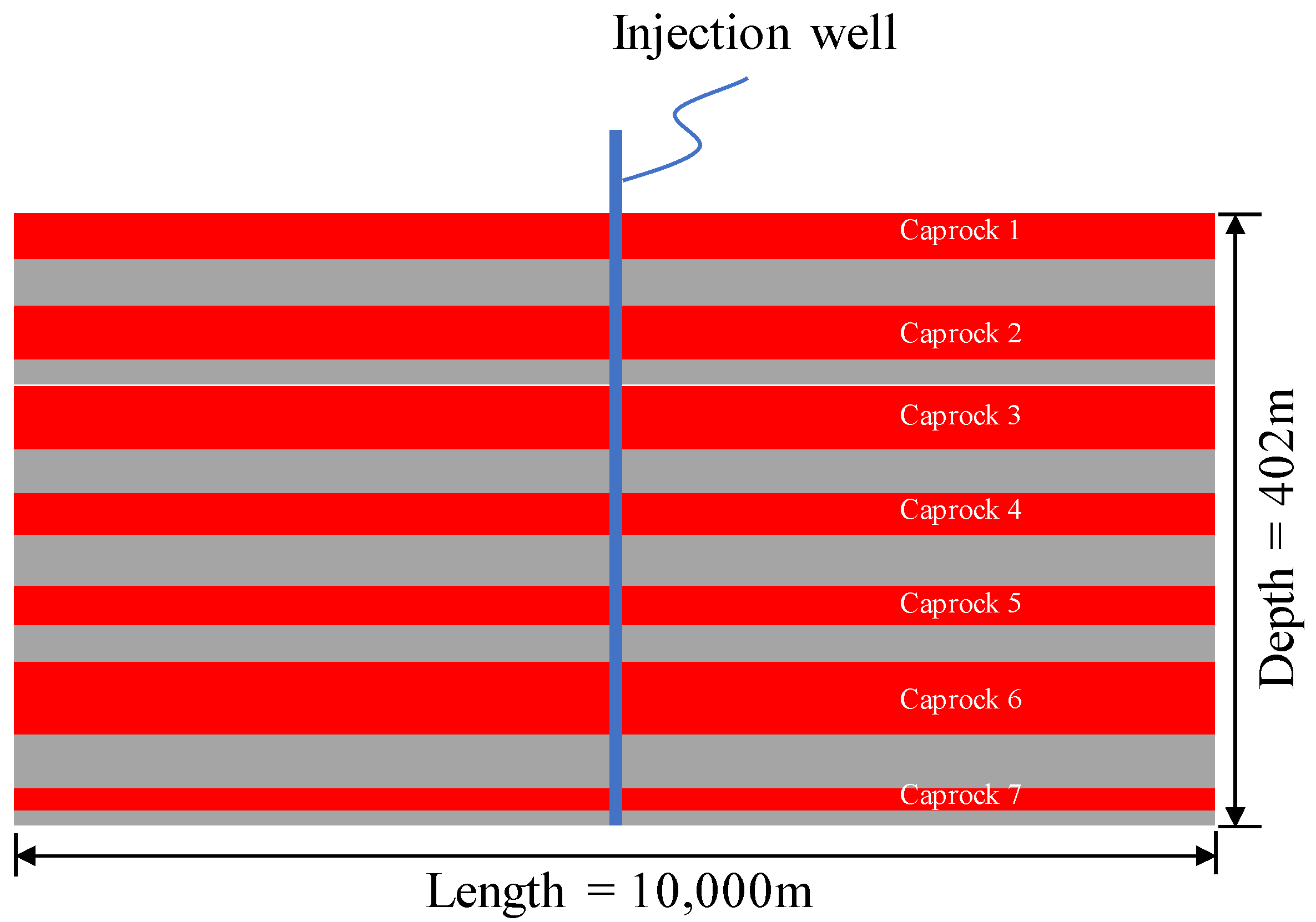

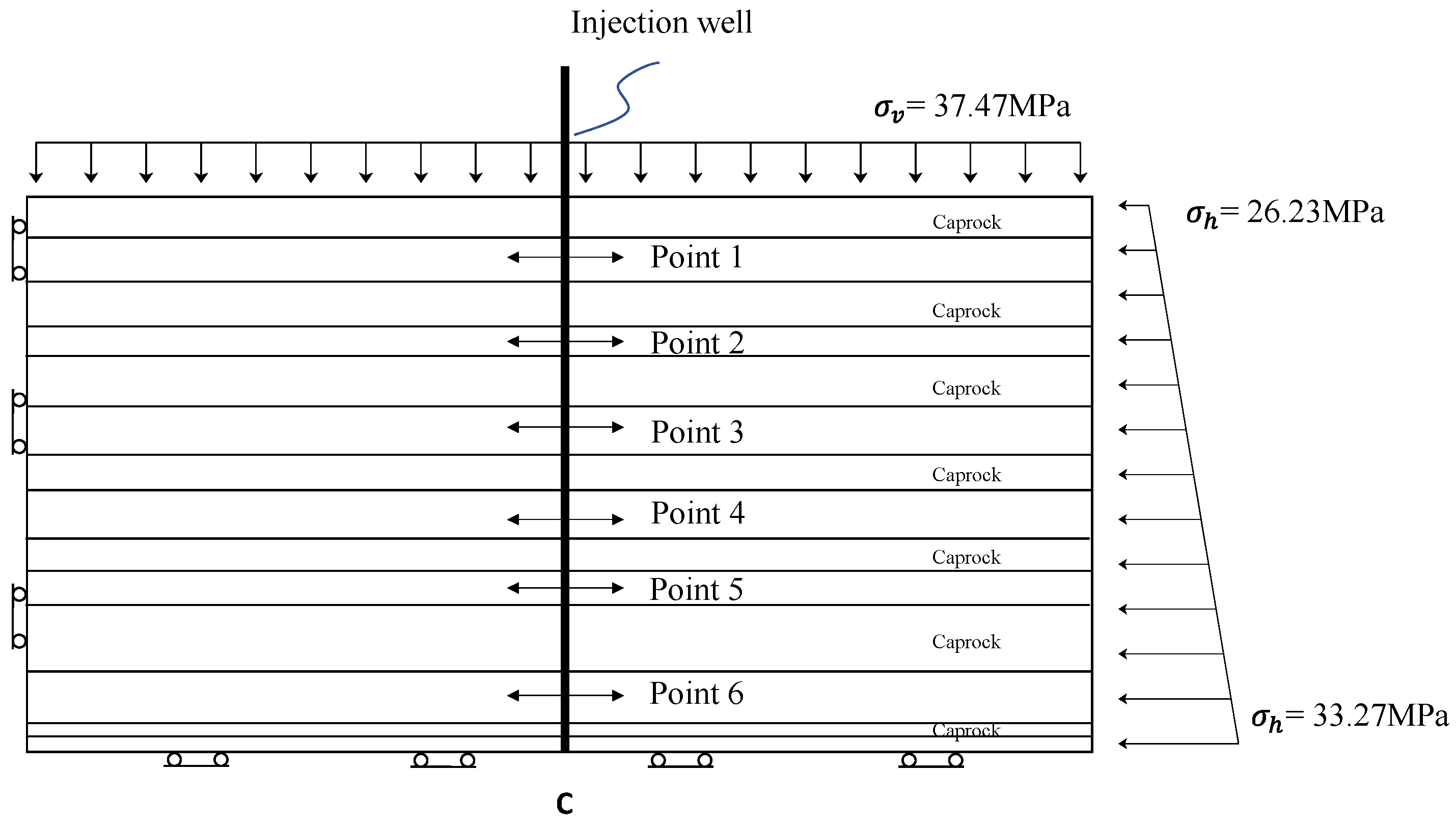

2. Numerical Model

2.1. Location of the CCUS Project

2.2. TOUGH-FLAC Model

3. Numerical Simulation Results

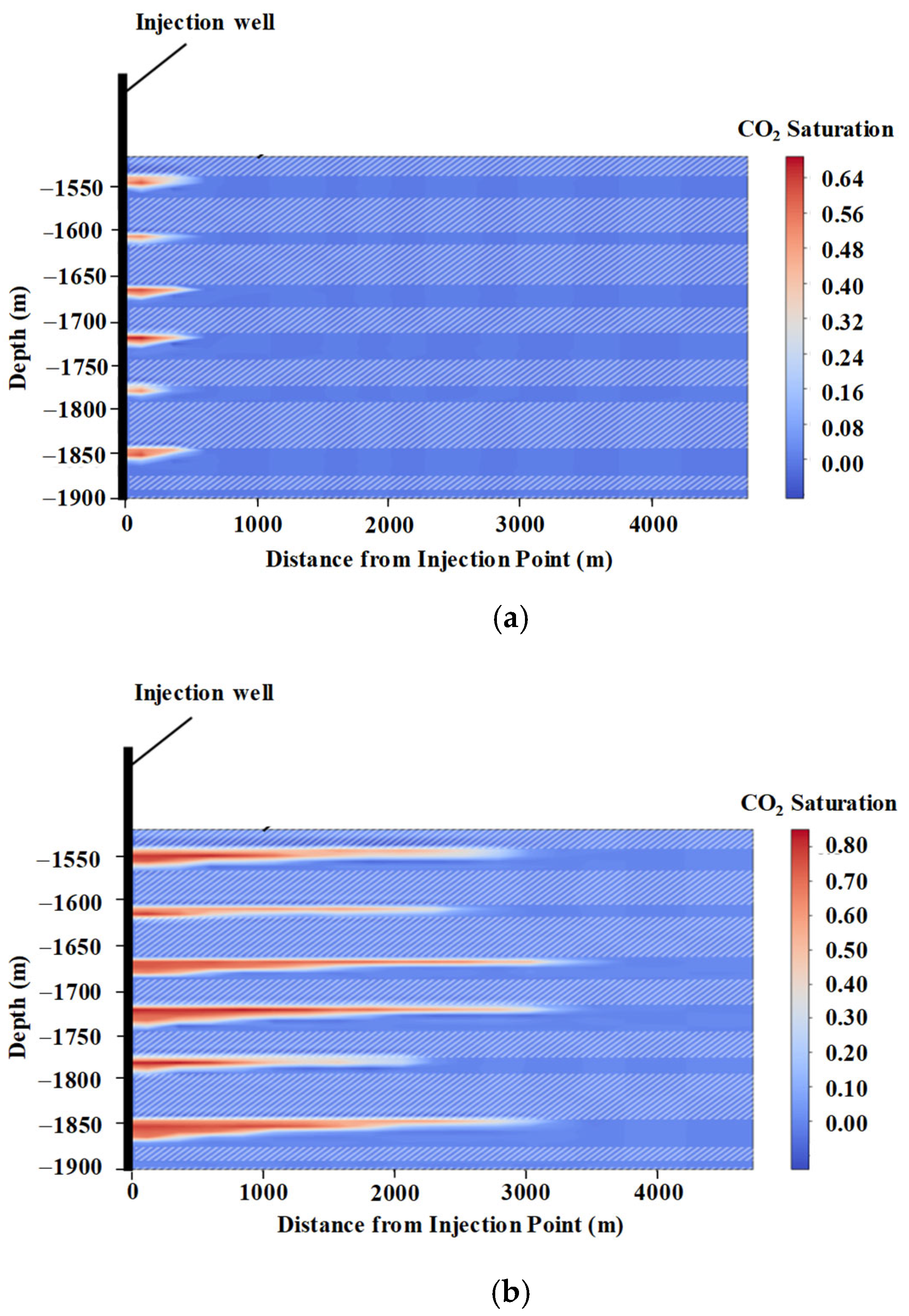

3.1. CO2 Saturation

3.2. Pore Pressure

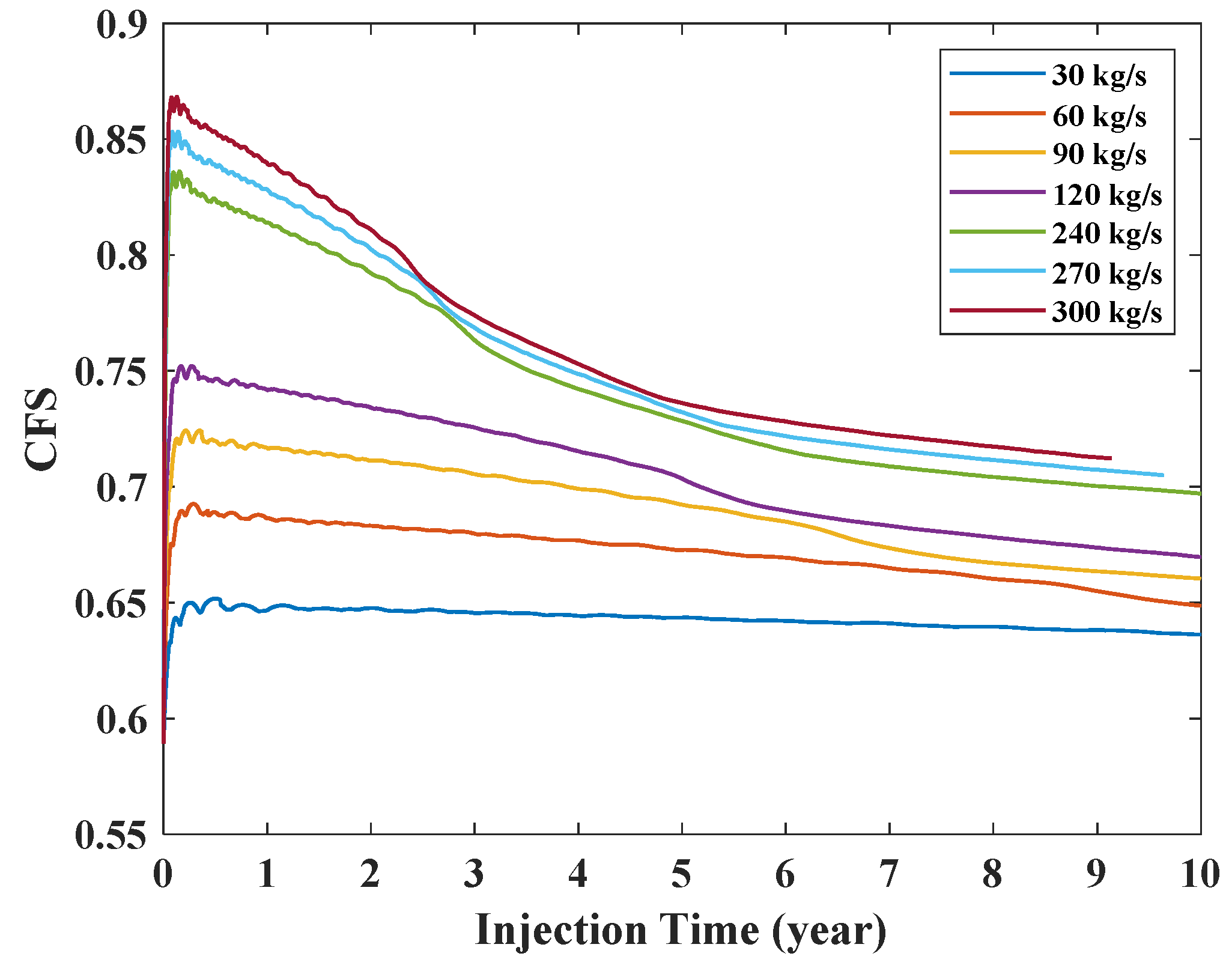

3.3. The Coulomb Failure Stress

4. Sensitivity Analysis for Each Site Parameter

5. Conclusions

- A total injection rate of 30 kg/s (equivalent to 1 Mt/year), distributed across six reservoir layers, was demonstrated to be geomechanically safe over a 10-year period, with the CFS values remaining below the critical thresholds in saline aquifers.

- The average CO2 migration distance increased by 5.6 times over the injection period, with Reservoirs 3 and 4 showing the greatest lateral migration distances (3505 m and 3300 m), indicating high storage potential and favorable containment conditions. From an engineering perspective, the results provide practical guidance for offshore CO2 storage site selection and injection planning.

- Sensitivity analyses showed that the permeability of the reservoirs and the friction angle of the reservoirs and caprocks were the dominant factors influencing mechanical safety and injection efficiency. This finding implies that accurate characterization of these parameters is essential in field applications to ensure caprock integrity and optimized injection design.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, P.; Zhang, Z.; Zhang, L.; Liu, X.; Liu, X. Influence of different CO2 phase states on fluid flow pathways in coal: Insights from image reconstruction and fractal study. Bull. Eng. Geol. Environ. 2023, 82, 266. [Google Scholar] [CrossRef]

- Leng, J.; Bump, A.; Hosseini, S.; Meckel, T.; Wang, Z.; Wang, H. A comprehensive review of efficient capacity estimation for large-scale CO2 geological storage. Gas Sci. Eng. 2024, 126, 205339. [Google Scholar] [CrossRef]

- Kumar, S.; Foroozesh, J.; Edlmann, K.; Rezk, M.; Lim, C. A comprehensive review of value-added CO2 sequestration in subsurface saline aquifers. J. Nat. Gas Sci. Eng. 2020, 81, 103437. [Google Scholar] [CrossRef]

- Qin, J.; Zhong, Q.; Tang, Y.; Rui, Z.; Qiu, S.; Chen, H. CO2 storage potential assessment of offshore saline aquifers in China. Fuel 2023, 341, 127681. [Google Scholar] [CrossRef]

- Calvo, R.; Taragan, R.; Rosenzweig, R. Influence of geostatistical interpolation method and cell-size resolution on CO2 storage capacity estimates: Application to saline aquifers with sparse data availability in Israel. Int. J. Greenh. Gas Control 2022, 130, 104013. [Google Scholar] [CrossRef]

- Ye, L.; Liu, Z.; Du, J.; Jia, C.; Zhu, H.; Liu, F. Geological storage test and transport rule of CO2 in saline aquifers: A case study of Dezhou carbon storage demonstration zone in Shandong Province. Fuel 2024, 377, 132752. [Google Scholar] [CrossRef]

- Wang, F.; Cao, J.; Zhang, Y.; Aviso, K.; Tan, R.; Li, Z.; Jia, X. Safety risk assessment of the large-scale carbon capture, utilization, and storage demonstration project in Dongying, China. J. Clean. Prod. 2023, 414, 137699. [Google Scholar] [CrossRef]

- Marshall, J. A social exploration of the West Australian Gorgon Gas, carbon capture and storage project. Clean Technol. 2016, 86, 371–380. [Google Scholar] [CrossRef]

- Chen, B.; Li, Q.; Tan, Y.; Zhang, Y.; Yu, T.; Zhong, Y.; Ma, J.; Li, X. Key indicators of caprock sealing assessment with consideration of faults in potential CO2 geological storage sites in Subei Basin, China. Gas Sci. Eng. 2024, 129, 205414. [Google Scholar] [CrossRef]

- Xu, J.; Wan, H.; Wu, Y.; Liu, S.; Yan, B. Study on CO2-Enhanced Oil Recovery and Storage in Near-Depleted Edge–Bottom Water Reservoirs. J. Mar. Sci. Eng. 2024, 12, 2065. [Google Scholar] [CrossRef]

- Agada, S.; Kolster, C.; Williams, G.; Vosper, H.; MacDowell, N.; Krevor, S. Sensitivity analysis of the dynamic CO2 storage capacity estimate for the Bunter Sandstone of the UK Southern North Sea. Energy Procedia 2017, 114, 4564–4570. [Google Scholar] [CrossRef]

- Li, Q.; Cai, B.; Chen, F.; Liu, G.; Liu, L. Review of environmental risk assessment methods for carbon dioxide geological storage. Environ. Eng. 2019, 37, 13–21. [Google Scholar]

- Lu, P.; Hao, Y.; Bai, Y.; Liu, W.; Chen, X.; Zheng, H.; Liu, J.; Chen, Y.; Gao, J. Optimum selection of favorable areas for CO2 geological storage in the Majiagou Formation in the Ordos Basin. Int. J. Greenh. Gas Control 2021, 109, 103360. [Google Scholar] [CrossRef]

- Zhong, Y.; Li, Q.; Xu, L.; Wen, Y.; Hou, Y.; Gao, W. Tow-phase flow behavior in CO2 geological storage considering spatial parameter heterogeneity. Greenh. Gases-Sci. Technol. 2023, 14, 11–25. [Google Scholar] [CrossRef]

- Liu, H.; Hou, Z.; Were, P.; Gou, Y.; Sun, X. Simulation of CO2 plume movement in multilayered saline formations through multilayer injection technology in the Ordos Basin, China. Environ. Earth Sci. 2014, 45, 216–232. [Google Scholar] [CrossRef]

- Li, C.; Zhang, K.; Wang, Y.; Guo, C.; Maggi, F. Experimental and numerical analysis of reservoir performance for geological CO2 storage in the Ordos Basin in China. Int. J. Greenh. Gas Control 2016, 8, 948–966. [Google Scholar]

- Zhu, Q.; Zuo, D.; Zhang, S.; Zhang, Y.; Wang, Y.; Wang, L. Simulation of geomechanical responses of reservoirs induced by CO2 multilayer injection in the Shenhua CCUS project, China. Int. J. Greenh. Gas Control 2015, 42, 405–414. [Google Scholar] [CrossRef]

- Shi, L.; Bai, B.; Wu, H.; Li, X. Evaluating reservoir risks and their influencing factors during CO2 injection into multilayered reservoirs. Geofluids 2017, 6059142. [Google Scholar] [CrossRef]

- Rasmusson, K.; Tsang, C.; Tsang, Y.; Rasmusson, M.; Pan, L.; Fagerlund, F.; Bensabat, J.; Niemi, A. Distribution of injected CO2 in a stratified saline reservoir accounting for coupled wellbore-reservoir flow. Greenh. Gases-Sci. Technol. 2015, 5, 419–436. [Google Scholar] [CrossRef]

- Bai, B.; Li, X.; Wu, H.; Wang, Y.; Liu, M. A methodology for designing maximum allowable wellhead pressure for CO2 injection: Application to the Shenhua CCUS demonstration project, China. Greenh. Gases-Sci. Technol. 2017, 7, 158–181. [Google Scholar] [CrossRef]

- Ma, J.; Cheng, G.; Li, X. Influencing factors of caprock sealing performance of CO2 multi-formation injection technology. Rock Soil Mech. 2024, 45, 3447–3460. [Google Scholar]

- Li, C.; Tien, N.; Zhang, K.; Jen, C.; Hsieh, P.; Huang, S.; Maggi, F. Assessment of large-scale offshore CO2 geological storage in Western Taiwan Basin. Int. J. Greenh. Gas Control 2013, 19, 281–298. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Zhou, D.; Liang, X. Geological characterization and numerical modelling of CO2 storage in an aquifer structure offshore Guangdong Province, China. Energy Procedia 2018, 154, 48–53. [Google Scholar] [CrossRef]

- Tang, W.; Xie, X.; Wang, Y.; Xiong, L.; Guo, J.; Li, X. Evolution of Cenozoic sedimentary architecture in Central and Southern South China Sea basins. J. Palaeogeogr. 2024, 13, 35–53. [Google Scholar] [CrossRef]

- Izadpanahi, A.; Blunt, M.; Kumar, N.; Ali, M.; Tassinari, C.; Sampaio, M. A review of carbon storage in saline aquifers: Mechanisms, prerequisites, and key considerations. Fuel 2024, 369, 131744. [Google Scholar] [CrossRef]

- Rutqvist, J.; Tsang, C.F. A study of caprock hydromechanical changes associated with CO2-injection into a brine formation. Environ. Geol. 2002, 42, 296–305. [Google Scholar] [CrossRef]

- Kim, T.; Park, C.; Watanabe, N.; Park, E.; Park, J.; Jung, Y.; Kolditz, O. Numerical modeling of two-phase flow in deformable porous media: Application to CO2 injection analysis in the Otway Basin, Australia. Liquids 2021, 80, 121. [Google Scholar] [CrossRef]

- Basmanov, O.; Kiryukhin, A.; Maguskin, M.; Dvigalo, V.; Rutqvist, J. Thermo-hydrogeomechanical modeling of vertical ground deformation during the operation of the Mutnovskii Geothermal Field. J. Volcanol. Seismol. 2016, 10, 138–149. [Google Scholar] [CrossRef]

- Qi, L.; Zhang, Y. Numerical simulation analysis of parameters in an artificial gas cap of CO2 enhanced oil recovery and storage. Chem. Technol. Fuels Oils 2025, 61, 258–267. [Google Scholar] [CrossRef]

- Jiang, X. A review of physical modelling and numerical simulation of long-term geological storage of CO2. Appl. Energy 2011, 88, 3557–3566. [Google Scholar] [CrossRef]

- Lin, K.; Wei, N.; Zhang, Y.; Liu, S.; Ali, M.; Wang, W.; Chen, Q.; Wang, Y. Hydro-mechanical interactions in CO2 storage: Critical parameters influencing coal mine at Shenhua’s CCUS site. Eng. Geol. 2025, 352, 108087. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Park, Y.-G. A Review of CO2 Plume Dispersion Modeling for Application to Offshore Carbon Capture and Storage. J. Mar. Sci. Eng. 2024, 12, 38. [Google Scholar] [CrossRef]

- Cheng, Q.; Tang, J.; Liu, Y.; Jia, Y.; Lu, Y.; Sun, X.; Zhao, G.; Liu, Y. Pore alteration of Yanchang shale after CO2-brine-rock interaction: Influence on the integrity of caprock in CO2 geological sequestration. Fuel 2024, 363, 130952. [Google Scholar] [CrossRef]

- Petersen, H.; Springer, N.; Weibel, R.; Schovsbo, N. Sealing capability of the Eocene MioceneHorda and Lark formations of the Nini West depleted oil field implications for safe CO2 storage in the North Sea. Int. J. Greenh. Gas Control 2022, 118, 103675. [Google Scholar] [CrossRef]

- Li, C.; Laloui, L. Impact of material properties on caprock stability in CO2 geological storage. Geomech. Energy Environ. 2017, 11, 28–41. [Google Scholar] [CrossRef]

- Chen, B.; Li, Q.; Tan, Y.; Zhang, Y.; Yu, T.; Ma, J.; Zhong, Y.; Li, X. Caprock sealing integrity and key indicators of CO2 geological storage considering the effect of hydraulic-mechanical coupling: X field in the Bohai Bay Basin, China. Eng. Geol. 2024, 342, 107741. [Google Scholar] [CrossRef]

- Lan, Z.; Gong, B. Uncertainty analysis of key factors affecting fracture height based on box-behnken method. Eng. Fract. Mech. 2020, 228, 106902. [Google Scholar] [CrossRef]

- Wei, X.; Li, Q.; Li, X.; Sun, Y. Impact indicators for caprock integrity and induced seismicity in CO2 geosequestration: Insights from uncertainty analyses. Nat. Hazards 2016, 81, 1–21. [Google Scholar] [CrossRef]

| Indicators | Parameters | Values | Units |

|---|---|---|---|

| Caprock | |||

| Young’s modulus | Ec | 8 | GPa |

| Poisson’s ratio | νc | 0.3 | - |

| Permeability | kc | 1 × 10−17 | m2 |

| Void ratio | nc | 0.01 | - |

| Angle of friction | φc | 30 | ° |

| Dry density | ρc | 2550 | kg/m3 |

| Reservoir | |||

| Young’s modulus | Er | 8 | GPa |

| Poisson’s ratio | νr | 0.3 | - |

| Permeability | kr | 5 × 10−13 | m2 |

| Void ratio | nr | 0.24 | - |

| Angle of friction | φr | 30 | ° |

| Dry density | ρr | 2550 | kg/m3 |

| Number of Reservoir | Injection Rate, kg/s | Thickness of Reservoir, m | Horizontal Migration Distance, m | |

|---|---|---|---|---|

| 1 Year | 10 Years | |||

| 1 | 5.5 | 30 | 572 | 3008 |

| 2 | 3.1 | 18 | 500 | 2650 |

| 3 | 5.2 | 30 | 572 | 3505 |

| 4 | 6.2 | 36 | 572 | 3300 |

| 5 | 4.1 | 24 | 400 | 2270 |

| 6 | 6.2 | 36 | 572 | 3200 |

| Location | Increase in Pore Pressure, MPa | Effective Stress, MPa | ||

|---|---|---|---|---|

| 1 Year | 10 Years | 1 Year | 10 Years | |

| A | 1.3 | 1.1 | 33.0 | 32.0 |

| B | 0.56 | 0.64 | 32.8 | 32.5 |

| C | 0.91 | 0.76 | 39.5 | 39.5 |

| D | 0.37 | 0.38 | 39.5 | 39.5 |

| Indicators | 60% | 80% | 100% | 120% | 140% | |

|---|---|---|---|---|---|---|

| Depth, m | Z | 898.8 | 1198.4 | 1498 | 1797.6 | 2097.2 |

| Top caprock thickness, m | H | 18 | 24 | 30 | 36 | 42 |

| Caprock | ||||||

| Young modulus, GPa | Ec | 4.8 | 6.4 | 8.0 | 9.6 | 11.2 |

| Poisson’s ratio | νc | 0.18 | 0.24 | 0.3 | 0.36 | 0.42 |

| Permeability, 10−17 m2 | kc | 0.6 | 0.8 | 1.00 | 1.20 | 1.40 |

| Void ratio | nc | 0.006 | 0.008 | 0.01 | 0.012 | 0.014 |

| Angle of friction, ° | φc | 18 | 24 | 30 | 36 | 42 |

| Dry density, kg/m3 | ρc | 1530 | 2040 | 2550 | 3060 | 3570 |

| Reservoir | ||||||

| Young modulus, GPa | Er | 4.8 | 6.4 | 8.0 | 9.6 | 11.2 |

| Poisson’s ratio | νr | 0.18 | 0.24 | 0.3 | 0.36 | 0.42 |

| Permeability, 10−13 m2 | kr | 3.00 | 4.00 | 5.00 | 6.00 | 7.00 |

| Void ratio | nr | 0.144 | 0.192 | 0.24 | 0.288 | 0.336 |

| Angle of friction, ° | φr | 18 | 24 | 30 | 36 | 42 |

| Dry density, kg/m3 | ρr | 1530 | 2040 | 2550 | 3060 | 3570 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Mo, F.; Tao, Z.; Hong, Y.; Gao, B.; Xuan, T. Numerical Investigation of Offshore CCUS in Deep Saline Aquifers Using Multi-Layer Injection Method: A Case Study of the Enping 15-1 Oilfield CO2 Storage Project, China. J. Mar. Sci. Eng. 2025, 13, 1247. https://doi.org/10.3390/jmse13071247

Shen J, Mo F, Tao Z, Hong Y, Gao B, Xuan T. Numerical Investigation of Offshore CCUS in Deep Saline Aquifers Using Multi-Layer Injection Method: A Case Study of the Enping 15-1 Oilfield CO2 Storage Project, China. Journal of Marine Science and Engineering. 2025; 13(7):1247. https://doi.org/10.3390/jmse13071247

Chicago/Turabian StyleShen, Jiayi, Futao Mo, Zhongyi Tao, Yi Hong, Bo Gao, and Tao Xuan. 2025. "Numerical Investigation of Offshore CCUS in Deep Saline Aquifers Using Multi-Layer Injection Method: A Case Study of the Enping 15-1 Oilfield CO2 Storage Project, China" Journal of Marine Science and Engineering 13, no. 7: 1247. https://doi.org/10.3390/jmse13071247

APA StyleShen, J., Mo, F., Tao, Z., Hong, Y., Gao, B., & Xuan, T. (2025). Numerical Investigation of Offshore CCUS in Deep Saline Aquifers Using Multi-Layer Injection Method: A Case Study of the Enping 15-1 Oilfield CO2 Storage Project, China. Journal of Marine Science and Engineering, 13(7), 1247. https://doi.org/10.3390/jmse13071247